Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

277results about How to "Low aromatic content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

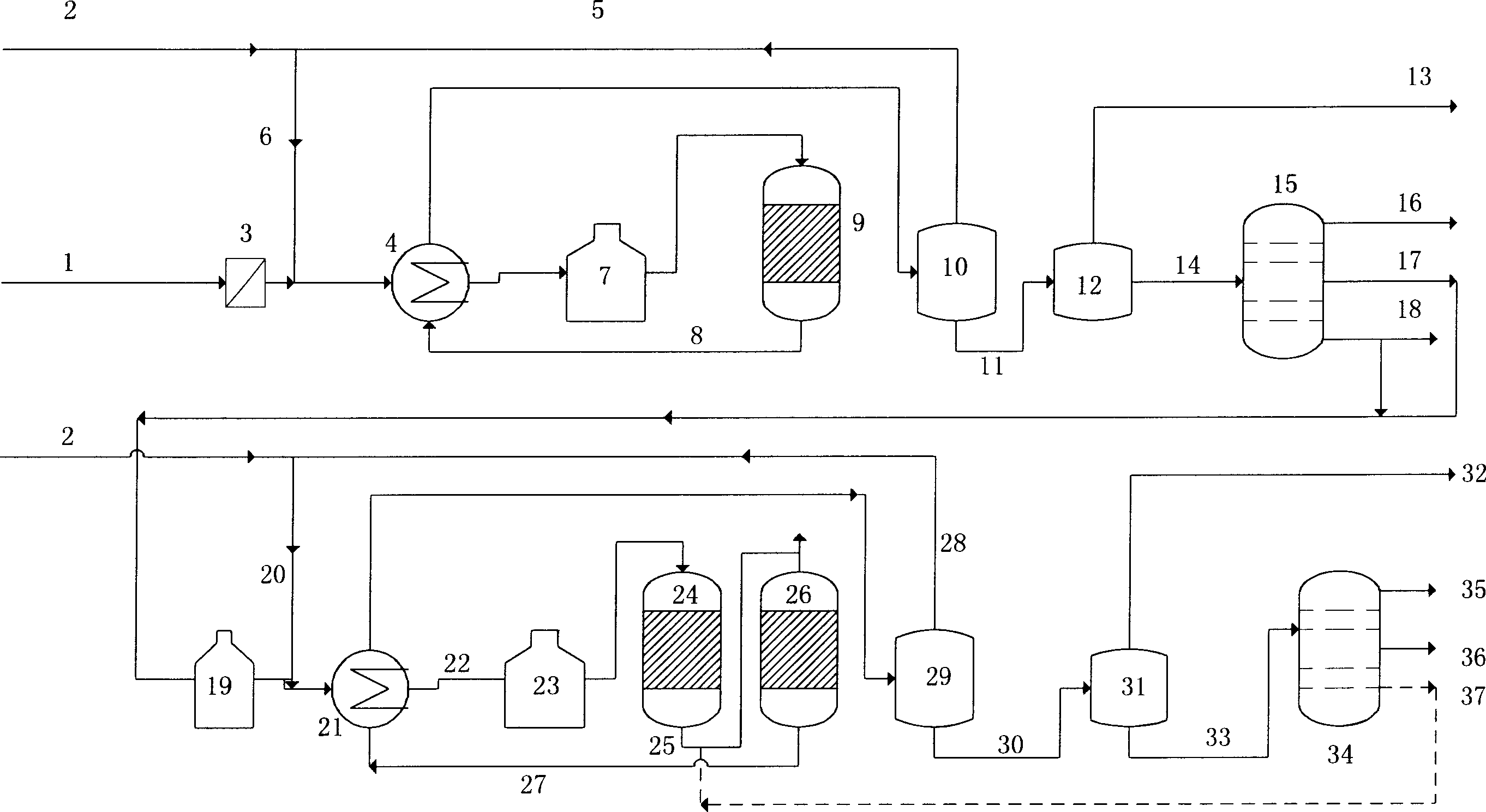

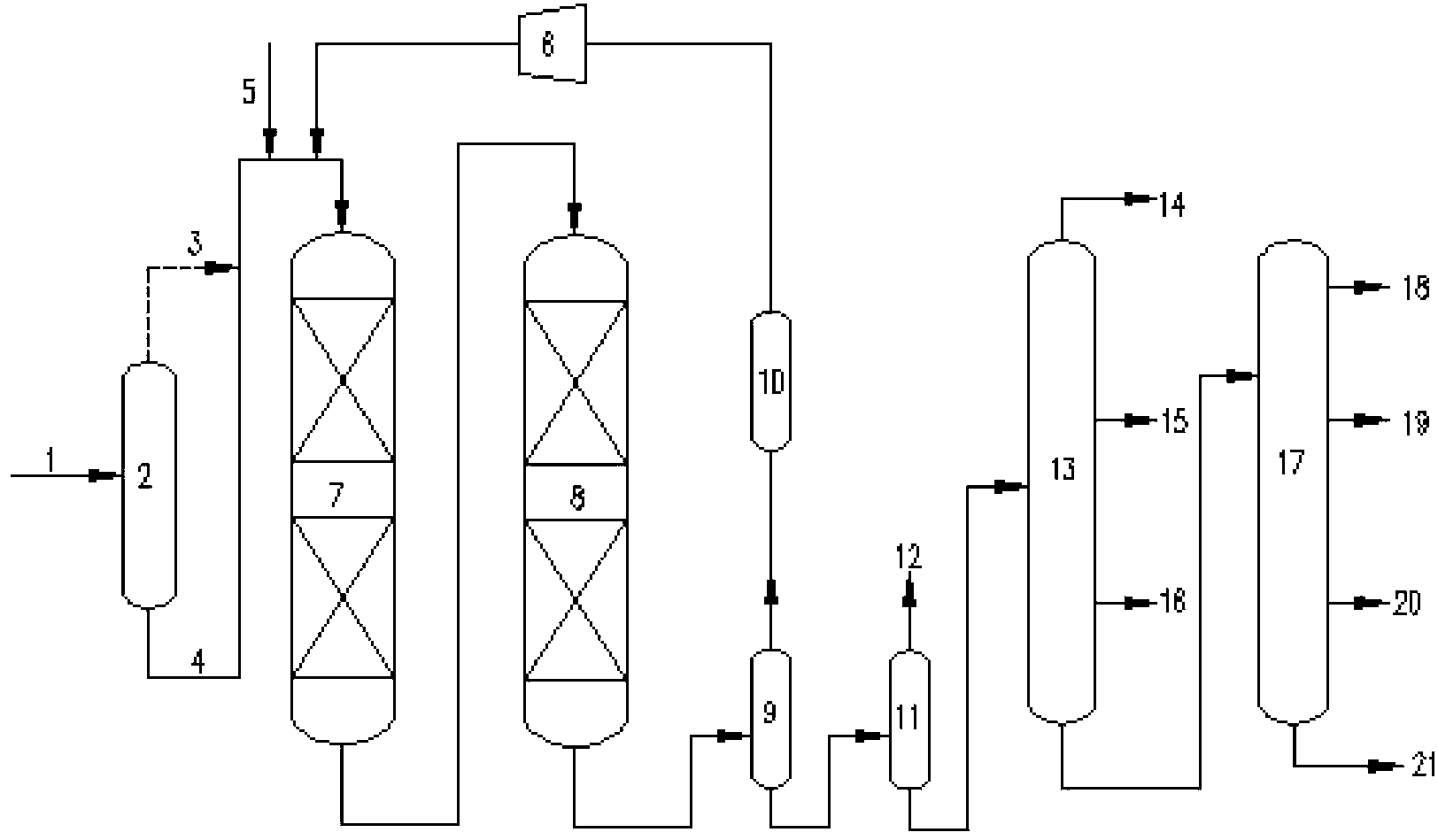

Two-way combined process of wax-oil hydrogenation treatment and catalytic cracking

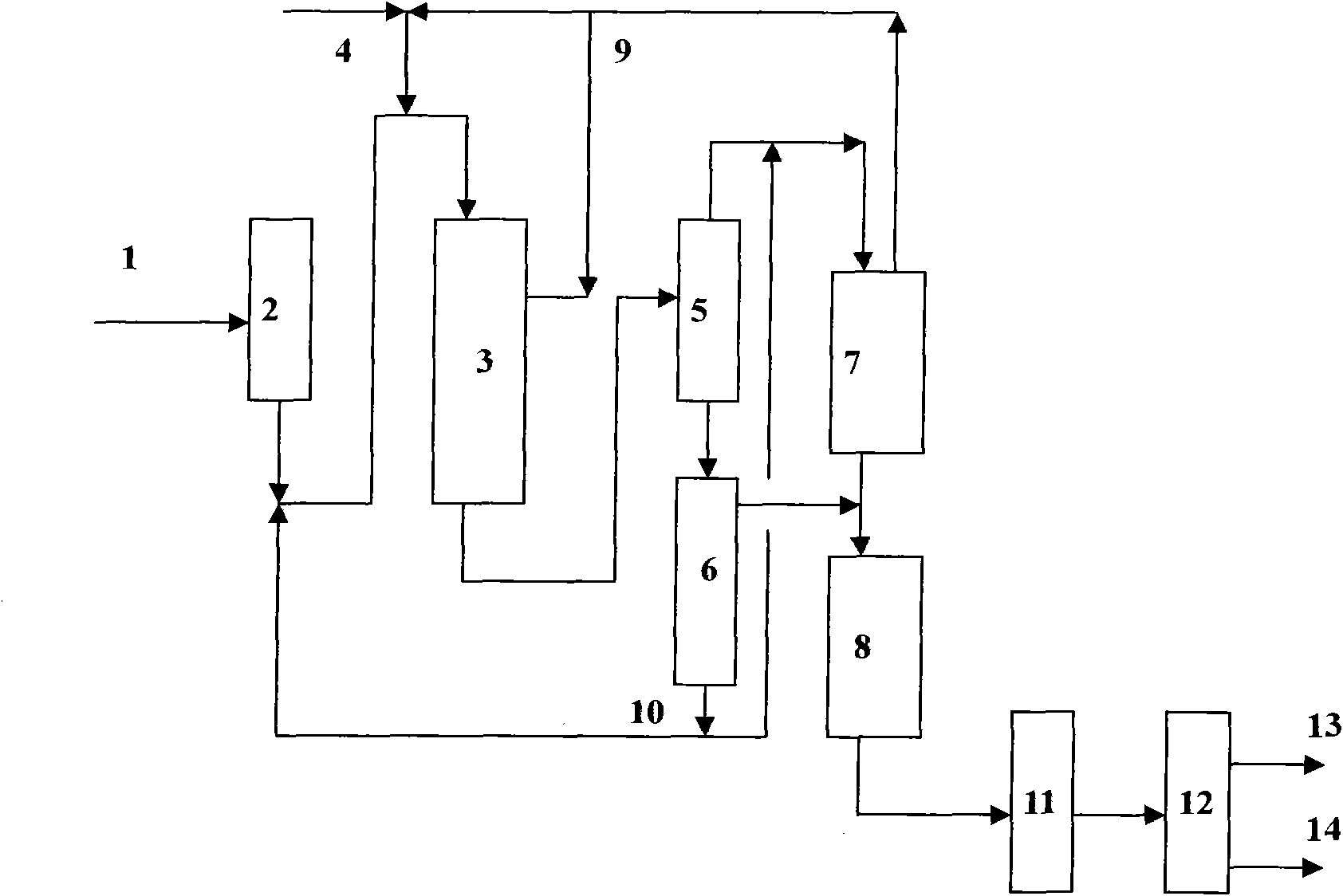

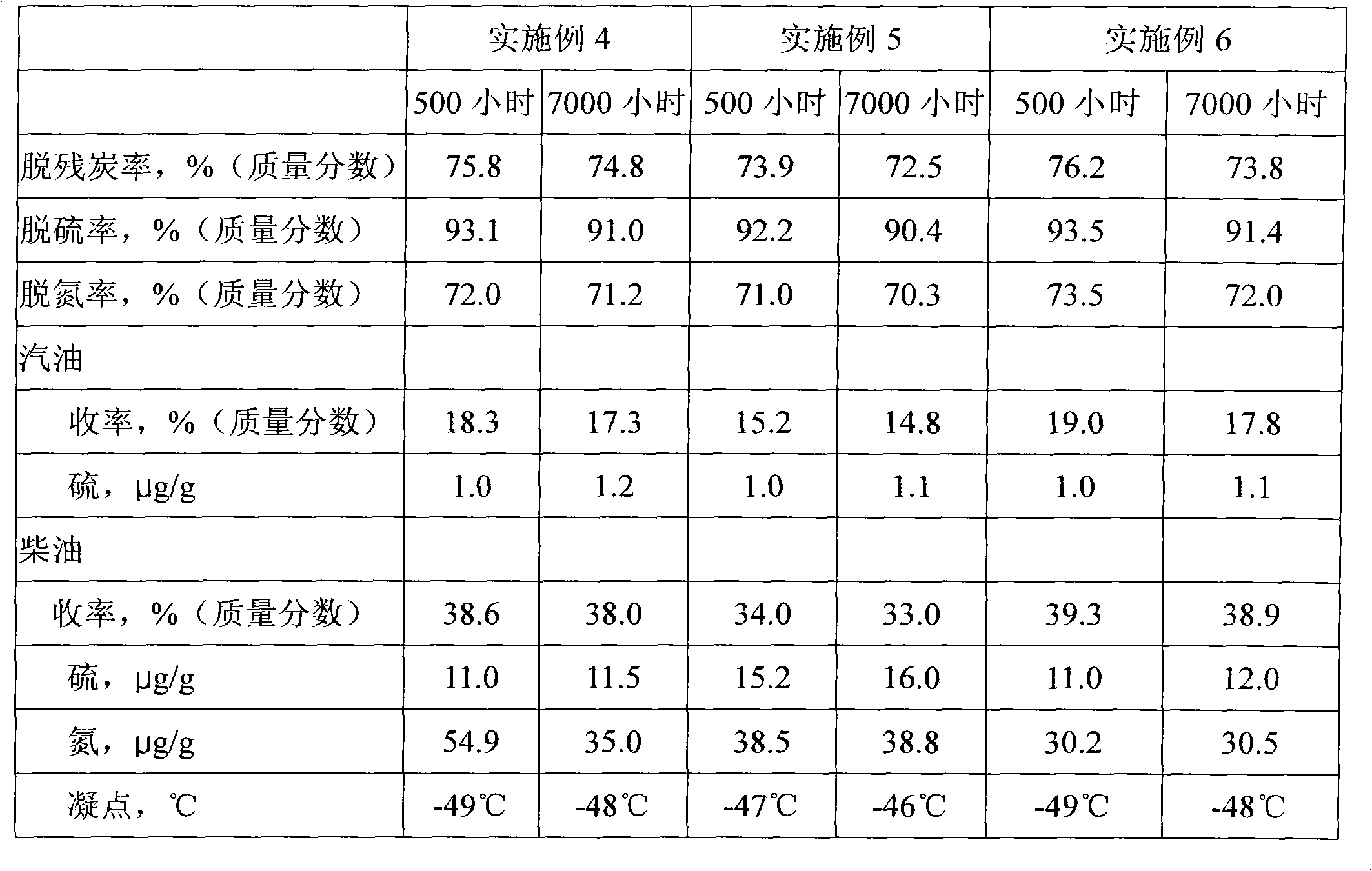

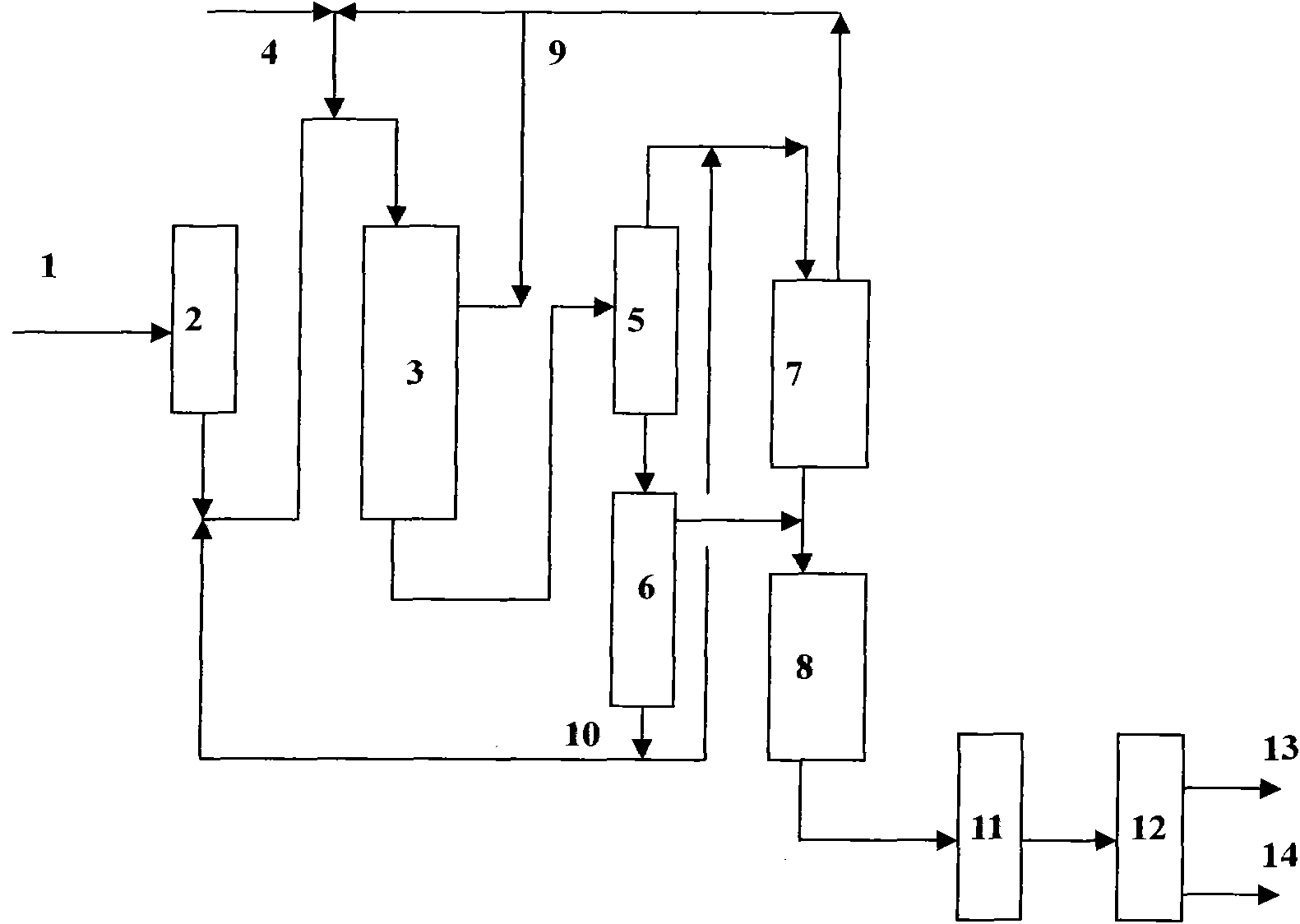

A two-way combined process of wax oil hydro-process and catalytic crack is carried out by entering wax oil, catalytic cracking re-circulating oil and catalytic cracking diesel oil into hydro-processor, hydrogenation reacting under existence of hydrogen and hydrogenation catalyst, separating for reactant to obtain gas, hydrogenation naphtha oil, hydrogenation diesel oil and hydrogenation tail oil, entering hydrogenation tail oil into catalytic cracker, crack reacting under existence of catalytic cracking agent, separating to obtain dry gas, liquefied gas, catalytic cracking gasoline, catalytic cracking diesel oil and catalytic cracking re-circulating oil and oil slurry, and circulating for catalytic cracking diesel oil and catalytic cracking re-circulating oil to hydro-processor. It has higher recovery rate and cetyl value, less sulfur content, arene content and coke output.

Owner:CHINA PETROLEUM & CHEM CORP +1

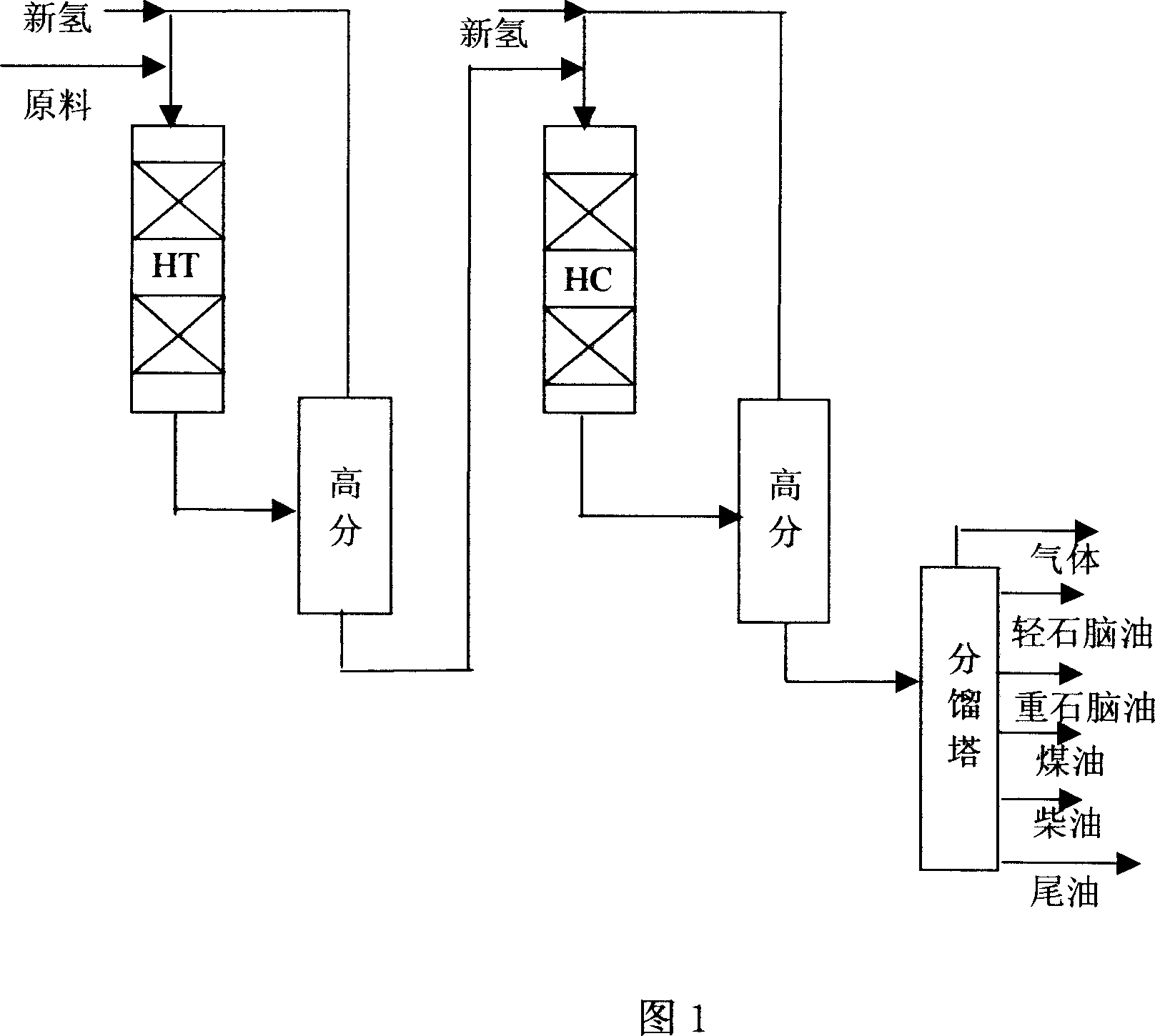

Two-stage hydrocracking method

ActiveCN1955262AEfficient processingLow BMCITreatment with hydrotreatment processesHexadecaneNaphtha

This invention discloses a poor quality catalytic cracking diesel hydrogenation method. This invention includes two stages hydrocracking dealing with catalytic cracking diesel, especially the poor quality catalytic cracking diesel from catalytic hydrogen transfer process. The density of the related poor quality catalytic cracking diesel is 0.90g / ml at 20deg.C, and its aromatic hydrocarbon is over 60wt%, and the value of hexadecane is less than 30. Mixing poor quality catalytic cracking diesel and heavy cracking material and conducting hydrogenation, hydrocracking is conducted after removal of sulphur, nitrogen and other impurities from reaction oil. It is a sufficient utilization of the feature that low hydrogen and high aromatic hydrocarbon content of catalytic cracking diesel to produce Gaofangqian heavy naphtha in order to realize the effective utilization of the poor quality catalytic cracking diesel.

Owner:CHINA PETROLEUM & CHEM CORP +2

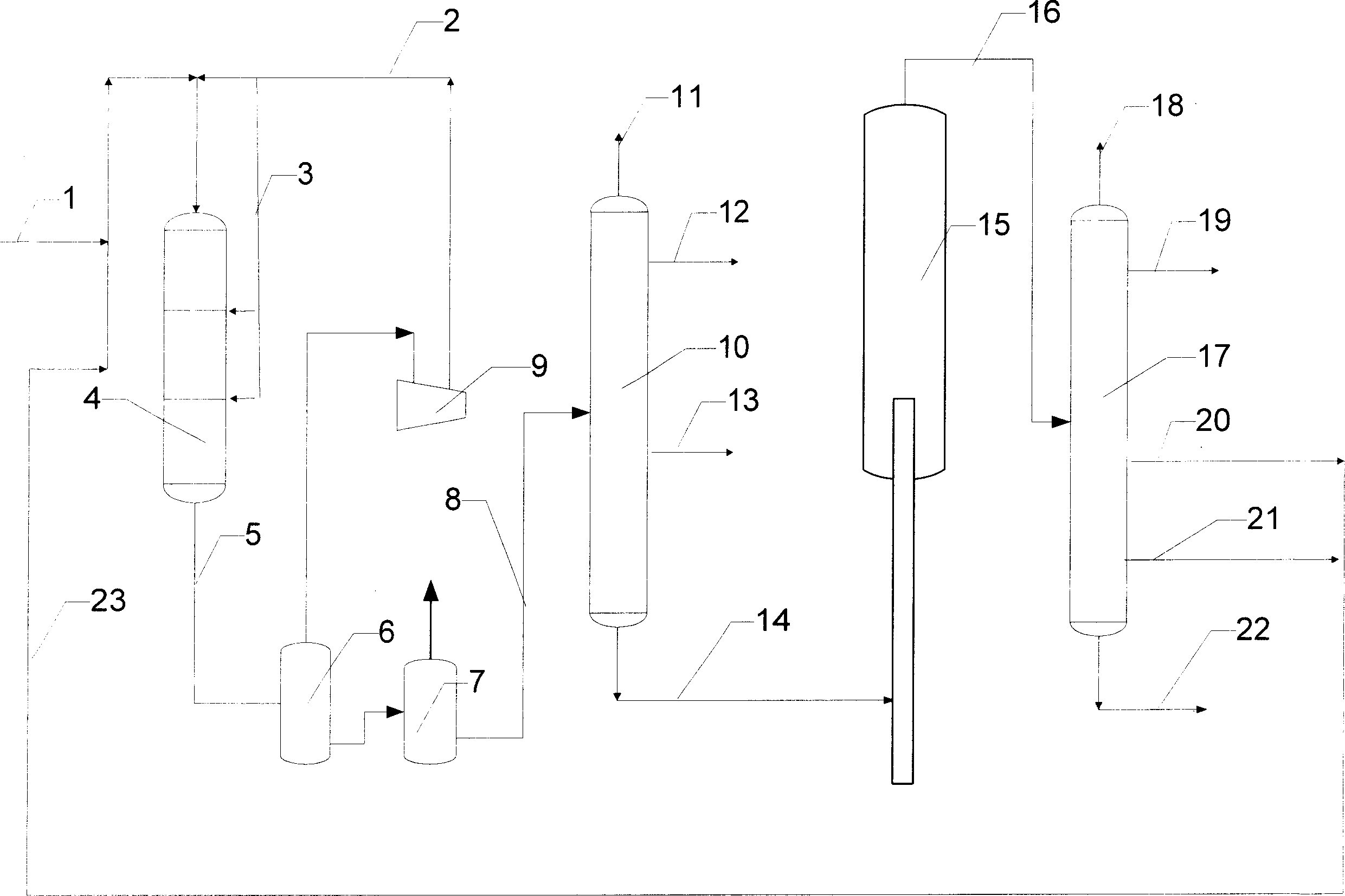

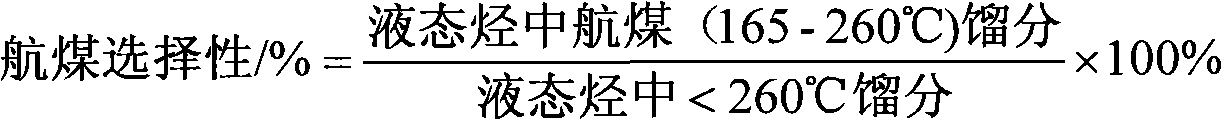

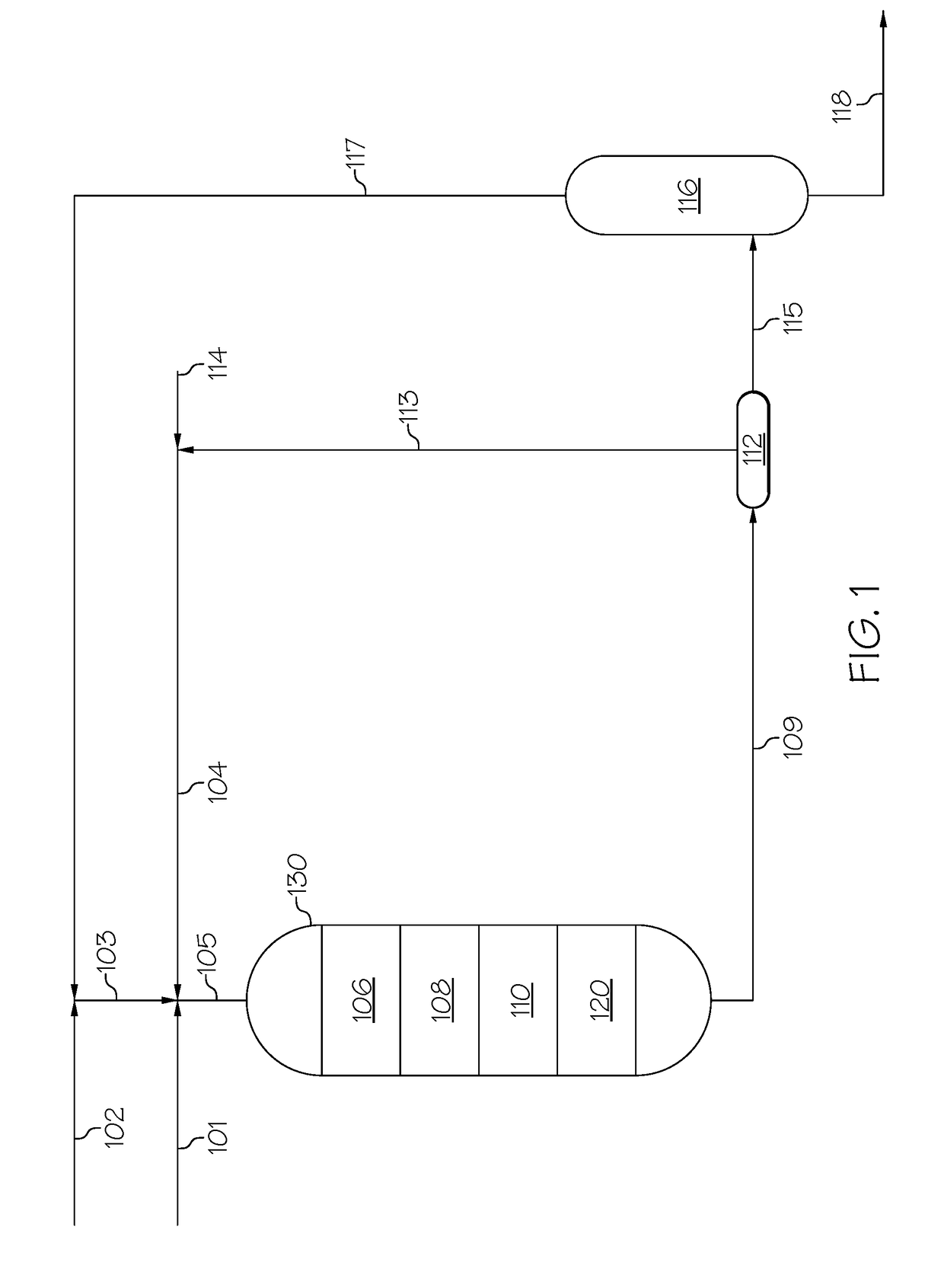

Hydrocracking method for selective increasing of aviation kerosene yield

ActiveCN103013559AGuaranteed selectivityQuality improvementTreatment with hydrotreatment processesHydrogenSmoke point

The invention discloses a hydrocracking method for selective increasing of an aviation kerosene yield. The hydrocracking method comprises that raw oil and hydrogen are mixed and then orderly undergo a hydrofinishing reaction and a hydrocracking reaction; a reaction effluent is cooled and is subjected to separation so that a heavy diesel fraction is obtained; and the heavy diesel fraction having the content of 10 to 100% and a temperature of 320 to 370 DEG C is fed back to a raw material tank and then undergoes a reaction sequentially, wherein the heavy diesel fraction has low aromatic hydrocarbon content and naphthenic hydrocarbon content and is an appropriate fraction for selective increasing of aviation kerosene yield. The hydrocracking method realizes high selectivity of an aviation kerosene fraction. The recycle heavy diesel fraction is fed into the raw material tank and undergoes a hydrofinishing reaction in a hydrofinishing reactor and a hydrocracking reaction in a hydrocracking reactor so that an aromatic hydrocarbon further undergoes a hydrogenation saturation reaction. Therefore, the hydrocracking method is conducive to improvement of a smoke point of aviation kerosene and reduction of aromatic hydrocarbon content of aviation kerosene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of hydro up grading isomerizing pour point depression to produce diesel oil

ActiveCN1718683ALittle impact on yieldExtended operating cycleHydrocarbon oils refiningNaphthaSulfur

A process for preparing the clean diesel oil by hydromodifying, isomerizing and lowering pour point features that the fractional oil raw material and H2 pass through a catalyst bed to obtain clean high-quality diesel and the naphtha product with low contents of sulfur and nitrogen and high content of arylhydrocarbon. Said catalyst bed contains hydrocatalyst bed containing beta zeolite (0.5-20 wt.%).

Owner:CHINA PETROLEUM & CHEM CORP +1

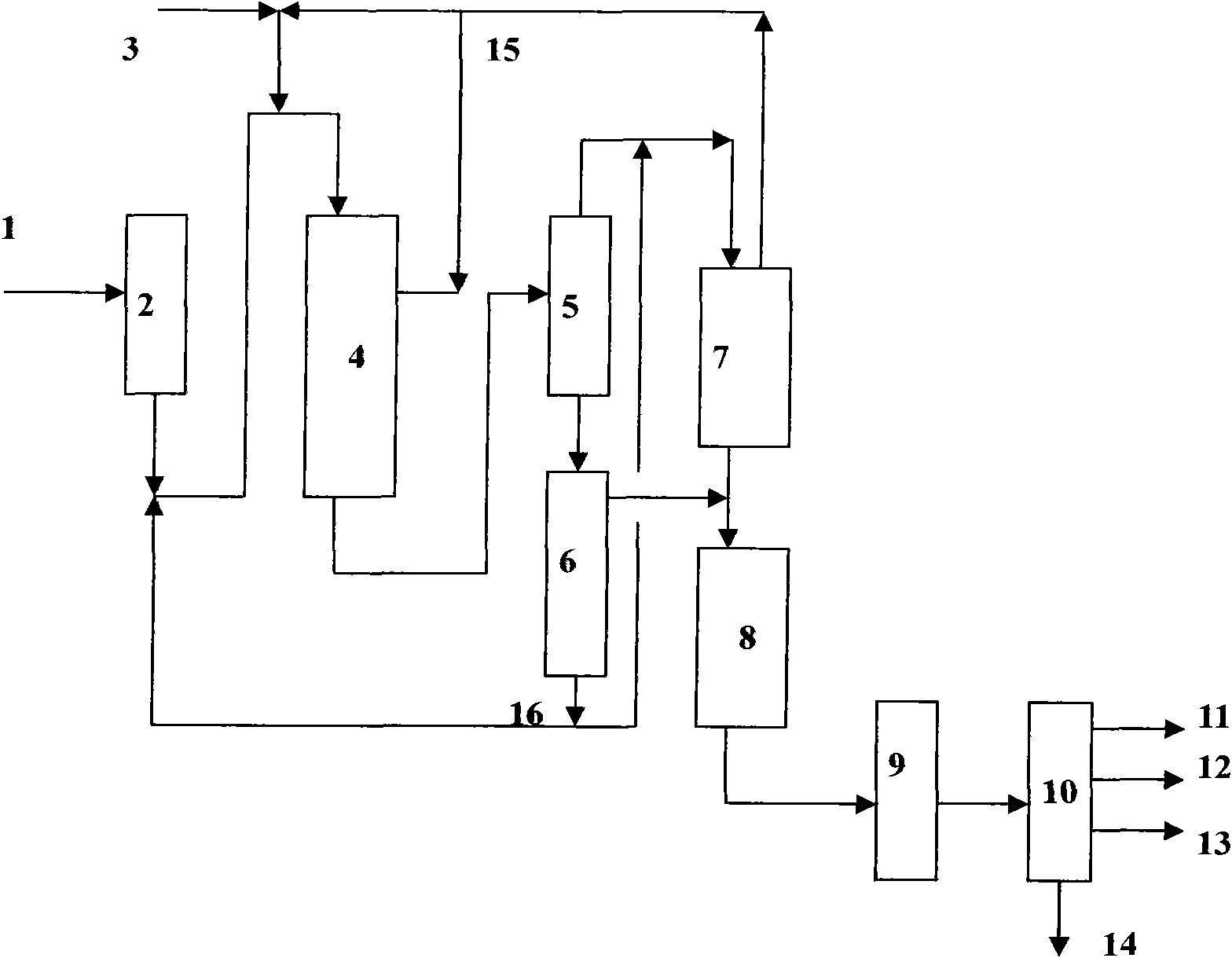

Coal tar hydrogenating modified method by two-stage method

ActiveCN101307257AGood Ring Opening Cracking PerformanceGood nitrogen resistanceTreatment with hydrotreatment processesGas phaseDistillation

The invention discloses a two-stage method coal tar hydro-upgrading method. Coal tar is subject to the atmospheric distillation and / or the reduced pressure distillation and is cut into coal tar light cut and coal tar heavy cut; after the coal tar light cut and optional distillate oil are mixed with hydrogen, the mixture enters a first hydrogeneration reaction zone and performs the contact reaction with hydrorefining catalyst; gas phase impurities of a reaction effluent is removed through an intermediate flash distillation column or a high-pressure stripping tower, and then the reaction effluent enters a second hydrogeneration reaction zone to perform the contact reaction with the hydro-upgrading catalyst or the hydrocracking catalyst; and the obtained reaction effluent is cooled, separated and fractionated to produce diesel fraction and naphtha cut. The invention provides a clean and effective coal tar processing and utilizing method, the coal tar light cut is hydro-upgraded to produce diesel oil for vehicles, the sulfur content of the obtained diesel product is less than 50 mu g / g, the content of polycyclic aromatic hydrocarbon is less than 11 weight percent, and the diesel oil cetane number of the product is improved by not less than 20.

Owner:CHINA PETROLEUM & CHEM CORP +1

Systems and methods of improving diesel fuel performance in cold climates

InactiveUS7354462B2Reduce yieldIncrease cetane numberNon-fuel substance addition to fuelCombustion enginesParaffin waxPetroleum product

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

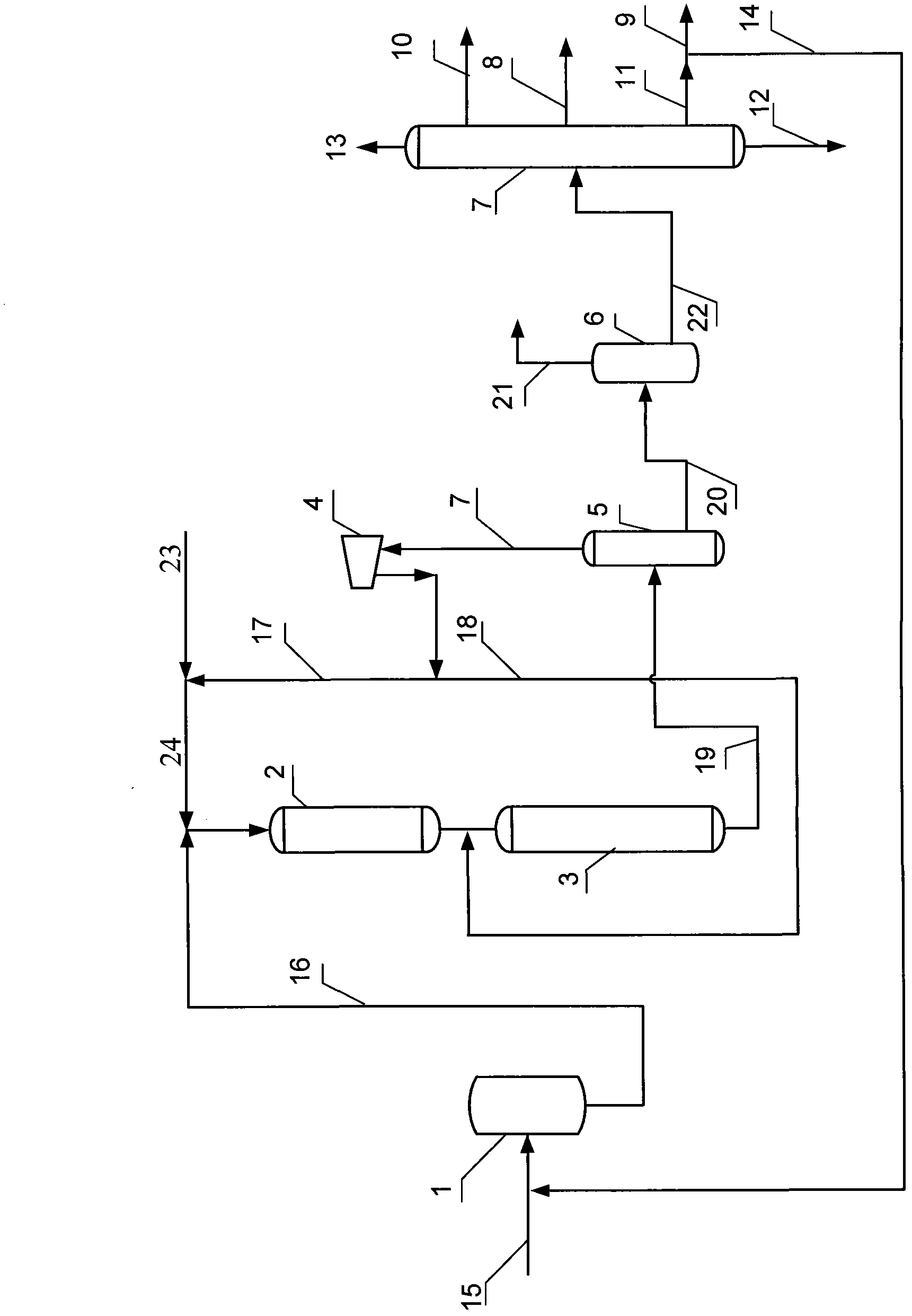

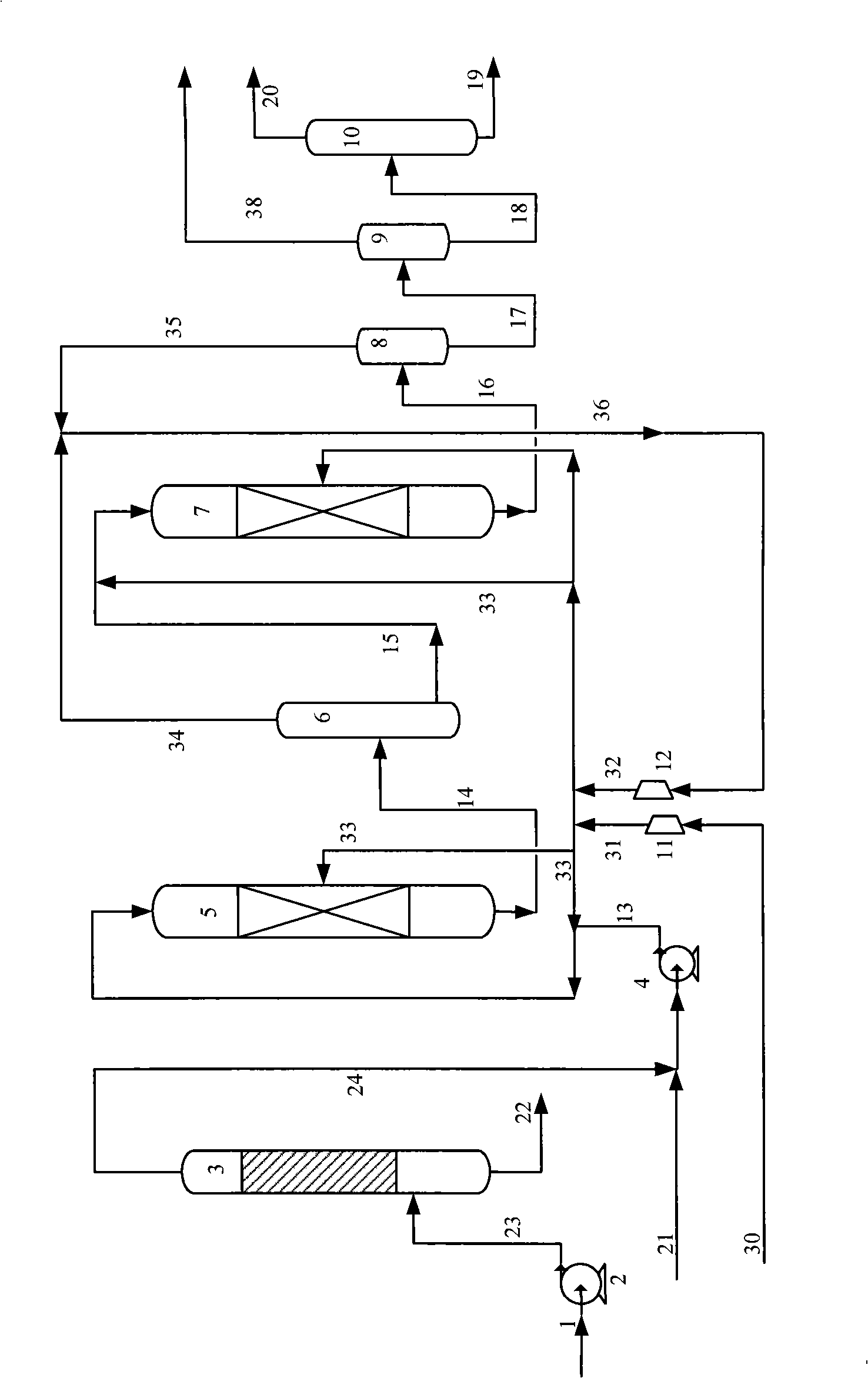

Process for greatly preparing hihg-quality diesel oil or jet fuel from liquefied coil oil

A process for preparing high-quality diesel oil or jet fuel from liquefied coal oil with the highest output includes filtering, stable hydrogenation to obtain diesel oil fraction and tail oil fraction, modifying them by deep hydrogenation, separating its product to obtain gas, naphtha fraction, diesel oil fraction, jet fuel, and tail oil fraction, and cyclic use of hydrogen-enriched gas. Its advantages are high output rate of diesel oil (more than 70 wt.%), low contents of S and N, low density and high hexadecane number.

Owner:CHINA PETROLEUM & CHEM CORP +1

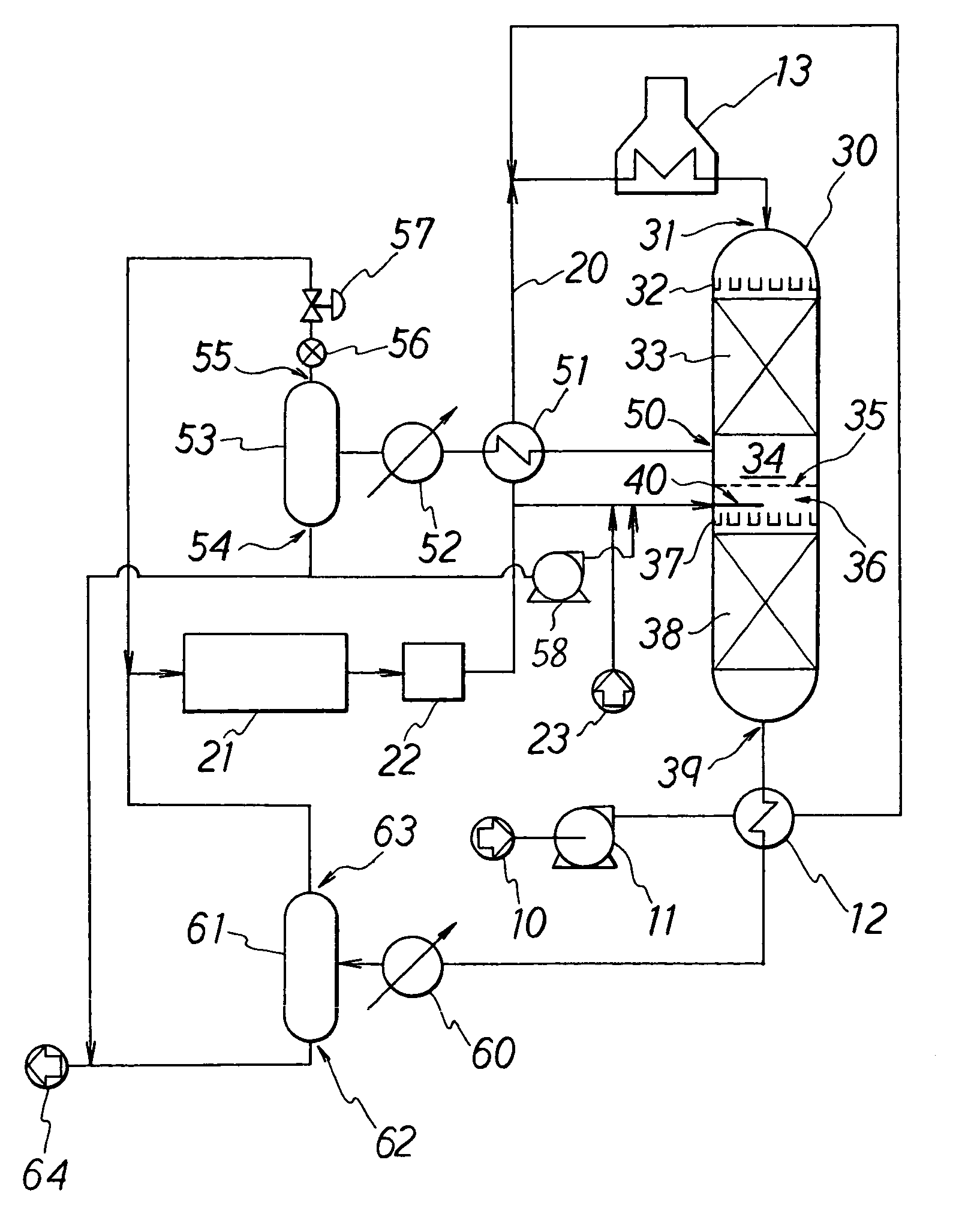

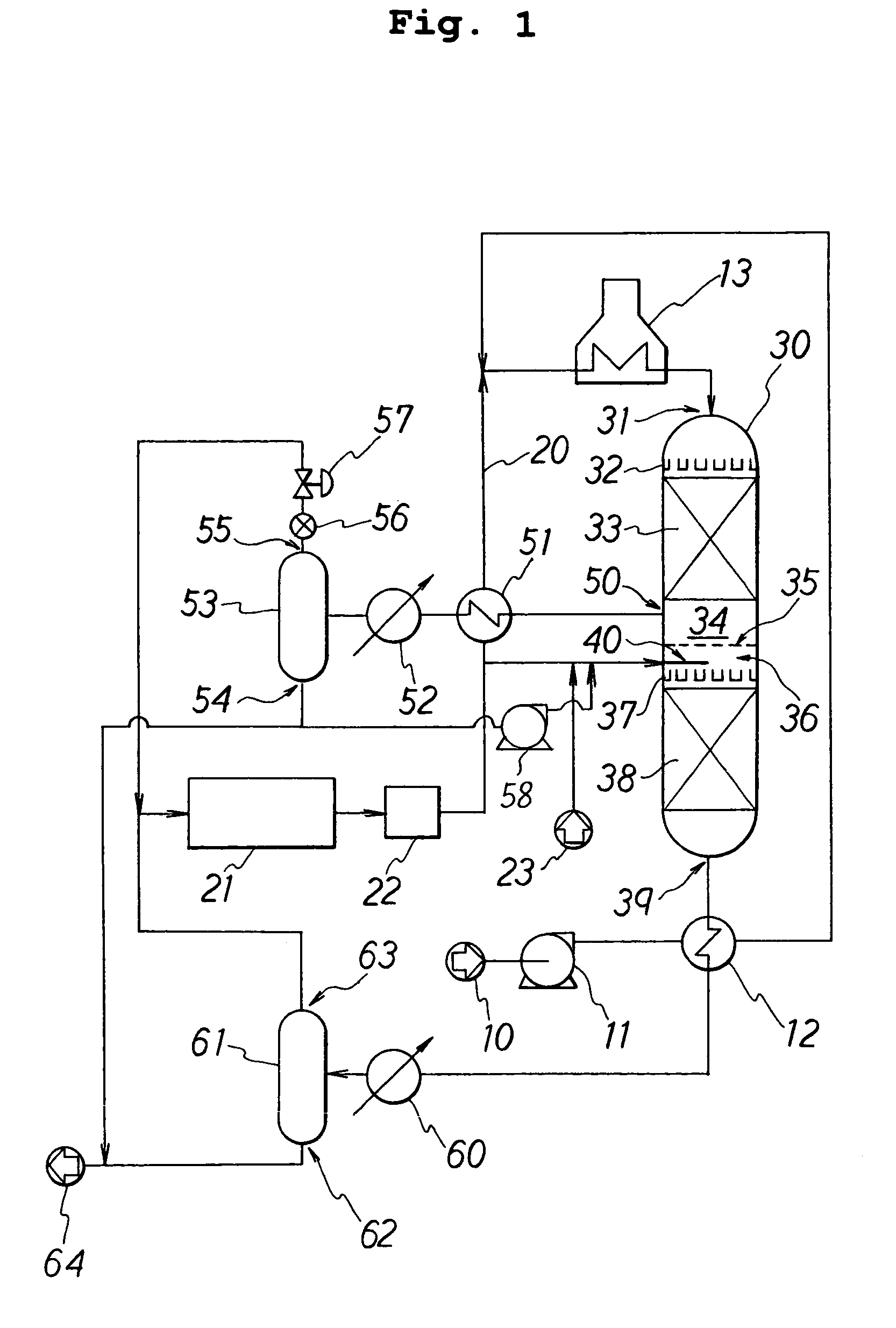

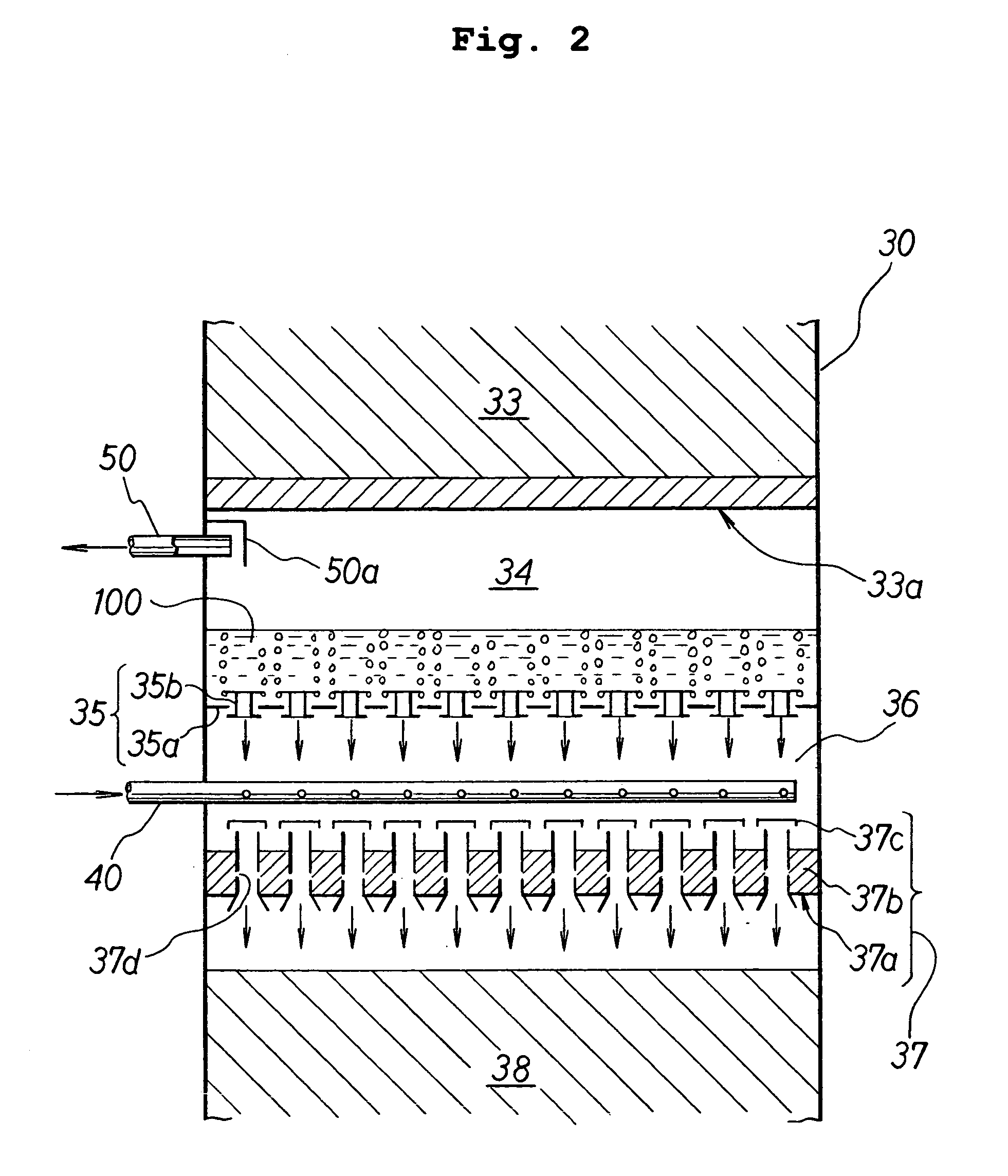

Method and apparatus for stripping sulfur-containing compounds from hydrocarbon feed stock in hydrorefining of petroleum distillates

InactiveUS7001503B1Reduce contentSimple structureHydrocarbon oil crackingTreatment with hydrotreatment processesDistillates petroleumHydrogen

A unit for hydrorefining of hydrocarbon crude oil comprising sulfur-containing compounds comprises first catalyst layer 33 and second catalyst layer 38, top space 34 for separating vapor component and liquid component, bottom space 36, and valve tray 35 that divides top space 34 and bottom space 36. Hydrogen released from hydrogen nozzle 40 placed in the bottom space is passed through liquid component that has accumulated in the valve tray and stripping of liquid components is performed. Hydrogen released from hydrogen nozzle 40 is again introduced, to second catalyst layer 38 as a cocurrent with the stripped liquid component. By stripping, it is possible to reduce the sulfur content, the nitrogen content and reduce the aromatic content of the hydrocarbon crude oil when compared to the conventional method. Since the hydrorefining unit has a simple structure, the unit can be easily made by modifying existing units.

Owner:JAPAN ENERGY CORP +1

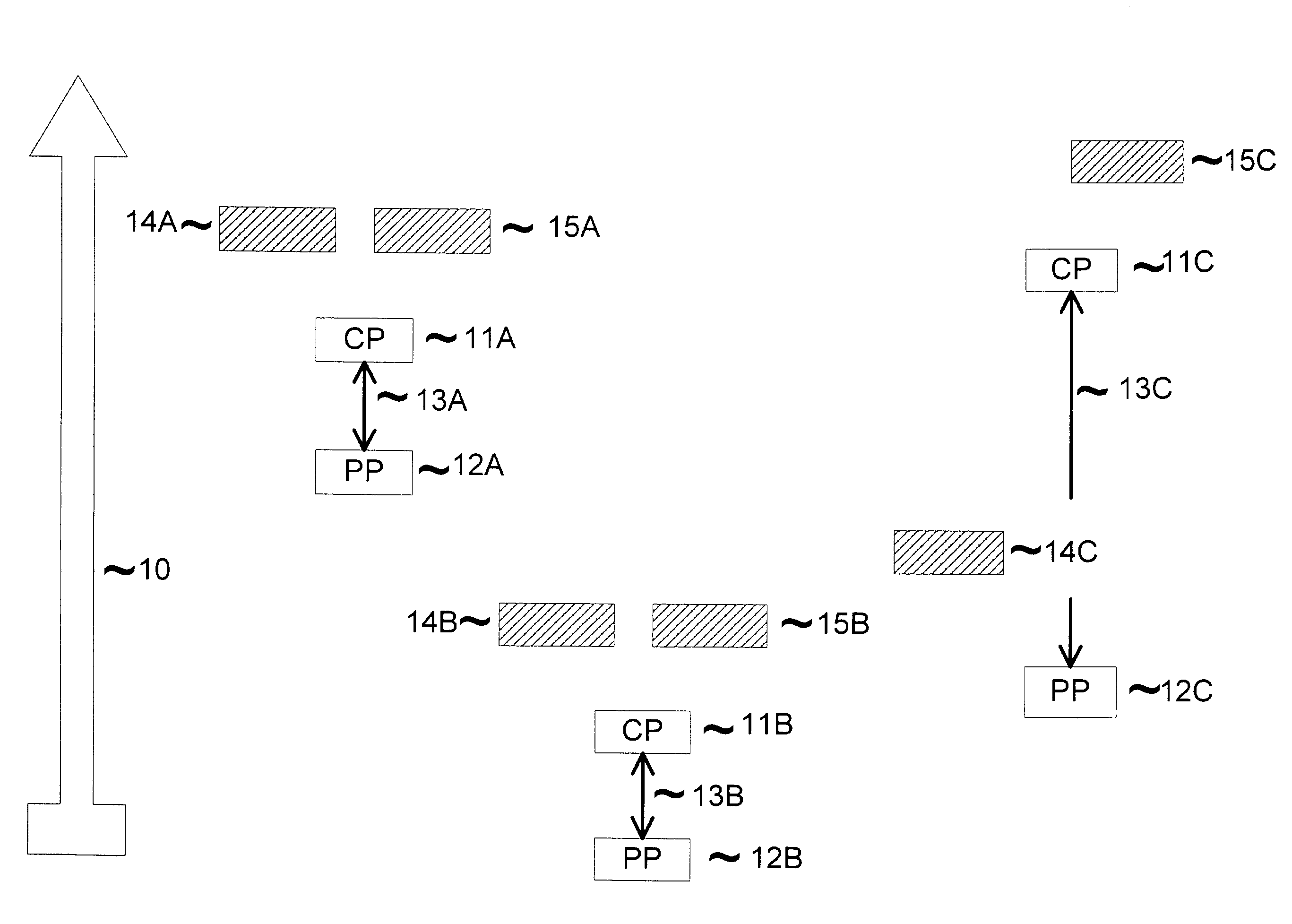

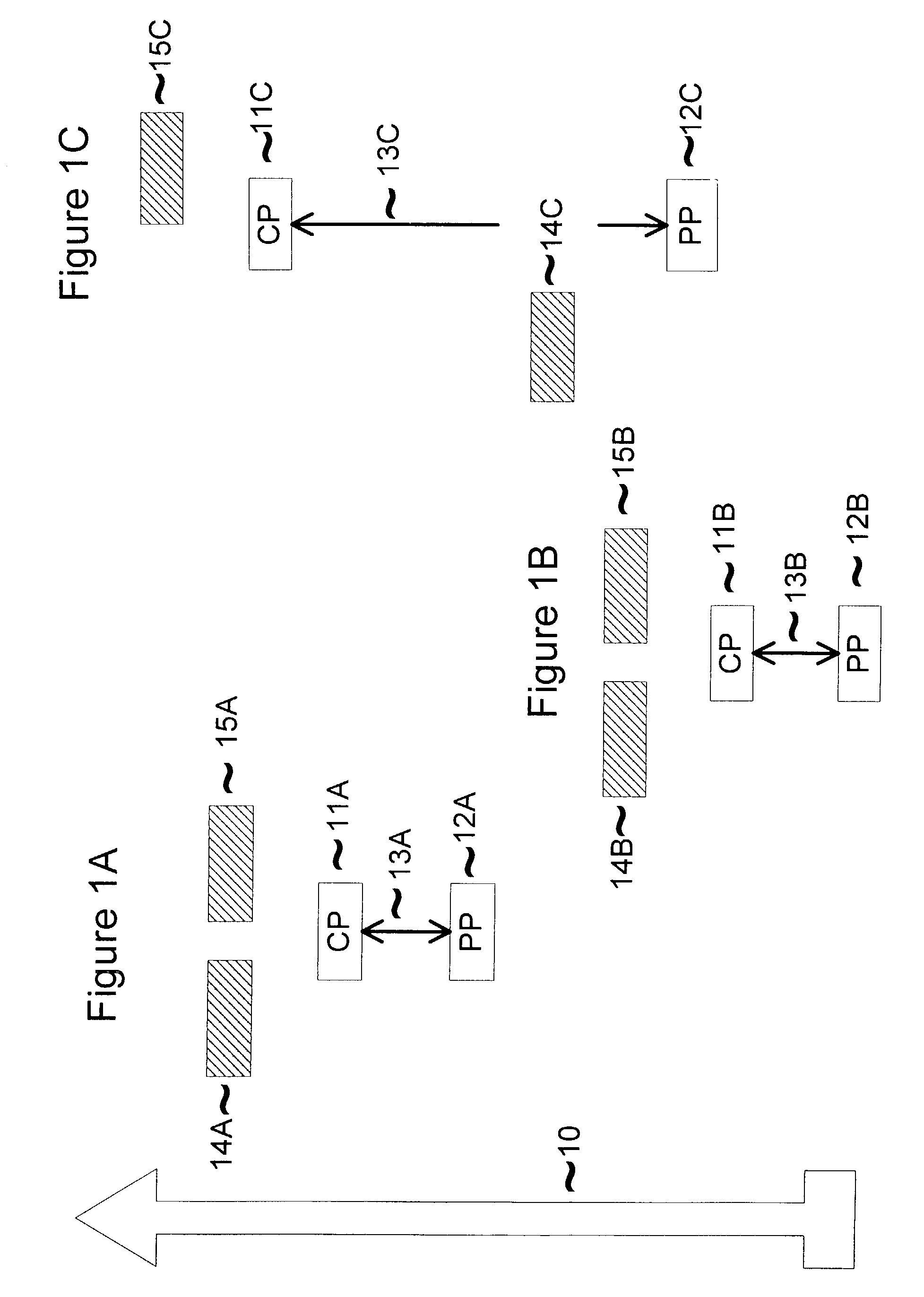

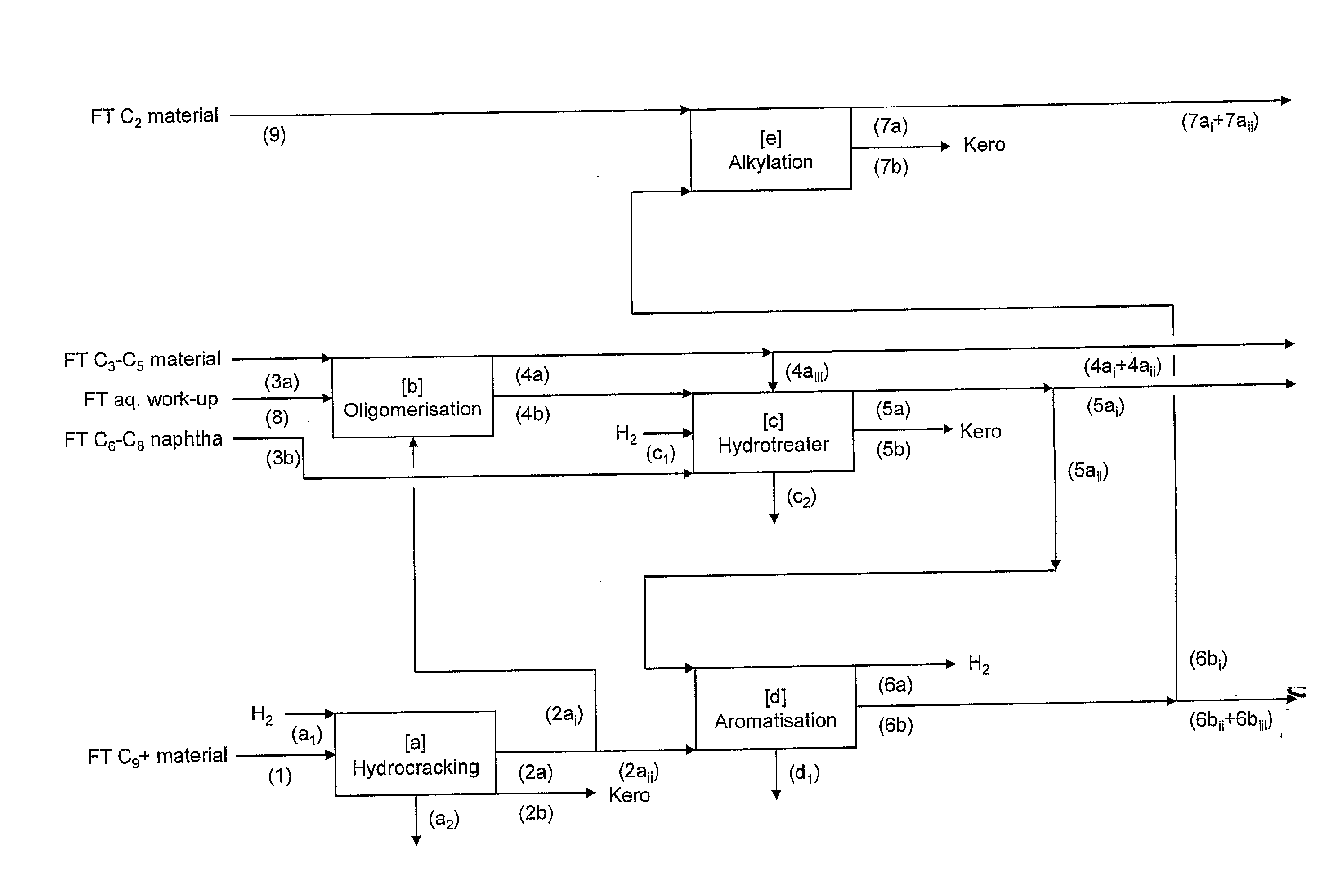

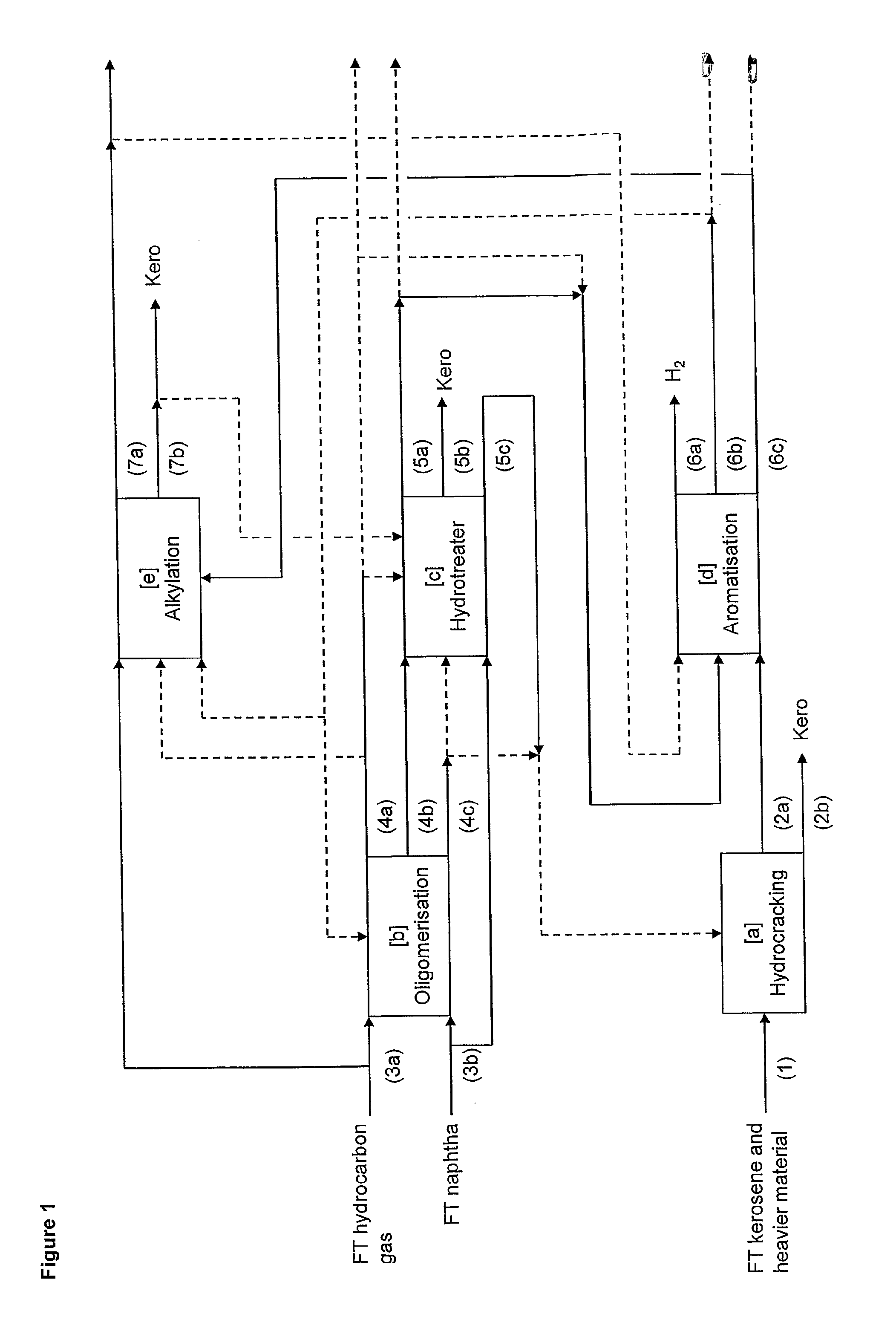

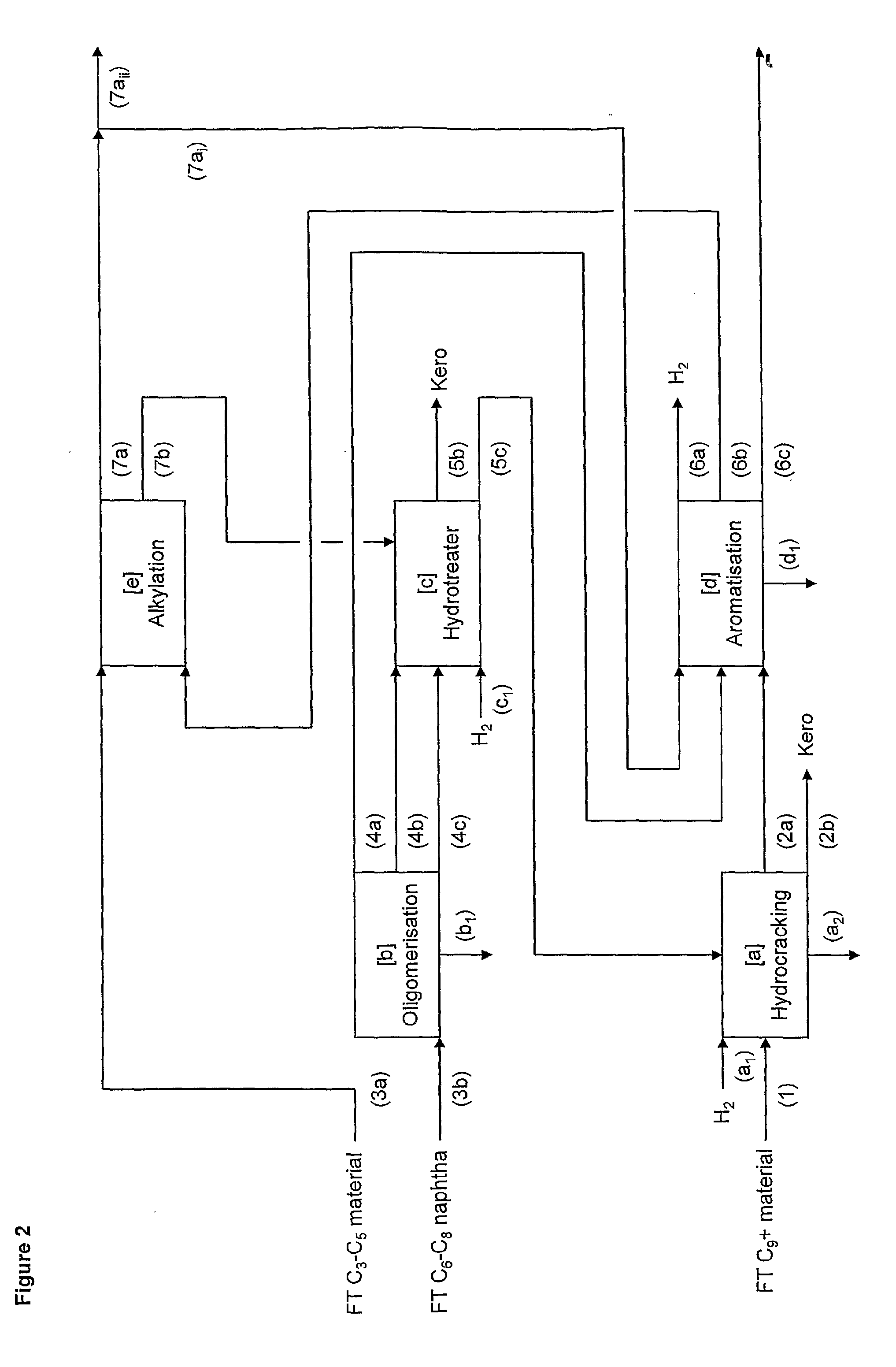

Fischer-tropsch jet fuel process

InactiveUS20100108568A1Reduce complexityMeet specificationsCatalytic naphtha reformingLiquid hydrocarbon mixtures productionAlkyl transferKerosene

The invention provides a Fischer-Tropsch jet fuel refining process which has a jet fuel yield in excess of 60% by mass, said process including at least four of the following five conversion processes: a. hydrocracking one or more of a FT kerosene and heavier material fraction and a C9 and heavier FT syncrude fraction; b. oligomerising an FT syncrude fraction including hydrocarbons in the range C2 to C8; c. hydrotreating one or more of an FT syncrude fraction, a product from process b., and an alkylated FT syncrude fraction; d. aromatizing one or more of an FT syncrude fraction including hydrocarbons in the range C2 to C8, a product from process a., a product from process b, a product from process c., and a product from an aromatic alkylation process; and e. alkylating one or more of an FT syncrude fraction including hydrocarbons in the C2 to C6 range, a product from process b., and a product from process d.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

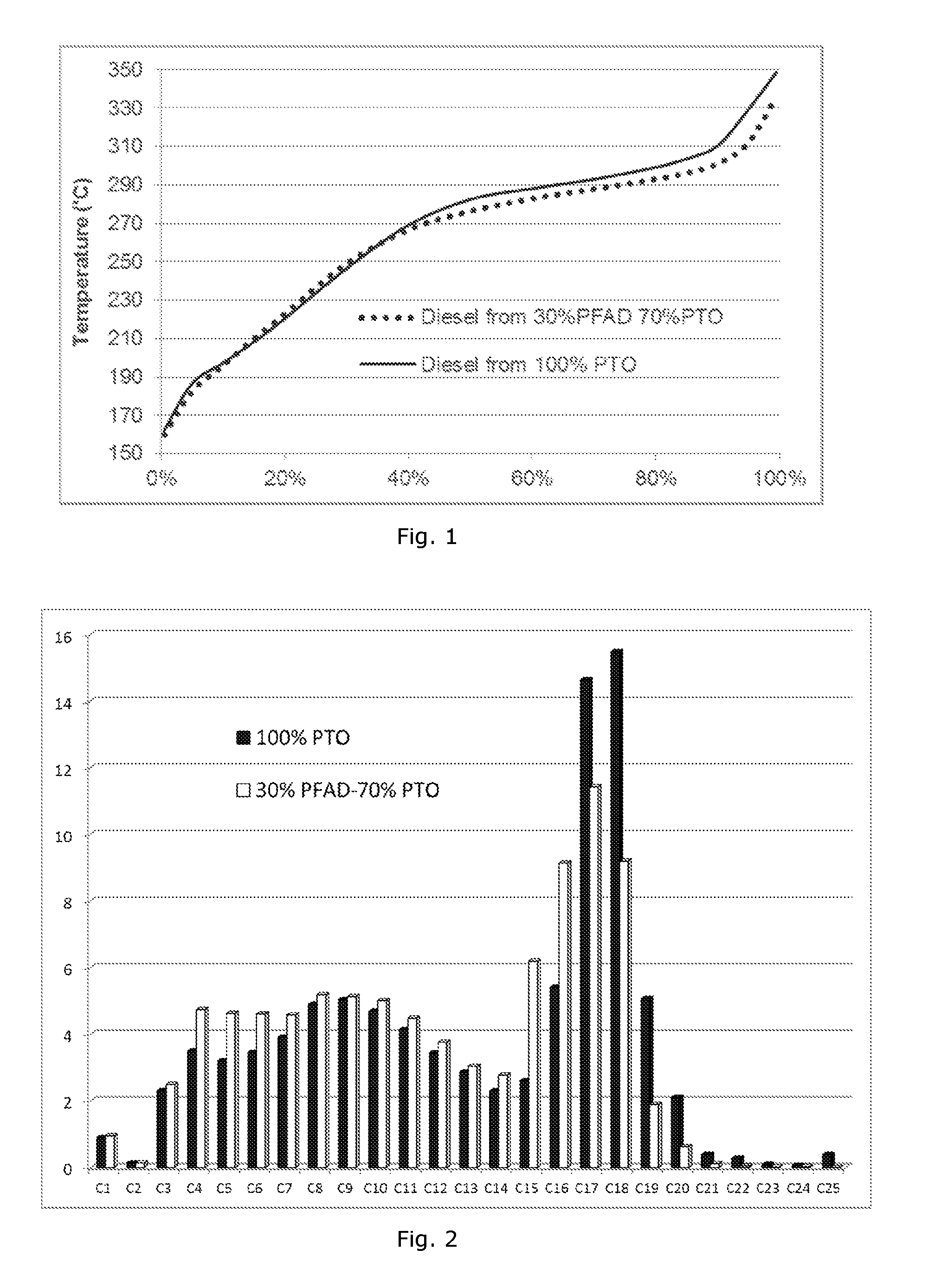

Process for producing hydrocarbons

ActiveUS20160177188A1Improve performanceGuaranteed uptimeRefining to change hydrocarbon structural skeletonLiquid carbonaceous fuelsDiluentFatty acid

The present invention relates to process for producing hydrocarbons, wherein starting material comprising tall oil material and polar co-feed, which polar co-feed comprises fatty acids, is diluted with a non-polar diluent to obtain feedstock, and said feedstock is catalytically hydroprocessed to obtain hydrocarbons, suitable as fuels, fuel blending components and fuel additives.

Owner:UPM-KYMMENE OYJ

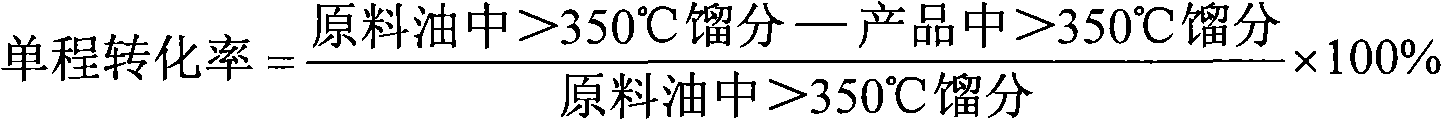

Hydrocracking process for maximally producing middle distillate

InactiveCN1493667ALow aromatic contentIncrease profitHydrocarbon oil crackingTreatment with hydrotreatment processesChemistryPetroleum

A hydrocracking process for increasing the output of intermediate fractional oil to maximum features that the hydrorefined heavy petroleum hydrocarbon is contacted first with the beta-zeolite hydrocracking catalyst for cracking the most of raw material and then with the Y-zeolite hydrocracking catalyst for cracking the rest of raw material. Its advantages are high selectivity and low content of olefin in intermediate fractional oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for the production of hydrocarbon fluids

ActiveUS7311814B2Low sulphur levelPoint become highSilicon organic compoundsPhysical/chemical process catalystsSolventMetal working

Hydrocarbon fluids are produced by hydrocracking a vacuum gas oil stream, fractionating and / or hydrogenating the hydrocracked vacuum gas oil. The fluids typically have ASTM D86 boiling point ranges within the range 100° C. to 400° C. the range being no more than 75° C., they also have a naphthenic content greater than 60%, the naphthenics containing polycyclic materials, an aromatic content below 2% and an aniline point below 100° C. The fluids are particularly useful as solvents, for printing inks, drilling fluids, metal working fluids and as silicone extenders.

Owner:EXXONMOBIL CHEM PAT INC +1

Method for producing propene using silicoaluminophosphate molecular sieve catalytic cracking

ActiveCN1762931ALow purity requirementLow aromatic contentMolecular sieve catalystsBulk chemical productionMolecular sieveHydrocarbon mixtures

The present invention relates to propylene producing catalytically cracking process, and is especially propylene producing process with catalytically cracking aluminum silicophosphate. In fixed bed or fluidized bed reactor and at the conditions of temperature 350-550 deg.c, pressure 0.1-0.3 MPa and space velocity 0.1-300 / hr, dry gas, C4 component and other material are cracked in catalyst containing aluminum silicophosphate molecular sieve SAPO-34. The output hydrocarbon mixture is separated to obtain destination product propylene before the other components are returned to the reactor for circular use. The process of the present invention has low reaction temperature, pressure near normal pressure, simple technological process and high propylene selectivity. The present invention can utilizes dry gas and C4 component effectively.

Owner:TSINGHUA UNIV

Hydrocarbon fluids

ActiveUS7056869B2Limited compatibilityReduce amountOrganic detergent compounding agentsOrganic chemistrySolventMetal working

Hydrocarbon fluids are provided which have ASTM D-86 boiling point ranges within 235° C. to 400° C. and a naphthenic content greater than 60%, the naphthenics containing polycyclic materials, the fluids preferably have an aromatic content below 2% and an aniline point below 100° C. The fluids are particularly useful solvents for printing inks, drilling fluids, metal working fluids and as silicone extenders.

Owner:EXXONMOBIL CHEM PAT INC

Method for producing super-low sulfur gas oil blending component or super-low sulfur gas oil composition, and super-low sulfur gas oil composition

InactiveUS7938955B2Reduce sulfur contentLow aromatic contentRefining with metalsLiquid carbonaceous fuelsAdverse effectFuel injection

Provided are a method for producing a super-low sulfur gas oil blending component or a super-low sulfur gas oil composition having a sulfur content of less than 5 mass ppm, under relatively mild conditions, without greatly increasing the hydrogen consumption and without remarkably decreasing the aromatic content; and a super-low sulfur gas oil composition having a sulfur content of less than 5 mass ppm which exhibits a high heating value, is excellent in fuel economy and output power, and is free from an adverse effect on a sealing rubber member or the like used in the fuel injection system and thus does not cause the leakage of a fuel. A method for producing a super-low sulfur gas oil blending component or a super-low sulfur gas oil composition having a sulfur content of less than 5 mass ppm is also disclosed.

Owner:JAPAN ENERGY CORP

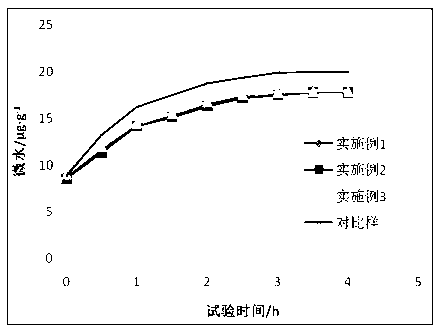

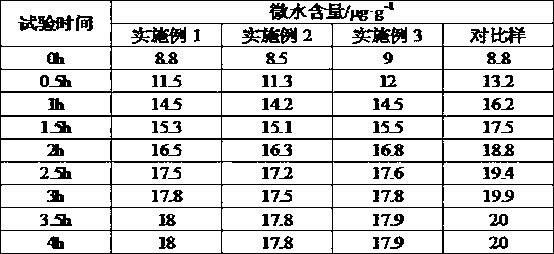

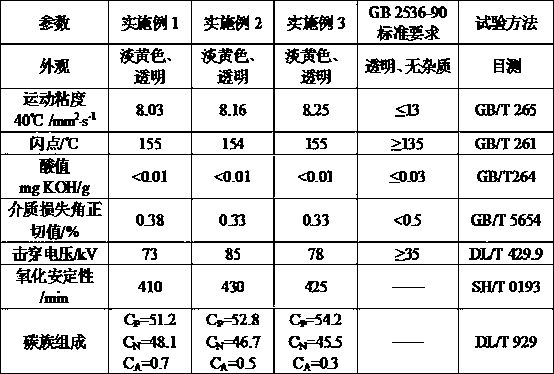

Transformer oil with excellent cooling heat-radiating and moisture preventing properties and preparation method thereof

The invention discloses transformer oil with excellent cooling heat-radiating and moisture preventing properties. The transformer oil is mainly prepared from the following raw materials: hydrogenated stock oil, naphthene thickened oil, an antioxidant and a metal passivator, wherein the ratio of the hydrogenated stock oil to the naphthene thickened oil is (72-82):(18-28) in terms of parts by weight, the amount of the used antioxidant accounts for 0.3-0.5% relative to the total mass of the hydrogenated stock oil and the naphthene thickened oil, and the amount of the used metal pasivator accounts for 0.1-0.2% relative to the total mass of the hydrogenated stock oil and the naphthene thickened oil. The invention further discloses a preparation method of the transformer oil. The transformer oil has excellent cooling heat-radiating and moisture preventing properties, thus being very suitable for being used in southern areas of China.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

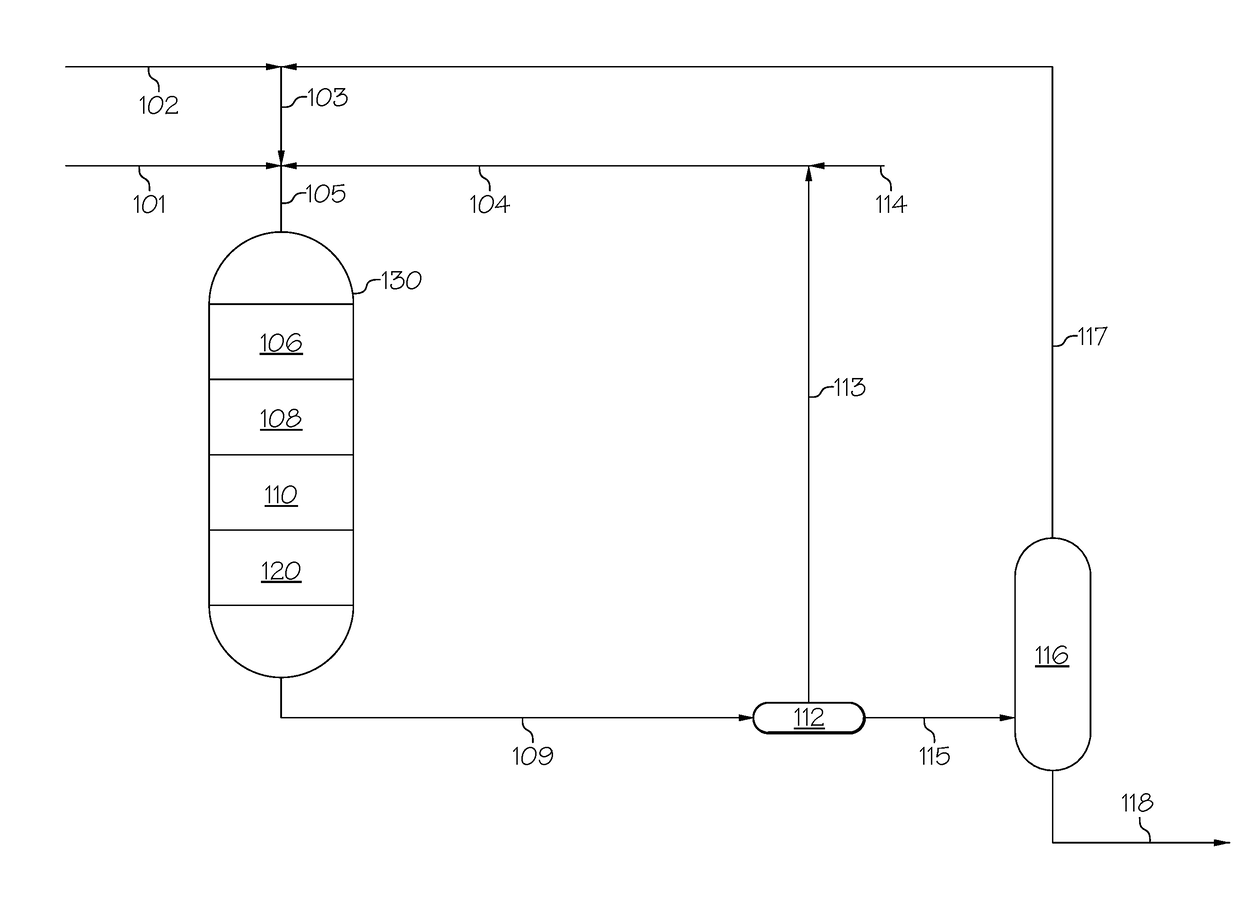

Systems and methods for upgrading heavy oils

ActiveUS20170349846A1Improve functionalityFunction increaseTreatment with hydrotreatment processesRefining to eliminate hetero atomsNitrogenFuel oil

In accordance with one embodiment of the present disclosure, a heavy oil may be upgraded by a process that may include removing at least a portion of metals from the heavy oil in a hydrodemetalization reaction zone to form a hydrodemetalization reaction effluent, removing at least a portion of metals and at least a portion of nitrogen from the hydrodemetalization reaction effluent in a transition reaction zone to form a transition reaction effluent, removing at least a portion of nitrogen from the transition reaction effluent in a hydrodenitrogenation reaction zone to form a hydrodenitrogenation reaction effluent, and reducing aromatics content in the hydrodenitrogenation reaction effluent in a hydrocracking reaction zone by contacting the hydrodenitrogenation reaction effluent to form an upgraded fuel.

Owner:SAUDI ARABIAN OIL CO

Hydrocracking method for blending ethylene tar

ActiveCN102234542AIncrease saturation rateHigh yieldTreatment with hydrotreatment processesChemistryLight crude oil

The invention discloses a hydrocracking method for blending ethylene tar, which comprises the following steps of: blending light fraction of ethylene tar into heavy distillate for hydrocracking, and contacting a hydrogenation protecting catalyst, a hydrogenation refining catalyst, a hydrogenation carbon residue removing catalyst and a hydrocracking catalyst in the presence of hydrogen to obtain hydrocracking crude oil, wherein partial hydrocracking crude oil is circulated and mixed with the light fraction and heavy distillate of the ethylene tar to enter a hydrocracking area, and the rest hydrocracking crude oil is future separated to obtain light fuel oil. By the method, the problem of high temperature rise of a hydrogenation reactor bed can be effectively solved; meanwhile, a method of grading the hydrogenation catalysts, the light fraction of the ethylene tar can be processed, and diesel with high cetane number and low condensation point and naphtha with high potential aromatic content can be produced; and compared with a state that the ethylene tar is not blended, the method has the advantage that the bureau of mines correlation index (BMCI) value of tail oil and the smoke point of jet fuel are not obviously changed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for hydrogenation of medium-low temperature coal tar to produce large-specific weight aviation kerosene

ActiveCN103789034AImprove featuresExcellent carbon deposition performanceTreatment with hydrotreatment processesKeroseneFractionation

The invention discloses a method for hydrogenation of medium-low temperature coal tar to produce large-specific weight aviation kerosene. The method includes: fractionating the medium-low temperature coal tar to obtain light fraction and heavy fraction, mixing the light fraction with hydrogen and leading the mixture into a hydrotreating reaction area to contact a hydrogenation protective catalyst and a hydrofining catalyst in order to undergo hydrogenation reaction; separating the hydrofining effluent, making the obtained liquid phase product enter a fractionating tower; bringing the 140-290DEG C kerosene fraction obtained by fractionation into a hydro-upgrading reaction area where a hydro-upgrading catalyst containing amorphous aluminium silicon and modified Y zeolite is adopted, and performing hydro-upgrading reaction in the presence of hydrogen; subjecting the hydro-upgrading effluent into a hydrofinishing reaction area to undergo hydrofinishing reaction, and separating the hydrofinishing product to obtain the large-specific weight aviation kerosene. The method provided by the invention adopts the medium-low temperature coal tar as the raw material to maximumly produce the large-specific weight aviation kerosene with the advantages of high density, volume, high volume calorific value, low aromatic hydrocarbon content, and good low temperature performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation catalyst carrier and production thereof

A carrier of hydrocatalyst for the hydrocracking of heavy oil, hydromodifying of poor diesel oil, etc is prepared from amorphour silicon aluminium, modified beta-molecular sieve and aluminium oxide. Its preparing process is also disclosed. Said catalyst has high catalytic activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

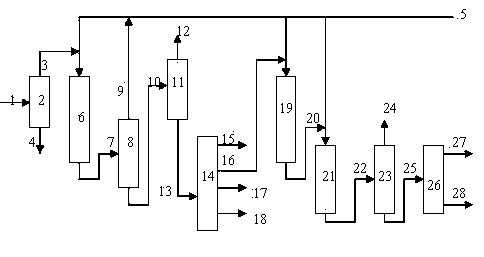

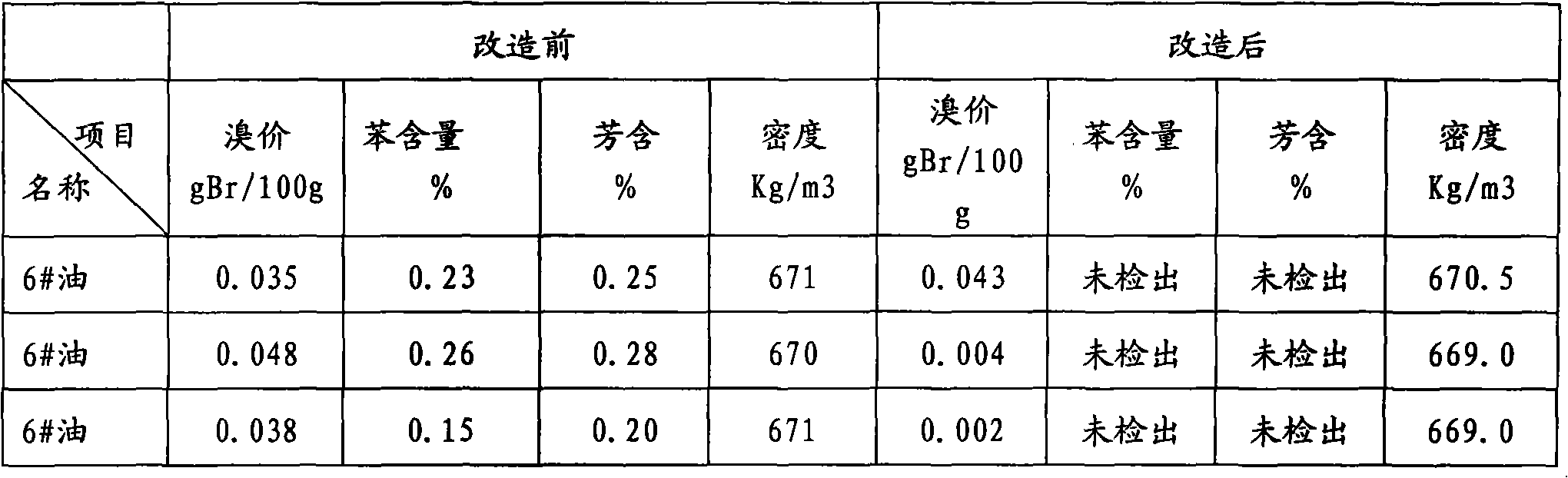

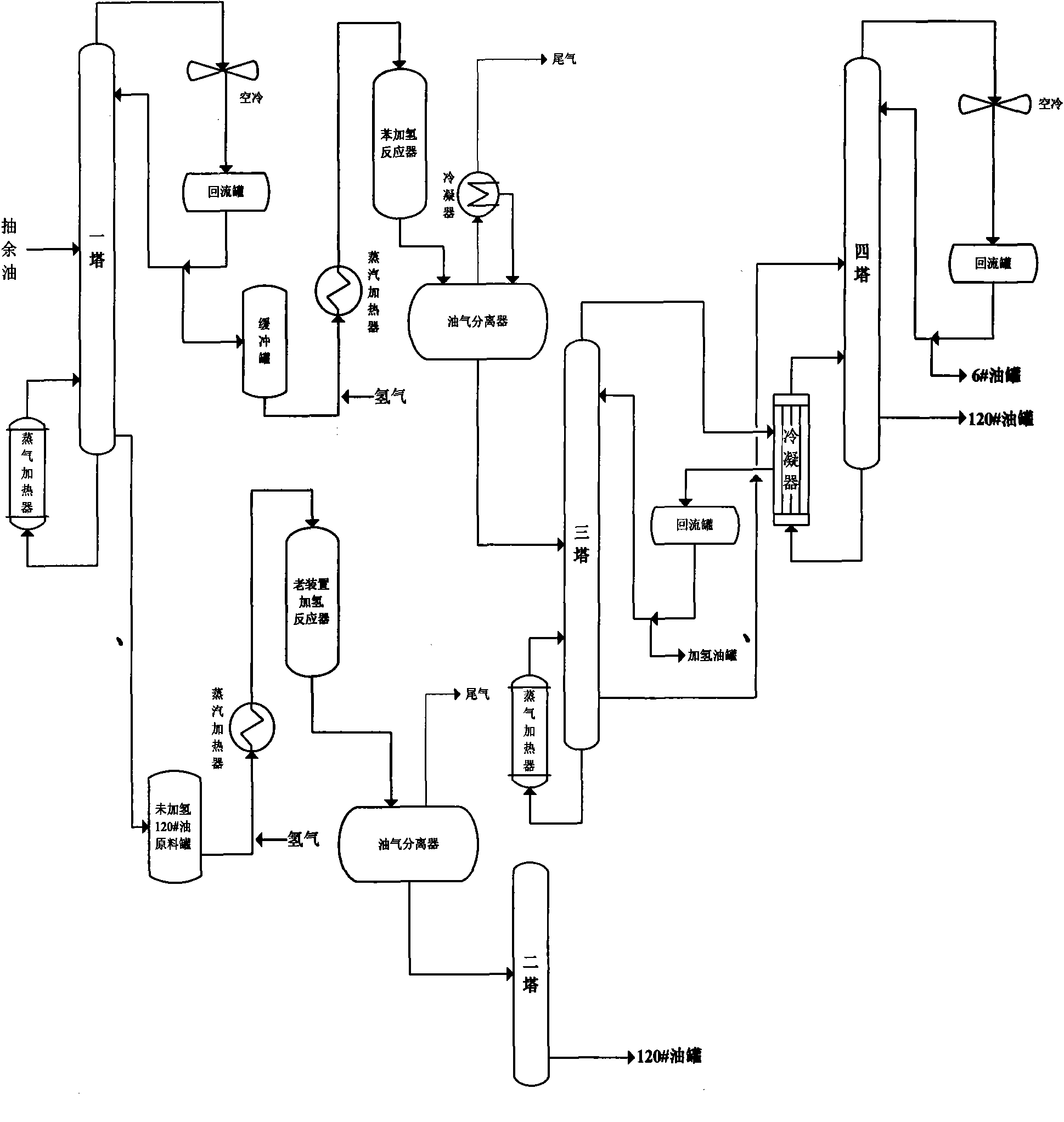

Process for producing solvent oil by removing aromatic hydrocarbon from raffinate oil

ActiveCN101974347ANot easy to cokeHigh activityTreatment with hydrotreatment processesBromine numberSulfolane

The invention discloses a process for producing solvent oil by removing aromatic hydrocarbon from raffinate oil, which comprises the following steps of: (1) rectifying raffinate oil, and removing sulfolane, water and colloid substances from the raffinate oil; (2) completely hydrogenating the raffinate oil obtained in the step (1) under the action of a benzene hydrogenation catalyst; and (3) removing excessive hydrogen from the product of the step (2) by separating, rectifying and collecting the product at the top of a rectifying tower to obtain solvent oil No.6 or normal hexane. In the method, all the raw materials are cleaned, hydrogenated and separated, reformed circulating hydrogen can be used, and the distillation range of the product is controllable. The content of aromatic hydrocarbon in the obtained product is trace, and the bromine number is lower than 100 mgBr / 100g.

Owner:TIANJIN JINGHUA PETROCHEM

Combined process for delayed coking and hydrotreating

ActiveCN101638588AOptimize processLess investmentTreatment with hydrotreatment processesWaxChemistry

The invention discloses a combined process for delayed coking and hydrotreating, which comprises the following steps that: a coking raw material is heated to enter a coking tower to react, oil gas escapes from the top of the coking tower, gas components and liquid components are separated, and the cycle ratio in a coking process is 0; and the liquid components are mixed with hydrogen to react in ahydrogenation reactor, then the obtained hydrogenated reaction effluent is distilled to obtain hydrogenated naphtha, hydrogenated diesel oil and hydrogenated wax oil, and the hydrogenated wax oil used as a high-quality raw material is fed into a catalytic cracking device or a hydrocracking device. By adopting the process flow of zero circulation of a coking device, the method provided by the invention furthest improves the yield of a liquid product, improves the processing depth of heavy oil, saves a coking fractionating tower, and achieves the aims of optimizing the flow and reducing the investment; and by adopting reasonable graduation of a hydrogenation catalyst, the method can furthest take account of the running period and the refining depth of each coking product fraction.

Owner:CHINA PETROLEUM & CHEM CORP +1

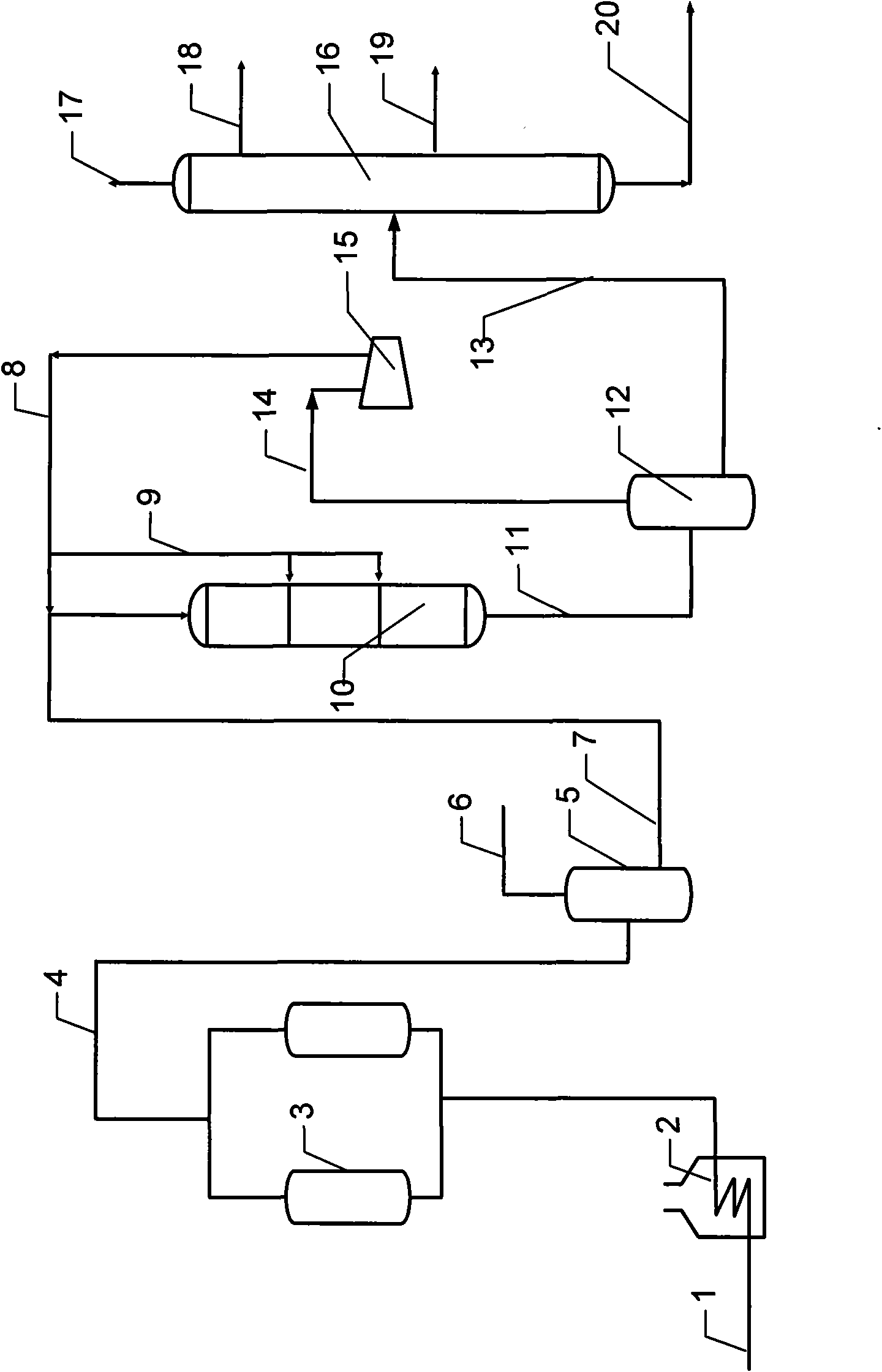

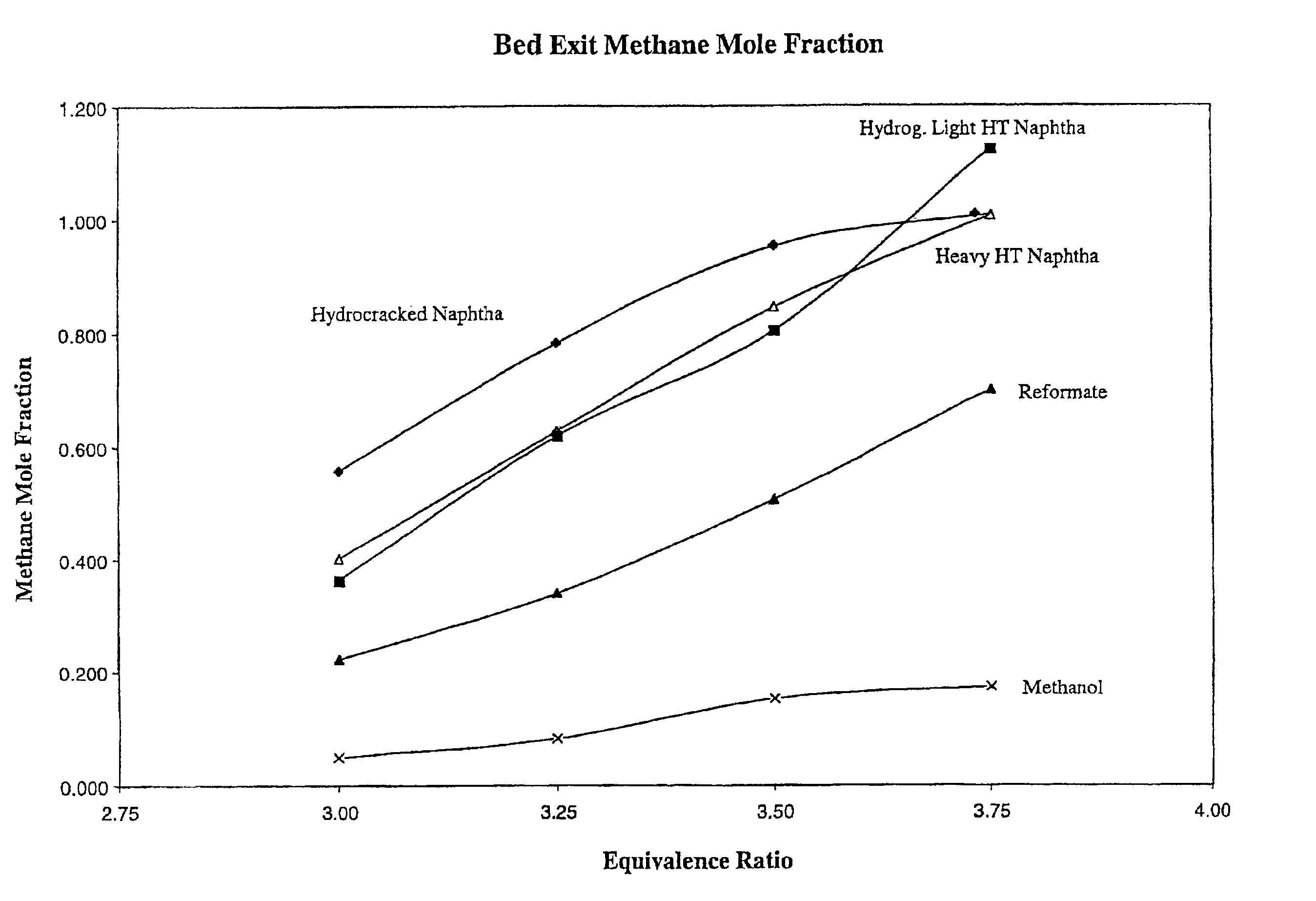

Liquid hydrocarbon based fuels for fuel cell on-board reformers

InactiveUS6884531B2Sulfur contentIncrease contentSolid fuelsLiquid carbonaceous fuelsNaphthaFuel cells

Naphtha-based fuels which have less than 1 ppm of sulfur and in excess of 15%, by weight, of hydrogen and an aromatics content of less than 1%, by weight, have been found to be useful as a fuel source for vehicular fuel cells.

Owner:SAUDI ARABIAN OIL CO

Hydrocracking method for increasing quality of refined diesel oil

InactiveCN1488731AIncrease the volume ratioReduced inlet temperature requirementsTreatment with hydrotreatment processesSulfurHydrodesulfurization

The present invention discloses a hydrocracking process for raising refined diesel oil quality, and is mainly characterized by that the poor diesel oil is undergone the process of hydrodesulfurization treatment, then the desulfurized refined diesel oil is mixed with the refined hydrocracked raw material oil, and fed into the hydrocracking reactor, and the sulfur and nitrogen contents in the mixed oil of the refined diesel oil and refined hydrocracked raw material oil must meet the feeding requirements of hydrocracking reactor. As compared with existent technology said invention can utilize hydrocracking equipment to raise the quality of refined poor diesel oil and can obtain high-quality clean fuel.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for hydrotreating ethylene tar

The invention discloses a method for hydrotreating ethylene tar, which comprises the following steps of: performing fractional distillation on the ethylene tar by selecting a proper cutting point to obtain light and heavy fractions; making the light fraction contact a hydrogenation protective agent, a hydrogenation refining catalyst, a hydrogenation carbon residue catalyst and a hydrocracking catalyst in turn, reacting to obtain products, and separating the products to obtain gasoline and diesel fractions; and making the heavy fraction contact a hydrogenation protecting catalyst, a hydrogenation carbon residue removing catalyst and a hydro-conversion catalyst in turn to obtain hydro-conversion generated oil, wherein partial hydro-conversion generated oil is circulated to enter a hydrogenation reaction area, and the rest hydro-conversion generated oil is separated to form gasoline and diesel fractions. In the method, according to composition characteristics of the light and heavy fractions of the ethylene tar, different hydrotreating schemes are selected, so that the ethylene tar is converted into fuel oil to the greatest extent, the problem of high temperature rise of a hydrogenation reactor bed can be effectively solved, the running period of the device is prolonged, full fractions of the ethylene tar are fully utilized and the added value of the ethylene tar is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

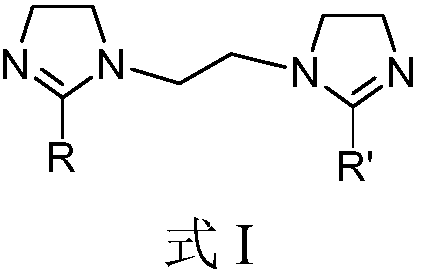

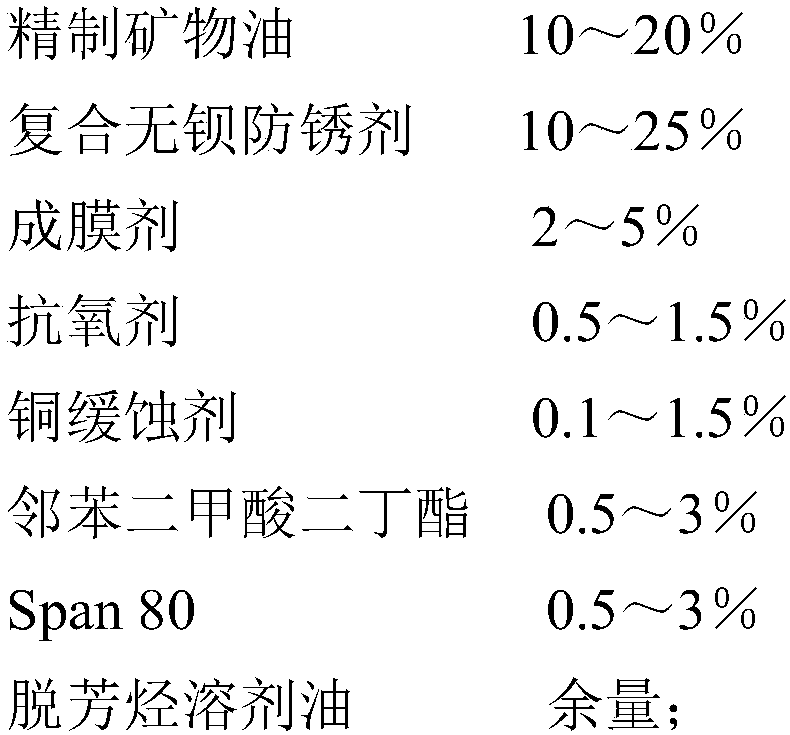

Barium-free soft film antirust oil

ActiveCN109897718ASatisfy the environmental protection requirement that barium should not be containedLow aromatic contentLubricant compositionAntioxidantSolvent

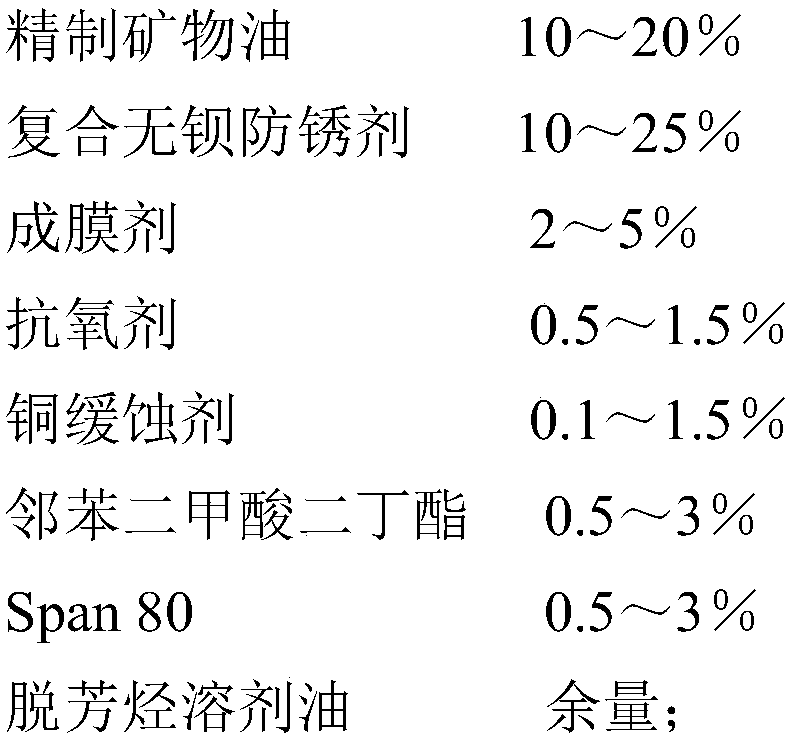

The invention relates to a barium-free soft film antirust oil. In terms of 100% of the total weight of the barium-free soft film antirust oil, the barium-free soft film antirust oil comprises the following components: 10-20% of refined mineral oil, 10-25% of a compound barium-free antirust agent, 2-5% of a film-forming agent, 0.5-1.5% of an antioxidant, 0.1-1.5% of a copper corrosion inhibitor, 0.5-3% of dibutyl phthalate, 0.5-3% of Span 80, and the balance dearomatization solvent oil. Specifically, the compound barium-free antirust agent comprises petroleum calcium sulfonate, calcium dinonylnaphthalene sulfonate and a gemini imidazoline corrosion inhibitor. The soft film antirust oil provided by the invention has low solvent oil aromatic hydrocarbon content, does not contain barium or other heavy metals, while meeting the environmental protection requirements of foreign environmental protection laws and regulations for exported metal product antirust materials, greatly improves the rust-proof performance of products, is applicable to medium and long-term storage and package rust prevention of ferrous metal products and copper-containing metal workpieces, also has excellent storage stability, is free of precipitate after long-term placement, and the oil film is thin and easy to clean, and can achieve assembly with oil.

Owner:PETROCHINA CO LTD

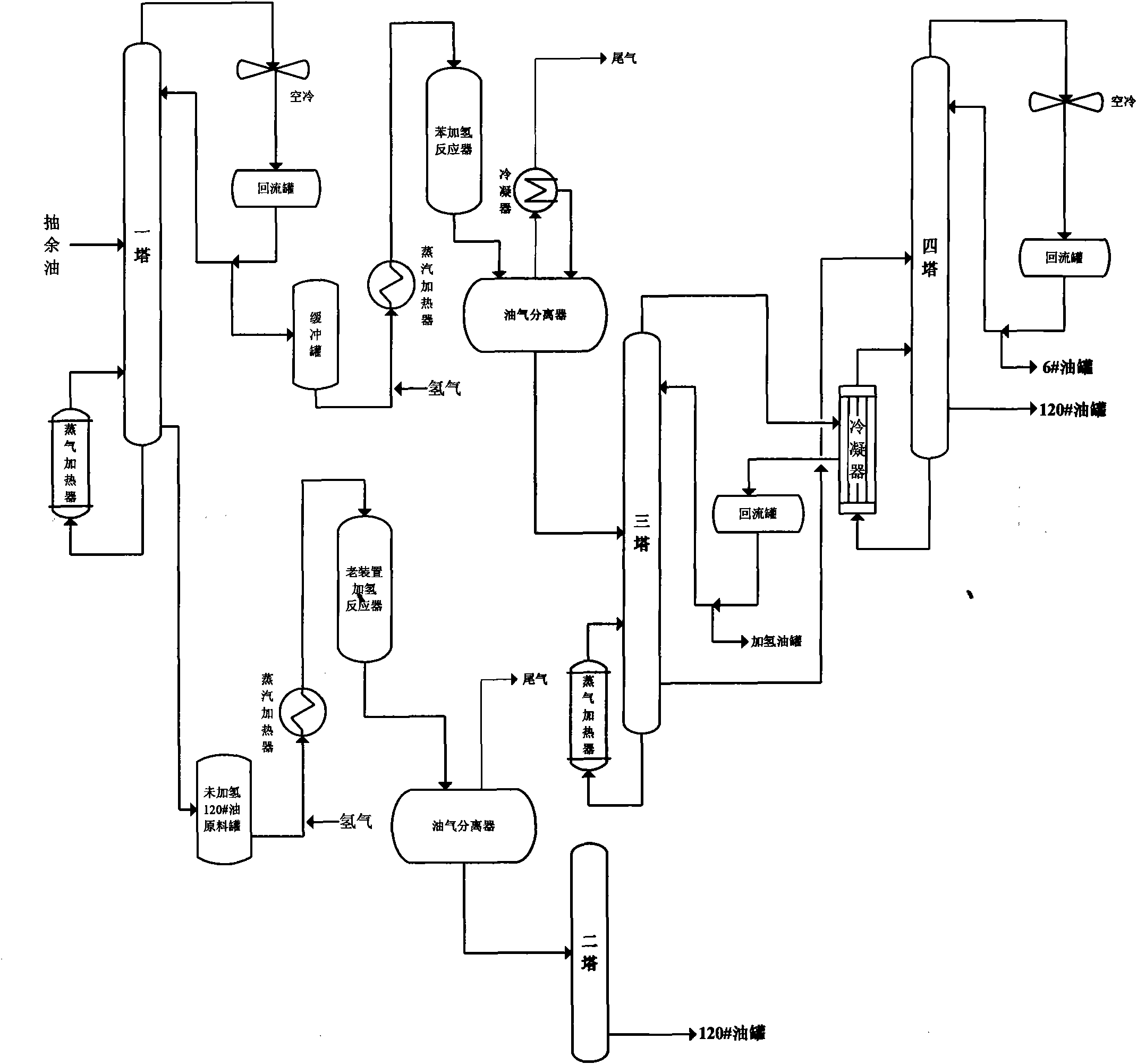

Coal liquefied oil boiling bed hydrogenation technique

ActiveCN101085933AHigh mechanical strengthImprove wear resistanceRefining to eliminate hetero atomsFiberSulfur

The invention discloses a process of hydrogenation for coal liquification oil on boiling bed. The process employs hydrogenation catalyst which contains fiber adjuvant, the fiber adjuvant content in catalyst is 3- 10 wt%. The mechanical strength and wearing resistance are strong, so it can remove nitrogen and sulfur from coal liquification oil maximumly, reduces olefin and aromatic hydrocarbons content, increases product stability and provides high performance coal liquification solvent oil.

Owner:神华煤制油研究中心有限公司

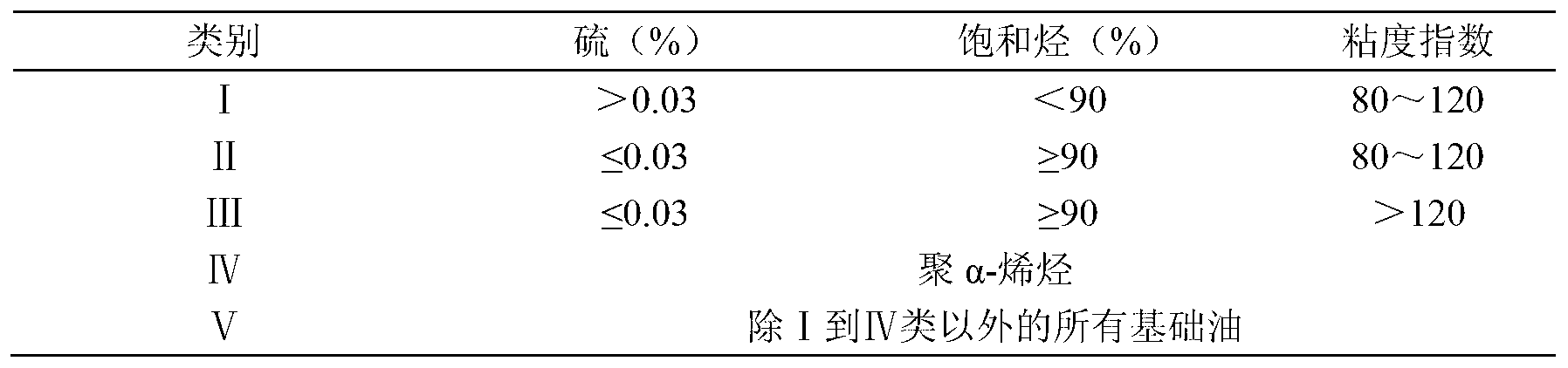

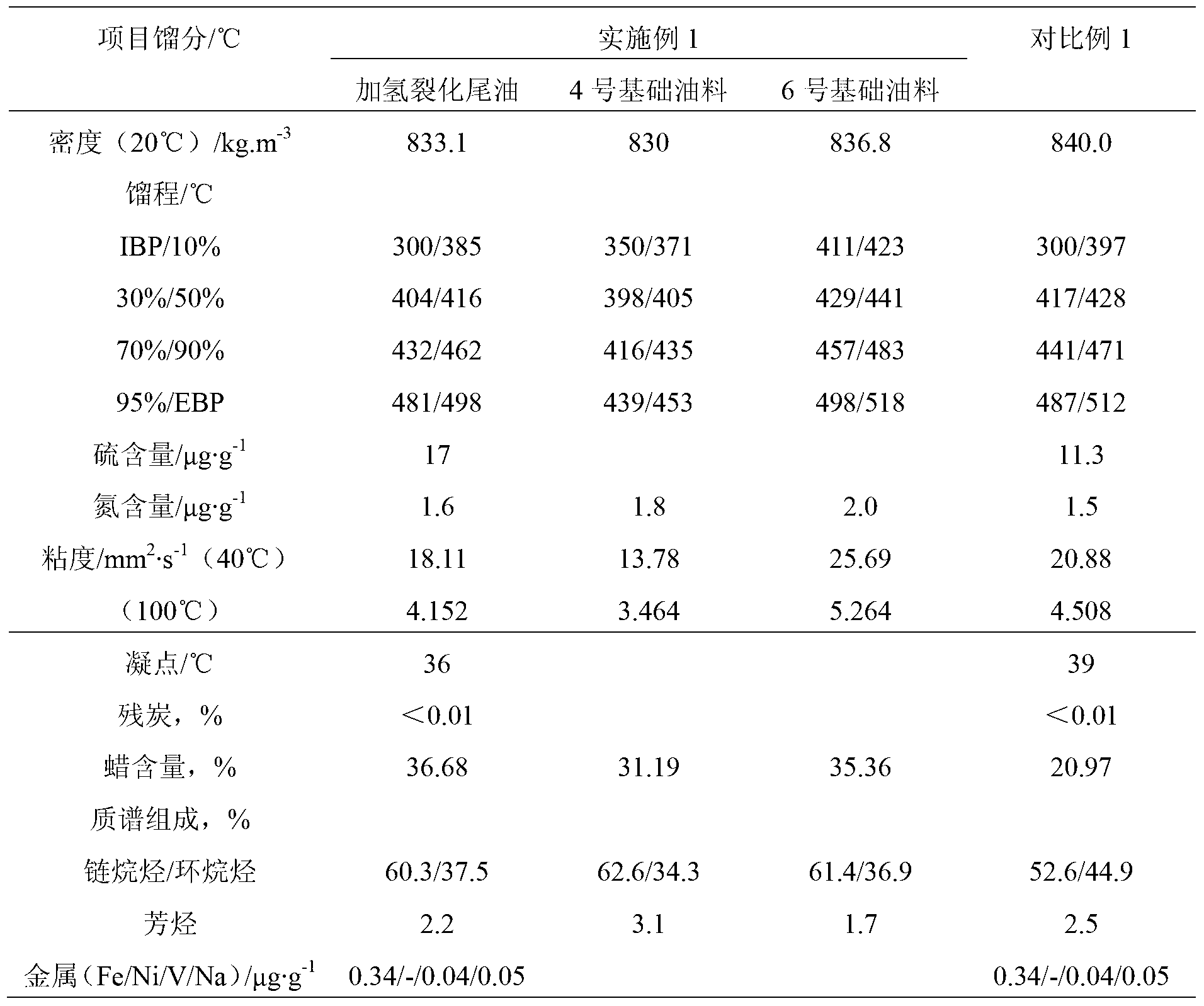

Method for producing high-grade lubricant base oil through hydrogenating of hydrocracking tail oil

ActiveCN103305267AHigh selectivityIncreased production flexibilityTreatment with hydrotreatment processesMixed feedingHydrogen

The invention discloses a method for producing high-grade lubricant base oil through hydrogenating of hydrocracking tail oil. The method comprises the steps of: by taking the hydrocracking tail oil as a raw material, firstly carrying out decompression pre-fractionation to obtain NO.4 base oil stock with final boiling point of less than or equal to 430 DEG C and NO.6 base oil stock with initial boiling point of more than 430 DEG C; leading in the NO.4 base oil stock and NO.6 base oil stock into an isodewaxing reactor and a supplementary refining reactor together with hydrogen by adopting a feeding switching mode or respective feeding mode, so as to carry out hydrogenation isodewaxing reaction and supplementary refining reaction, wherein the isodewaxing reactor and the supplementary refining reactor are connected in series; after reaction is finished, separating out gas from liquor to obtain a liquor phase, and fractionating the liquor phase to obtain the high-grade lubricant base oil. By adopting a method of switching or independently feeding plus mixed feeding, the selectivity of raw materials and the flexibility of production can be improved. The base oil produced can achieve the requirement of API II type and III type lubricant base oil, and the yield of the obtained API III base oil is high.

Owner:SINOPEC NANJING ENG & CONSTR +1

Method for producing high-quality low-freezing diesel oil

ActiveCN103059977ALowering the freezing pointHigh yieldTreatment with hydrotreatment processesFractionationDiesel fuel

The invention relates to a method for producing a high-quality low-freezing diesel oil, which is characterized in that a diesel oil raw material is contacted with a Hydrobon catalyst in a first hydrogenation reaction zone for reaction, an effluent is directly introduced in a second reaction zone without separating, and is contacted with a hydrogenation modified pour point depression catalyst for a pour point depression reaction, an effluent in the second reaction zone is introduced in the separating system and the fractionation system, the heavy diesel fuel fraction at the bottom of a fractionate tower is circularly introduced in an inlet of the second reaction zone. According to the invention, the hydrogenation modified pour point depression catalyst is employed for obviously reducing the condensation point of the diesel oil fraction, the heavy diesel fuel component with high condensation point is circularly introduced in the second reaction zone for remodifying the pour point depression reaction, and the target product yield can be increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

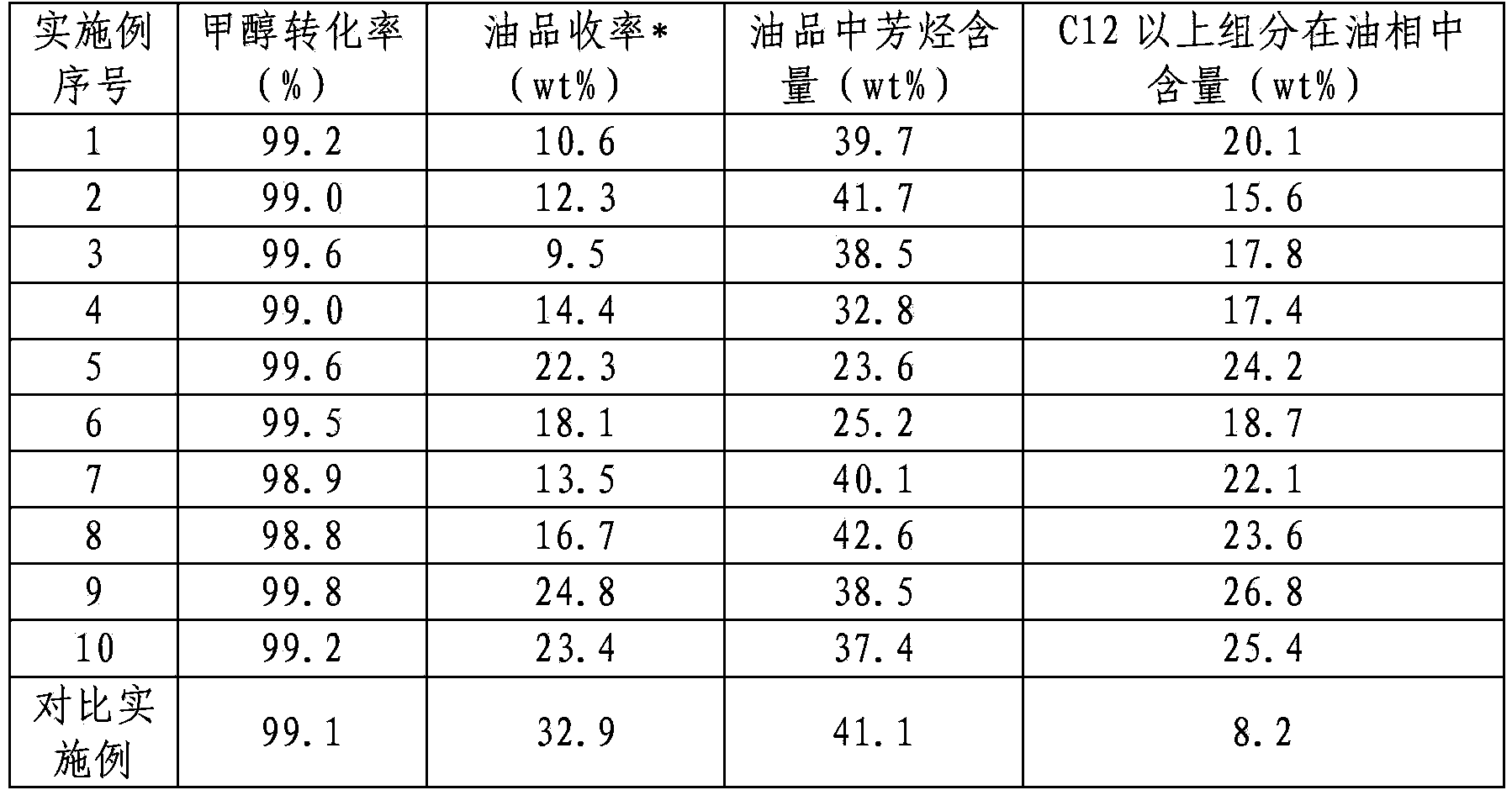

ZSM-5/MCM-48 composite molecular sieve, preparation method and application thereof

ActiveCN104043477AHigh selectivityLow aromatic contentMolecular sieve catalystsLiquid hydrocarbon mixture productionReaction temperatureGasoline

The invention relates to methanol-to-gasoline catalysts, in particular to a ZSM-5 / MCM-48 composite molecular sieve, a preparation method and application thereof. The composite molecular sieve adopts a ZSM-5 microporous molecular sieve as the seed crystal, on the surface of which a MCM-48 mesoporous structure composite molecular sieve that is chemically interlinked at a mesoporous and micropore interface is obtained by overgrowth. The composite molecular sieve undergoes acidification, and then is mixed with a binder to undergo molding and roasting, and the product is used as a catalyst for methanol-to-gasoline (MTG) reaction. The catalyst provided by the invention is used for overgrowth of the mesoporous molecular sieve on the microporous molecular sieve surface, integrates the advantages of the microporous material and the mesoporous material so as to develop the strong points and avoid the weak points and reach a synergistic effect. The catalyst shows good catalytic properties to the methanol-to-gasoline (MTG) reaction, has high selectivity to gasoline products and a low aromatic hydrocarbon content, and extends the carbon chain length. More importantly, the problems of high reaction temperature, high aromatic hydrocarbon content in oil products, and limitation of hydrocarbon compounds only to less than C11 in traditional MTG technologies are solved.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com