Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

169 results about "Light crude oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Light crude oil is liquid petroleum that has a low density and flows freely at room temperature. It has a low viscosity, low specific gravity and high API gravity due to the presence of a high proportion of light hydrocarbon fractions. It generally has a low wax content. Light crude oil receives a higher price than heavy crude oil on commodity markets because it produces a higher percentage of gasoline and diesel fuel when converted into products by an oil refinery.

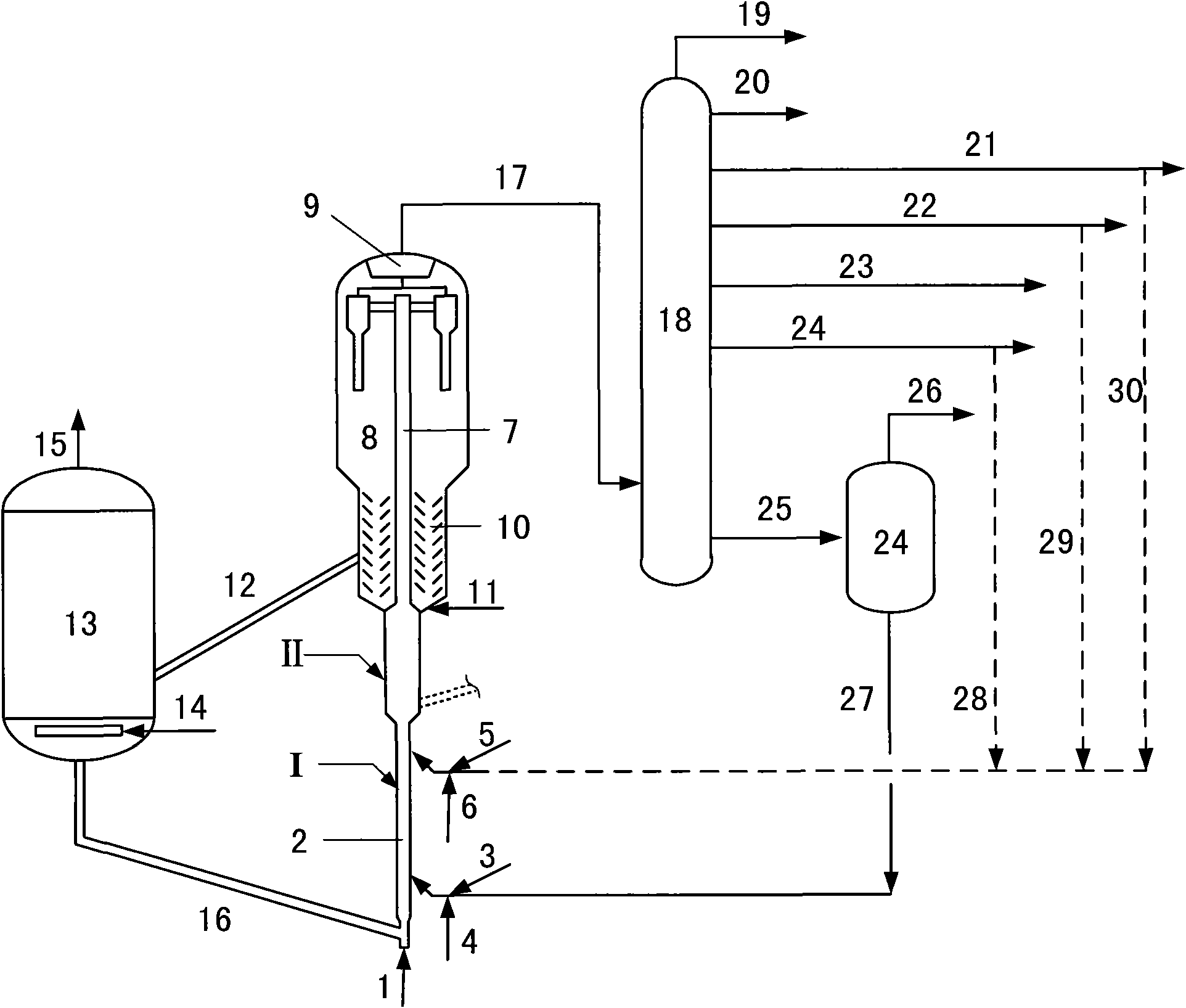

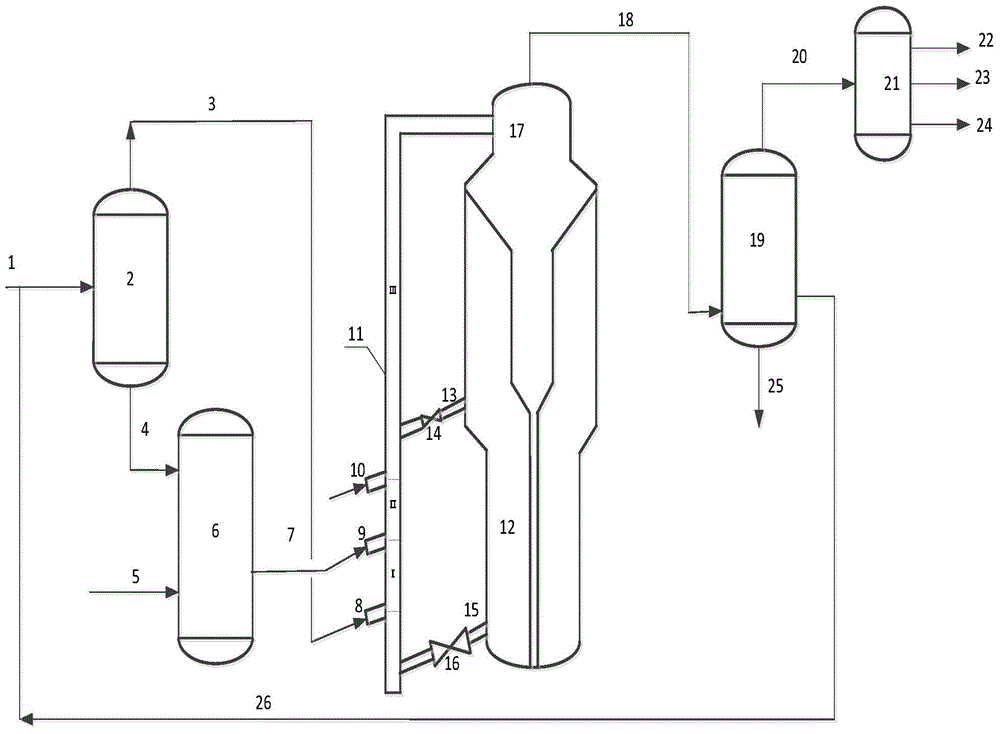

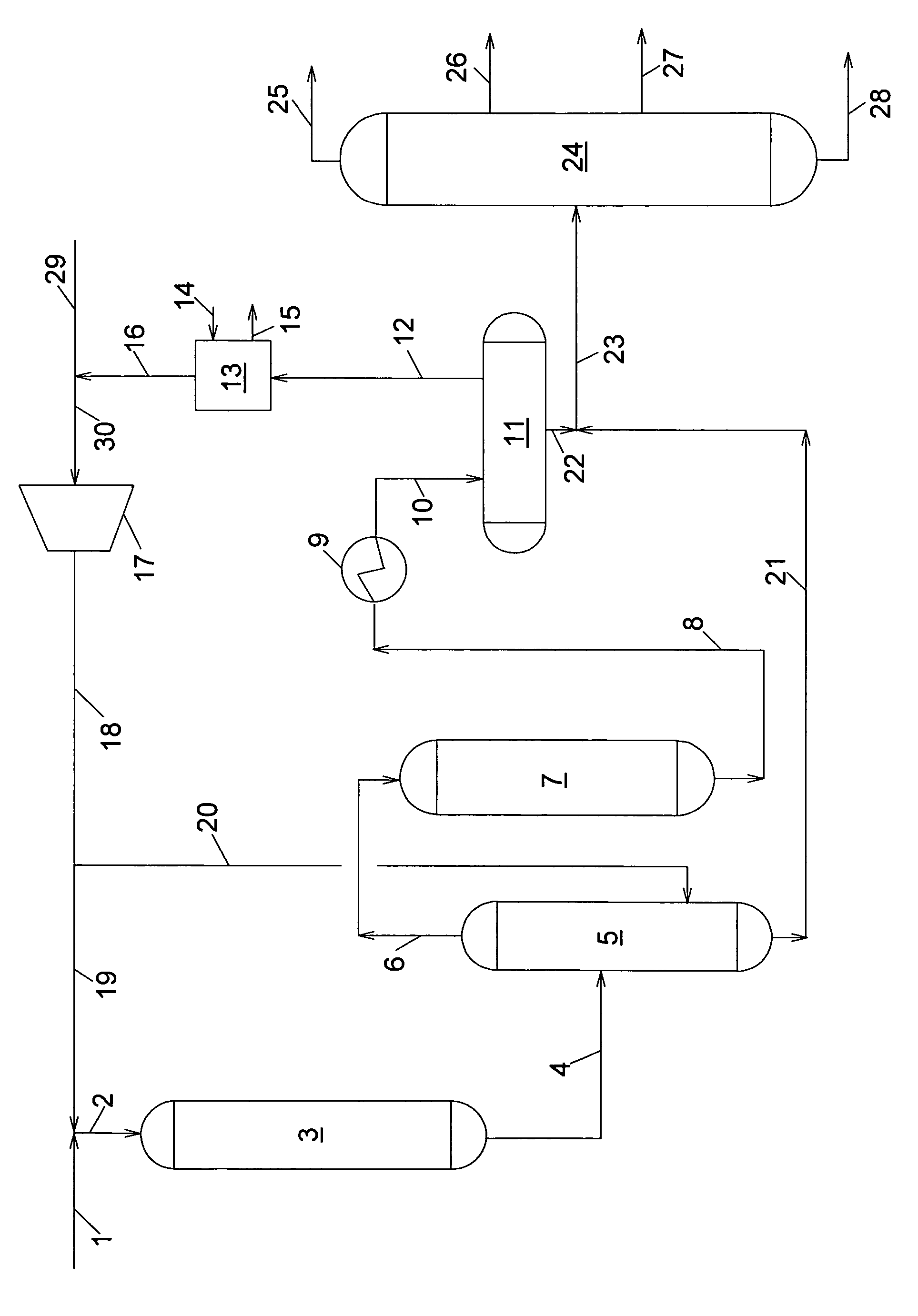

Method for preparing light fuel oil and propylene from inferior raw material oil

ActiveCN101942340AImproved raw material propertiesExtended operating cycleTreatment with plural serial stages onlyTreatment with hydrotreatment processesGas solidWax

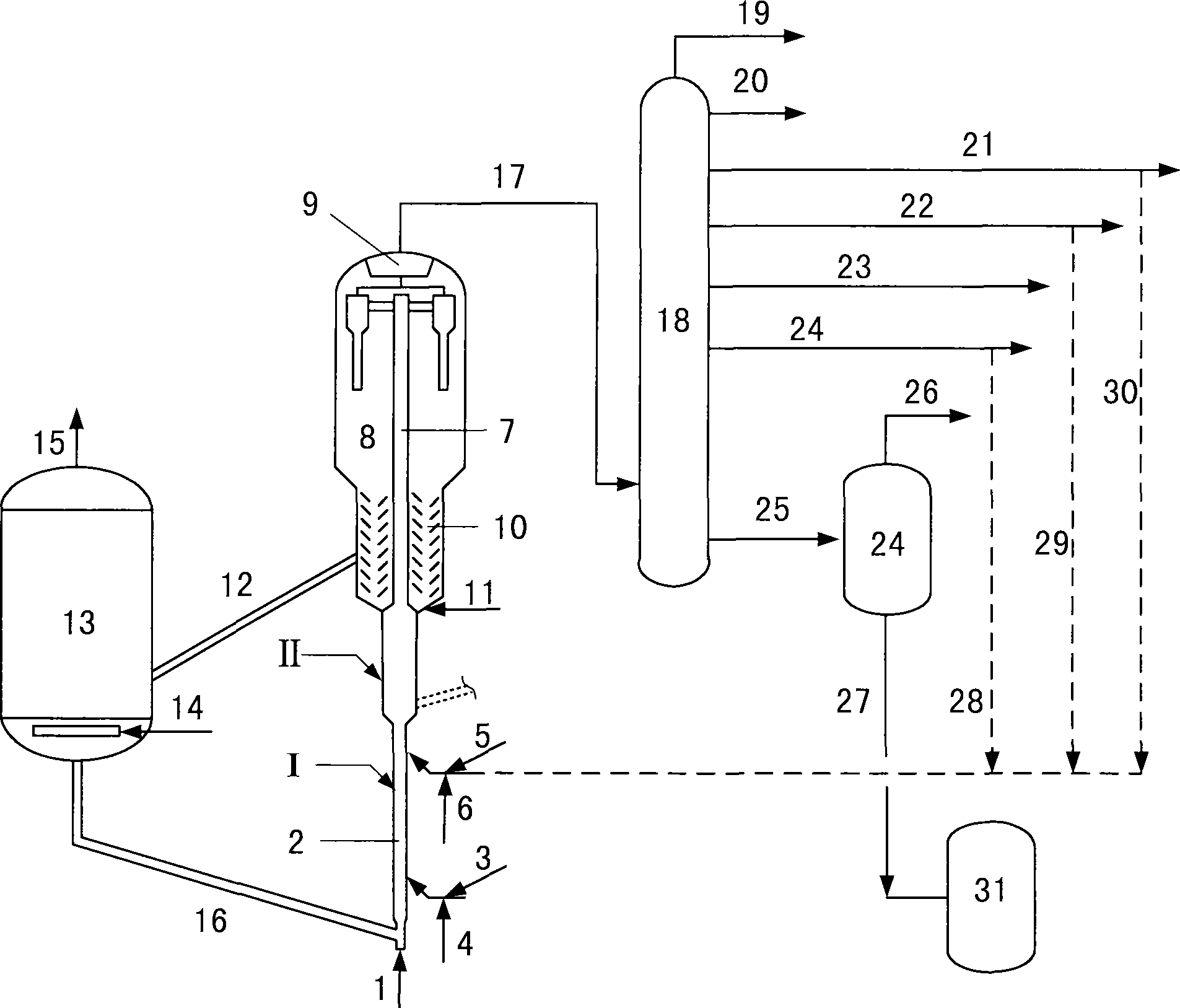

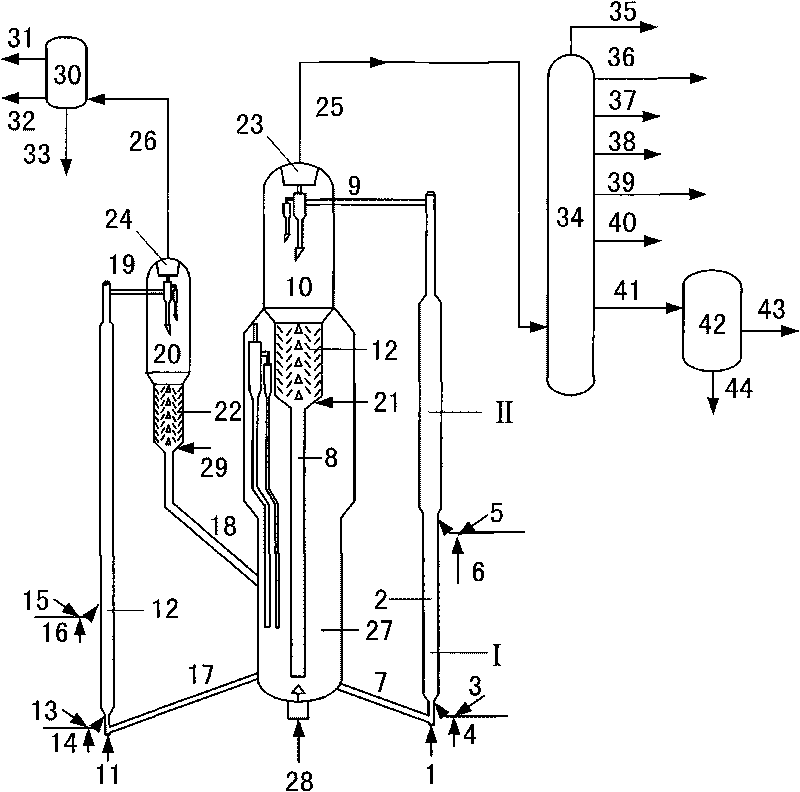

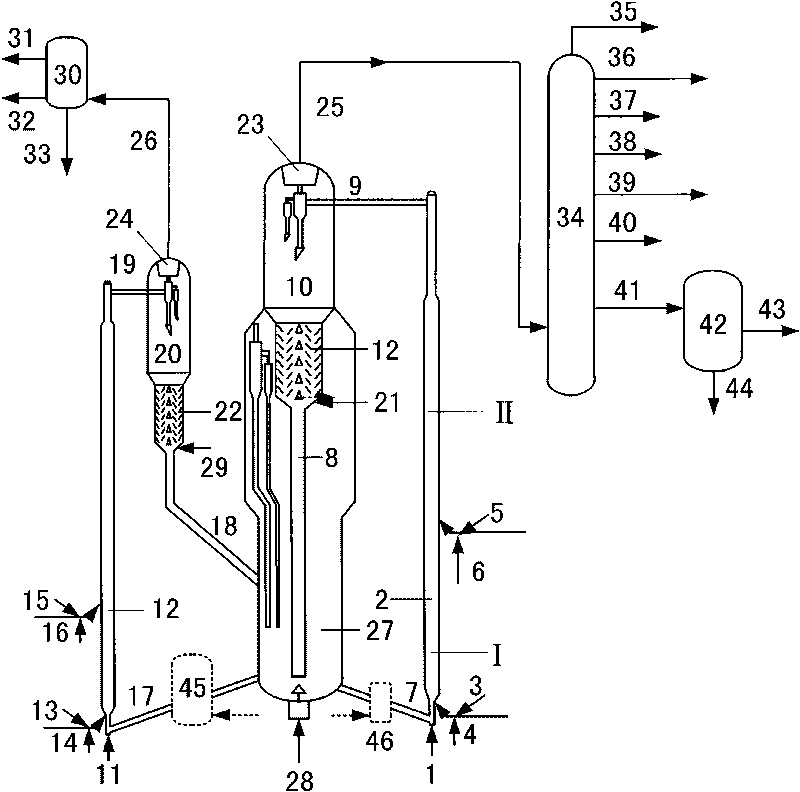

The invention discloses a method for preparing light fuel oil and propylene from inferior raw material oil. The inferior raw material oil enters a first reaction area and a second reaction area of a catalytic conversion reactor in turn to contact a catalytic conversion catalyst with coarse particle size distribution so as to perform primary reaction and secondary reaction respectively; after the reaction product and the spent catalyst undergo gas-solid separation, the spent catalyst is subjected to steam stripping and charring in turn and then returned to the reactor for recycling; and the reaction product is separated to obtain propylene, gasoline, catalytic wax oil and other products, wherein the catalytic wax oil enters at least one of hydrotreatment device, an arene extraction device and a hydrocracking device so as to obtain hydrogenated catalytic wax oil, raffinate oil and hydrocracking tail oil. The method improves the yield of the light oil, reduces the yield of oil slurry, realizes efficient utilization of petroleum resources, reduces the consumption of the catalyst, and reduces the catalyst content of the catalytic wax oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing light fuel oil and propylene from poor-quality raw oil

ActiveCN101531924AImprove propertiesDry gas reductionTreatment with hydrotreatment processesSlurryFuel oil

A method for preparing light fuel oil and propylene from poor-quality raw oil comprises the following steps: the poor-quality raw oil sequentially enters a first reaction zone and a second reaction zone of a catalytic conversion reactor so as to be contacted with a catalytic conversion catalyst to generate first reaction and second reaction respectively, and after gas-solid separation is implemented to reaction products and spent catalyst, the spent catalyst returns to the reactor for recycling after steam stripping and burning; the reaction products are separated to obtain propylene, gasoline, heavy oil and other products, wherein the heavy oil is contacted with hydrogen and a hydrotreating catalyst for reaction, the obtained hydrogenated heavy oil circulates to the first reaction zone of the catalytic conversion reactor or / and other catalytic conversion devices for further reaction to obtain the target products of the propylene and the gasoline. The characteristic of the heavy oil obtained by hydrotreating after the mild catalytic conversion of the poor-quality raw oil is significantly improved, thereby significantly increasing light oil, reducing dry gas, reducing the yield of oil slurry and realizing the high-efficient utilization of petroleum resources.

Owner:CHINA PETROLEUM & CHEM CORP +1

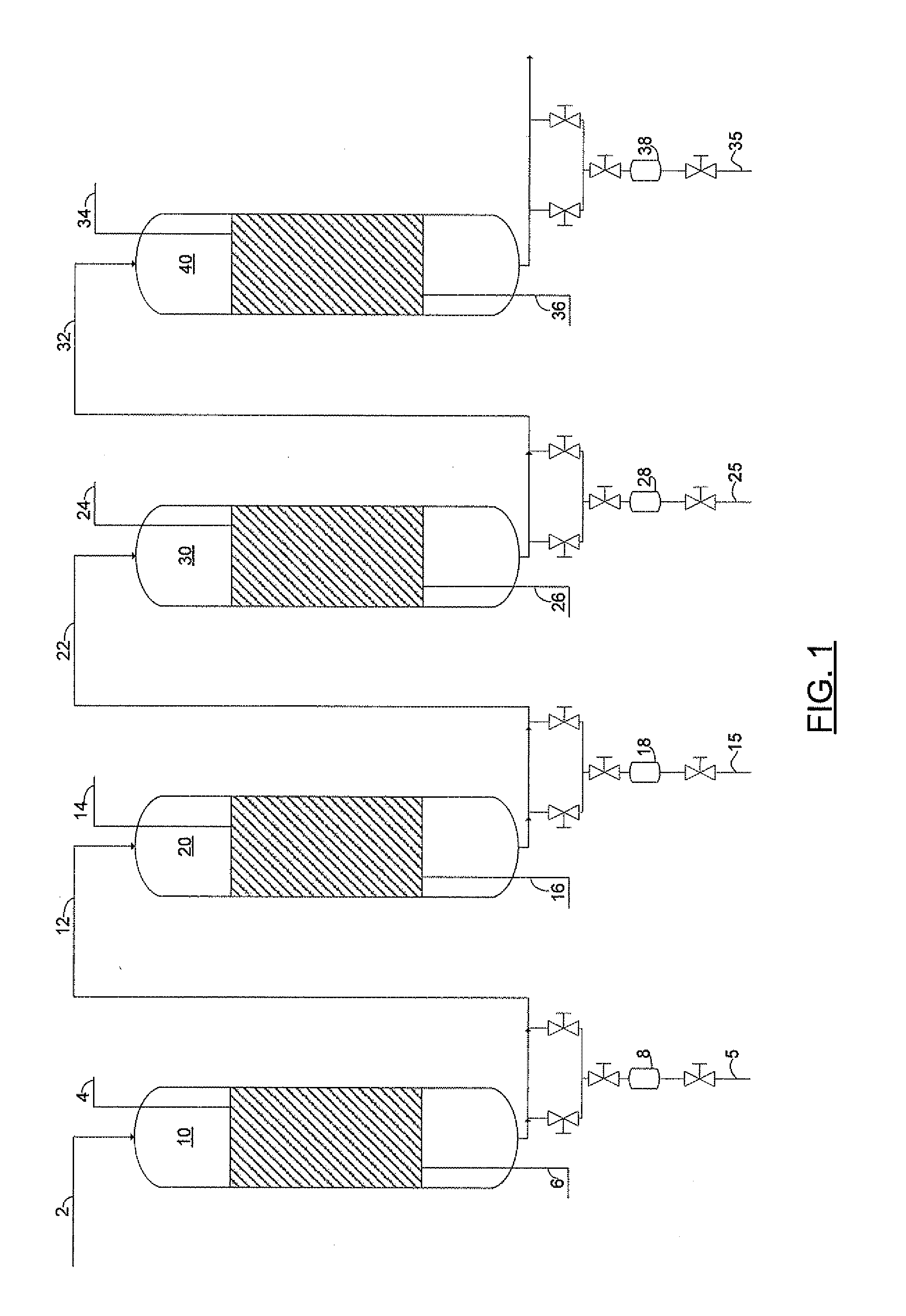

Process of hydrotreating heavy hydrocarbon oil

ActiveUS7651605B2Increase deactivation rateImprove throughputCoke ovensHydrocarbon distillationReaction temperatureHeavy crude oil

When a heavy fuel oil with a sulfur content of 1 percent by mass or lower is produced from a feedstock consisting of a heavy hydrocarbon oil derived from a heavy crude oil having an API degree of 30 or less and containing sulfur and metal components in amounts larger than those of ordinary crude oil, the conventional processes requires higher reaction temperature and was accompanied with a remarkably enhanced deactivation rate of the catalyst which results in a remarkable shortened lifetime thereof. Therefore, it is regarded as substantially impossible to treat the feedstock. However, the present invention makes it possible to produce a low sulfur heavy fuel oil with a sulfur content of 1 percent by mass or less by hydrotreating a mix oil of 100 parts by volume of a heavy hydrocarbon oil derived from a heavy crude oil with an API degree of 30 or less and 30 to 1000 parts by volume of a heavy hydrocarbon oil derived from a light crude oil with an API degree of 35 or greater, without lowering the degree of demetallization while retarding the deactivation rate of the catalyst.

Owner:NIPPON OIL CORP

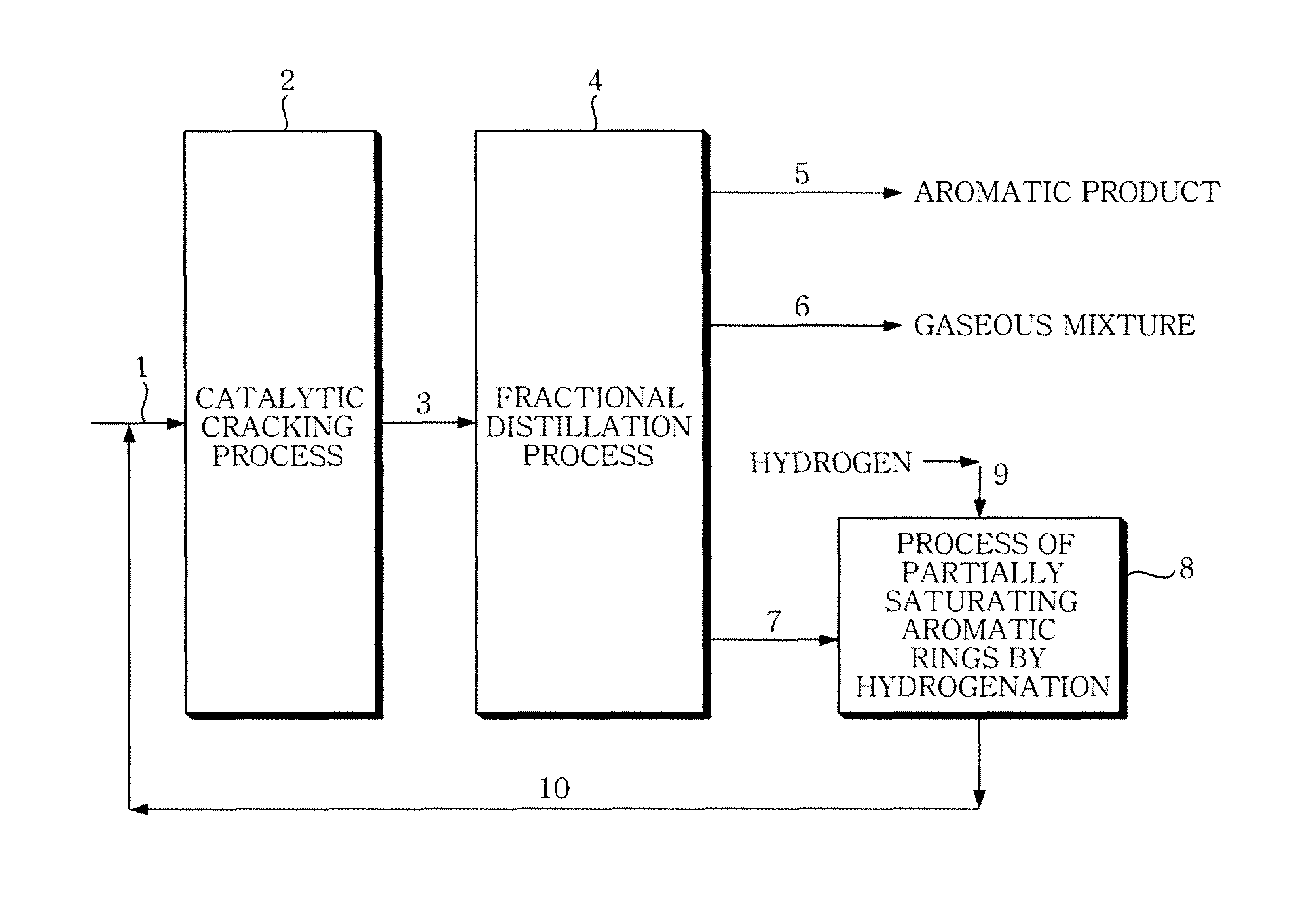

Method for producing high value aromatics and olefin from light cycle oil produced by a fluidized catalytic cracking process

ActiveUS20110207979A1Increase productionMaximize processing efficiencyCatalytic crackingHydrocarbonsHigh concentrationPetroleum

The present invention relates to a method of producing aromatic products (benzene / toluene / xylene) and olefin products from petroleum fractions obtained by fluid catalytic cracking, and, more particularly, to a method of producing products comprising high-concentration aromatic products and high value-added light olefin products from light cycle oil obtained by fluid catalytic cracking.

Owner:SK INNOVATION CO LTD

Method of simultaneously manufacturing high quality naphthenic base oil and heavy base oil

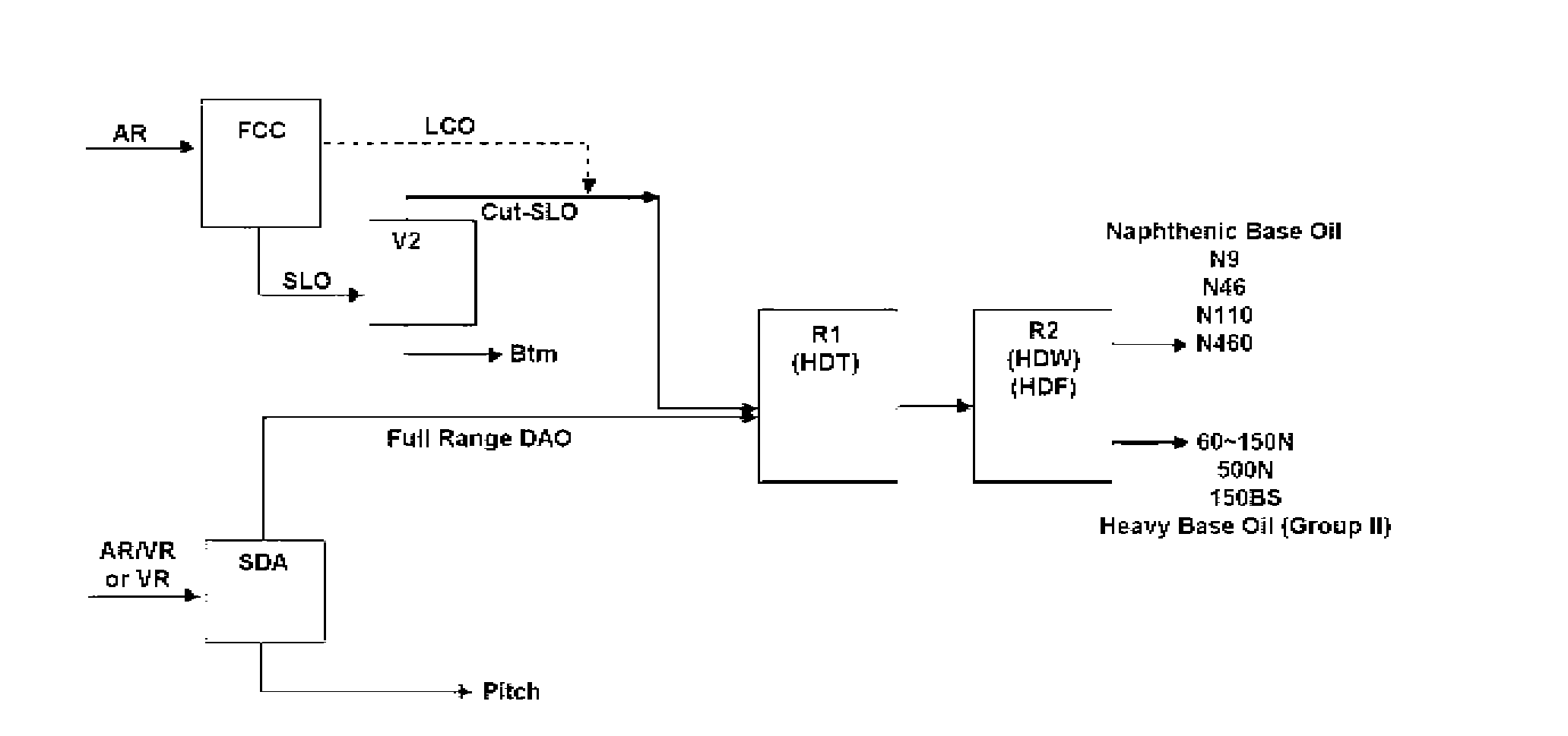

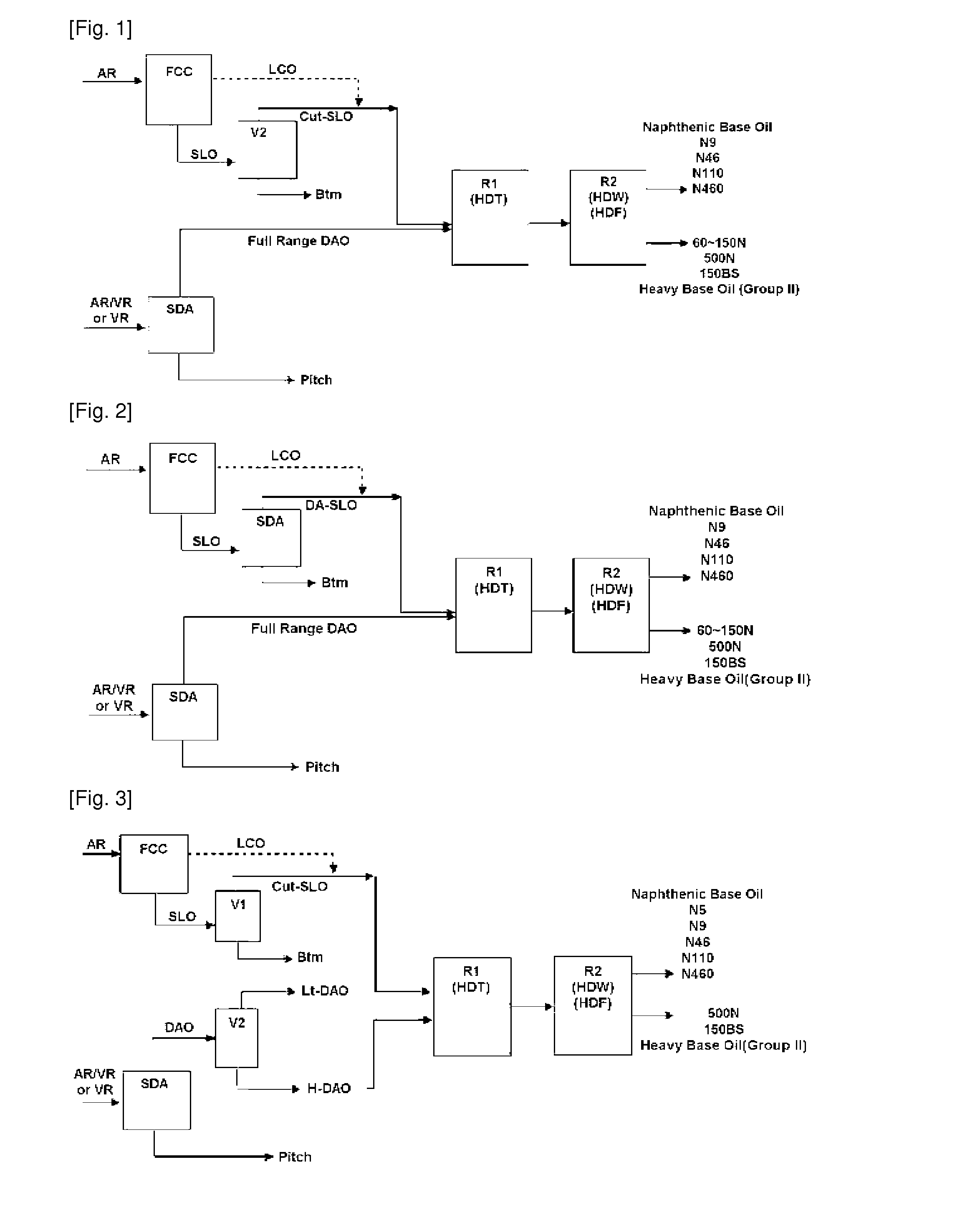

ActiveUS20130048537A1Improve efficiencyHigh viscosityCatalytic crackingMolecular sieve catalystsEconomic benefitsSolvent

Disclosed is a method of simultaneously manufacturing high quality naphthenic base oil and heavy base oil using a single catalyst system, by subjecting an oil fraction (slurry oil or light cycle oil) produced by fluid catalytic cracking and an oil fraction (deasphalted oil) produced by solvent deasphalting to hydrotreating, catalytic dewaxing and hydrofinishing of the single catalyst system, thereby obtaining not only products having low viscosity but also heavy base oil products (150BS) having high viscosity which was impossible to obtain using a conventional catalytic reaction process, and also thereby producing base oil products having different properties using the single catalyst system, thus generating economic benefits and exhibiting superior efficiency.

Owner:SK INNOVATION CO LTD

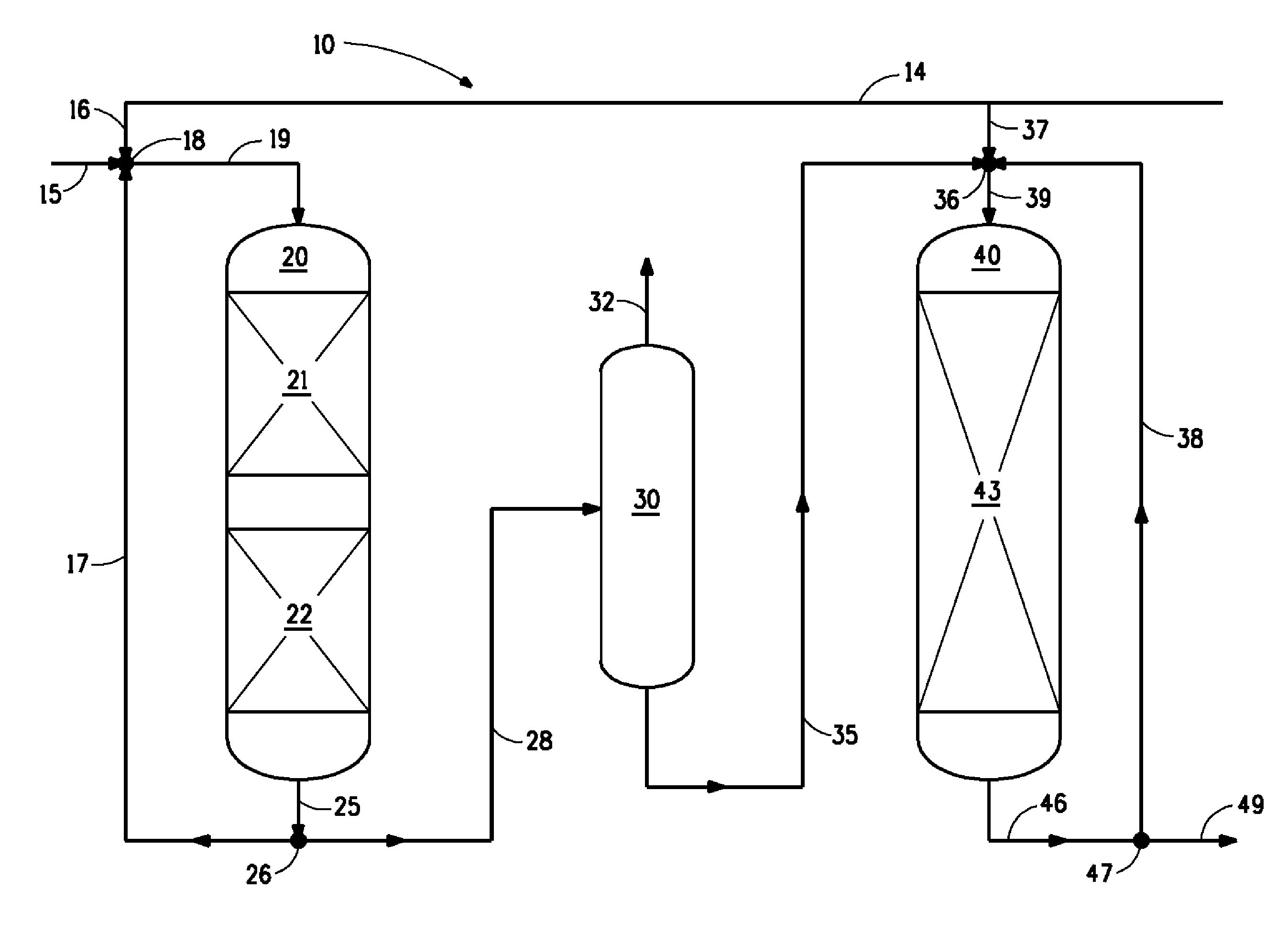

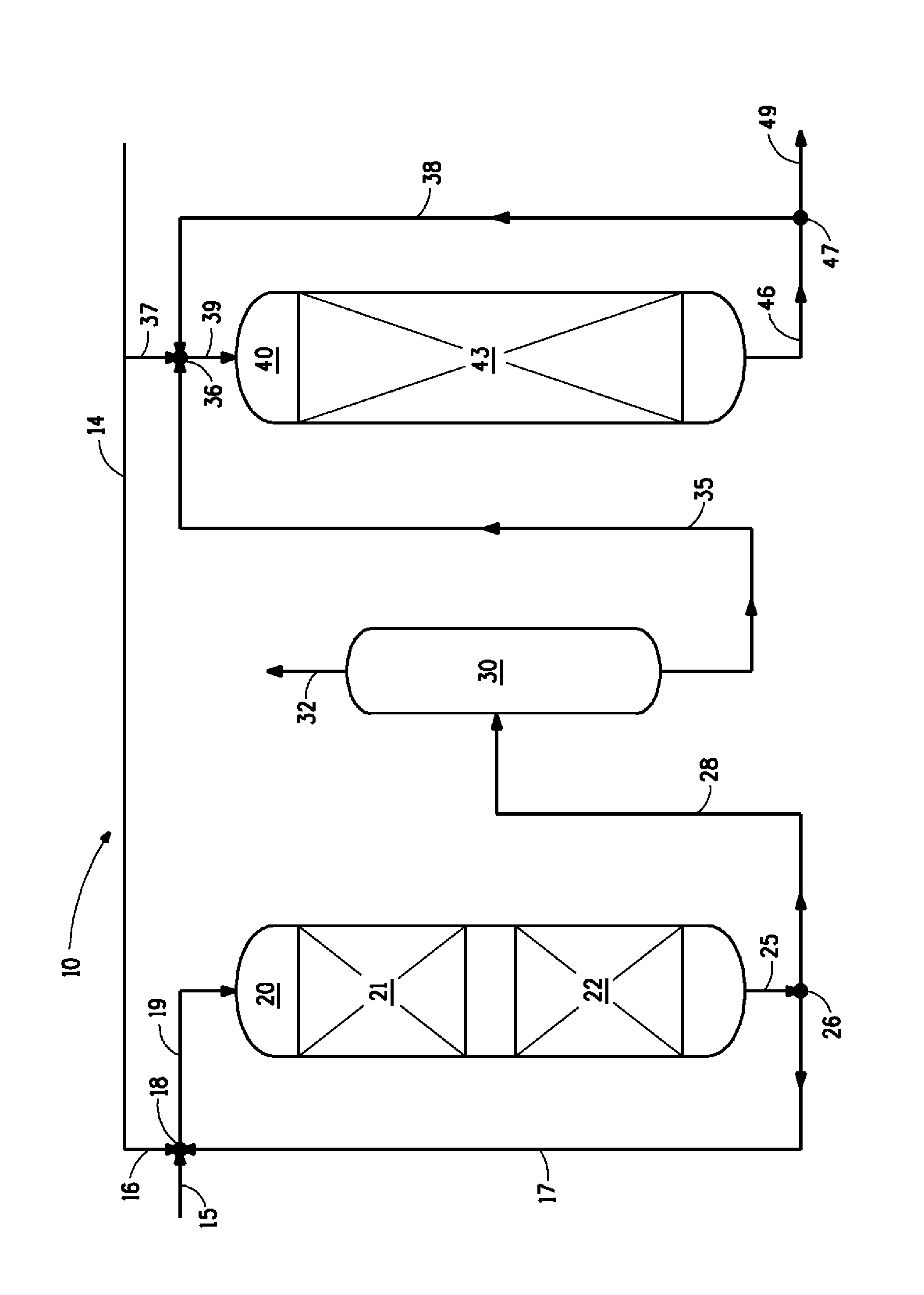

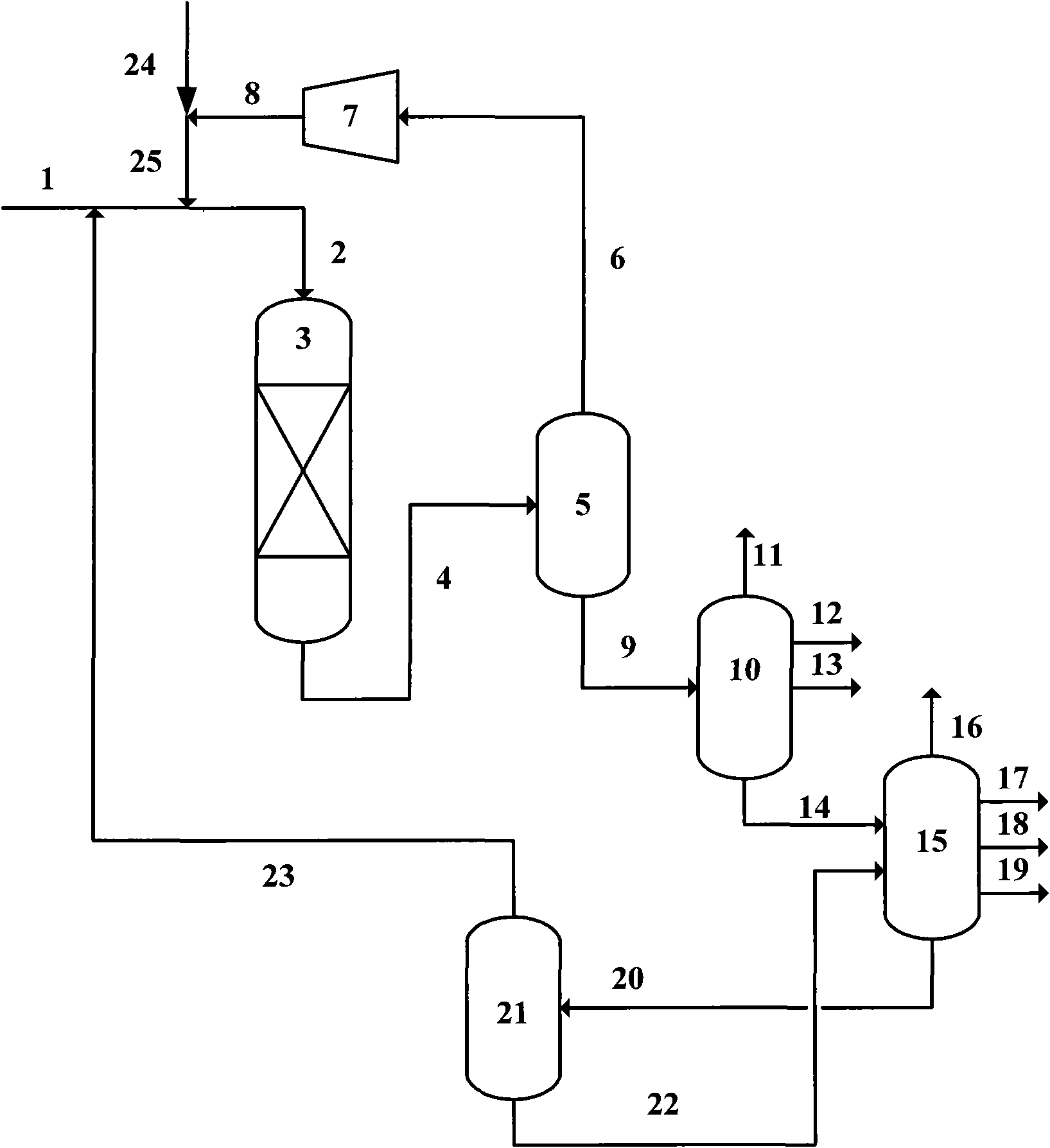

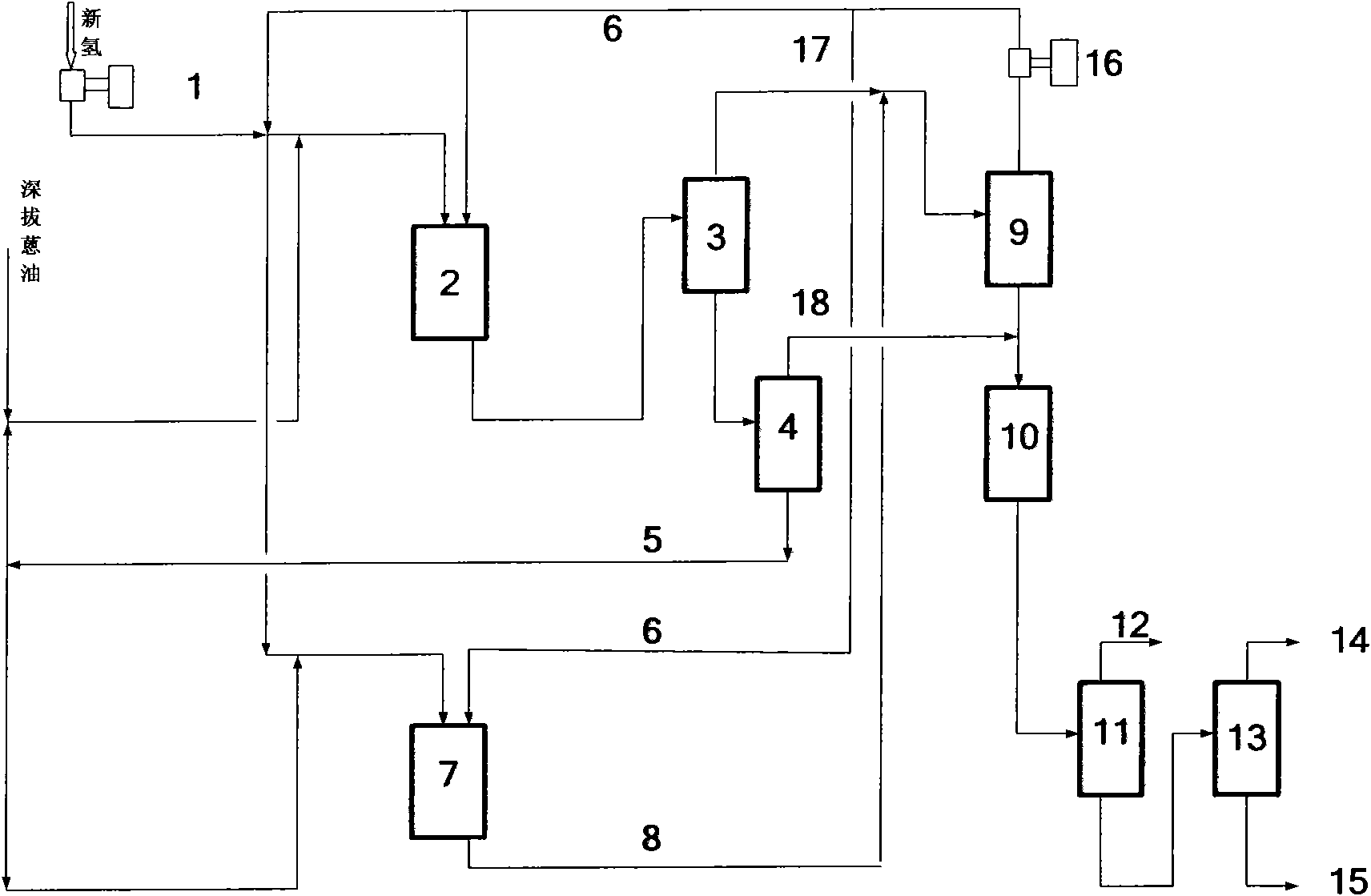

Improved integrated process for hydrogenation and catalytic cracking of hydrocarbon oil

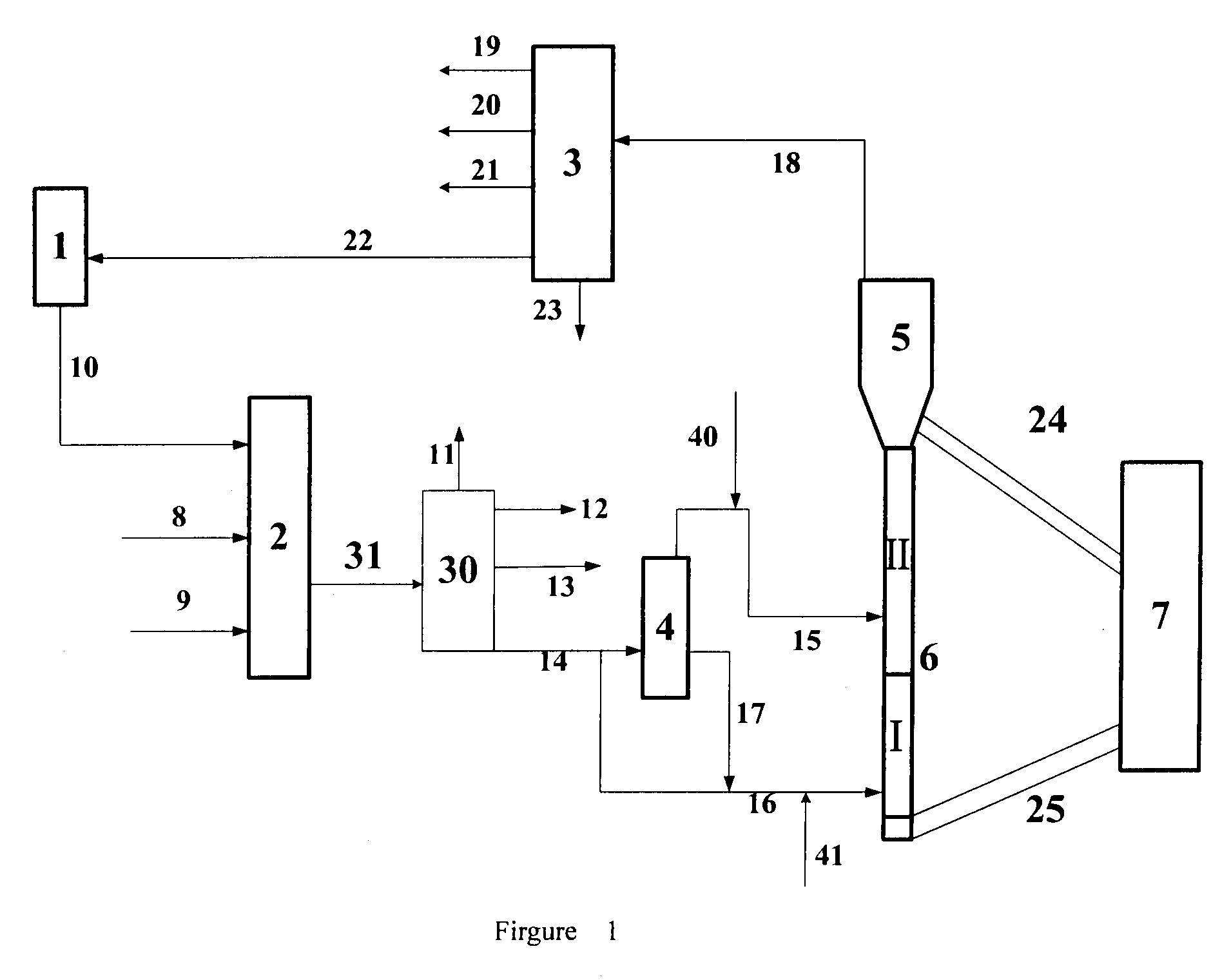

ActiveUS20110062054A1Improve conversion depthIncrease productionCatalytic crackingTreatment with plural parallel cracking stages onlyQuantum gasNatural gas

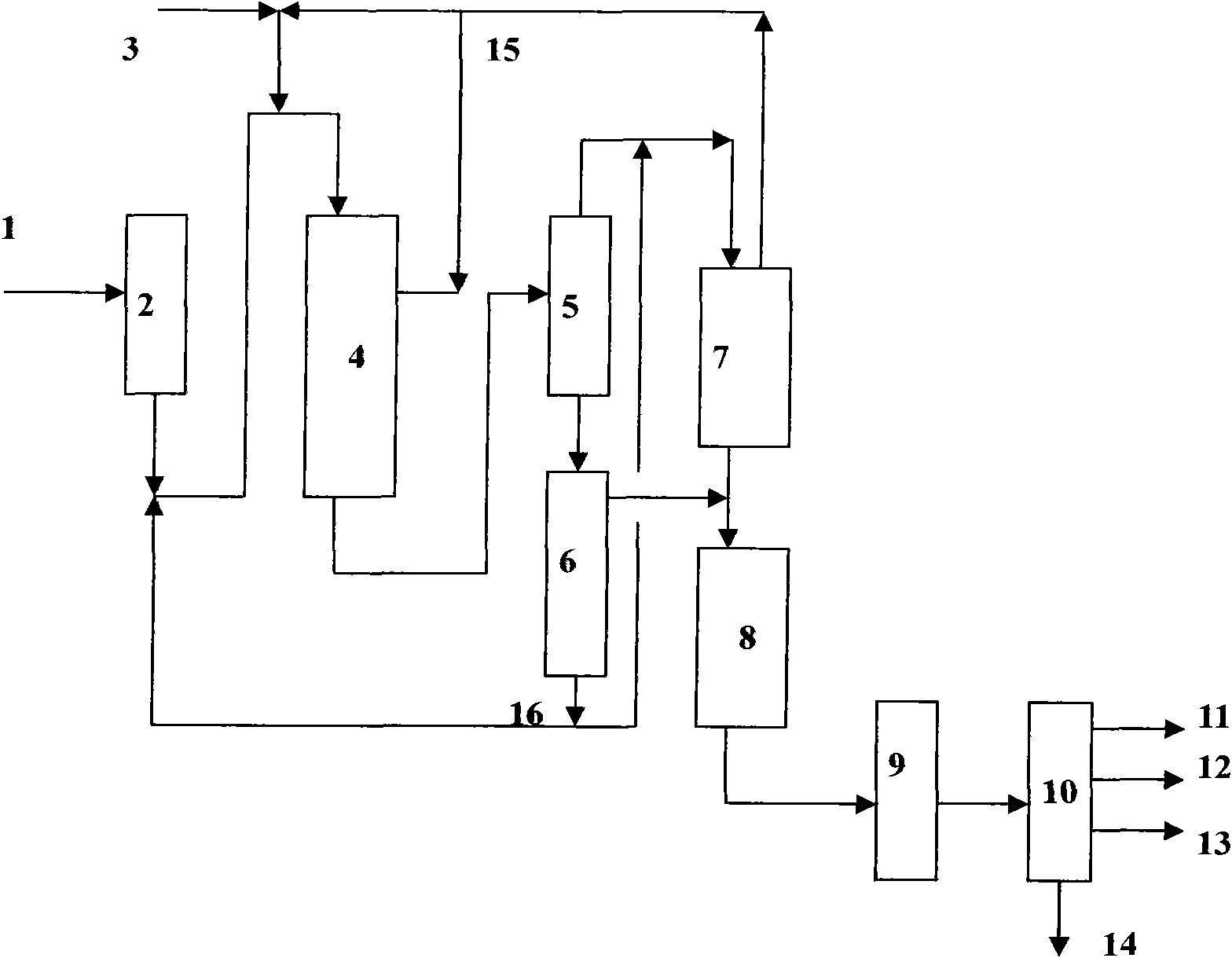

Disclosed is a combination process for improved hydrotreating and catalytic cracking of hydrocarbon oils, including: contacting residual oil, catalytic cracking cycle oil, and optional distillate oil with a hydrotreating catalyst under hydrotreating conditions in the presence of hydrogen followed by separation of the reaction products to obtain gas, hydrogenated naphtha, hydrogenated diesel oil, and hydrogenated tail oil; contacting the hydrogenated tail oil and optional normal catalytic cracking feedstock oil with a cracking catalyst under catalytic cracking conditions followed by separation of the reaction products to obtain dry gas, hydrogenated naphtha, liquefied petroleum gas, catalytic cracked gasoline, catalytic cracked diesel oil, and catalytic cracking cycle oil; wherein the hydrogenated tail oil and / or normal catalytic cracking feedstock oil are separated into at least two fractions, the light and the heavy fractions or normal catalytic cracking heavy feedstock oil and normal catalytic cracking light feedstock oil, prior to contacting the hydrogenated tail oil and / or normal catalytic cracking feedstock oil with the cracking catalyst. The process according to the present invention is especially suitable for conversion of hydrocarbon oils to produce more products of gasoline or diesel oil.

Owner:CHINA PETROCHEMICAL CORP +1

Hydrocracking method for blending ethylene tar

ActiveCN102234542AIncrease saturation rateHigh yieldTreatment with hydrotreatment processesChemistryLight crude oil

The invention discloses a hydrocracking method for blending ethylene tar, which comprises the following steps of: blending light fraction of ethylene tar into heavy distillate for hydrocracking, and contacting a hydrogenation protecting catalyst, a hydrogenation refining catalyst, a hydrogenation carbon residue removing catalyst and a hydrocracking catalyst in the presence of hydrogen to obtain hydrocracking crude oil, wherein partial hydrocracking crude oil is circulated and mixed with the light fraction and heavy distillate of the ethylene tar to enter a hydrocracking area, and the rest hydrocracking crude oil is future separated to obtain light fuel oil. By the method, the problem of high temperature rise of a hydrogenation reactor bed can be effectively solved; meanwhile, a method of grading the hydrogenation catalysts, the light fraction of the ethylene tar can be processed, and diesel with high cetane number and low condensation point and naphtha with high potential aromatic content can be produced; and compared with a state that the ethylene tar is not blended, the method has the advantage that the bureau of mines correlation index (BMCI) value of tail oil and the smoke point of jet fuel are not obviously changed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Prerefining Process for the Hydrodesulfurization of Heavy Sour Crude Oils to Produce Sweeter Lighter Crudes Using Moving Catalyst System

InactiveUS20100018904A1Increase flow rateHydrocarbon oil crackingTreatment with hydrotreatment processesHydrodesulfurizationModerate temperature

A pre-refining catalytic hydrotreating process for the desulfurization, demetallization, and upgrading of heavy, sour crude oils operating at a moderate temperature and pressure through the utilization of moving catalyst bed technology.

Owner:SAUDI ARABIAN OIL CO

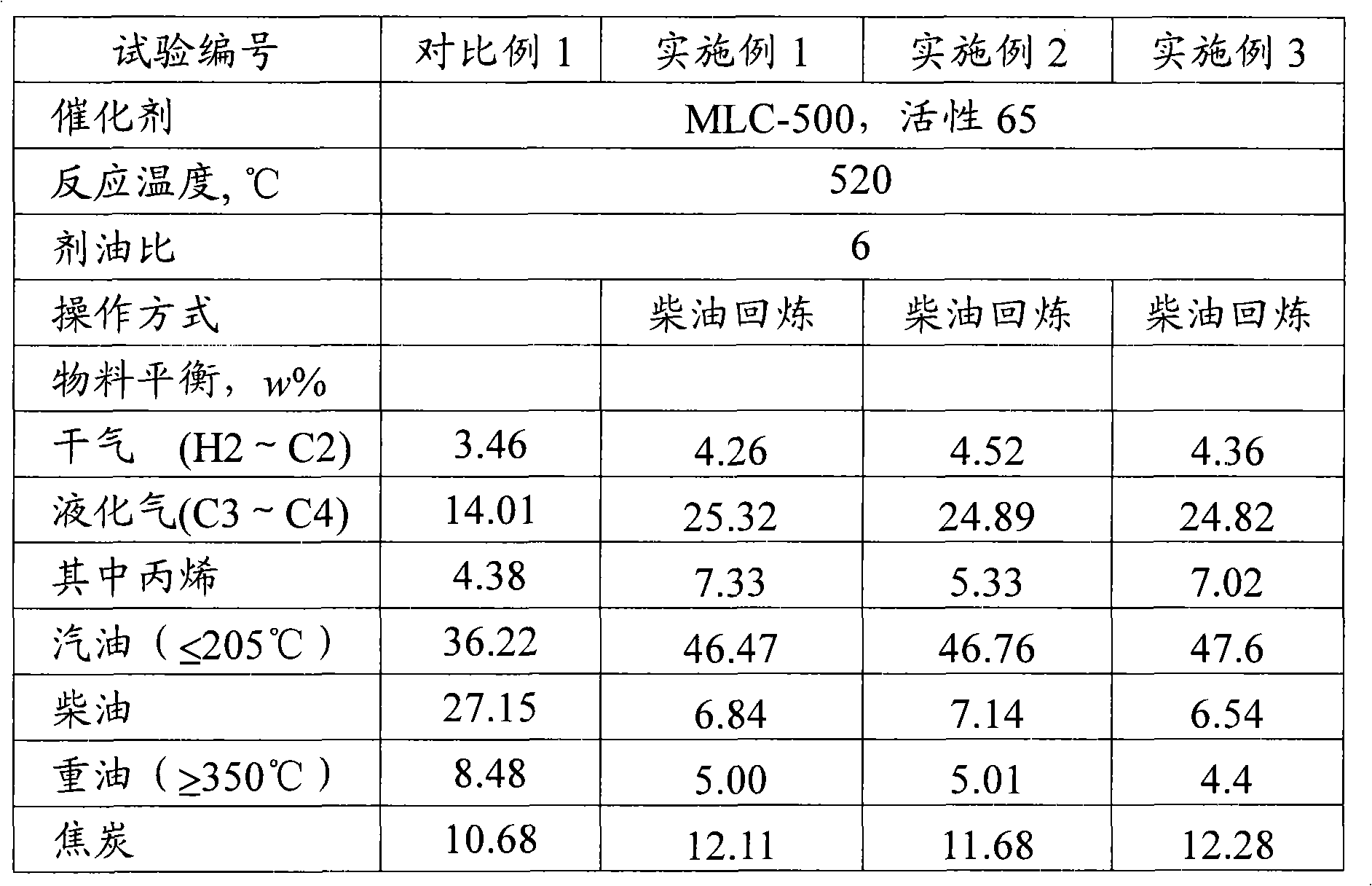

Method for producing high-octane gasoline with bastard crude oil

ActiveCN101314736AImprove economyAvoid defectsTreatment with hydrotreatment processesDistillationCracking reaction

A method for producing high-octane petrol from low-quality crude oil comprises the following steps: pre-heating preprocessed crude oil with total acid number larger than 0.5 mgKOH / g and characterization factor K less than 12.5, introducing into a catalytic cracking reaction system to contact with a catalyst, reacting under catalytic cracking reaction conditions, separating oil and gas and the spent catalyst after reaction, transporting the oil and gas into a separation system to obtain products with different distillation ranges, returning all or a portion of diesel to the reaction system for further reaction, and recycling the spent catalyst by stripping and regeneration. The method can simplify the flow, obviate the disadvantages of the prior art that can generate much diesel with lower cetane number while processing the crude oil, improve the yield of the high-octane petrol and greatly improve the economy for processing the low-quality crude oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydroprocessing light cycle oil in liquid-full reactors

ActiveUS8721871B1High yieldQuality improvementThermal non-catalytic crackingTreatment with plural serial cracking stages onlyNaphthaHydrogen supply

Owner:REFINING TECH SOLUTIONS LLC

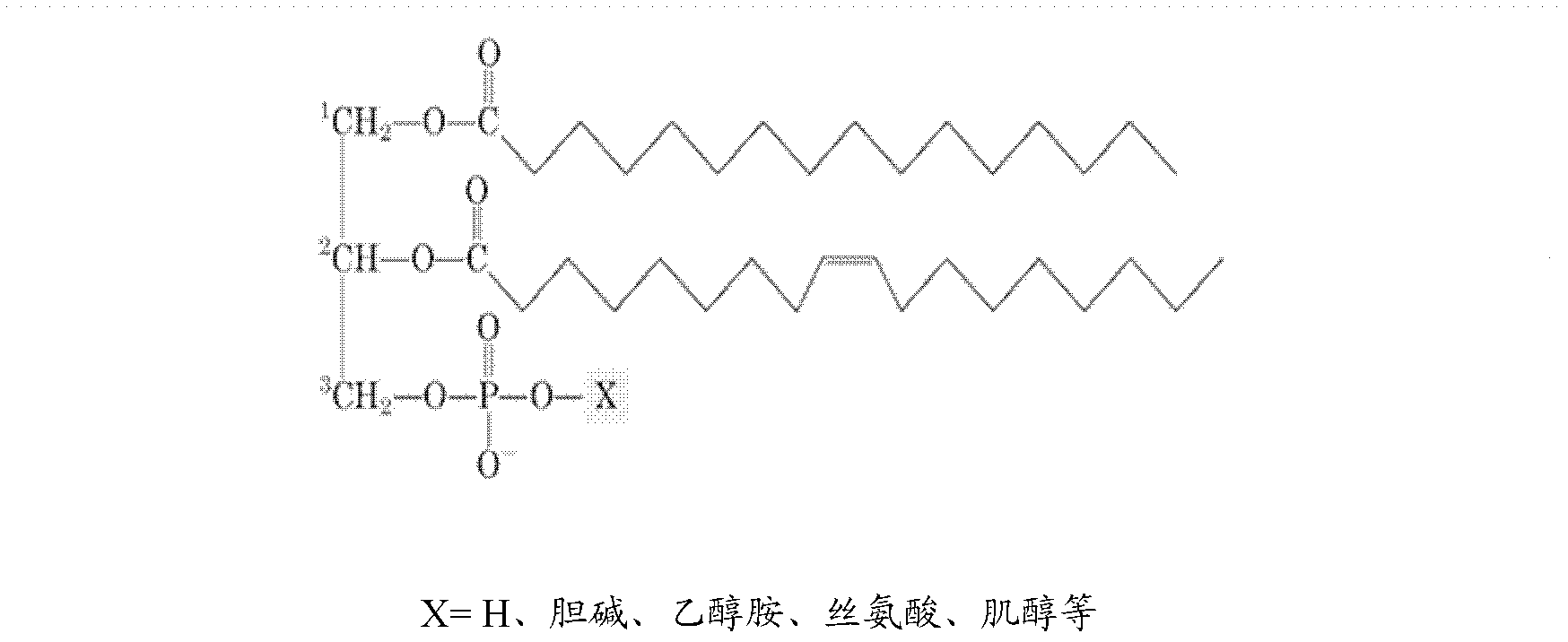

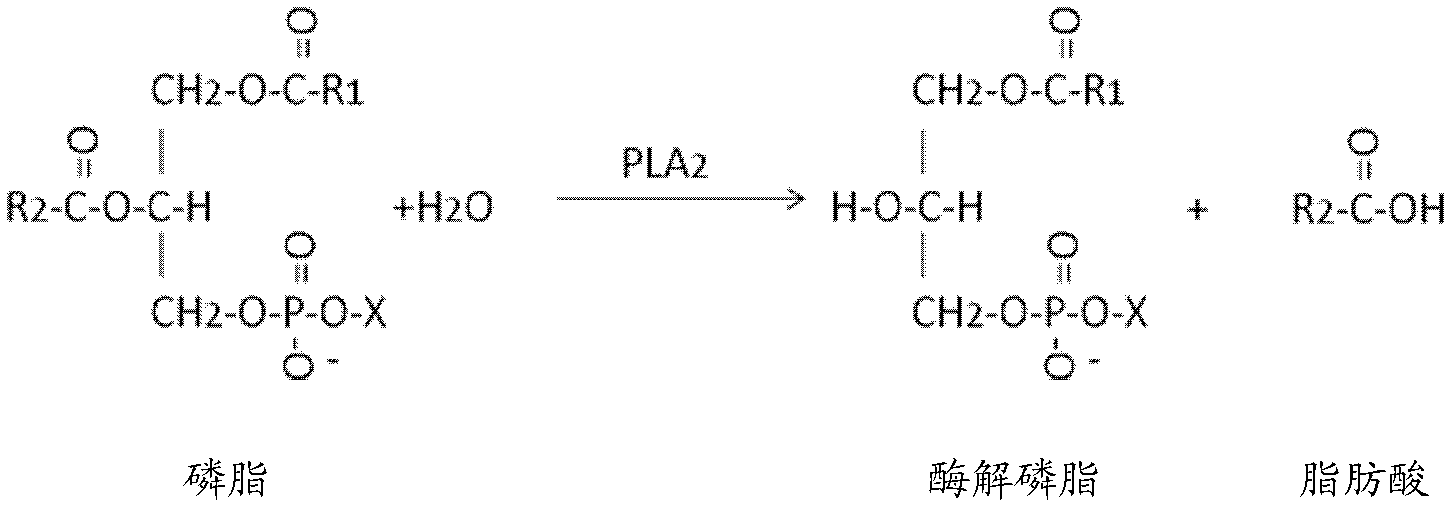

Method for degumming vegetable fat by using phosphatidase A2

ActiveCN102586011AIncrease valueStrong specificityFatty-oils/fats refiningPhospholipase A2Phosphatidase

The invention discloses a method for degumming vegetable fat by using phosphatidase A2. The method comprises the following steps of: A, heating crude oil to 40-50 DEG C; B, adding a 45 percent (W / W) citric acid solution till the final concentration is 0.01-0.02 percent, stirring (at the speed of more than or equal to 40 revolutions per minute) or homogenizing for 10 seconds, and preserving heat for 30 minutes; C, adding water in an amount of 1-5 percent based on the weight of the crude oil, and stirring uniformly; and D, adding enzyme in an amount of 0.005-0.015 percent (W / W) based on the weight of the crude oil, stirring and reacting for 1-3 hours, and centrifuging or naturally precipitating for separating degummed oil from a gum deposit. The method is practicable, and is easy and convenient to operate; when phosphatidase A2 is used for degumming, high-value enzyme hydrolyzed phospholipid can be obtained, so that energy consumption is lowered; and expressed (or leached) crude oil with very high phosphorus content or hydrated degummed oil with relatively low phosphorus content can be directly used for degumming in the method, so that the method has a wider application range.

Owner:HUAZHONG AGRI UNIV

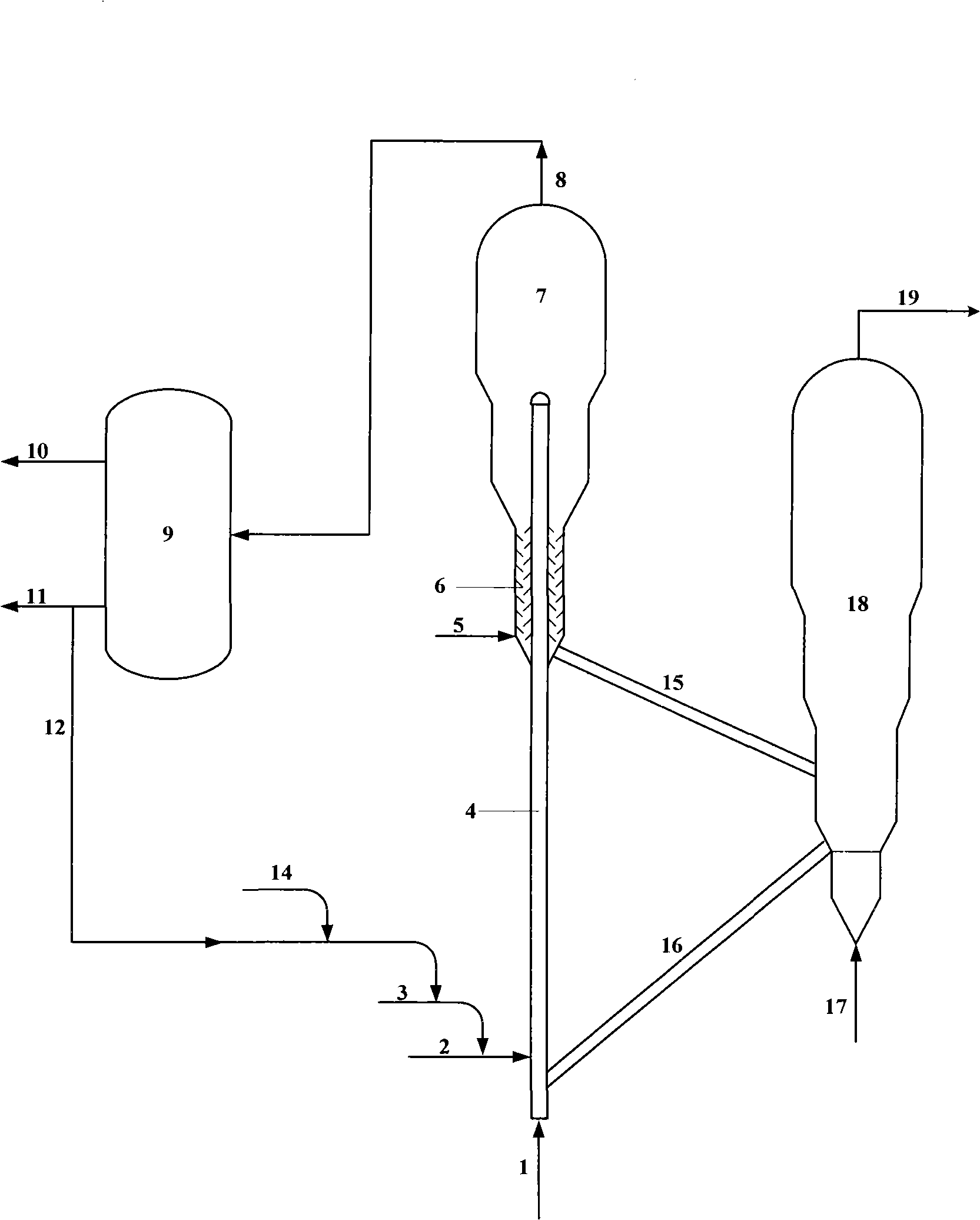

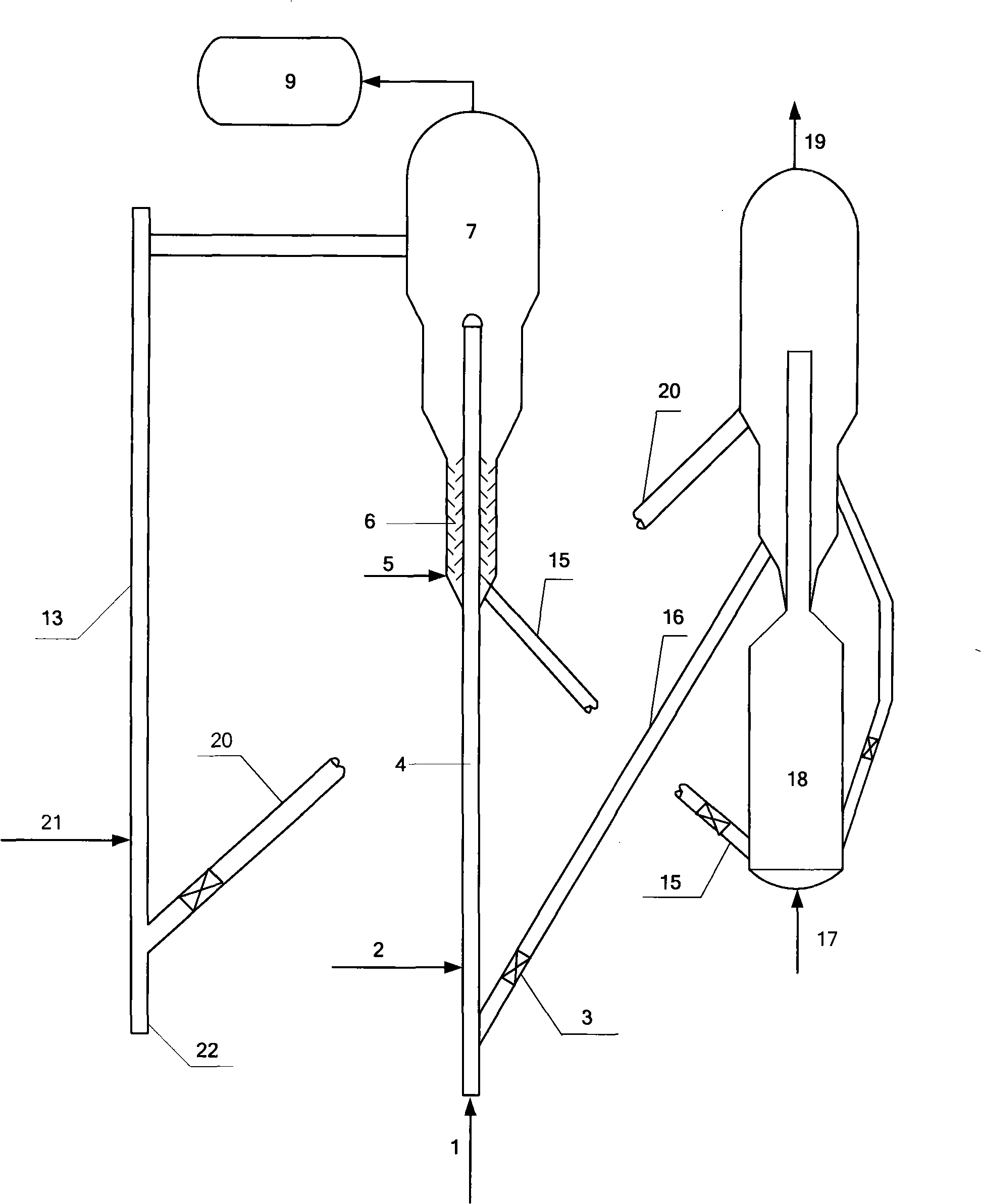

Catalytic conversion method of hydrocarbon oil

ActiveCN104560167AReduce hydrogen consumptionImprove operating conditionsTreatment with hydrotreatment processesHydrocarbon oils treatment productsGasolineCatalytic cycle

The invention provides a catalytic conversion method of hydrocarbon oil. The method comprises the following steps: cutting light catalytic cycle oil into light fraction and heavy fraction; hydrotreating the heavy fraction to obtain hydrotreated heavy fraction; adding the light fraction, the hydrotreated heavy fraction and heavy hydrocarbons raw materials into a riser reactor from bottom to top by layering; cracking in the presence of a catalytic cracking catalyst; and separating a reaction product to obtain a product containing gasoline and light cycle oil. According to the method, the raiser is divided into different areas at three layers, and a regenerated catalyst is supplemented at different positions to respectively process different fractions of heavy oil and light cycle oil, which is beneficial for the optimizing of operation conditions of the three raw materials, and therefore, catalytic gasoline with high octane number can be produced to the maximum.

Owner:CHINA PETROLEUM & CHEM CORP +1

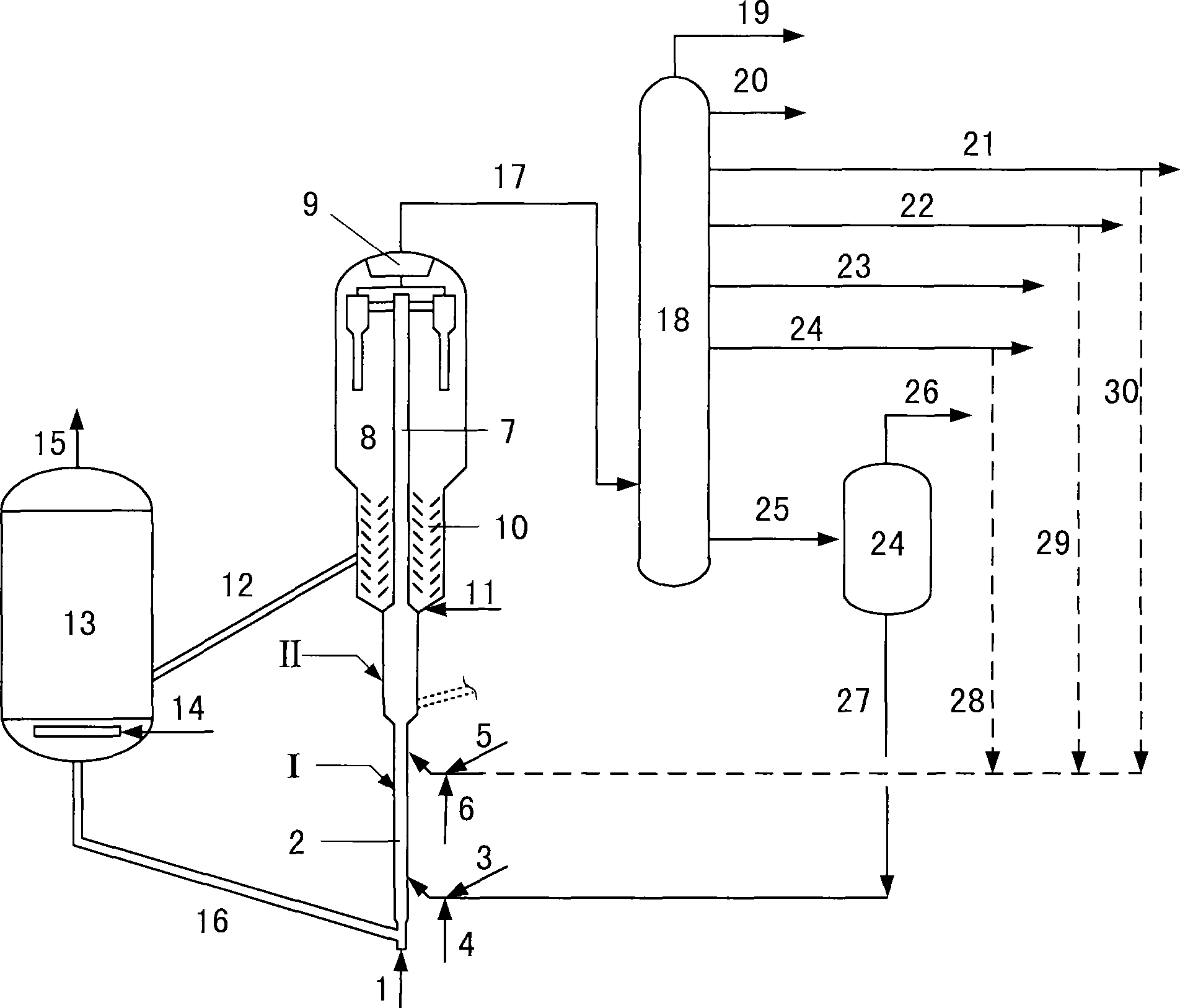

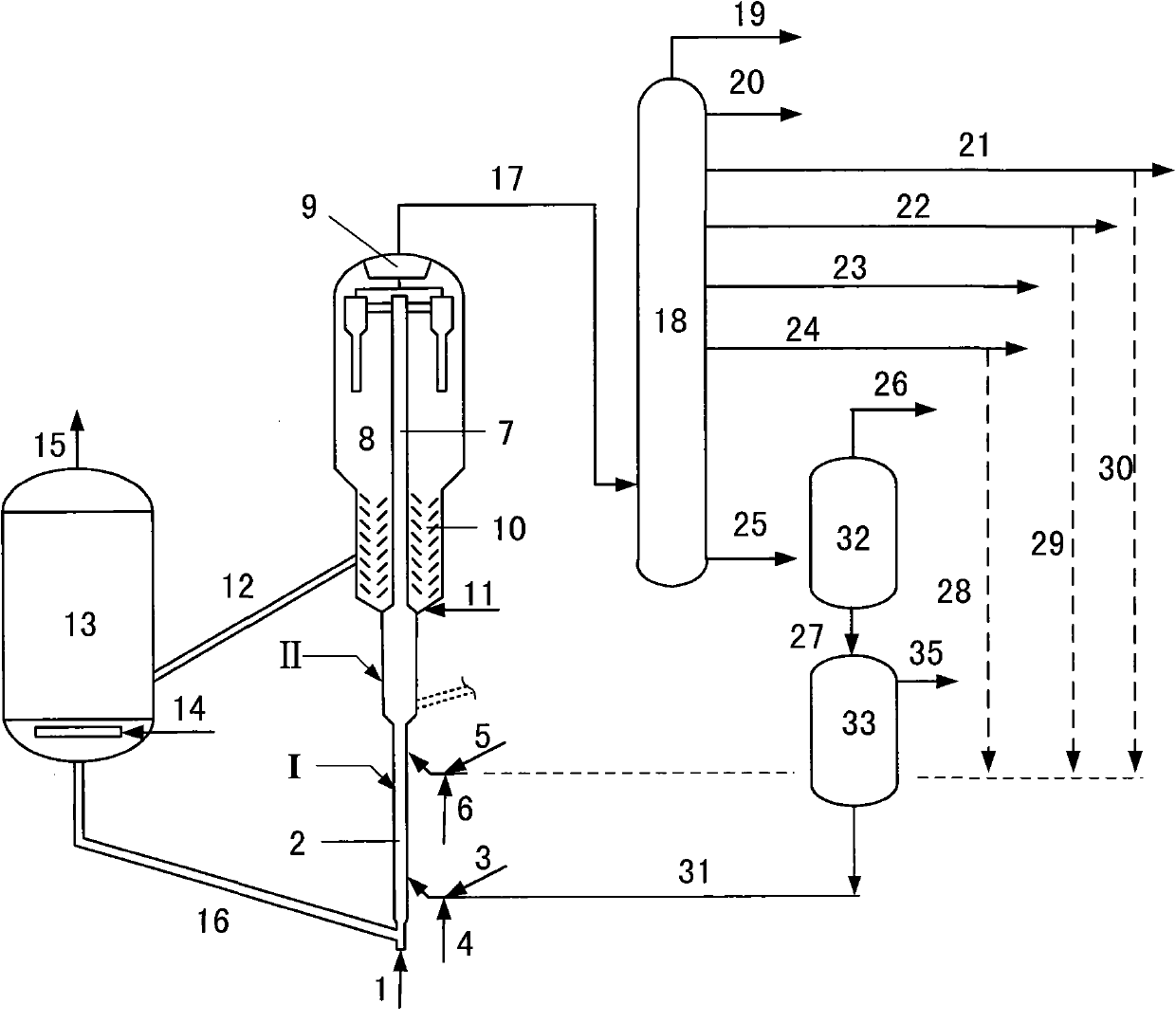

Method producing light fuel oil and propylene from poor residual oil

ActiveCN102373084AEfficient use ofTreatment with hydrotreatment processesChemical recyclingLighter fuelFuel oil

The invention discloses a method producing light fuel oil and propylene from poor residual oil, wherein residual oil raw materials and the extract oil of catalytic cracking heavy oil aromatics extraction are reacted in a residual oil hydrogenation unit, the obtained hydrogenation residual oil and the extract oil of the catalytic cracking heavy oil aromatics extraction enter a catalytic cracking device to react, the obtained catalytic cracking heavy oil enters an aromatics extraction device, then the raffinate oil and the extract oil are obtained after the treatment, the obtained extract oil is circulated to the residual oil hydrogenation unit, and the raffinate oil is circulated to the catalytic cracking device. The method organically combines hydrotreatment, catalytic cracking and aromatics extraction technologies, and produces propylene and light fuel oil from poor raw materials to the maximum extent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cycle oil conversion process

InactiveUS6837989B2Treatment with plural serial cracking stages onlyCatalytic crackingNaphthaCracking reaction

The invention relates to a process for converting cycle oils produced in catalytic cracking reactions into olefin and naphtha. More particularly, the invention relates to a process for hydroprocessing a catalytically cracked light cycle oil, and then re-cracking it in an upstream zone of the primary FCC riser reactor.

Owner:EXXON RES & ENG CO

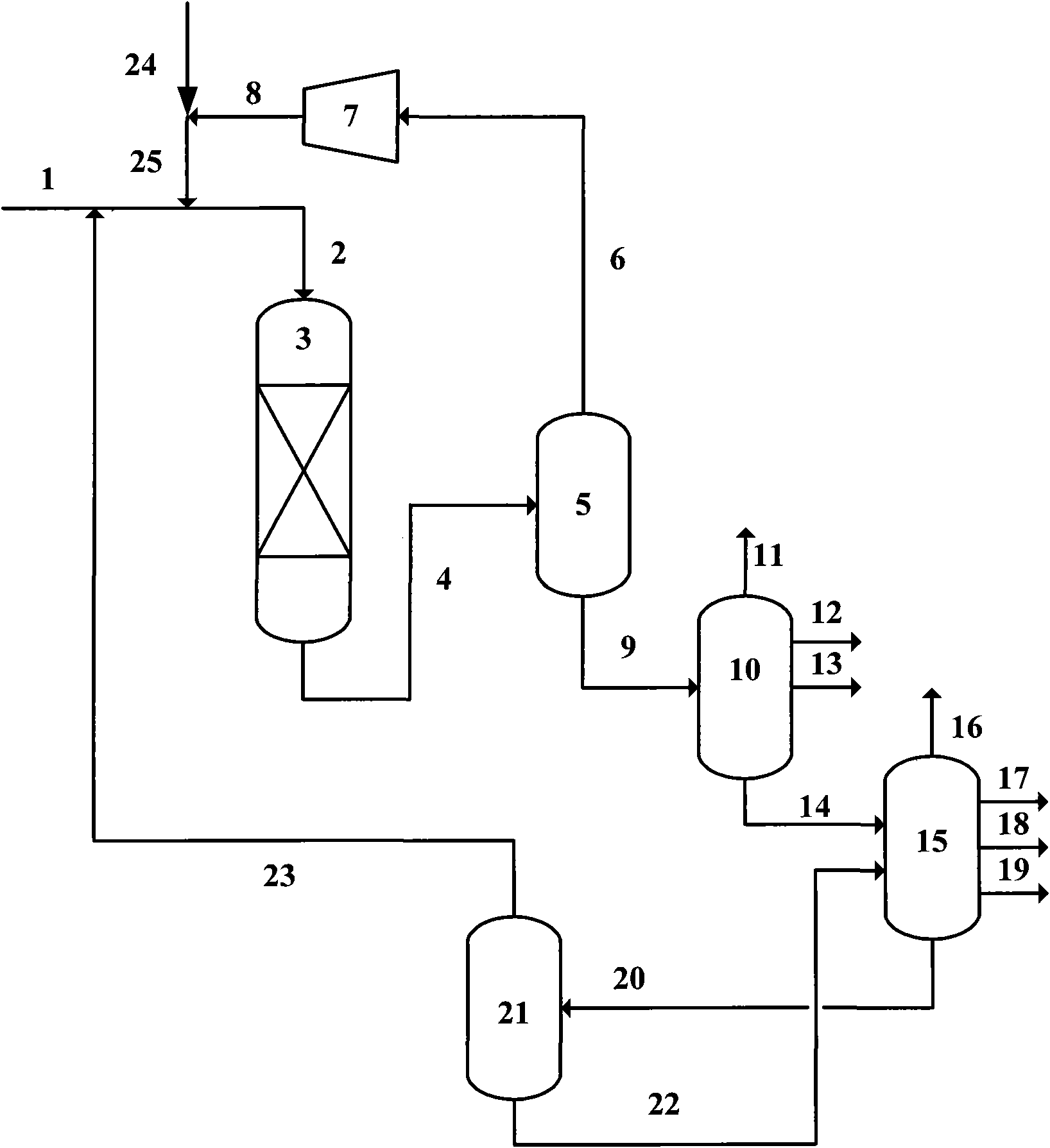

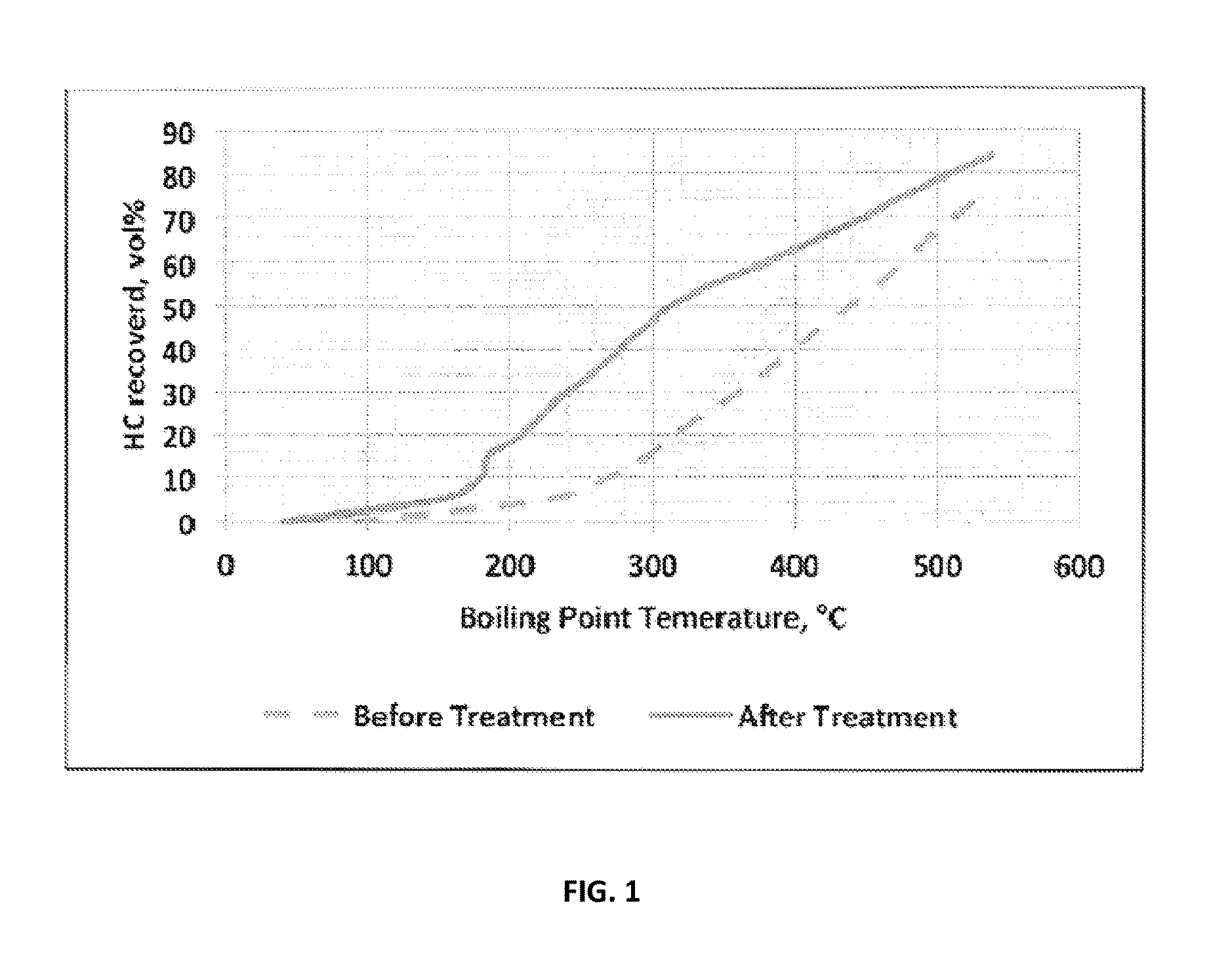

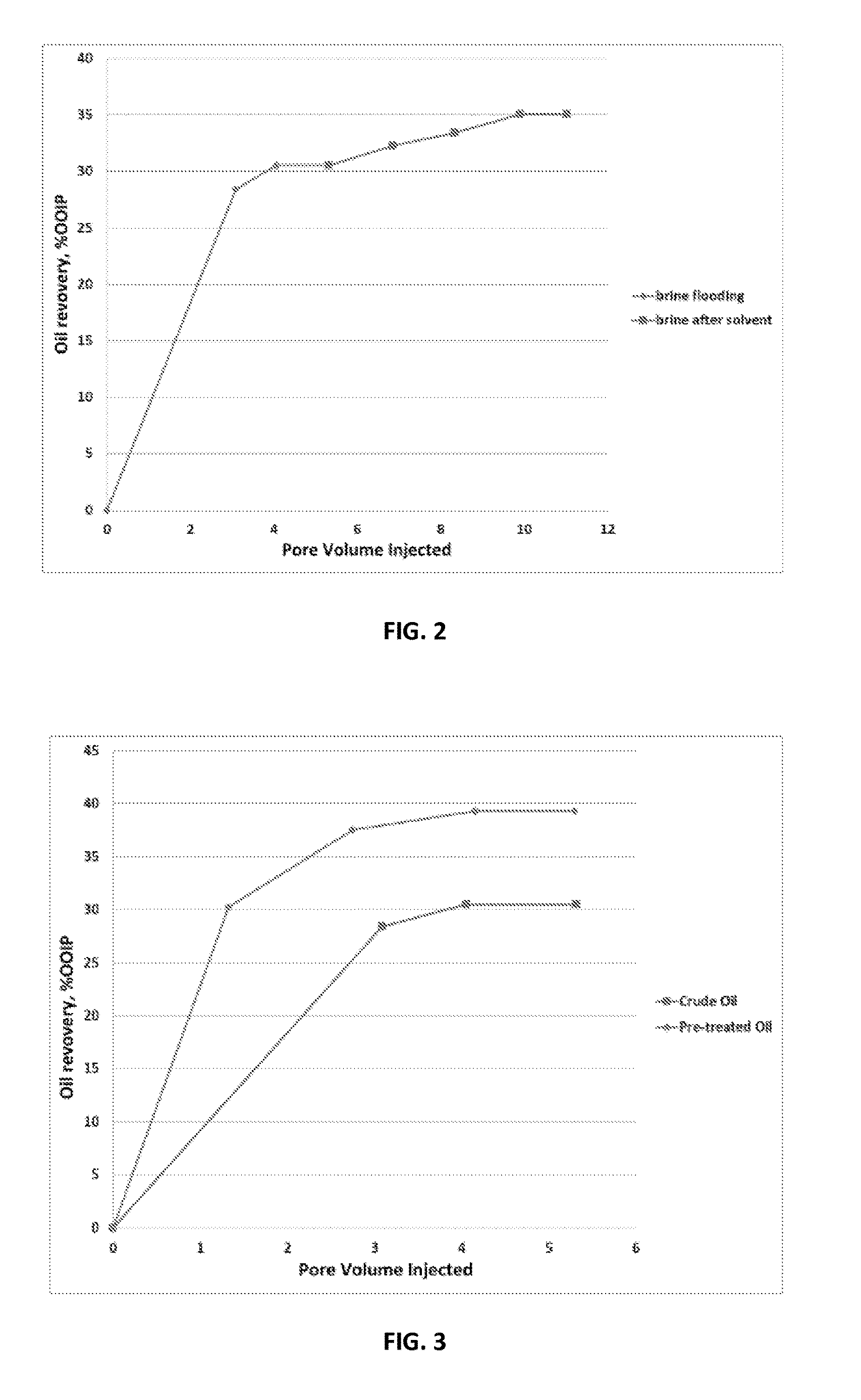

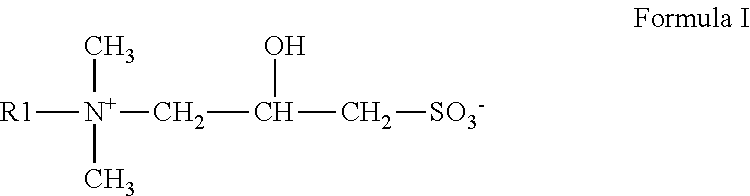

Enhanced oil recovery method for producing light crude oil from heavy oil fields

The present invention relates to a nano-fluid composition for use in a method for enhanced oil recovery comprising a sultaine compound, a solvent or mixture of solvents comprising hydrocarbons having 5 to 12 carbons, and nanoparticles selected from Magnesia, Alumina and Zinc Oxide. The present invention provides also a novel method for enhanced oil recovery involving injection of the said nano-fluid composition into a subterranean formation and obtaining material comprising petroleum from a subterranean formation downhole.

Owner:MANSOUR AWAD RASHEED SULEIMAN

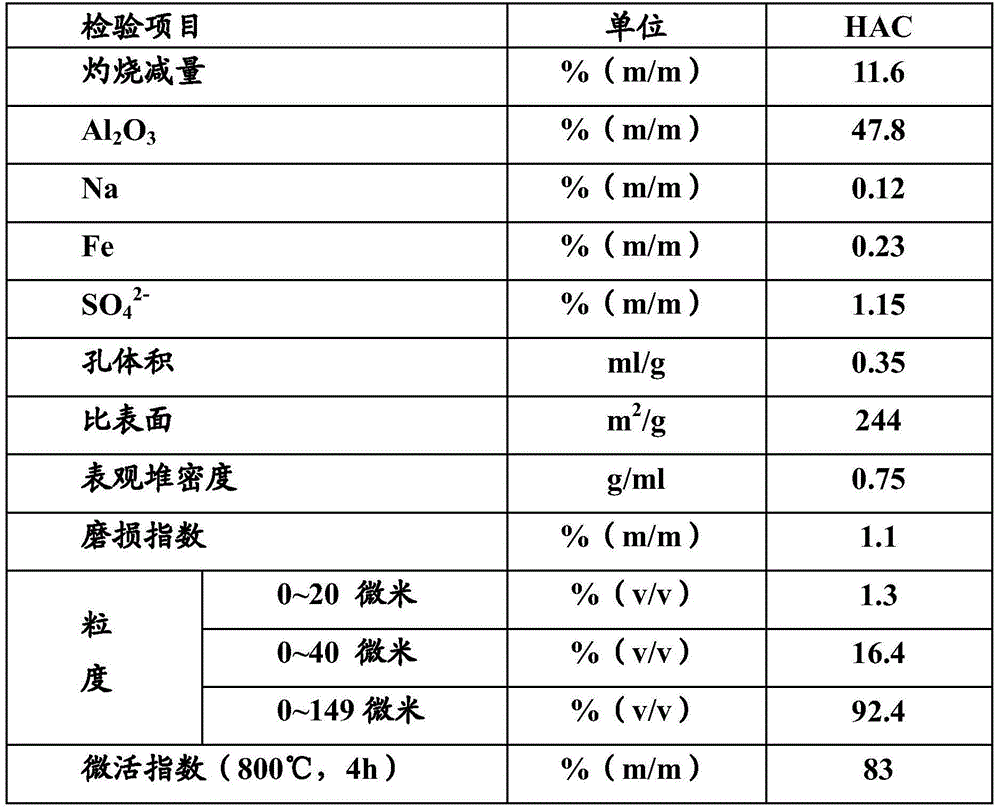

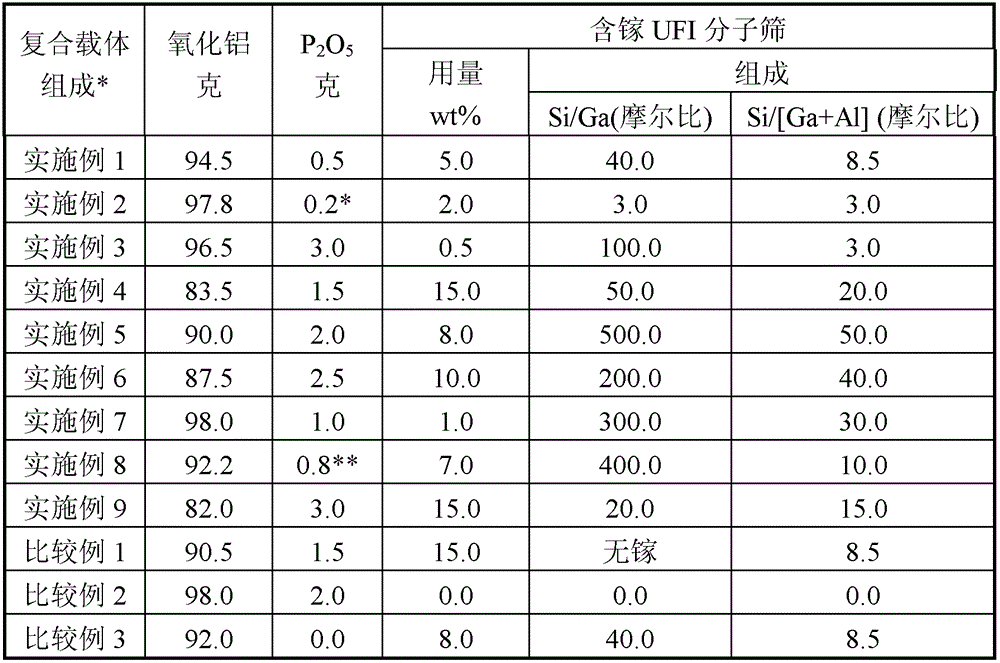

Hydrocracking catalyst for preparing valuable light aromatic hydrocarbons from polycyclic aromatic hydrocarbons

ActiveUS20130210611A1Molecular sieve catalystsMolecular sieve catalystPolycyclic aromatic hydrocarbonAromatic hydrocarbon

This invention relates to a hydrocracking catalyst for preparing valuable light aromatic hydrocarbons from polycyclic aromatic hydrocarbons derived from oil, which includes (i) beta-zeolite, (ii) pseudo-boehmite, and (iii) one or more metals selected from among metals of Groups VIII and VIB, and which further includes a cocatalyst component, thereby producing a maximum amount of BTX (Benzene, Toluene, Xylene) from LCO (Light Cycle Oil).

Owner:SK INNOVATION CO LTD

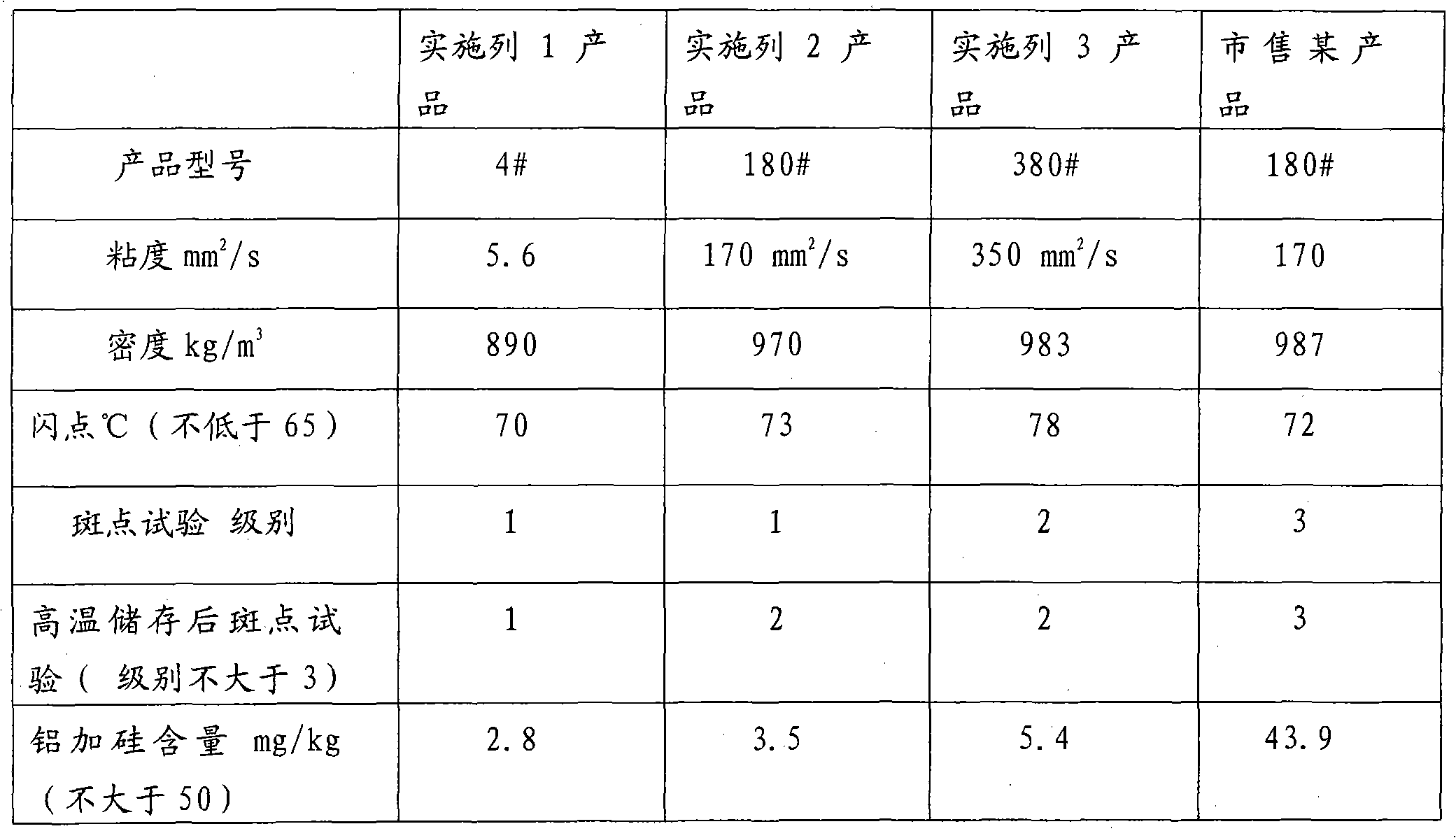

Fuel oil composition

InactiveCN101921633AGood compatibilityGood storage stabilityLiquid carbonaceous fuelsCombustionLighter fuel

The invention relates to a fuel oil composition suitable for bunker fuel oil industry, industrial generation, civil boilers and the like. The fuel oil composition comprises the following materials: 10-60 parts by weight of heavy oil residues as petroleum byproducts, 5-50 parts by weight of low-temperature coal tar, 5-53 parts by weight of light fuel oil and 2-20 parts by weight of diesel oil or absorber oil. A fuel oil finished product prepared from the fuel oil composition has the advantages of good cleanness and stability, low abrasion and corrosion effects on combustion equipment and favorable storage stability.

Owner:锦州港船舶燃料供应有限责任公司

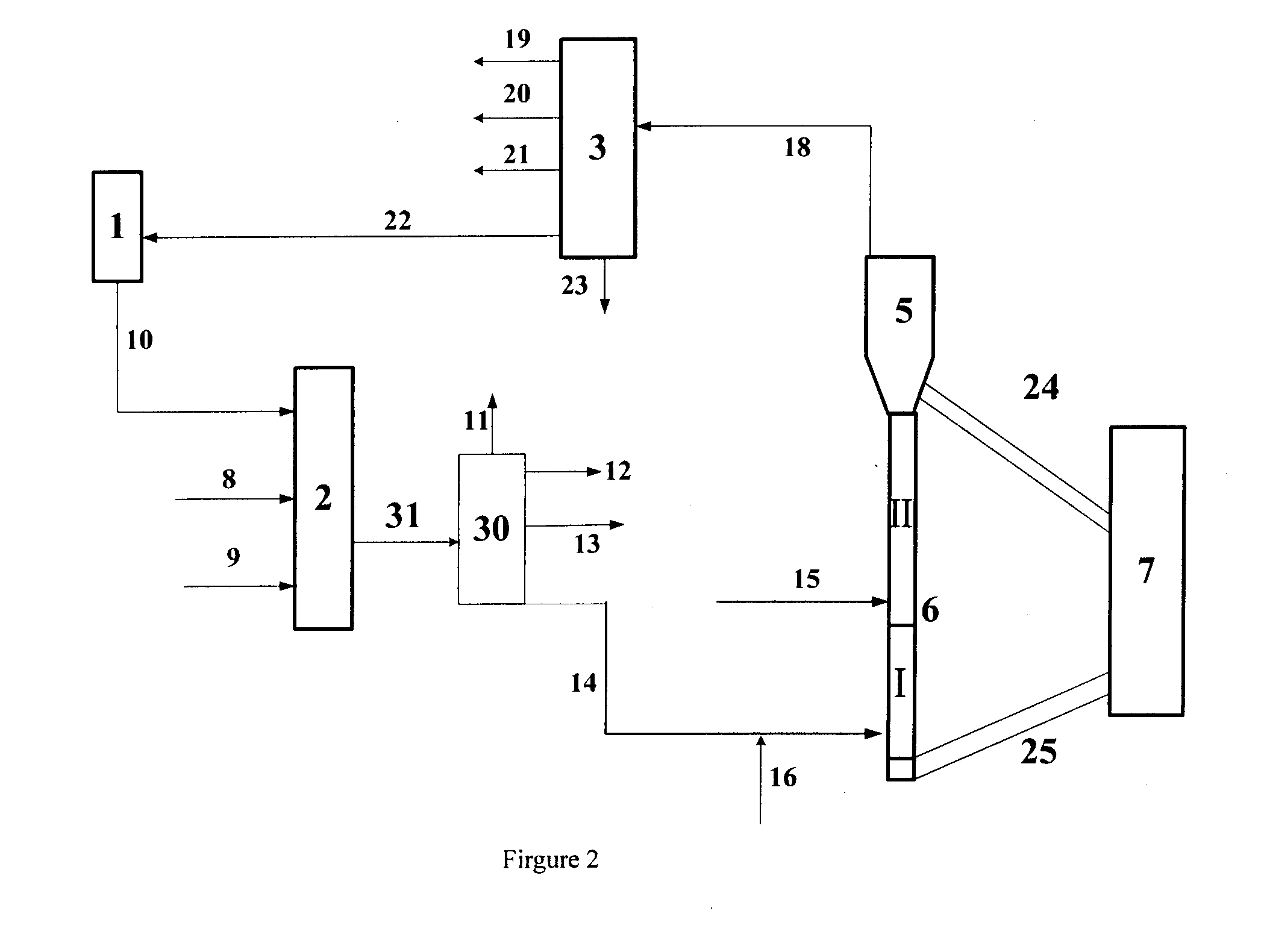

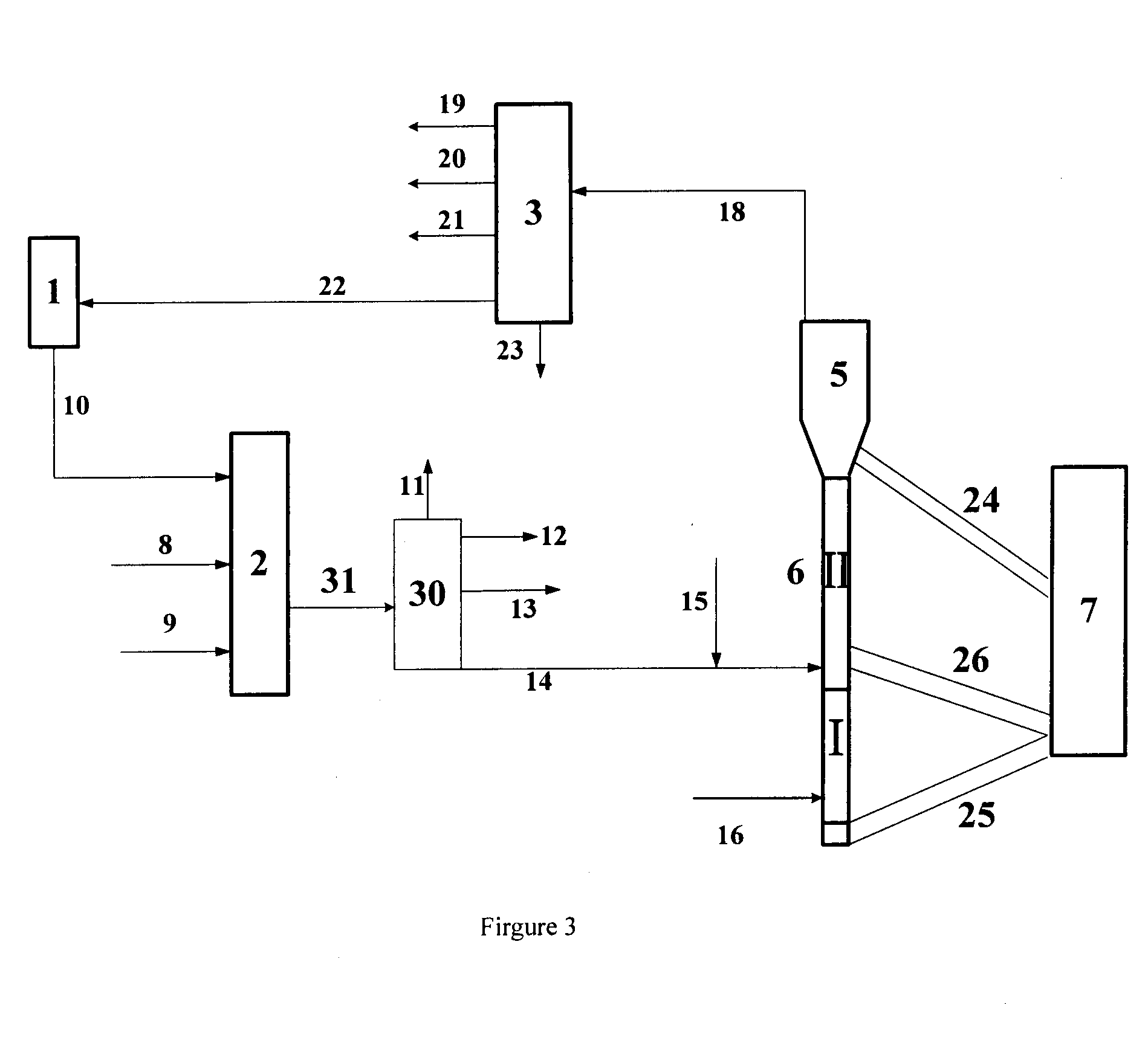

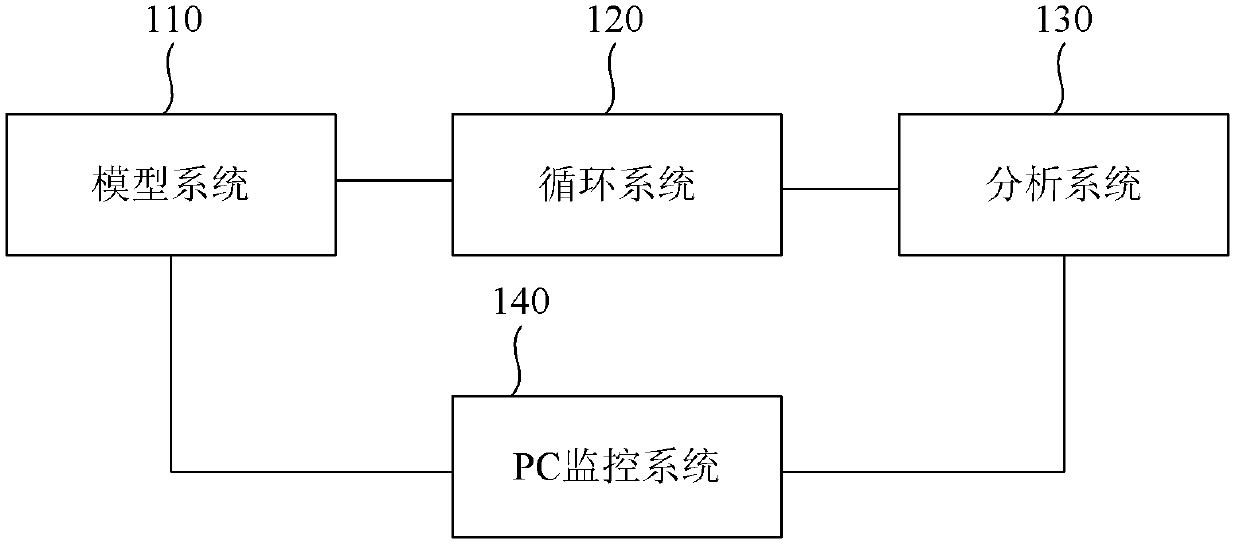

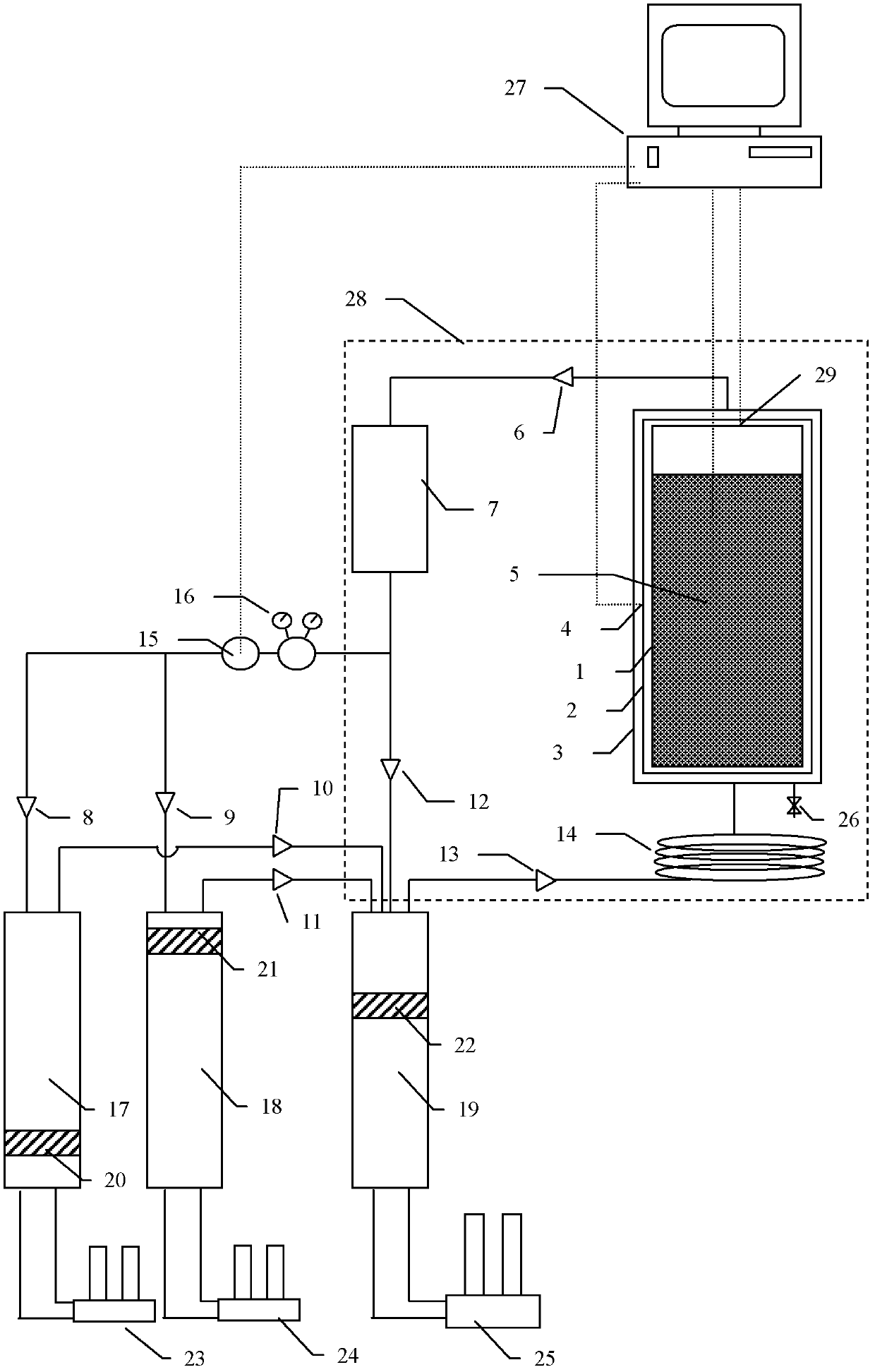

Light crude-oil circular gas-injection low-temperature oxidization experimental method and device

ActiveCN102384970ALess likely to cause reactivityNot easy to produce resultsMaterial testing goodsExperimental methodsGas composition

The invention discloses a light crude-oil circular gas-injection low-temperature oxidization experimental method and device. The experimental device comprises a modeling system, a circulating system, an analysis system and a personal computer (PC) monitoring system; the model system is used for simulating the oil reservoir pressure and for simulating an oil reservoir temperature, and the produced gas is sent into the analysis system through the circulating system; the analysis system is used for analyzing the composition of the produced gas and for sending the produced gas after being analyzed into the circulating system; the circulating system is used for returning the produced gas to the modeling system to realize the circular monitoring; and the PC monitoring system is used for monitoring the simulated oil reservoir pressure and the simulated oil reservoir temperature of the modeling system and for recording the gas composition which is circularly monitored by the analysis system. The method and the device adopts a circular gas injection way, so the problem that the experimental balance is broken because of the gas sampling analysis in the reaction system during the experimental process can be avoided.

Owner:PETROCHINA CO LTD

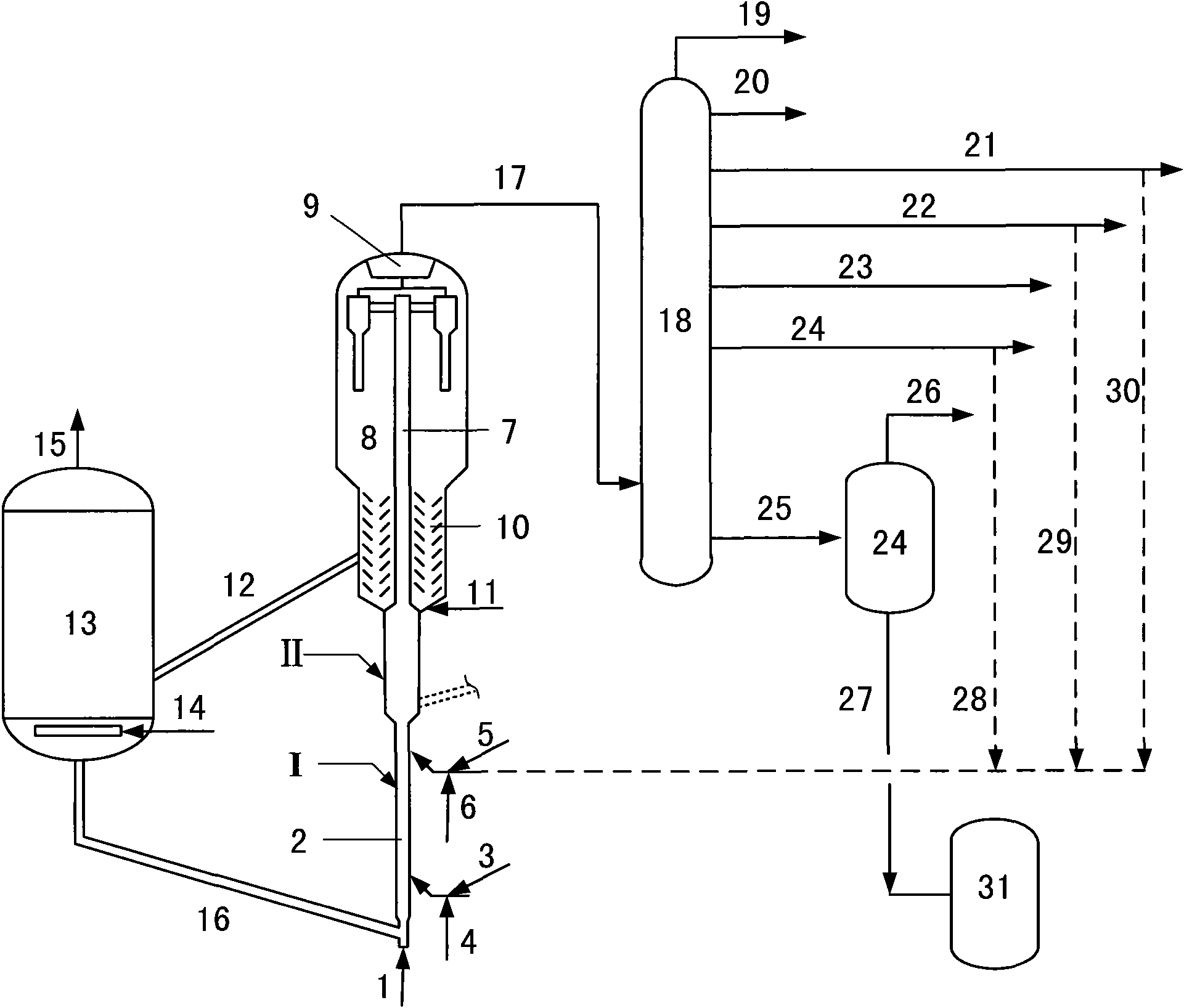

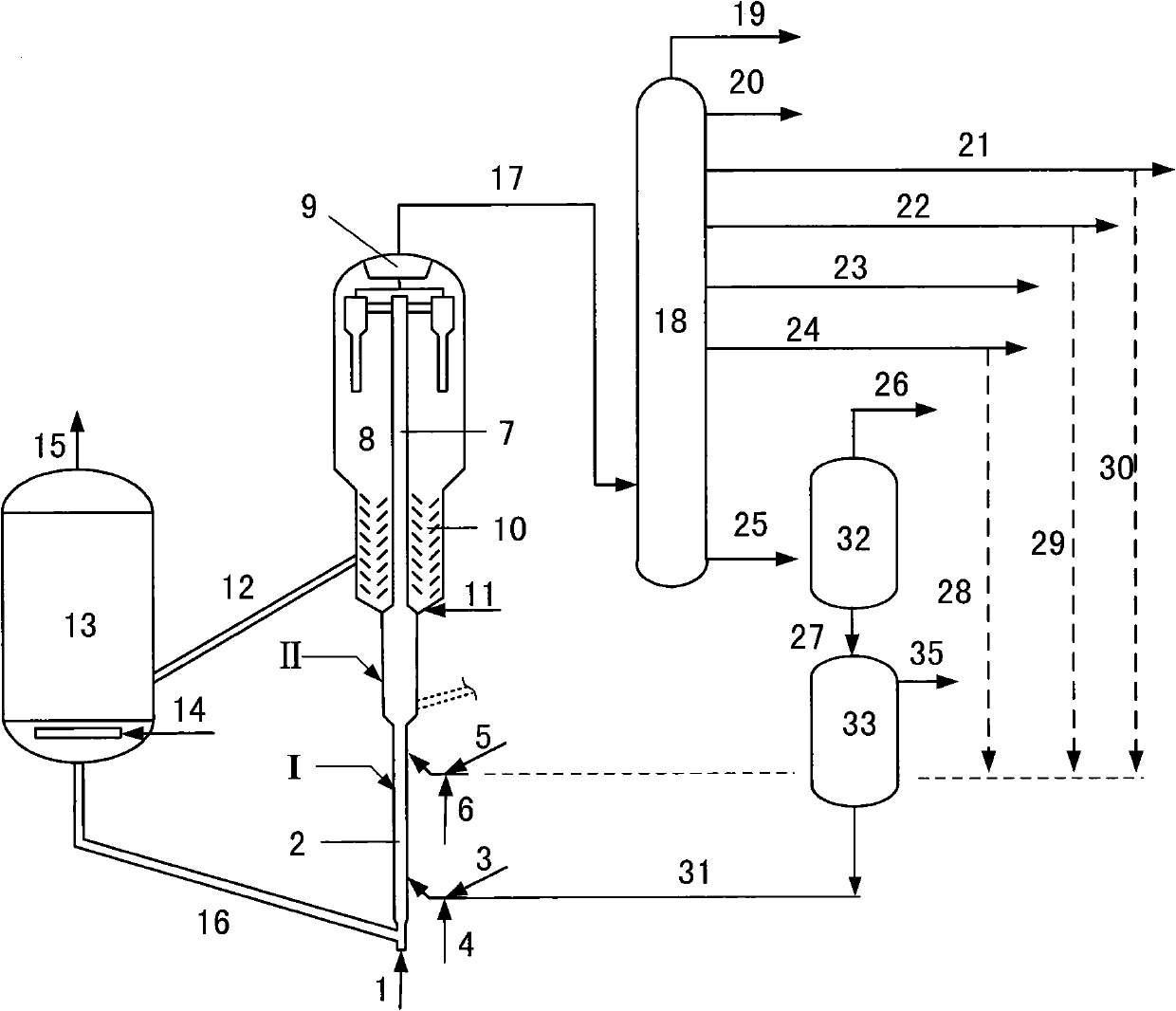

Catalytic conversion method for preparing light fuel oil and propylene

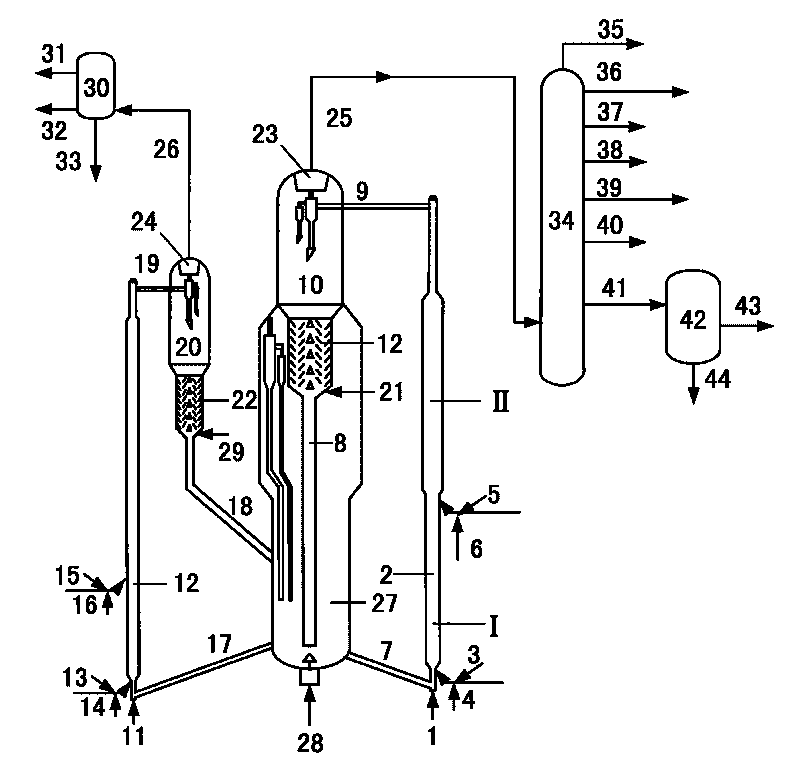

ActiveCN101724431AImprove propertiesExtended operating cycleCatalytic crackingChemical recyclingAlkaneCycloparaffins

The invention relates to a catalytic conversion method for preparing light fuel oil and propylene, comprising: leading inferior crude oil to enter a catalytic conversion reactor to be contacted with catalyst and have reaction; separating the reaction product, and obtaining the product containing the propylene, crude gasoline and catalytic wax oil, wherein leading the crude gasoline to enter another catalytic conversion reactor to be contacted with catalytic conversion catalyst to have reaction; treating the catalytic wax oil by hydrotreating or / and solvent extraction; and taking the catalyticwax oil obtained by hydrotreating or / and raffinate oil of the catalytic wax oil as raw material of the catalytic conversion reactor or other catalytic conversion reactors. In the method, after the catalytic wax oil which is obtained by carrying out mild catalytic conversion on the inferior crude oil is treated by hydrotreating or / and solvent extraction, the obtaining catalytic wax oil obtained byhydrotreating or / and raffinate oil contains alkane or cycloparaffin, and is very suitable for catalytic conversion, thus realizing high efficiency utilization of oil resources.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocarbon conversion process

A process for the conversion of a feedstock containing light cycle oil and vacuum gas oil to produce naphtha boiling range hydrocarbons and a higher boiling range hydrocarbonaceous stream having a reduced concentration of sulfur.

Owner:UOP LLC

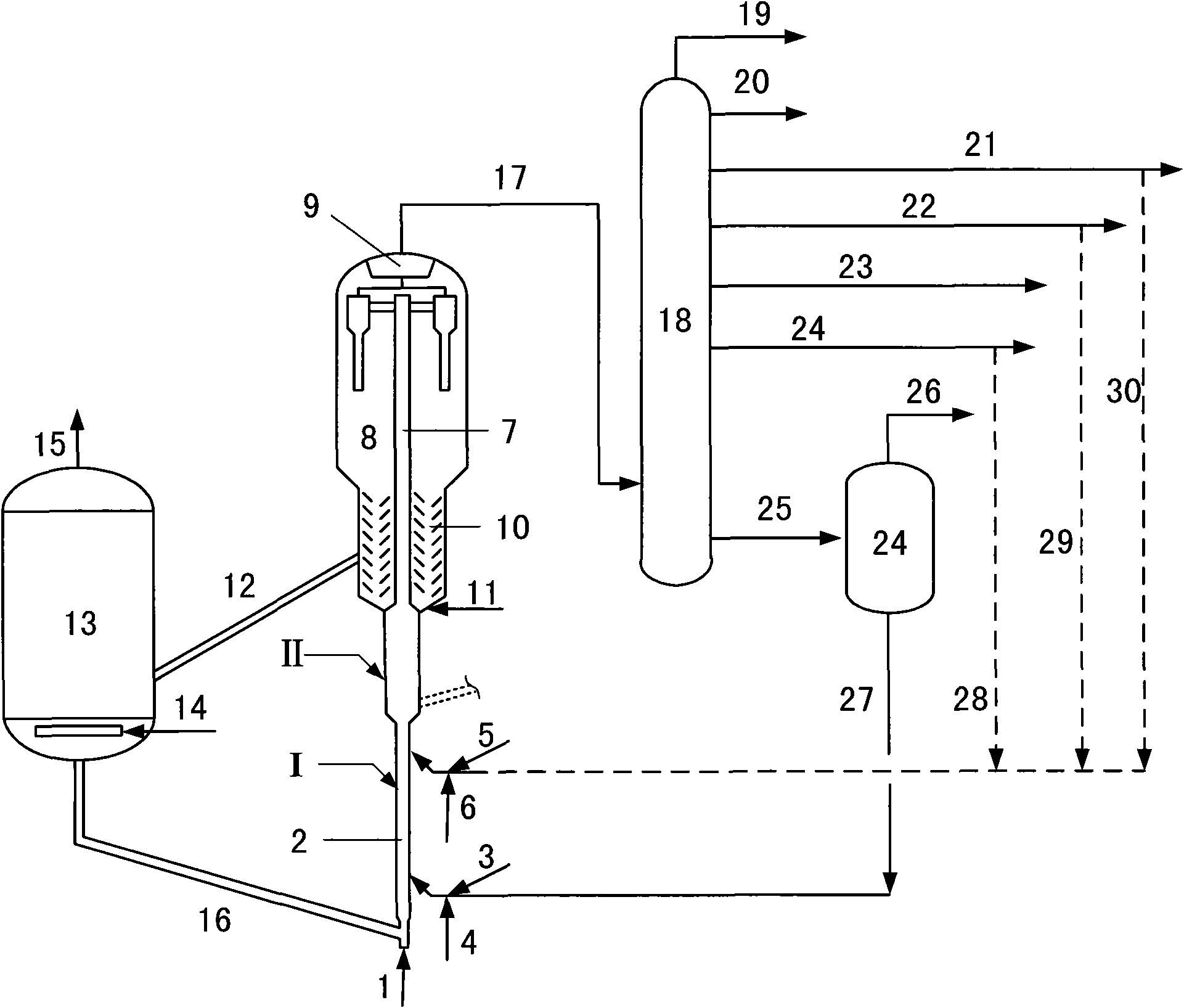

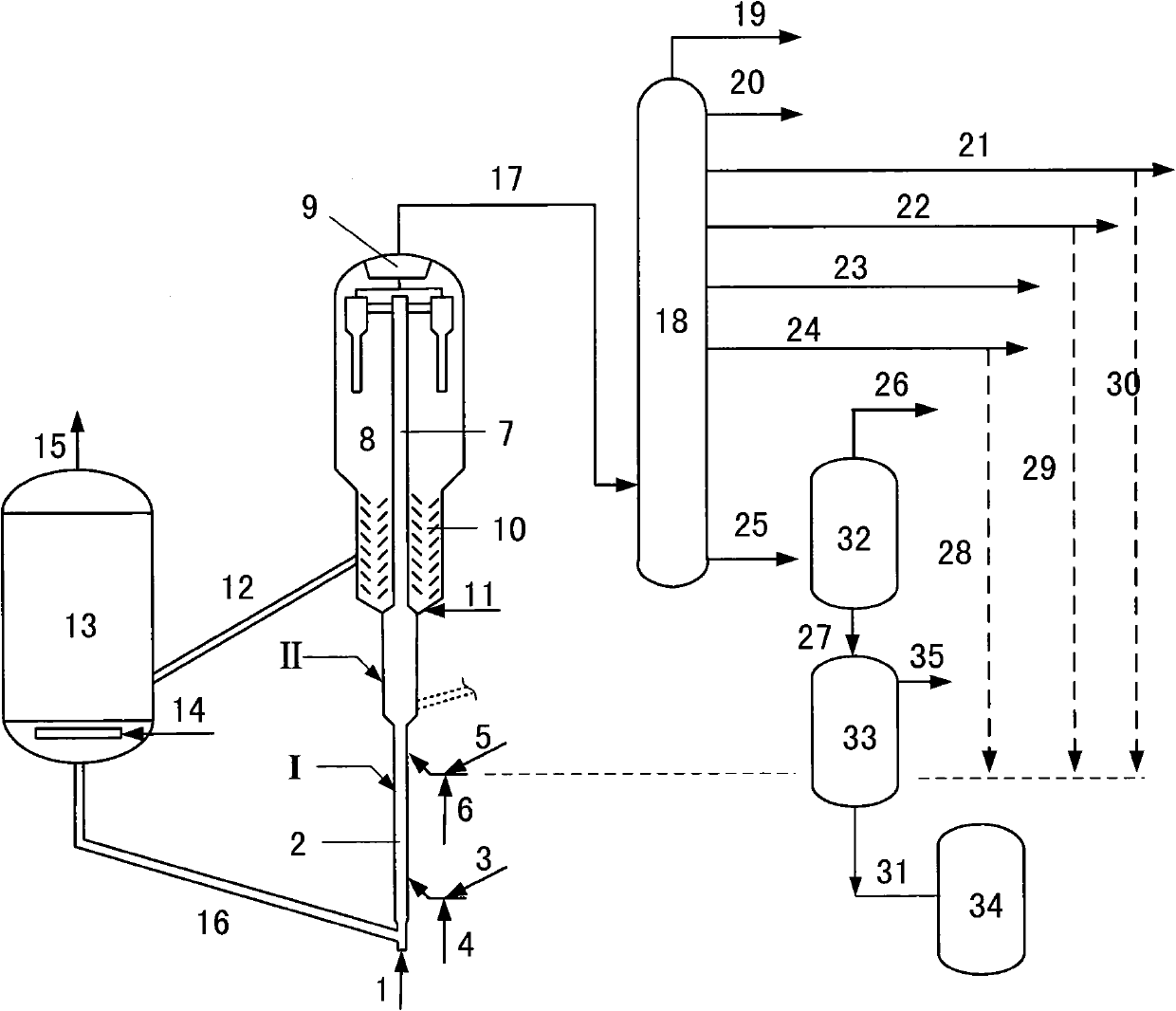

Method for preparing superior fuel oil from inferior crude oil

ActiveCN102021031AImproved raw material propertiesImprove propertiesTreatment with hydrotreatment processesWaxLighter fuel

The invention discloses a method for preparing superior fuel oil from inferior crude oil. The inferior crude oil enters first and second reaction areas of a catalytic conversion reactor in turn to contact a catalytic conversion catalyst to respectively generate primary reaction and secondary reaction, reaction products and the spent catalyst are subjected to gas-solid separation, and the spent catalyst is subjected to steam stripping and burning in turn and returns to the reactor to be recycled; and the reaction products are separated to form propylene, light fuel oil, catalytic wax oil and other products, wherein after the catalytic wax oil is extracted, the obtained extracted oil is subjected to hydrotreatment, and the obtained hydrogenated extracted oil is circulated to the first reaction area of the catalytic conversion reactor or / and other catalytic conversion devices for further reaction to form the target product of light fuel oil. The method integrates catalytic cracking, hydrotreatment, aromatic hydrocarbon extraction, conventional catalytic cracking and other processes, and the light fuel oil and the propylene are prepared from the inferior crude oil to the greatest degree, so that the oil resources are efficiently utilized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing high value aromatics and olefin from light cycle oil produced by a fluidized catalytic cracking process

ActiveUS8912377B2Increase productionMaximize processing efficiencyCatalytic crackingHydrocarbon by hydrogenationHigh concentrationPetroleum

The present invention relates to a method of producing aromatic products (benzene / toluene / xylene) and olefin products from petroleum fractions obtained by fluid catalytic cracking, and, more particularly, to a method of producing products comprising high-concentration aromatic products and high value-added light olefin products from light cycle oil obtained by fluid catalytic cracking.

Owner:SK INNOVATION CO LTD

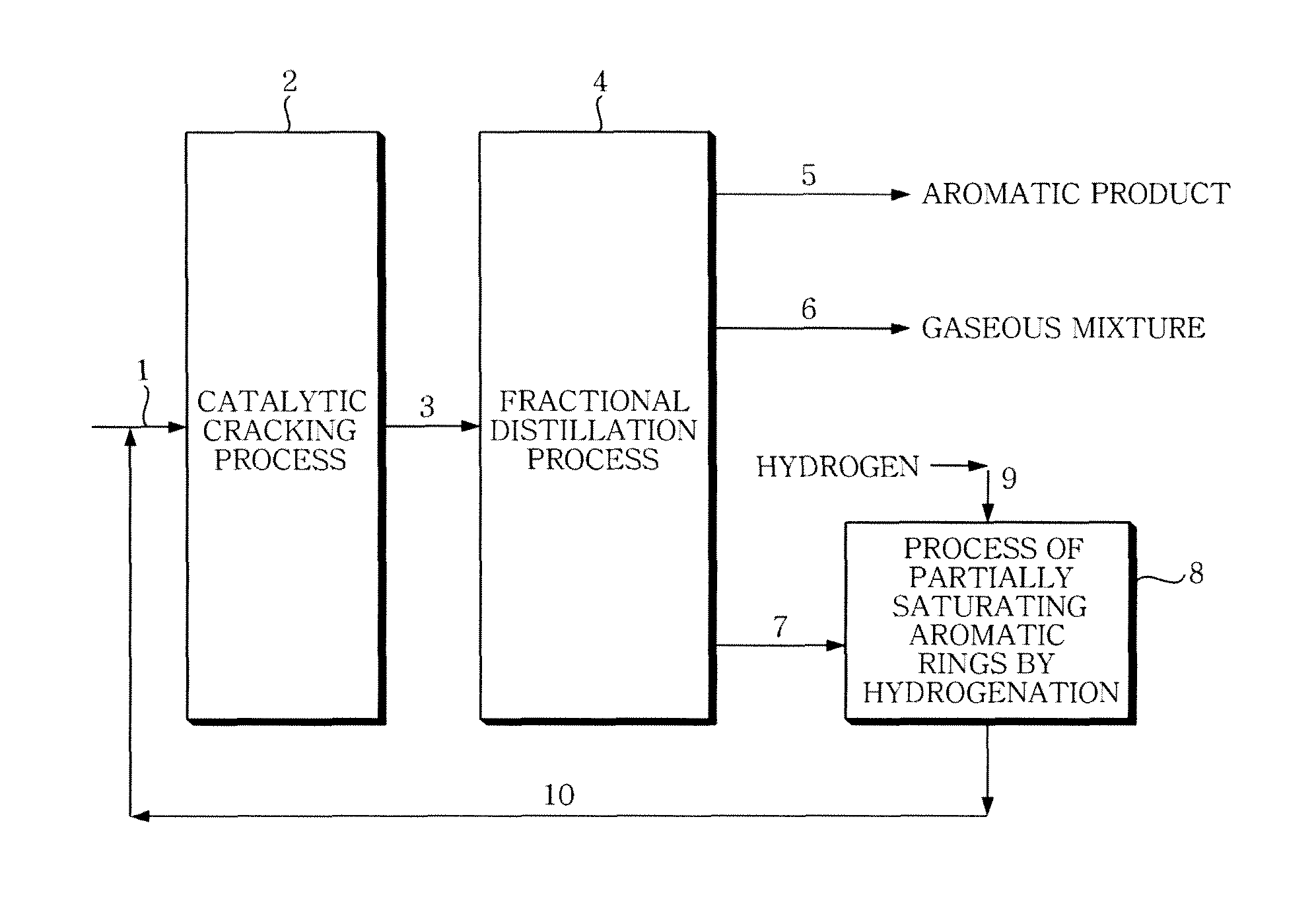

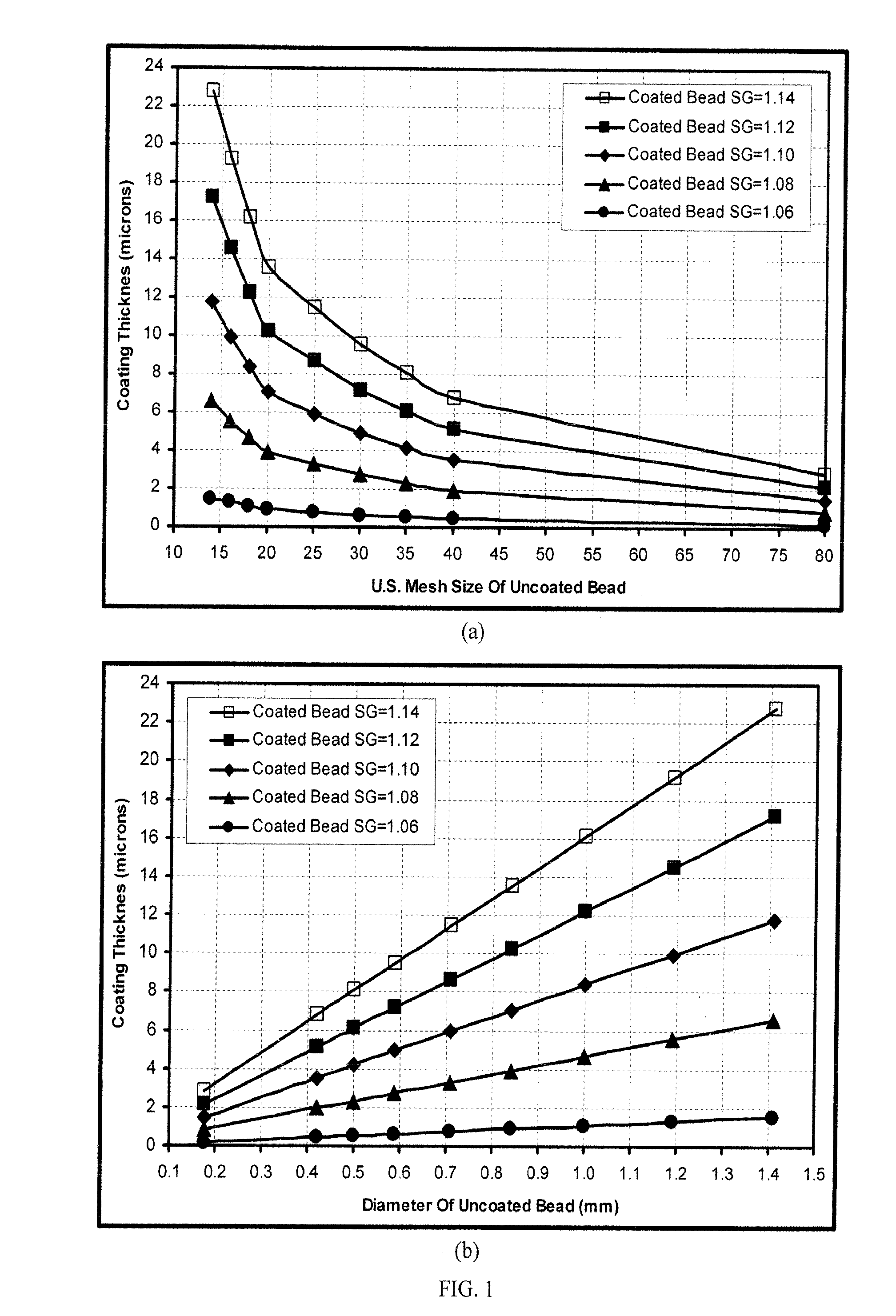

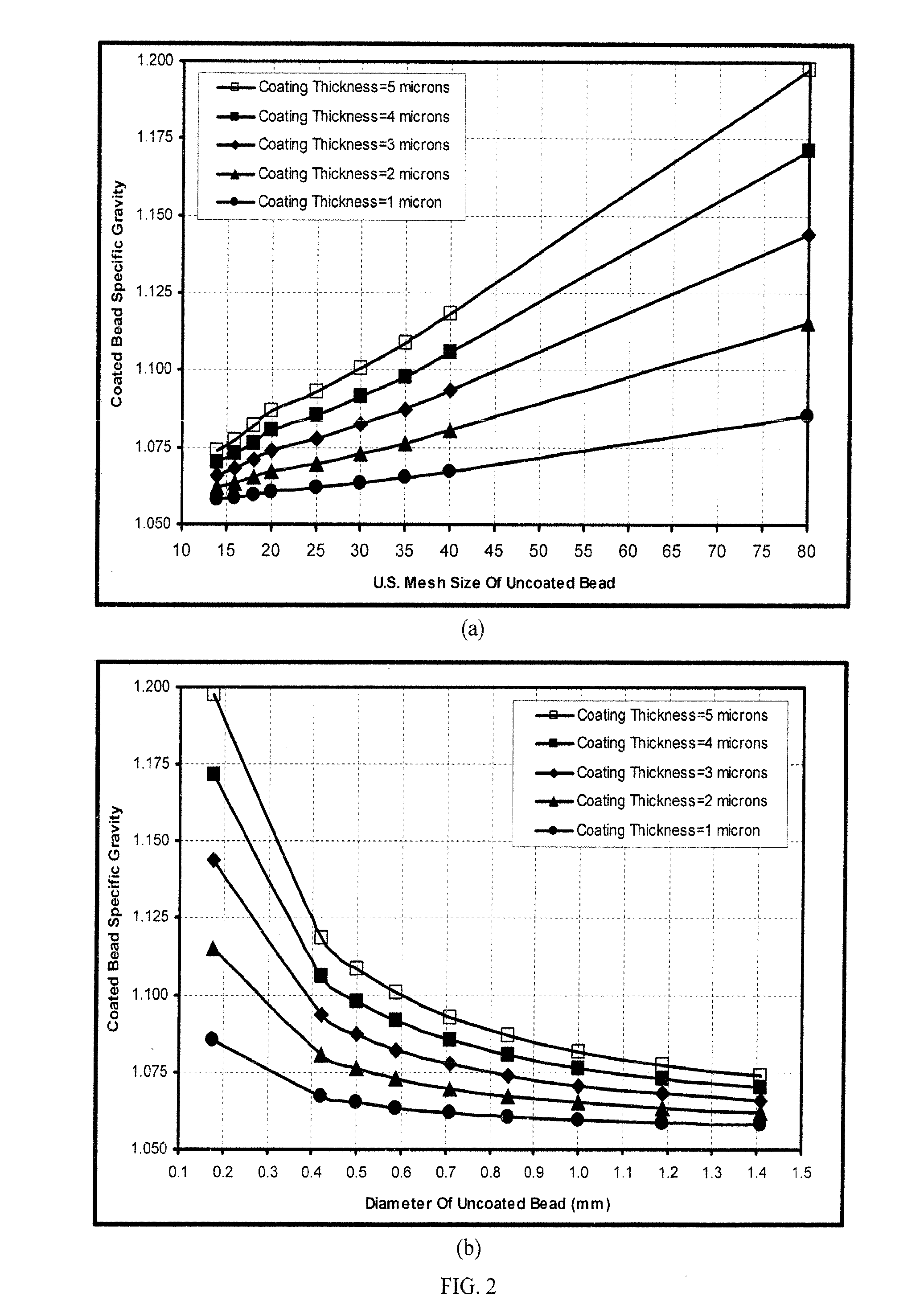

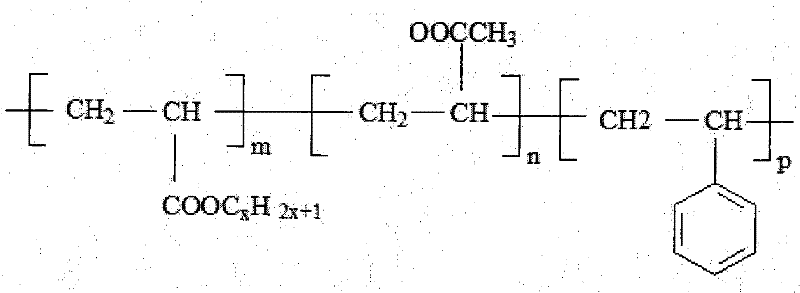

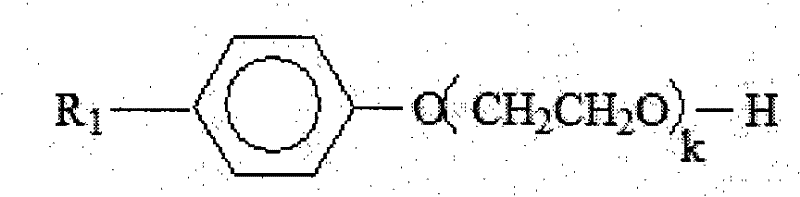

Catalytic polymer bead compositions; processiing for their production; and their use in generating and extracting natural gas, light crude oil, or sequences or mixtures thereof

InactiveUS20120325473A1Increase generationStress resistantMaterial nanotechnologyOrganic-compounds/hydrides/coordination-complexes catalystsHigh rateNeutral buoyancy

In one aspect, this invention provides a method for the in-situ production of natural gas, light crude oil, or sequences or mixtures thereof, comprising the steps of: (a) suspending a catalytic polymer bead in a fracturing medium, wherein said catalytic polymer bead is nearly neutrally buoyant in said fracturing medium; (b) introducing said suspension into a formation at sufficiently high rates and pressures that the formation fails and fractures to accept said suspension; and (c) collecting the natural gas, light crude oil, or sequences or mixtures thereof, generated by the subterranean formation. In another aspect, this invention provides compositions of matter for said catalytic polymer beads. In yet another aspect, this invention provides processing methods for producing said catalytic polymer beads.

Owner:SUN DRILLING PRODS

Integrated fluid catalytic cracking process

InactiveUS7601254B2Thermal non-catalytic crackingTreatment with plural serial cracking stages onlyBoiling pointAlkene

A process for the conversion of a hydrocarbon feedstock to produce olefins, aromatic compounds and ultra low sulfur diesel wherein the hydrocarbon feedstock is reacted in a fluid catalytic cracking (FCC) zone to produce olefins and light cycle oil. The effluent from the FCC is preferably separated to produce a stream comprising ethylene and propylene, a stream comprising higher boiling olefins and light cycle oil (LCO). The stream containing the higher boiling olefins is cracked to provide additional ethylene and propylene. The LCO is selectively hydrocracked to produce aromatic compounds and ultra low sulfur diesel.

Owner:UOP LLC

Light cycle oil selective hydrorefining method

ActiveCN103059917AIncrease acidityHigh retention rateHydrocarbon oils treatmentPolycyclic aromatic hydrocarbonBenzene

The invention relates to a light cycle oil selective hydrorefining method, and mainly aims at solving the problem that at present arene is largely lost in the hydrorefining process. The problem is well solved by adopting the technical scheme that light cycle oil of which the sulfur content is 2000-15000ppm and hydrogen are used as raw materials; under the condition that the volume ratio of hydrogen to light cycle oil is 300-800 : 1, the temperature is 250-450 DEG C, the weight air speed is 0.5-3 per hour and the pressure is 3-12MPa, the raw materials are contacted with a catalyst; and after the reaction, the removal rate of sulfur in the light cycle oil is larger than 96.0% according to weight percent, the denitrification percent is large than 96.0%, the polycyclic aromatic hydrocarbon conversion rate is larger than 40.0%, and the total remaining rate of arene in a product is larger than 97.0% according to weight percent. The light cycle oil selective hydrorefining method can be applied to industrial production of benzene and dimethylbenzene in a light cycle oil selective hydrogenation mode.

Owner:CHINA PETROLEUM & CHEM CORP +1

Light fuel oil

InactiveUS7695610B2Improve stabilityIncrease rangeLiquid organic insulatorsSolid fuelsLighter fuelTar

The invention relates to oil refining, more particularly to a composition of a light fuel oil for use in medium-speed diesel engines of marine power units. The inventive light fuel oil comprises, in % by wt.: black oil—(4-10), tar—(2-10), light catalytic cracking gas oil—(10-30), heavy catalytic cracking gas oil—(5-10), a straight-run diesel fuel—(8-10), a viscosity breaking residuum of a heavy oil fraction—the rest. The selected component ratio will enable to improve the fuel stability in transportation and storage, expand the range of available fuels and increase the production volumes of quality fuels, while rationally using poor-quality products readily available at refineries.

Owner:OILTREID LIABILITIES

Catalyst for producing light fuel oil using oily rock as raw material and its method

InactiveCN1786115AGood miscibilityImprove stabilityLiquid hydrocarbon mixture productionLighter fuelParaffin oils

The present invention relates to a catalyst for producing light fuel oil by using oil-bearing rock and its method. Said catalyst raw material composition includes (by wt%) 20-35% of cobalt naphthenate, 30-40% of ethylene glycol monomethyl ether, 3-5% of acidified active clay, 10-20% of stearin and 20-37% of chlorinated paraffin. The described chlorinated paraffin is industrial chlorinated paraffin 70. Said invention also provides the concrete method and steps of utilizing said catalyst to produce light fuel oil.

Owner:曹志德

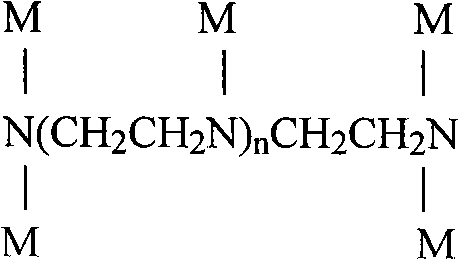

Modifier for high-pour-point crude oil

The invention provides a modifier for high-pour-point crude oil which is a complex composed of the following components in percentage by weight: 0.5-6% of antiwax pour point depressant, 10-45% of sodium petroleum sulfonate, 1-5% of alkyl phenol polyoxyethylene ether, 0.5-5% of an AE-type nonionic surfactant, 3-15% of an AR-type nonionic surfactant and the balance of a solvent. The modifier can result in an ideal antiwax effect of different water-containing oil well, prolong wax cleaning period, and guarantee the normal production of oil well under various working conditions, and has the characteristics of multiple effects and high adaptability.

Owner:天津中油科远石油工程有限责任公司

Hydrocracking method of deep cut anthracene oil

ActiveCN102041087ALow aromatic contentHigh aromatic content, resulting in lower catalyst bed temperature riseTreatment with hydrotreatment processesAnthraceneBoiling point

The invention provides a hydrocracking method of deep cut anthracene oil. The method comprises the following steps of: refining deep cut anthracene oil by means of hydrogenation, then subjecting the deep cut anthracene oil into gas-liquid separation by means of a hot high-pressure separator and a hot low-pressure separator, partially recycling the hot low boiling point oil obtained into the hydrofining region to mix with the deep cut anthracene oil, infusing the residual hot low boiling point oil into the hydrocracking region and then orderly adding a hydrofining catalyst, a hydrodecarbonation catalyst and a hydrocracking catalyst, wherein the hydrocracking product and the gas separated from the hot high-pressure separator are entered into a cold high-pressure separator, the liquid separated during the hydrocracking process and the gas separated from the hot low-pressure separator are entered into a cold low-pressure separator, and the liquid separated during the hydrocracking process is infused into the product distillation column after stripping so as to obtain gasoline and diesel fractions. The hydrocracking method of deep cut anthracene oil provided by the invention has the advantages that the deep cut anthracene oil can be processed, the range of raw material is enlarged, the deep cut anthracene oil can be inversed in the maximum extent and the yield of light fuel oil is improved; simultaneously, the activity of hydrocracking catalyst is effectively protected and the device can be run in a long period.

Owner:CHINA PETROLEUM & CHEM CORP +1

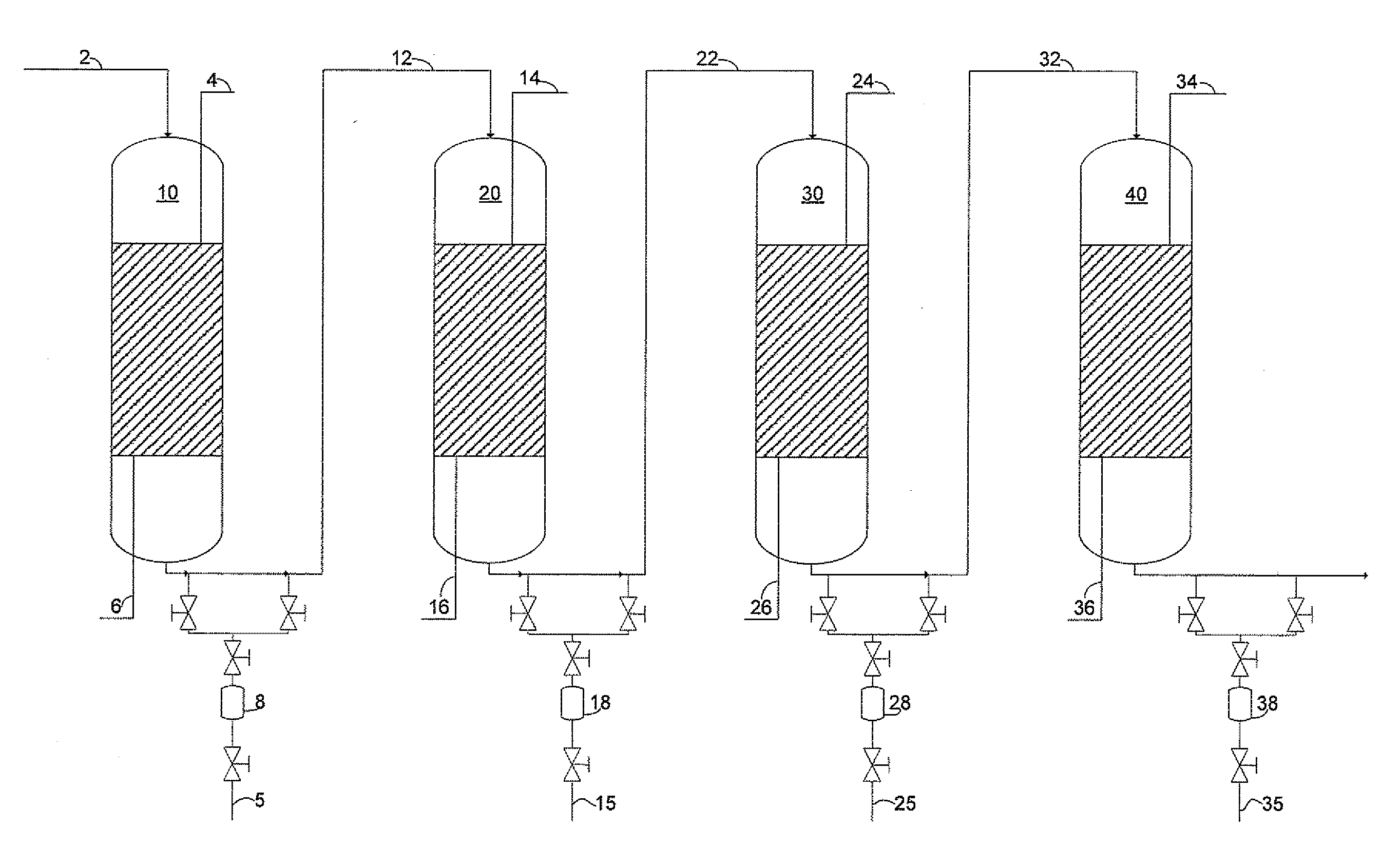

Hydroprocessing light cycle oil in liquid-full reactors

ActiveUS20140124407A1High yieldQuality improvementTreatment with plural serial cracking stages onlyCoke ovensNaphthaHydrogen supply

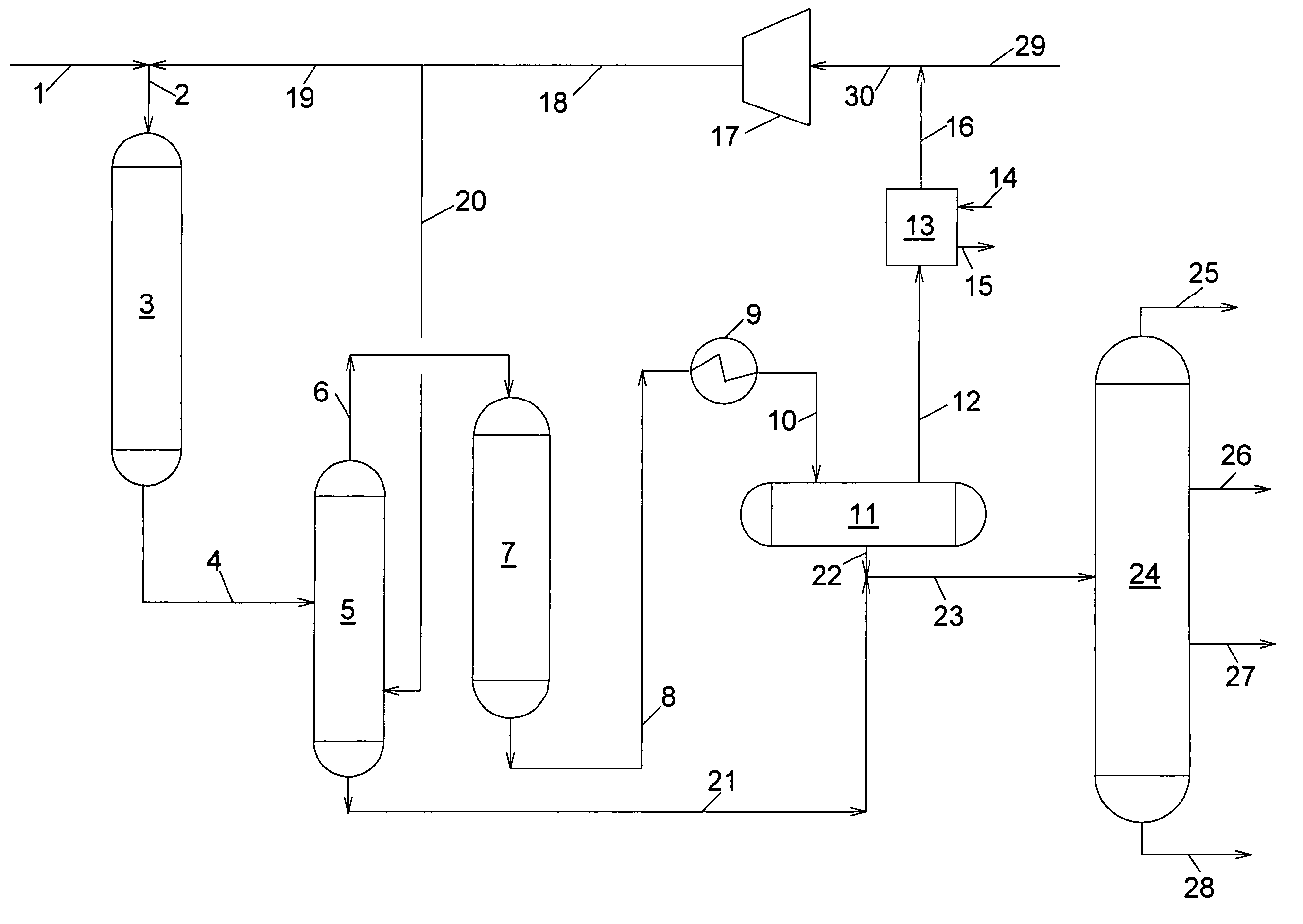

A process for the hydroprocessing of a low value light cycle oil (LCO) hydrocarbon feed to provide a high-value diesel-range product. The process comprises a hydrotreatment stage followed by a hydrocracking stage, each of which is conducted under liquid-full reaction conditions wherein substantially all the hydrogen supplied to the hydrotreating and hydrocracking reactions is dissolved in the liquid-phase hydrocarbon feed. Ammonia and other gases formed during hydrotreatment are removed in a separation step prior to hydrocracking. The LCO feed is advantageously converted to diesel in high yield with little loss of hydrocarbon to naphtha.

Owner:REFINING TECH SOLUTIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com