Efficient low-phosphorus compound water treatment agent

A water treatment agent, high-efficiency technology, applied in water/sludge/sewage treatment, descaling and water softening, chemical instruments and methods, etc. High-level problems, to achieve good synergistic effect, small impact, low phosphorus content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Preparation of composite water treatment agent: 30% polyaspartic acid (PESA), 11% 2-phosphonobutane-1,2,4-tricarboxylic acid (PBTCA), 2% zinc sulfate heptahydrate, 1 % benzotriazole, 28% maleic acid-acrylic acid copolymer (brand SQ-934, produced by Shandong Tianqing Technology Development Co., Ltd.), and 28% deionized water were added to the reaction vessel at room temperature and stirred evenly That is, the desired high-efficiency composite water treatment agent is obtained.

[0023] The above-mentioned test water quality was used to carry out the calcium carbonate scale inhibition and rotary coupon tests. The dosage of the composite water treatment agent was 16mg / L, the static scale inhibition rate was 84.38%, the corrosion rate to carbon steel was 0.034mm / a, and the corrosion rate to copper was 0.0017mm / a, the corrosion rate of stainless steel is 0.0004mm / a.

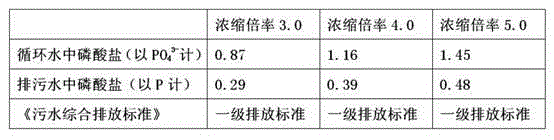

[0024] Example 1 Phosphate control and discharge standards in circulating water at different magnification...

Embodiment 2

[0027] Preparation of composite water treatment agent: 36% polyaspartic acid (PESA), 9% 2-phosphonobutane-1,2,4-tricarboxylic acid (PBTCA), 1% zinc chloride, 0.5% Benzotriazole, 25% maleic acid-acrylic acid copolymer (brand SQ-934, produced by Shandong Tianqing Science and Technology Development Co., Ltd.), and 28.5% deionized water were added to the reaction vessel at room temperature, and stirred evenly. Get the desired high-efficiency composite water treatment agent.

[0028] The above-mentioned test water quality was used to carry out the calcium carbonate scale inhibition and rotary coupon tests. The dosage of the composite water treatment agent was 20mg / L, the static scale inhibition rate was 85.73%, the corrosion rate to carbon steel was 0.047mm / a, and the corrosion rate to copper was 0.0015mm / a, the corrosion rate of stainless steel is 0.0005mm / a.

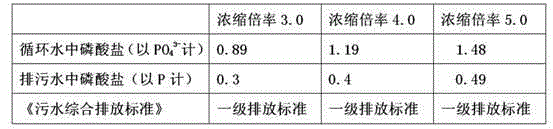

[0029] Example 2 Phosphate Control Standards and Emissions in Circulating Water at Different Rates (Table 3)

[0030] ...

Embodiment 3

[0032] Preparation of composite water treatment agent: 38% polyaspartic acid (PESA), 12% 2-phosphonobutane-1,2,4-tricarboxylic acid (PBTCA), 4% zinc sulfate, 0.5% benzene Paratriazole, 18% maleic acid-acrylic acid copolymer (brand SQ-934, produced by Shandong Tianqing Science and Technology Development Co., Ltd.), and 27.5% deionized water were added to the reaction vessel at room temperature, and stirred evenly to obtain The required high-efficiency composite water treatment agent.

[0033]The above-mentioned test water quality was used to carry out the calcium carbonate scale inhibition and rotary coupon tests. The dosage of the composite water treatment agent was 15mg / L, the static scale inhibition rate was 87.3%, the corrosion rate to carbon steel was 0.046mm / a, and the corrosion rate to copper was 0.0014mm / a, the corrosion rate of stainless steel is 0.0002mm / a.

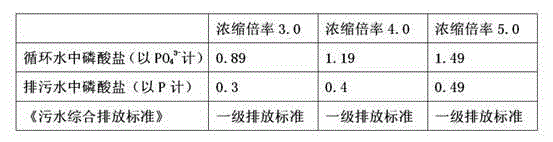

[0034] Example 3 Phosphate Control Standards and Emissions in Circulating Water at Different Rates (Table 4)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com