Reaction device with outer circulation device and method for controlling the reaction process

A reaction device and reaction process technology, applied in the field of chemical engineering, can solve the problems of limited heat exchange capacity, high production cost and maintenance cost, complex structure, etc., and achieve wide viscosity range, low construction cost and operation cost, and heat exchange high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

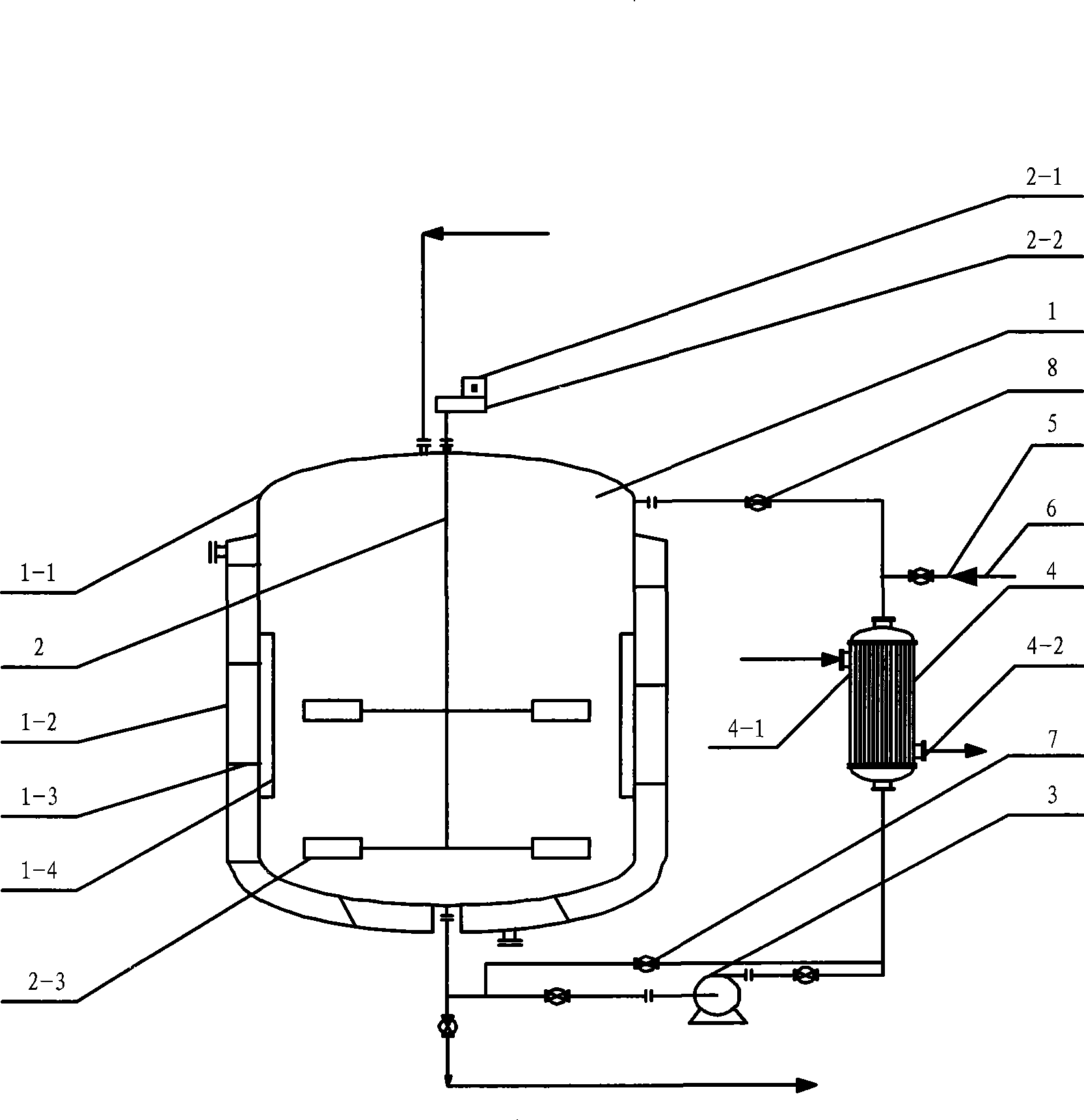

[0028] The invention increases the heat exchange efficiency by adding fluid conveying equipment and a heat exchanger outside the reactor, so that the reactant and the cold or hot medium can exchange heat outside the reactor.

[0029] Simultaneously, the present invention is also equipped with a stirring device in the reaction kettle, the reactor outer jacket is arranged on the reaction kettle, and the jacket inner baffle is arranged in the said kettle outer jacket. In combination, the device of the present invention is not only suitable for liquid-phase reactions with relatively high heat exchange in the reaction process, but also can effectively stir materials when the viscosity of the system has a large range of variation.

[0030] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] refer to figure 1 Shown is a structural schematic diagram of the reaction device with external circulation eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com