Novel foam separation equipment for restoring heavy metal polluted soil

A foam separation and polluted soil technology, applied in the field of contaminated soil remediation, can solve the problem of low efficiency in removing heavy metals, and achieve the effect of low cost, simple equipment structure and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

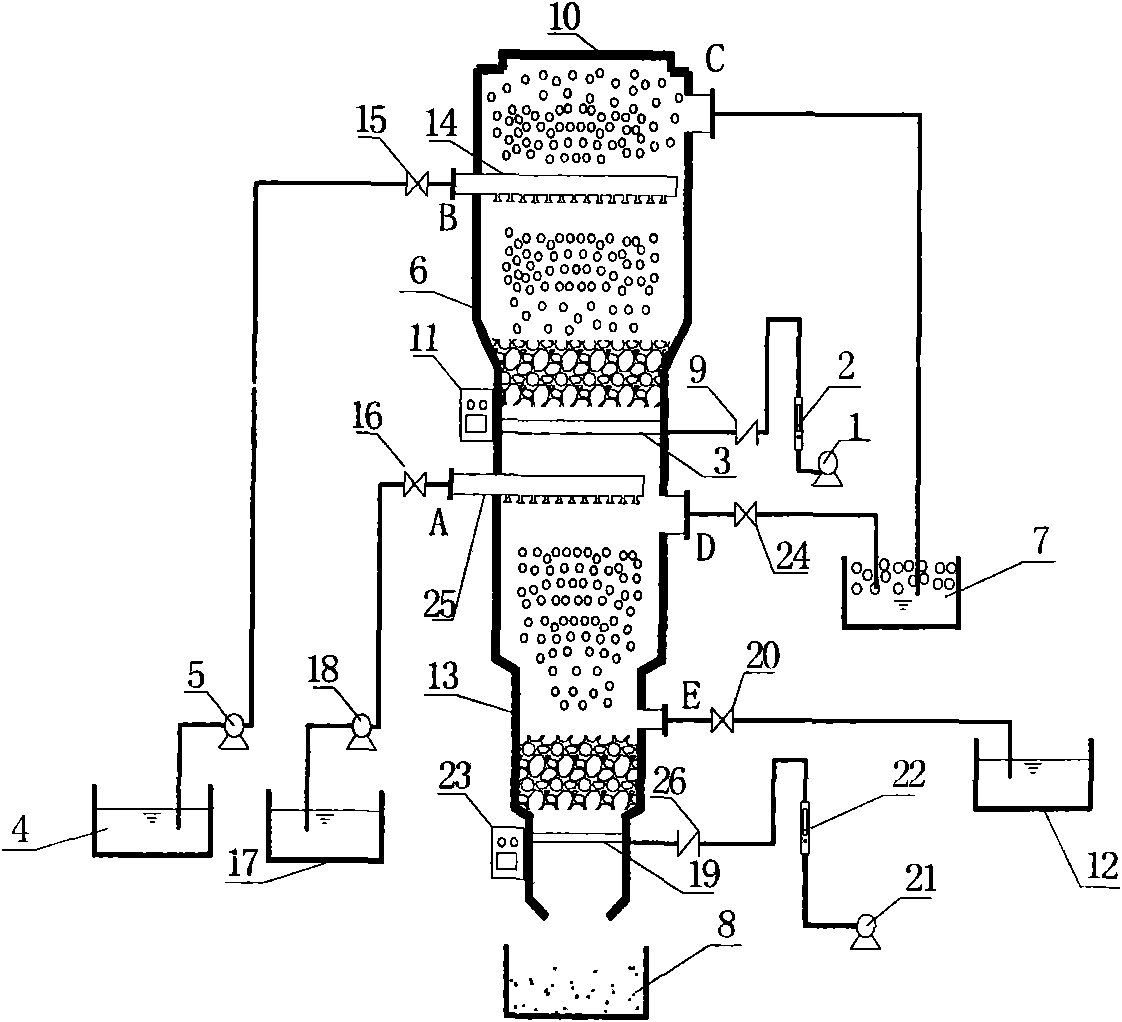

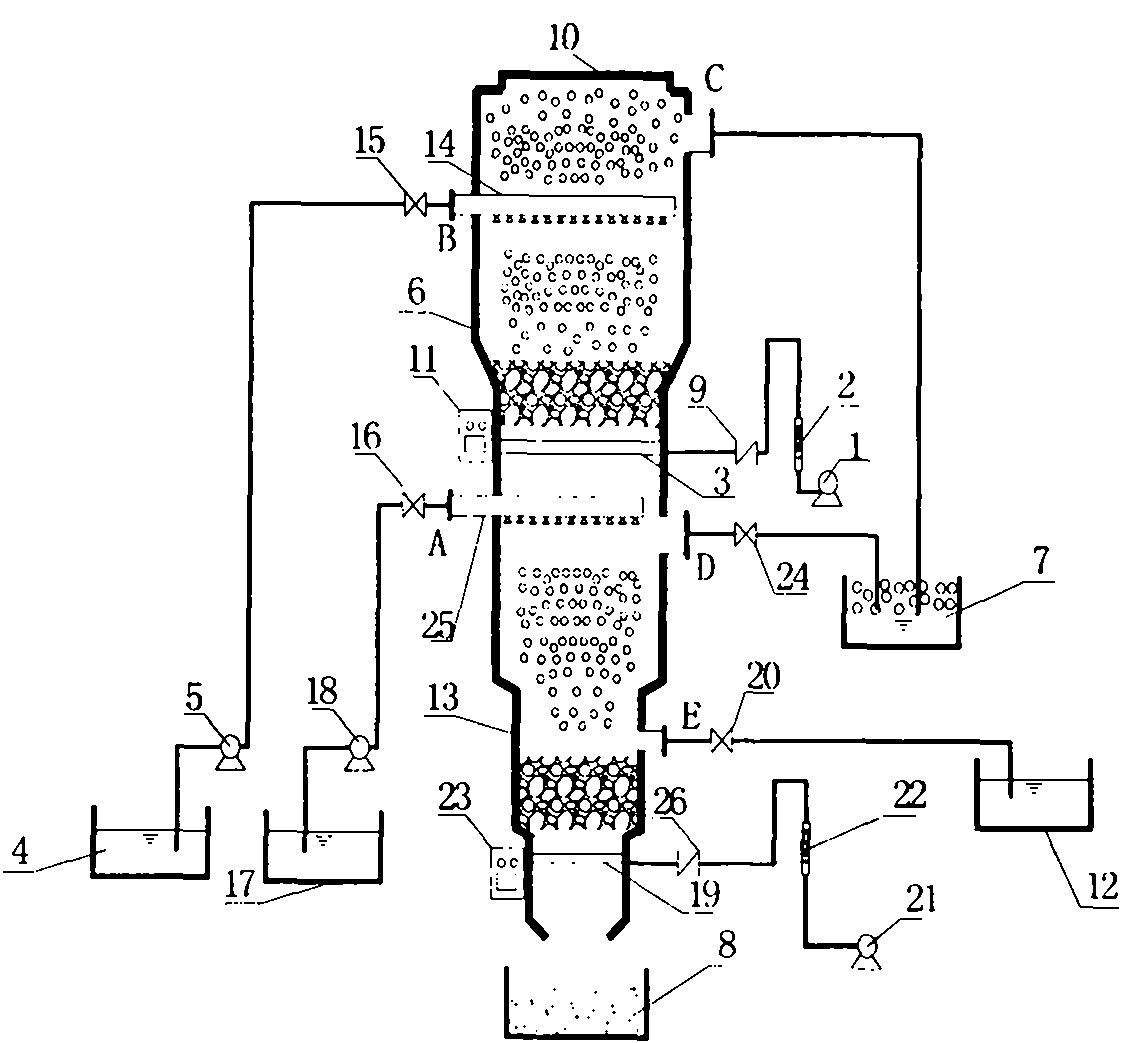

[0016] combine figure 1 The specific description of the embodiment of the present invention is as follows:

[0017] The soil to be cleaned enters the primary foam separation tower (6) from the soil feed port (10). Open the valve (15), and the surfactant mixture is lifted to the dosing port B through the metering pump (5), and evenly sprayed on the soil through the annular water distribution device (14) and submerged. At the same time, the air is introduced from the air compressor (1), passes through the rotameter (2), the check valve (9), and finally distributes the air evenly through the air distribution plate (3), so that the surfactant and the heavy metal are fully contacted and complexed , the foam attached to the heavy metal complex enters the foam collection device (7) from the foam liquid outlet C to collect. After the primary separation reaction is finished, the valve (15) and the air compressor are closed, and the upper air distribution plate (3) is turned over by c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com