Phosphating and chemical nickel-plating mixed comprehensive wastewater treatment process and automated device

A comprehensive wastewater and electroless nickel plating technology, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of large amount of chemical agents, low treatment efficiency, and insufficient purification to achieve high water quality standards, high treatment efficiency, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

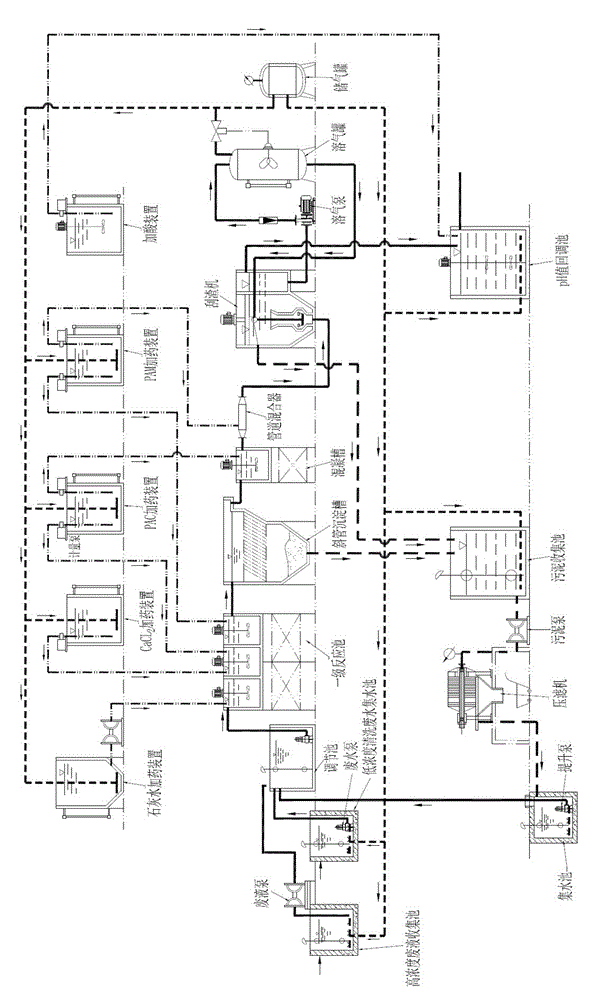

[0029] Combine below figure 1 The present invention will be further described.

[0030] like figure 1 Shown, a kind of phosphating and electroless nickel plating mixed comprehensive wastewater treatment automation equipment, including PLC control system ( figure 1 Not expressed in), waste water treatment system, dosing device, air mixing system,

[0031] The wastewater treatment system is connected sequentially by the wastewater collection system, regulating tank, primary reaction tank, inclined tube settling tank, and air flotation system;

[0032] The waste water collection system consists of a high-concentration waste liquid collection pool and a low-concentration cleaning waste water collection pool. The high-concentration waste liquid collection pool passes through the waste liquid pump and pipeline to the regulating pool, and the low-concentration cleaning waste water collection pool passes through the waste water pump and pipeline to the regulating pool. pool;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com