Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

443 results about "Primary reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A primary circular reaction is when the infant tries to reproduce an event that happened by accident (ex: sucking thumb) 3.Secondary circular reactions( 4-8 Months Old) Children become aware of things beyond their own body and become more object oriented.

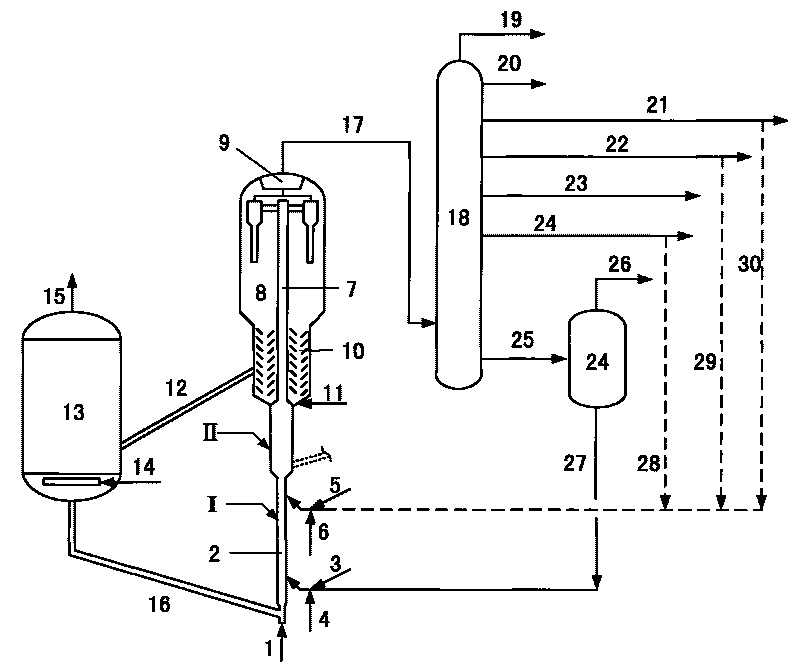

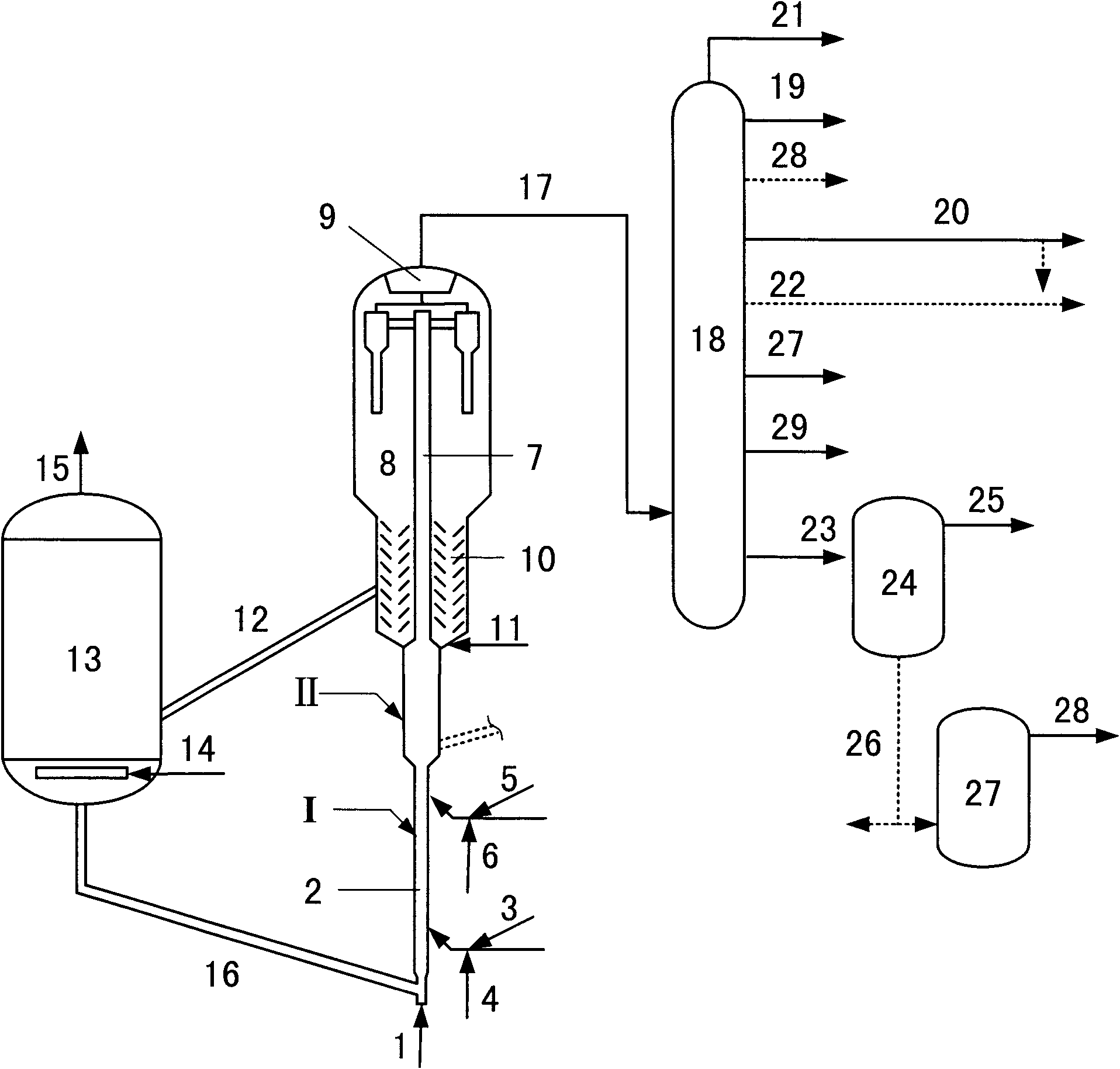

Method for preparing light fuel oil and propylene from inferior raw material oil

ActiveCN101942340AImproved raw material propertiesExtended operating cycleTreatment with plural serial stages onlyTreatment with hydrotreatment processesGas solidWax

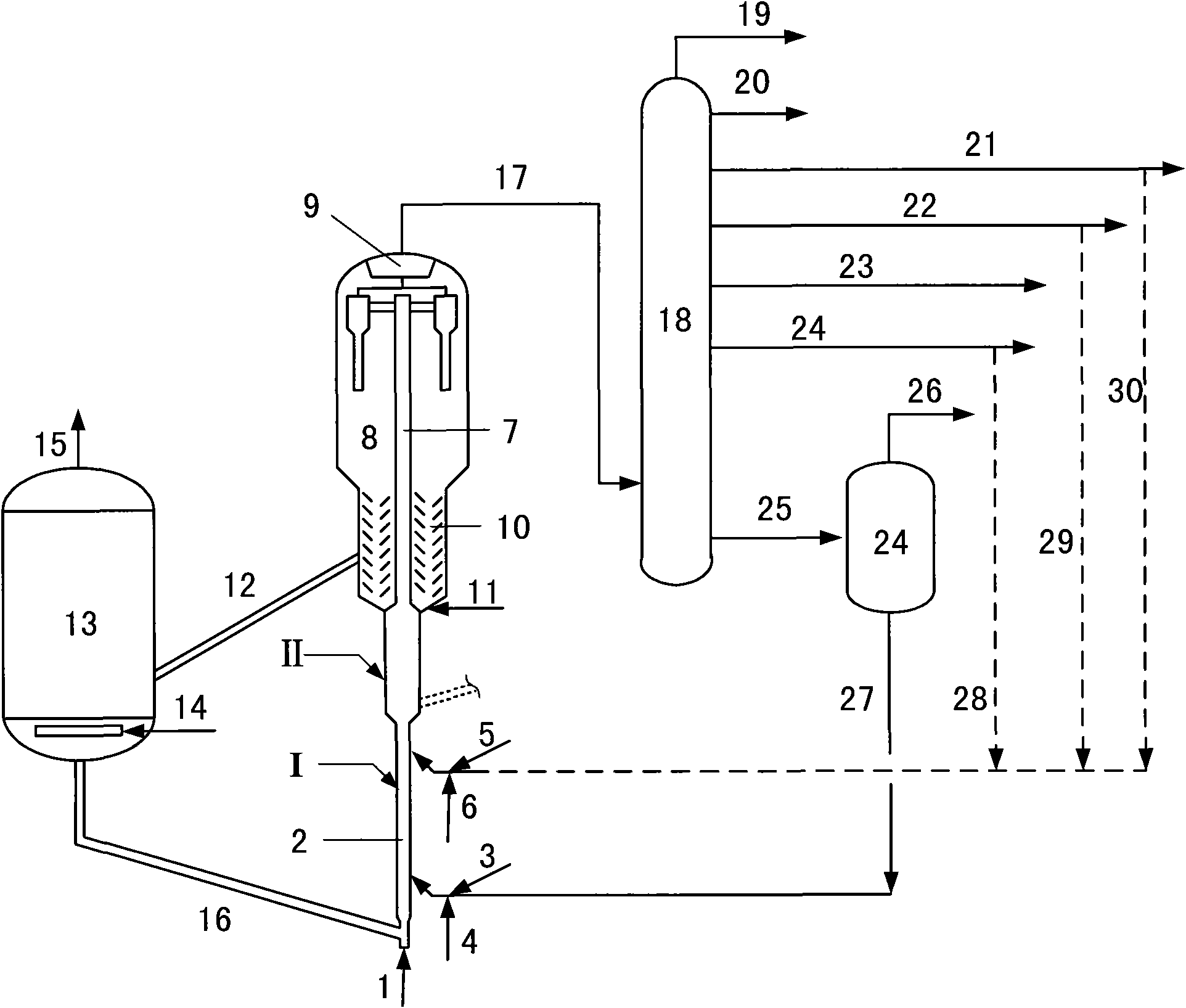

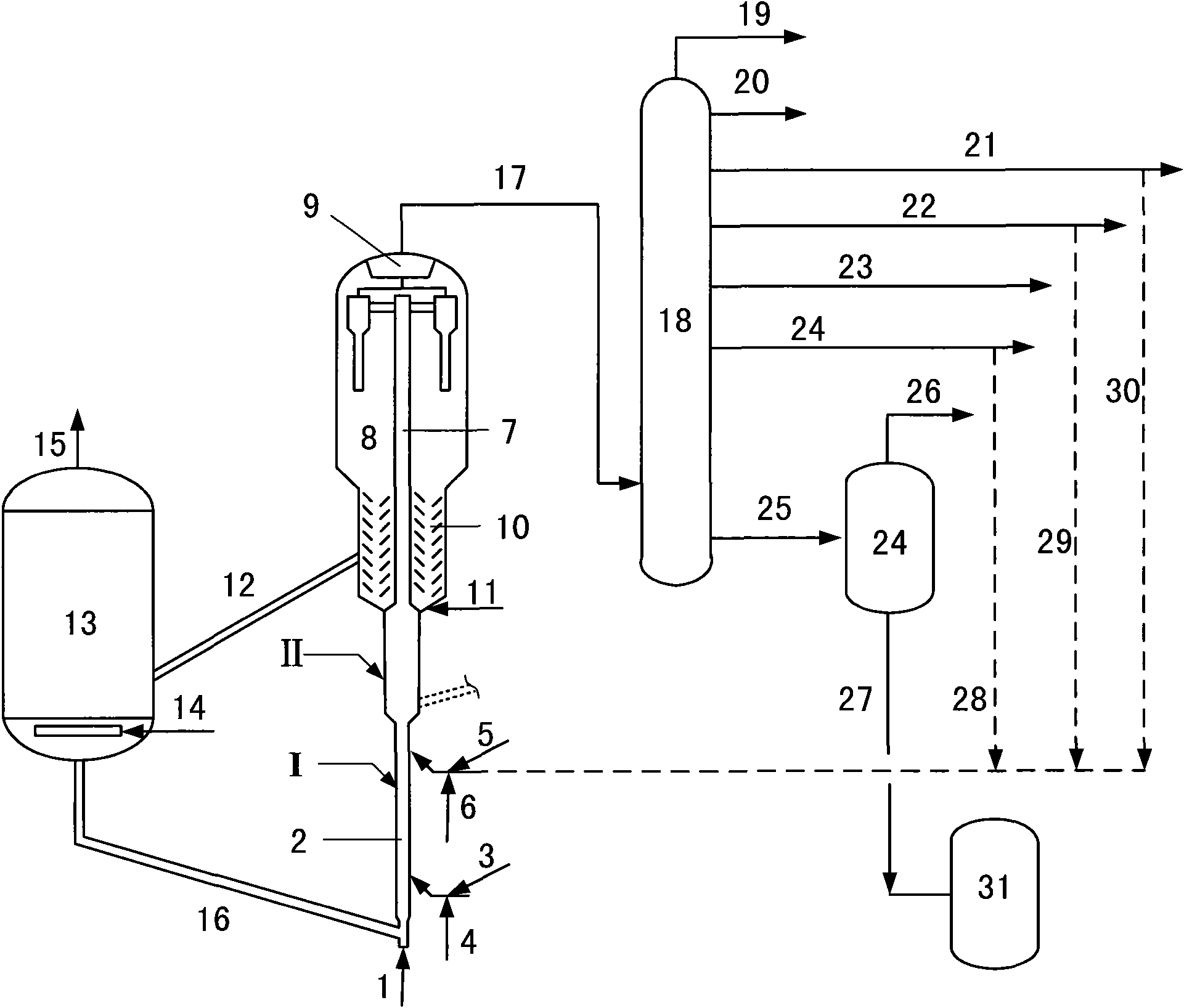

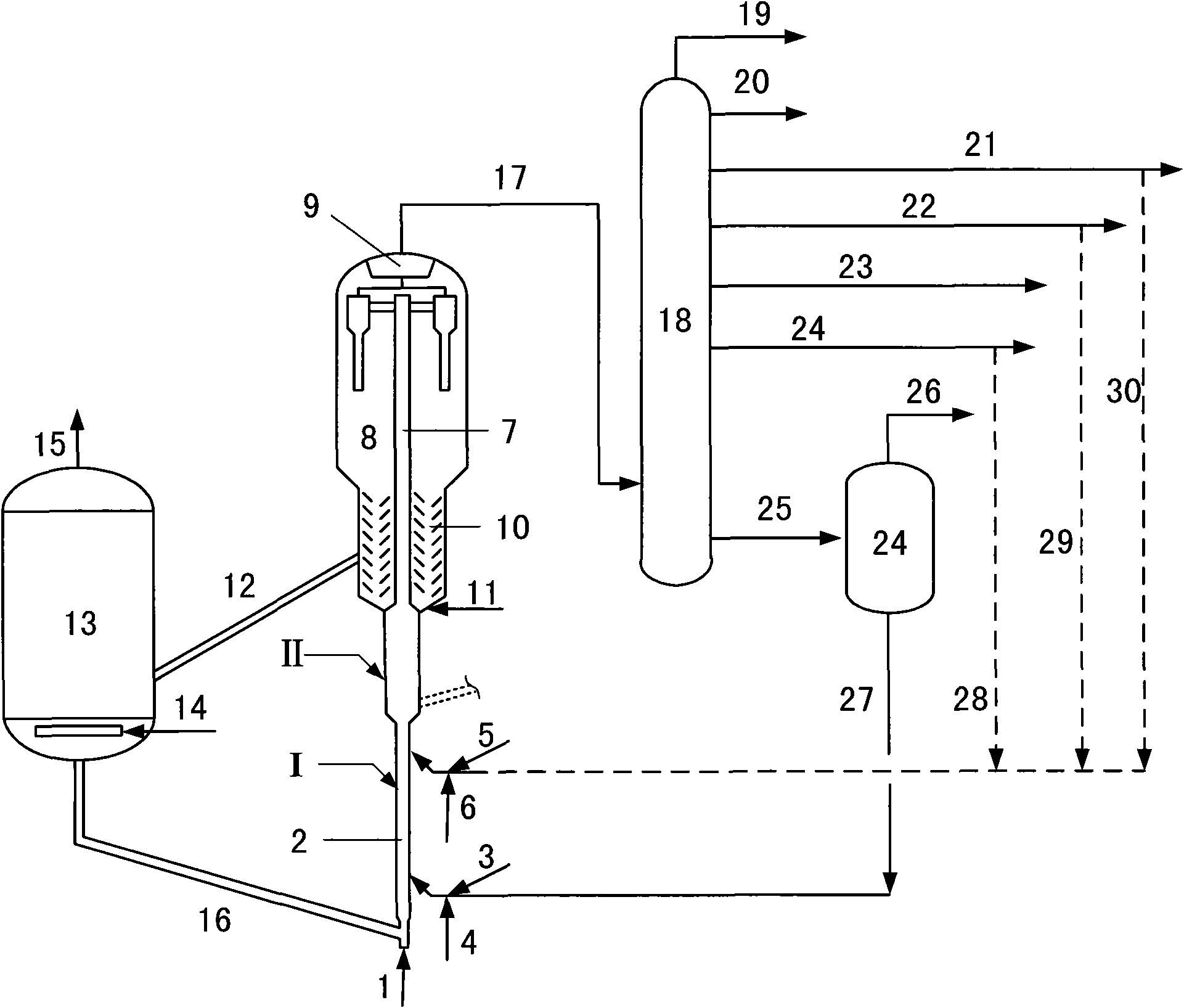

The invention discloses a method for preparing light fuel oil and propylene from inferior raw material oil. The inferior raw material oil enters a first reaction area and a second reaction area of a catalytic conversion reactor in turn to contact a catalytic conversion catalyst with coarse particle size distribution so as to perform primary reaction and secondary reaction respectively; after the reaction product and the spent catalyst undergo gas-solid separation, the spent catalyst is subjected to steam stripping and charring in turn and then returned to the reactor for recycling; and the reaction product is separated to obtain propylene, gasoline, catalytic wax oil and other products, wherein the catalytic wax oil enters at least one of hydrotreatment device, an arene extraction device and a hydrocracking device so as to obtain hydrogenated catalytic wax oil, raffinate oil and hydrocracking tail oil. The method improves the yield of the light oil, reduces the yield of oil slurry, realizes efficient utilization of petroleum resources, reduces the consumption of the catalyst, and reduces the catalyst content of the catalytic wax oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

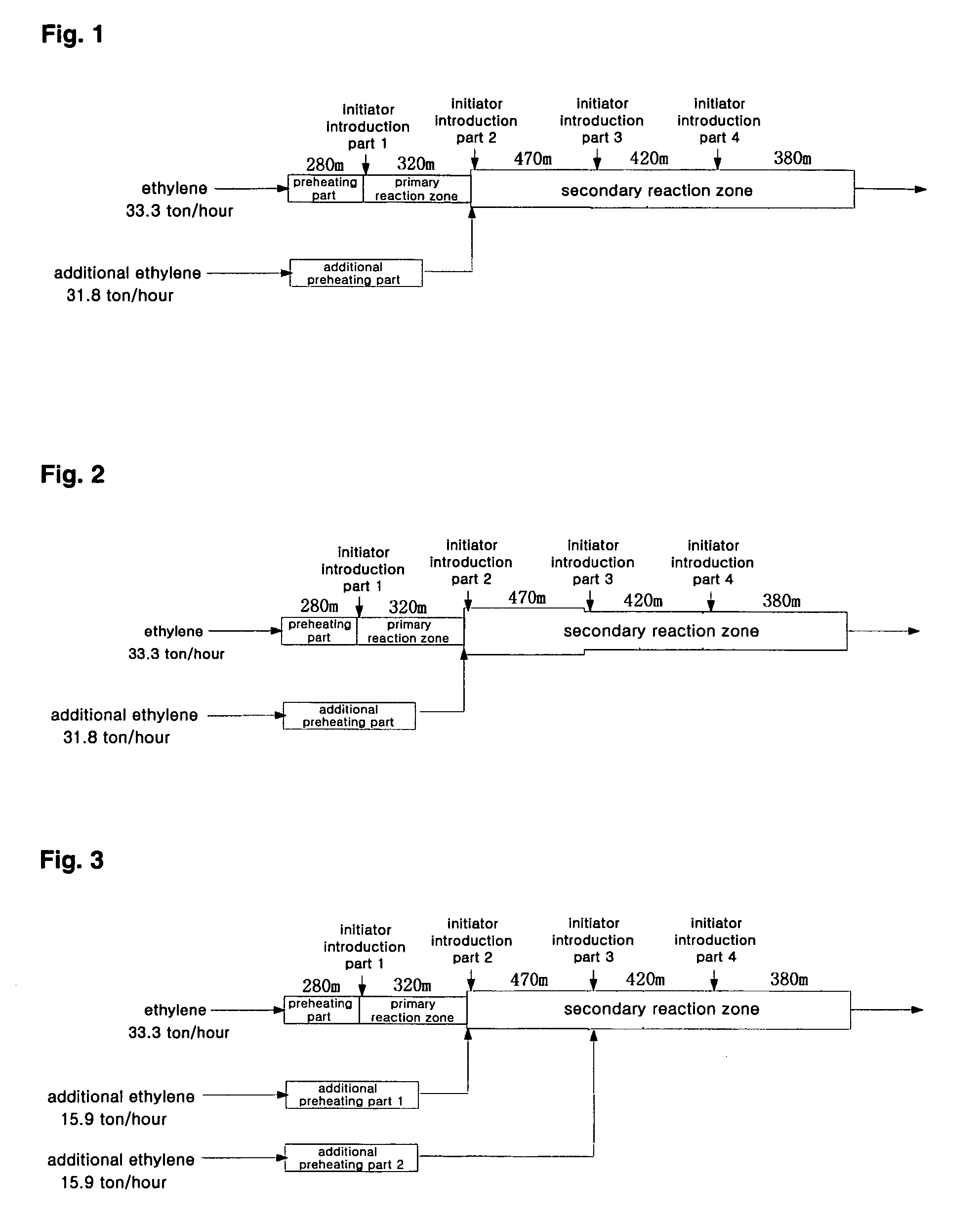

Method of ethylene polymerization for producing products having various properties with high productivity and a tubular reactor used therefor

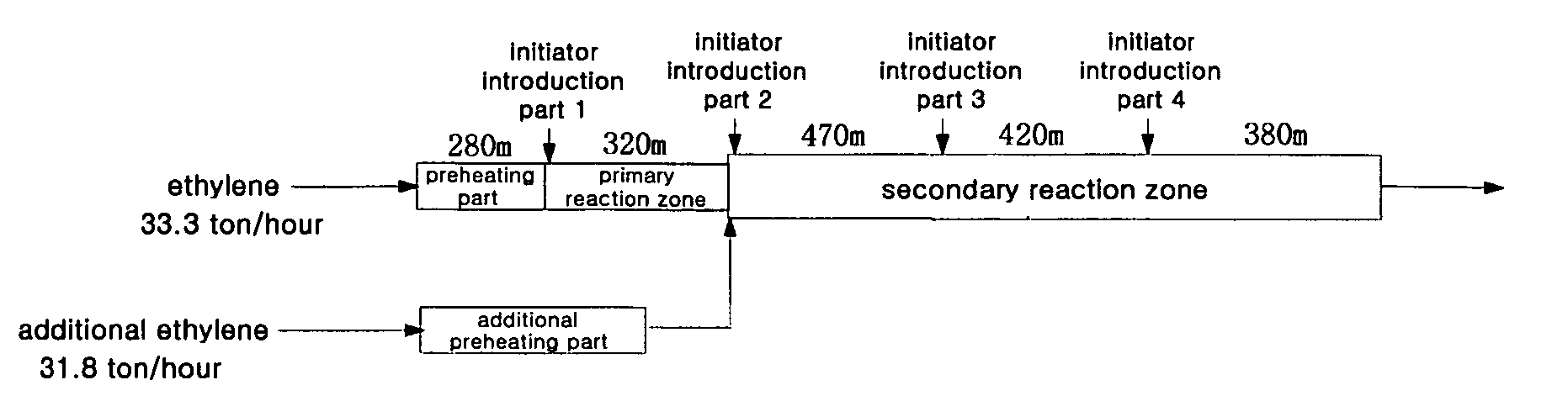

ActiveUS20060149004A1Improve productivityMaintain physical propertiesChemical/physical/physico-chemical stationary reactorsChemical/physical/physico-chemical processesProduction rateReaction zone

A method for continuous ethylene polymerization under high pressure using a polymerization reaction zone comprises a primary reaction zone and a secondary reaction zone wherein the secondary reaction zone has a length of 1.5-6.5 times the length of the primary reaction zone and a cross-sectional area of 1.2-4 times the cross-sectional area of the primary reaction zone. Ethylene is fed continuously into the primary reaction zone at the starting point of the primary reaction zone. Low temperature initiator alone, or an initiator mixture containing mainly low temperature initiator is introduced into the primary reaction zone at the starting point of the primary reaction zone. Initiator alone or an initiator mixture is introduced into the secondary reaction zone at two or more different points of the secondary reaction zone. Ethylene polymer products of various physical properties are produced with high productivity, while the pressure drop is minimized.

Owner:HANWHA TOTALENERGIES PETROCHEMICAL CO LTD

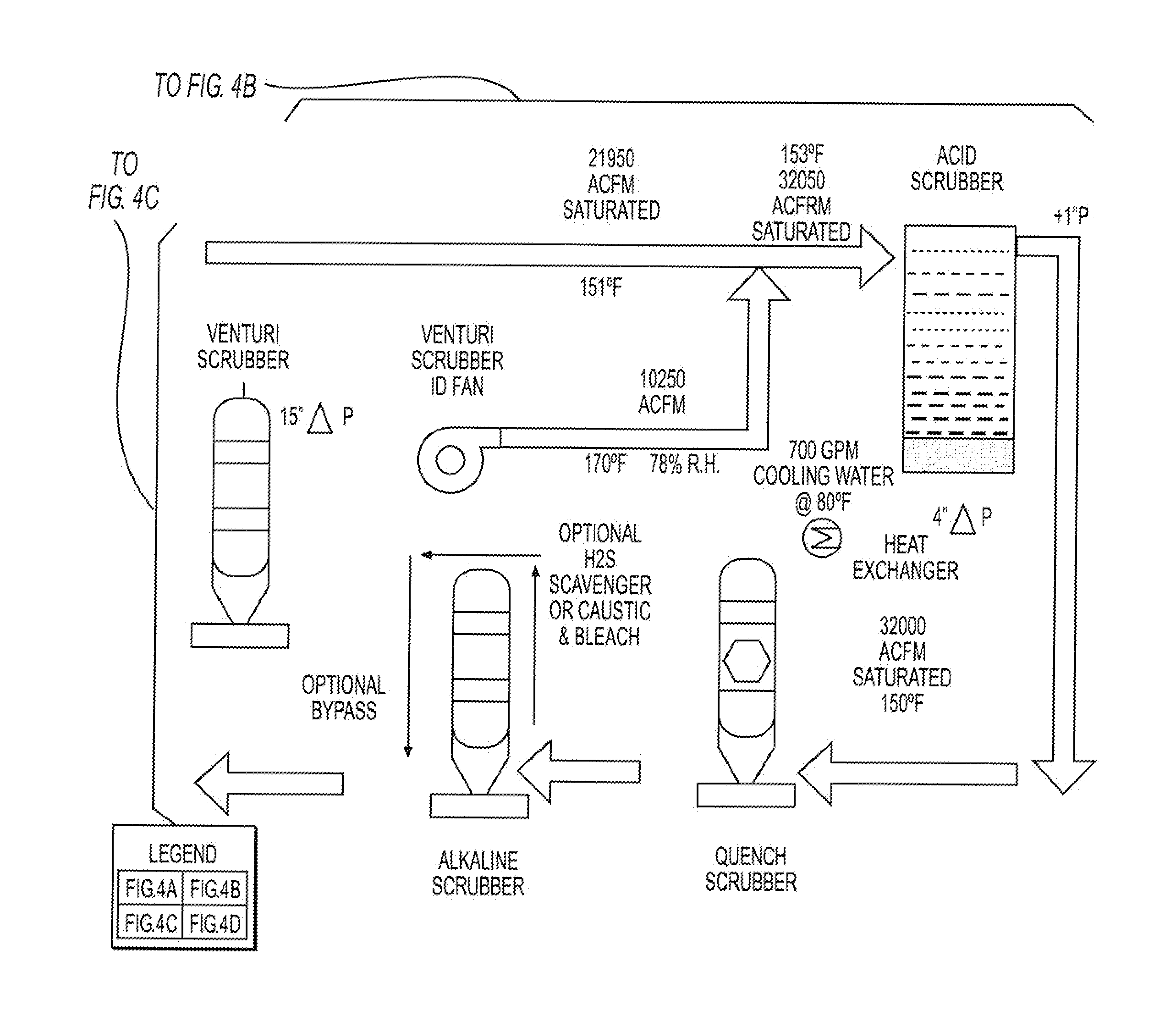

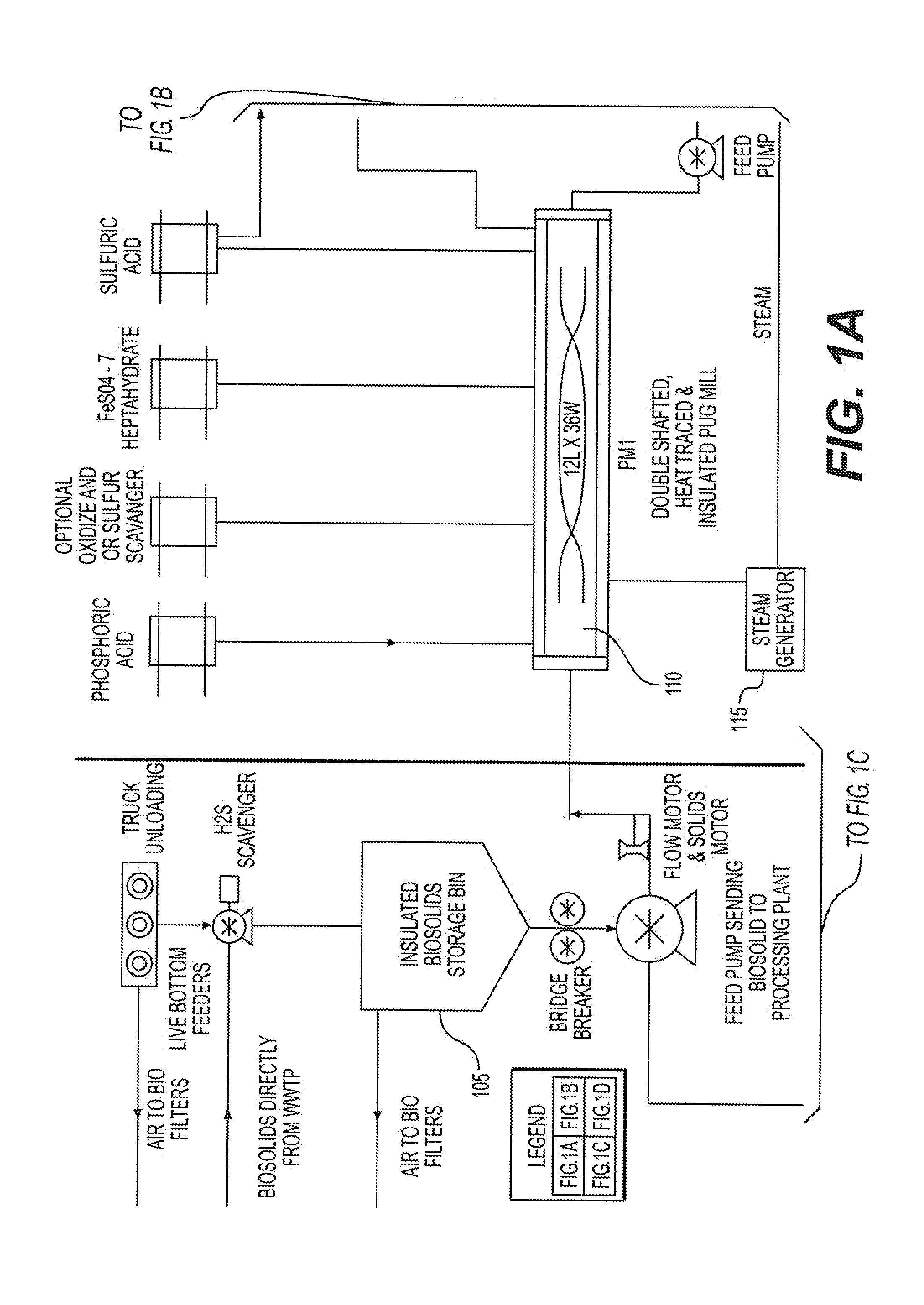

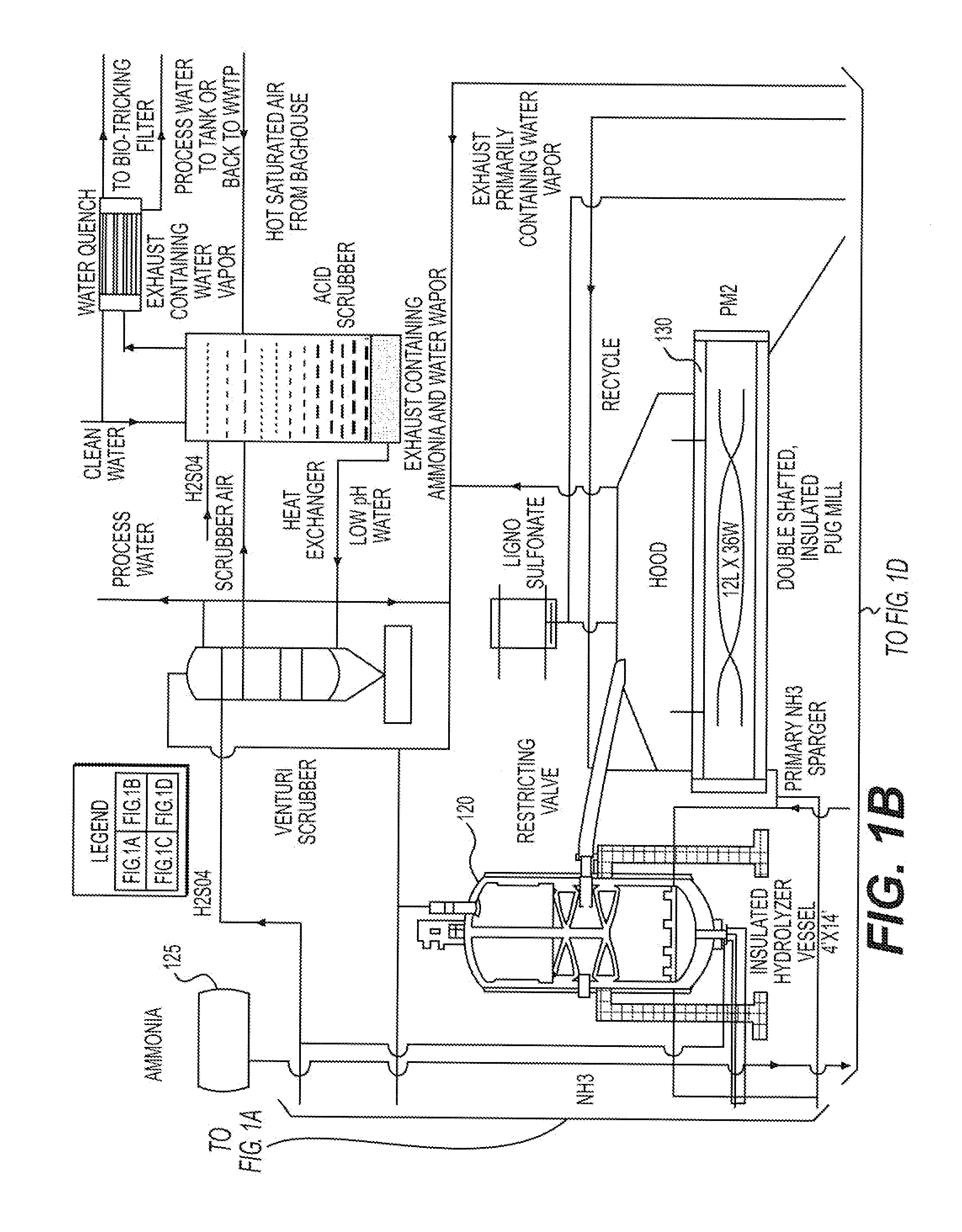

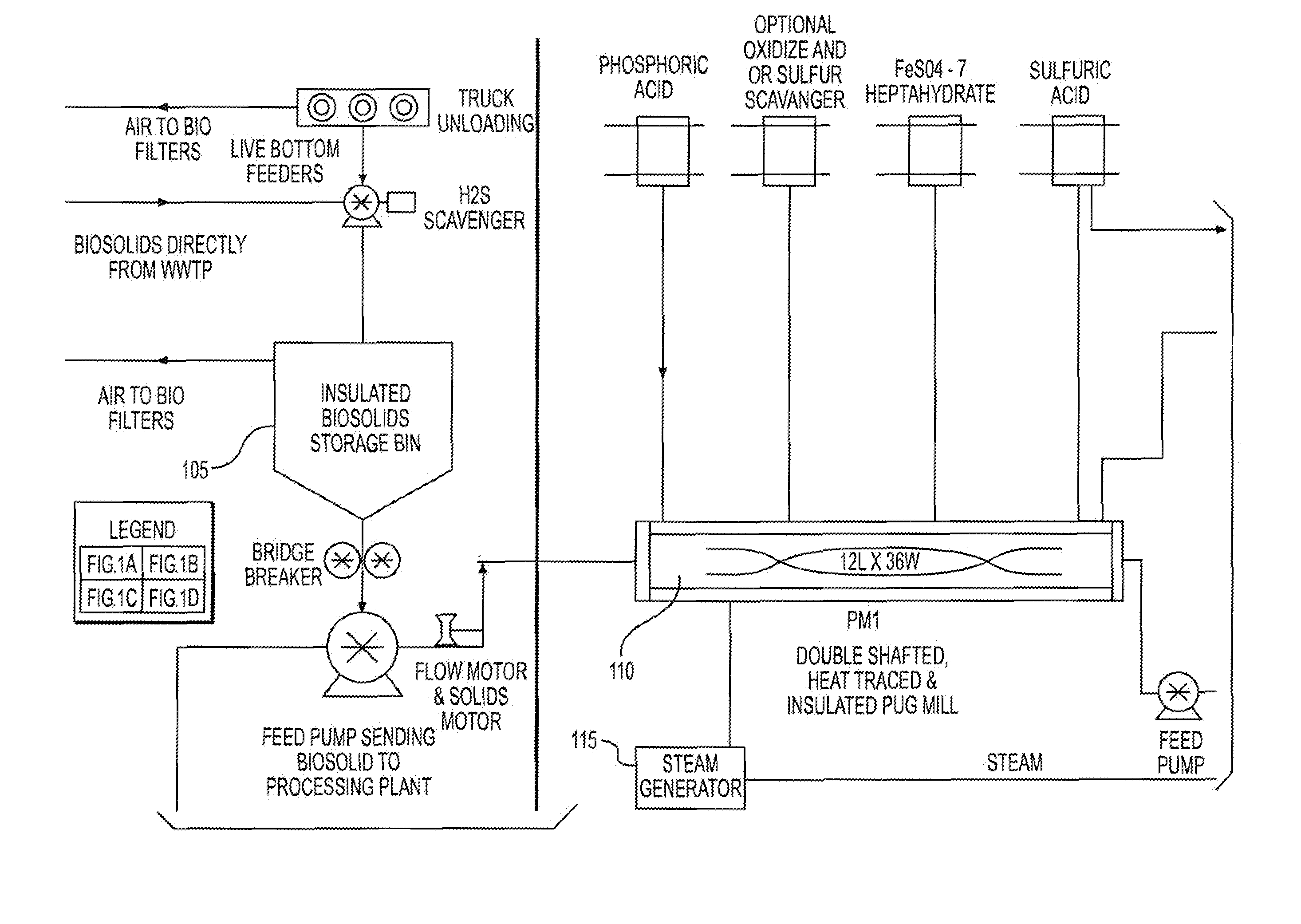

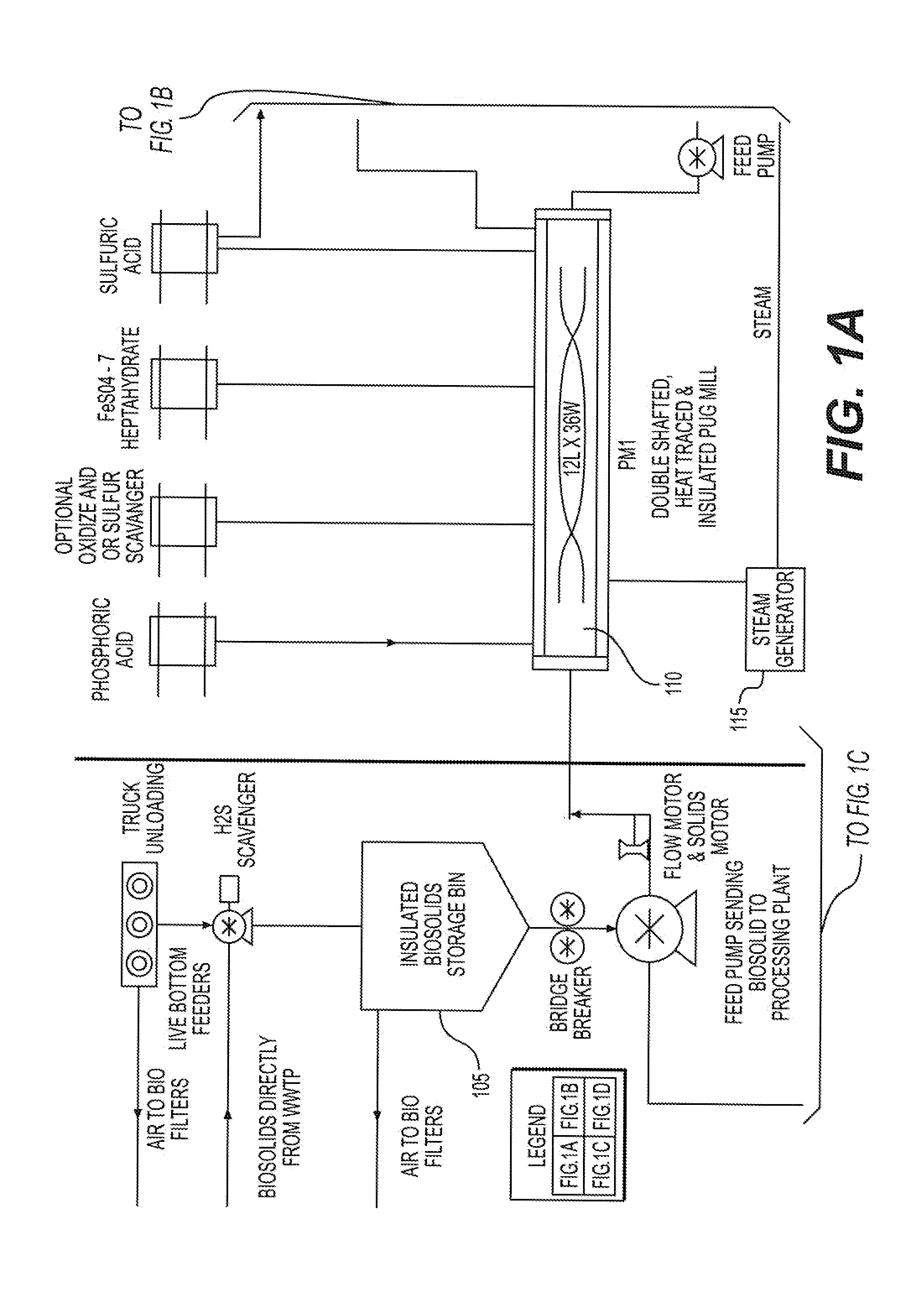

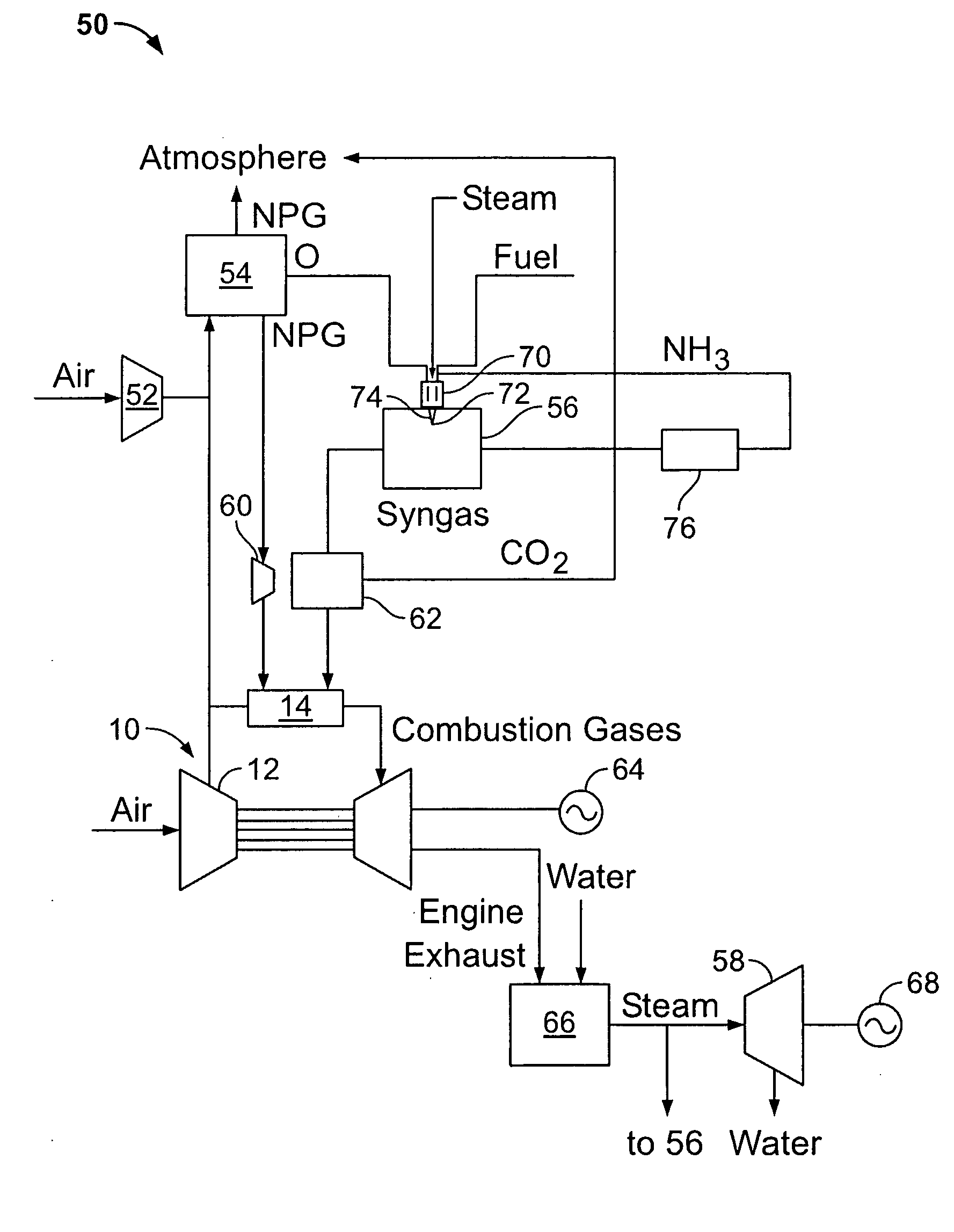

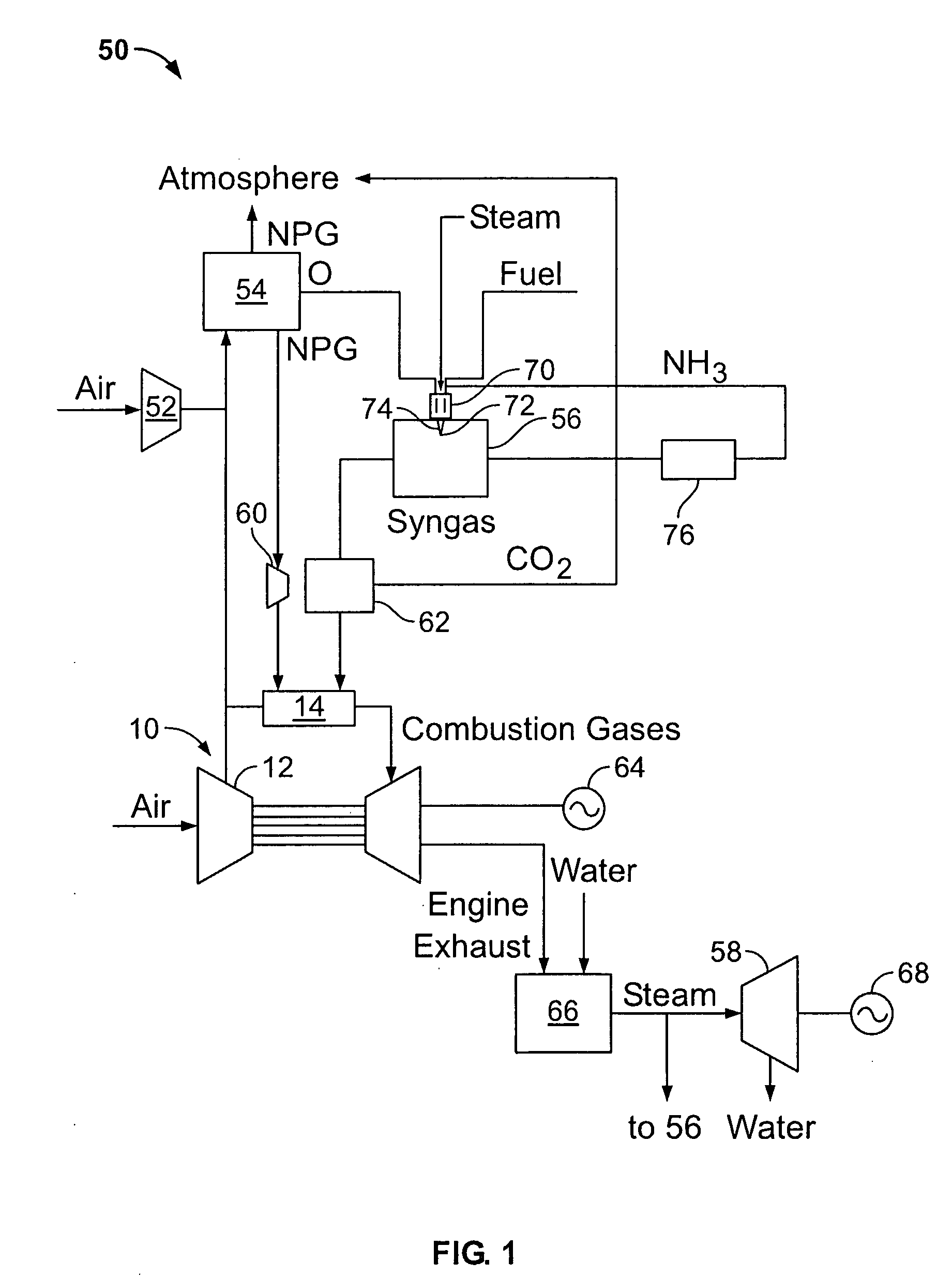

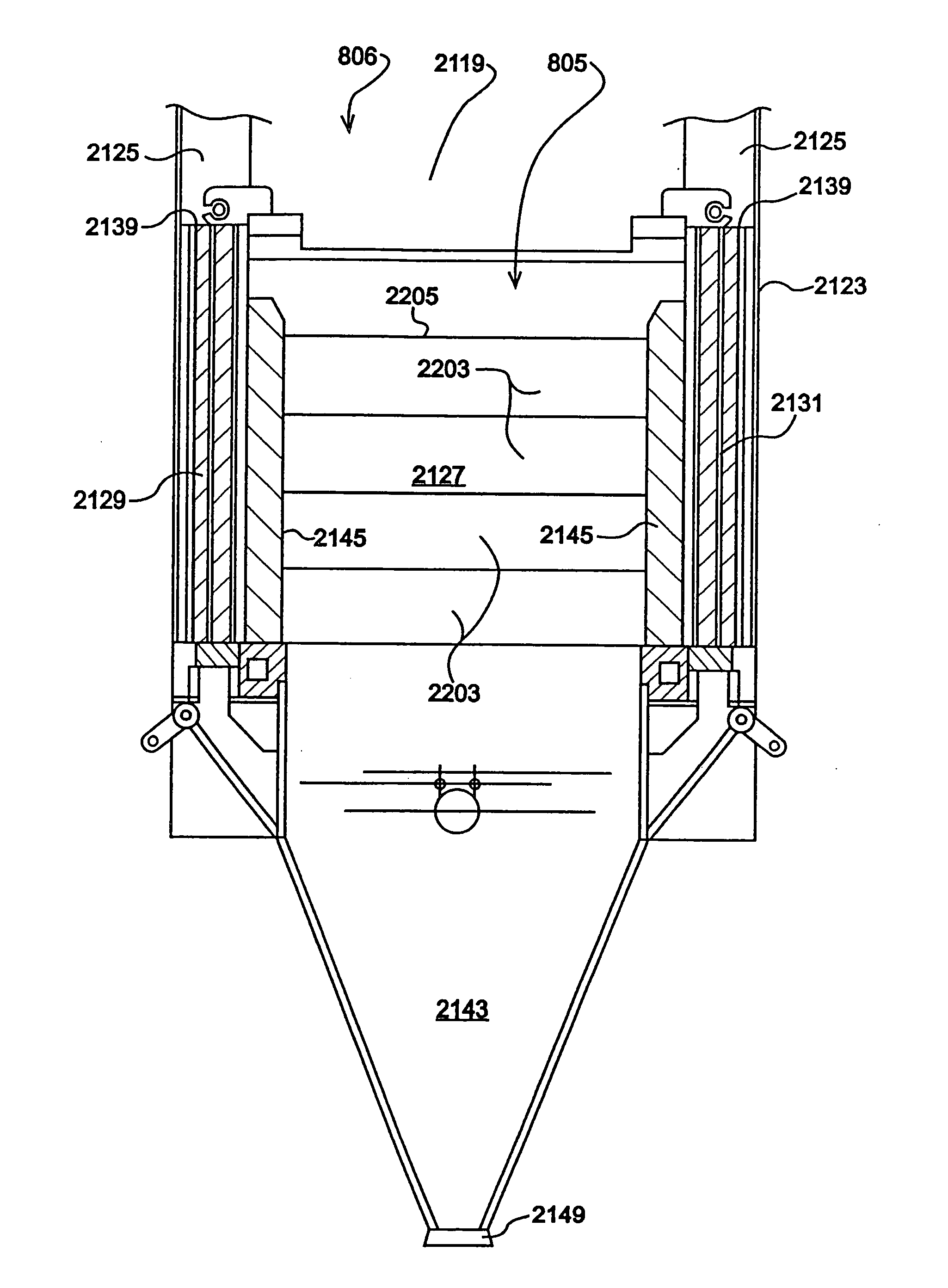

Bioorganically-augmented high value fertilizer

ActiveUS20110154873A1Method is newBio-organic fraction processingExcrement fertilisersClosed loopNitrogen

The invention is directed to processes for treating biosolids that result in high-value, nitrogen-containing, slow-release, organically-augmented inorganic fertilizer that are competitive with less valuable or more costly conventional commercially manufactured fertilizers. The process involves conditioning traditional waste-water biosolids and processing the conditioned biosolids continuously in a high throughput manufacturing facility. The exothermic design and closed loop control of the primary reaction vessel decreases significantly the amount of power necessary to run a manufacturing facility. The process utilizes green technologies to facilitate decreased waste and enhanced air quality standards over traditional processing plants. The fertilizer produced from recovered biosolid waste is safe and meets or exceeds the United States Environment Protection Agency (USEPA) Class A and Exceptional Quality standards and is not subject to restrictions or regulations.

Owner:GENERATE LENDING LLC +1

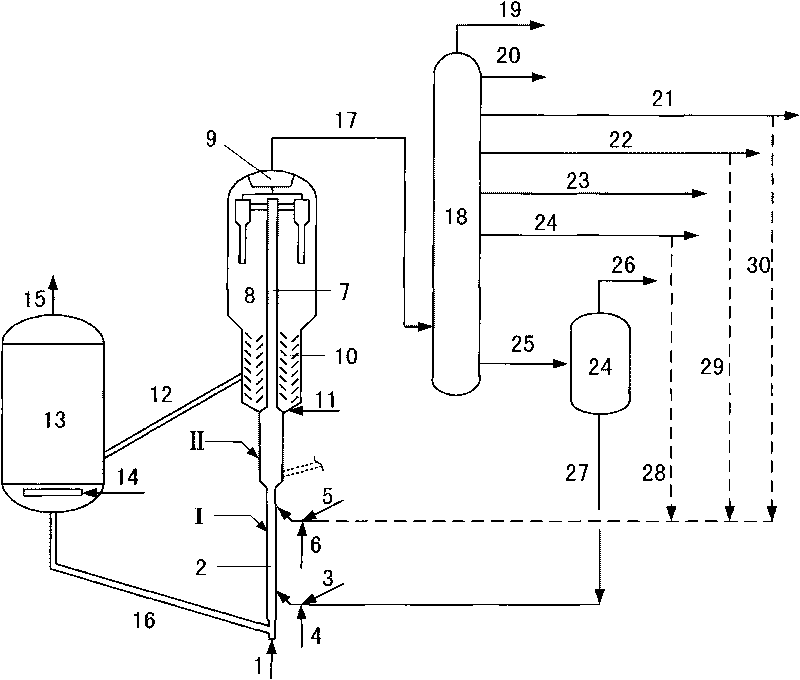

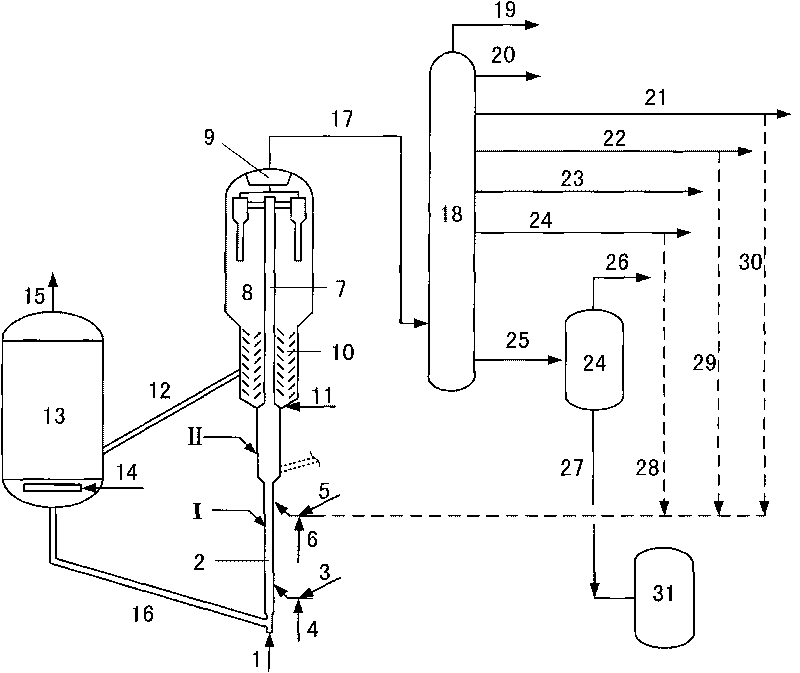

Method for preparing light-weight fuel oil and propylene from inferior raw oil

ActiveCN101724430AExtended operating cycleImprove propertiesCatalytic crackingOrganic chemistryAlkaneWax

The invention provides a method for preparing light-weight fuel oil and propylene from inferior raw oil. The method comprises the following steps that: the inferior raw oil enters a first and second reaction areas of a catalytic conversion reactor in sequence to contact the catalytic conversion catalyst to undergo the primary reaction and the secondary reaction, the reaction products and the spent catalyst undergo solid-liquid separation, and the spent catalyst undergoes steam stripping and singeing in sequence and then is returned to the reactor for recycling; the reaction products are separated to obtain propylene, gasoline, catalytic wax oil and other products, wherein the catalytic wax oil enters an aromatic extraction device for separation so as to obtain extract oil and raffinate oil; and the raffinate oil is cycled to the first reaction area of the catalytic conversion reactor or / and other catalytic conversion devices for further reaction to obtain the target products of propylene and gasoline. In the method, the inferior raw oil undergoes the mild catalytic conversion, the obtained catalytic wax oil undergoes aromatic extraction, and the extract oil richly contains double ring arenas and is a quite good chemically raw material; and the raffinate oil richly contains alkanes and naphthenic hydrocarbons, and is quite suitable for catalytic conversion, so that the highly efficient utilization of gasoline resources is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

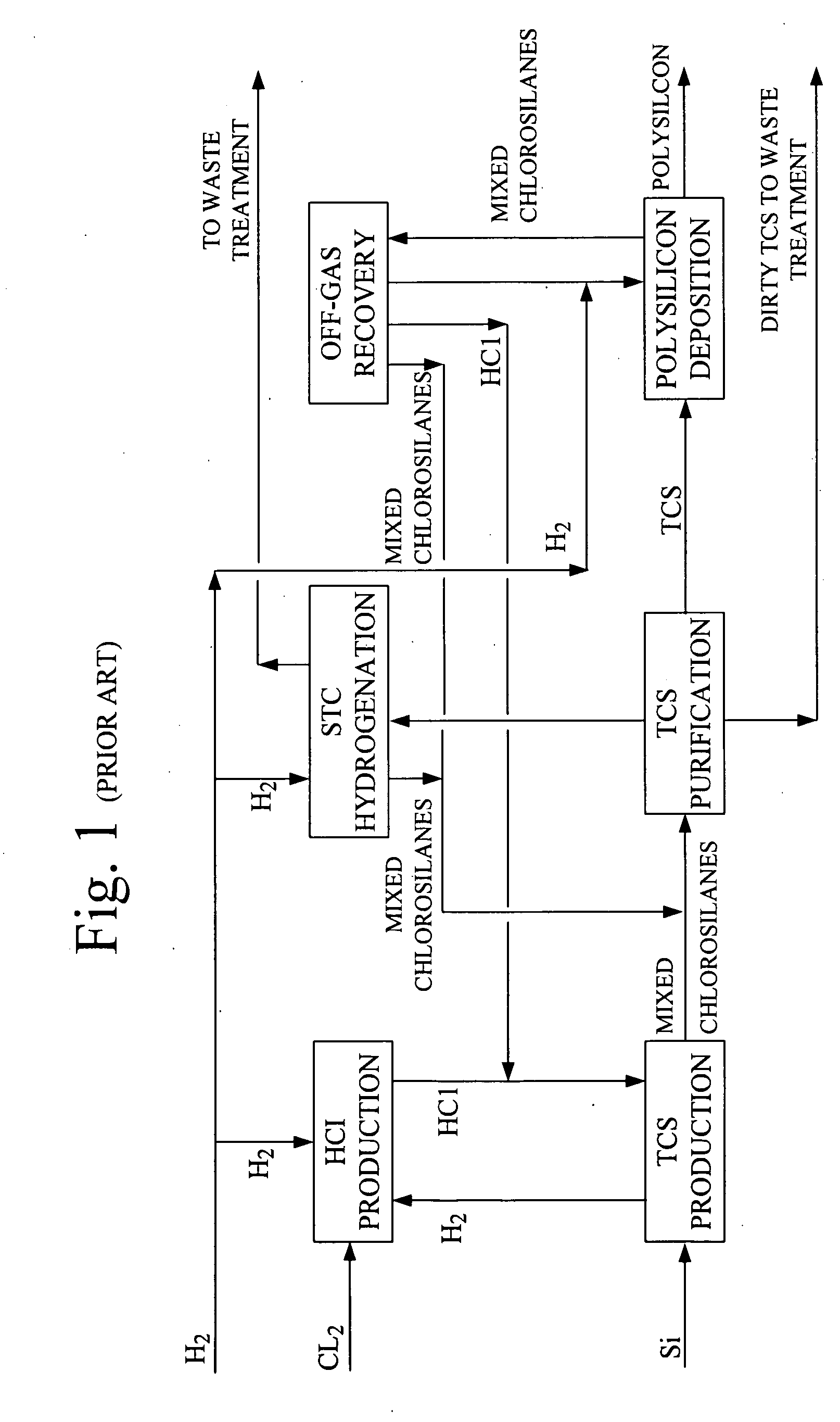

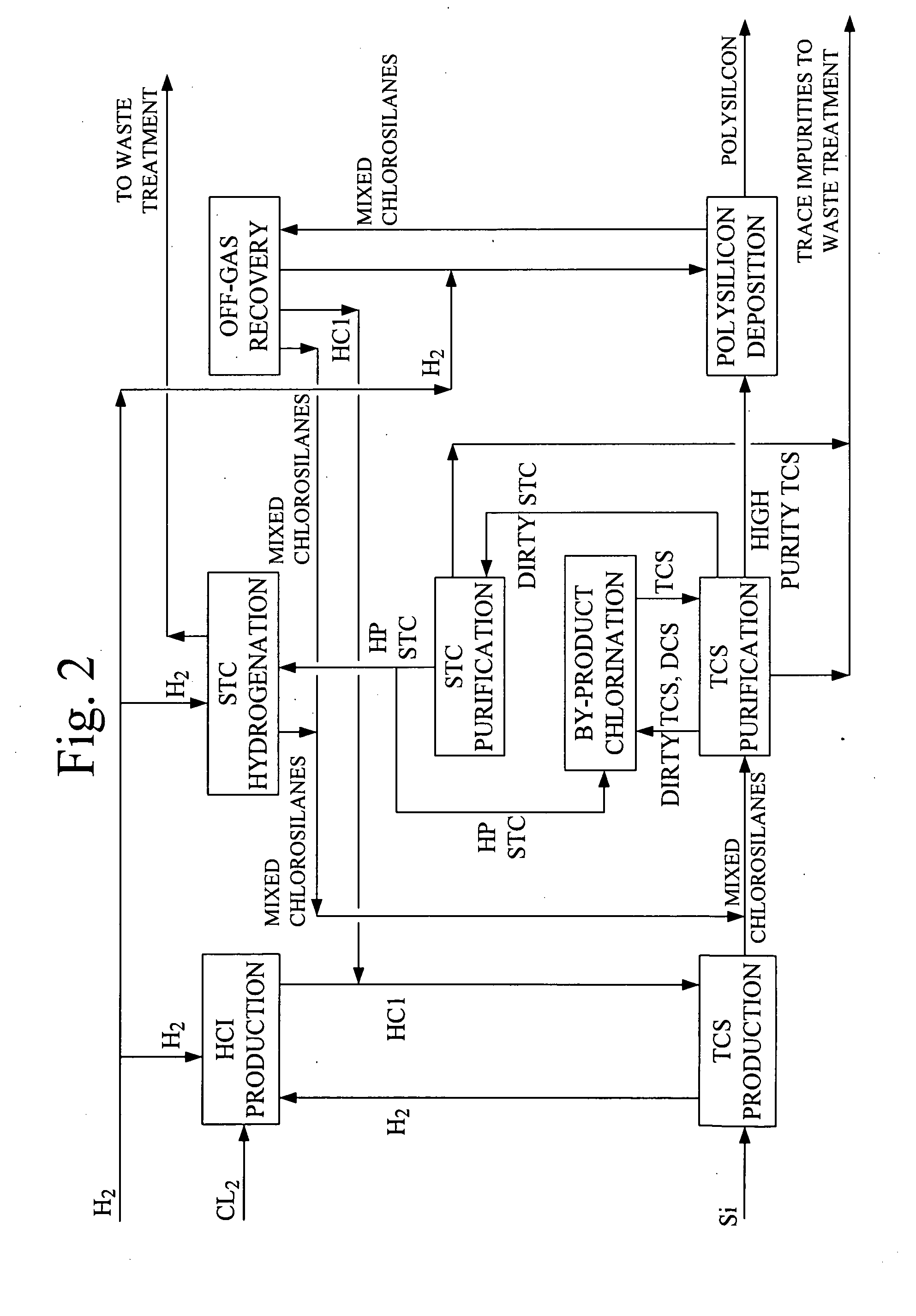

Process for producing trichlorosilane

InactiveUS20090060819A1Reduce kilogramLower requirementChemical/physical/physico-chemical stationary reactorsMetal/metal-oxides/metal-hydroxide catalystsBoiling pointDichlorosilane

A process for preparing high purity trichlorosilane (TCS) utilizing contaminated by-products of primary reaction products hydrogen chloride, metallurgical or chemical grade silicon stock, and / or by-products of the improved Siemens process, including “dirty” TCS containing low boiling impurities such as dichlorosilane (DCS) and “dirty” STC containing high boiling impurities. The “dirty” STC is first purified and a portion is reacted with “dirty” TCS containing DCS to produce additional TCS feedstock for the TCS purification process. Another portion of the purified STC is hydrogenated and converted back to TCS providing another feedstock to the TCS purification process. Overall net yield of high purity TCS produced is increased over established practice.

Owner:DYNAMIC ENG

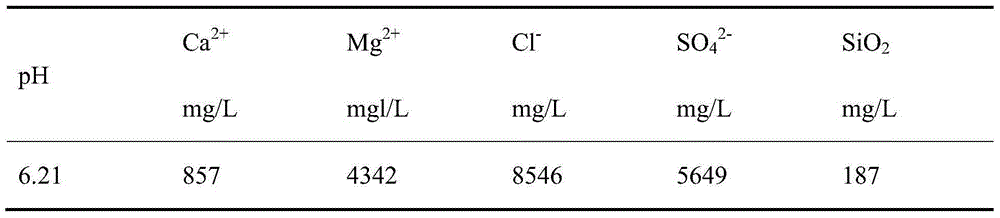

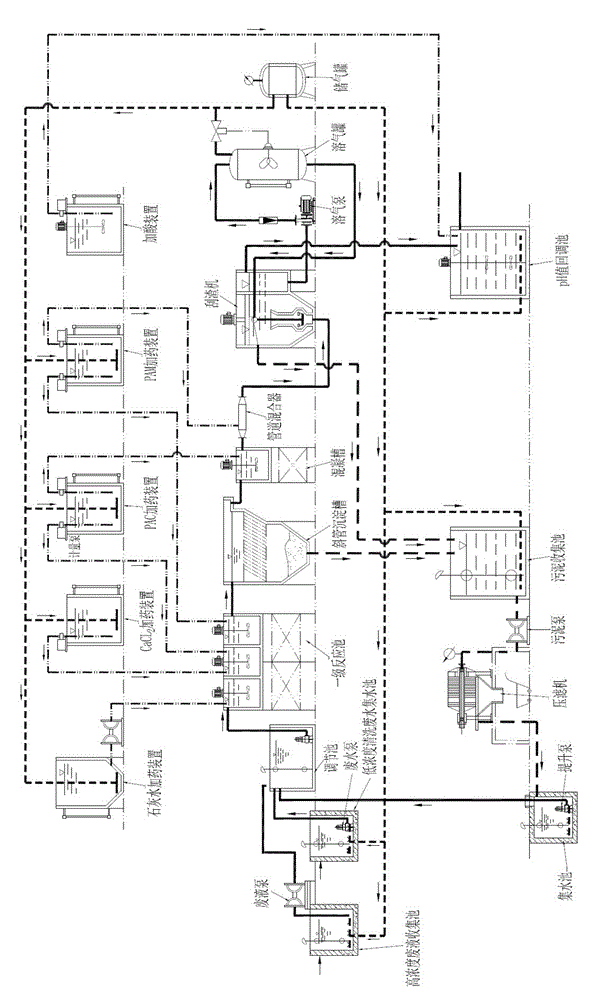

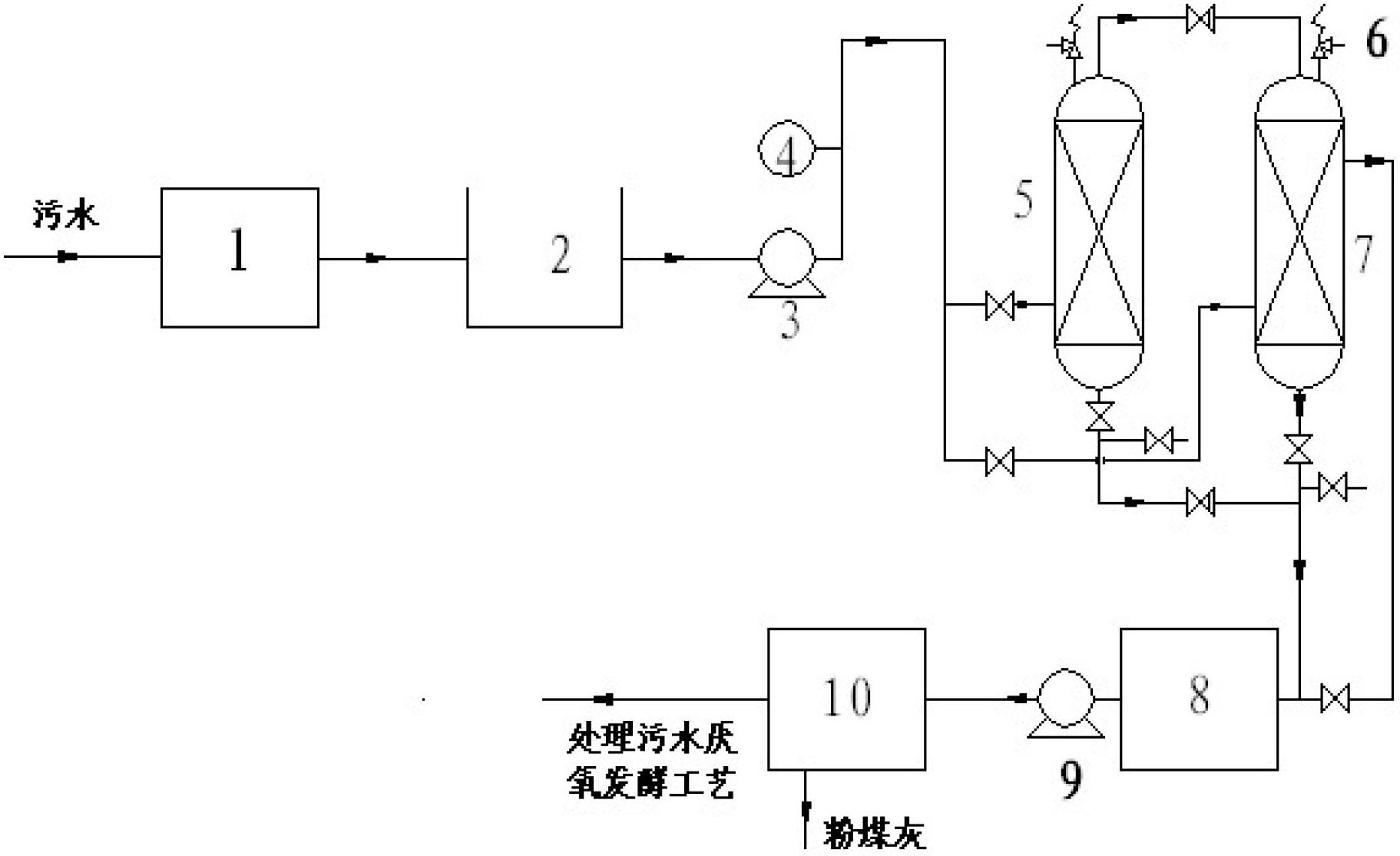

System and method for softening treatment of desulfurization wastewater of coal-fired power plant

ActiveCN105060545AReduce ammonia nitrogenReduce ammonia nitrogen contentWaste water treatment from gaseous effluentsMultistage water/sewage treatmentSulfateEconomic benefits

The invention discloses a system and a method for softening treatment of desulfurization wastewater of a coal-fired power plant. A primary reaction tank, a primary clarification tank, a secondary reaction tank and a secondary clarification tank are arranged, lime milk, sodium sulfate, polymeric ferric sulfate and polyacrylamide are added to the primary reaction tank for a primary reaction and clarified through the primary clarification tank, Mg(OH)2 and CaSO4*2H2O in the wastewater after the primary reaction are removed, the mixture has a secondary reaction in the secondary reaction tank, smoke is fed into the secondary reaction tank and is settled in the secondary clarification tank, CaCO3 is settled, and softening treatment of the desulfurization wastewater of the coal-fired power plant is completed. The system is simple in structure and easy to implement and facilitates industrial production; when the softening treatment effect is met, that is, the content of Mg<2+> is smaller than or equal to 5 mg / L and the content of Ca<2+> is smaller than or equal to 5 mg / L, the adding amount of chemical is reduced, and the chemical operation cost is reduced, so that the operation cost of a zero discharging system for the desulfurization wastewater of the coal-fired power plant is reduced, and the system has important economic benefits and environmental benefits.

Owner:XIAN TPRI WATER & ENVIRONMENTAL PROTECTION

Method for manufacturing high-density fiber reinforced ceramic composite materials

ActiveUS20130011654A1Simple structureHigh strengthMaterial nanotechnologyPretreated surfacesCeramic compositeHigh density

Disclosed herein is a method of manufacturing a high-density fiber reinforced ceramic composite material, including the steps of: 1) impregnating a fiber preform material multi-coated with pyrolytic carbon and silicon carbide to form impregnated fiber reinforced plastic composite material; 2)carbonizing the impregnated fiber reinforced plastic composite material to form carbonized fiber composite material; 3) a primary reaction-sintering of the fiber composite material; 4) cooling the primarily reaction-sintered fiber composite material down to room temperature and then impregnating the primarily reaction-sintered fiber composite material with a solution in which a polymer precursor for producing silicon carbide (SiC) is dissolved in a hexane (n-hexane) solvent; and 5) a secondary reaction-sintering of the fiber composite material; and a high-density fiber reinforced ceramic composite material manufactured using the method.

Owner:KOREA INST OF ENERGY RES

Phosphating and chemical nickel-plating mixed comprehensive wastewater treatment process and automated device

InactiveCN104909490ASimple processReduce dosageMultistage water/sewage treatmentLiquid wasteHigh concentration

The invention provides a phosphating and chemical nickel-plating mixed comprehensive wastewater treatment process and an automated device. According to the process, high-concentration wastewater and low-concentration washing wastewater are respectively collected; the high-concentration wastewater and the low-concentration washing wastewater are mixed in a wastewater adjustment tank; the mixture sequentially enters a primary reaction tank, an inclined tube sedimentation tank, a secondary reaction tank, a floatation system, and a pH value correction tank; obtained clear water can reach a discharge standard and can be discharged; sludge produced during the wastewater treatment process enters a sludge collection tank, and is subjected to pressure filtration through a filter press; and an obtained solid matter is separately collected and disposed. The automated device comprises a PLC control system, a wastewater collection system, an adjustment tank, a primary reaction tank, an inclined tube sedimentation tank, a secondary reaction tank, a flotation system, dosing devices and an air stirring system. The phosphating and chemical nickel-plating mixed comprehensive wastewater is subjected to multiple levels of treatments. The entire process is automatically controlled by PLC. The entire wastewater treatment process is displayed dynamically. According to the invention, the process is simple, dosing amount is low, the quality standard of treated water is high, and processing efficiency is high.

Owner:DONGFENG PISTON & BEARING

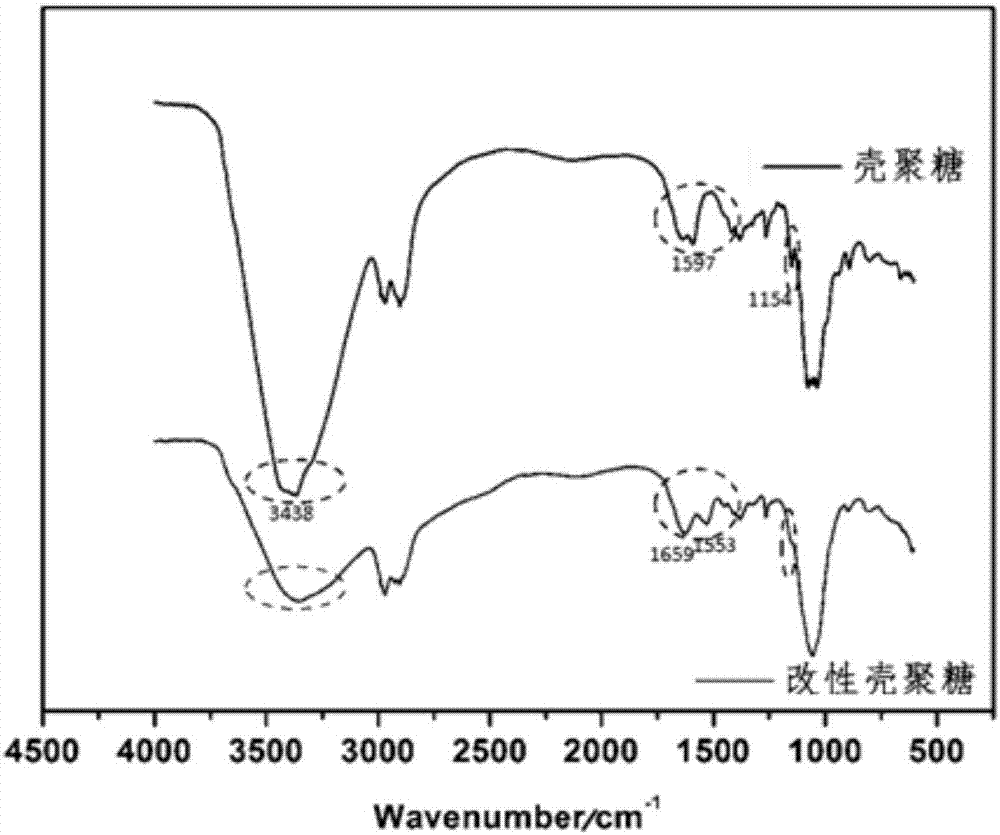

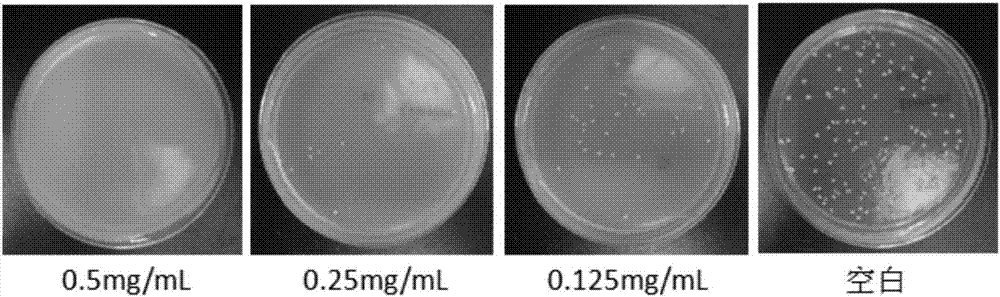

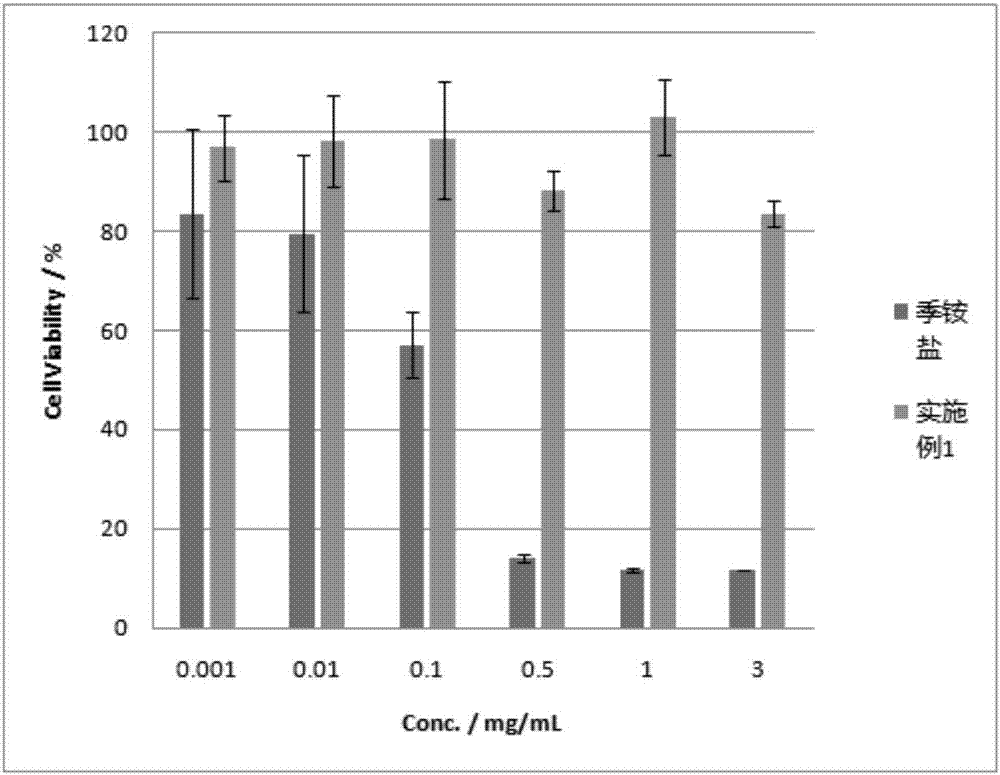

Novel water soluble natural polysaccharide antibacterial material and preparation method thereof

ActiveCN107383236AGood water solubilityImprove antibacterial propertiesBiocideDisinfectantsCytotoxicityHydroxylamine Hydrochloride

The invention discloses a novel water soluble natural polysaccharide antibacterial material. The molecules of the novel water soluble natural polysaccharide antibacterial material not only have guanidyl but also have amino acid groups, so that the biosafety of the novel water soluble natural polysaccharide antibacterial material is considered while the antibacterial property of chitosan is improved, and the novel water soluble natural polysaccharide antibacterial material is small in cytotoxicity and is a green antibacterial product. The invention also discloses a method of preparing the material. The method comprises the following steps: 1) dissolving chitosan in a diluted acid solution to obtain a diluted acid aqueous solution of chitosan; 2) adding cyanamide or dicyanamide into the diluted acid solution of chitosan for reaction; 3) adding an amino acid activated solution into a reaction system in the step 2) for amidation; 4) adding hydroxylamine hydrochloride for terminating reaction; and 5) dialyzing a reaction liquid which is filtered with deionized water, and performing microwave vacuum drying treatment to obtain the novel water soluble natural polysaccharide antibacterial material. The novel water soluble natural polysaccharide antibacterial material can be prepared in a reaction kettle by a primary reaction, and the used primary raw materials are rich in source and low in price and are suitable for industrial production.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

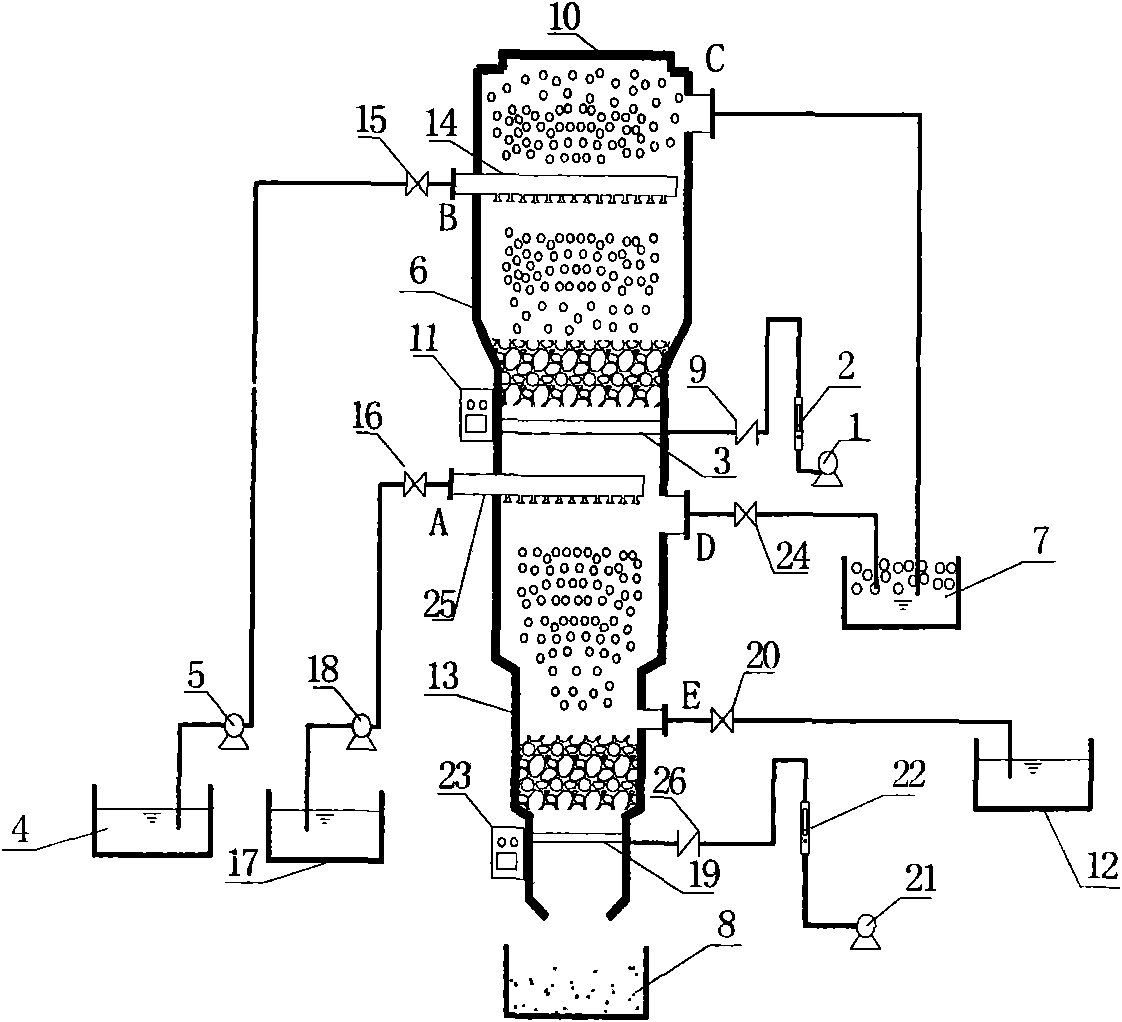

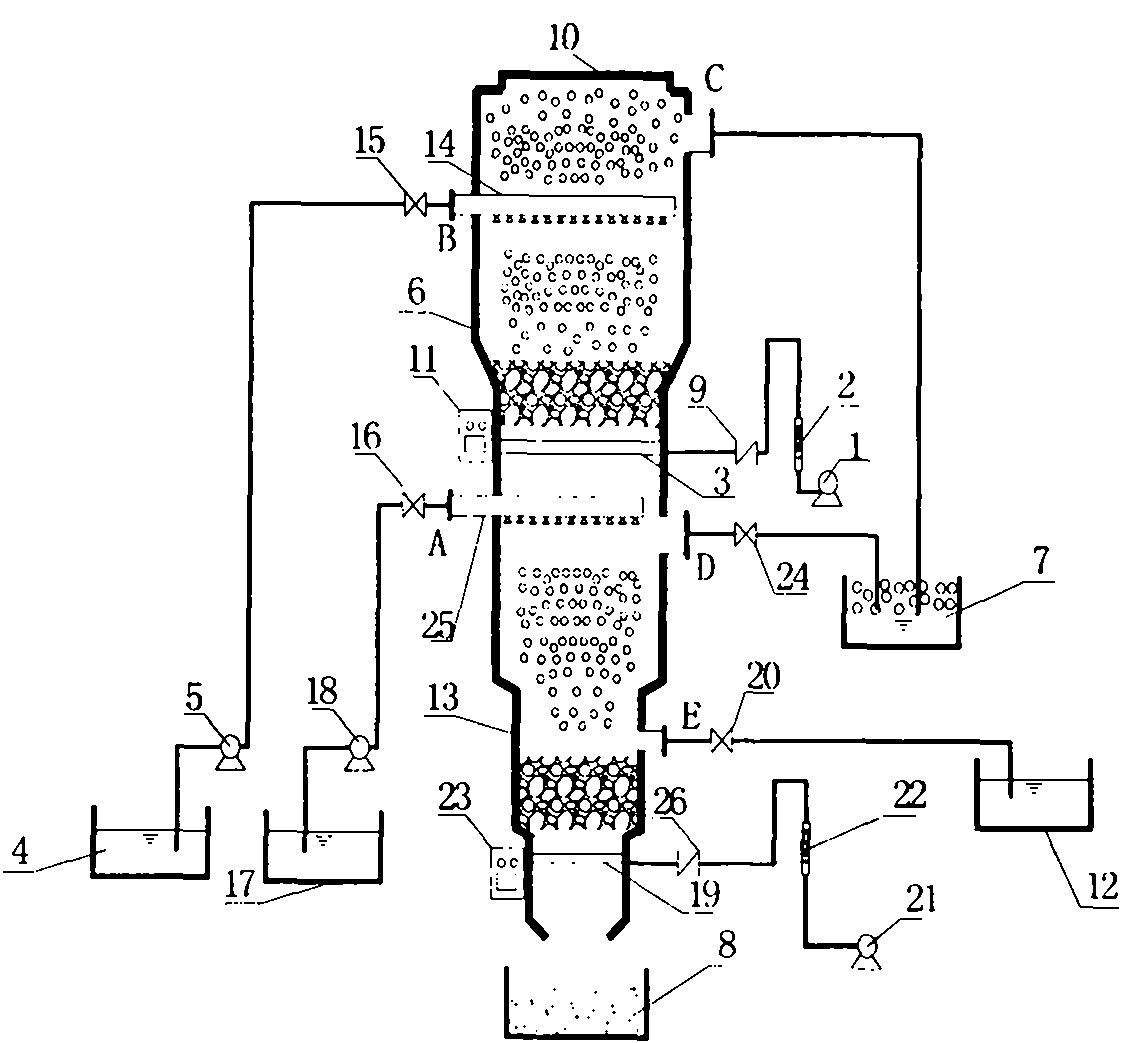

Method and apparatus for treating water or wastewater to reduce organic and hardness contamination

A method of treating liquid including mixing coagulant with the liquid, introducing mixed coagulant and liquid into a primary reaction zone, containing an agitator, of a reactor which is substantially concentrically positioned with respect to a secondary reaction zone of the reactor, introducing flocculant into the primary reaction zone at a location between the agitator and where the mixed coagulant and liquid are introduced into the primary reaction zone, mixing the mixed coagulant and liquid with the flocculant and causing the resulting mixture to flow into the secondary reaction zone, introducing an encapsulating agent into the secondary reaction zone, recirculating the liquid and encapsulated flocs through the primary and secondary reaction zone, and passing the liquid and encapsulated flocs outwardly of the reactor, and an apparatus for treating liquids including a reactor, a draft tube substantially concentrically positioned within the reactor and being positioned such that the liquids may flow inwardly and outwardly of the draft tube from opposed end portions of the draft tube, wherein space inwardly of the draft tube forms a primary mixing zone and space in the reactor, but outwardly of the draft tube forms a secondary mixing zone, an agitator positioned within the draft tube, an inlet positioned approximate one end portion of the draft tube which introduces liquid and coagulant into the primary mixing zone, an inlet connected to the draft tube and positioned between the agitator and the end portion of the draft tube through which coagulant and liquid are introduced into the primary mixing zone, an encapsulating agent inlet positioned in the secondary reaction zone between the opposed end portions of the draft tube, and an outlet downstream of the encapsulating agent inlet.

Owner:INFILCO DEGREMONT INC

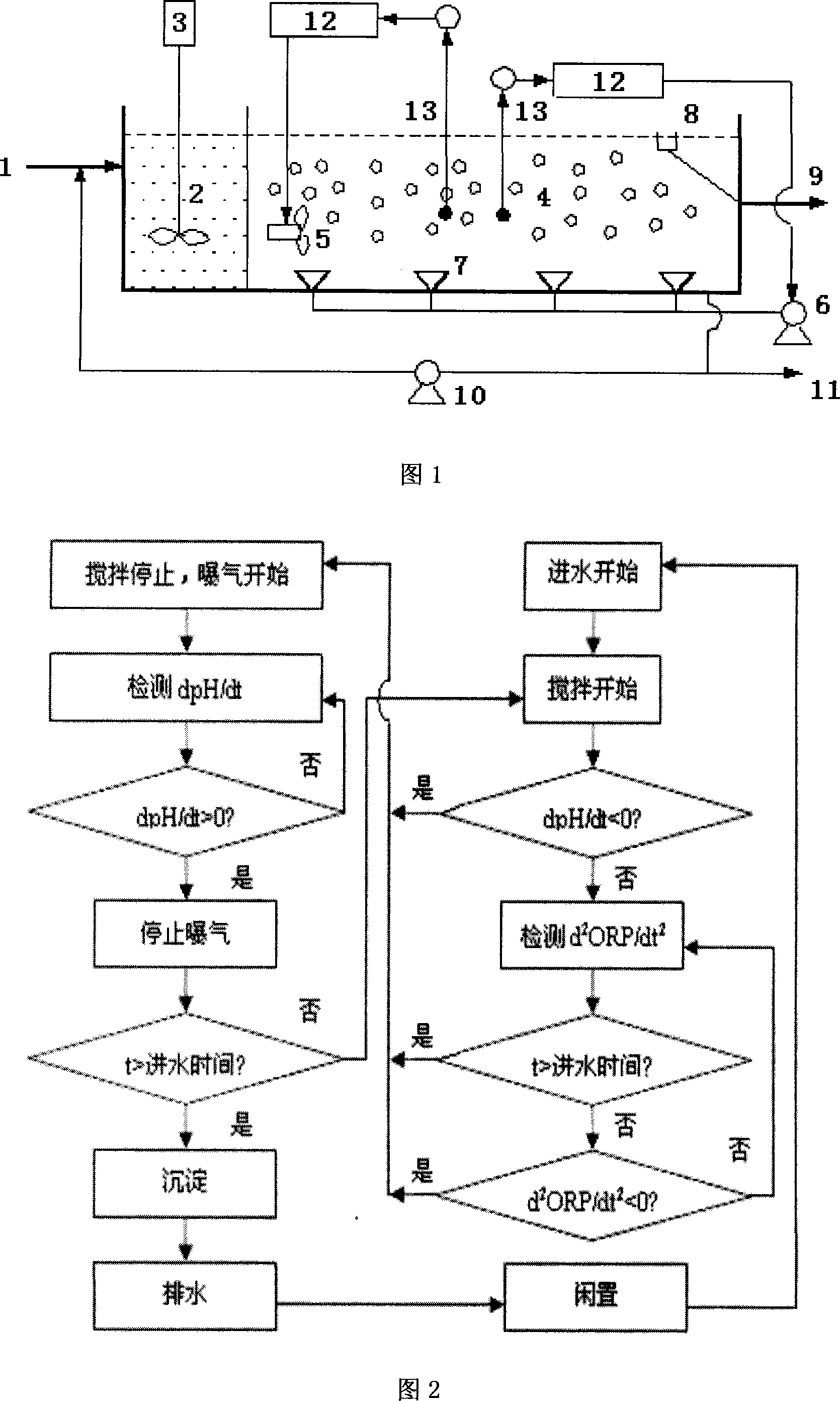

Real-time controlling method for denitrification by reinforced circulating type active sludge process

ActiveCN101182074AAvoid wastingControlled Aerobic AerationTreatment with aerobic and anaerobic processesElectric programme controlReal-time Control SystemSludge bulking

The invention discloses a real-time control method for denitrification by an enhanced circulating activated sludge method, which belongs to the field of biological denitrification of sewage and is suitable for advanced treatment of urban sewage. The effect of circulating activated sludge method on nitrogen and phosphorus removal is not ideal. The steps of the present invention: open the agitator in the main reaction zone at the same time as entering the water, and carry out the denitrification process under the anoxic condition, and stop stirring when a maximum value appears on the pH value curve and an inflection point appears on the ORP curve; Oxygen is supplied to the mixed solution to degrade organic matter and nitrify nitrogenous compounds, and stop aeration when a minimum value appears on the pH curve; repeat the above steps until the end of the water inflow stage, and react with the aerobic aeration stage end of period. The following process is similar to the traditional CAST method. It enters the sedimentation, drainage, and idle stages in turn, repeating all steps in turn and discharging sludge regularly. The whole process is completed by a real-time control system, which is easy to operate, low in cost, strong in impact load resistance, and not prone to sludge bulking.

Owner:CHONGQING KANGDA ENVIRONMENTAL PROTECTION IND GRP

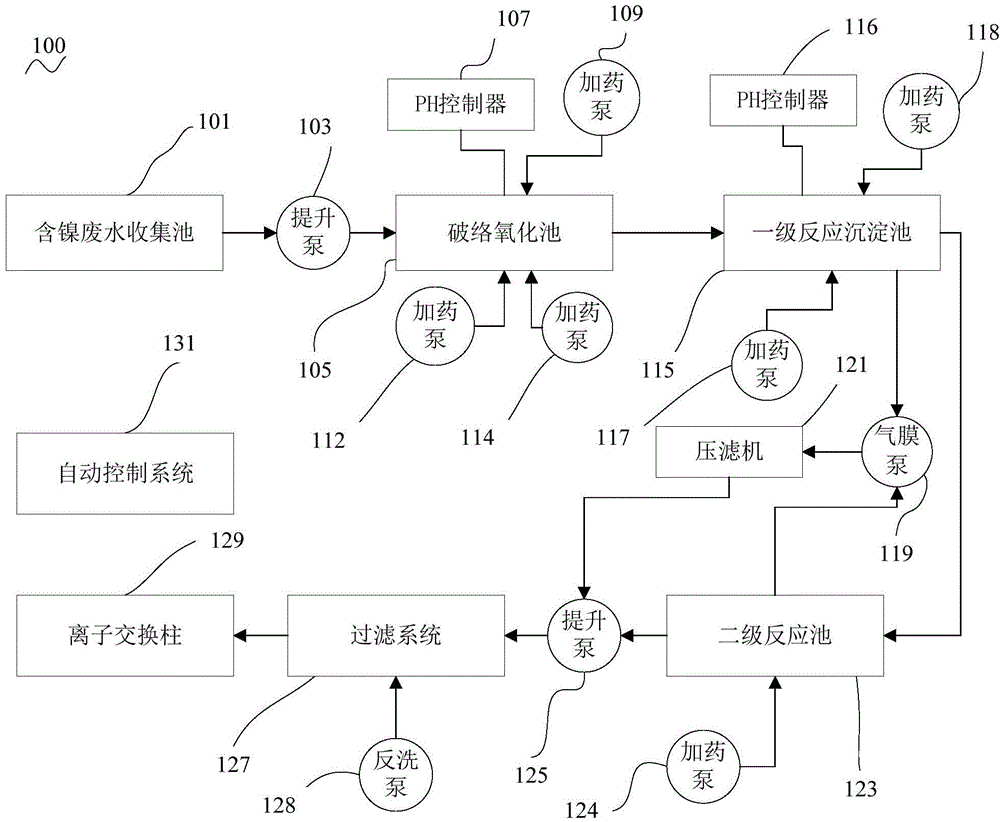

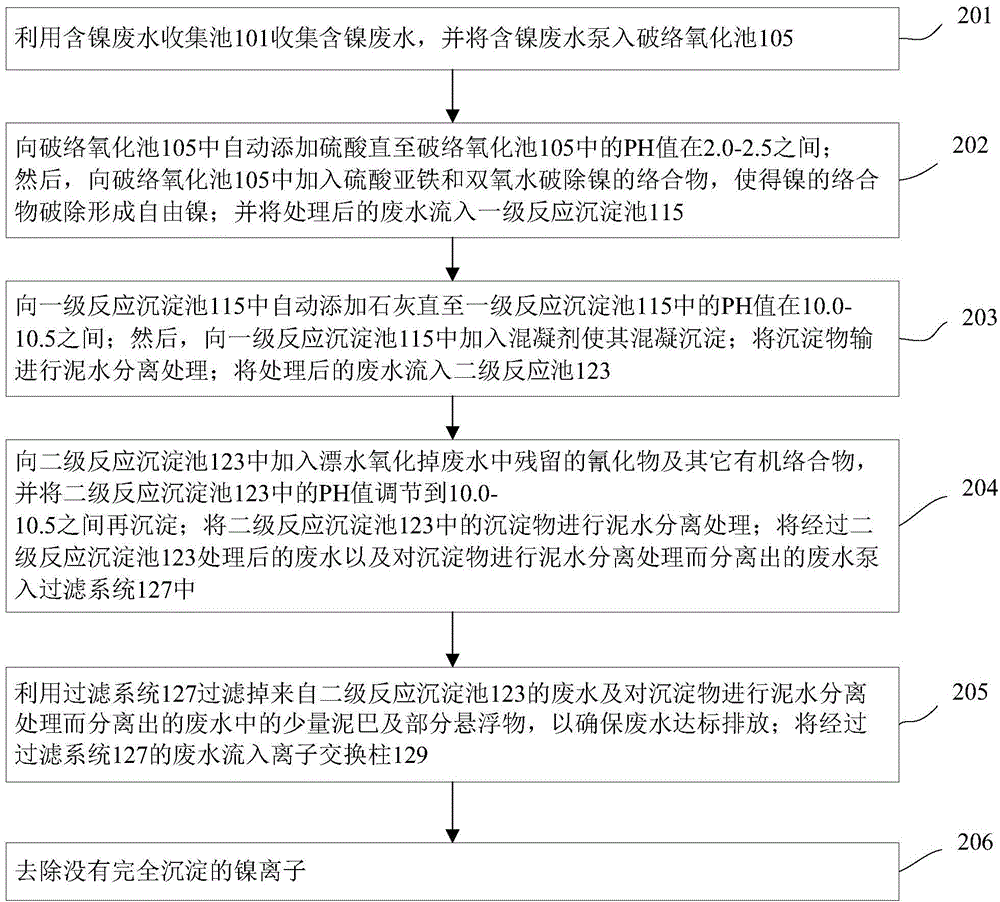

Nickel-containing wastewater treatment method and equipment

InactiveCN104528987AEfficient removalWater contaminantsWater/sewage treatment by ion-exchangeCyanideSulfate

The invention discloses a nickel-containing wastewater treatment method, comprising the following steps: collecting nickel-containing wastewater, and pumping the nickel-containing wastewater into a complex breaking oxidation pool; adding sulfuric acid into the complex breaking oxidation pool until the pH value in the complex breaking oxidation pool is 2.0-2.5; adding ferrous sulfate and hydrogen peroxide into the complex breaking oxidation pool to break a nickel complex to enable the nickel complex to form free nickel; conveying the treated wastewater into a primary reaction sedimentation tank; adding lime into the primary reaction sedimentation tank until the pH value in the primary reaction sedimentation tank is 10.0-10.5; adding a coagulant into the primary reaction sedimentation tank to generate coagulating sedimentation; conveying the treated wastewater into a secondary reaction tank; adding drift ice into a secondary reaction sedimentation tank to remove residual cyanides and other organic complexes in the wastewater by oxidization, regulating the pH value in the secondary reaction sedimentation tank to 10.0-10.5, and precipitating; pumping the wastewater treated in the secondary reaction sedimentation tank into a filtering system; filtering a small amount of mud and a part of suspended solids in the wastewater via the filtering system.

Owner:深圳市祐林环保有限公司

Preparation method of silicon carbide nano-wire

The invention relates to a preparation method of a silicon carbide nano-wire, which comprises the following steps that: phenolic resin is added into industrial sodium silicate to prepare carbon-silicon gel; the prepared gel is dried for 5 to 30 hours under the temperature of 60 to 110 DEG C; the dried gel is heated to the temperature of 1100 to 1400 DEG C to carry out the carbothermal reduction for 3 to 20 hours under the protection of argon gas, and a primary reaction product is obtained after the reactant is cooled to the room temperature after the reaction; the primary reaction product is roasted for 1 to 5 hours under the temperature of 600 to 800 DEG C so as to remove the carbon which is not reacted; and the primary reaction product is immersed in the mixed acid of the hydrochloric acid and the hydrofluoric acid for 12 to 48 hours so as to remove the surplus silicon dioxide in the product, and then the primary reaction product is washed, filtered and dried to obtain the silicon carbide nano-wire. The preparation method has the advantages of simple process, low cost and large-scale preparation.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Bioorganically-augmented high value fertilizer

The invention is directed to processes for treating biosolids that result in high-value, nitrogen-containing, slow-release, organically-augmented inorganic fertilizer that are competitive with less valuable or more costly conventional commercially manufactured fertilizers. The process involves conditioning traditional waste-water biosolids and processing the conditioned biosolids continuously in a high throughput manufacturing facility. The exothermic design and closed loop control of the primary reaction vessel decreases significantly the amount of power necessary to run a manufacturing facility. The process utilizes green technologies to facilitate decreased waste and enhanced air quality standards over traditional processing plants. The fertilizer produced from recovered biosolid waste is safe and meets or exceeds the United States Environment Protection Agency (USEPA) Class A and Exceptional Quality standards and is not subject to restrictions or regulations.

Owner:GENERATE LENDING LLC +1

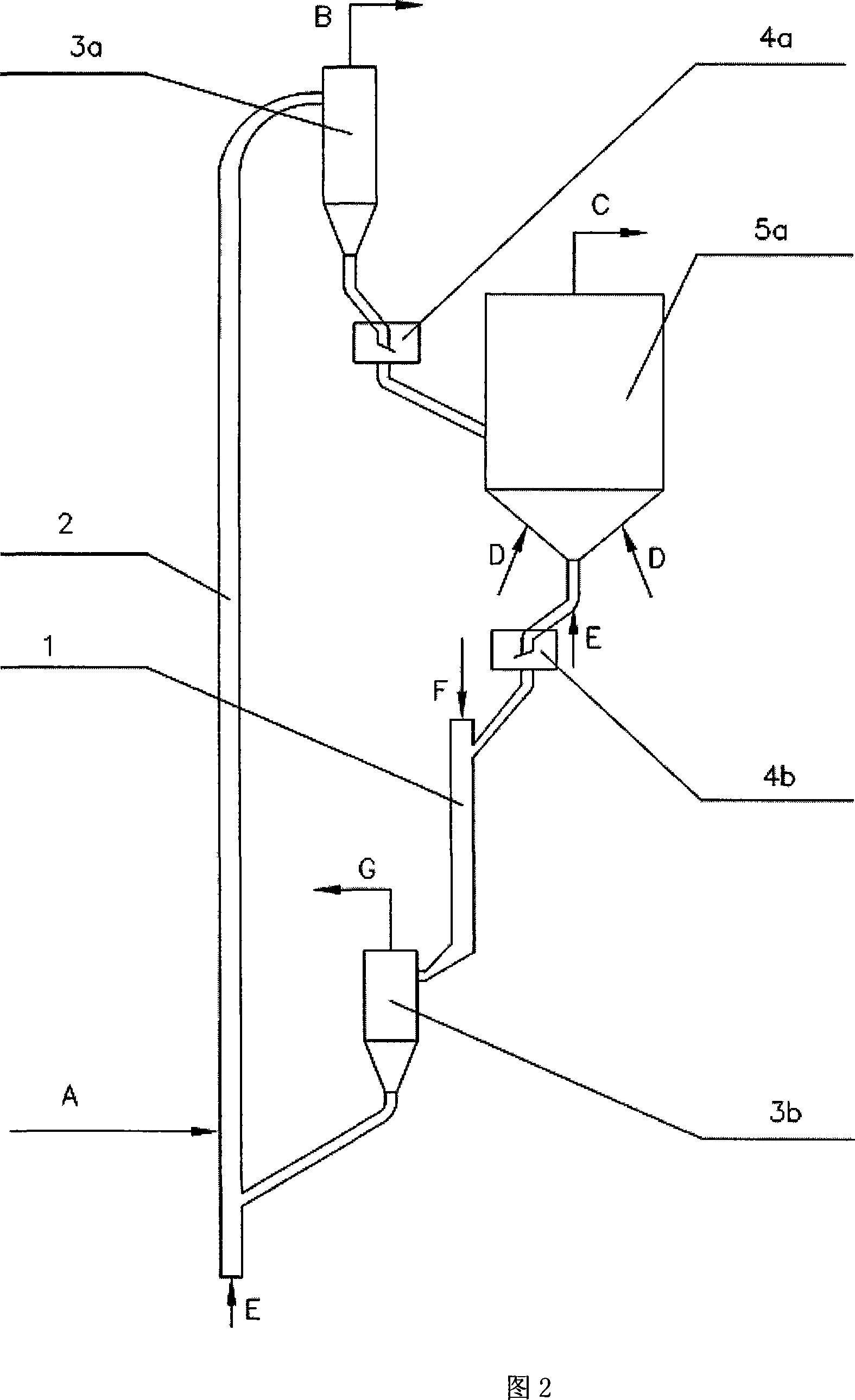

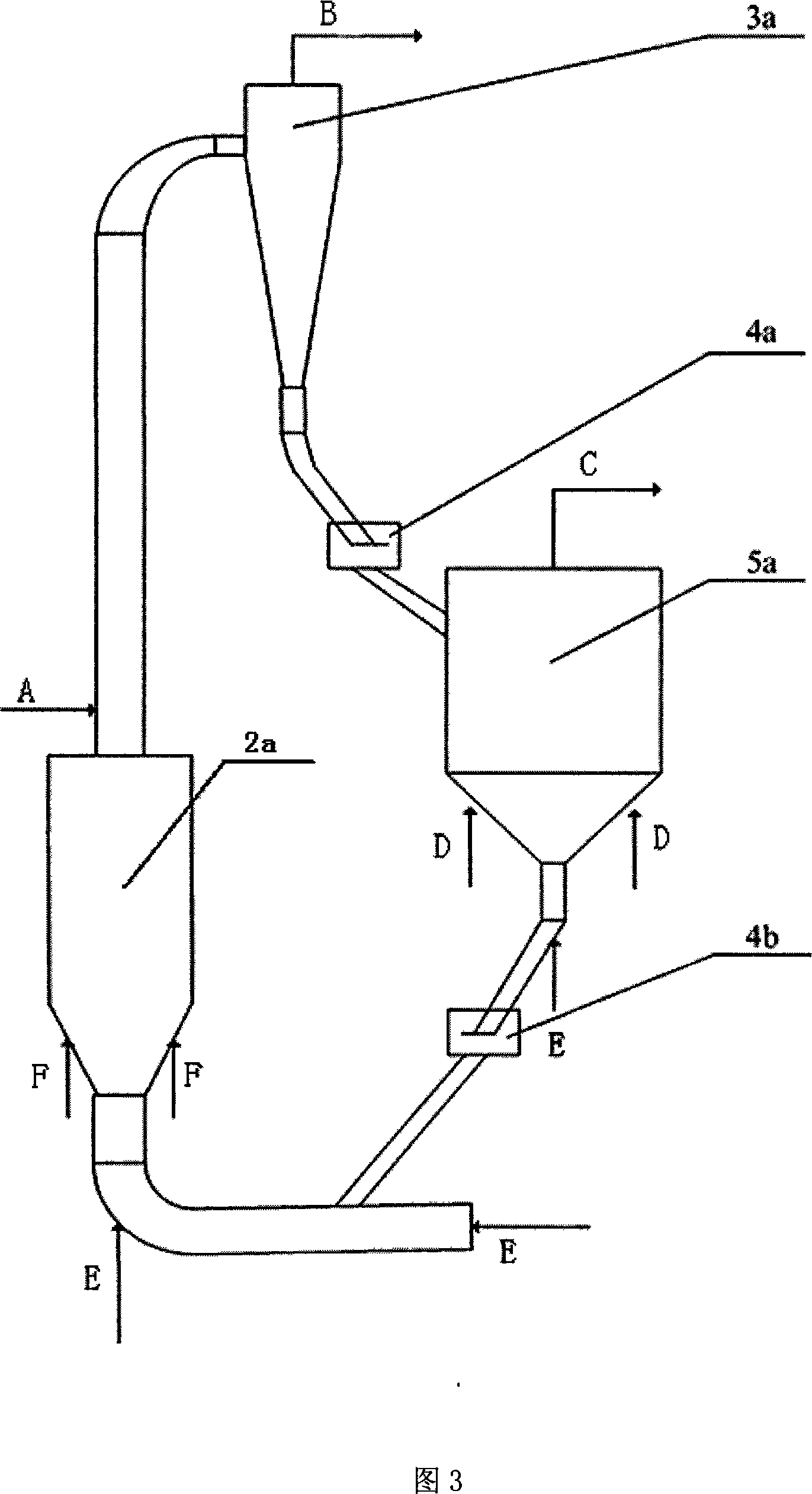

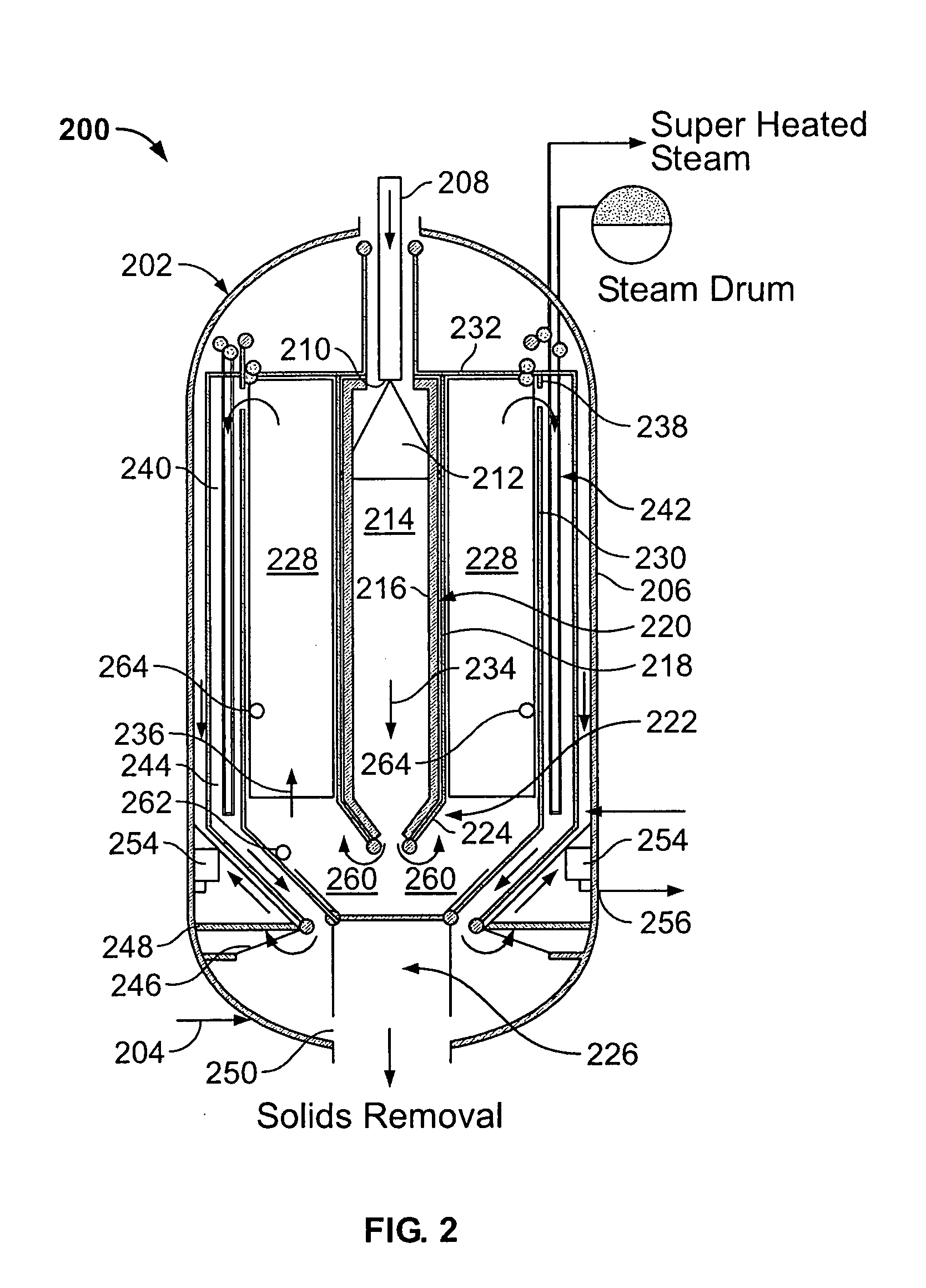

Circulation fluid bed hydrogen preparation reaction technology and reaction device by reforming methane and water steam

InactiveCN101054161ACause inactivationLow costHydrogen separationChemical recyclingSteam reformingWater vapor

A reaction technics of producing hydrogen from methane reforming with steam on circulating fluidized bed and reaction apparatus thereof, belongs to petrochemical industry technique field. The technics comprises three main steps of reforming methane with steam, oxidating catalyst for removing carbon deposit and reducing and regenerating catalyst, the whole process combines selfrecharging of reaction heat with catalyst regeneration to reduce energy consumption and increase productivity of hydrogen; the invention utilizes combination of endothermic and exothermic and reaction combination of reduction of metal oxide and metal oxidizing reaction, uses catalyst solid particles as carrier of heat and oxygen to realize binary cycle of heat and oxygen; main reaction apparatus of the technics comprises: a riser reactor for reforming methane with steam, a fluidized bed combustion reactor for removing catalyst oxidation and carbon deposit, and a catalyst regeneration device; whole apparatus of the invention have simple and compact structure.

Owner:TSINGHUA UNIV

Method for preparing high-quality fuel oil from inferior crude oil

ActiveCN101993726AImproved raw material propertiesExtended operating cycleTreatment with hydrotreatment processesChemical recyclingWaxLighter fuel

The invention discloses a method for preparing high-quality fuel oil from inferior crude oil. The inferior crude oil enters first and second reaction zones of a catalytic conversion reactor in turn to contact a catalytic conversion catalyst and respectively perform primary reaction and secondary reaction, and after a reaction product and a spent catalyst are subjected to gas-solid separation, the spent catalyst is stripped and scorched in turn and is returned to the reactor for recycling; the reaction product is separated to obtain propylene, light fuel oil, catalyzed wax oil and other products, wherein the catalyzed wax oil enters a hydrocracking device and is separated to obtain products such as gasoline, an aviation fuel, diesel oil, hydrocracked tail oil and the like; and the hydrocracked tail oil is circulated to the first reaction zone of the catalytic conversion reactor and / or other catalytic conversion devices for further reaction to obtain a desired product, namely the light fuel oil, and a byproduct, namely the propylene. By the method, a diesel cetane number is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Novel foam separation equipment for restoring heavy metal polluted soil

InactiveCN101879520AEasy to separateHigh removal rateContaminated soil reclamationSurface-active agentsTower

In order to restore heavy metal polluted soil, the invention provides novel foam separation equipment for restoring the heavy metal polluted soil. The whole foam separation equipment is provided with two stages of foam separation towers, firstly, soil to be treated is placed into the primary foam separation tower, a surface active agent mixed solution is uniformly sprayed through an annular water distribution device for soaking the soil, at the same time, the aeration is carried out through a water distribution plate, heavy metals in the soil carry out complexation with the surface active agent through sufficient contact via the stripping effect, complex compounds are attached on air bubbles to be separated from the soil, the air distribution plate is opened after the primary reaction is completed, and soil particles enter the secondary foam separation tower to carry out further separation treatment and to be cleaned. The invention has the advantages of little secondary pollution and high removal rate of heavy metal.

Owner:长春联创水质工程有限公司

Continuous large-scale production method for p-aramid nanofiber dispersion liquid

ActiveCN106750265AThe polymerization process went wellForm evenlyMonocomponent polyamides artificial filamentNanofiberChloride

The invention relates to a continuous large-scale production method for p-aramid nanofiber dispersion liquid, and belongs to the technical field of novel polymer materials. A proper aid is added in a process of generating poly-p-phenylene terephthamide (PPTA) through a reaction of p-phenylenediamine and paraphthaloyl chloride, so that the PPTA can directly generate nanofiber instead of random particles under control. Double screws are taken as a main reactor of PPTA polymerization, and an aid damaging molecular molecular aggregation of the PPTA is added into a PPTA polymerization system, so that successful proceeding of a PPTA polymerization process can be ensured on the one hand, interaction between the aid and the PPTA can be accelerated under the strong shear stirring action of a screw element on the other hand, and uniform nanofiber is formed instead of random particles by the PPTA. Moreover, a dispersing process of the nanofiber is finished directly in the screws under the shearing action of the double screws. The method is simple in equipment and is urgent in production links, major reaction and dispersion processes are finished in the double screws, and the production stability and continuity are enhanced greatly.

Owner:山东聚芳新材料股份有限公司

Method to extend the utilization of a catalyst in a multistage reactor system

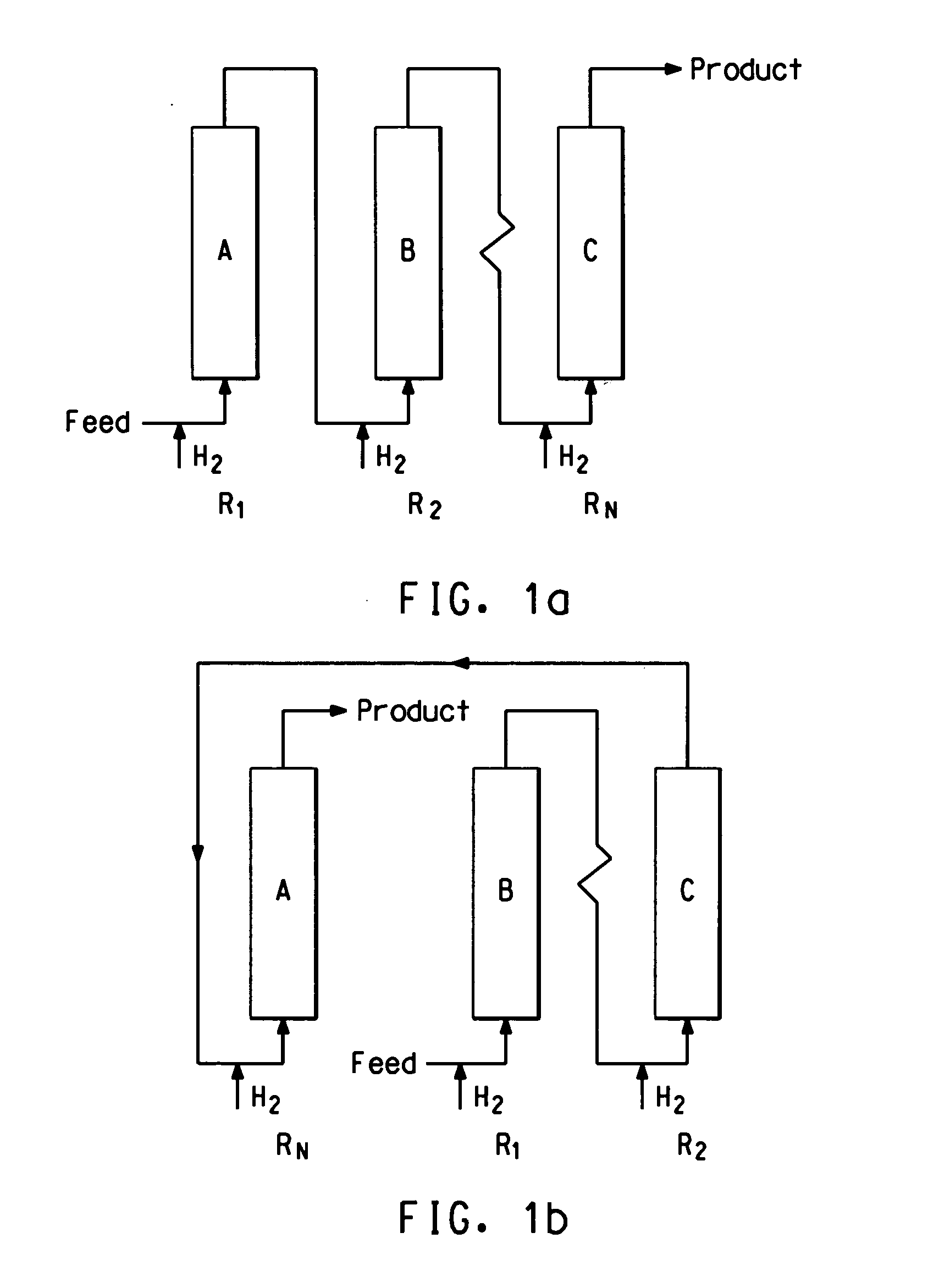

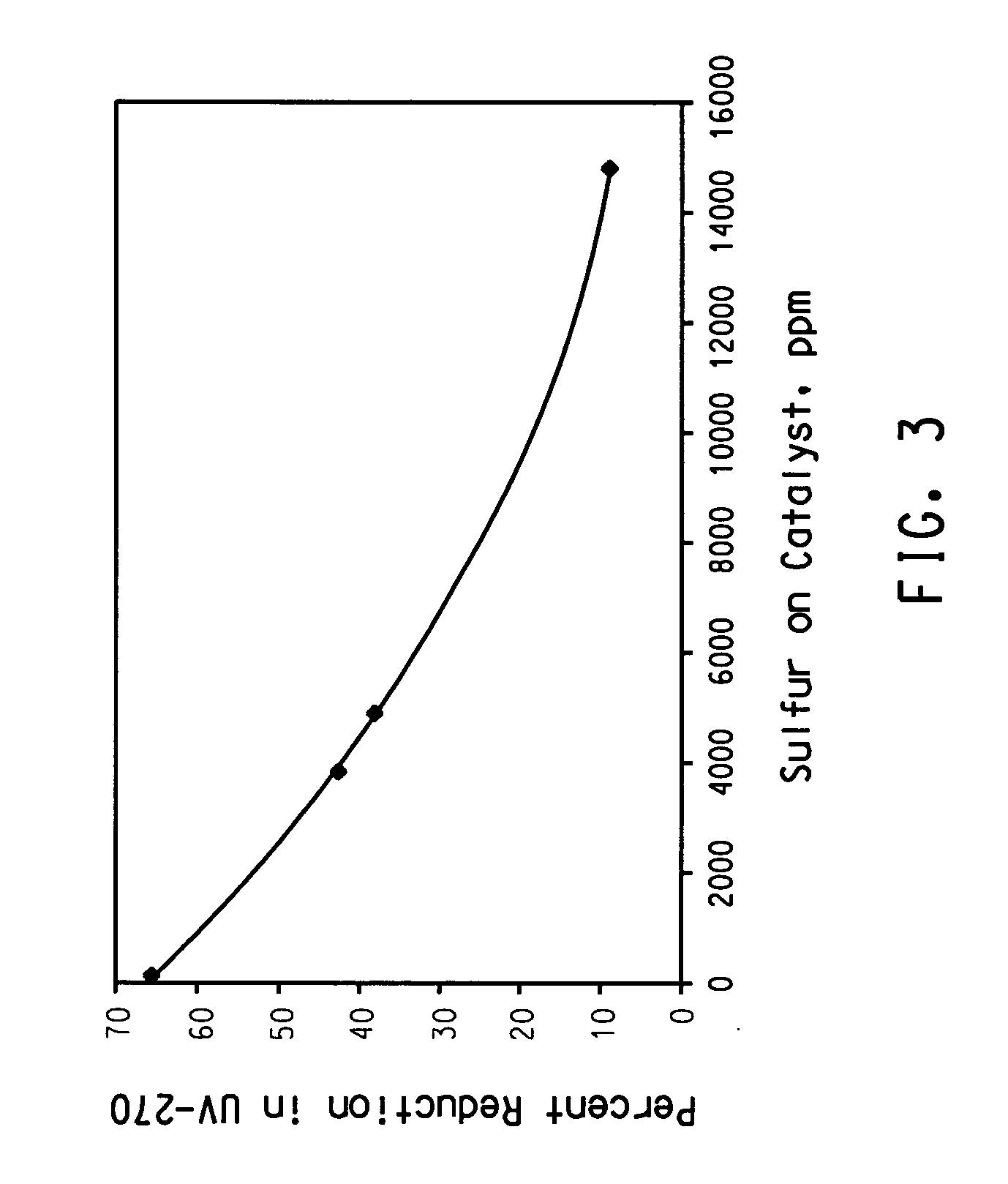

InactiveUS20060070918A1Reduce the temperaturePhysical/chemical process catalystsHydrocarbon oil crackingReaction speedPrimary reaction

The invention provides a method to extend the utilization of a catalyst in a multistage reaction system, provided that a primary reaction and a secondary (or more) catalyst-poisoning reaction occur on the same catalyst, and the rate of the secondary (or more), catalyst-poisoning reaction is faster than the rate of the primary reaction.

Owner:EI DU PONT DE NEMOURS & CO

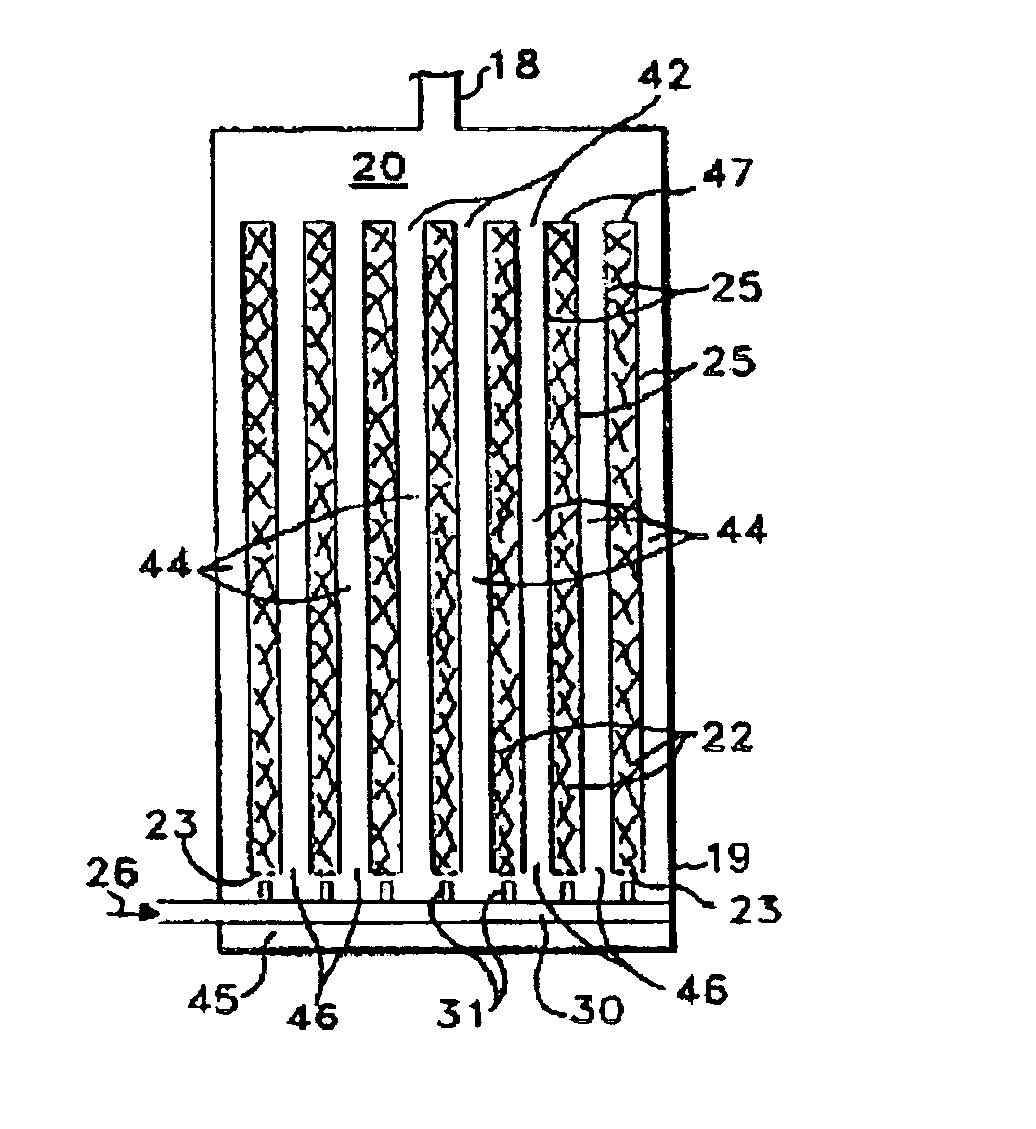

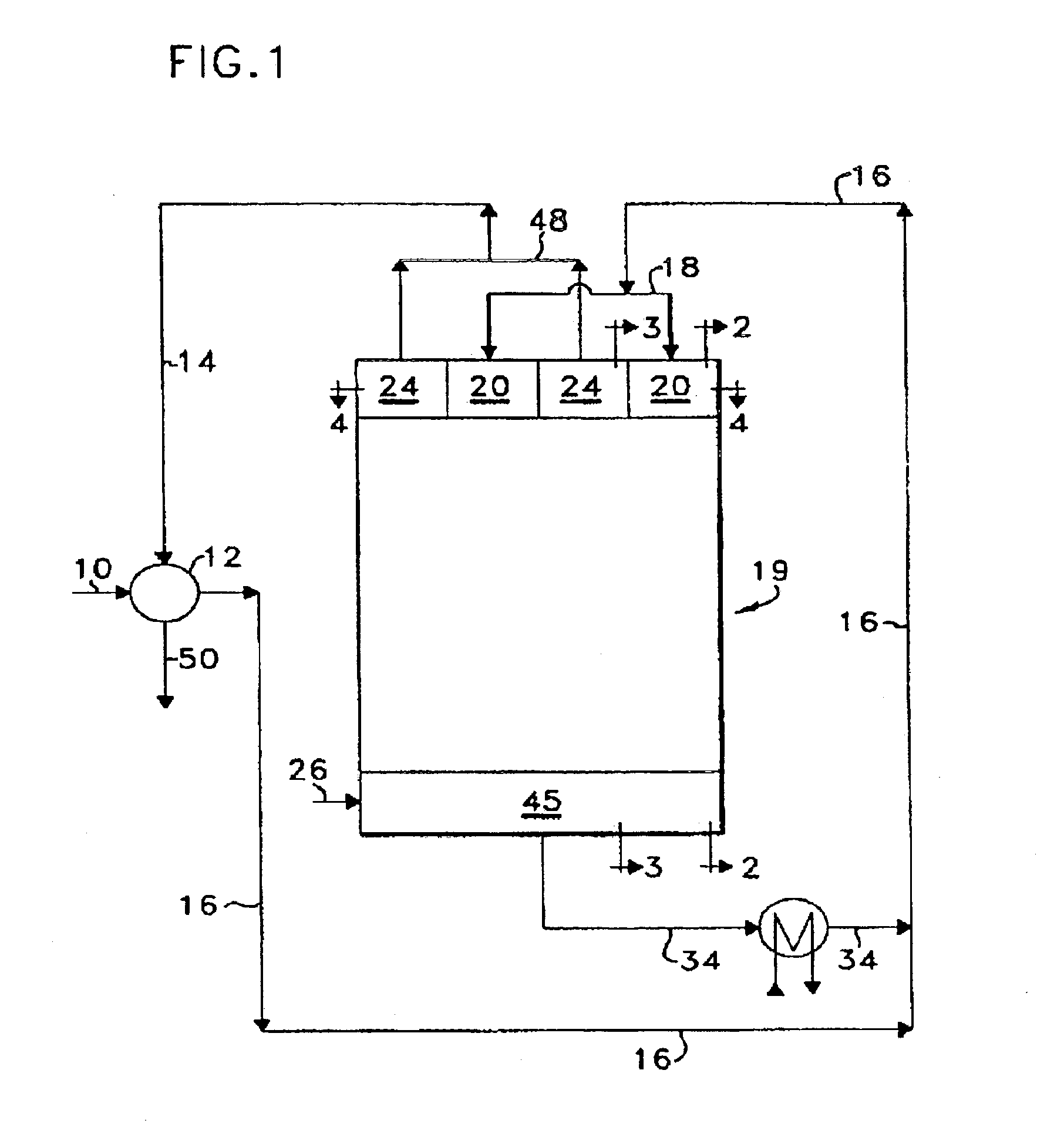

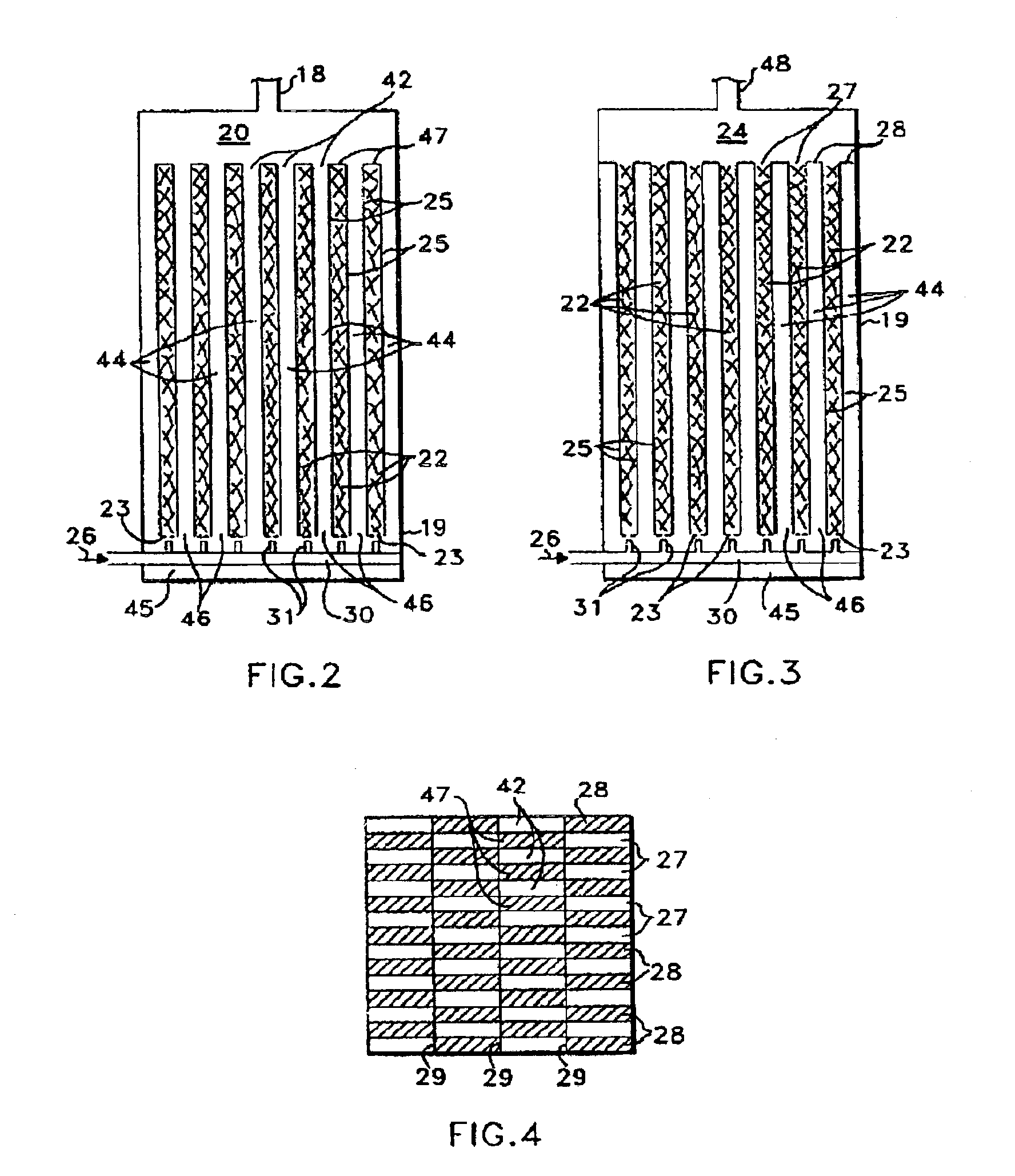

Apparatus using plate arrangement for exothermic reactions

InactiveUS6869578B1Easy transferEliminate weldsHydrogenPhysical/chemical process catalystsTemperature controlDiluent

A process and apparatus cools a heat exchange type reaction zone by passing the incoming reactants through heat exchange channels in heat exchange relationship with the reaction zone. The invention simplifies the operation and construction of the heat exchanging type reaction zone by directly communicating reaction channels that contain the reaction with the heating channels that heat reactant across an open manifold located at the end of the channels. Additional reactants, cooling fluids, or other diluents may enter the process directly through the manifold space to permit further temperature control of the reaction zone. The invention promotes better heat transfer efficiency than tube and shell heat transfer arrangements that have been used for similar purposes. The narrow channels are preferably defined by corrugated plates. The reaction channels will contain a catalyst for the promotion of the primary reaction.

Owner:UOP LLC

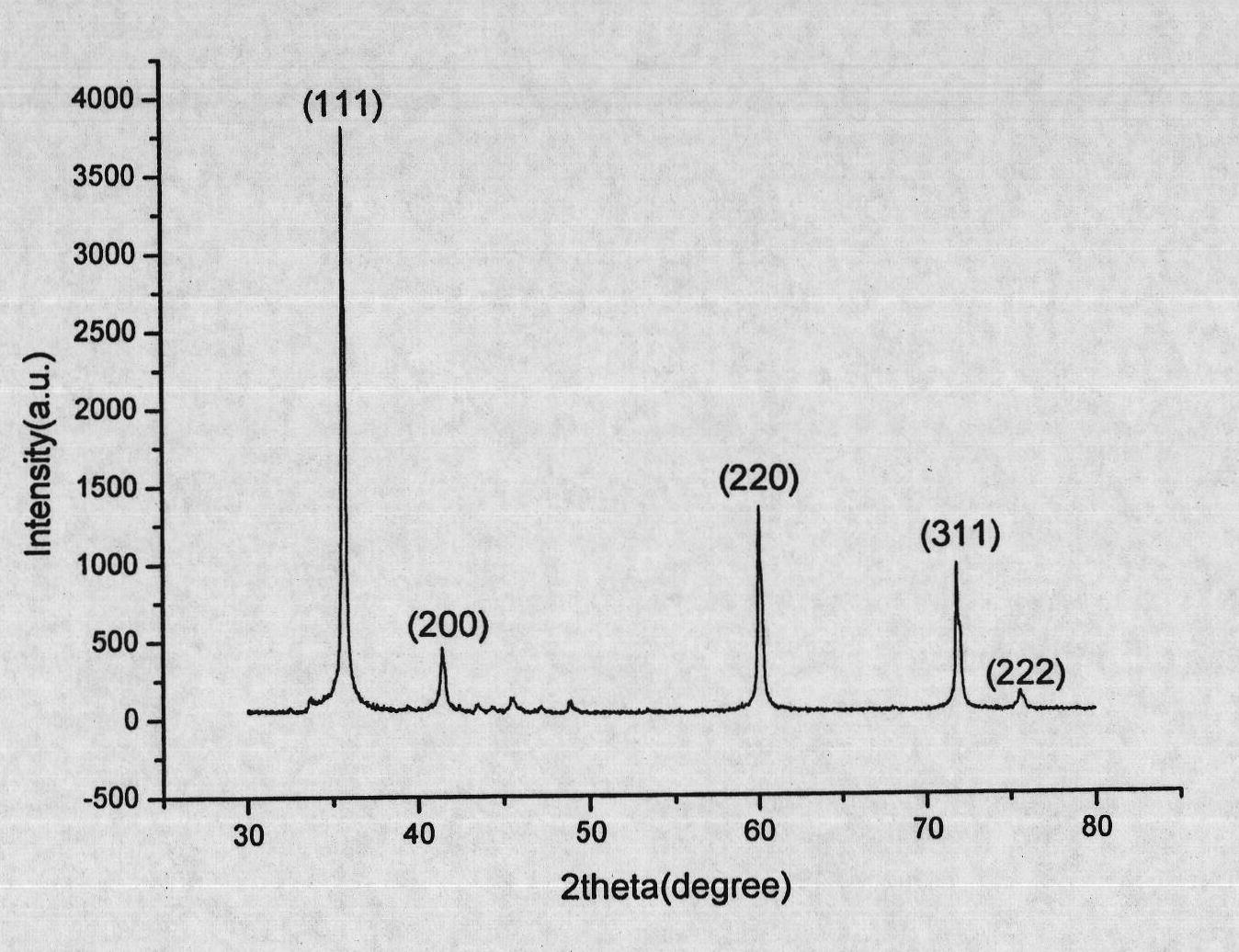

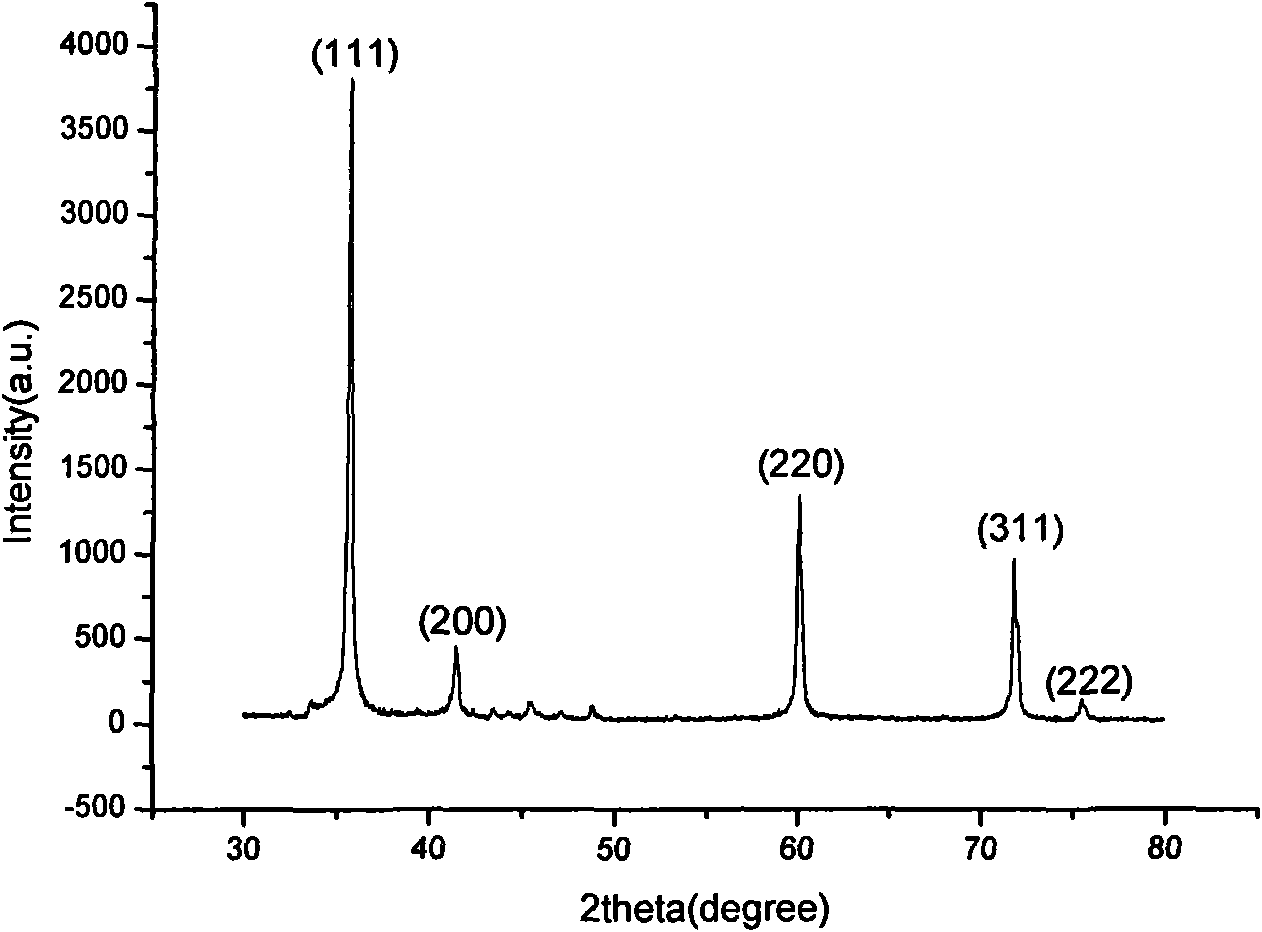

Preparation method of beta-nano-SiC

ActiveCN102432013AReduce manufacturing costRapid mass productionCarbon compoundsNanotechnologyHydrofluoric acidNitrate

A preparation method of beta-nano-SiC comprises the following steps of: mixing starch or cane sugar with soluble glass according to the mass ratio of 1:1-5, or mixing starch or cane sugar with nitrate according to the mass ratio of 1:0.01-0.5, then mixing with soluble glass with the mass ratio of starch to soluble glass being 1:1-5, standing for 5-30 minutes after uniformly mixing, dying the mixture at the temperature of 60-120 DEG C for 5-20 hours to obtain a dried substance; carrying out a carbothermal reduction reaction for 3-20 hours by heating the dried substance to 1100-1400 DEG C underthe protection of argon gas, and naturally cooling to room temperature after the reaction so as to obtain a primary reaction product; roasting the primary reaction product at the temperature of 600-800 DEG C for 1-5 hours, and removing unreacted carbon; immersing for 12-48 hours by using a mixed acid composed of hydrochloric acid and hydrofluoric acid at the volume ratio of 1:1-5, removing superfluous silica from the product, washing, filtering and drying to finally obtain beta-nano-SiC. The preparation method provided by the invention requires low cost, has a simple technology, and is suitable for large-scale industrial production.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Methods and systems for partial moderator bypass

ActiveUS20070137103A1Improve concentrationGasifier mechanical detailsGas modification by gas mixingPartial oxidationFuel gas

Methods and systems for a gasifier having a partial moderator bypass are provided. The gasifier includes a partial oxidation reactor including an inlet and an outlet and a primary reaction zone extending therebetween, the partial oxidation reactor configured to direct a flow of products of partial oxidation including fuel gases, gaseous byproducts of partial oxidation, and unburned carbon, and a secondary reaction chamber coupled in flow communication with the partial oxidation reactor, the secondary reaction chamber is configured to mix a flow of moderator with the flow of gaseous byproducts of partial oxidation and unburned carbon such that a concentration of fuel gases is increased.

Owner:AIR PROD & CHEM INC

Three phase electrocoagulation effluent treatment apparatus and methods

InactiveUS20100116686A1Reduce maintenanceMeet cutting requirementsElectrolysis componentsReverse osmosisElectrocoagulationSludge

Electrocoagulation effluent treatment apparatus and methods are disclosed, the apparatus including a primary electrocoagulation reactor chamber having treatment electrodes maintained therein and an effluent inlet and treated effluent outlet. An integrated flotation chamber is located above the reaction chamber, a vacuum device connectable with a vacuum source being received in the flotation chamber and including a foam intake and an output. A sludge chamber is defined below and integrated with the primary reaction chamber and has a settled sludge output.

Owner:ROCKWATER RESOURCE

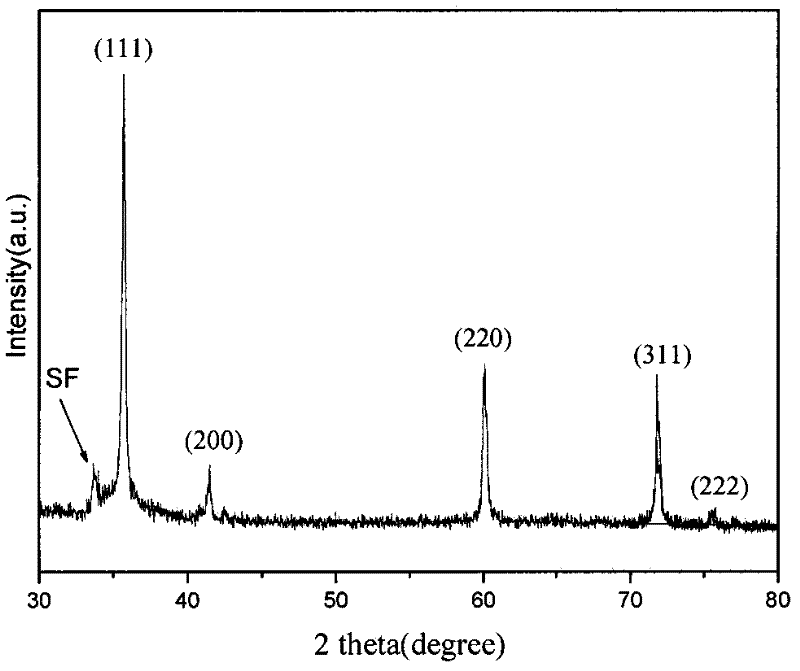

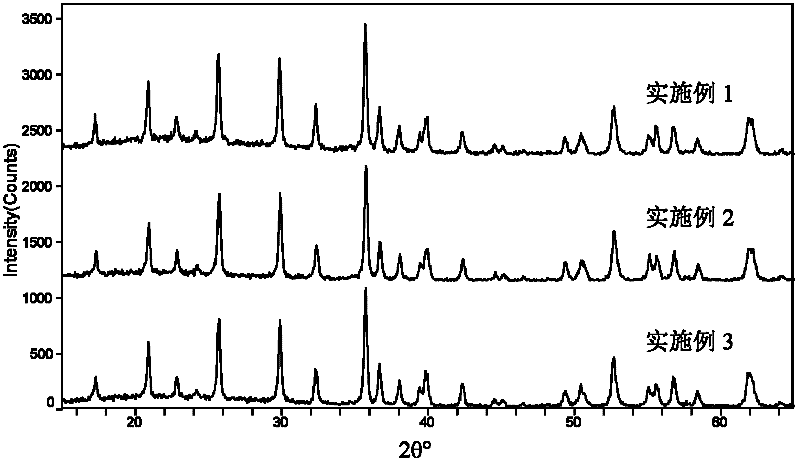

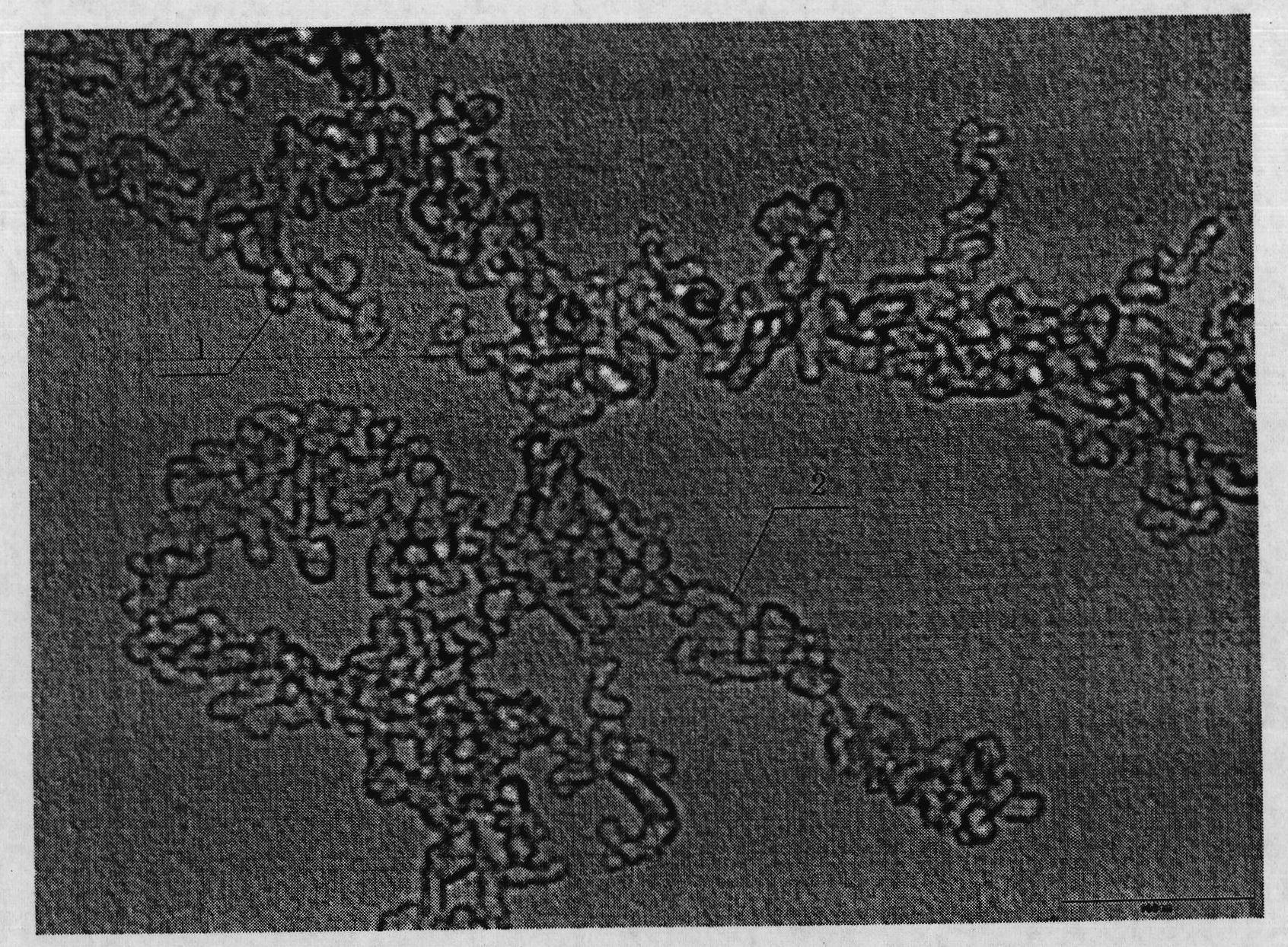

Microwave-hydrothermal method for preparing cathode materials of nano lithium iron phosphate batteries

InactiveCN102530906AImprove conductivityMicroscopic Morphology ControlPhosphorus compoundsLithium iron phosphateMicrowave

The invention provides a microwave-hydrothermal method for preparing cathode materials of nano lithium iron phosphate batteries, which includes the following steps that water-soluble lithium source compounds, iron source compounds and phosphorus source compounds serve as main reactants and are added with reaction additives, and are arranged in a microwave reaction instrument to have a microwave-hydrothermal reaction after being uniformly fixed in water or mixed solvent of water and other solvent, thereby obtaining ideal cathode materials of the nano lithium iron phosphate batteries under mild conditions (the temperature is 100-250 DEG C and the intensity of pressure is 0.1-1.5MPa ). The microwave-hydrothermal method for preparing cathode materials of nano lithium iron phosphate batteries has the advantages of being simple in process, energy-saving, high in efficiency, mild in conditions, low in cost, excellent in purity of products, uniform and fine in particles, high in controllability and excellent in reproducibility.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

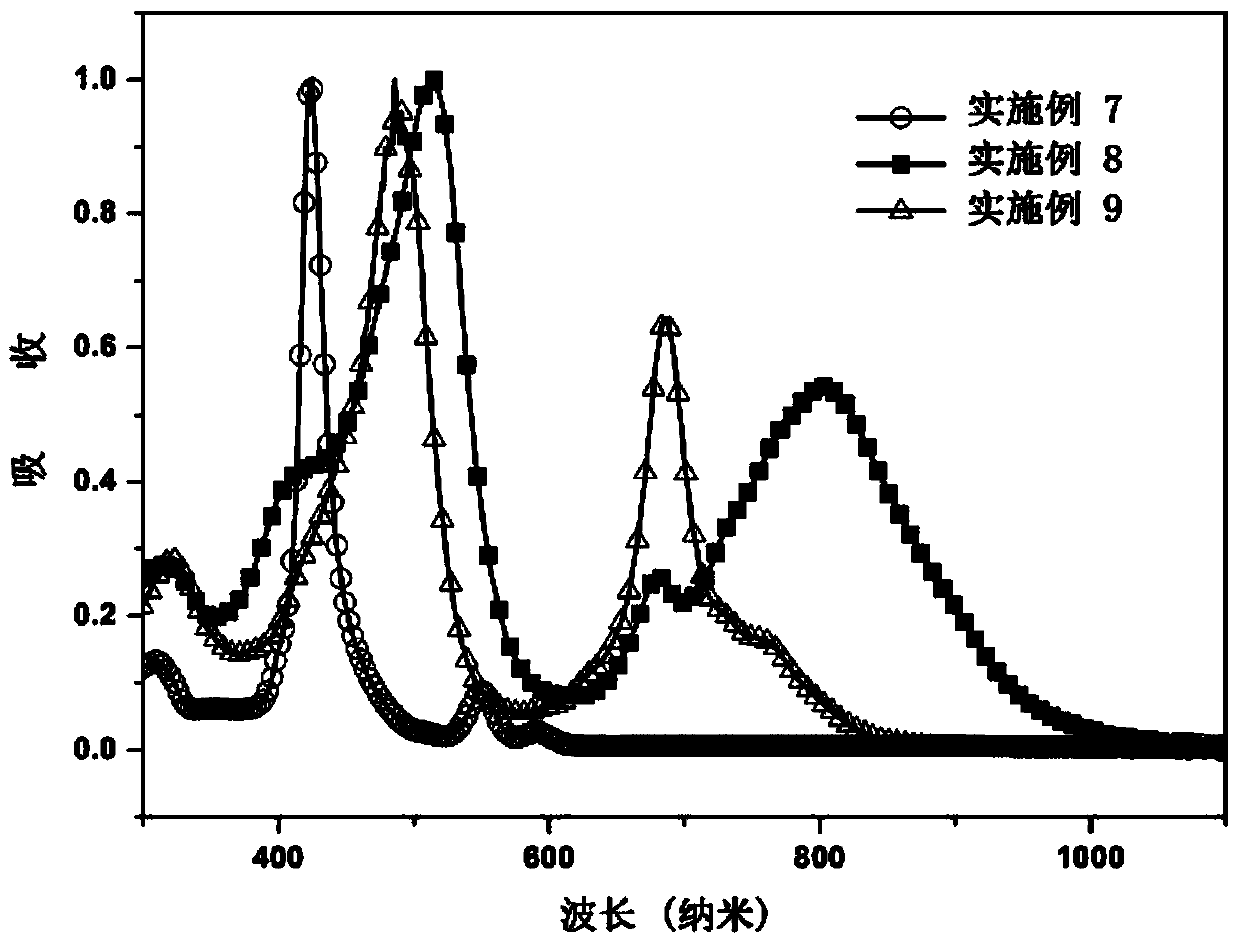

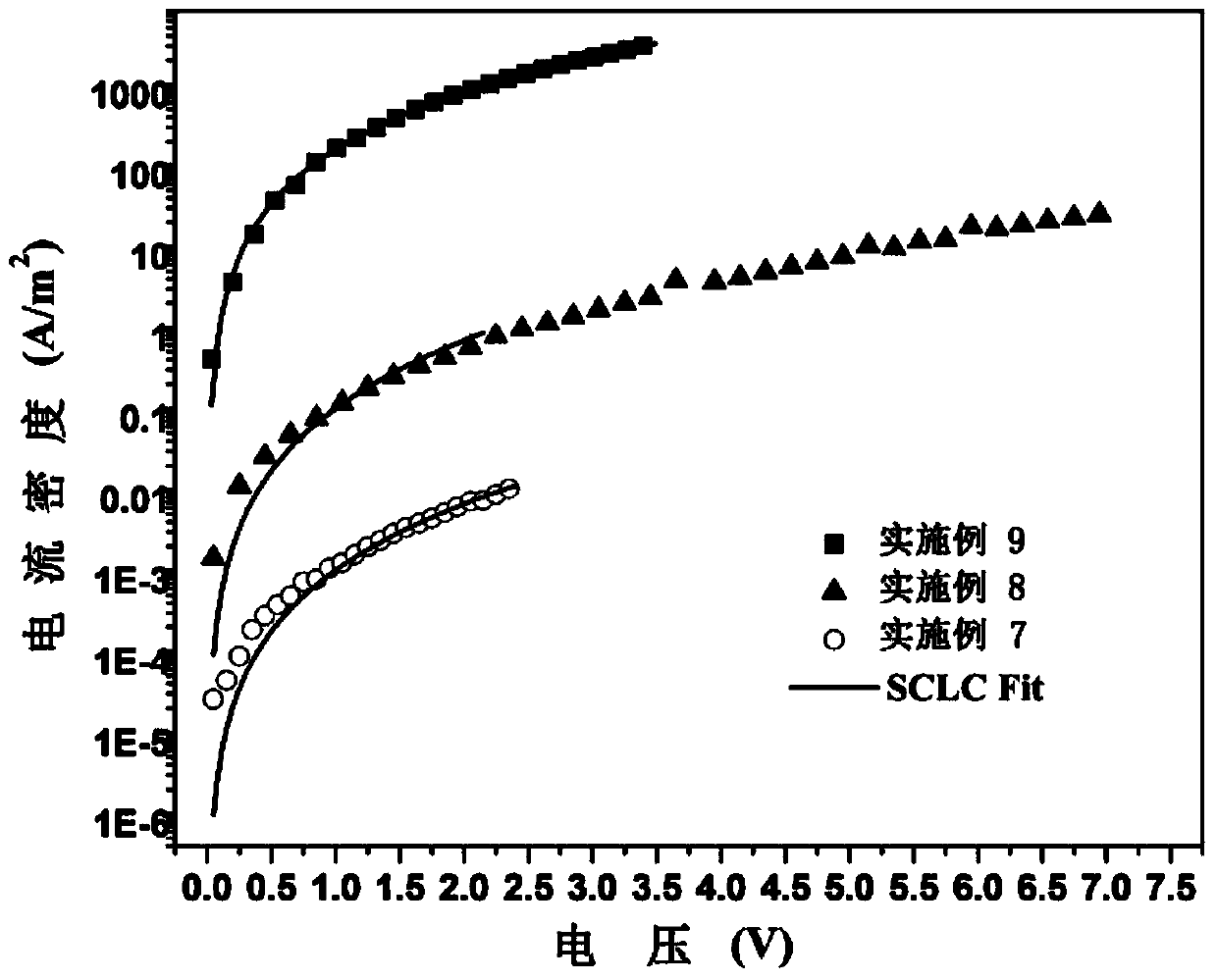

Porphyrin organic small molecular photovoltaic material and preparation method thereof

InactiveCN103724355AIncreased π conjugated systemIncreased intramolecular charge transferOrganic chemistrySolid-state devicesSolar energy conversion efficiencyPorphyrin

The invention discloses a porphyrin organic small molecular photovoltaic material and a preparation method thereof. The disclosed porphyrin organic small molecular photovoltaic material adopts a porphyrin ring as a framework, one radical is in each of four meso-position positions of the porphyrin ring, wherein two radicals are acceptor units, and the other two radicals are aromatic substituted radicals. The invention further discloses the preparation method of the above porphyrin organic small molecular photovoltaic material. Pyrrole is used as a primary reaction material, then subjected to a series of simple reactions, and finally coupled with different acceptor units under the catalysis of palladium to obtain the porphyrin organic small molecular photovoltaic material. Compared with the prior art, the porphyrin organic small molecular photovoltaic material, disclosed by the invention, is improved in the ability to absorb light, intramolecular electric charge transmission performance and Pi-Pi stacking of molecules in a film forming state; the film forming performance of the material is improved, an organic photovoltaic battery prepared by using the material and adopting a solution processing method has better device performance, and the highest conversion rate of solar energy reaches 7.2 percent, so that the porphyrin organic small molecular photovoltaic material has a very important application prospect in solar batteries.

Owner:SOUTH CHINA UNIV OF TECH

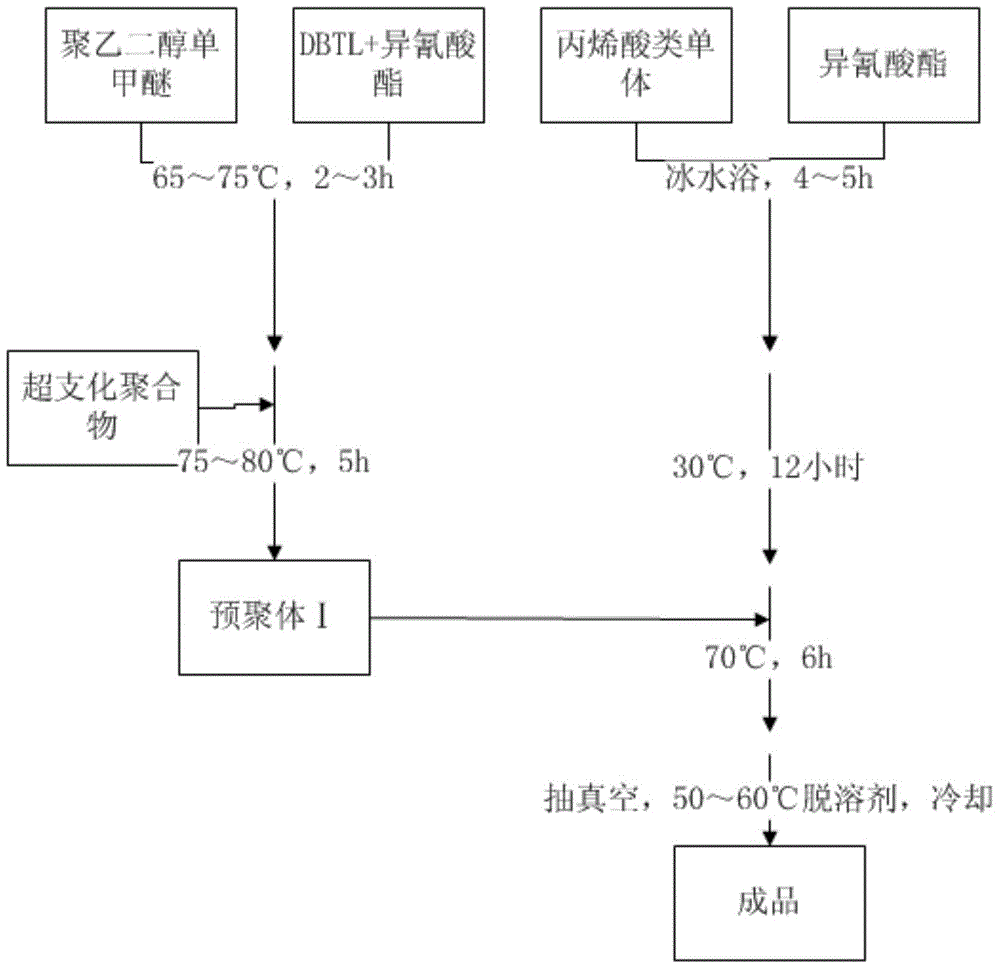

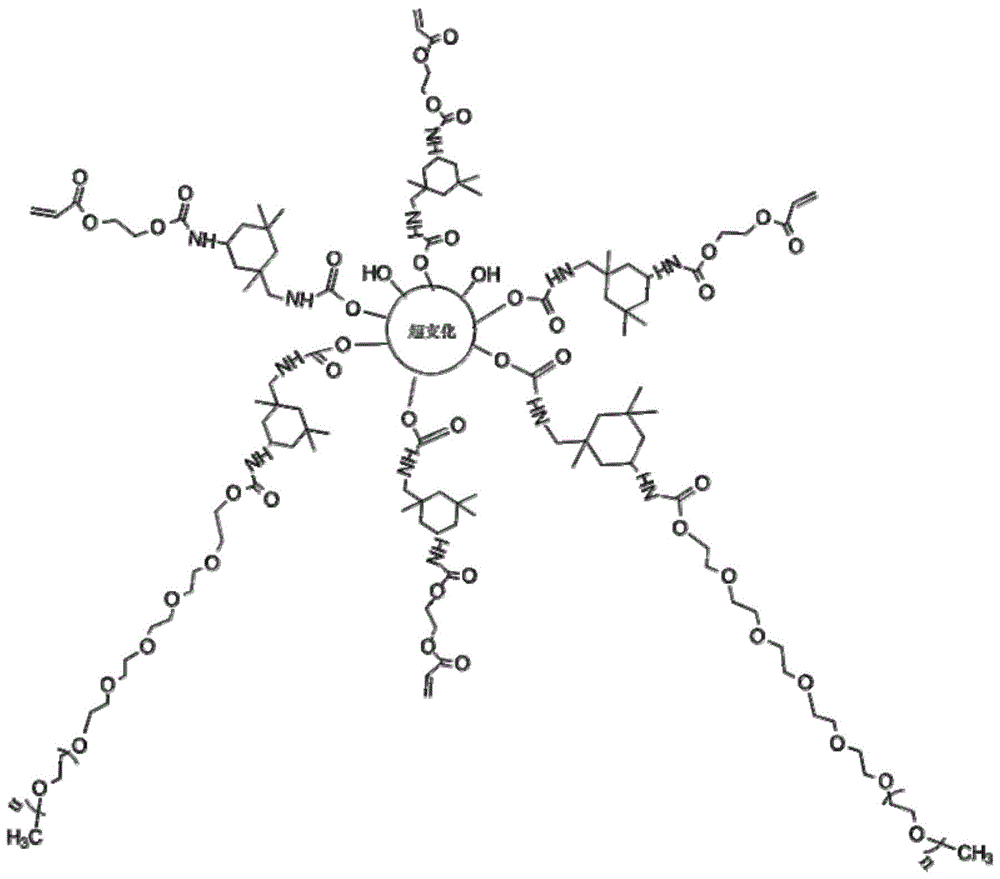

Hydrophilic UV (Ultraviolet) coating hardness assistant and preparation method thereof

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS +1

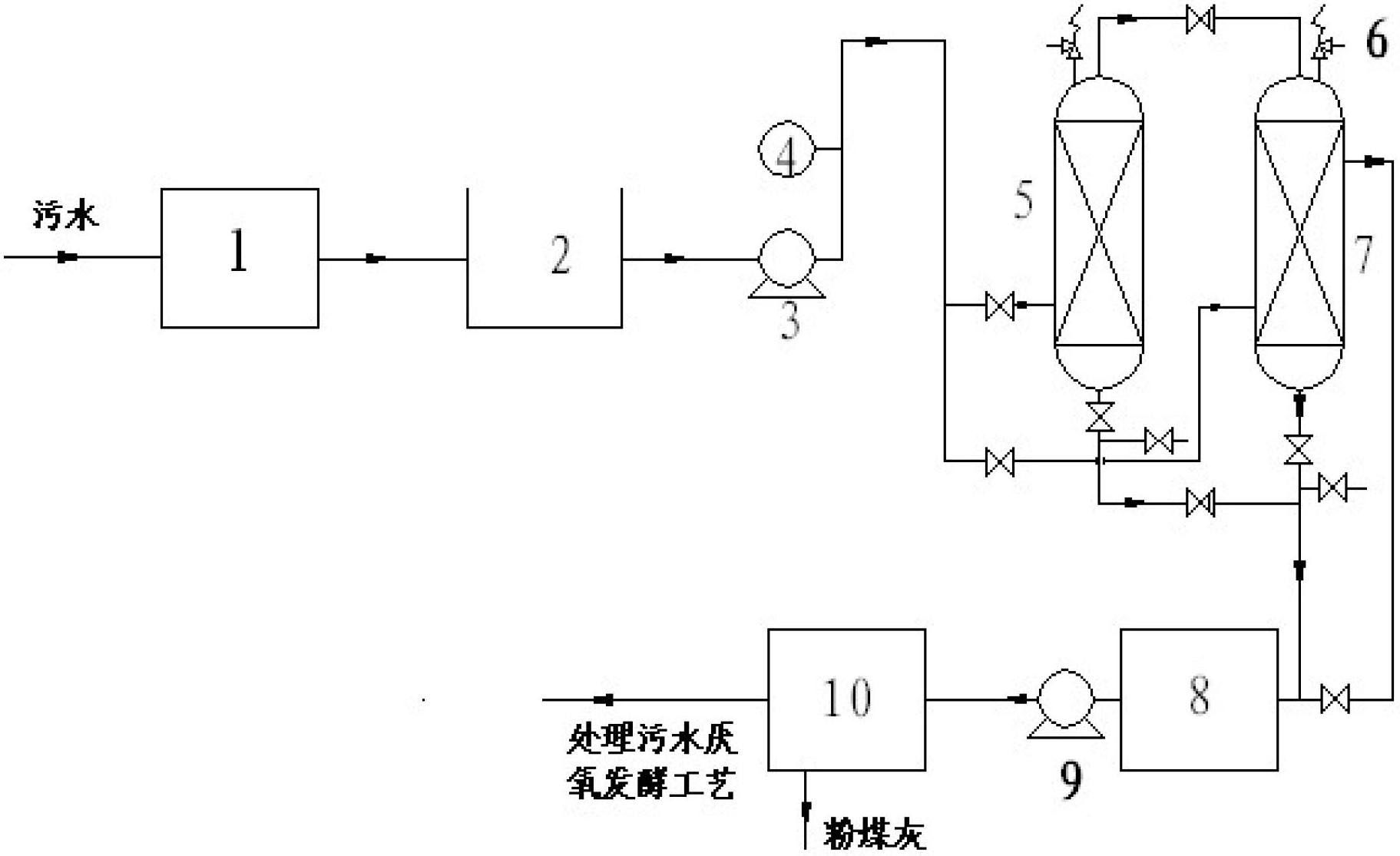

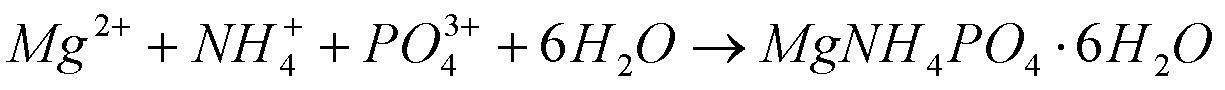

Method for treating sewage with high ammonia, nitrogen and phosphorus contents in livestock and poultry farms by chemical precipitation

ActiveCN102690001AHigh removal rateWide variety of sourcesWaste water treatment from animal husbandryMultistage water/sewage treatmentFixed bedSettling basin

The invention discloses a method for treating sewage with high ammonia, nitrogen and phosphorus contents in livestock and poultry farms by chemical precipitation. The method comprises the following steps of: performing solid-liquid separation on the sewage by using a solid-liquid separator, wherein liquid is discharged into a sedimentation tank for further separation; pumping the sewage which is obtained after separation and deposition into a fixed bed reaction tower in which calcium, magnesium and phosphate fertilizers serve as main reactants, wherein substances which contain the ammonia, the nitrogen or the phosphorus are removed from the sewage in the reaction tower simultaneously; importing sediment and the sewage into a crystallizing pond, and crystallizing to generate struvite; separating the struvite by using the solid-liquid separator; and performing a sewage anaerobic fermentation process on the liquid for further treatment. According to the method, the removal rate of the phosphorous can reach 80 to 90 percent, the removal rate of the ammonia and the nitrogen can reach 70 to 80 percent, and the discharged water can meet the requirement of anaerobic fermentation. The method is high in reaction speed, not influenced by temperatures and low in cost, raw materials are readily available, and the generated sediment, namely the struvite is an efficient sustained-release fertilizer.

Owner:GUANGXI UNIV

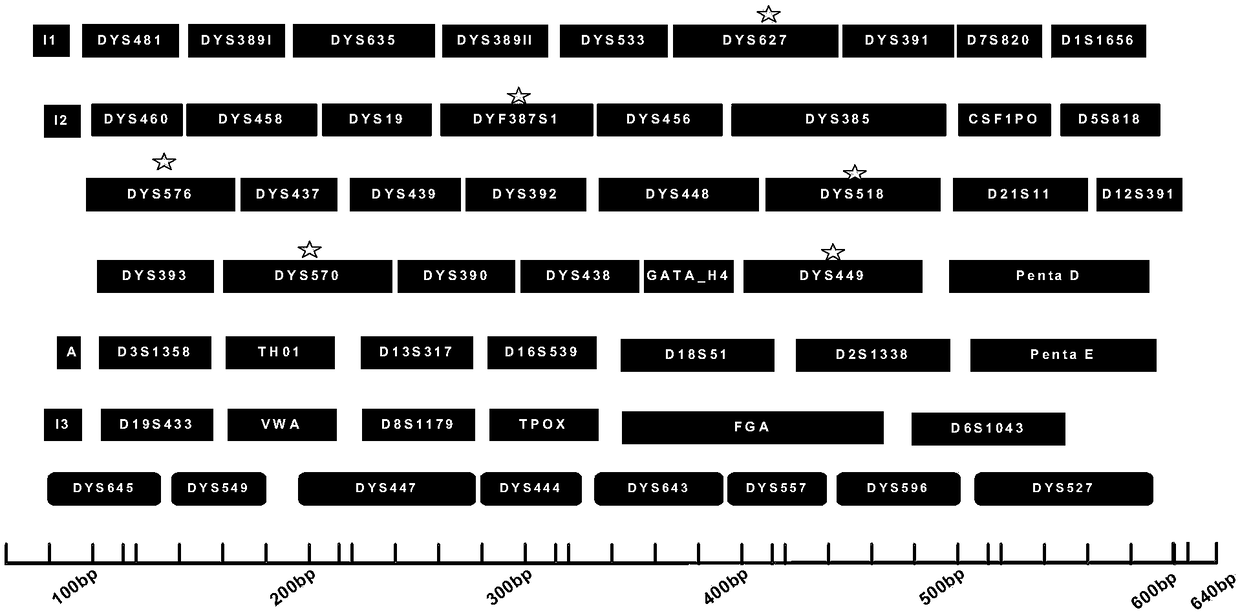

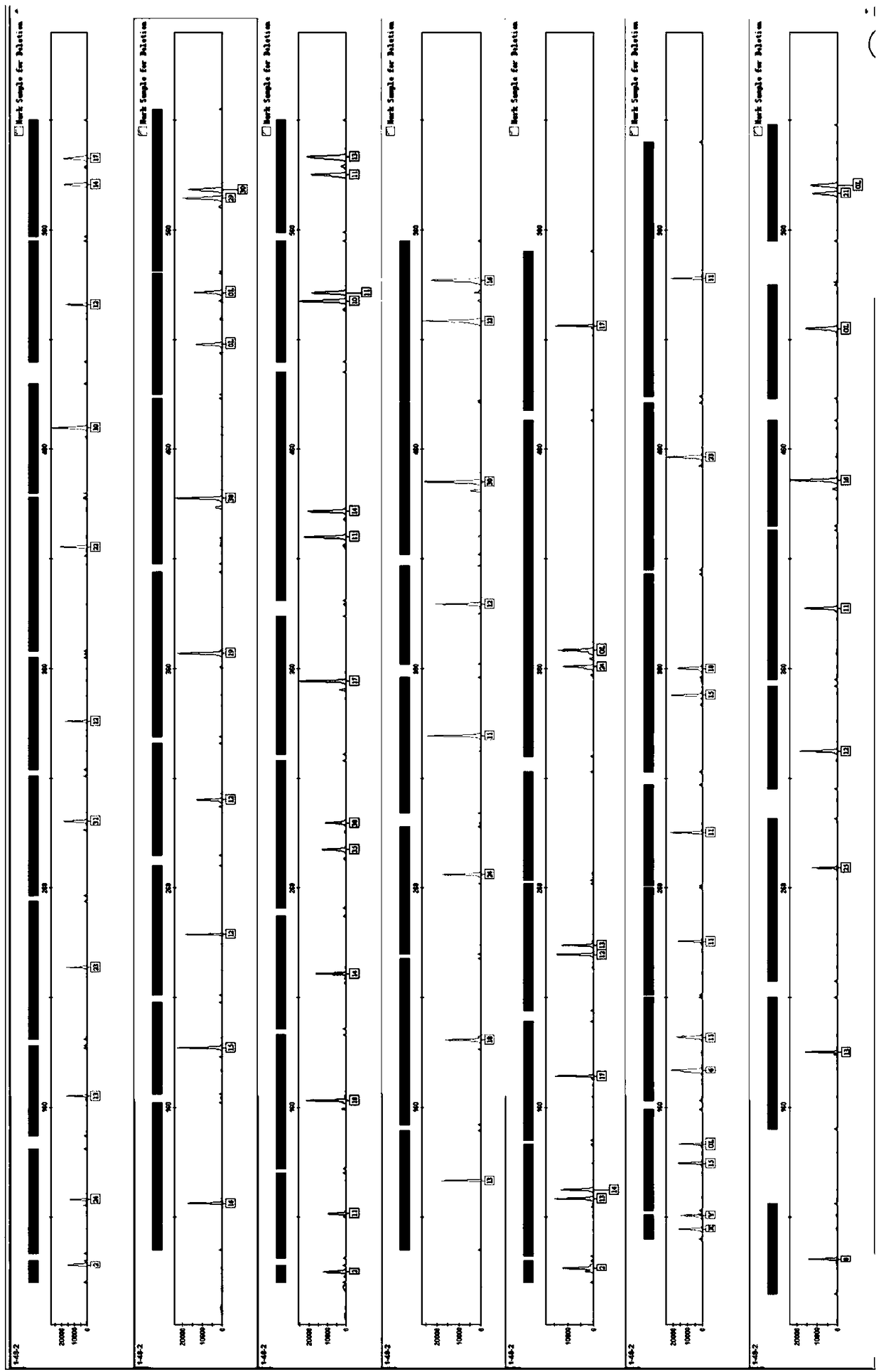

Multiplex amplification detection kit for detecting 60 loca of autosomes and Y-chromosomes simultaneously

ActiveCN109439765ARapid expansionImprove balanceMicrobiological testing/measurementCapillary electrophoresisMagnetic bead

The invention discloses a multiplex amplification detection kit for detecting 60 loca of autosomes and Y-chromosomes simultaneously. The 60 loca are amplified in a multiplex manner through a polymerase chain reaction, and amplification products of the loca are detected by using a gene sequencer. The kit can be used for detecting the 60 loca of the autosomes and the Y-chromosomes simultaneously, which is a case that most STR loca can be detected by a primary reaction with a capillary electrophoresis method at present, and databases can be built for autosome STR and Y-chromosome STR simultaneously by the primary reaction. The kit has strong adaption to biomaterials, namely, one kit can be used for amplifying various biomaterial samples, wherein different biomaterial samples comprise a male genome DNA extracted by a Chelex100 method, a magnetic bead extracting method or an organic extracting method and male blood or oral cells of human, which is / are collected by any one carrier of filterpaper, an FTA card, a cotton bud, gauze and the like. The kit has higher amplification specificity and higher thermal tolerance.

Owner:江苏苏博生物医学科技南京有限公司 +1

Organic-silicon modified acrylic acid resin superhydrophilic antifogging coating and preparation method thereof

ActiveCN109135487ALow preparation temperatureImprove stabilityChemical industryCoatingsGlycidyl methacrylateN dimethylformamide

The invention relates to the field of coating preparation, and discloses an organic-silicon modified acrylic acid resin superhydrophilic antifogging coating and a preparation method thereof. The primary reaction raw materials comprises, by weight, 6.3-10.7% of methymethacrylate, 4.5-7.9% of butyl acrylate, 8.8-15.3% of gamma-methacryloxypropyl trimethoxysilane, 8.1-13.9% functional monomer hydroxyethyl methylacrylate, 16.0-27.0% of the reaction produict of diethanol amine and glycidyl methacrylate 3-(bis(2-hydroxyethyl)amino)-2-hydroxypropyl methacrylate and 7.4-12.8% of 2-acrylamide-2-methylpropionic sulfonic acid, the using amount of the azobisisobutyronitrile is 0.2%-0.4%, and the reaction solvent is N, N-dimethylformamide which takes up the 25.3%-45.6% of the total amount. The coatinghas the advantages of lower preparation temperature, good stability, simple production process, the purpose of energy saving is achieved, invested equipment is less, the coating is transparent leveledand has high adhesion force, -40 DEG C low temperature fog resisting and 80 DEG C high-temperature fog resisting can be achieved, the coating does not wrinkle, there exists no crack, and the coatingcan be repeatedly used for over 100 times.

Owner:CHONGQING UNIV

Method for preparing hollow silicon carbide nano material

The invention relates to a method for preparing hollow silicon carbide nano material. Phenolic resin is dissolved in anhydrous ethanol, nitrate is added and stirred until the nitrate is dissolved, dry product is obtained after the natural volatilization of the ethanol and drying, and is ground into powder, the dry powder is added into sodium silicate, and is constantly stirred to form gel, and the gel is then dried, so that xerogel is obtained; under the argon atmosphere, the xerogel is heated to 1200 DEG C to 1400 DEG C, reacts under the constant temperature for 3 to 20 hours, and is naturally cooled to the room temperature, so that primary reaction product is obtained; the primary reaction product is oxidated in the air, unreacted carbon is removed, and the primary reaction product is then washed by mixed acid, and is finally washed by water, filtered and dried, so that hollow silicon carbide particles and nano tubes are obtained. The invention has the advantages of simple technique, low cost, high product purity and mass production.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com