Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1058results about How to "Not easy to form" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hyper-concentrated liquid detergent and preparation technique thereof

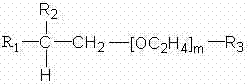

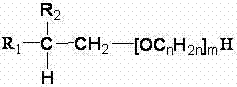

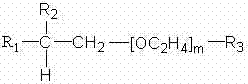

ActiveCN102643725ANo gel phenomenonEasy to dumpAnionic-cationic-non-ionic surface-active compoundsDetergent compounding agentsPreservativeSolvent

Hyper-concentrated liquid detergent comprises, in percentage by weight, 8-30% of anionic surfactant, 40-60% of nonionic surfactant, 5-15% of cosolvent, 0-10% of auxiliary, 0.005-1% of deflocculant, 0-0.5% of fluorescent brightener, 0-2% of detergent enzymes, 0-0.1% of preservative, 0.1-1% of essence, and the balance of water. The hyper-concentrated liquid detergent has the advantages of high solid content and high deterging effect.

Owner:CHINA RES INST OF DAILY CHEM IND

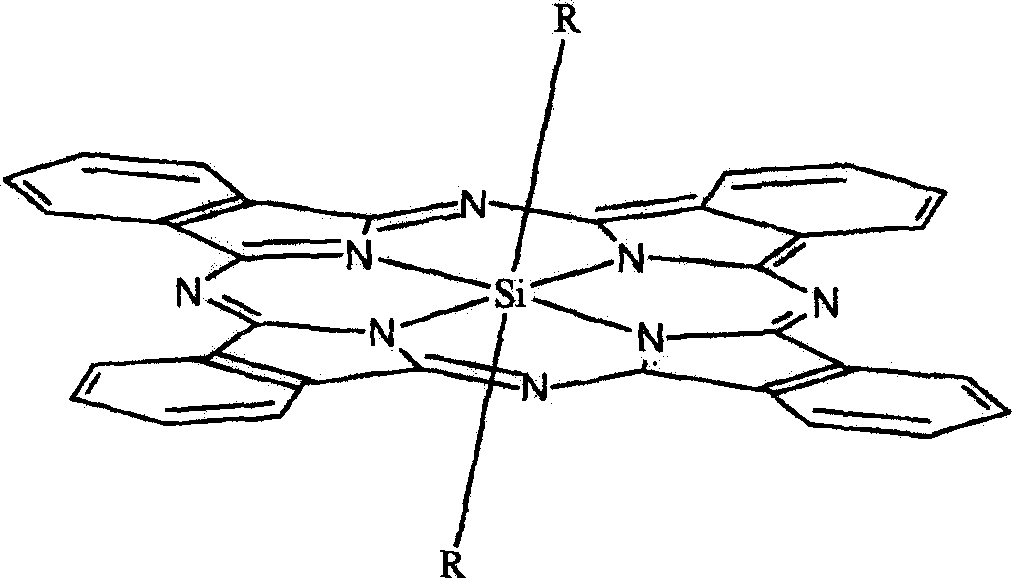

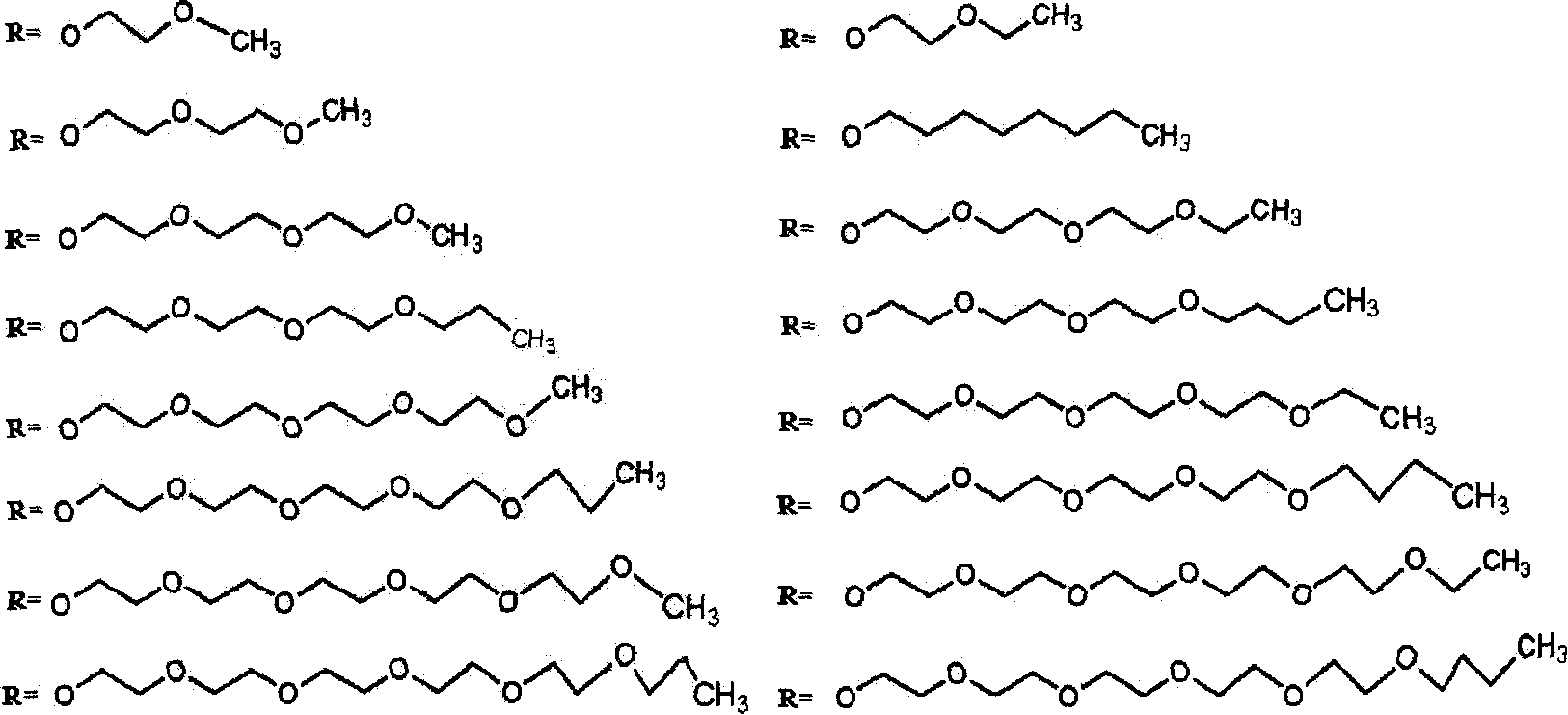

Silicon phthalocyanine compound and composite, their preparation and application thereof

ActiveCN1861603AStrong photosensitivityClear structureSilicon organic compoundsSilicon compound active ingredientsCompound sDisease

An axially substituted silicon-phthalocyanin match and its composition are disclosed, which have high optical spectrum characteristics and can be used as the photosensitizer used for photodynamic therapy to tumor and the diseases other than cancer, photodynamic diagnosis and photodynamic disinfecting.

Owner:FUZHOU UNIVERSITY

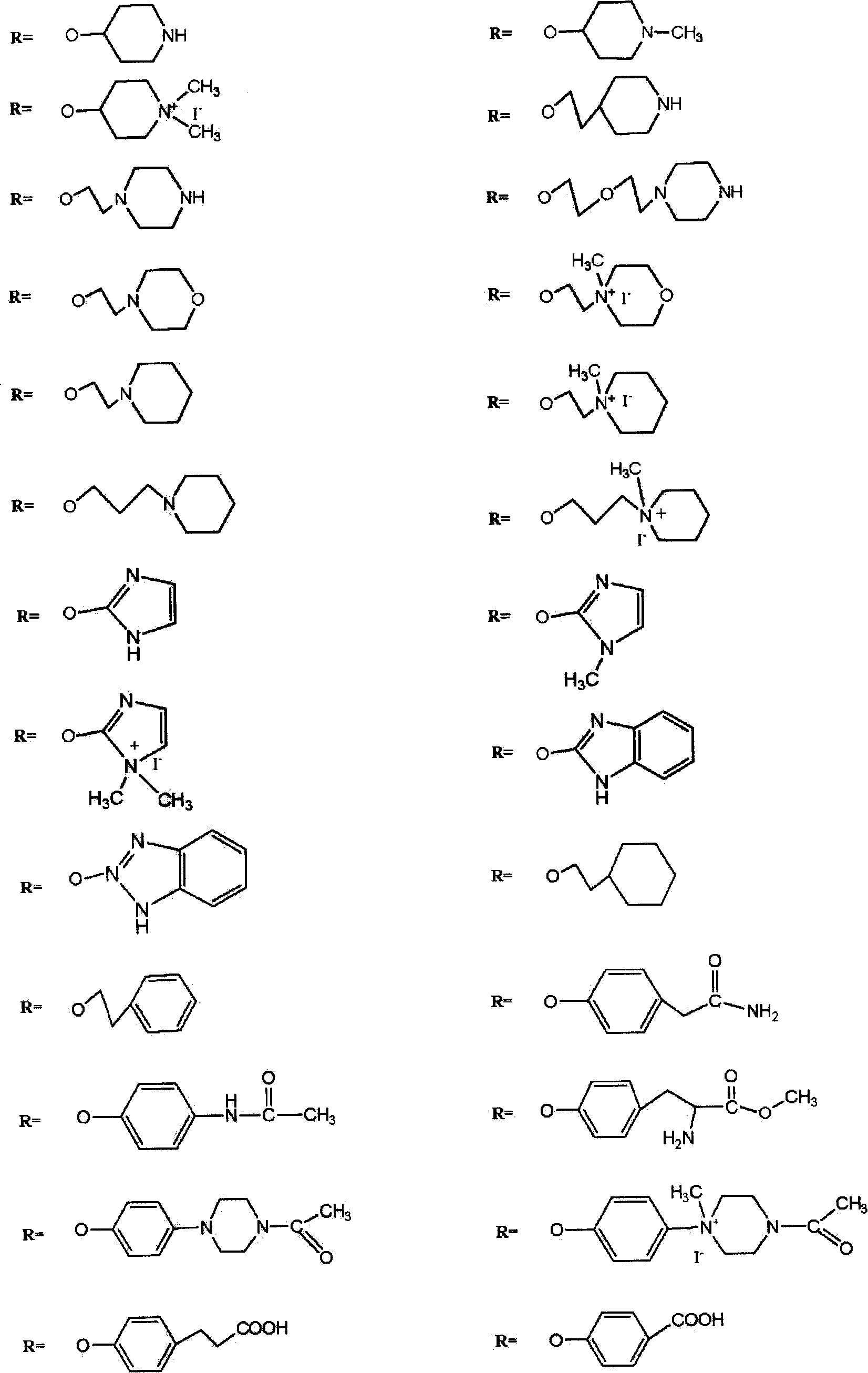

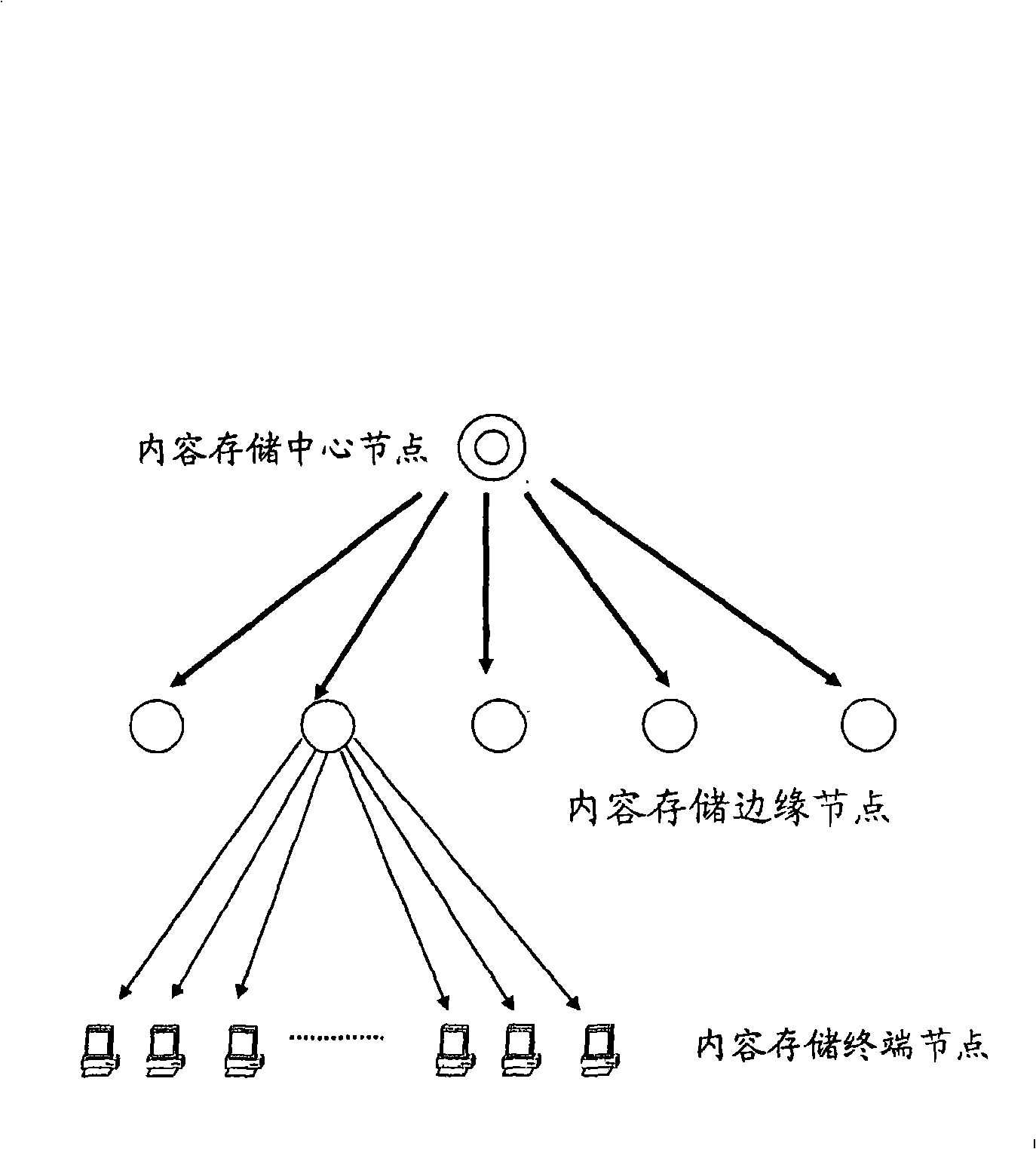

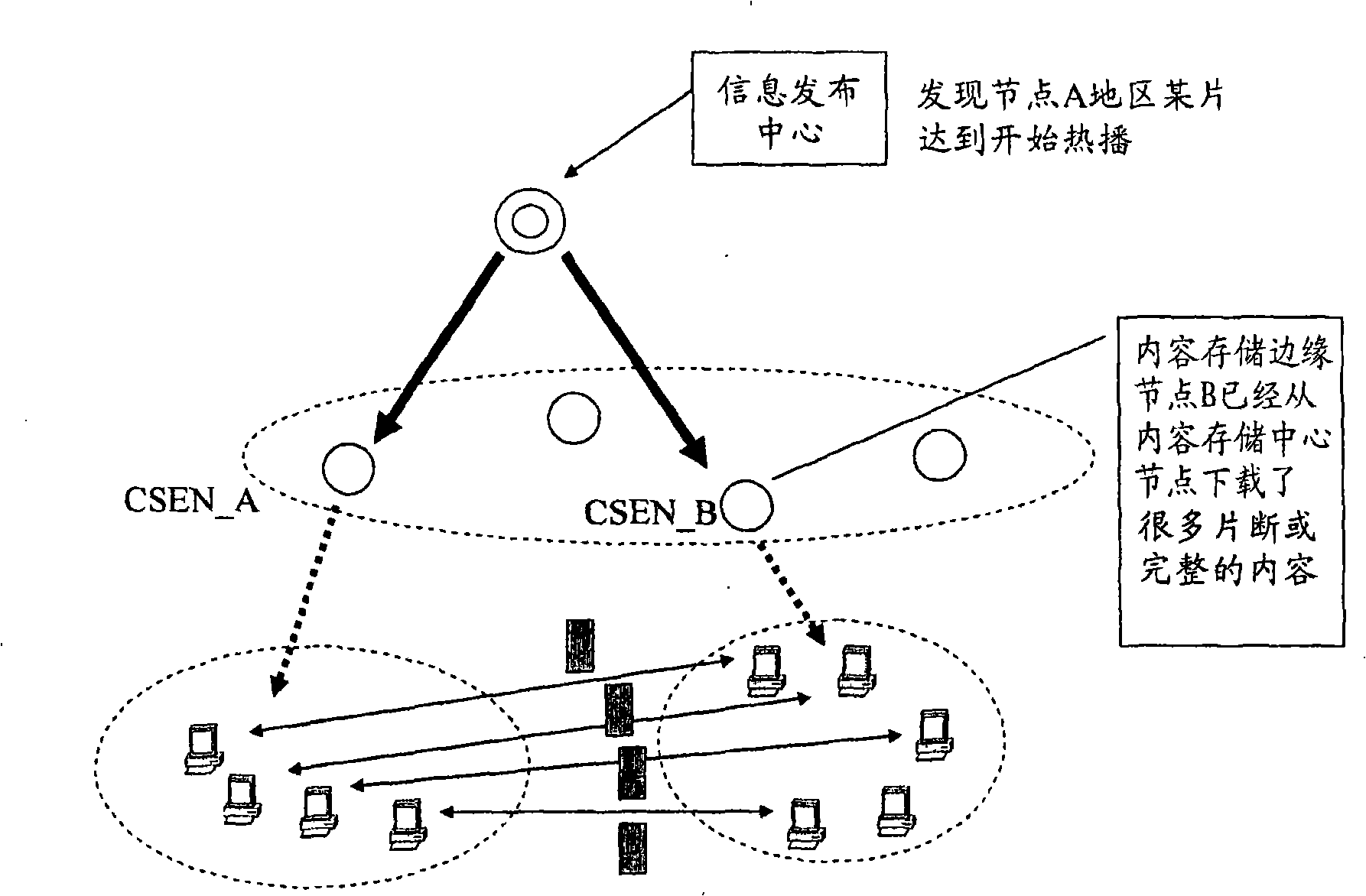

Contents grading memory of telecommunication level P2P network and transmission method

ActiveCN101345690AEnsure legalityEnsure integrityStore-and-forward switching systemsNetwork onEdge node

The invention relates to a content staging memory storage and transmission method of a communication level P2P network, wherein all sharing content is stored on three kinds of nodes with P2P alternation capability, namely: a content storage central node, a content storage fringe node and a content storage terminal node. According to the invention, the content is downloaded in priority order of the content storage terminal node, the content storage fringe node and the content storage central node. The scheme of the invention satisfies the requirement of the communication level network on stability, high efficiency, high quality and saved cost, thereby solving the problems of lower efficiency of prior distributivity storing frame, deficient content, 'uneven cold and hot' of content storage and distribution.

Owner:CHINA TELECOM CORP LTD

Preparation method of NdFeB magnet with high coercivity

InactiveCN107578912AReduce machining costsSimple production processInductances/transformers/magnets manufactureMagnetic materialsMicrometerTerbium

The invention relates to a preparation method of an NdFeB magnet with high coercivity. The method includes the following steps that heavy rare earth powder is mixed with an anti-oxidizing agent, a binder and an organic solvent to prepare uniform slurry, wherein the heavy rare earth powder refers to one or a mixture of Dy, hydrogenated dysprosium, Tb and terbium hydride, the mass ratio of the heavyrare earth powder in the slurry is 40-80%, the mass ratio of the anti-oxidizing agent is 5-20%, the mass ratio of the binder is 2-10% and the balance organic solvent, and the anti-oxidizing agent refers to the anti-oxidizing agent containing fluorine; after the slurry covers the surface of a sintered magnet, the thickness of the slurry is controlled to 20-100 micrometers, and drying is then conducted; the dried magnet is then sintered, and aging treatment is conducted. The method can reduce the use amount of heavy rare earth powder such as Dy and Tb, meanwhile, the requirement of the grain boundary diffusion technology for the size of a product is met, the problem that fluoride and oxide coating powder is easy to fall off is solved, and the manufacturing process is simple.

Owner:YANTAI ZHENGHAI MAGNETIC MATERIAL

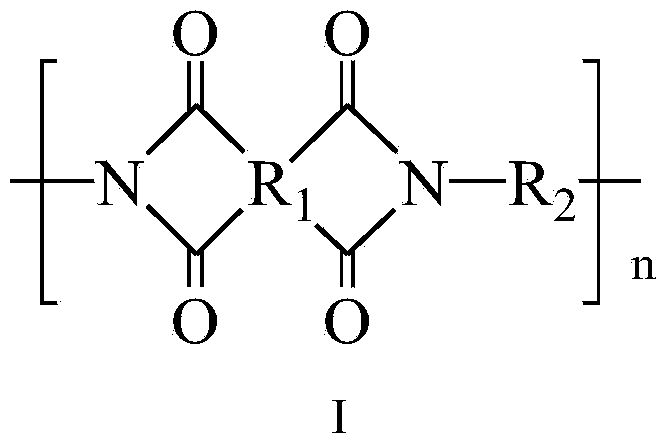

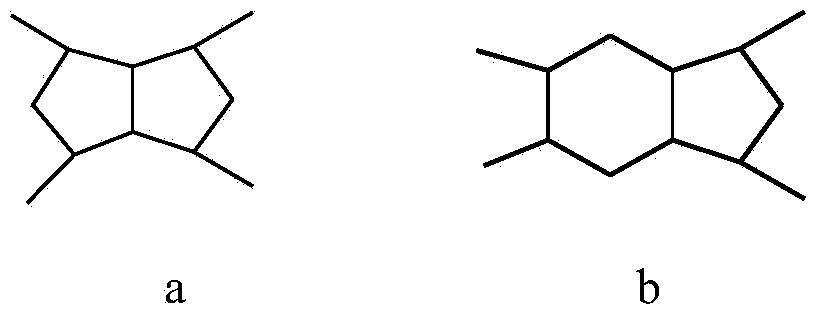

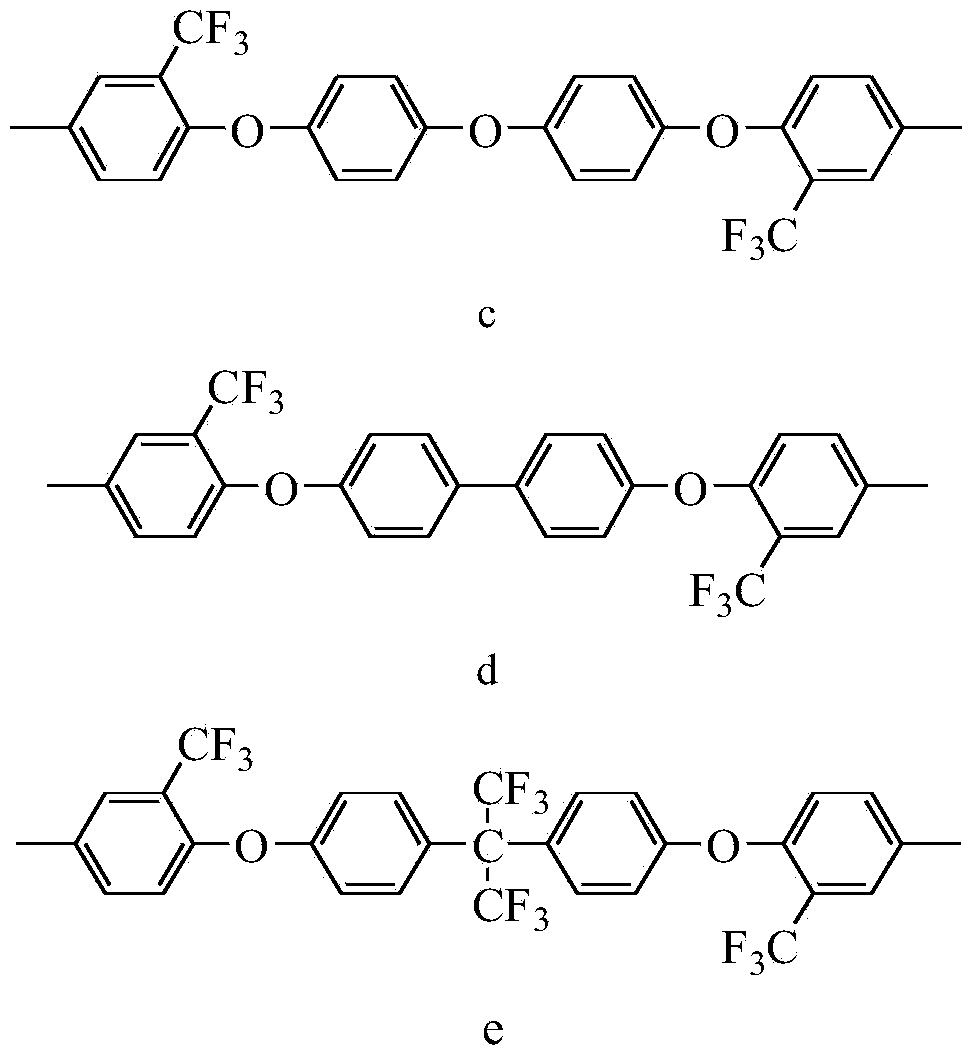

Colorless and transparent polyimide film and preparation method thereof

ActiveCN103788650AHigh glass transition temperature and thermal decomposition temperatureReduce intermolecular interactionsDiamineTransmittance

The invention discloses a colorless and transparent polyimide film, the molecular structural formula as shown in a formula I. A preparation method of the polyimide film comprises the following steps: polymerizing a fluorine-containing diamine monomer and a dianhydride monomer which have same moles in a polar aprotic solvent to produce a colorless and transparent poly(amicacid) solution, carrying out dehydration and ring closing on the colorless and transparent poly(amicacid) solution by using a hot imidization method or a chemical imidization method to produce the colorless and transparent polyimide film, wherein the dianhydride monomer is one or two of compounds selected from bicyclic (3,3,0)octane-2,4,6,7-tetracid dihydride or bicyclic (4,3,0)nonane-3,4,7,9-tetracid dihydride, the fluorine-containing diamine monomer is one or a combination of two of compounds selected from 4,4'-di(4-amino-2-trifluoromethylphenoxy)diphenyl ether, 4,4'-di(4-amino-2- trifluoromethylphenoxy) biphenyl and 2,2'-di(4-(4-amino-2- trifluoromethylphenoxy) phenyl) hexafluoropropane. The colorless and transparent polyimide film produced by using the alicyclic type dianhydride monomer has excellent performances such as good heat resistance, good solubility and high light transmittance.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

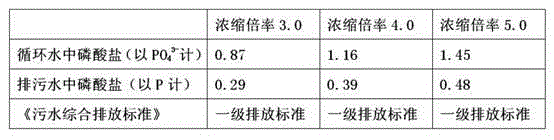

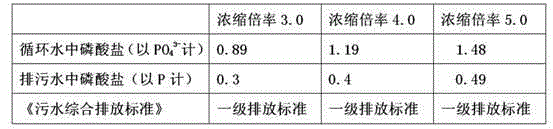

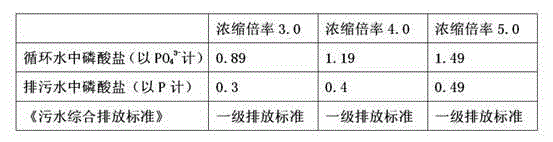

Efficient low-phosphorus compound water treatment agent

InactiveCN102718333AReduce manufacturing costPrevent scalingScale removal and water softeningPolyaspartic acidTricarboxylic acid

The invention provides an efficient low-phosphorus compound water treatment agent and belongs to the technical field of industrial circulating cooling water treatment. The water treatment agent consists of the following raw materials: polyaspartic acid (PESA), 2-phosphonobutane-1,2,4-tricarboxylic acid (PBTCA), zinc salt, azoles, maleic acid-acrylic copolymer (MA / AA) and deionized water, wherein PESA is taken as a main scale inhibitor, PBTCA and MA / AA are taken as auxiliary scale inhibitors, a corrosion inhibitor is formed by the zinc salt, the azoles, PBTCA and PESA, and MA / AA is taken as a dispersing agent. By fully utilizing the synergistic effect of various components, a multifunctional low-phosphorus compound water treatment agent with scale and corrosion inhibition functions is formed.

Owner:SHANDONG TIANQING TECH DEV

Low-phosphorus water treatment composition

InactiveCN101746904AReduce phosphorus contentReduce contentScale removal and water softeningWater/sewage treatment using germicide/oligodynamic-processCarboxylic saltWater quality

The invention relates to a low-phosphorus water treatment composition, which comprises the following compositions in part by weight: 1 to 3 parts of phosphorus carboxylate, 1 to 30 parts of dirt dispersion agent and 1 to 5 parts of bactericide and algicide. When the concentration multiple is 2 to 6, the corrosion rate and the scale deposition rate of a circulating cooling water system of carbon steel and copper pipelines are all smaller than circulating water quality monitoring and controlling indexes, the industrial water is saved, the environmental pollution is reduced, and the low-phosphorus water treatment composition is widely applied to similar circulating cooling water systems in chemical engineering, petrifaction, steel, electric power and the like, and has great social and economic benefits and promotion value.

Owner:NANJING UNIV OF TECH

Composite treating method for nitriding surface of metal material after coating

ActiveCN103805996ASmall grain sizeReduce defect densityVacuum evaporation coatingSputtering coatingMetallic materialsHigh surface

The invention belongs to the field of material surface modification, and particularly relates to a composite treating method for nitriding the surface of a metal material after coating. The composite treating method is suitable for surface strengthening of tools, molds and metal accessories. The composite treating method comprises the following steps: firstly depositing a layer of nitride thin film on the surface of a metal material substrate by adopting magnetron sputtering or arc ion plating, wherein the thickness of the thin film is 0.1-50 micrometers; then carrying out ion nitriding treatment on the surface of the coating film by adopting an ion nitriding technology for 0.5-10 hours. Due to adoption of the composite treating method, the problem of low film-substrate bonding strength and the like caused by a black layer easily occurring in a composite treating process of coating after nitriding are solved. The workpiece obtained by adopting the coating-nitriding composite treating method of carrying out ion nitriding treatment after depositing a layer of thin film has the characteristics of high surface hardness, good wear resistance, high film-substrate binding force, reliable quality, stability and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

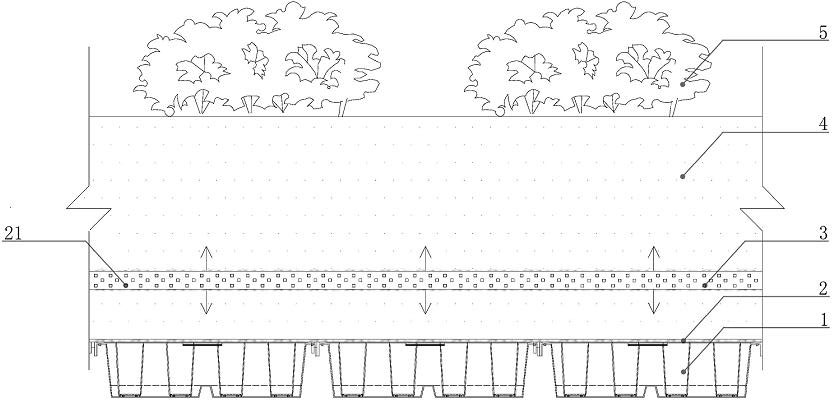

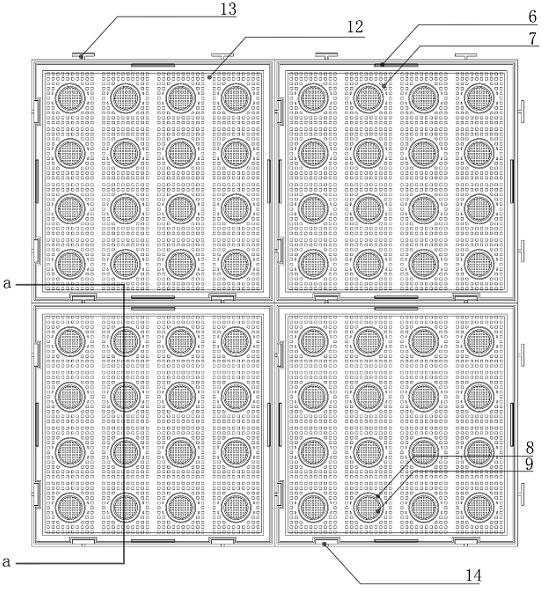

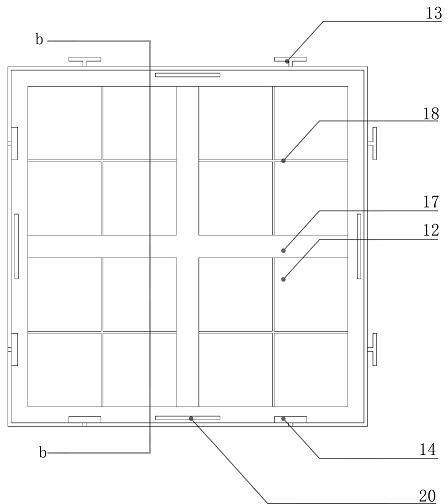

Ecological energy-saving and environment-friendly sustainable plant growing system

ActiveCN102415293ABeautify environmentPurifying airSelf-acting watering devicesClimate change adaptationNutrientSoil horizon

The invention discloses an ecological energy-saving and environment-friendly sustainable plant growing system. The plant growing system is characterized by comprising a water storage and supply module (1), a permeable isolating unit (2), a nutrient soil layer (4) and a drip irrigation system (3), wherein a single or a plurality of water storage and supply modules (1) form a plant growing base, the plant growing base is arranged on a roof or a soilless foundation, and the water storage and supply module (1) consists of an upper module and a lower module which are connected by splicing; the permeable isolating unit (2) is placed on the plant growing base, namely the upper part of the water storage and supply module (1); the nutrient soil layer (4) is encircled on the upper part of the permeable isolating unit (2); and the drip irrigation system (3) is arranged in the nutrient soil layer (4). The plant growing system is simple in structure and convenient to manufacture, and does not needmanual irrigation and maintenance under normal conditions.

Owner:JIANGSU PIPA LANDSCAPE

Separating agent for extracting asphalt from oil-sand

InactiveCN101260308AHigh recovery rateSimple processWorking-up pitch/asphalt/bitumenLiquid hydrocarbon mixture productionPhosphateSilicic acid

The invention discloses a separating agent for extracting asphaltum from oil sand, the separating agent comprises components with the weight percentage as follows: sodium (or potassium) hydroxide (0.1-0.5 percent); sodium (or potassium) phosphate (0.5-2 percent), sodium (or potassium) silicic acid (1-5.5 percent), sodium (or potassium) carbonate (0.5-1 percent), sodium chloride (0.1-0.5 percent), oil solvent (3-7 percent), surfactant (0.1-0.5 percent), and water (85-94 percent). The technology with the separating agent to extract asphaltum is simple and easy to control. The recovery ratio of the asphaltum reaches to more than 94 percent, with significant separating effect. Meanwhile, the dose of sodium hydroxide needed by the separating agent is small, the agent can be used repeatedly with little loss, low price and cost, thereby greatly decreasing the separation cost, improving the economic benefits, and being favorable for environmental protection.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

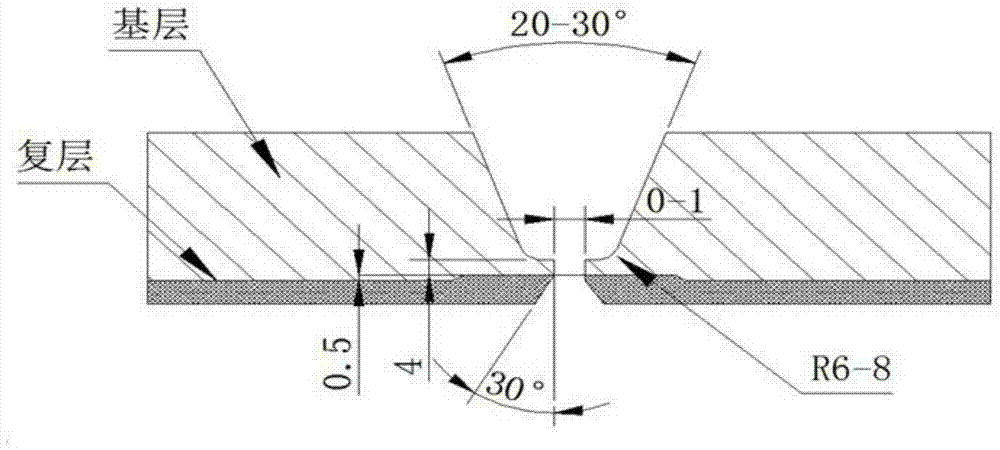

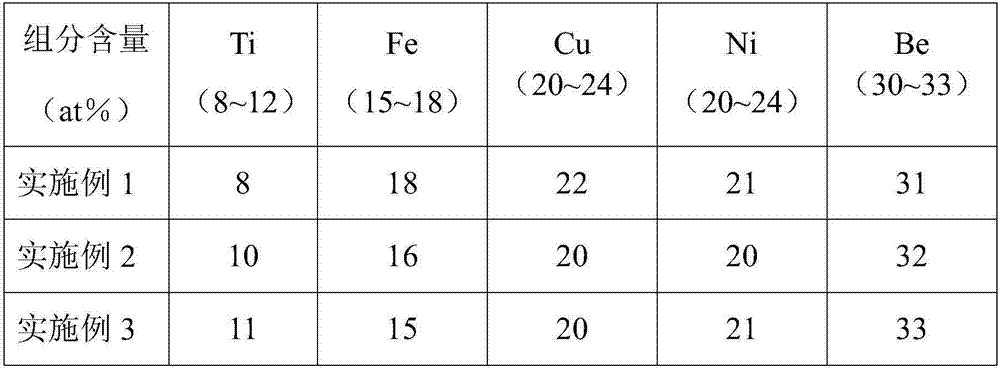

Welding material and welding method for titanium-steel composite board

InactiveCN103567654AHigh strengthImprove toughnessArc welding apparatusWelding/cutting media/materialsTO-18High entropy alloys

The invention discloses a high- entropy alloy welding wire for welding a titanium-steel composite board. The high-entropy alloy welding wire consists of the following components by atomic percent: 8 to 12 percent of Ti, 15 to 18 percent of Fe, 30 to 33 percent of Be, 20 to 24 percent of Ni, 20 to 24 percent of Cu, and the total percentage is 100 percent. The invention also disclosese a method for welding the titanium-steel composite board by utilizing the high-entropy alloy welding wire. The high-entropy alloy welding wire has excellent strength, flexibility and corrosion resistance, an embrittlement intermetallic compound is unlikely to form, a welding structural steel base layer of the titanium and steel composite board with high performance is easy to obtain, a composite layer stripping procedure for the composite board is not needed, and the preweld treatment is greatly simplified; and the welding of a steel base layer and a titanium composite layer of the titanium-steel composite board can be completed in one step by adopting TIG weld. No crack exists in a weld seam transitional area; and the tensile strength of the welding head is high.

Owner:XIAN UNIV OF TECH

Nickel base single crystal superalloy with low cost and low density

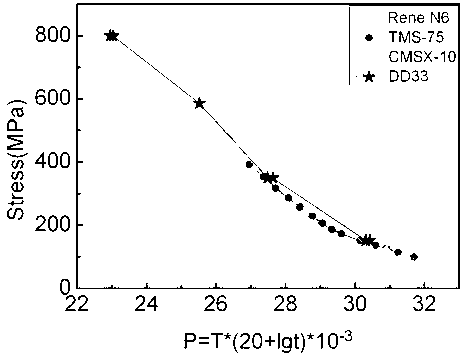

ActiveCN102732750AImprove durabilityImprove tensile propertiesPolycrystalline material growthSingle crystal growth detailsSingle crystal superalloySingle crystal

A nickel base single crystal superalloy with low cost and low density comprises, in percentage by weight, 2.5-4.5% of Cr, 7.0-11.0% of Co, 0.5-2.3% of Mo, 5.0-7.5% of W, 7.0-10.0% of Ta, 3.3-4.5% of Re, 5.0-7.0% of Al, 0-0.5% of Ti, 0-0.2% of Hf, 0-0.05% of C, 0-0.01% of B, and the balance being Ni. Compared with the conventional nickel base single crystal superalloys, the nickel base single crystal superalloy in the invention has excellent stress rupture property and tensile property and the cost is reduced obviously.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

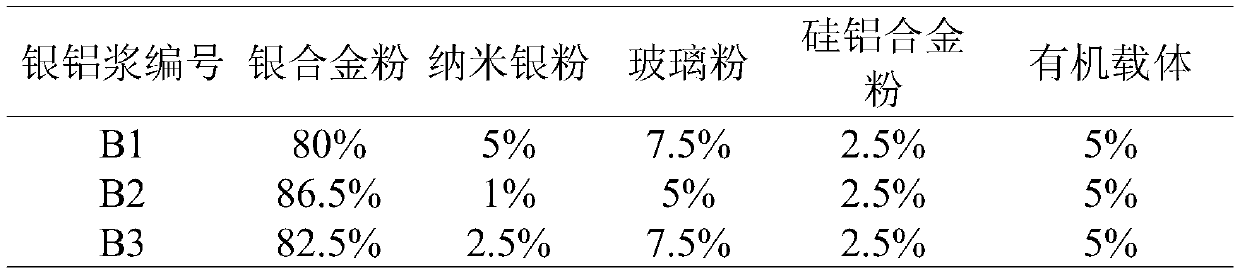

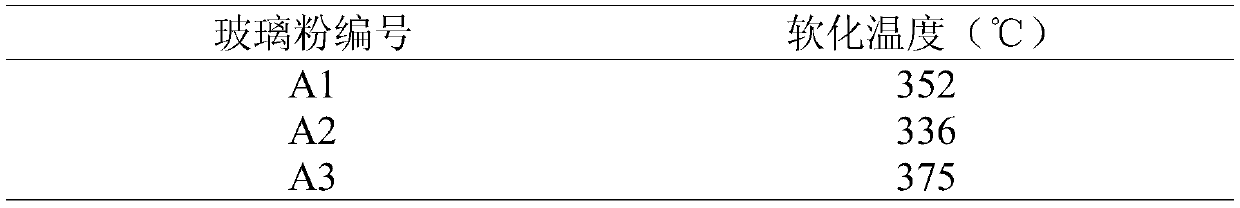

Glass powder and silver aluminum paste comprising glass powder and used on positive side of N-type double-sided solar cell

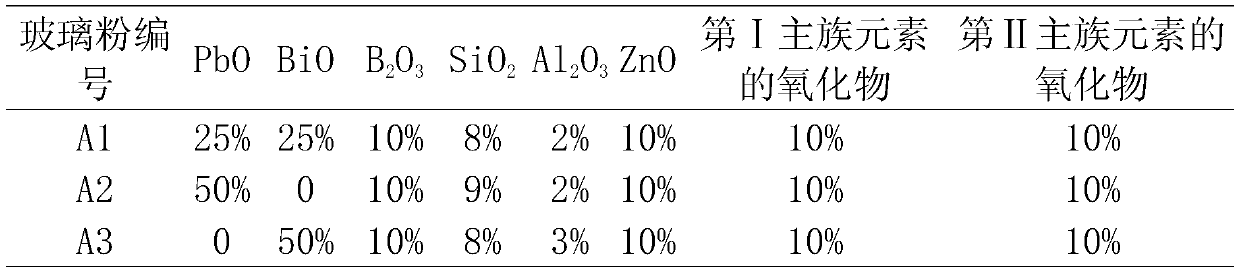

PendingCN110040968ALow softening temperatureIncrease the degree of vitrificationTransportation and packagingMetal-working apparatusMass ratioSilicon solar cell

The invention discloses glass powder and silver aluminum paste which comprises the glass powder and used on the positive side of an N-type double-sided solar cell. The silver aluminum paste comprisesconductive silver powder, silicon aluminum alloy powder, the glass powder and an organic carrier, wherein the glass powder is prepared from the following components in percentage by weight: 0-50% of PbO, 0-50% of BiO, 5-15% B2O3, 8-9% of SiO2, 2-3% of Al2O3 and 5-15% of ZnO; the mass ratio of silicon to aluminum in the glass powder is (4-5) to 1; the content of the conductive silver powder is 80wt% to 90wt%; the conductive silver powder comprises nano silver powder and silver alloy powder in a mass ratio of 1 to (18-90). The glass powder not only guarantees the corrosiveness of SiNx, but alsodoes not cause relatively strong metallized composition. The silver aluminum paste prepared by using the glass powder solves the problem of the contradiction between contact resistance and open circuit voltage when the silver aluminum paste is printed on the positive side of an N-type crystalline silicon solar cell.

Owner:NANTONG T SUN NEW ENERGY CO LTD

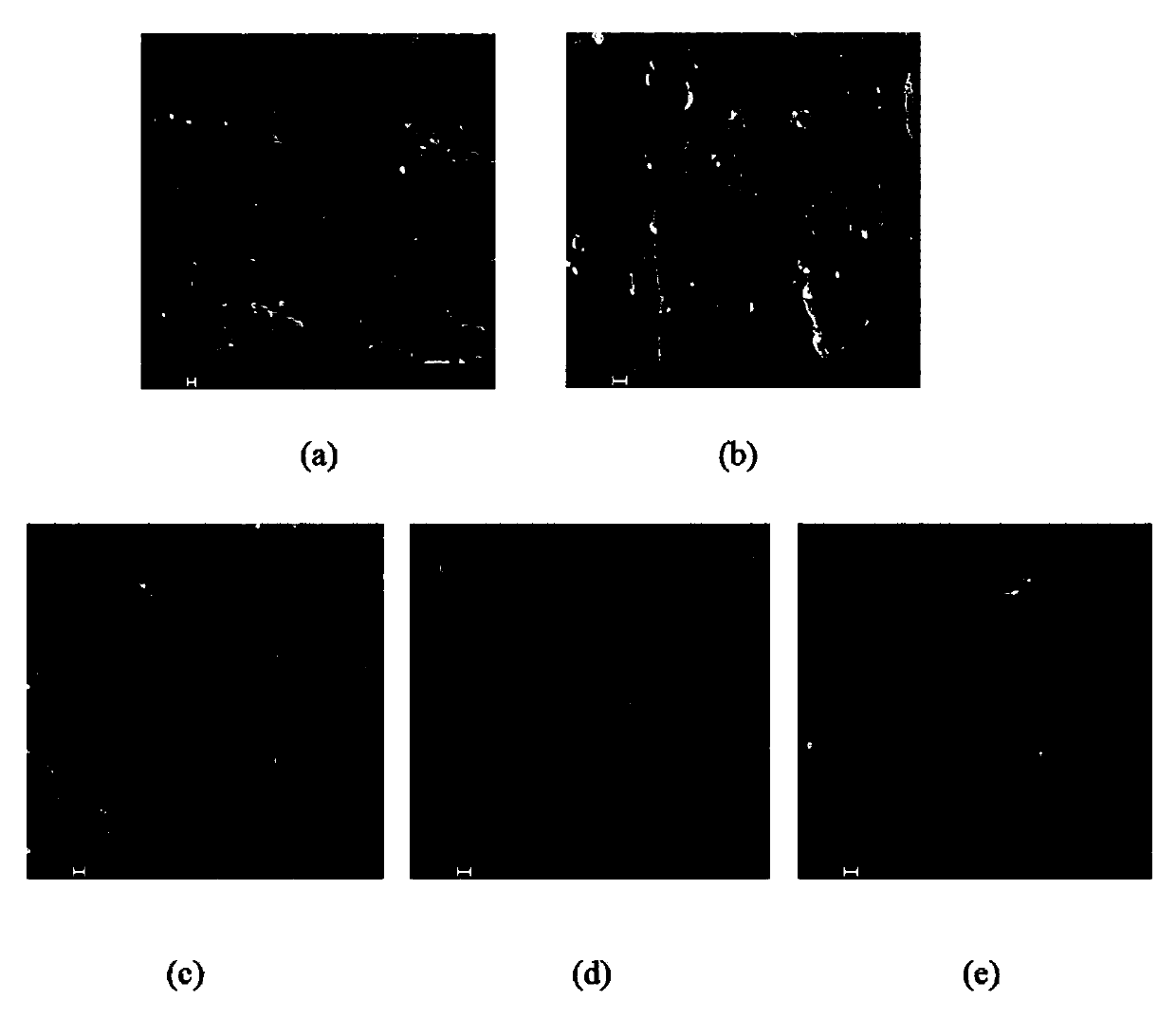

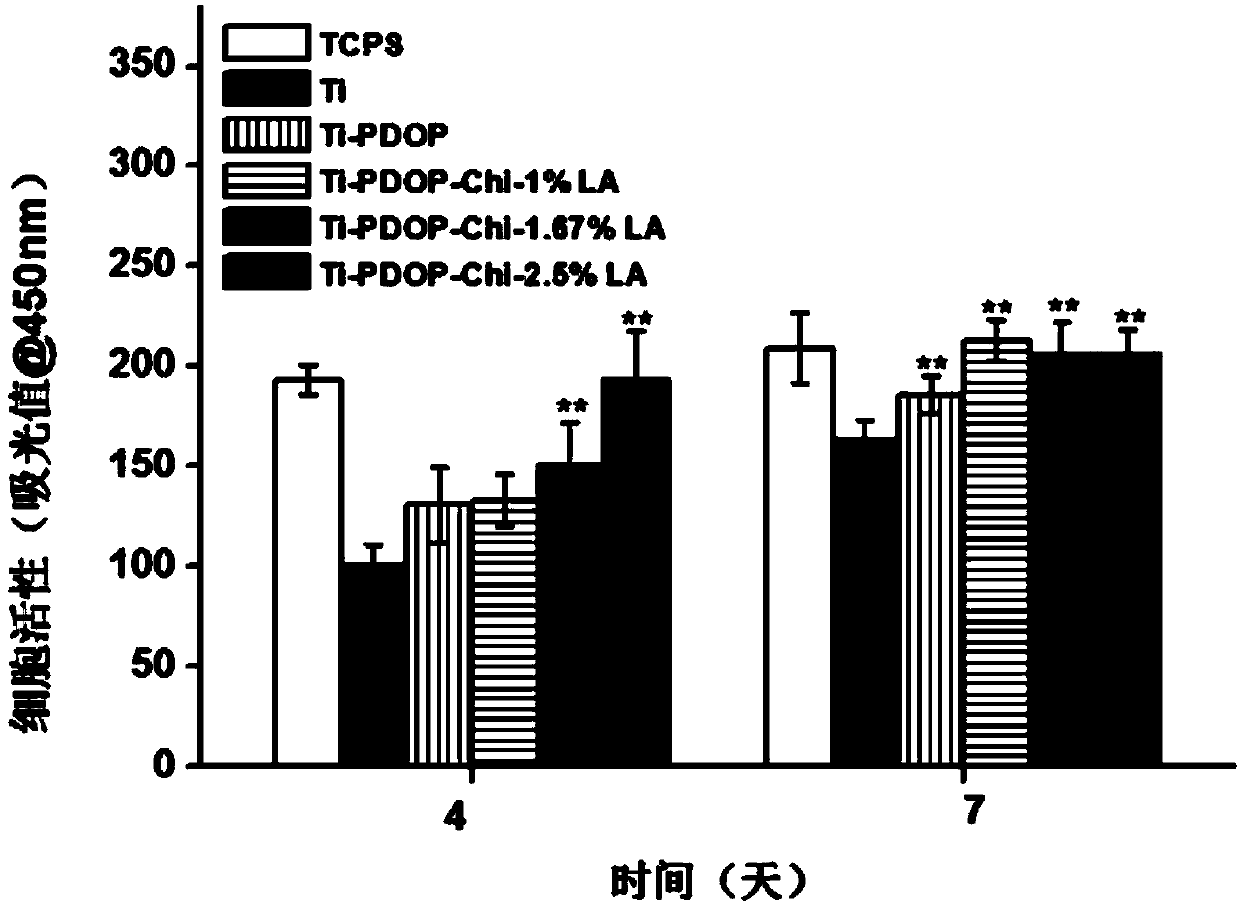

Medical titanium alloy with antibacterial and osteocyte-facilitating functions and preparation method thereof

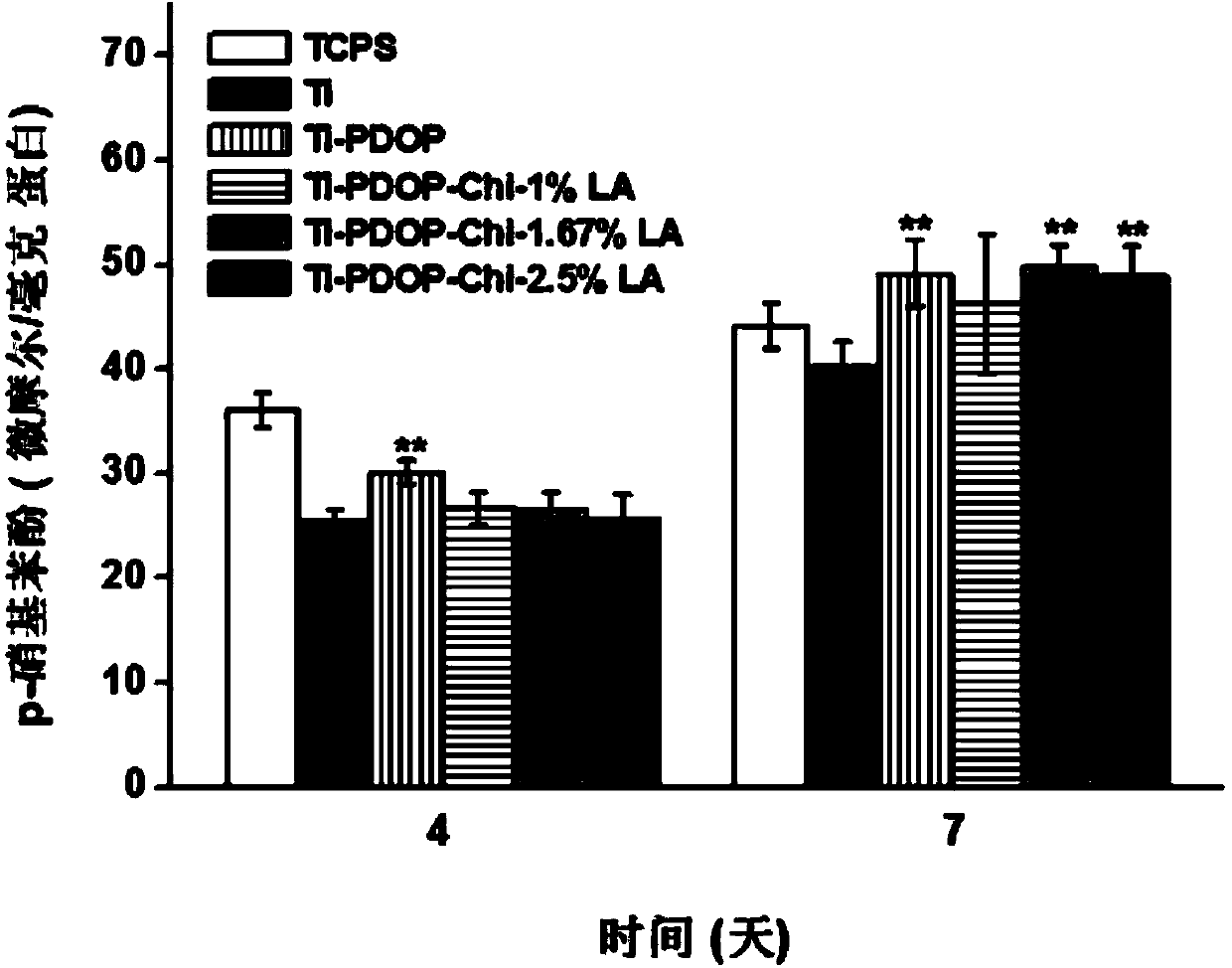

InactiveCN104005016AImprove antibacterial propertiesImprove osseointegrationMetallic material coating processesProsthesisBone cellAdsorption method

The invention provides a preparation method of nanolayer medical titanium alloy with antibacterial and osteocyte-facilitating functions. The method comprises the following steps: firstly, preparing different concentrations of chitosan-lauric acid (1%, 1.67% and 2.5%) conjugates by esterification reaction; secondly, utilizing a physical adsorption method and a chemical fixation method, adopting poly-dopamine as an intermediate layer, fixing the chitosan-lauric acid conjugates on the surface of a titanium implant, so as to build a nano structure layer with dual antibacterial and osteocyte proliferation facilitating properties on the titanium material surface, so as to regulate and control the biological function of the osteocyte, and improve the short-term antimicrobial capability of the titanium implant.

Owner:CHONGQING UNIV

Solar energy silicon crystal chip scavenger

ActiveCN101020866AImprove washing effectImprove stabilityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsScavengerPotassium hydroxide

The solar energy silicon crystal chip scavenger is compounded with sodium triacetate complex 10-30 wt%, C10-C13 carbonyl ethoxyl compound surfactant 5-10 wt%, fatty alcohol alkoxyl surfactant 3-5 wt%, sodium salt of acylate copolymer 0.05-0.15 wt%, hydrogen peroxide as oxidant 0.5-2 wt%, butyl glycol ether as organic solvent 5-10 wt%, potassium hydroxide 1-5 wt%, and water for the rest. It contains no toxic, harmful and pollutant matter, and has high detergency, biodegradability and environment friendship.

Owner:CHANGZHOU JUNHE TECH

Cathode slurry of lithium battery, its producing method and lithium battery

InactiveCN101154720AImprove cycle performanceNot easy to dropElectrode manufacturing processesFinal product manufactureAdhesiveSlurry

The invention relates to a cathode slip for lithium battery, which is made by nanometer carbon, weak acid, adhesive and solvent. The adhesive is preferably polyvinylidene fluoride. The solvent is preferably N-formyl sarcolysine ketopyrrolidine which has the weight ratio of 100:0.1-2:1-8:150-250 of nanometer carbon and weak acid, polyvinylidene fluoride and N-formyl sarcolysine ketopyrrolidine. The invention further discloses the cathode slip for lithium battery and prepared lithium battery. The invention provides a cathode slip for lithium battery, preparing method and lithium battery which can effectively improve circulation performance of lithium battery.

Owner:SHENZHEN BAK BATTERY CO LTD

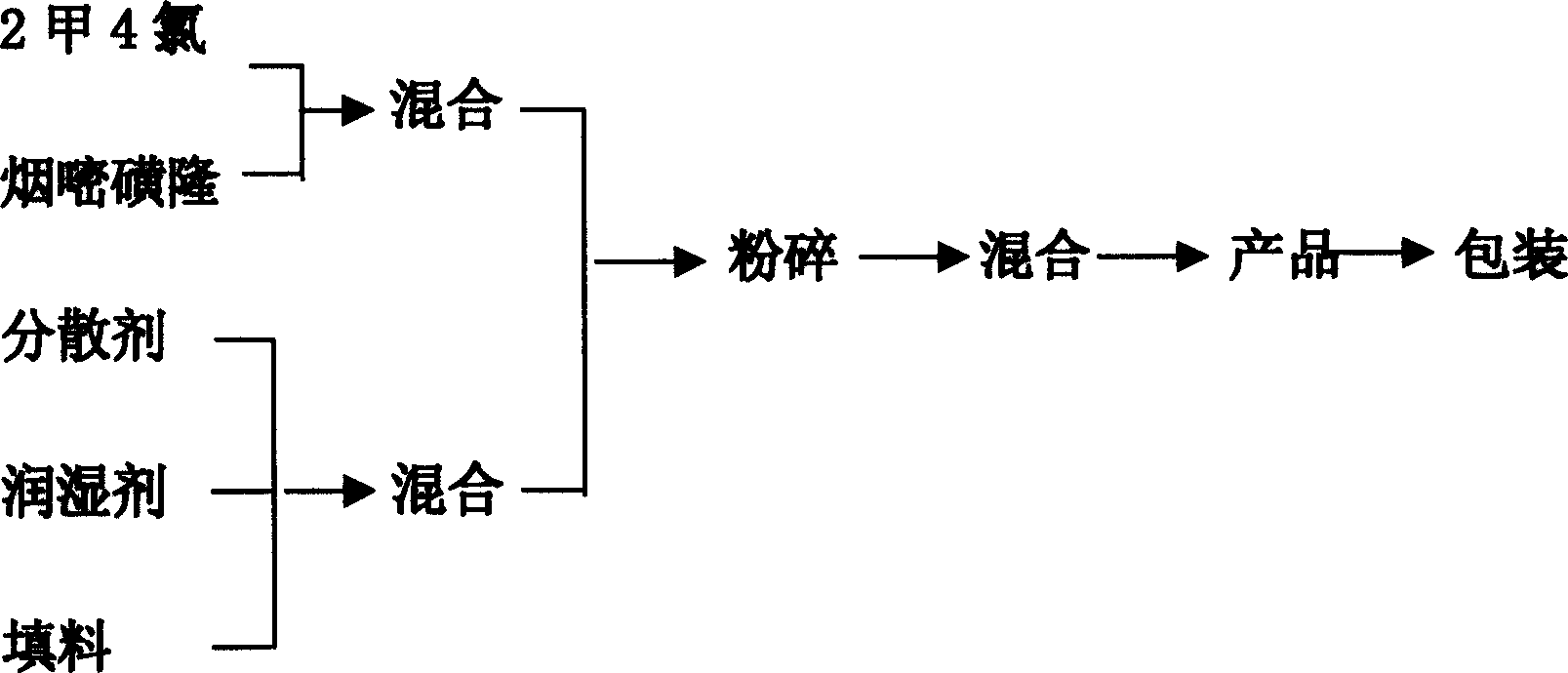

Composite of herbicide

A composite herbicide for corn field contains phenyloxyacetic acid kind of herbicide chosen from 2,4-D sodium, MCPA, MCPA sodium, 2,4-D butylate, etc, and sulfonylurea kind of herbicide chosen from nicosulfuron, rimsulfuron, etc in weight ratio of (1-80):1. The preparation is wattable powder and soluble powder.

Owner:河北宣化农药有限责任公司

Nano hard alloy material containing spherical face-centered cubic structure cobalt powder and preparation process thereof

The invention provides a nano hard alloy material containing spherical face-centered cubic structure cobalt powder and a preparation process thereof and belongs to the technical field of hard alloy preparation. The method comprises the steps of using 12-14 wt.% of the spherical face-centered cubic structure cobalt powder with the average grain diameter in a range of 200-300nm, 65-70 wt.% of tungsten carbide with the average grain diameter in a range of 200-300nm, 16-23 wt.% of tungsten carbide-titanium carbide-vanadium carbide-tantalum carbide-chromium carbide solid solution powder with the average grain diameter in a range of 300-400nm and a proper amount of an active and surface dispersing agent, and combining with airtight inert gases to protect high-speed ball milling, spray drying and overpressure sintering, so that sintering bodies are compact to the maximum extent, grain growth is restrained, the high-temperature performance of an alloy is optimized, and finally the high-hardness high-strength hard alloy material is obtained. The process is optimal in technology, easy to operate and applicable to industrial production.

Owner:重庆金锐新材料技术研究院有限公司

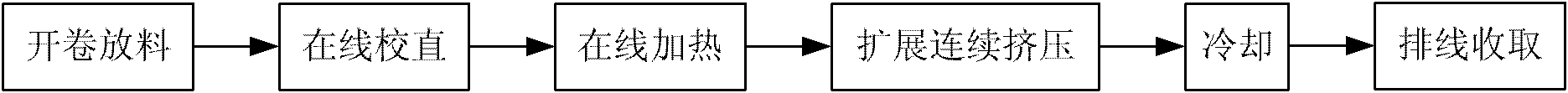

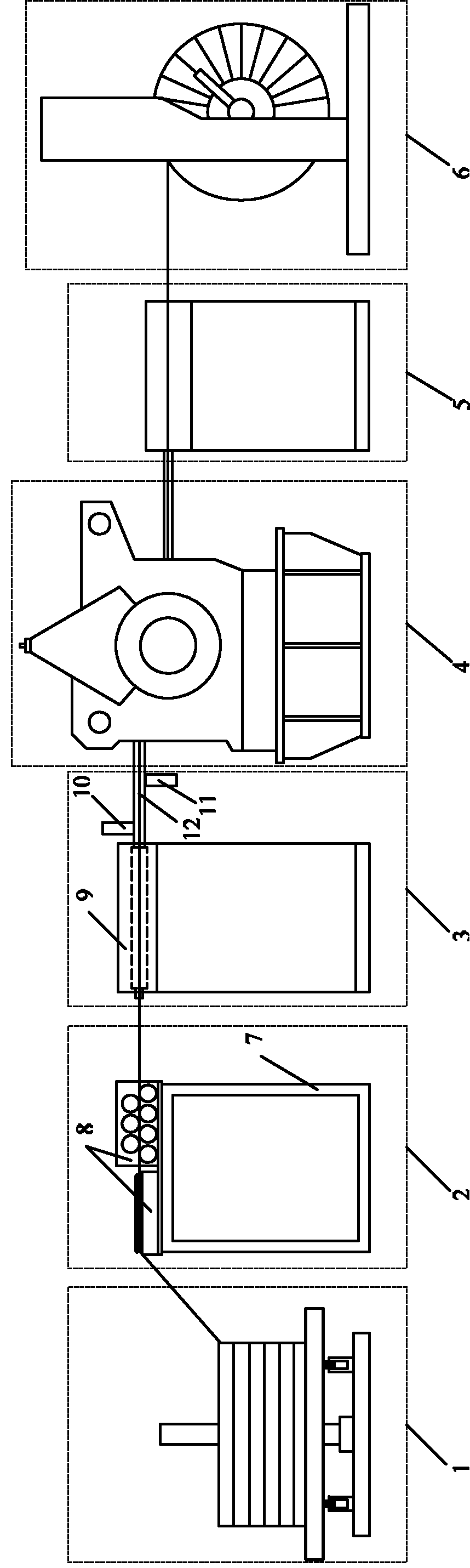

System and method for continuous extrusion production of fine-grain magnesium alloy strip

ActiveCN102688907AShort processIncrease productivityExtrusion control devicesProduction lineLine heating

The invention discloses a system and a method for continuous extrusion production of a fine-grain magnesium alloy strip. The system comprises a decoiling emptying device, an on-line straightening device, an on-line heating device, a continuous extrusion device, a cooling device and a winding displacement collection device. Through control of a temperature of a rod, a good extrusion driving force is produced between the rod and an extrusion wheel groove. Through an expansion mold cavity and a flow-blocking mold, magnesium alloy expansion flowing in a width direction is realized. In order to extrude a plate having larger width, the system adopts a two / three rod feeding-type extrusion mode so that joining and intermetallic welding of multiple rods in a corresponding multi-rod mold cavity are realized. The system and the method have the advantages that a process route is short; production efficiency is high; a grain refinement degree of a product microstructure is high; plate formability is good; and a continuous production line provided by the invention is suitable for industrial application.

Owner:DALIAN JIAOTONG UNIVERSITY

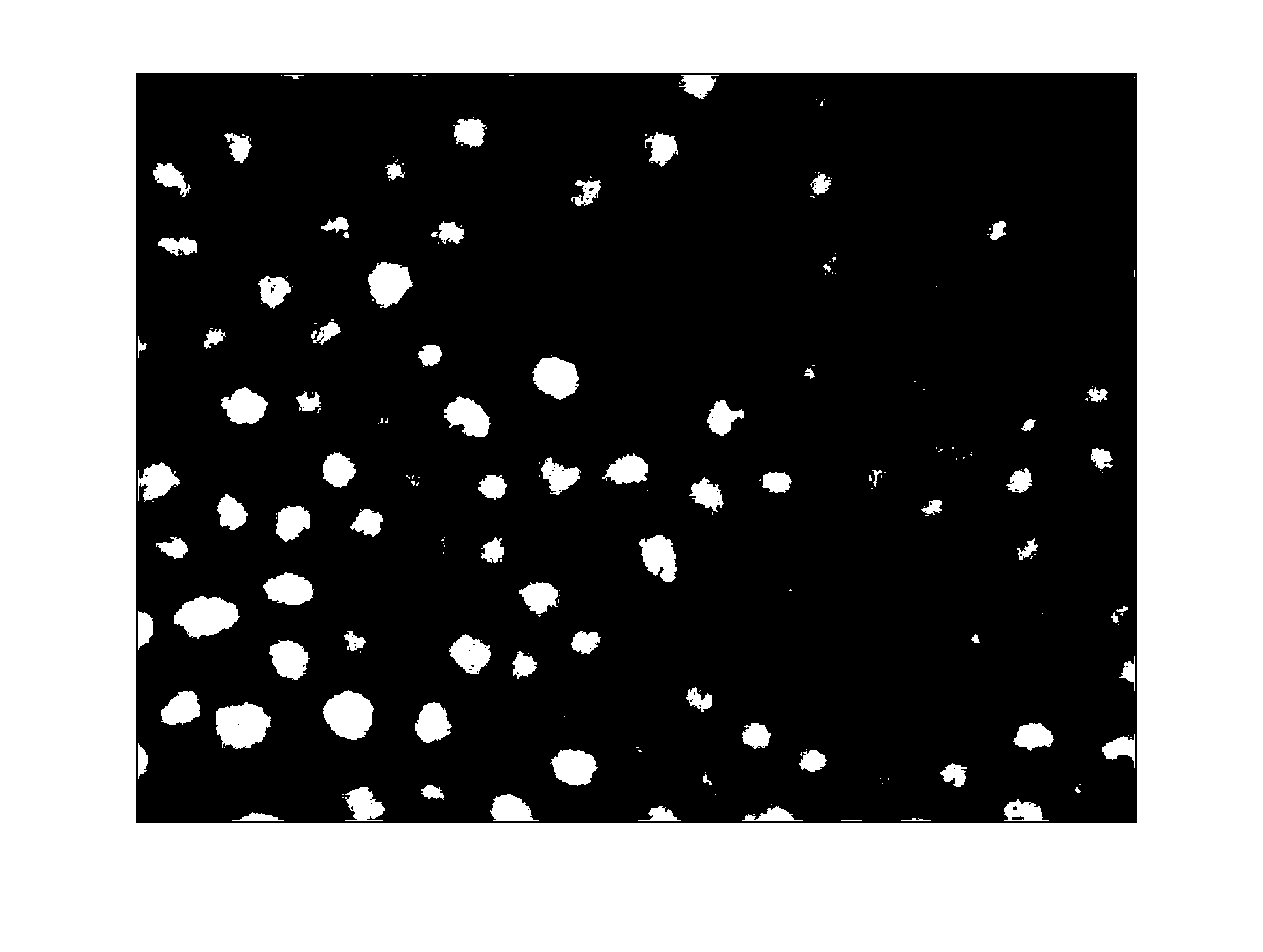

Electrophoretic coating liquid and electrophoretic display layer and preparation methods thereof

ActiveCN103834285AGood lookingReduce the phenomenon of reunionNatural resin coatingsAmylose/amylopectin derivative coatingsPolymer scienceElectrophoresis

The invention provides an electrophoretic coating liquid and a preparation method thereof, the electrophoretic coating liquid includes an adhesive and a microcapsule dispersing in the adhesive, the microcapsule comprises a suspension and charged pigment particles dispersing in the suspension, the outer capsule wall of the microcapsule is prepared by use of a natural water-soluble polymer compound, and the adhesive comprises the water-soluble polymer compound and aqueous polyurethane. The invention also provides an electrophoretic display layer and a preparation method thereof, and the electrophoretic display layer is prepared by use of the electrophoretic coating liquid. The electrophoretic coating liquid achieves a good balance in mechanical properties, coating film properties, photoelectric properties and other aspects, and has the characteristic of being easy to coat a film, excellent in coating film appearance and the like, and the electrophoretic display layer prepared by use of the electrophoretic coating liquid has high mechanical performances and good photoelectric performances.

Owner:GUANGZHOU OED TECH INC

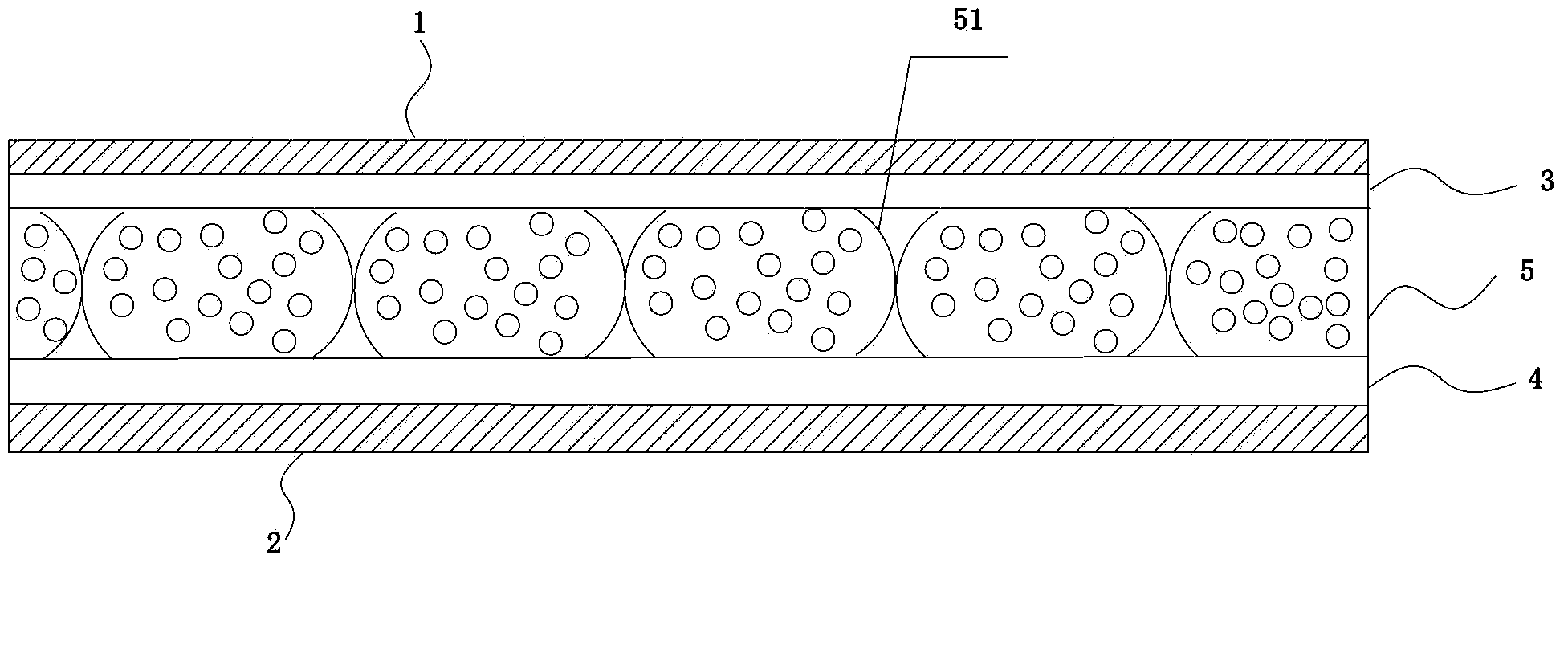

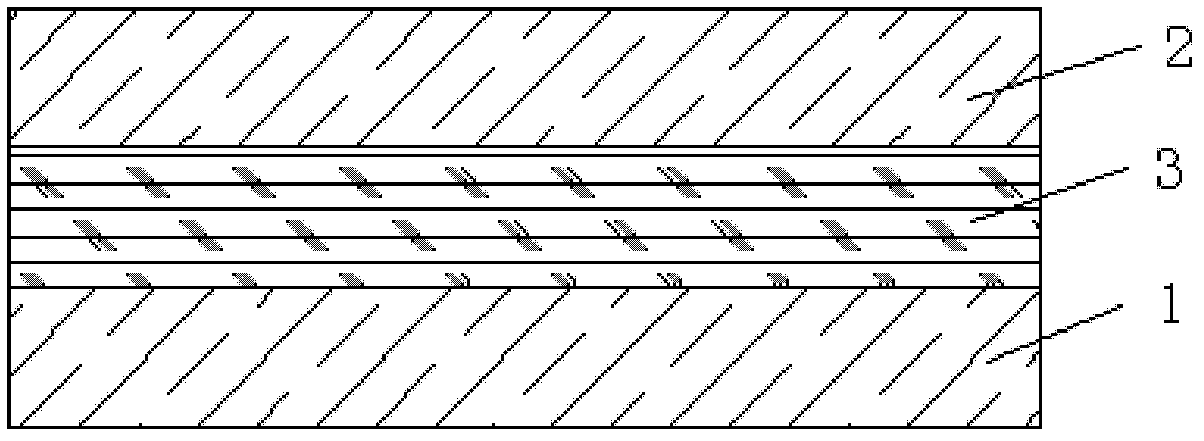

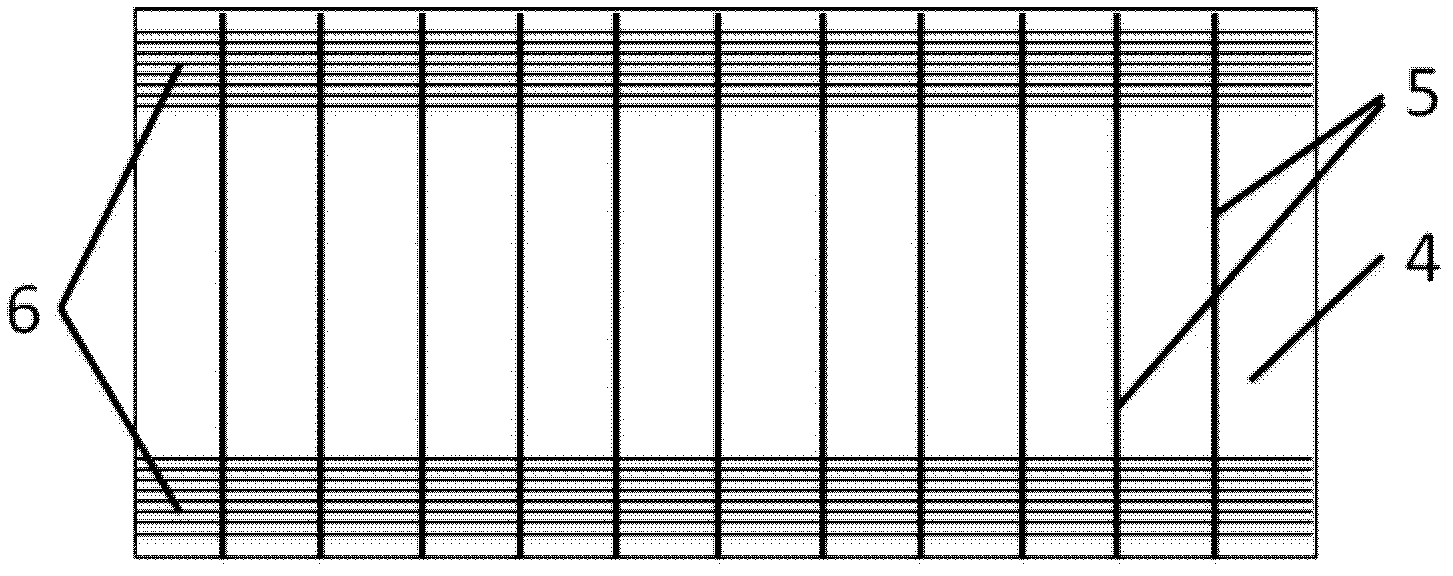

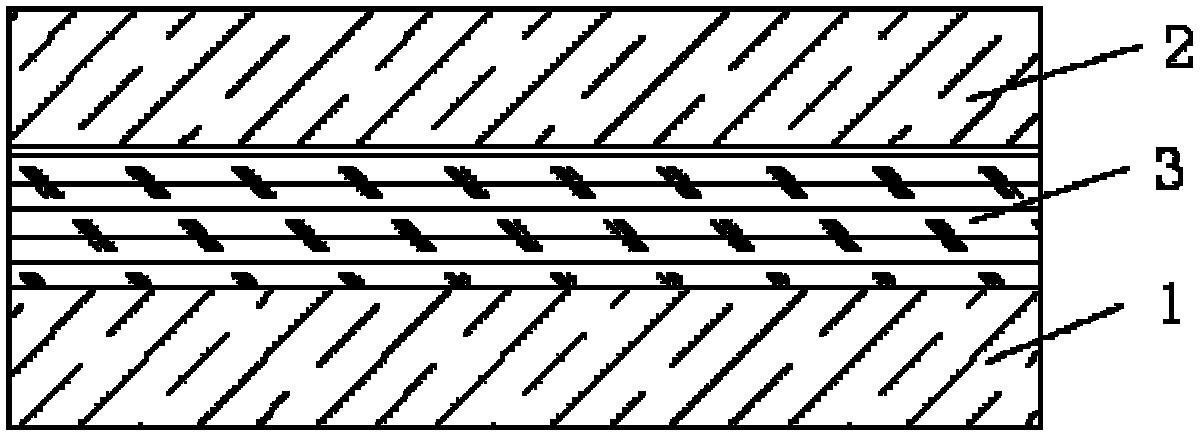

Self-limiting temperature electrothermal membrane of PTC high-molecular conductive fiber and preparation method thereof

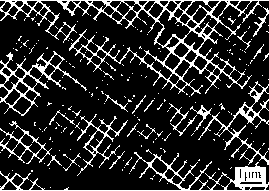

ActiveCN102307403ANot easy to formThe coefficient of thermal expansion is roughly equivalent toWoven fabricsHeating element materialsFiberSelf limiting

The invention relates to a self-limiting temperature electrothermal membrane of a high-molecular conductive fiber with a positive temperature coefficient (PTC). The electrothermal membrane comprises a first insulating layer, a second insulating layer and a high-molecular PTC conductive braid layer, wherein the high-molecular PTC conductive braid layer consists of a braid lower layer, a plurality of polyvinyl PTC conductive fibers with carbon black filled type and two current carrying strips. The polyvinyl PTC conductive fiber with carbon black filled type is composed of the following raw materials: a polyethylene resin, an ethylene-vinyl acetate copolymer, carbon black and a carbon fiber and the like. The electrothermal membrane has advantages of stable electrothermal function and good flame retardant property. The preparation method comprises the following steps: preparing polyvinyl PTC conductive fibers with carbon black filled type; preparing a high-molecular PTC conductive braid layer; and carrying out calendaring moulding on a first insulating layer, a second insulating layer and the high-molecular PTC conductive braid layer. The method has advantages of simple process flow, low cost and easy realization.

Owner:XIAN GAIWO THERMAL ENERGY TECH

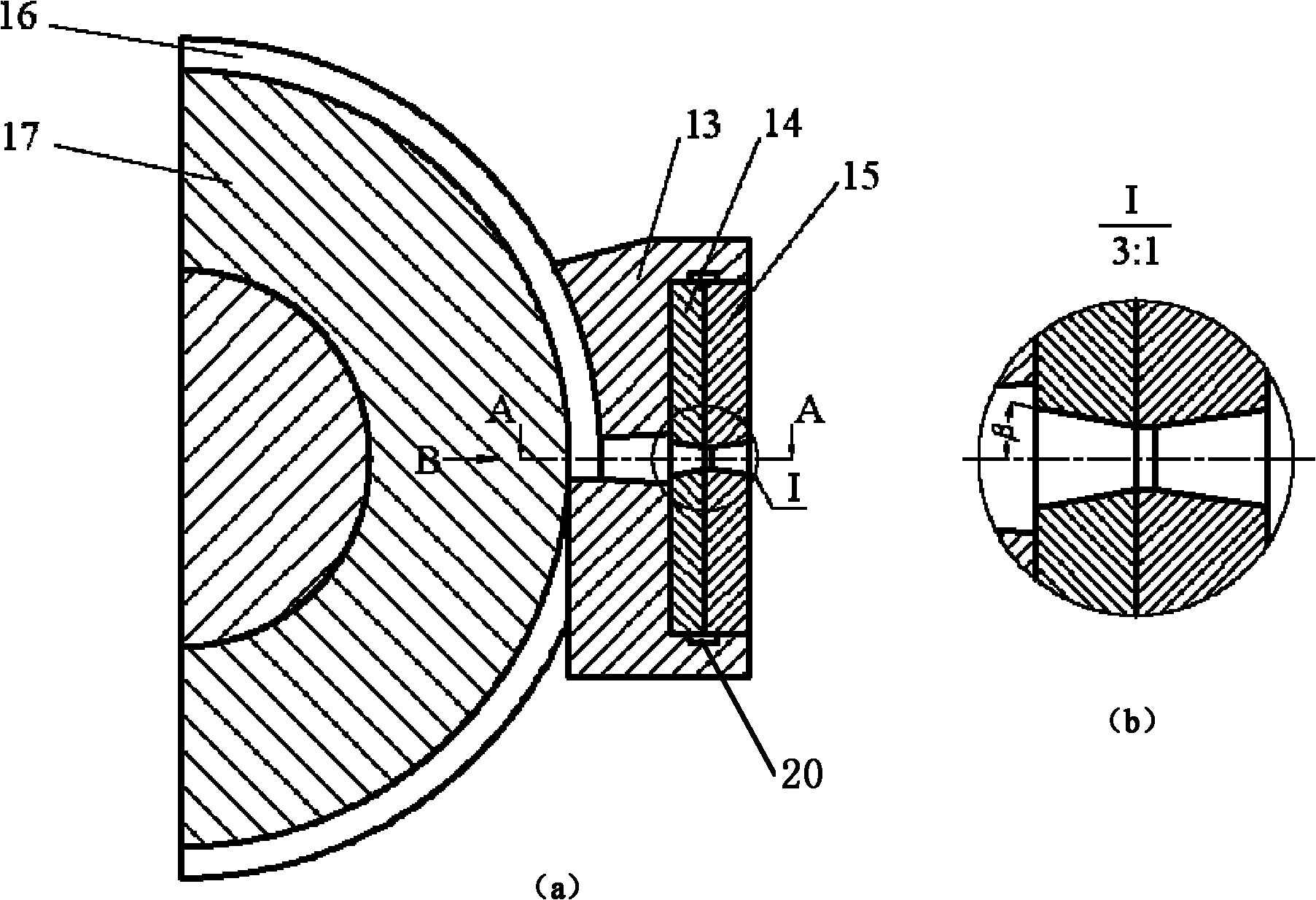

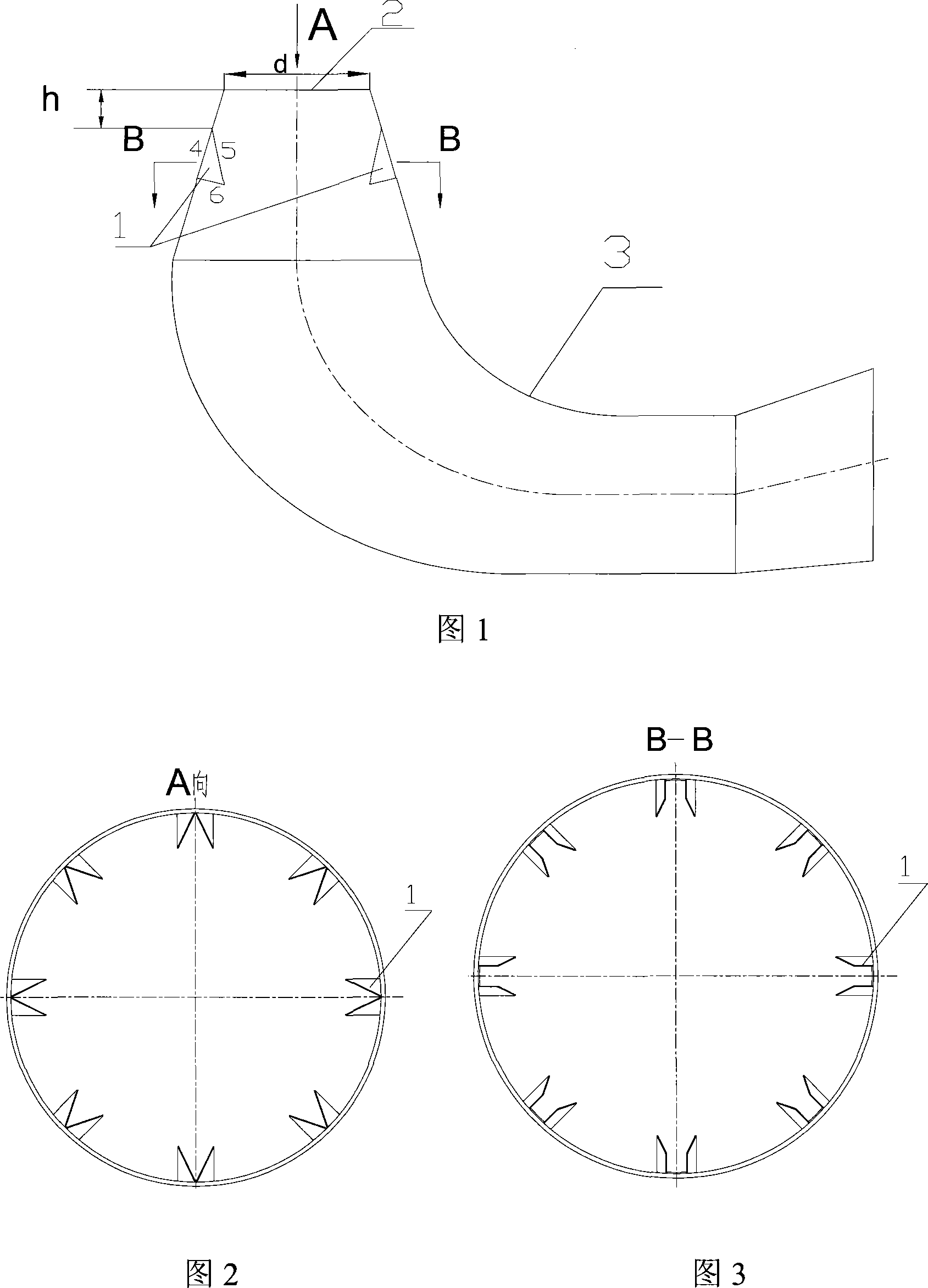

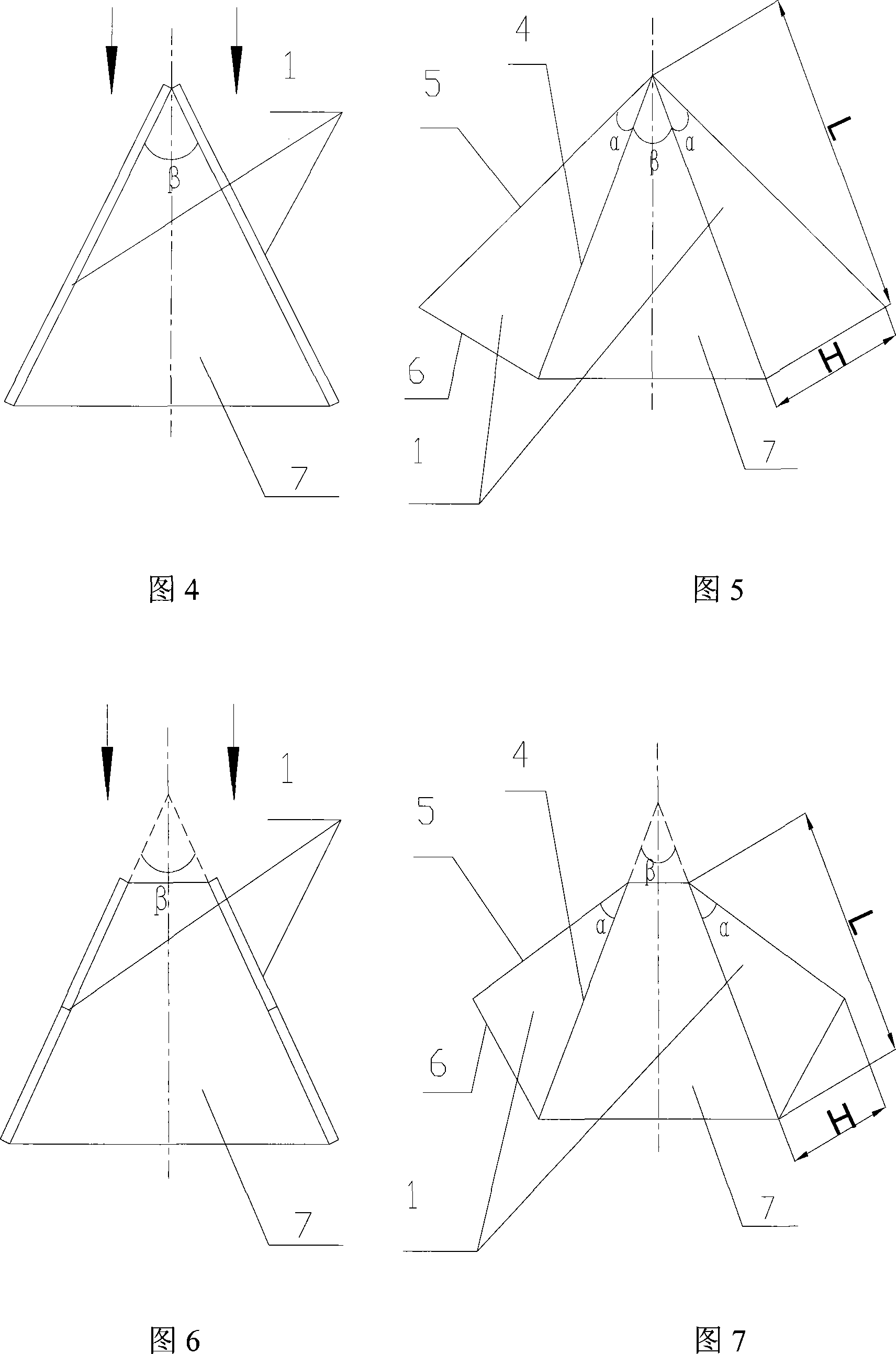

Novel draft-tube and preparation method thereof

InactiveCN101158328AAvoid generatingReduce thicknessFinal product manufactureHydro energy generationEngineeringHigh pressure

The invention relates to a draft tube used for a hydraulic turbine outlet and a manufacture method of the draft tube. The high pressure recovery coefficient of the draft tube of an existing hydraulic turbine is not enough, and the hydraulic turbine can not stably work with high efficiency. The internal wall of the water inlet of the draft tube body of the invention is fixedly provided with 8-30 triangle leaf pairs in the circumference direction. Each triangle leaf pair comprises two triangle leaves which are symmetrically arranged; each triangle leaf comprises a long edge, a short edge, and an installation edge which is connected with the whole edge of the internal wall of the water inlet; wherein, the long edge is arranged at one side close to the end surface of the water inlet; the short edge is arranged at one side far away from the end surface of the water inlet. The invention has the advantages of simple structure, smart arrangement, cheap cost, and wide applicable range, and can ensure the high-efficient and stable operation of hydraulic generator units with different capabilities on all flux working conditions.

Owner:HANGZHOU DIANZI UNIV

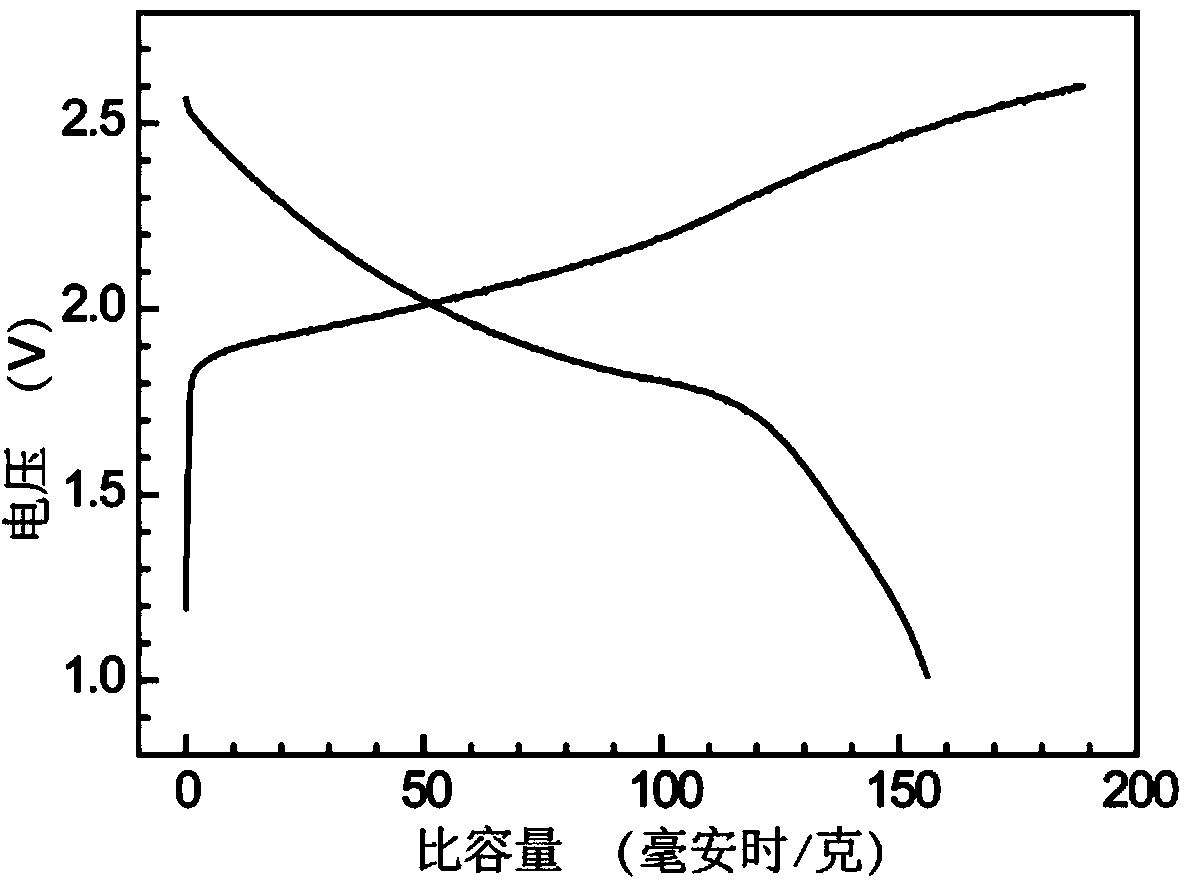

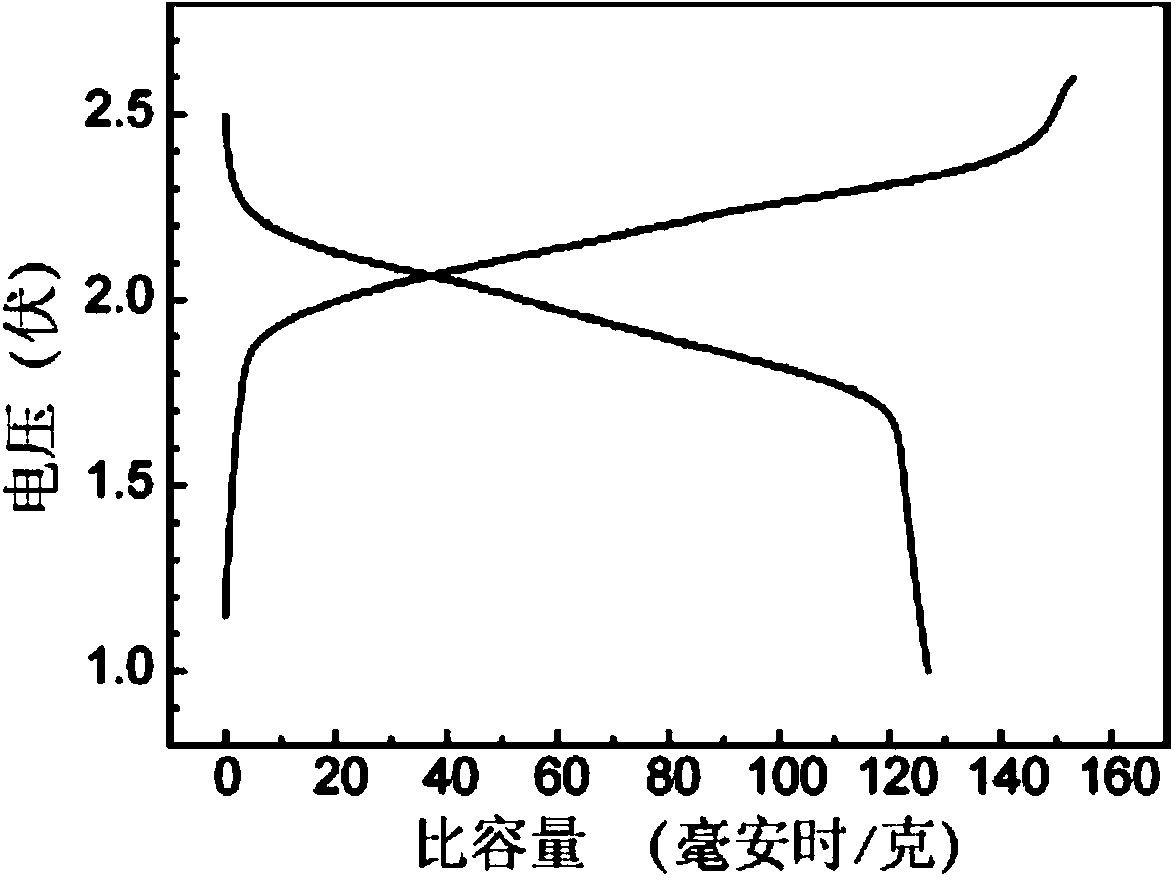

Lithium ion selenium battery with long service life

ActiveCN103700820AImprove securityHigh specific capacityCell electrodesFinal product manufactureAdhesiveWater soluble

The invention discloses a novel lithium ion battery system with long service life. A lithium ion battery comprises a positive electrode, a negative electrode and an electrolyte, wherein the negative electrode comprises elemental selenium or a composite thereof and an adhesive; the adhesive comprises a water-soluble adhesive. The lithium ion battery provided by the invention has the characteristics of high safety, high specific capacity and circulating stability.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Material and method used for TA2/0Cr18Ni9Ti welded by high-entropy effect

InactiveCN102676904AGood strengthImprove performanceWelding/cutting media/materialsSoldering mediaCorrosionSpot welding

The invention discloses a high-entropy interlayer alloy, which comprises the following components in atomic percentage: 5-10% of Ti, 5-10% of Fe, 25-30% of Al, 15-20% of Ni, 30-35% of Cu and 5-10% of Cr. The invention also discloses a method for welding TA2 / 0Cr18Ni9Ti by the high-entropy effect, which comprises the following steps that: high-entropy interlayer alloy is placed between the two plates to be welded, the high-entropy interlayer alloy is in a foil folding structure, and the high-entropy interlayer alloy and local parent metal are subjected to heat fusing by an interface resistor ina resistance spot welding mode, so that the high performance welding of TA2 / 0Cr18Ni9Ti can be realized. According to the method and the high-entropy interlayer alloy of the method, which are disclosed by the invention, the high-entropy interlayer alloy has the advantages of favorable strength, toughness and corrosion resistance, is easy to process and form and is convenient to weld and assembly. The preparation method has the advantages of simple step and low manufacture cost and is convenient to popularize.

Owner:XIAN UNIV OF TECH

High-entropy alloy welding wire for TIG (tungsten inert gas) welding of titanium and steel and preparation method

InactiveCN103639619AHigh strengthImprove toughnessWelding/cutting media/materialsWelding/soldering/cutting articlesHigh entropy alloysCrack free

The invention discloses a high-entropy alloy welding wire for TIG (tungsten inert gas) welding of titanium and steel. The high-entropy alloy welding wire comprises, in total atomic percent of 100%, 30-33% of Zr, 8-12% of Cu, 15-18% of Fe, 20-24% of Ni and 20-24% of Be. The invention further discloses a preparation method of the high-entropy alloy welding wire for TIG welding of the titanium and the steel. The amorphous high-entropy alloy welding wire is fine in smelting and machining property and low in manufacturing cost, and the preparation method and the process of the welding wire are simple. The titanium / steel TIG welding process by the amorphous high-entropy alloy welding wire is simple, the welding wire is effectively matched with the titanium and the steel, a welding zone is crack-free, a welding line is basically a single-phase solid solution texture, and the general mechanical performance of a joint is high.

Owner:XIAN UNIV OF TECH

Method for welding titanium and steel by applying high-entropy effect and welding material

InactiveCN102672328AWide adaptabilityEasy to processWelding/cutting media/materialsSoldering mediaWeld seamTitanium

The invention discloses a method for welding titanium and steel by applying the high-entropy effect. A folded middle-layer alloy foil is arranged between a titanium plate to be welded and a steel plate to be welded, and the welding operation is carried out by adopting a resistance spot-welding mode, then the interface resistance heat melts the middle-layer alloy and local base materials, and the molten metals are mixed, so that the high-performance welding of titanium and steel is realized. The invention also discloses a middle-layer alloy and a preparation method of the middle-layer alloy. The middle-layer alloy comprises the following components in the terms of atomic percent: 20-30% of Al, 35-40% of Ni and 35-40% of Cu, wherein the total percent is 100%. The invention has the advantages that the middle-layer alloy is well matched with the titanium and the alloy steel in welding, welding seams (nugget) are single-phase fcc solid-solution structures, and the comprehensive mechanical performance of joints is obviously improved. The preparation method of the middle-layer alloy foil is simple in process and low in manufacturing cost.

Owner:XIAN UNIV OF TECH

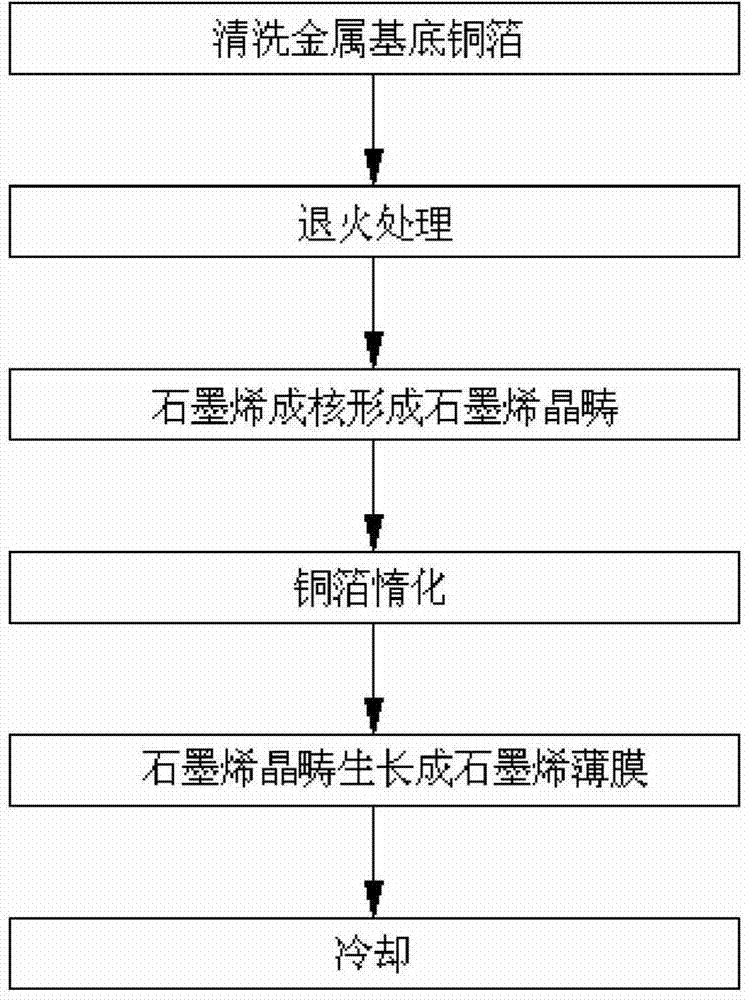

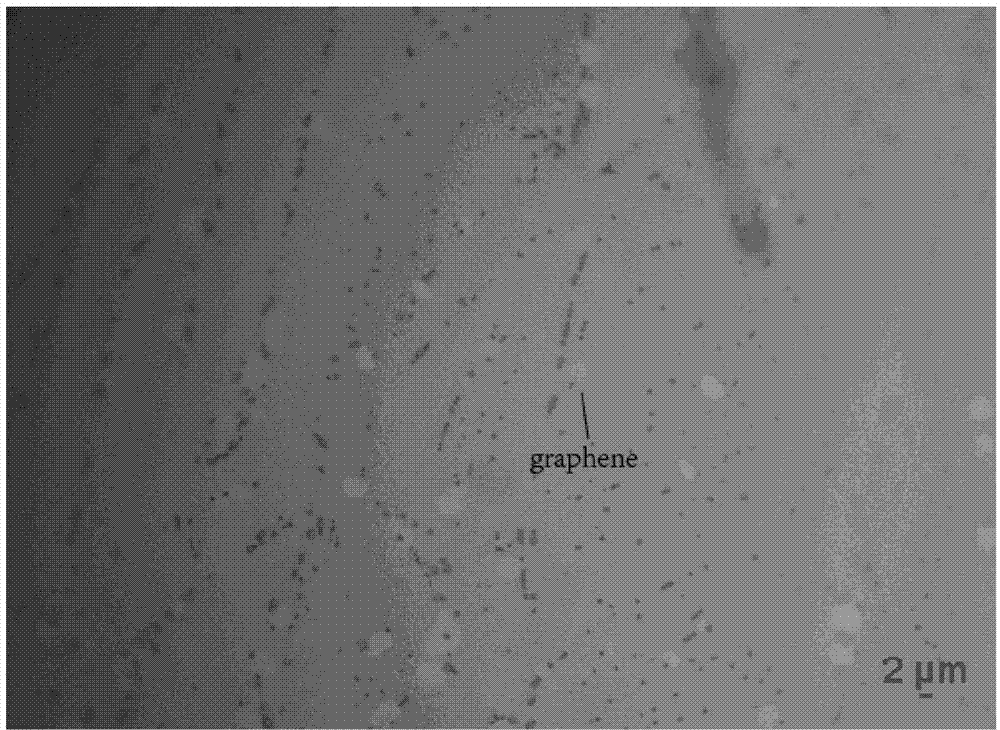

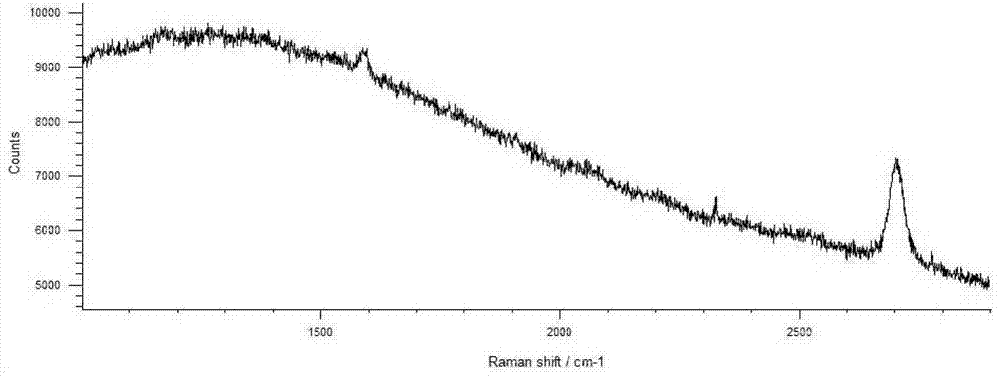

Preparation method of graphene film by virtue of normal-pressure chemical vapor deposition

ActiveCN104498902AQuality improvementSimple stepsChemical vapor deposition coatingGas phaseVolumetric Mass Density

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI +1

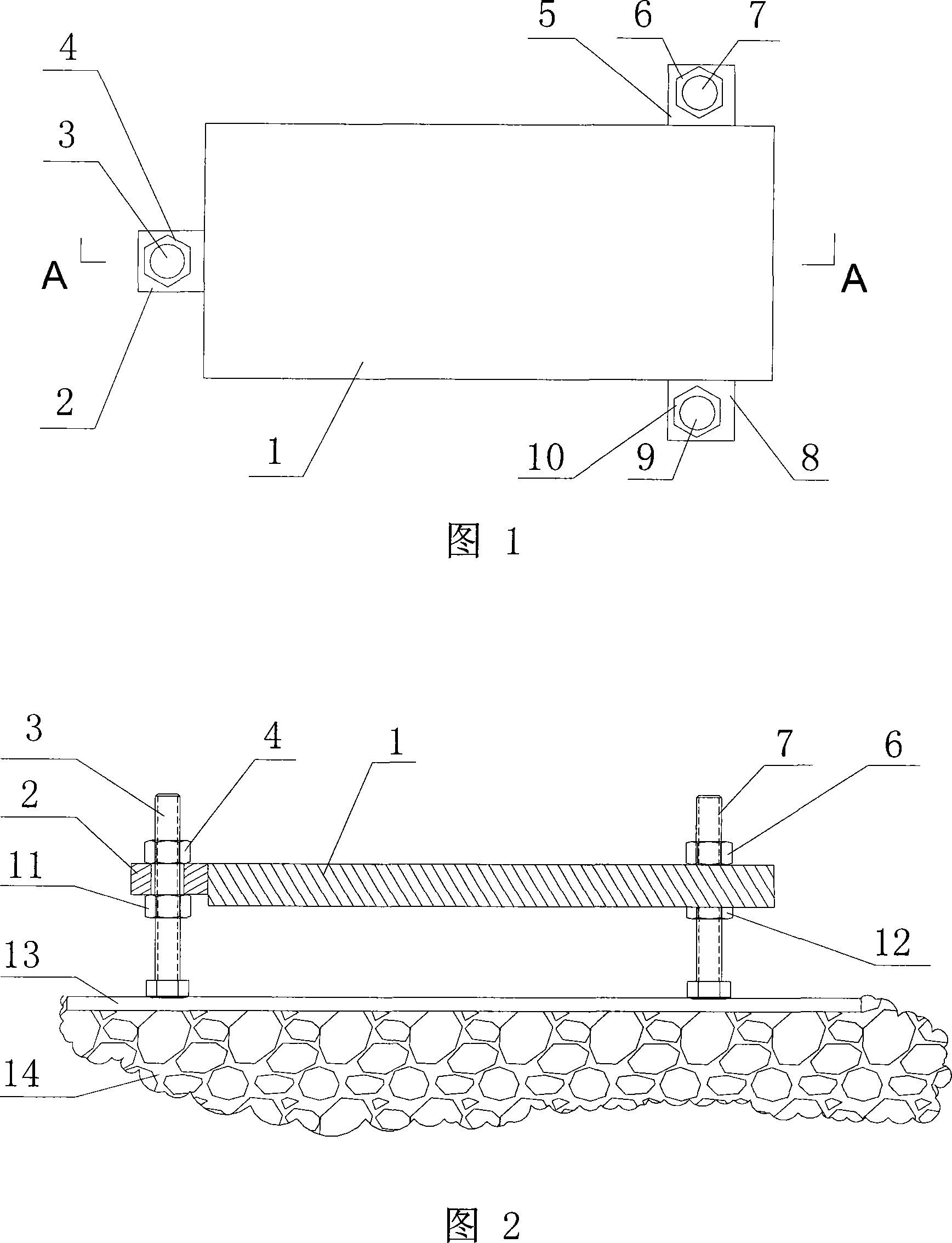

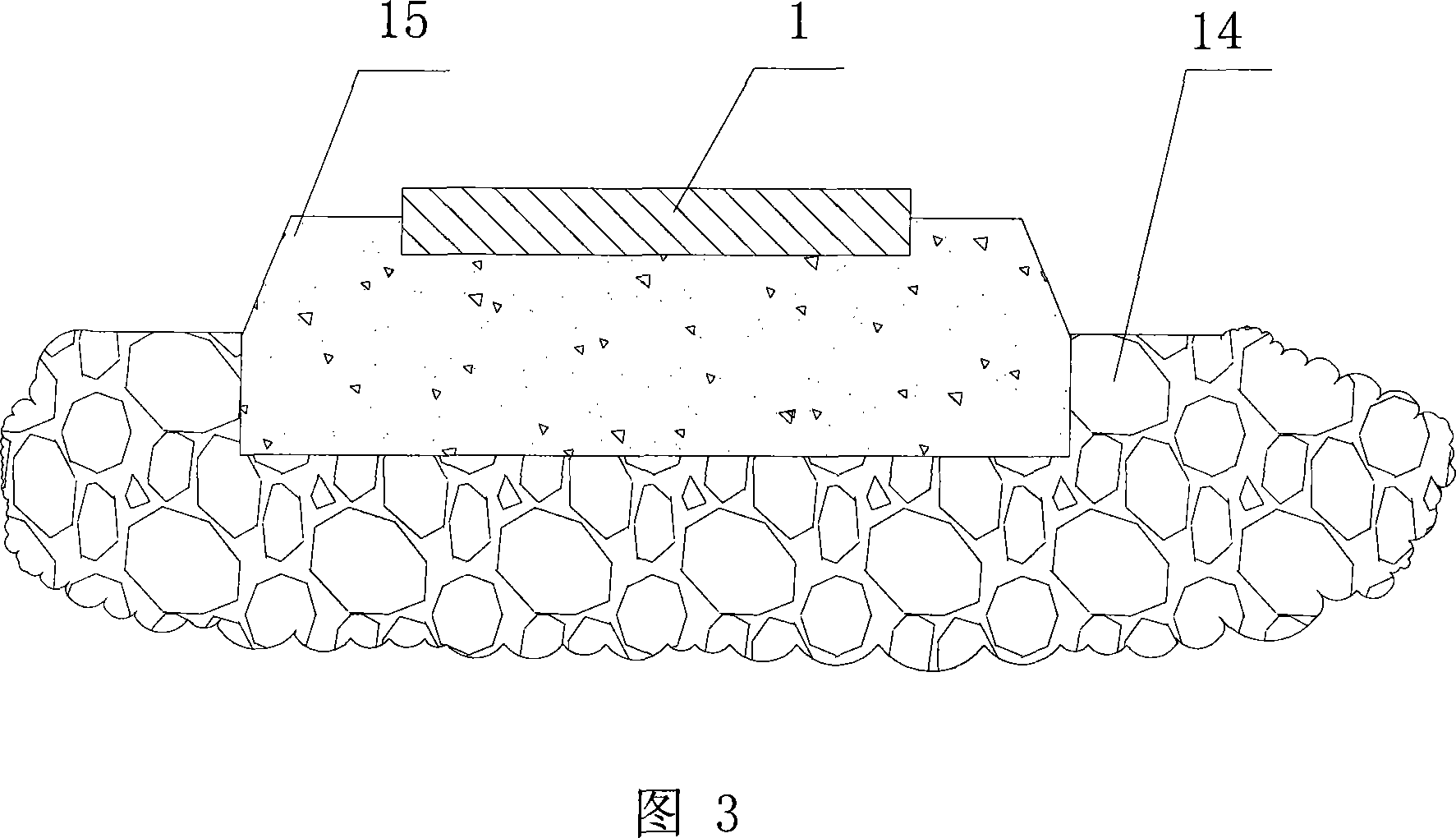

Method for installation of seat slurry method construction packing plate

The invention relates to an installment method of a backing plate in a seat slurry method construction. The installment method of the backing plate in a seat slurry method construction is characterized in that the installment method comprises the following steps: V1ing, the backing plate (1) is respectively welded with a first steel plate (2), a second steel plate (5) and a third steel plate (8) which are equipped with a bolt through hole, a first bolt (3), a second bolt (7) and a third bolt (9) are respectively rotated with a corresponding first regulating nut (11), a second regulating nut (12) and a third regulating nut. V2ing, the lower ends of the first bolt (3), the second bolt (7) and the third bolt (9) are respectively welded on a foundation reinforcement (13) which is arranged on a foundation (14). V3ing, the first regulating nut (11), the second regulating nut (12) and the third regulating nut are regulated, and the backing plate (1) reaches to a needed levelness and an elevation. V4ing, a seat slurry layer is formed through grouting between the backing plate (1) and the foundation (14). The installment method of a backing plate in a seat slurry method construction has the advantages that: 1, the operation is simple, the elevation and the levelness are convenient to regulate, and the accuracy is high. 2, the backing plate is not capable of producing deformation. 3, bubble is not easy to form between the seat slurry layer and the backing plate.

Owner:CHINA FIRST METALLURGICAL GROUP

Spray coating material prepared by titanium-containing high-chromium-nickel alloy, preparation method and use thereof

InactiveCN101260487AExtended service lifeImprove anti-sulfur performanceMetal-working apparatusRheniumVulcanization

The invention relates to a titanium contained high chromel alloy and application thereof in spraying materials. The components of the alloy are (by weight percentage) as follows: the content of chromium is more than or equal to 15 percent and less than or equal to 25 percent, the content of titanium is more than or equal to 1 percent and less than or equal to 6 percent, the content of silicon is more than or equal to 1 percent and less than or equal to 6 percent, the content of carbon is more than or equal to 0 percent and less than or equal to 0.02 percent, the content of nickel is more than or equal to 20 percent and less than or equal to 55 percent, the content of rhenium is more than or equal to 0.5 percent and less than or equal to 6 percent, the content of aluminum is more than or equal to 0 percent and less than or equal to 6 percent, the content of sulfur is more than or equal to 0 percent and less than or equal to 0.035 percent, he content of phosphorus is more than or equal to 0 percent and less than or equal to 0.035 percent, the content of manganese is more than or equal to 0 percent and less than or equal to 0.2 percent, and the rest is iron. After the parts of working equipment are sprayed at high temperature oxidation and high temperature corrosion environments by the spraying material produced by the alloy, since the coating has good high temperature oxidation and vulcanization resistance and hot corrosion resistance performances, the service life of the parts can be greatly improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

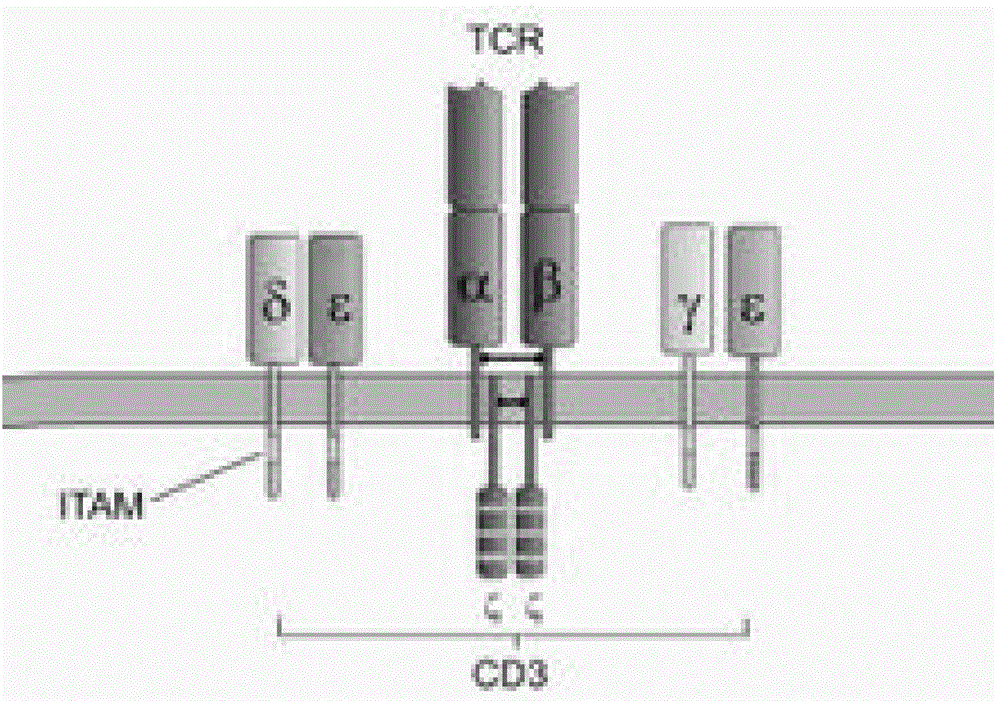

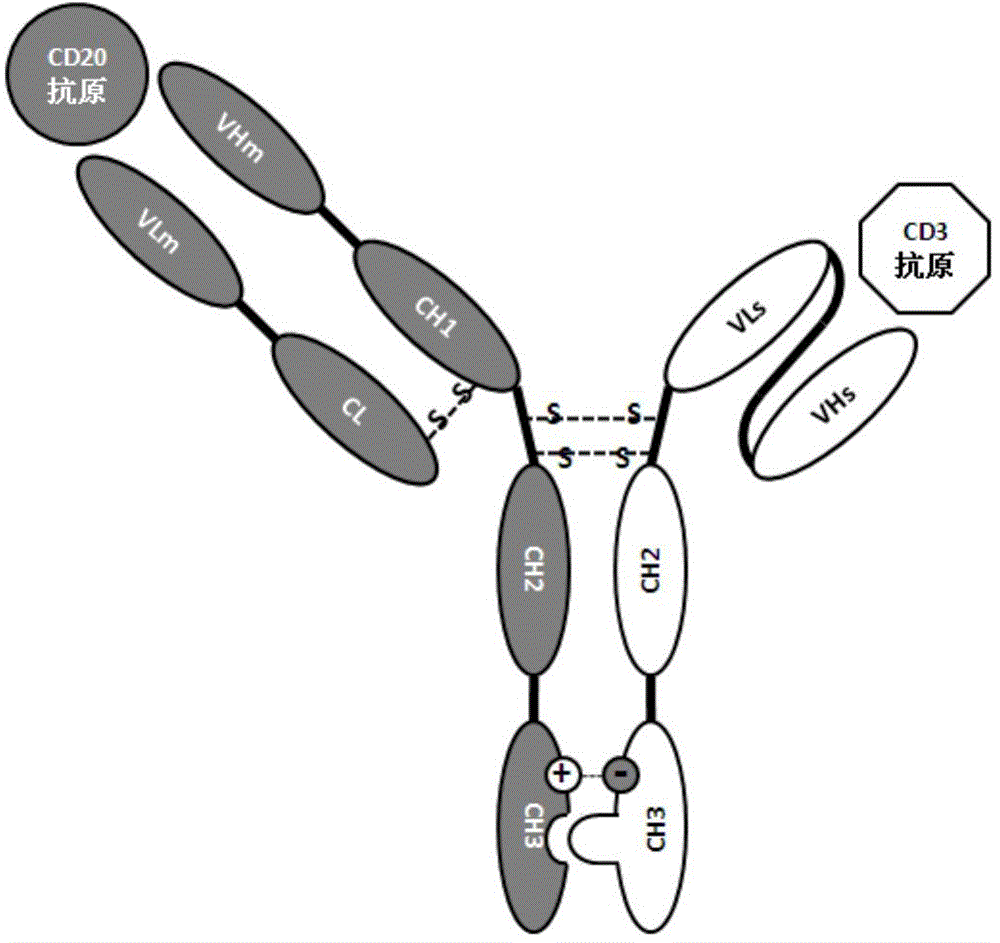

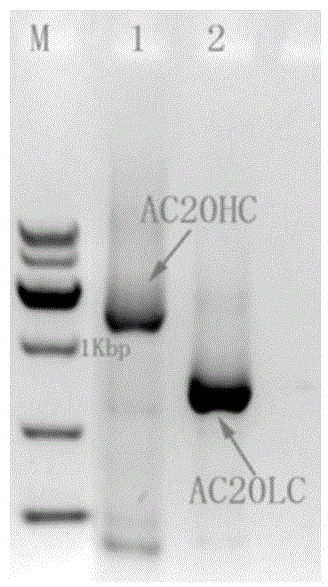

Construction and application of bispecific antibody CD20*CD3

ActiveCN104558191AIncrease lethalityIncreased immunotherapyHybrid immunoglobulinsImmunoglobulins against cell receptors/antigens/surface-determinantsAntigenHeavy chain

The invention provides a bispecific antibody. The bispecific antibody comprises a single-chain unit and a monovalent unit, wherein the single-chain unit has a specific binding capability against the surface antigen CD3 of an immune cell, and the monovalent unit has a specific binding capability against the surface antigen CD20 of a tumor cell; and the single-chain unit comprises a single-chain variable fragment (ScFv) which is fused with an Fc fragment, and the monovalent unit comprises light chain and heavy chain pairs. The invention further provides a method for preparing the bispecific antibody and the medicinal application of the antibody.

Owner:WUHAN YZY BIOPHARMA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com