Method for treating sewage with high ammonia, nitrogen and phosphorus contents in livestock and poultry farms by chemical precipitation

A chemical precipitation method and farm technology, applied in chemical instruments and methods, inorganic chemistry, animal husbandry wastewater treatment, etc., can solve the problem of not removing ammonia and nitrogen at the same time, and achieve low cost, simple operation and fast reaction speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

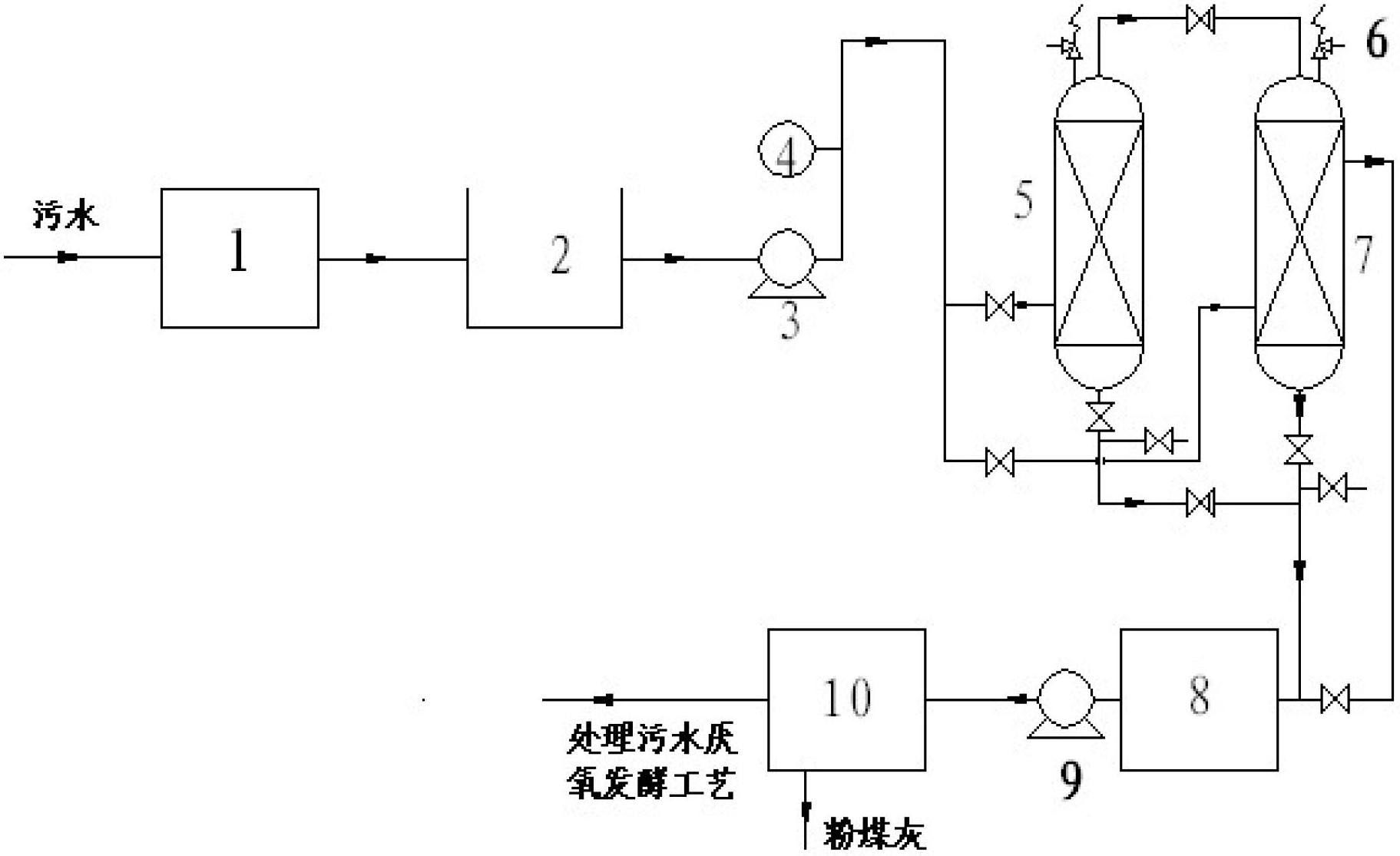

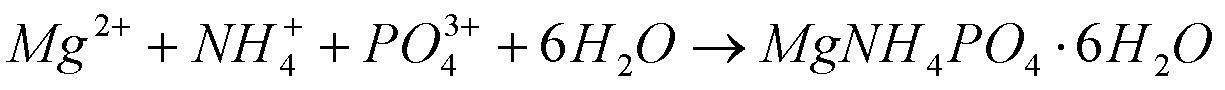

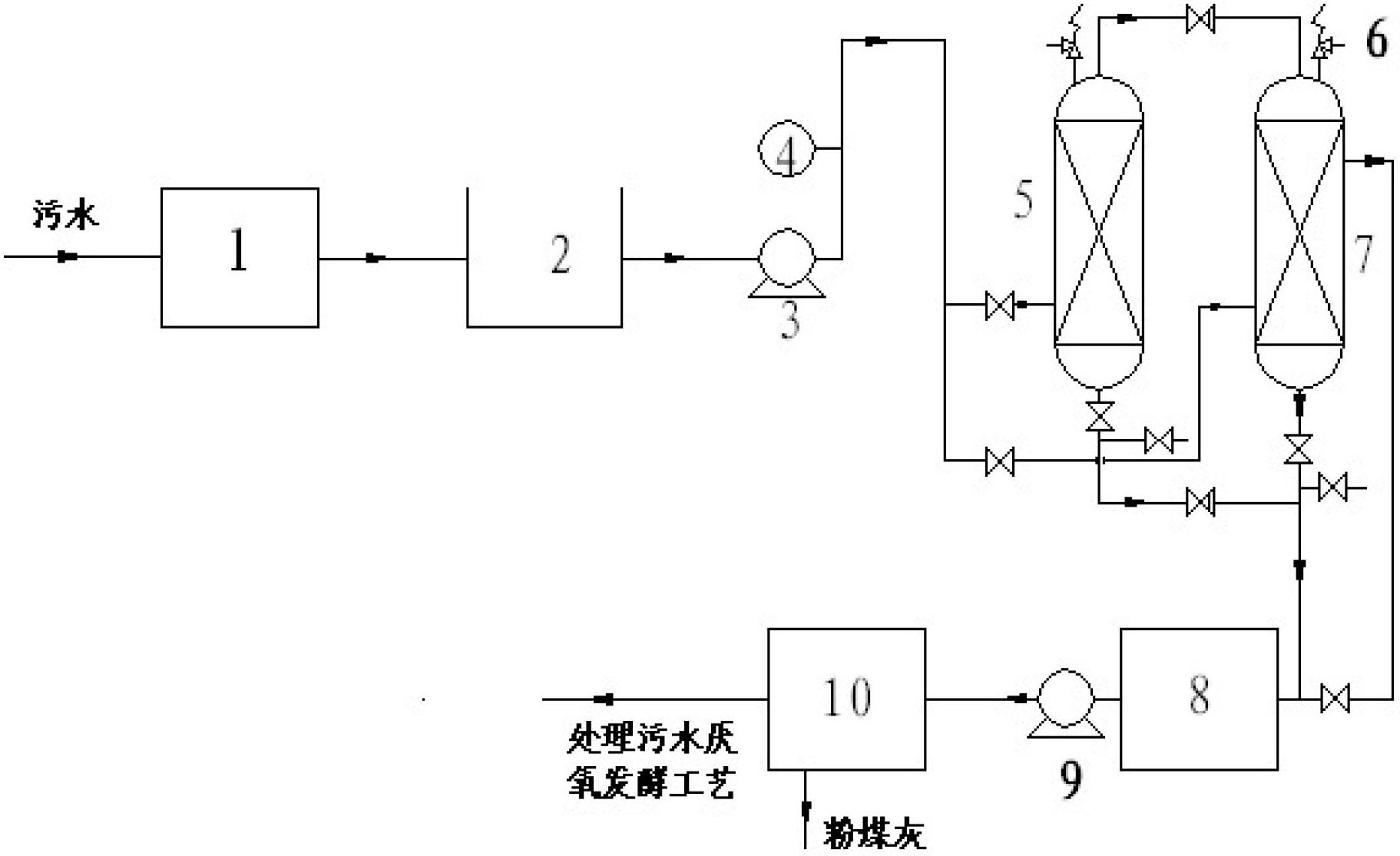

Method used

Image

Examples

Embodiment 1

[0029] The PH value of sewage discharged from a pig farm in eastern Guizhou is 6.3~6.5; the sewage contains pig manure, a small amount of feed residue, green feed residue and sewage from flushing pig farms. 3 / h. After the first-stage solid-liquid separation, the sewage enters the sedimentation tank, stands still for 60 minutes, and then is pumped into the fixed bed reaction tower. There are three layers of fixed beds in the tower, and the distance between the beds is 1m; the reactants placed on the bed Medium, calcium magnesium phosphate fertilizer, CaO and Mg(OH) 2 Accounting for 96%, 2% and 2% of the total mass respectively, the thickness of each bed of reactants is controlled at 20cm thick, and the flow rate of sewage in the tower is controlled at 0.5m / s; after passing through the two-stage reaction tower, struvite is precipitated and separated. The mass ratio of phosphorus removal rate is 84.5%, and the mass ratio of ammonia and nitrogen removal rate reaches 71.5%.

Embodiment 2

[0031] In a large cattle farm in eastern Yunnan, the PH value of the discharged sewage is 6.4~6.6. The sewage contains cow dung, feed residues, hay feed residues, and sewage for flushing cattle pens. The mass ratio of solids is 40~45%. The flow rate of sewage is 25 meters 3 / h. After the solid-liquid separation, the sewage enters the sedimentation tank, stands still for 60 minutes, and then is sent to the two-stage fixed bed reaction tower successively through the pump. There are three fixed beds in the tower, and the distance between the beds is 0.8m. The calcium, magnesium, and phosphate fertilizers in the bed reactants , CaO and Mg(OH) 2 Accounting for 98%, 1% and 1% of the total mass respectively, the thickness of each bed layer is controlled at 15cm, and the flow rate of sewage in the tower is controlled at 0.3m / s. Precipitation separates the struvite. The mass ratio of phosphorus removal rate is 86%, and the mass ratio of ammonia and nitrogen removal rate is 73%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com