Self-limiting temperature electrothermal membrane of PTC high-molecular conductive fiber and preparation method thereof

A technology of polymer conduction and conductive fibers, which is applied in the direction of electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of small cracks in the conductive film layer, potential safety hazards, and shedding of the conductive film layer, and achieve easy continuity The effect of simple production, simple structure, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

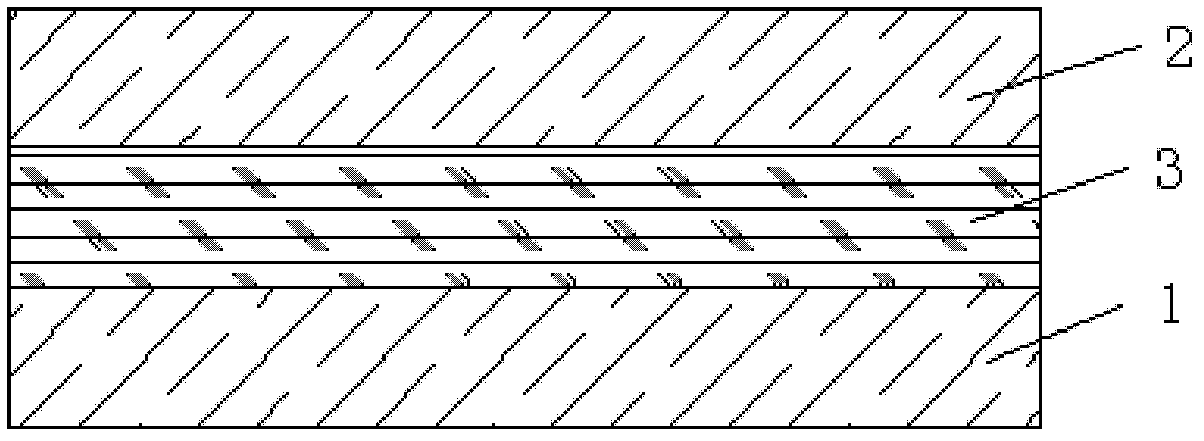

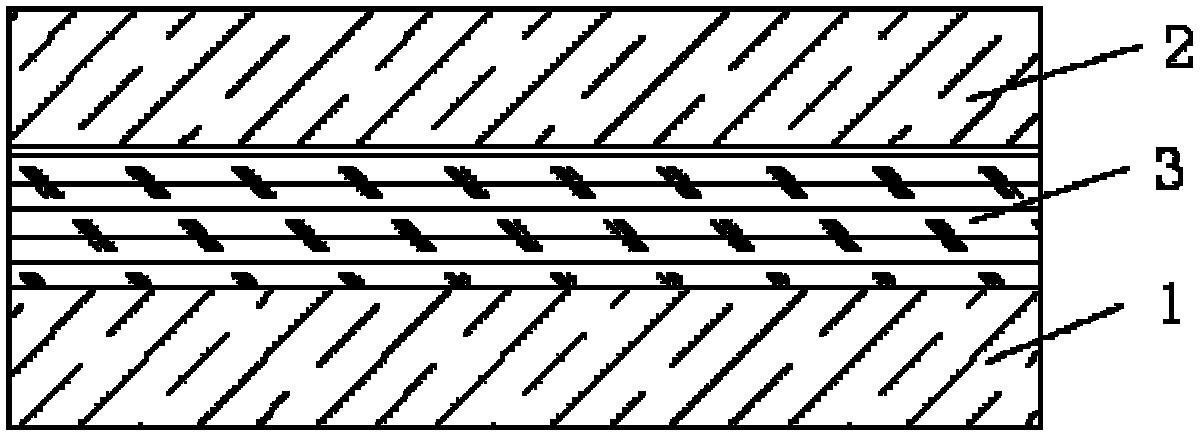

[0044] The preparation method of PTC polymer conductive fiber self-limiting temperature electric heating film of the present invention includes the following steps:

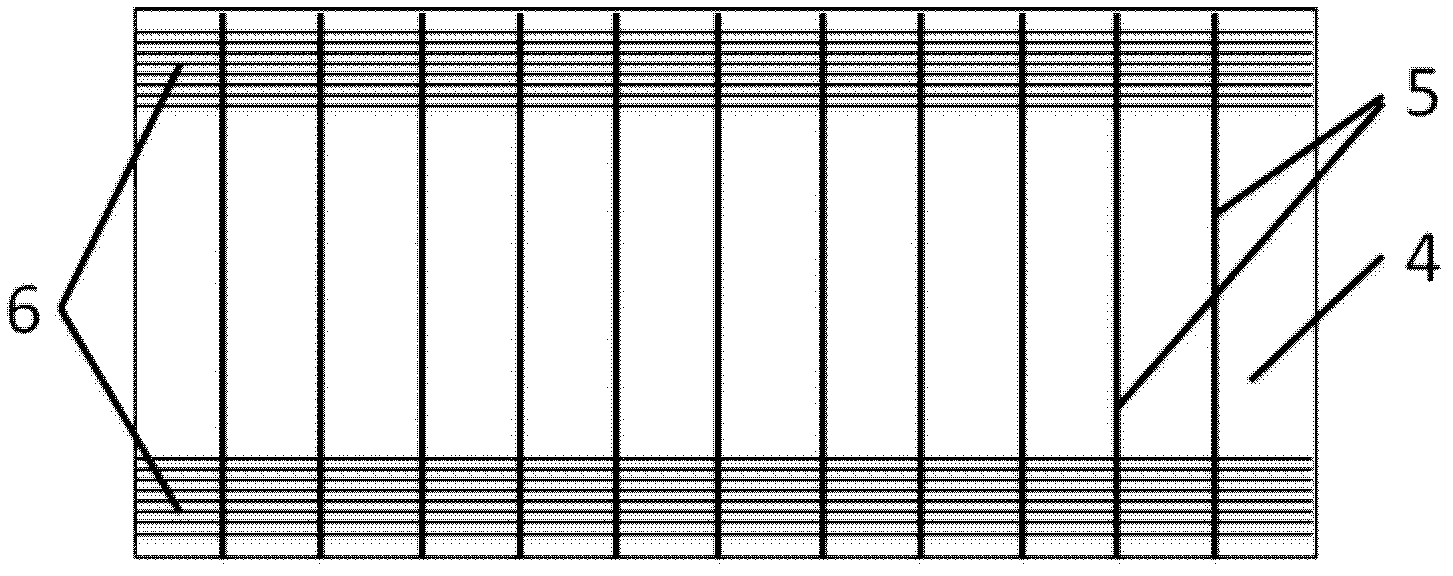

[0045] Step 1. Preparation of carbon black filled polyethylene-based PTC conductive fiber 5:

[0046] Weigh 10-50 parts by weight of carbon black, 1-11 parts by weight of carbon fiber, 20-50 parts by weight of nano calcium carbonate, 1-5 parts by weight of calcium stearate, 1-5 parts by weight of magnesium stearate, and diisopropyl peroxide 0.001 to 0.010 parts by weight of propylbenzene, 0.1 to 2.0 parts by weight of vinyl tris(2-methoxyethoxy) silane, 0.1 to 2.0 parts by weight of dodecylbenzene sulfonic acid, and salicylamide phthalate 1-10 parts by weight of imide, placed in a high-speed mixer and stirred at high speed for 20-25 minutes to obtain a carbon black composition;

[0047] Separately weigh 100 parts by weight of polyethylene resin and 1-50 parts by weight of ethylene-vinyl acetate copolymer for use;

[004...

Embodiment 1

[0057] Step 1. Preparation of carbon black filled polyethylene-based PTC conductive fiber 5:

[0058] Weigh 10kg of carbon black, 11kg of carbon fiber, 20kg of nano calcium carbonate, 1kg of calcium stearate, 5kg of magnesium stearate, 0.001kg of dicumyl peroxide, and 0.1 of vinyl tris(2-methoxyethoxy) silane. kg, 0.1 kg of dodecyl benzene sulfonic acid and 10 kg of salicylamidophthalimide, placed in a high-speed mixer and stirred at high speed for 20 minutes to obtain a carbon black composition;

[0059] Weigh 100kg of low-density polyethylene resin and 1kg of ethylene-vinyl acetate copolymer for use;

[0060] A reciprocating single-screw extruder is used for melting and extrusion spinning, wherein one feed port of the extruder conveys the carbon black composition, and the other feed port conveys low-density polyethylene resin and ethylene-vinyl acetate copolymer , The spinning speed is 1000m / min, and after water cooling at room temperature, it is reeled to obtain a carbon black-fi...

Embodiment 2

[0067] Step 1. Preparation of carbon black filled polyethylene-based PTC conductive fiber 5:

[0068] Weigh 50 kg of carbon black, 1 kg of carbon fiber, 50 kg of nano calcium carbonate, 5 kg of calcium stearate, 1 kg of magnesium stearate, 0.01 kg of dicumyl peroxide, and 2 kg of vinyl tris (2-methoxyethoxy) silane , 2 kg of dodecyl benzene sulfonic acid and 1 kg of salicylamide phthalimide are placed in a high-speed mixer and stirred at high speed for 25 minutes to obtain a carbon black composition;

[0069] Weigh 100kg of high-density polyethylene resin and 50kg of ethylene-vinyl acetate copolymer for use;

[0070] A reciprocating single-screw extruder is used for melting and extrusion spinning, wherein one feed port of the extruder conveys the carbon black composition, and the other feed port conveys high-density polyethylene resin and ethylene-vinyl acetate copolymer , The spinning speed is 100m / min, after water cooling at room temperature, rewinding, the carbon black-filled pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com