Microwave-hydrothermal method for preparing cathode materials of nano lithium iron phosphate batteries

A lithium iron phosphate battery and cathode material technology, applied in the microwave-hydrothermal field, can solve the problems of high energy consumption, complicated process, and large product particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

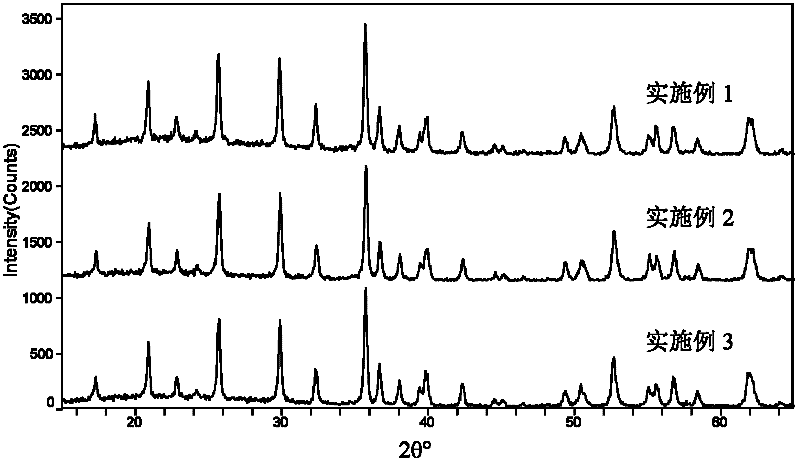

Embodiment 1

[0020] Weigh 0.333g of lithium hydroxide powder, dissolve it in deionized water, and prepare a 0.2g / mL lithium hydroxide aqueous solution. Weigh 0.736g of ferrous sulfate powder, dissolve it in a mixed solvent of deionized water and ethanol, add dropwise 0.15mL of phosphoric acid (85%), and stir magnetically for 5 minutes at a speed of 500 rpm to form a transparent mixed solution. Lithium hydroxide aqueous solution was added to this mixed solution to form a gray-green cloudy solution. Weigh 0.078g of ascorbic acid and 0.121g of hexadecyltrimethylammonium bromide respectively, add them into the turbid solution, stir magnetically for 10 minutes at a speed of 500 rpm, and measure the pH to be 5.8. Then, with a pressure of 1.5 MPa, the mixture was put into a quartz reaction tube, placed on a microwave reactor, heated to 150° C. by microwave, and kept at a constant temperature for 20 minutes. After the reaction, after centrifugation, ultrasonic cleaning, and vacuum heating and dry...

Embodiment 2

[0022] Weigh 0.333g of lithium hydroxide powder, dissolve it in deionized water, add dropwise 0.14mL of phosphoric acid (85%), and magnetically stir for 5 minutes at a speed of 500 rpm to form a white turbid solution. Weigh 0.736g of ferrous sulfate and 0.078g of ascorbic acid powder respectively, dissolve them in deionized water together, then add them to the white turbid liquid, stir magnetically for 10 minutes at a speed of 500 rpm, and form a gray-green turbid liquid. Measure the pH value of 6.0. Then, the gray-green turbid liquid was put into a quartz reaction tube, placed on a microwave reactor, heated to 150° C. by microwave, kept at a constant temperature for 20 minutes, and the pressure was 1.4 MPa. After the reaction, after centrifugation, ultrasonic cleaning and heating and drying, off-white loose nano-lithium iron phosphate powder is finally obtained, the microscopic appearance is nearly spherical particles, and the size is about 2.0nm.

Embodiment 3

[0024] Weigh 0.250g of lithium hydroxide powder, dissolve it in deionized water, add dropwise 0.11mL of phosphoric acid (85%), and magnetically stir for 5 minutes at a speed of 500 rpm to form a white turbid solution. Weigh 0.524g of ferrous sulfate and 0.017g of calcium acetate powder, dissolve them together in deionized water, add them to the white turbid solution, and stir magnetically for 10 minutes at a speed of 500 rpm to form a gray-green turbid solution. Weigh 0.182g of cetyltrimethylammonium bromide, add it into the turbid liquid and mix evenly, and measure the pH value to be 6.0. Then, the mixed turbid solution was put into a quartz reaction tube, placed on a microwave reactor, heated to 150° C. by microwave, kept at a constant temperature for 20 minutes, and the pressure was 1.1 MPa. After the reaction, after centrifugation, ultrasonic cleaning and heating and drying, off-white loose nano-lithium iron phosphate powder is finally obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com