Glass powder and silver aluminum paste comprising glass powder and used on positive side of N-type double-sided solar cell

A technology for solar cells and glass powder, applied in the field of solar cells, can solve the problems of unsuitable use of low-temperature sintering paste, can not meet the requirements of low-temperature sintering, etc., and achieve the effects of increasing open voltage, small contact resistance, and reducing boron precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

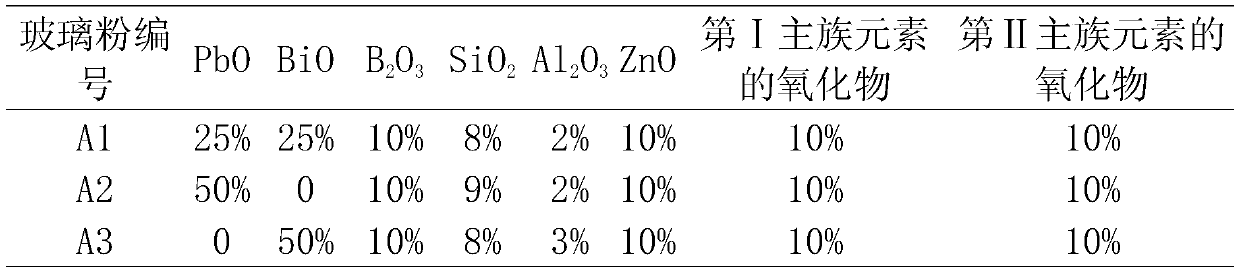

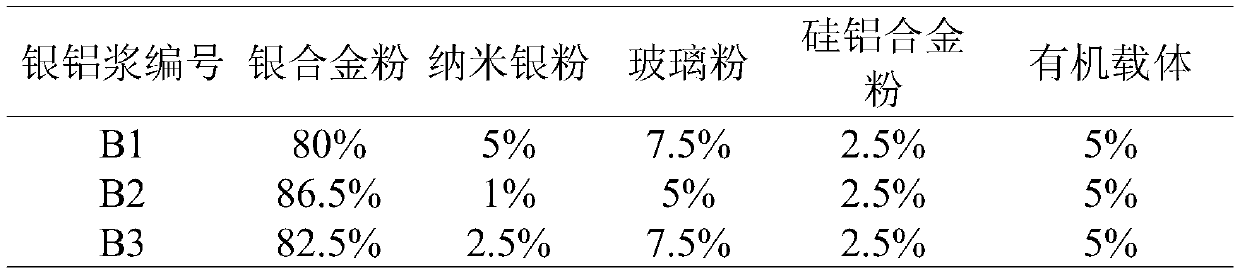

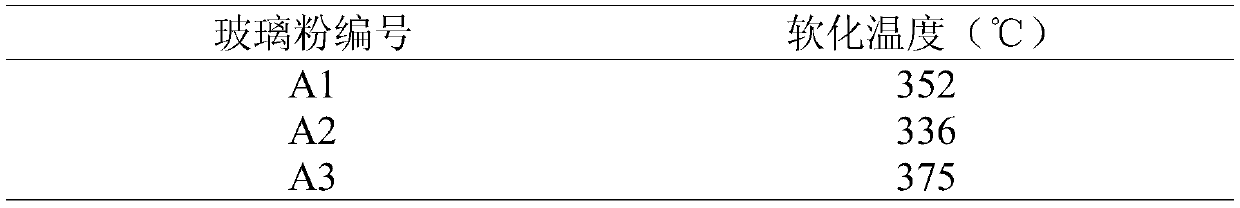

Embodiment 1

[0027] A kind of glass powder, according to A1 formula in table 1, prepare glass powder, PbO, BiO, B 2 o 3 , SiO 2 、Al 2 o 3 and ZnO were weighed and prepared in proportion, and the compound of the main group I elements included 5% Na 2 Compound of O and 5% LiO, group II elements including 3% K 2 O, 3% CaO and 4% BaO, the compounds of the main group I elements and the compounds of the main group II elements are also weighed and prepared according to the proportion, and the above glass powder raw materials are placed in a crucible and mixed at room temperature Evenly, place the crucible carrying the glass powder raw material in a high-temperature furnace and heat it to 1100°C for 1 hour to melt into a uniform molten glass. The above-mentioned molten glass is quenched with deionized water to form irregular glass cullets. Put the above-mentioned glass cullets in a ball mill and pulverize them for 6 hours, and set the speed at 250r / min, sieve the above-mentioned ball-milled g...

Embodiment 2

[0030] A kind of glass powder, according to A2 formula in table 1, prepare glass powder, PbO, B 2 o 3 , SiO 2 、Al 2 o 3 and ZnO were weighed and prepared in proportion, and the oxides of the main group I elements included 5% LiCl and 5% Cs 2 O, compound of group II elements including 5% K 2 O and 5% CaO, the compound of the main group I element and the compound of the main group II element are also weighed and prepared according to the proportion, the above-mentioned glass powder raw material is placed in a crucible and mixed evenly at room temperature, and the loaded The crucible of glass powder raw material is placed in a high-temperature furnace and heated to 1100°C for 1 hour to melt into a uniform molten glass. The above-mentioned molten glass is quenched with deionized water to form irregular glass cullets. The above-mentioned glass cullets are Put it in a ball mill and grind it for 6 hours, set the speed at 250r / min, sieve the above-mentioned ball-milled glass powd...

Embodiment 3

[0033] A kind of glass powder, according to A3 formula in table 1, prepare glass powder, BiO, B 2 o 3 , SiO 2 、Al 2 o 3 and ZnO were weighed and prepared in proportion, in which the compound of the main group I elements included 5% K 2 O and 5% Cs 2 O, compounds of the main group II elements include 3% SrO, 3% MgCO 3 and 4% BaO, the compound of the I main group element and the compound of the II main group element are also weighed and prepared according to the proportion, the above glass powder raw material is placed in a crucible and mixed evenly at room temperature, and the glass Place the crucible of the powdered raw material in a high-temperature furnace and heat it to 1100°C for 1 hour to melt into a uniform molten glass. The above-mentioned molten glass is quenched with deionized water to form irregular glass cullets, and the above-mentioned glass cullets are placed in Pulverize in a ball mill for 6 hours, set the speed at 250r / min, sieve the ball-milled glass powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com