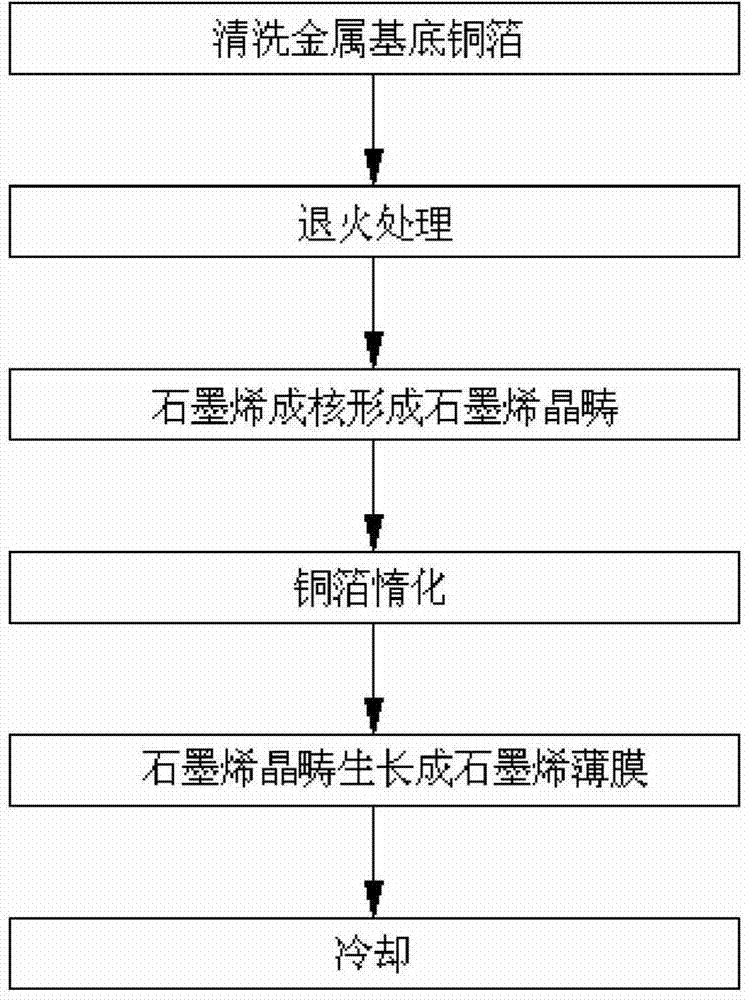

Preparation method of graphene film by virtue of normal-pressure chemical vapor deposition

A normal pressure chemical vapor phase, graphene film technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve problems such as difficulty in crystal domain control, affecting the quality of graphene film, etc., and achieve simple and convenient control. , easy to operate, simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

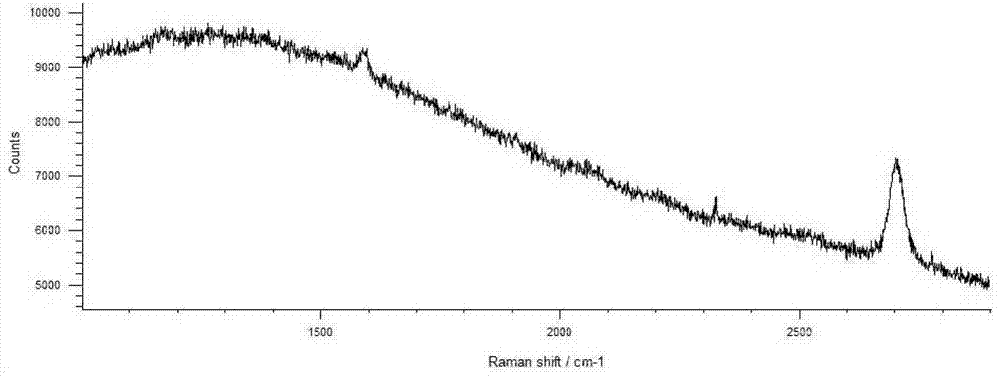

[0036] grow single-layer graphene films, such as image 3 As shown, the Raman spectrum of the grown single-layer graphene film, I 2D Peak and I G The ratio of the peaks is significantly greater than 1, indicating a single-layer graphene film. First, the copper foil with a length and width of 5 cm was cleaned with ethanol and acetone by ultrasonic cleaning for 20 minutes, and then cleaned in dilute nitric acid for 2 minutes to complete the cleaning of the copper foil. Then put the copper foil into the CVD tube furnace, under the condition of normal pressure, the H 2and Ar, the copper foil was heated to a temperature of 1000 °C in the mixed gas, and kept for annealing for 60 minutes. After the annealing of the copper foil is completed, the graphene nucleation is carried out, and the H 2 and Ar, while also passing 1sccm of CH 4 , holding time for 5 minutes, graphene nucleates to form graphene crystal domains. After the graphene crystal domains are formed, the copper foil is...

Embodiment 2

[0038] grow bilayer graphene films, such as Figure 4 As shown, the Raman spectrum of the grown double-layer graphene film, I 2D Peak and I G The peaks are almost at the same height, indicating a bilayer graphene film. First, the copper foil with a length and width of 5 cm was cleaned with ethanol and acetone by ultrasonic cleaning for 20 minutes, and then cleaned in dilute nitric acid for 2 minutes to complete the cleaning of the copper foil. Then put the copper foil into the CVD tube furnace, under the condition of normal pressure, the H 2 and Ar, the copper foil was heated to a temperature of 1000 °C in the mixed gas, and kept for annealing for 60 minutes. After the annealing of the copper foil is completed, the graphene nucleation is carried out, and the H 2 and Ar, while also passing 1sccm of CH 4 , holding time for 5 minutes, graphene nucleates to form graphene crystal domains. After the graphene crystal domains are formed, the copper foil is cooled to below 200°C,...

Embodiment 3

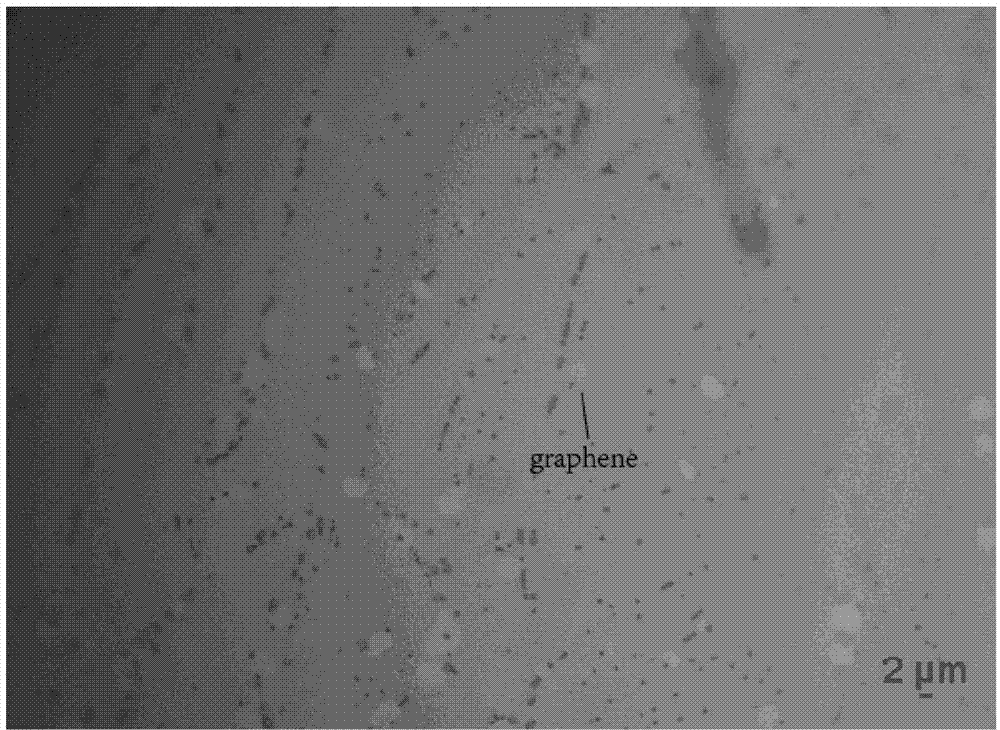

[0040] First, the copper foil with a length and width of 5 cm was cleaned with ethanol and acetone by ultrasonic cleaning for 20 minutes, and then cleaned in dilute nitric acid for 2 minutes to complete the cleaning of the copper foil. Then put the copper foil into the CVD tube furnace, under normal pressure conditions, the flow rate of 100 sccm and 200 sccm H 2 and Ar, the copper foil was heated to a temperature of 900 °C in the mixed gas, and kept for annealing for 60 minutes. After the annealing of the copper foil is completed, the graphene nucleation is carried out, and the H 2 and Ar, while also passing 0.1sccm of CH 4 , holding time for 20 minutes, graphene nucleates to form graphene crystal domains. After the graphene crystal domains are formed, the copper foil is cooled to below 200°C, then taken out from the CVD tube furnace, and the copper foil is heated in an environment with a temperature of 150°C for 1 minute, so that the copper foil that does not grow graphene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com