Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1051 results about "Oil quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process of converting rendered triglyceride oil from marine sources into bland, stable oil

Triglyceride oil derived from marine sources, mammalian and fish, is treated with a silica at relatively low temperature under vacuum and is then further treated with a bleaching clay under vacuum and at higher temperature. The silica and the bleaching clay are then separated from the oil. The oil treated by this method is essentially free of proteinaceous materials, phosphatides and mucilage, pro-oxidant metals and very low in colored compounds, and is suitable for deodorizing. The deodorized oil is completely bland, unchanged in the concentration of the long-chain highly unsaturated fatty acids (EPA, DPA and DHA), very low in color, peroxides and secondary oxidation products, free of pesticides and has very good flavor stability. The method avoids the use of any chemicals, such as in the acid and base treatments required in conventional degumming and alkali refining of oils of marine origin. This avoids the formation of artifacts in the oil and trace contamination with chemicals. It also reduces the number of process steps required to produce deodorized food oil from marine sources, which is advantageous in respect to oil quality, process losses and processing costs. The method is especially environmentally advantageous, since it avoids the need for soapstock and waste water processing entirely. Refined oil produced by the method is useful as a nutritional supplement and in methods of therapy or medical treatment.

Owner:MAG TED

Preparation technique of big-leaf seed tea seed oil

InactiveCN101665742AAvoid the drawbacks of emulsification that is not easy to separateNot easy to blockFatty-oils/fats refiningFatty-oils/fats productionNutritive valuesHusk

The invention discloses a preparation technique of big-leaf seed tea seed oil. The preparation technique comprises the following steps: (1) squeezing the big-leaf seed tea seed oil: removing impurities, drying, husking, separating husks and kernels, softening, rolling embryos, braising, stir-frying and squeezing; and (2) refining the big-leaf seed tea seed oil: degumming raw oil, deacidifying, washing with water, dewatering, decolouring, deodorizing and filtering. The big-leaf seed tea seed oil prepared by the technique has the advantages of high oil output rate, superior oil quality, clear, bright and transparent colour, no bitter taste, pure fragrance and good mouth feel, and the nutritive value of the big-leaf seed tea seed oil is furthest protected. The big-leaf seed tea seed oil is not easy to be oxidized and deteriorate, has stable oil quality, safety, no toxicity, no side effect, and favorable properties of storage resistance and high-temperature resistance, is a better materialfor processing powdered oil, oleomargarin, salad oil and shortening oil and also can be used for cosmetics and medical oil.

Owner:陈军 +2

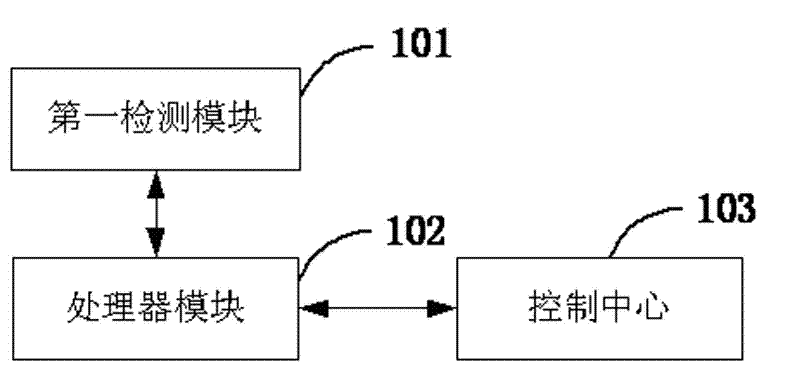

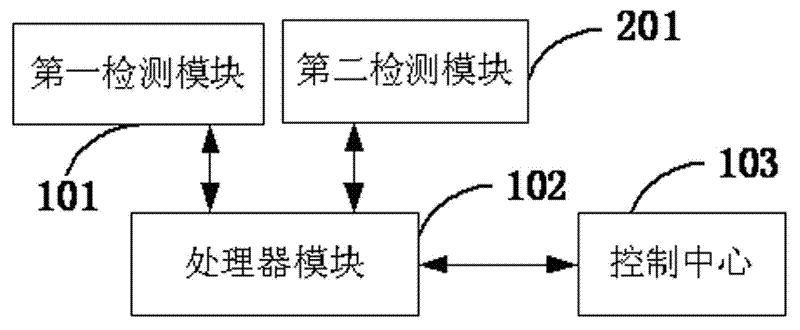

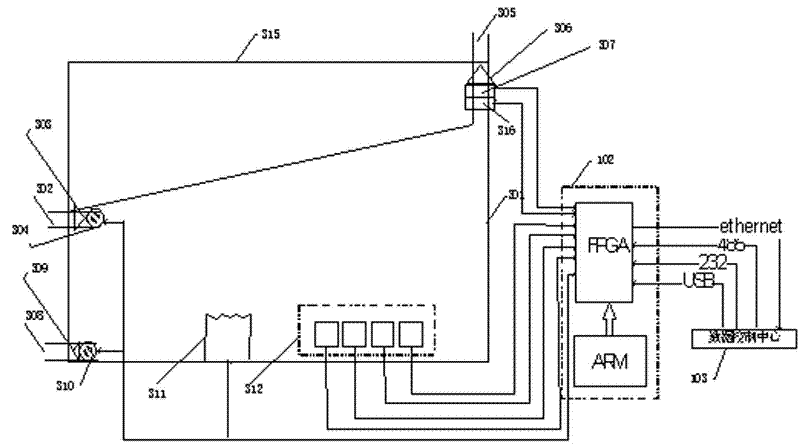

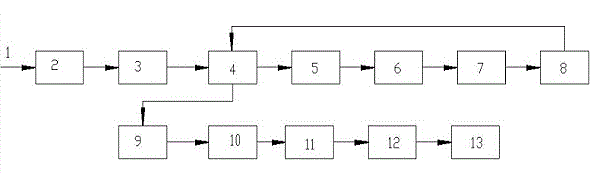

On-line monitoring system for diesel lubrication oil

ActiveCN102707037AReal-time monitoringReal-time fault warningMaterial testing goodsOil canMonitoring system

The invention discloses an on-line monitoring system for diesel lubrication oil, which comprises a host computer system and a slave computer system, wherein the slave computer system comprises an oil information monitoring sensor module, an automatic circularly oil-collecting module, a signal decoding and modulating module and an oil information gathering module; the oil information monitoring sensor module is respectively connected with the signal decoding and modulating module and the oil information gathering module; and the signal decoding and modulating module is connected with the oil information gathering module. The on-line monitoring system for diesel lubrication oil can realize the real-time and continuous monitoring and the fault warning for the diesel lubrication oil; monitoring and analyzing results of the on-line monitoring system are synchronous with the running state of a diesel engine; and the defects of artificial uncertainty influencing factors of off-line monitoring and delay of detecting and analyzing time of off-line sampling are overcome. Meanwhile, the defect of evaluating oil quality by using a single sensor is overcome by the on-line monitoring system, the complement characteristic of reflecting fault features by multi-information is achieved, and the accuracy of on-line monitoring and diagnosis is increased.

Owner:GUANGZHOU MECHANICAL ENG RES INST

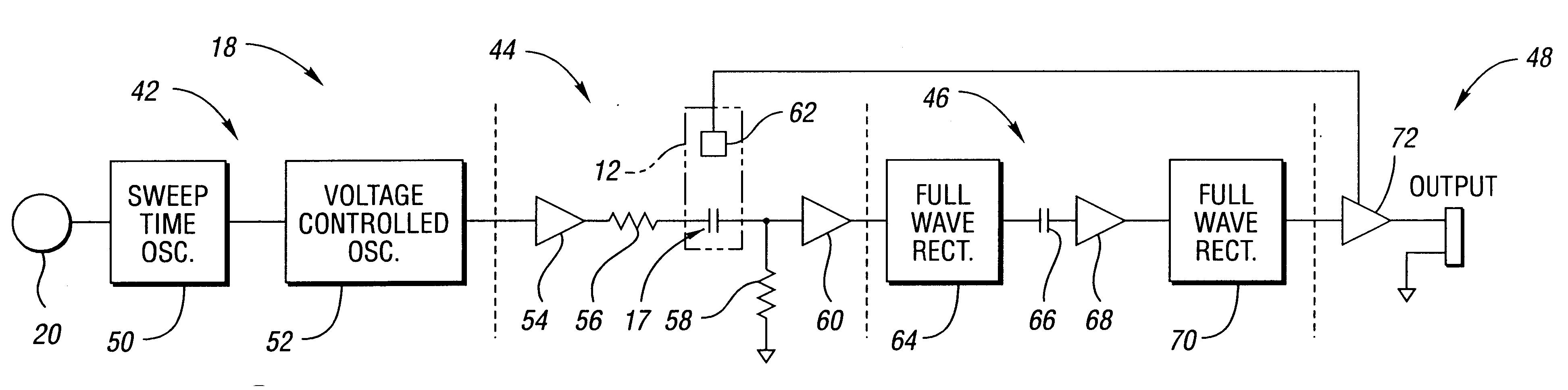

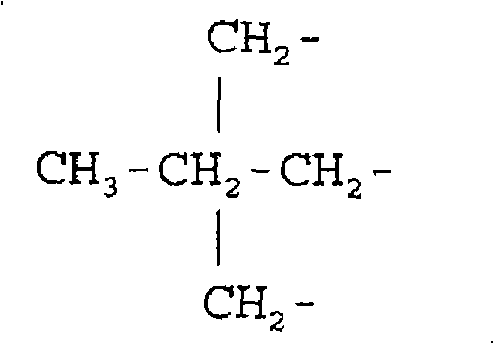

Method and system for determining oil quality

InactiveUS6268737B1Improve oil qualityMinimize contaminant buildupElectric/magnetic detection for well-loggingResistance/reactance/impedenceElectricityEngineering

A method for determining quality of lubricating oil includes positioning first and second electrodes in the oil, wherein the electrodes are coated with an electrically insulating material; applying a symmetrically balanced time-varying potential to the electrodes, the potential having a predetermined amplitude; sweeping the potential over a range of frequencies from a first frequency to a second frequency greater than the first frequency; monitoring magnitude of amplitude modulation of the potential over the range of frequencies; and determining the quality of the oil based on variation of the amplitude modulation. A system for practicing the method is also provided.

Owner:DETROIT DIESEL CORP

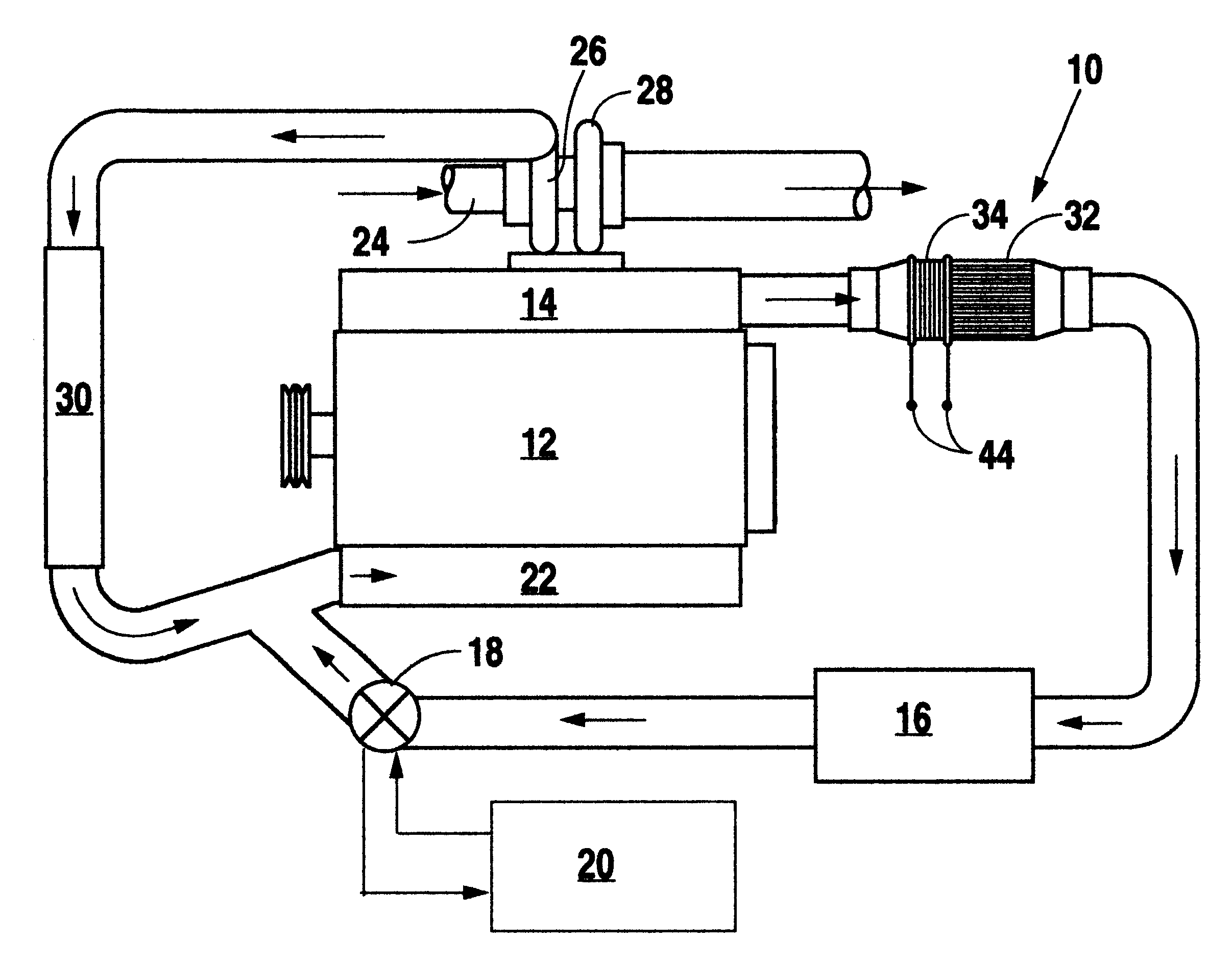

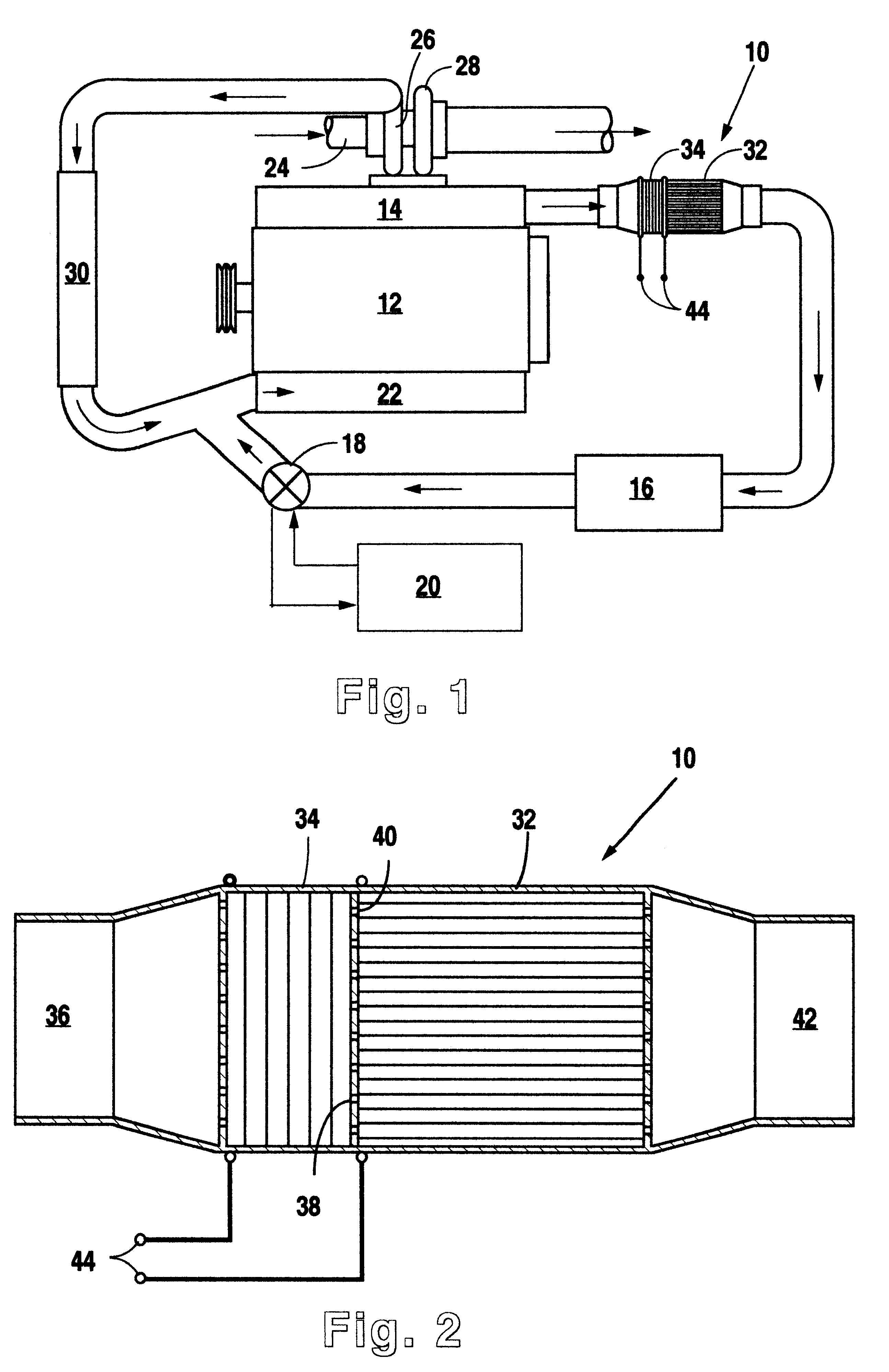

Exhaust gas recirculation filtration system

InactiveUS6474060B2Non-fuel substance addition to fuelInternal combustion piston enginesExternal combustion engineFiltration

A filtration system adapted to prevent diesel soot carried with recirculated exhaust gas from being recirculated through internal combustion engine. The filtration system provides continuous elimination of soot, thus reducing its negative impact on engine life, lubrication oil quality, and on components in the exhaust gas recirculation system. The filtration system comprises a non-thermal plasma generator that periodically, or continuously, oxidizes carbon deposited, or trapped, within a carbon filter disposed downstream of the non-thermal plasma generator.

Owner:SOUTHWEST RES INST

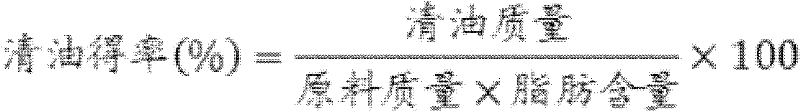

Method for extracting camellia oil and tea saporin from tea seeds

ActiveCN102250681AHigh oil extraction rateImprove economySugar derivativesSteroidsSaporinCamellia oleifera

The invention relates to a method for extracting camellia oil and tea saporin from tea seeds. The method provided by the invention comprises the following steps of: pre-treating tea seeds, extracting camellia oil in a water phase, extracting tea saporin, recycling a solvent and the like. The oil extracting rate obtained by using the method provided by the invention can be more than 95%, the recycling rate of the tea saporin is more than 85% and the oil quality of the camellia oil is good. In the method provided by the invention, ethanol or isopropanol is utilized as the solvent so that the camellia oil is safe and toxic, has a lower boiling point, is easily recycled and repeatedly utilized, can reduce manufacturing cost, is environmental-friendly and has a very wide application prospect.

Owner:JIANGNAN UNIV

System and method for monitoring liquid oil quality

The invention relates to a system and a method for monitoring liquid oil quality, which makes scientific and effective judgment on the quality of the liquid oil by simultaneously monitoring multiple physical and chemical parameters of the liquid oil. For instance, when being used for monitoring the qulaity of the lubricating oil of a motor, the system can provide scientific and reasonable advice about when to replace the lubricating oil according to multiple quality standards of the lubricating oil as well as monitoring parameters, thereby being capable of prolonging the service lifetime of a motor, reducing the fuel consumption, and and reducing pollution. Moreover, the system avoids unnecessary replacement, prolongs the service lifetime of the lubricating oil, reduces the quantity of waste oil, and accordingly reduces the pollution thus incurred. The system is also significant in monitoring the quality of transmission oil, transmission liquid oil, and hydraulic oil. Therefore, the system and method for monitoring the liquid oil quality are of significance.

Owner:BEIJING ANSAIBO TECH

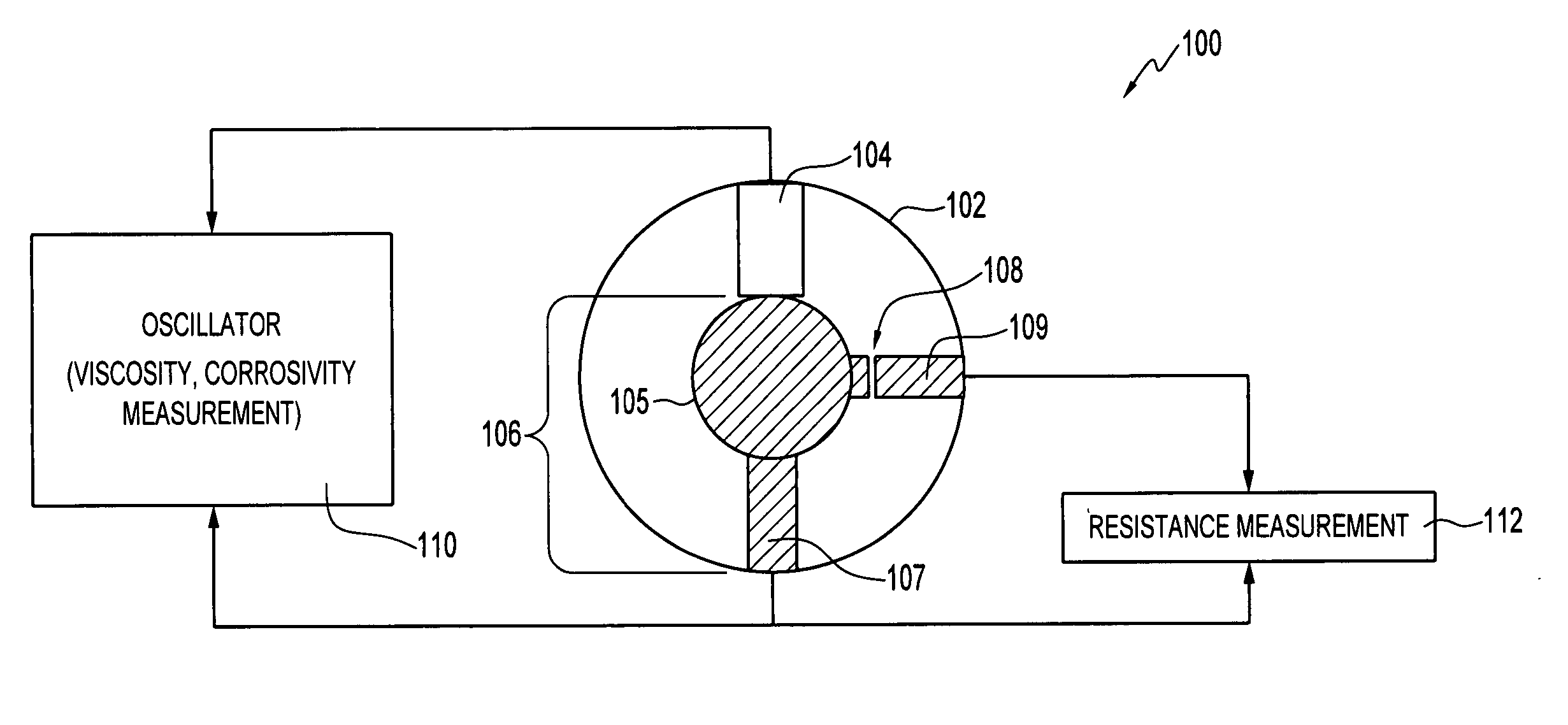

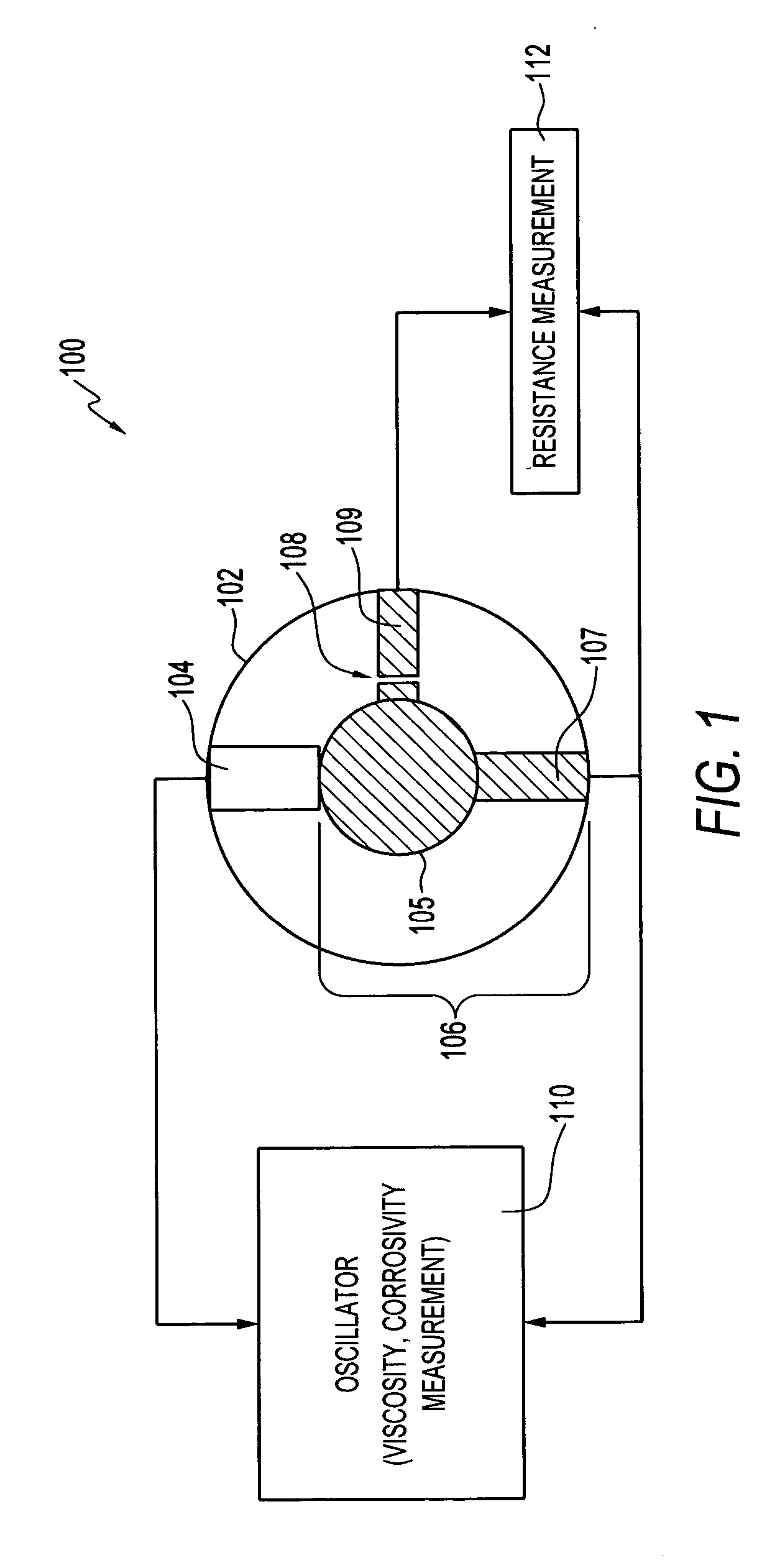

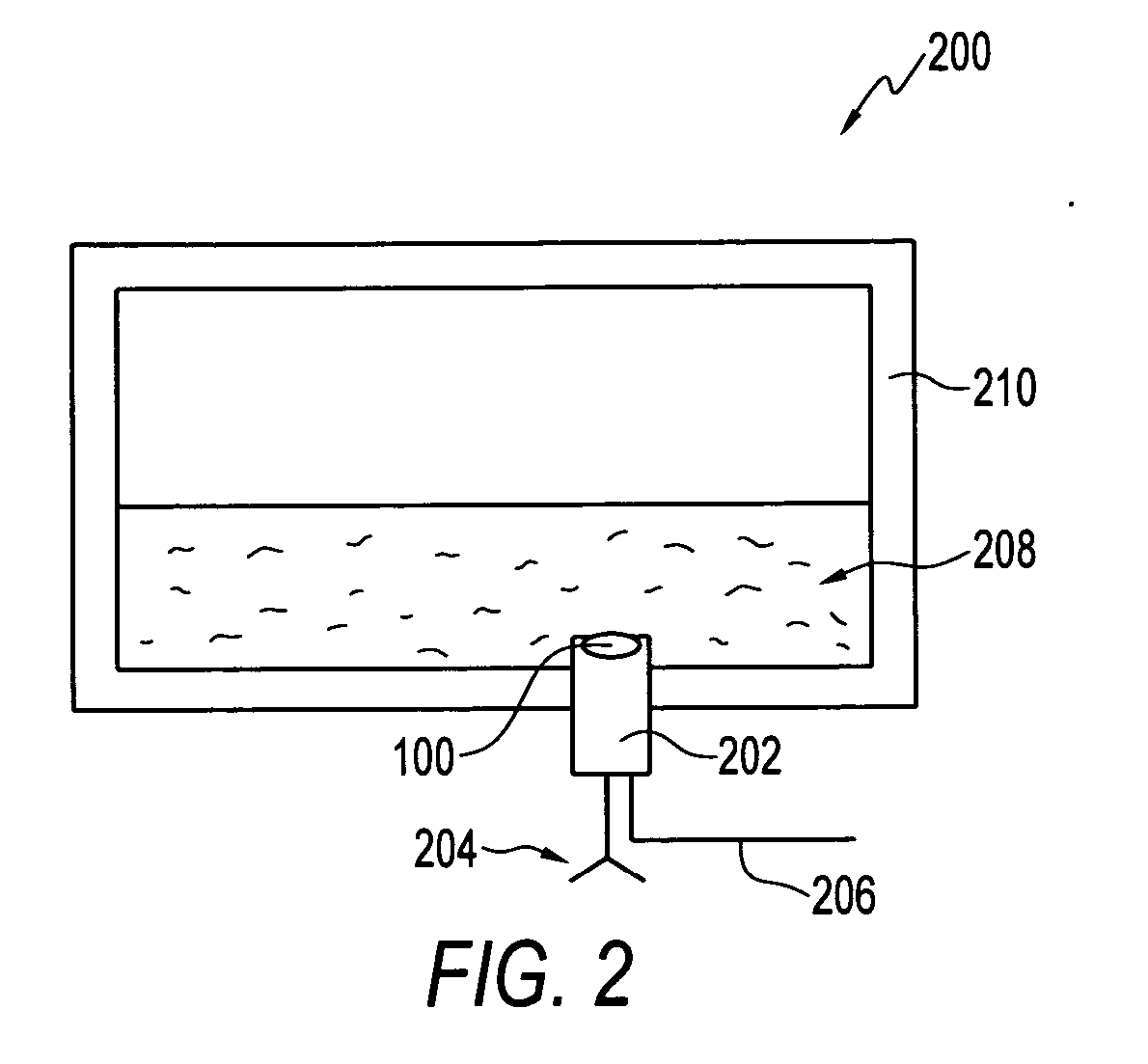

Engine wear and oil quality sensor

InactiveUS20070074563A1Material analysis using sonic/ultrasonic/infrasonic wavesSubsonic/sonic/ultrasonic wave measurementLiquid viscosityEngineering

A viscosity and corrosivity sensor apparatus includes a substrate upon which one or more electrodes are configured. The electrode(s) are exposed to a liquid, such as automotive oil. An oscillator can be connected to the electrode, wherein the oscillator assists in providing data indicative of the corrosivity and data indicative of the viscosity of the liquid in contact with the electrode(s). A viscosity and corrosivity sensor is therefore provided in the same package.

Owner:HONEYWELL INT INC

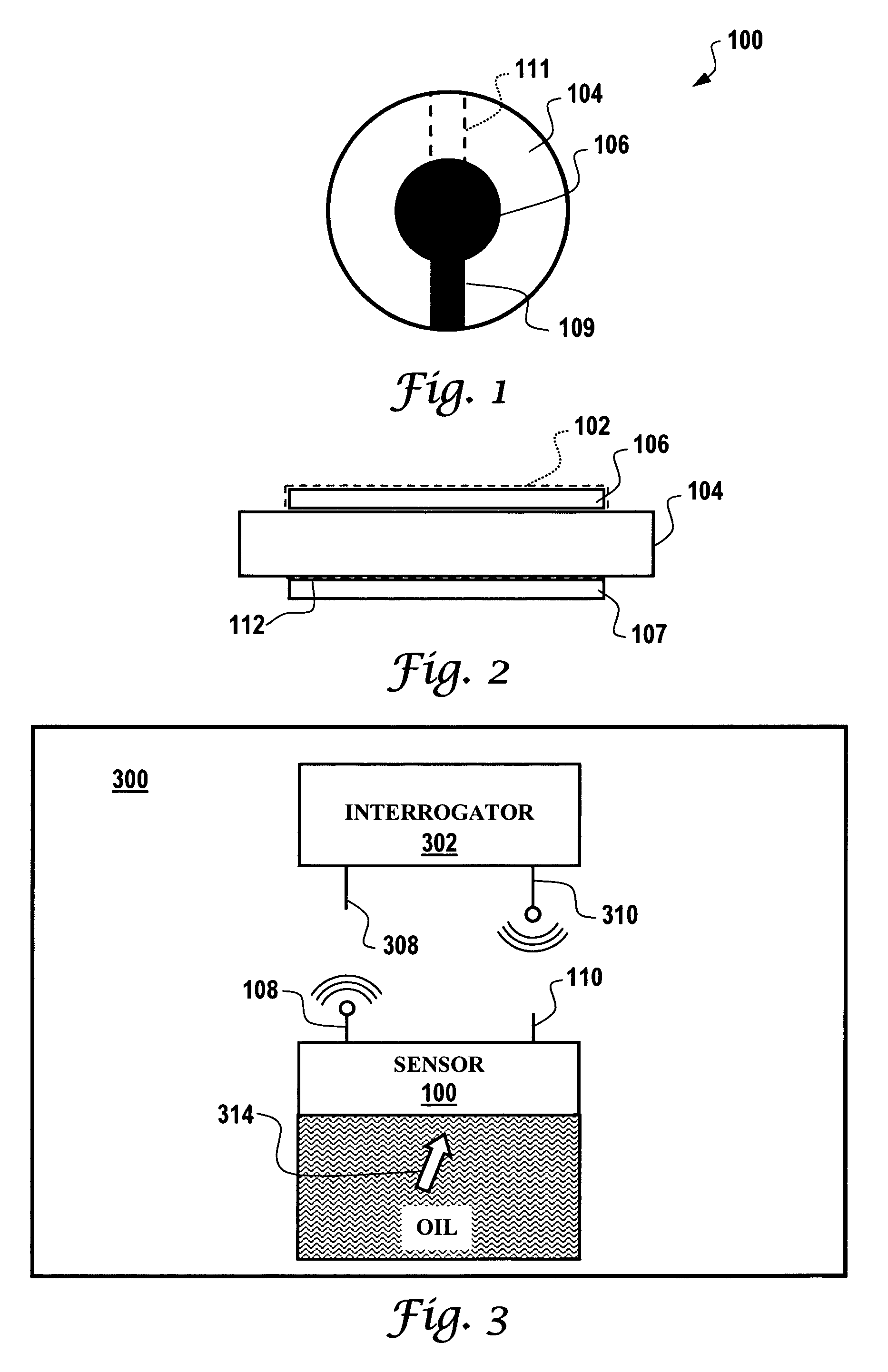

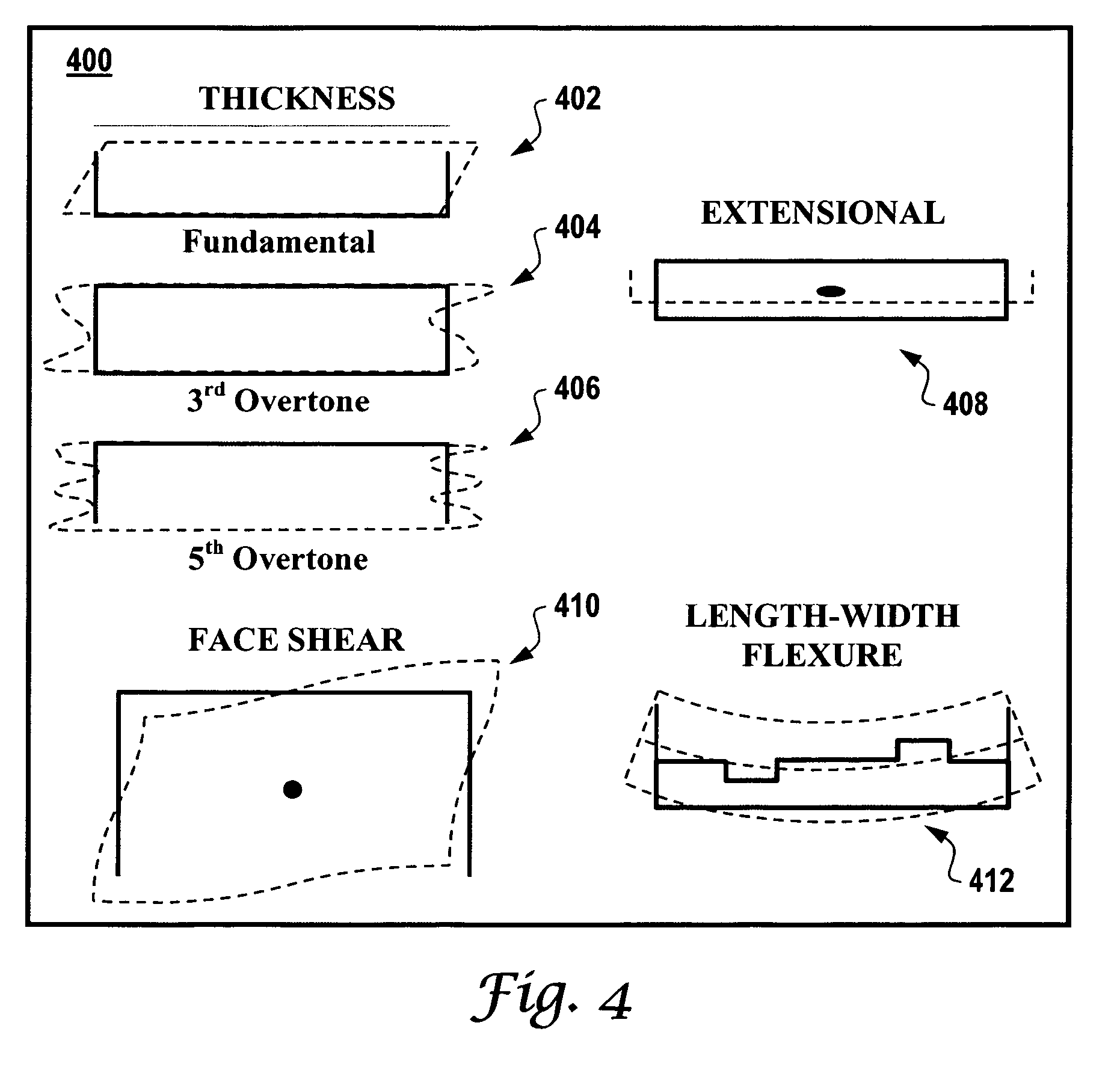

System and method to determine oil quality utilizing a single multi-function surface acoustic wave sensor

InactiveUS7219536B2Viscosity of the engine oil can additionally beAnalysing fluids using sonic/ultrasonic/infrasonic wavesFlow propertiesOil canFrequency measurements

A method and system for detecting oil quality. The quality of engine oil can be determined utilizing an acoustic wave sensor to obtain viscosity and corrosivity data associated with the engine oil. The acoustic wave sensor is coated with a material that selectively reacts to at least one type of an acid in order to provide data indicative of the presence of the acids in the engine oil. The etch rate or the corrosivity of the engine oil can be determined based on the frequency data obtained as a result of the frequency measurement utilizing the acoustic wave sensor. The viscosity of the engine oil can additionally be obtained based on a measurement of phase and amplitude obtained from the data utilizing the acoustic wave sensor. The etch rate and the viscosity measurement provide data indicative of the quality of the engine oil.

Owner:HONEYWELL INT INC

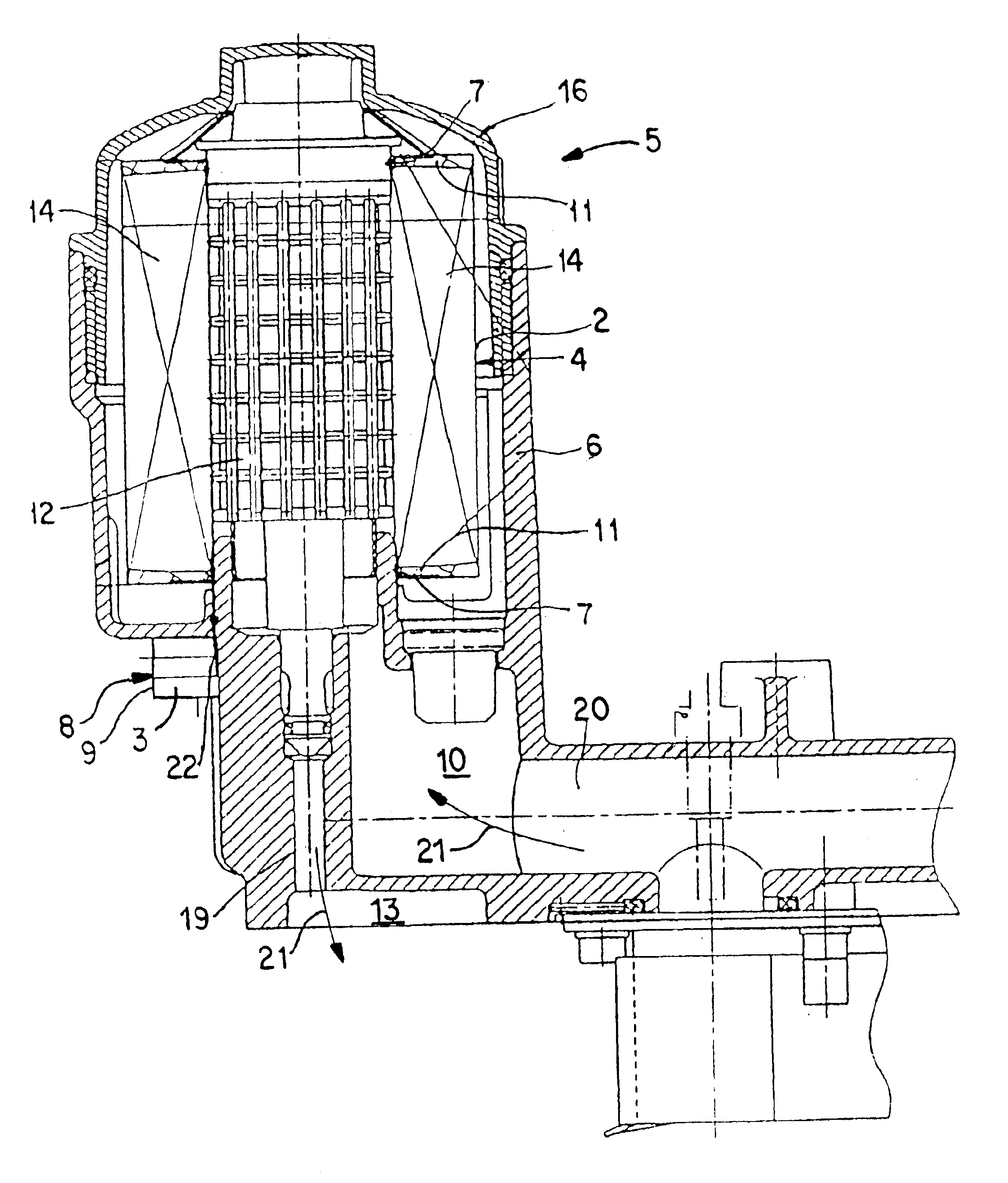

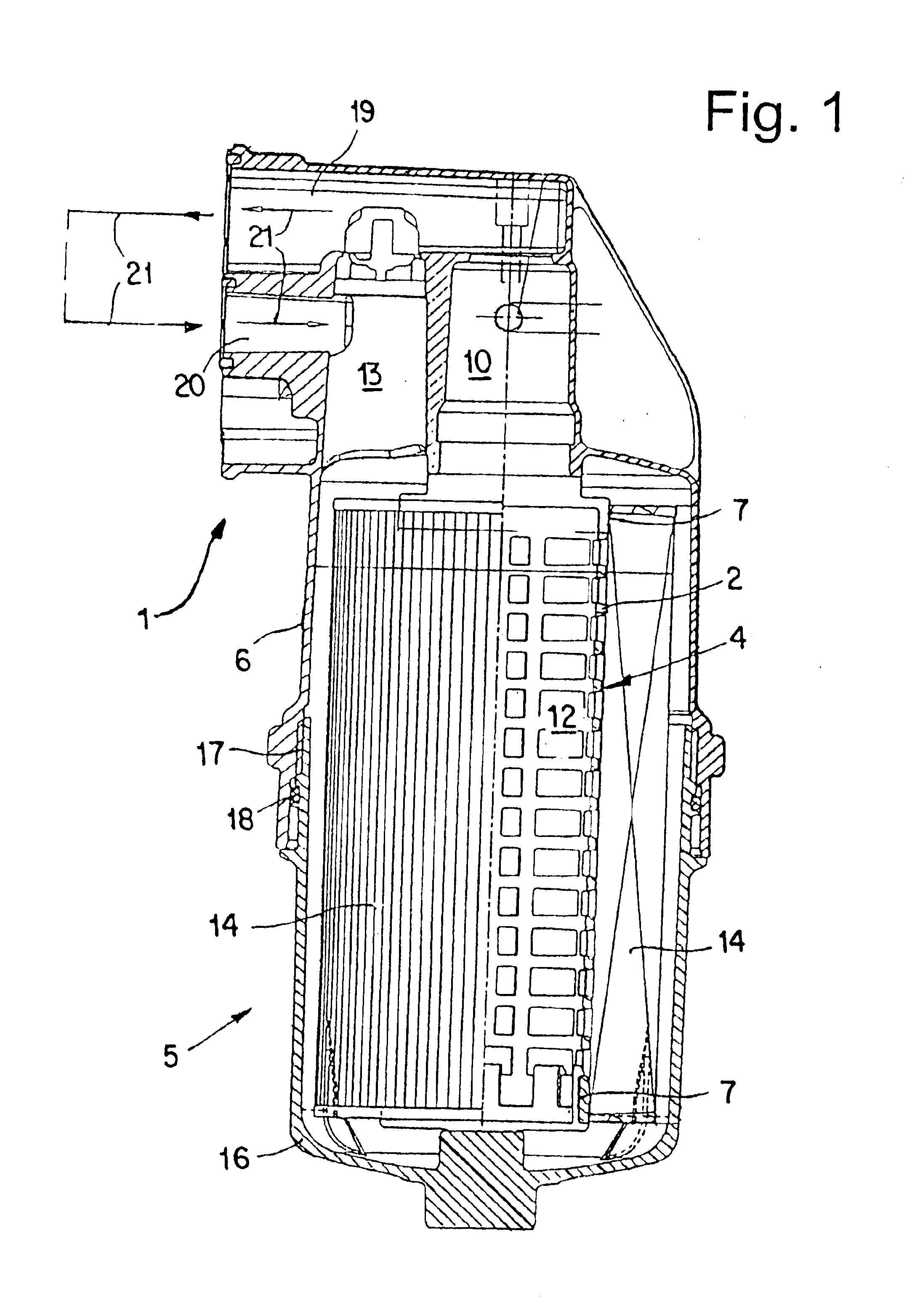

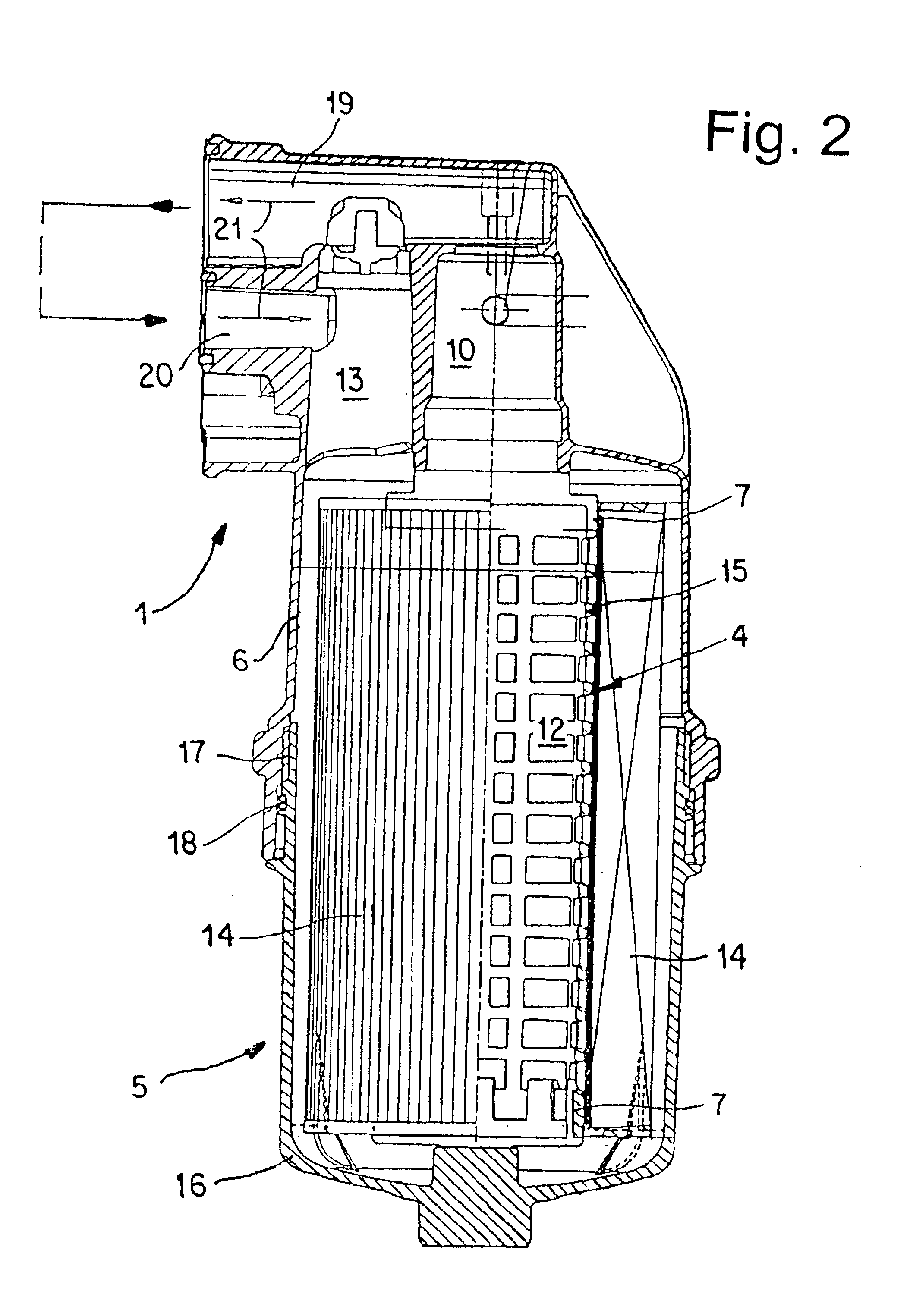

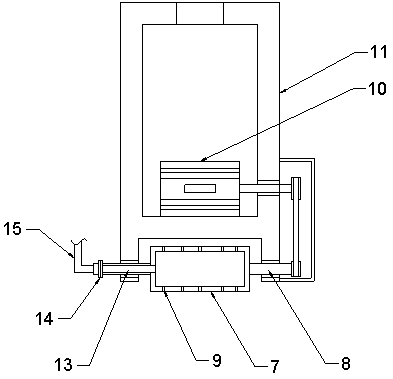

Oil quality measurement device

InactiveUS6853203B2High measurement accuracyPrecise and accurate resultResistance/reactance/impedenceMaterial testing goodsMeasurement deviceBiochemical engineering

An oil quality measurement device for an oil circuit (1), which includes an oil condition sensor (2) and an analysis circuit (3). The oil condition sensor (2) is constructed as a capacitive or impedance spectroscopic sensor (4) and attached to the filter element (14) in such a way that, when the filter element (14) is replaced, the oil condition sensor (2) is also automatically replaced.

Owner:MANN HUMMEL GMBH

Exhaust gas recirculation filtration system

InactiveUS20010042372A1Internal combustion piston enginesNon-fuel substance addition to fuelExternal combustion engineFiltration

A filtration system adapted to prevent diesel soot carried with recirculated exhaust gas from being recirculated through internal combustion engine. The filtration system provides continuous elimination of soot, thus reducing its negative impact on engine life, lubrication oil quality, and on components in the exhaust gas recirculation system. The filtration system comprises a non-thermal plasma generator that periodically, or continuously, oxidizes carbon deposited, or trapped, within a carbon filter disposed downstream of the non-thermal plasma generator.

Owner:SOUTHWEST RES INST

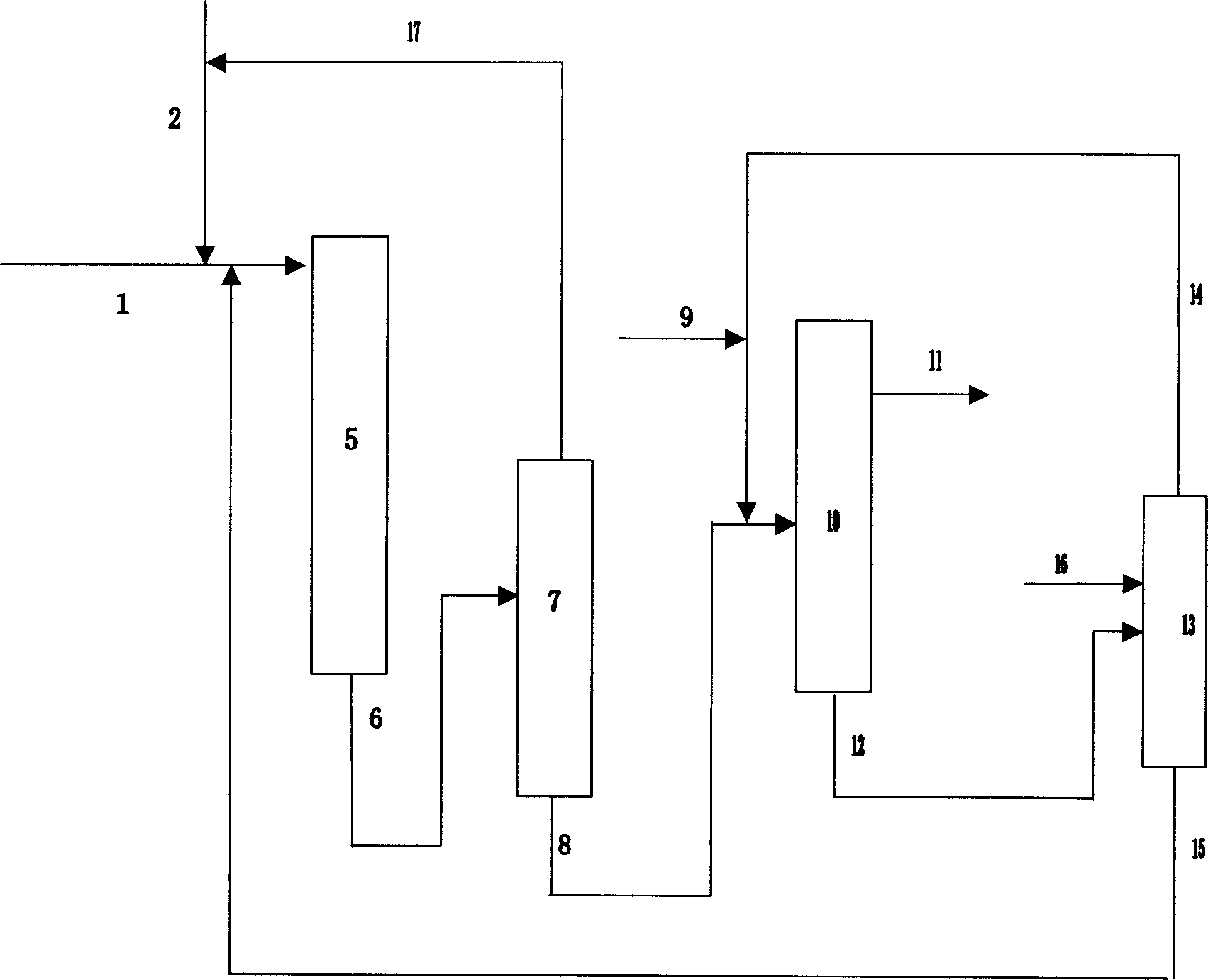

Inferior diesel oil quality change method

ActiveCN1769392AIncrease cetane numberReduce contentTreatment with hydrotreatment processesLiquid productSulfur

The invention provides a method of improving poor diesel. Said method is made up of two technique: quanlity-improving through hydrogenation and solvent extraction. Poor diesel raw material is treated through quality-improving hydrogenation catalysis bed to strip sulfur, nitrogen and aromatic hydrocarbons, then the final liquid product is extracted through solvent oil to make sure that most of the aromatic hydrocarbons are extracted and get clean diesel products which is low in sulfur, nitrogen and aromatic hydrocarbons, but high in cetane ratio, and the extracted aromatic hydrocarbons are circulated to catalysis bed. Group techniques in said invention could deeply decrease the content of sulfur, nitrogen and aromatic hydrogenation in diesel, increase the cetane ratio at the same time through making full use of their own features, therefore, making the quality of the production meet the need of fuel specification and environmental legislation, also maintain a higher diesel rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

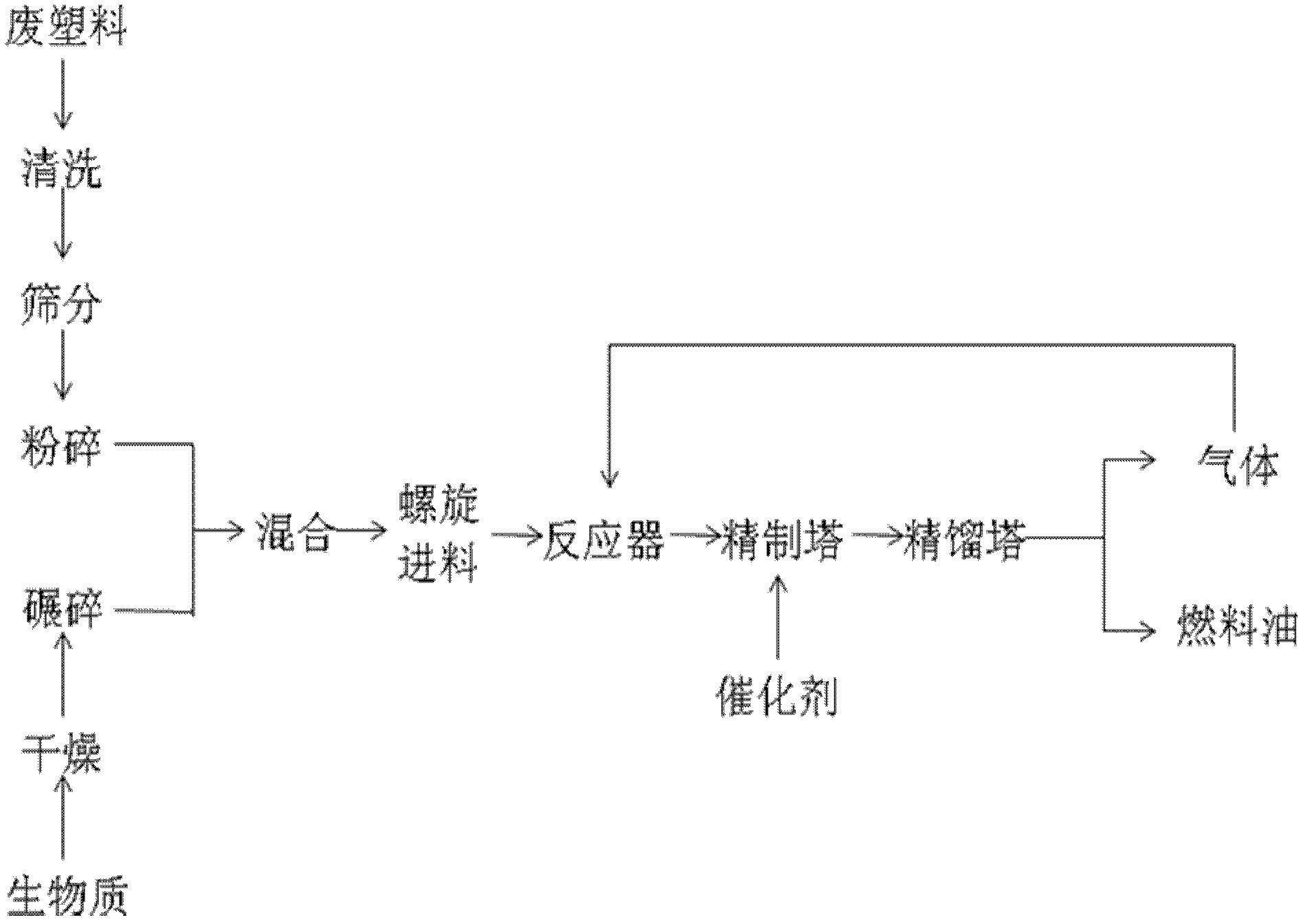

New method for preparing fuel oil by co-pyrolysis of biomass and waste plastic

ActiveCN102618312ARenewableOvercoming and mitigating pollution problemsLiquid hydrocarbon mixture productionCatalytic reformingLiquid product

The invention discloses a new method for preparing fuel oil by co-pyrolysis of biomass and waste plastic, belonging to the field of solid waste disposal and utilization technology and biomass energy. The method comprises the following steps: mixing evenly the biomass and the waste plastic according to a certain ratio; placing the mixture in a pyrolysis reactor; heating the mixture to the needed pyrolysis temperature for a pyrolytic reaction; introducing the gas generated from the pyrolysis into a refined reaction tower for catalytic reforming; carrying out rectification on the reformed liquid product to obtain fuel oil with different cut fractions; and returning a small quantity of the combustible gas and the residues to the pyrolysis reactor for burning and being used as supplementary heat source. In the method, the biomass and the waste plastic are comprehensively utilized in co-pyrolysis and synergetic promotion is generated by the biomass and the waste plastic, so that the oil productivity and the oil quality are improved. The novel method not only resolves the environmental problems caused by white pollution, but also relieves the energy crisis caused by petrochemical resource exhaustion, thereby having wide application prospect and being able to generate huge social and economic benefits.

Owner:TSINGHUA UNIV

Moderately processed vegetable oil and preparation method thereof

The invention provides a moderately processed vegetable oil and a preparation method thereof. The preparation method comprises the following steps: carrying out degumming twice (first deep degumming and then combining the secondary degumming) to realize efficient degumming and remove high boiling impurities as many as possible, so as to carry out alkali refining and neutralization at low temperature; then pre-decoloring with waste clay used for recycling, adding clay, decoloring under vacuum condition, and removing residual soap, phosphorus, pigment, metal, and the like; and finally carrying out combined deodorization of the plate column and the packed column, carrying out thermal decoloration, and removing fatty acid and micro-molecular stinking material, so as to reduce the generation of trans fatty acid, reduce the loss of vitamin E, save energy, reduce consumption, and improve the oil quality. According to the invention, vegetable oil products with low content of trans fatty acid (less than 1.0 %) and low loss rate of vitamin E can be produced.

Owner:SHANDONG BOHI INDUSTRY CO LTD +3

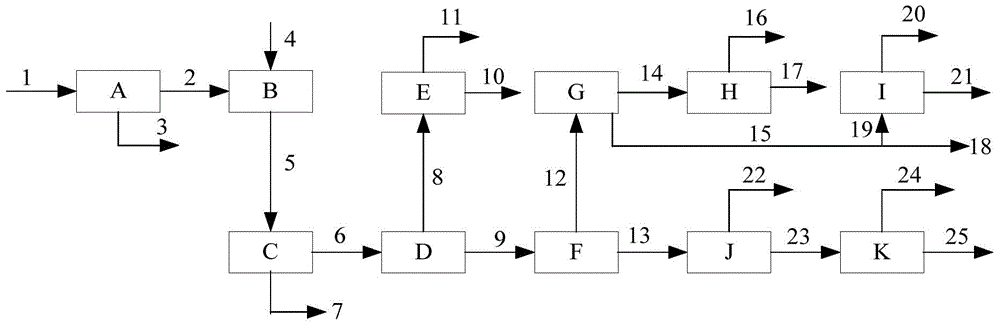

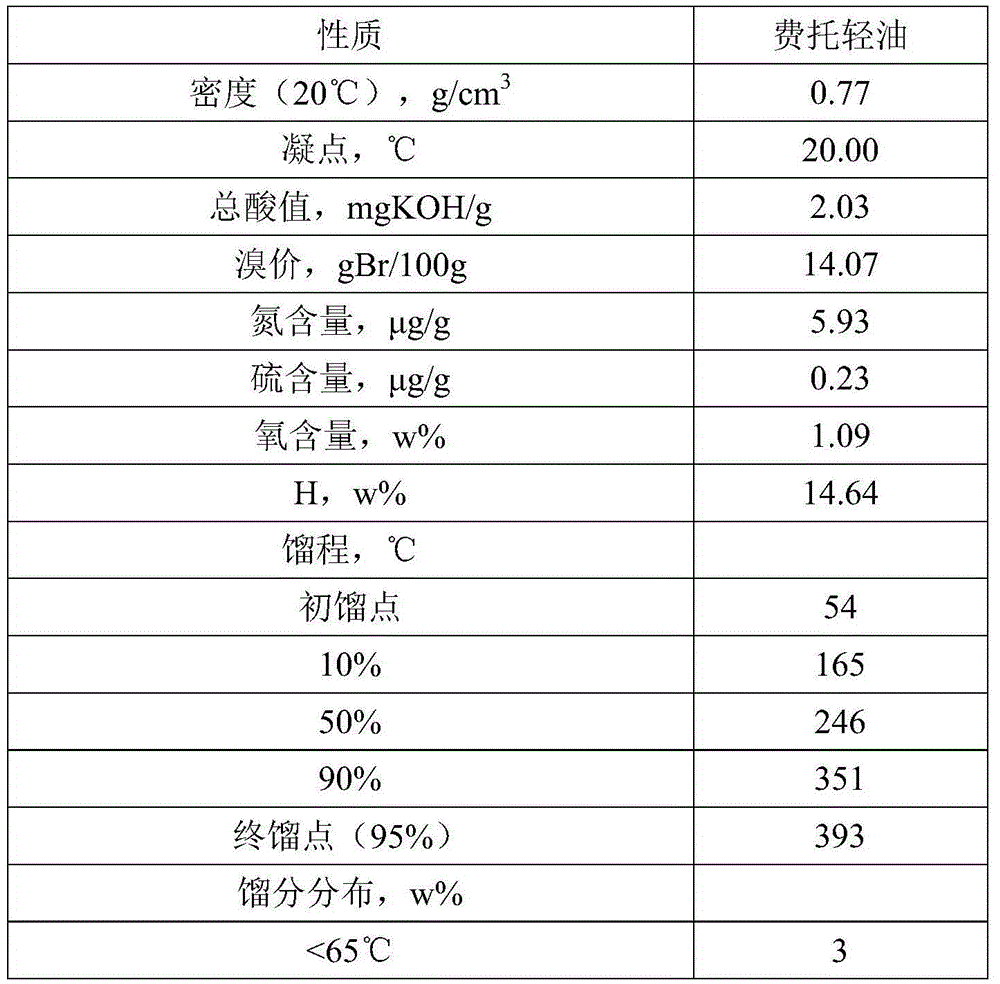

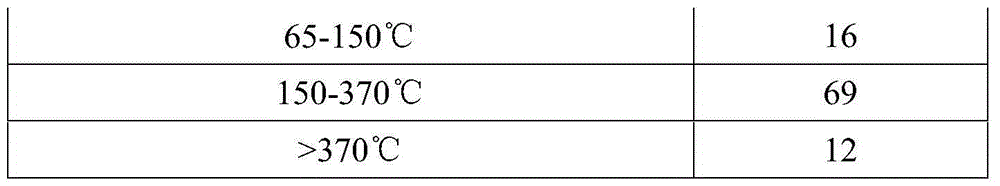

Method for producing n-alkane solvent oil from Fischer-Tropsch synthetic oil

ActiveCN104910960AMany modelsImprove qualityTreatment with hydrotreatment processesAlkaneDistillation

The invention relates to a method for producing n-alkane solvent oil from Fischer-Tropsch synthetic oil. According to the method, low-temperature Fischer-Tropsch synthetic light oil is adopted as a raw material, and is processed through upgrading and distillation separation processes with a fractionation tower, hydro-finishing, a degassing tower, a C6 / C7 cutting tower, a C5 / C6 cut tower, a C10 / C11 cutting tower, a C8 / C9 cutting tower, a C7 / C8 cutting tower, a C9 / C10 cutting tower, a C13 / C14 cutting tower, and a C17 / C18 cutting tower; such that various types of solvent oils such as n-pentane-rich, #6, #120, #140, #200, #D30, #D40, #D65, #D100 and #D120 solvent oils can be obtained. Compared to prior arts, all products produced with the method are n-alkane solvent oils. The method has the advantages of simple process flow, more produced solvent oil types, high solvent oil quality, and the like.

Owner:YANKUANG ENERGY R&D CO LTD

Curable epoxy resin-based adhesive compositions

ActiveCN101517029AImprove energy absorptionNatural rubber adhesivesNon-macromolecular adhesive additivesEpoxyAdhesive

Owner:HENKEL KGAA

Lubricating oil oil quality online detector

InactiveCN102279144AReduce blindnessSystem installation is simpleFlow propertiesMaterial testing goodsData acquisitionOil quality

An on-line detector for lubricating oil quality, relating to the field of mechanical lubrication, including a system control circuit, a sensor and a processing module, characterized in that: the system control circuit controls the sensor, and the sensor and the processing module perform information transmission, and the described The processing module includes system data processing software, which is set with oil quality standard value, can store data, and is also equipped with a display terminal and alarm equipment. The sensor adopts a fluid characteristic sensor, which can simultaneously monitor the viscosity of the oil, the concentration of wear particles and the transparency, and can also be connected with the secondary instrument or controller in the control room to detect ferrite particles larger than 1 μm in the lubricating oil. Real-time dynamic online monitoring of the amount of wear particles. The beneficial effects of the present invention are: due to the use of an intelligent data acquisition and analysis system and a high-sensitivity fluid characteristic sensor, online real-time monitoring can be performed to reduce the blindness of oil maintenance. Targeted maintenance and repair, simple system installation, can be applied to friction failure monitoring and early warning of various large-scale mechanical lubrication systems.

Owner:沈怡茹

Oil monitoring system

InactiveUS7521945B2Resistance/reactance/impedenceMaterial testing goodsSensor arrayMonitoring system

An embodiment of the present invention provides for a sensing element comprising a non-conductive housing with three chambers for detecting oil conductivity, additive depletion and oxidation, and water contamination, respectively. Through the monitoring of an array of oil sensors, an early warning of oil degradation due to oxidation is provided. The monitoring system further detects excess soot, water and other contaminants in the oil. The oil sensor array and related monitoring system decrease the likelihood of catastrophic engine failure through the early detection and warning of a decrease in oil quality thereby reducing vehicle owner outlays for servicing and disposal fees while further aiding in the satisfaction of environmental protection regulations.

Owner:VOELKER SENSORS

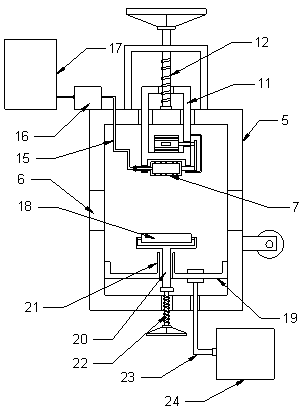

On-line engine oil quality monitoring system and method adopting multi-sensor information fusion

ActiveCN105065085AShield interferenceImprove detection accuracyLubrication indication devicesWater contentLubrication

The invention discloses an on-line engine oil quality monitoring system and method adopting multi-sensor information fusion. The engine oil quality monitoring system comprises a test oil circuit control valve, a metal abrasive grain detection device, a comprehensive quality detection device, a viscosity detection device, an engine oil cooling device, a data processing module, an STM32 measurement and control main unit, a man-machine interaction module and the like, wherein the viscosity detection device consists of an engine oil sampling device, a thermostatic oil-bath box, a heater, a constant-flow pump, a liquid level sensor, an oil-bath temperature sensor, a sampling temperature sensor, a pressure sensor, a balanced flow sensor and a pressure control valve. The on-line engine oil quality monitoring system is mounted at the downstream of a lubrication circuit oil pump of an automobile engine, can monitor the viscosity of engine oil, the content of metal abrasive grains and changes of such comprehensive qualities of engine oil as the pH value and the moisture content on line, adopts the multi-sensor information fusion technology to comprehensively analyze the oil state, displays information of the oil state through a display and sends an early-warning signal if necessary.

Owner:JILIN UNIV

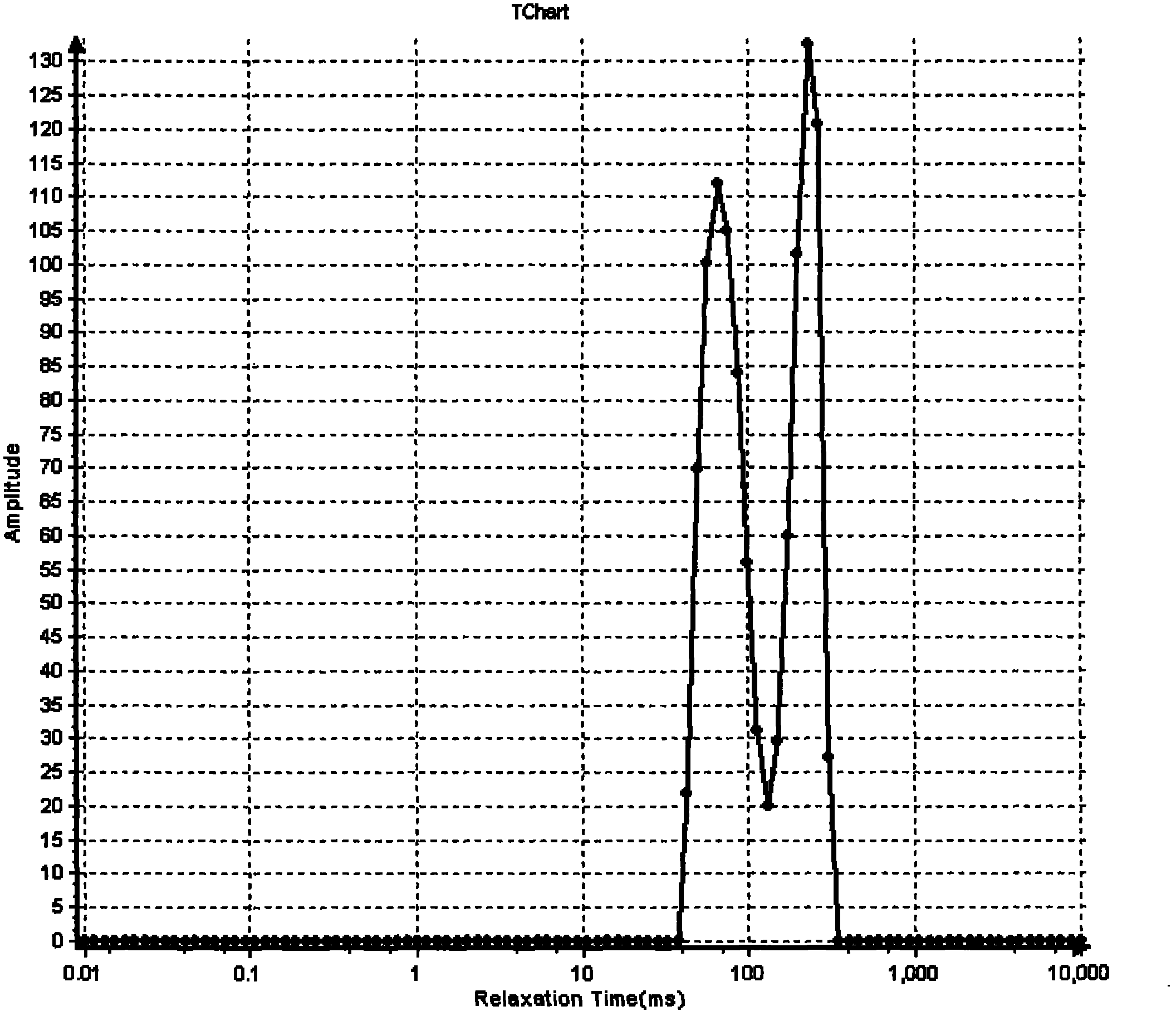

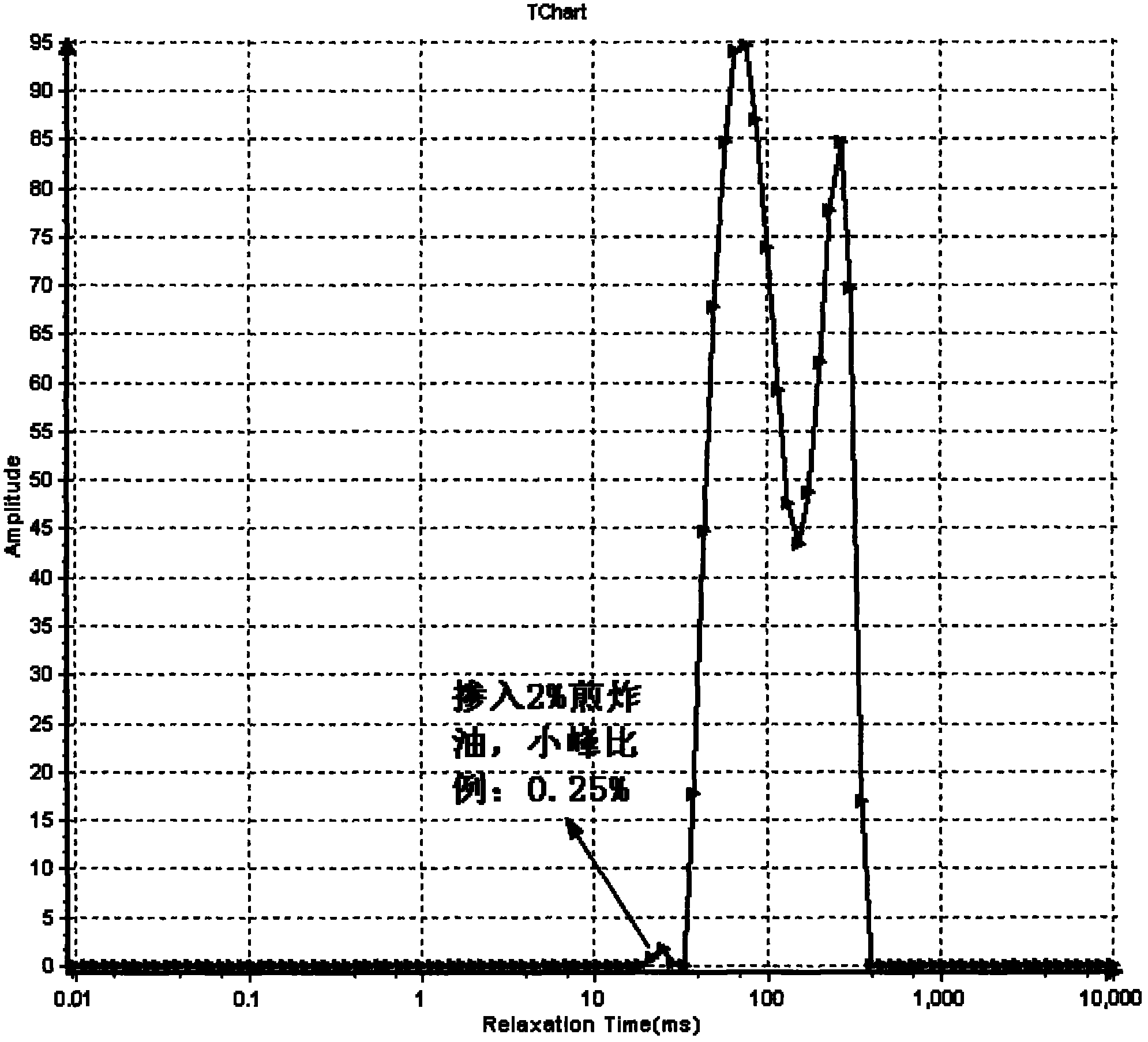

Method for identifying quality of edible oil with low-field NMR (Nuclear Magnetic Resonance)

ActiveCN101975788ARapid identificationAccurate identificationAnalysis using nuclear magnetic resonanceNMR - Nuclear magnetic resonanceLow field nuclear magnetic resonance

The invention discloses a method for identifying the quality of edible oil with low-field NMR (Nuclear Magnetic Resonance), suitable for identifying and measuring genuine edible oil and inferior drainage oil. The method rapidly and accurately identifies the genuine edible oil and the inferior drainage oil by using the difference between the relaxation time map data of the genuine edible oil and the inferior drainage oil as a main identification reference, using NMR signals of the genuine edible oil and the inferior drainage oil as main observation objects and using the comparison and the analysis of the transversal relaxation time map data of the genuine edible oil and the inferior drainage oil as main measures. The method of the invention has high measuring result accuracy, good repetition and stability, short duration, and the like, is beneficial to the realization of the one-site identification of the qualities of various kinds of edible oil and provides reliable oil quality information for detecting the qualities of various kinds of edible oil.

Owner:SUZHOU NIUMAG ELECTRONICS TECH +2

Welding method and silver based metal for hard-alloy heavy type cutting tools

InactiveCN101342626ALow melting pointEasy to breedOther manufacturing equipments/toolsWelding/cutting media/materialsAlloyEngineering

The invention discloses a welding method of heavy type hard-alloy cutting tool and silver based solder thereof. The welding method and the silver based solder can effectively avoid the welding crack during welding process, and consequently assure the welding quality of the heavy cutting tool. The welding method comprises the following procedures: surface treatment of the welding area, removal of oil, purities and rust-spotting, and enabling the welding surface to have the certain roughness; coating the welding flux and the silver based solder on the welding surface of hard-holly blade and steel substrate, putting the welding material into a vacuum heating furnace, and counterweighing the welding material with a metal block; filling inert gas into the vacuum heating furnace and heating up to 600 to 640 DEG C and insulating; decreasing to 280 to 300 DEG C and insulating, and finally decreasing to the room temperature for completing the welding process. The composition of the silver based solder in weight percentage is as follows: 40 to 50 percent of Argentum, 20 to 30 percent of Copper, 18 to 25 percent of Zinc, 1 to 3 percent of Stannum, 1 to 3 percent of Nickel and impurities.

Owner:王朝

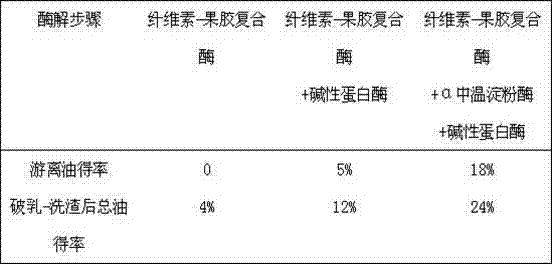

Method for extracting oil from peony seeds or peony seed dregs

ActiveCN103484235AReduce consumptionNo residueFatty-oils/fats productionEdible oils/fatsEmulsionProtein hydrolysates

The invention discloses a method for extracting oil from peony seeds or peony seed dregs. The method comprises the following steps: (1) pretreatment; (2) enzymolysis; (3) centrifuging; (4) demulsification; (5) dreg washing. Free oil, an emulsion layer, protein hydrolysate and dregs are obtained after enzymatic hydrolysate is centrifuged, wherein the free oil is peony seed oil, and a certain amount of oil can also be recovered after the emulsion layer and the dregs are subjected to demulsification and dreg washing respectively. According to the method, the peony seed oil can be extracted without drying raw materials, the operation is simple, the requirement for equipment is low, the oil yield is high, the oil quality is good, solvent residues and environmental pollution are avoided, and the obtained protein hydrolysate and dregs can also be further used comprehensively.

Owner:TONGLING RUIPU PEONY IND DEV +1

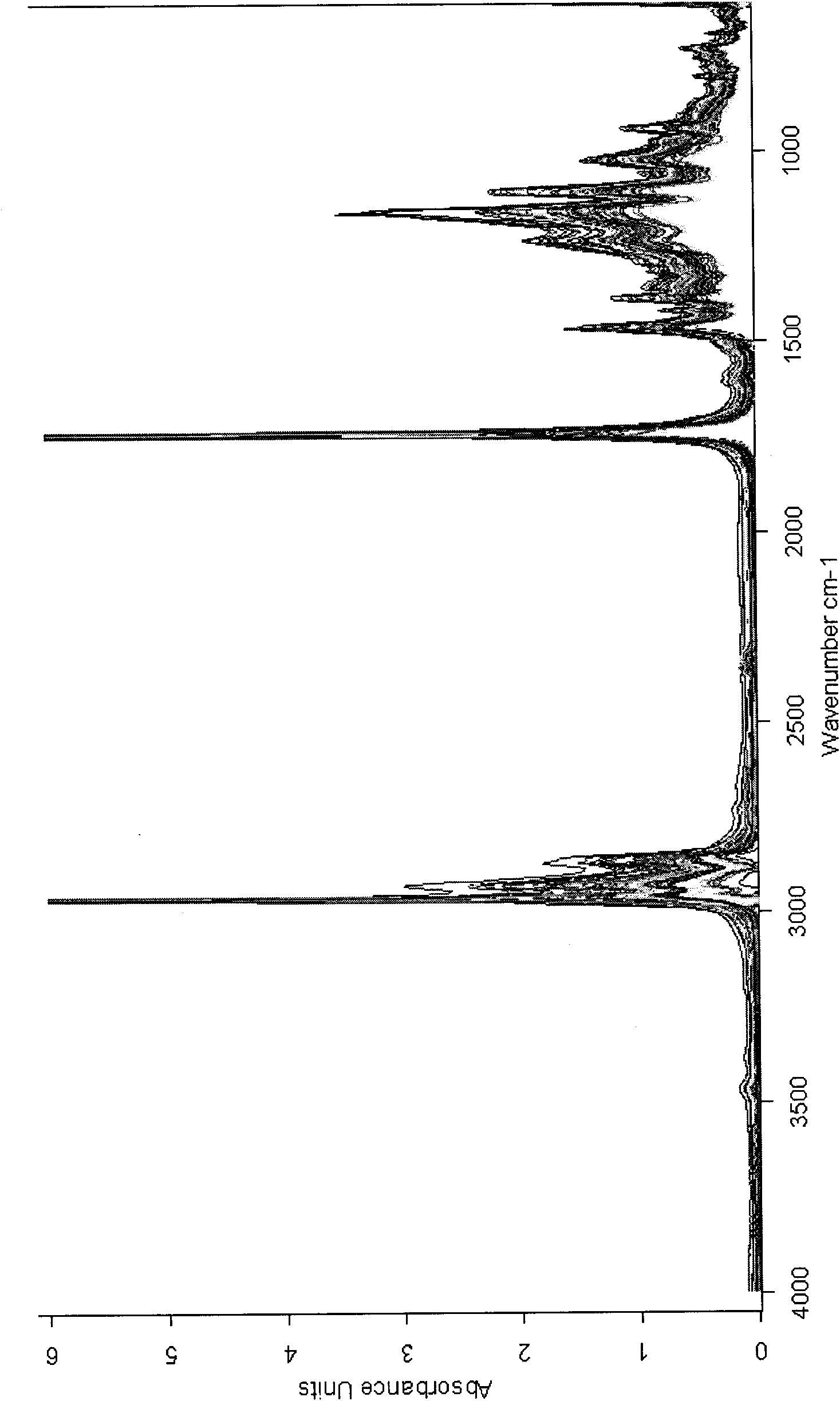

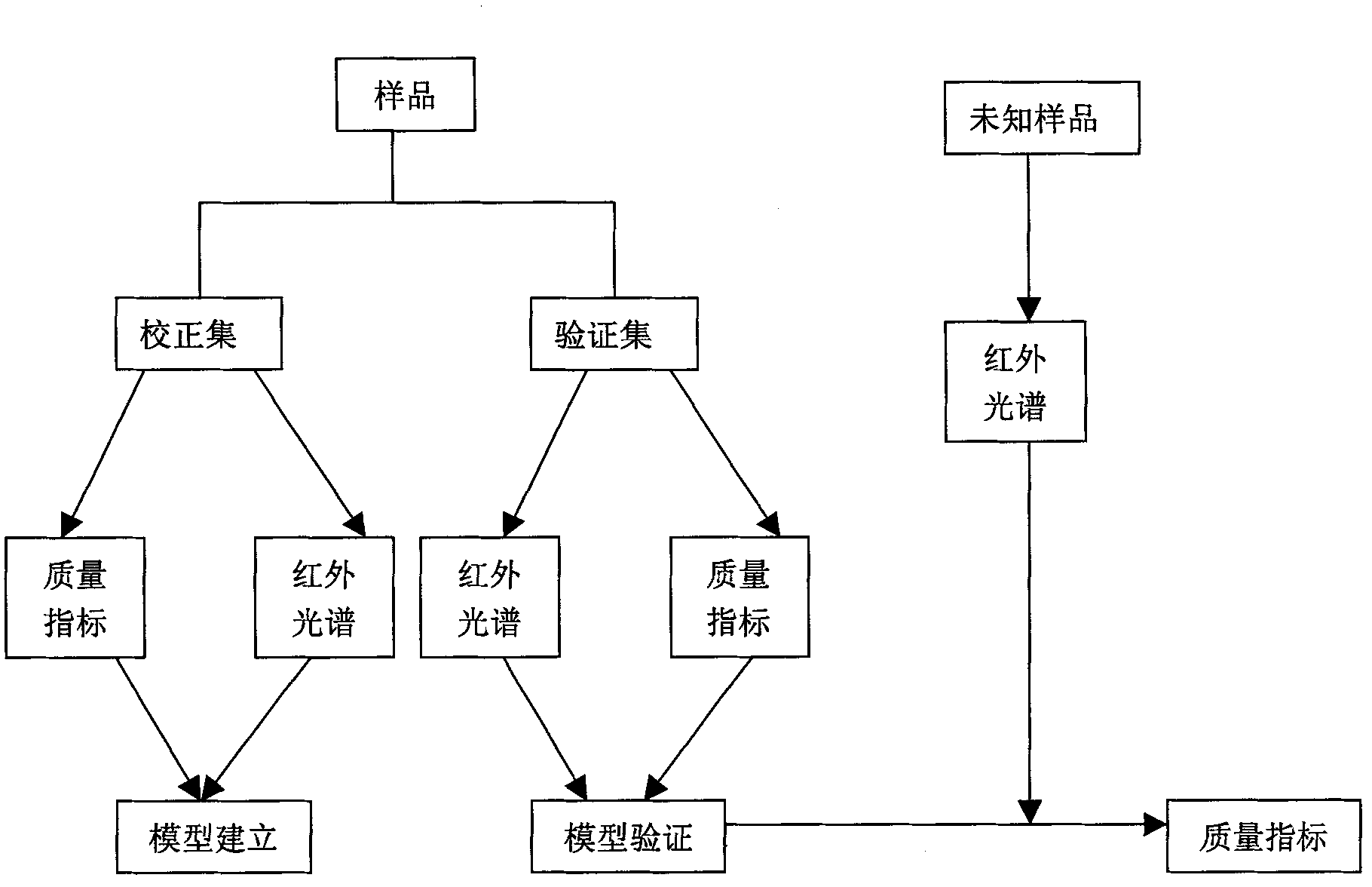

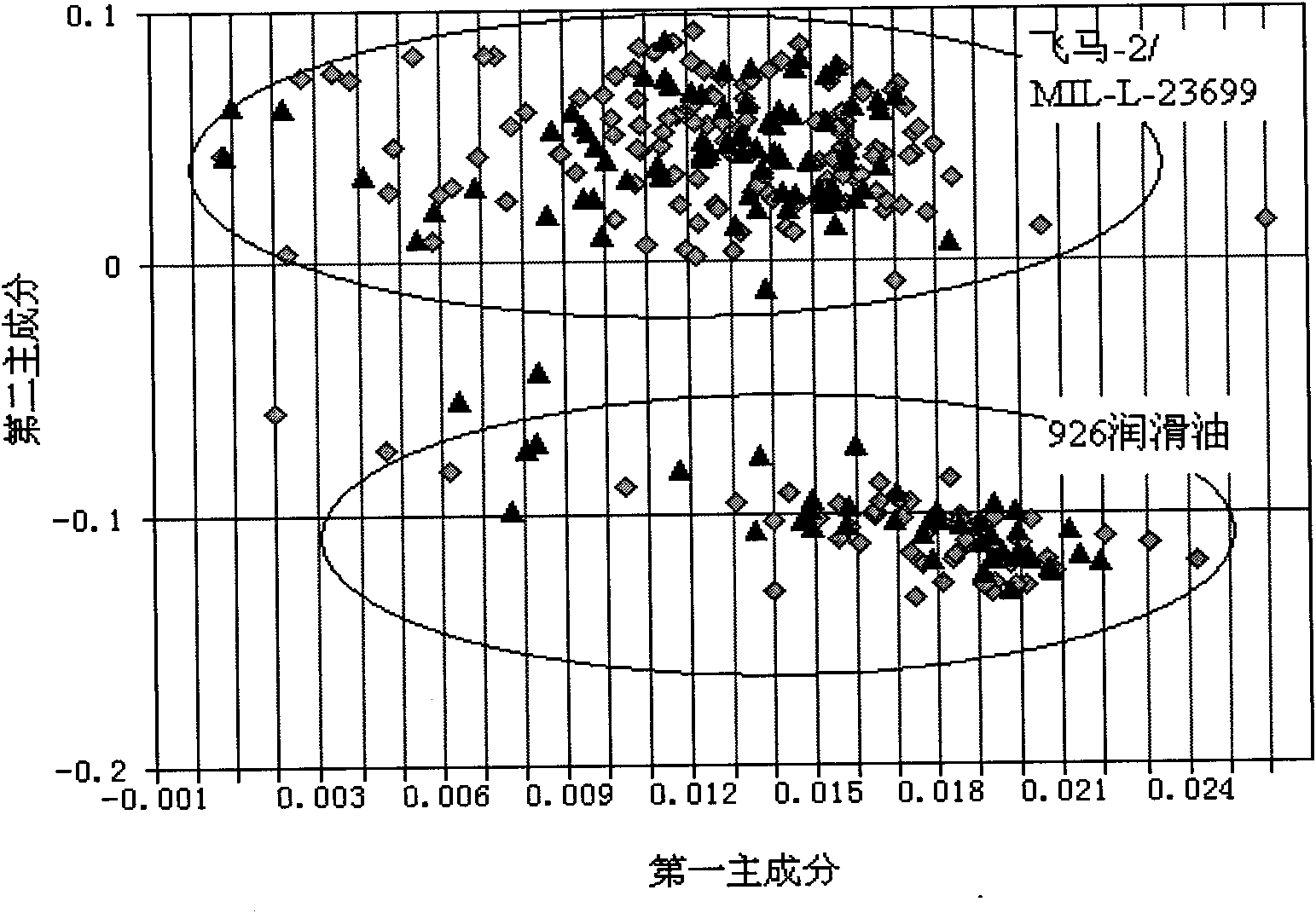

In-use lubricating oil quality rapid testing method

InactiveCN101806729AImprove monitoring effectLower requirementColor/spectral properties measurementsOil qualityRapid testing

The invention relates to an in-use lubricating oil quality rapid testing method which comprises the following steps that: (1) a representative lubricating oil sample is collected as a training set; (2) the infrared spectrum of the training set lubricating oil sample is determined, corresponding pre-treatment is carried out, and the spectrum data after pre-treatment serves as a variable; (3) through a multivariate calibration method, the relationship model between the in-use lubricating oil quality index and the spectrum is built; and (4) for the quality testing of the lubricating oil sample to be tested, first the infrared spectrum is determined, and then pre-treatment which is the same with that of Step (2) is carried out, and the lubricating oil quality index is determined through the lubricating oil quality analysis model built in Step (3). The method of the invention can rapidly determine 7 quality indexes, i.e. the in-use lubricating oil water content, TAN, TBN, 40DEG C viscosity, 100DEG C viscosity, the flash point, the pour point and the like, and the lubricating oil quality is monitored. The in-use lubricating oil quality rapid testing method has high analysis speed, is convenient to operate, and greatly improves the lubricating oil quality monitoring capability.

Owner:PETRO OIL & LUBRICANT RES INST OF THE GENERAL LOGISITIC DEPT OF PLA

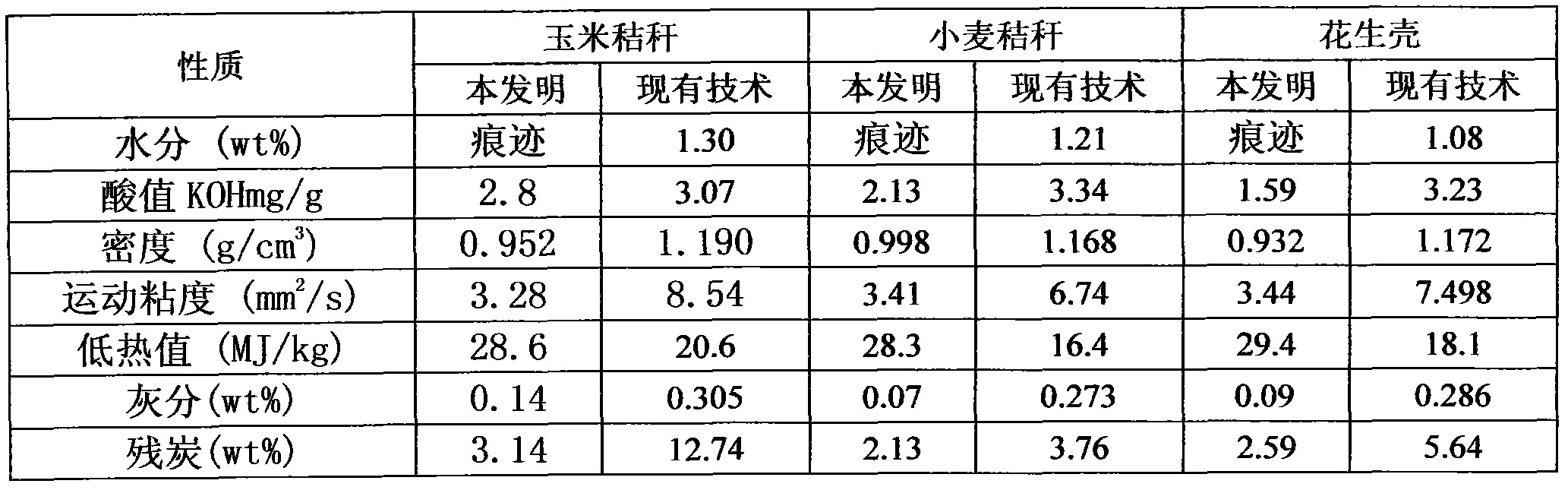

Biomass pyrolysis liquefied fuel oil technology

InactiveCN102277188AReduce the impactIncrease productionBiofuelsLiquid hydrocarbon mixture productionFixed bedLiquid fuel

The invention relates to the biomass thermal cracking liquefying fuel oil technology, which comprises the following process steps: (1) preprocessing biomass, namely preparing soak solution from water, 5 mol / L of hydrochloric acid and hydrofluoric acid in a volume ratio of 20:1:0.5, soaking for 30 minutes, and removing ash content; (2) performing thermal cracking of the biomass; and (3) refining biological oil, namely performing catalytic cracking on the prepared heavy biological oil, preheating the heavy biological oil to the temperature of 400 DEG C, and keeping the temperature of between 410 and 490 DEG C in a fixed bed reactor, wherein a catalyst is shape-selective molecular sieve based catalysts zeolite socony mobile-5 (ZSM-5), Na-ZSM-5, hydrogen zeolite socony mobile-5 (HZSM-5) or an aluminum phosphate molecular sieve, the feed rate is controlled at 3 to 6 m<3> / h according to the size of equipment, and the biological oil is catalyzed and subjected to the thermal cracking under the condition that the using amount of the catalyst is 2 percent of the mass of the biological oil. In the biomass thermal cracking liquefying fuel oil technology, the ash content is removed, and the influence of the ash content is reduced in the thermal cracking process, so that the yield of the biological oil is improved by 50 to 60 percent. In addition, the biological oil is refined by a catalytic cracking method after cracking reaction, and oxygen in the biological oil is removed in form of CO, CO and HO by the catalyst at intermediate temperature under normal pressure in a thermochemical method; and thus, the biological oil is converted into liquid fuel which is stable, high in oil quality and high in energy density and can be applied widely and directly at normal temperature.

Owner:青岛福瑞斯生物能源科技开发有限公司

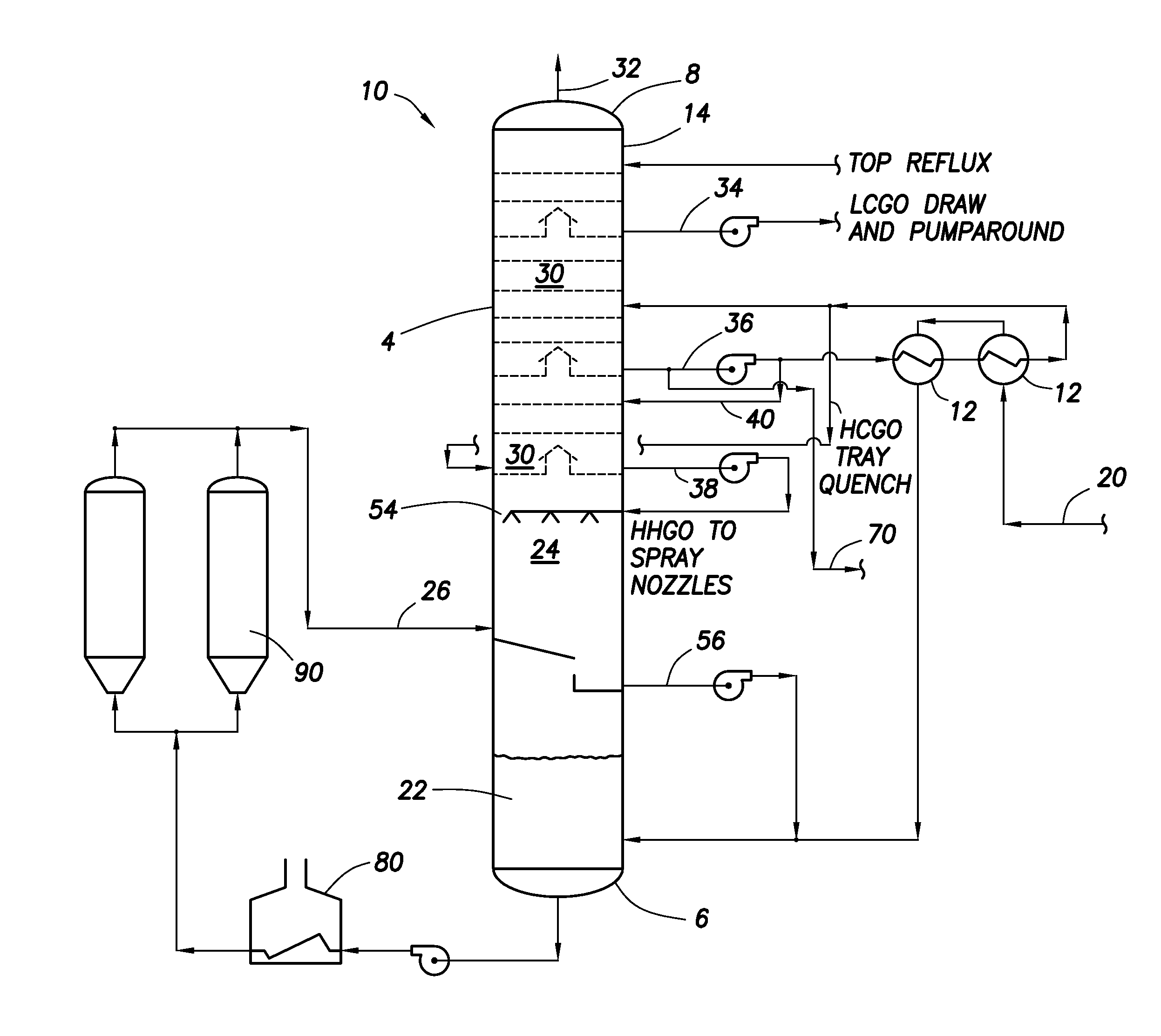

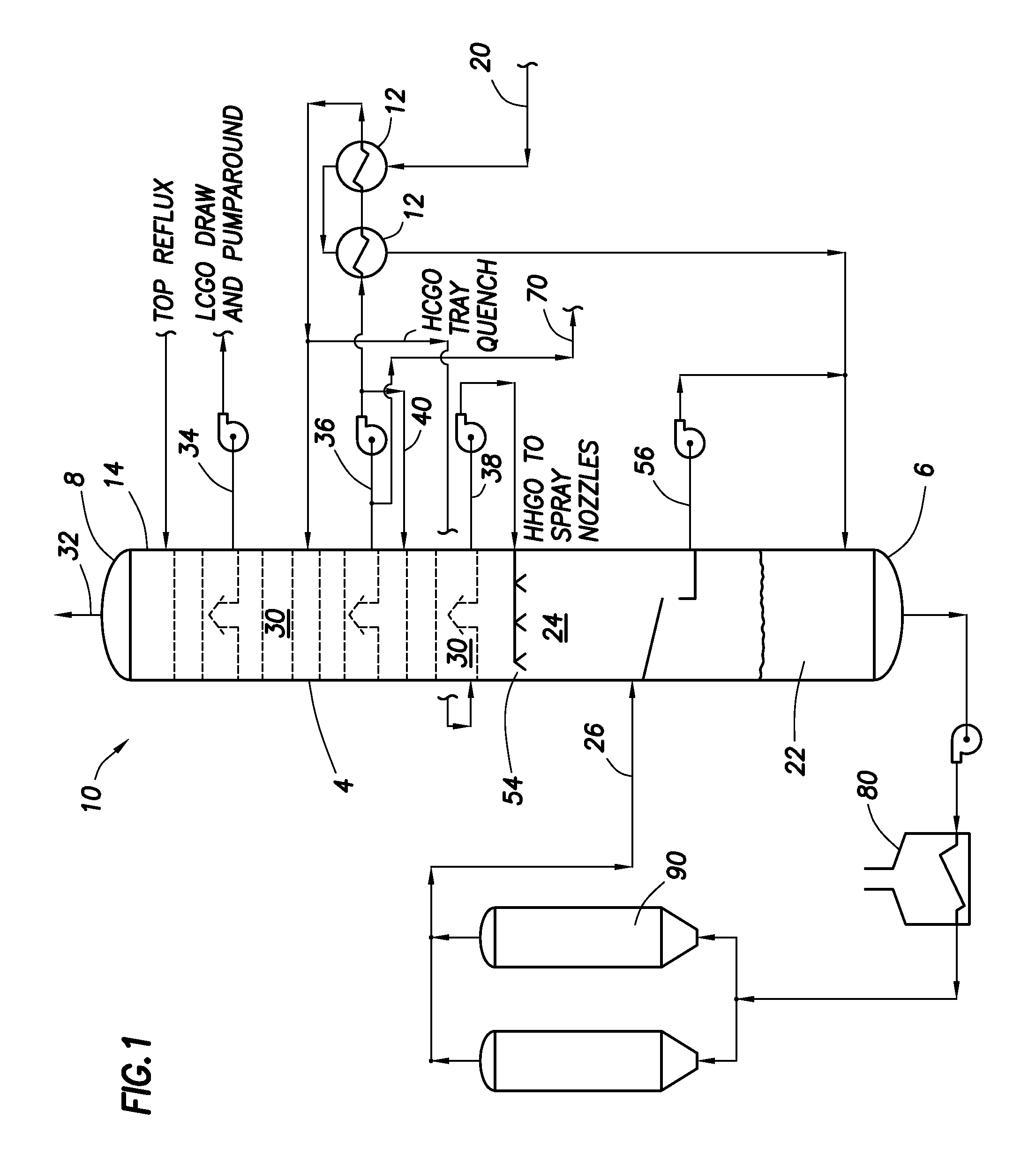

Efficient method for improved coker gas oil quality

ActiveUS20100270208A1Thermal non-catalytic crackingCombustible gas coke oven heatingEngineeringOil quality

An efficient delayed coking process improvement for producing heavy coker gas oil of sufficient quality to be used as hydrocracker feedstock.

Owner:BECHTEL ENERGY TECH & SOLUTIONS INC

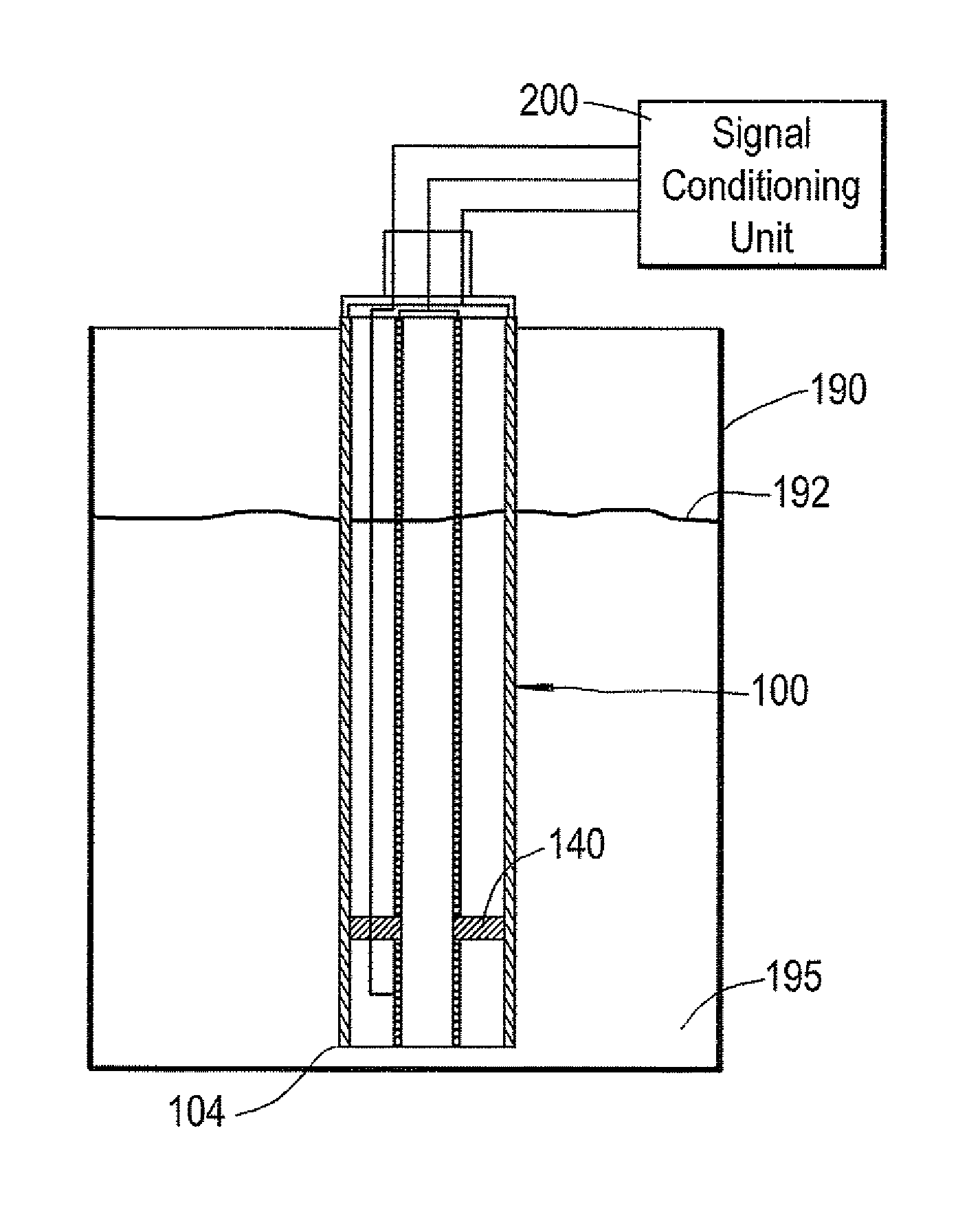

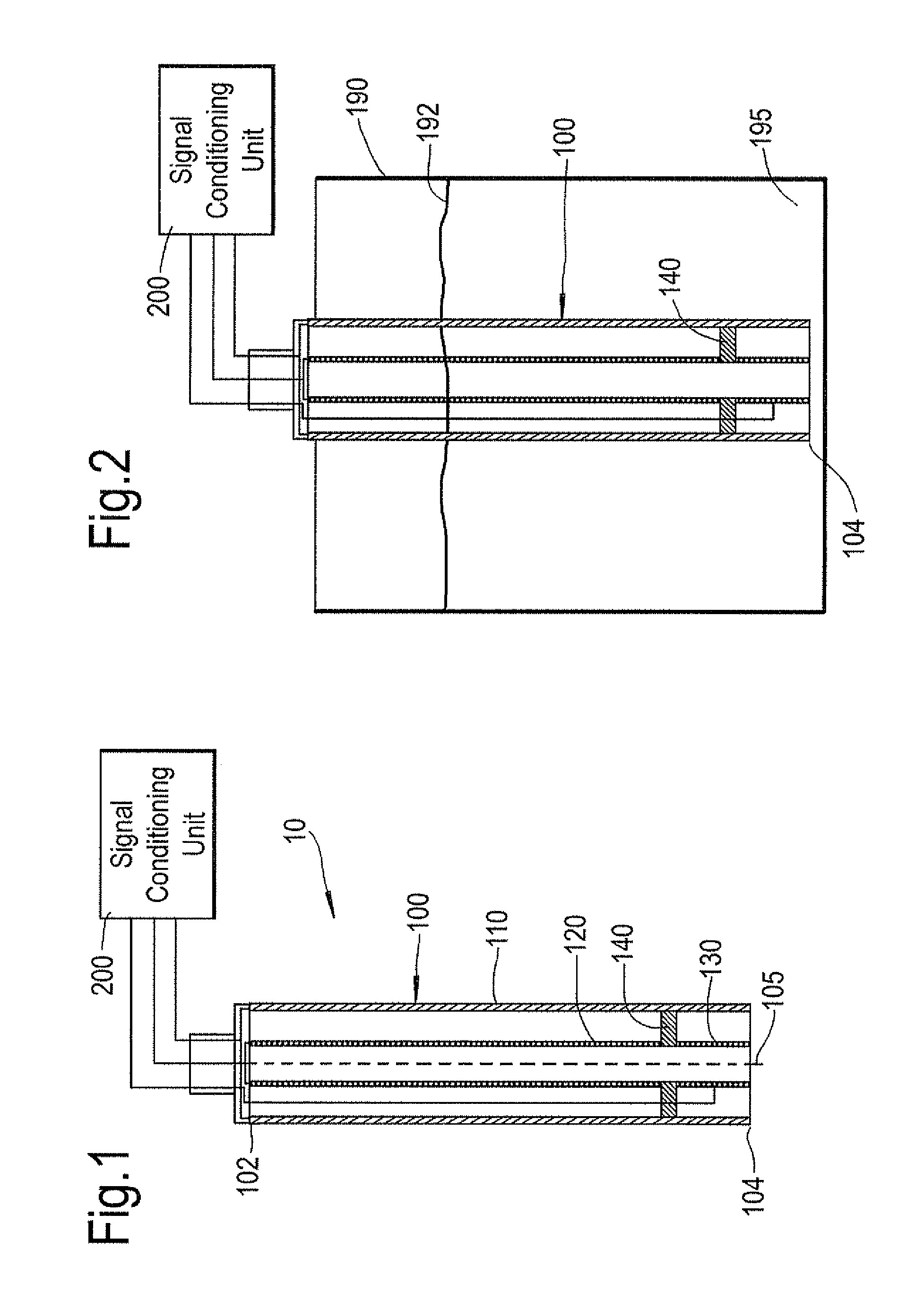

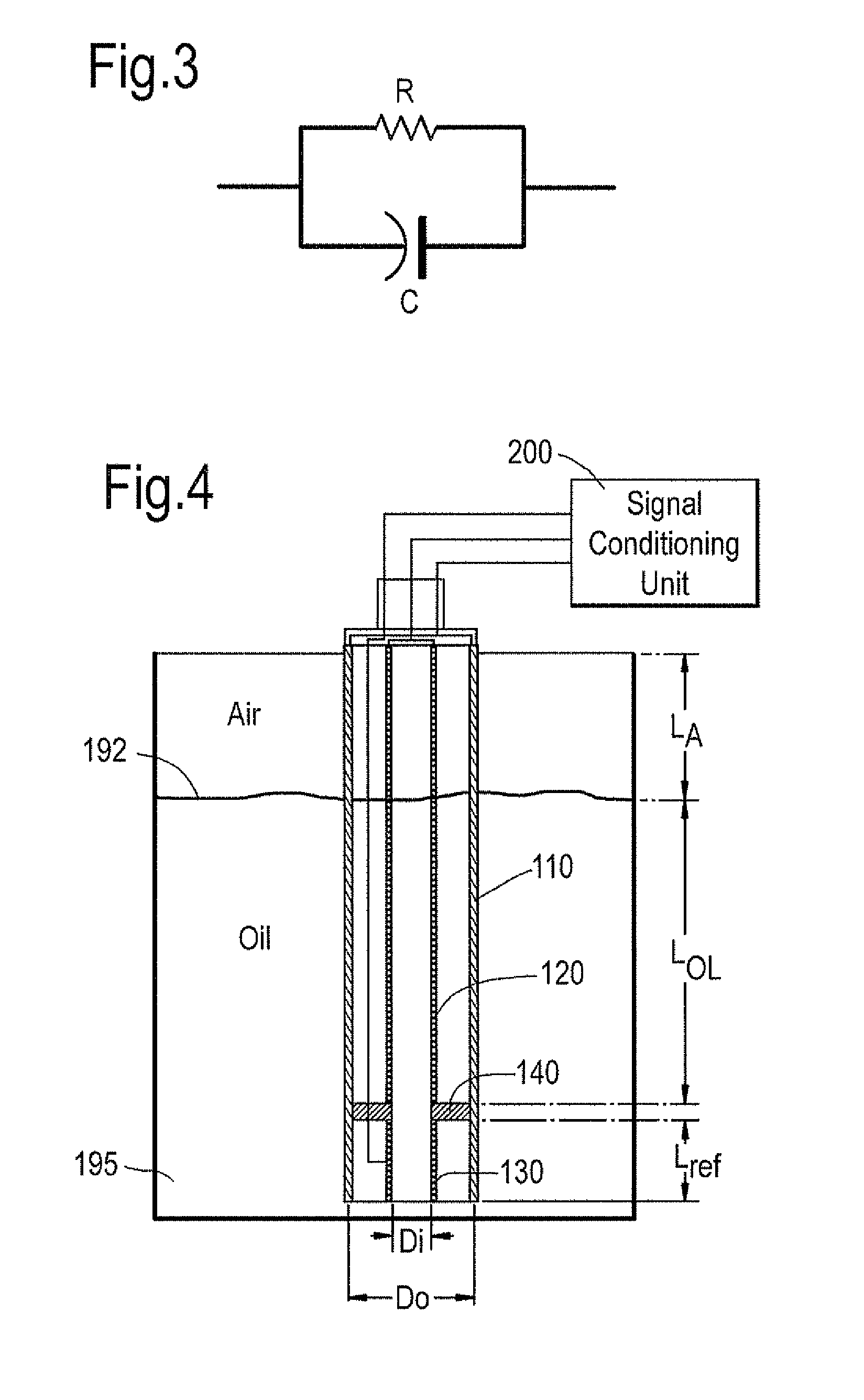

Oil sensor

ActiveUS20130068015A1Minimized size and weightMaterial analysis by electric/magnetic meansMachines/enginesPower flowAlternating current

A system and method for measuring oil level and quality is provided. The system and method uses an alternating current (AC) to determine oil level, and a lower frequency alternating current, or a direct current (DC), to measure oil quality. The system may comprise a single sensor that is used to measure both oil quality (by providing the lower frequency alternating current or direct current) and oil level (by providing the higher frequency alternating current). Using the lower frequency AC, or DC, enables the resistance of the oil to be determined, which gives an accurate indication of the oil quality.

Owner:ROLLS ROYCE PLC

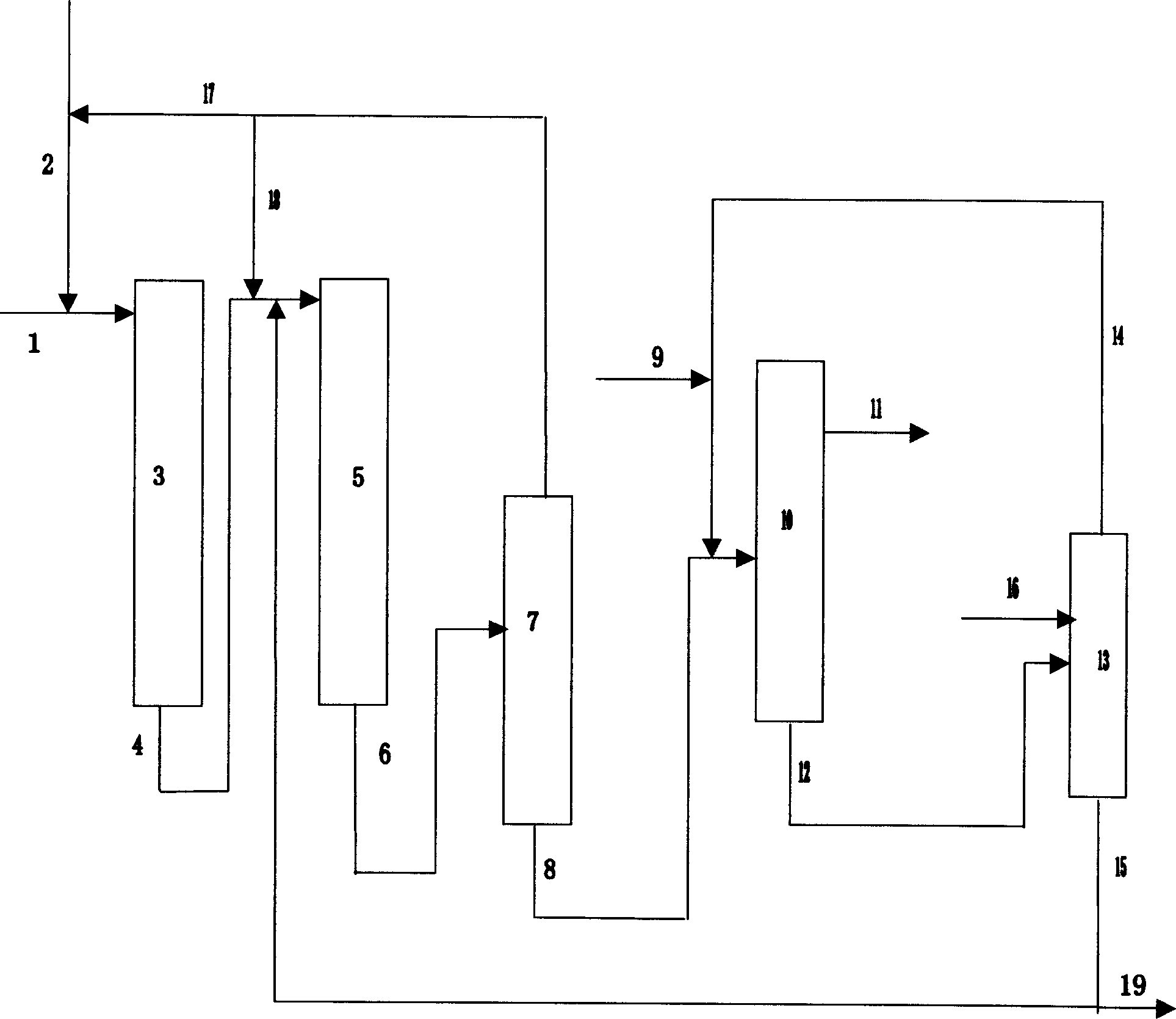

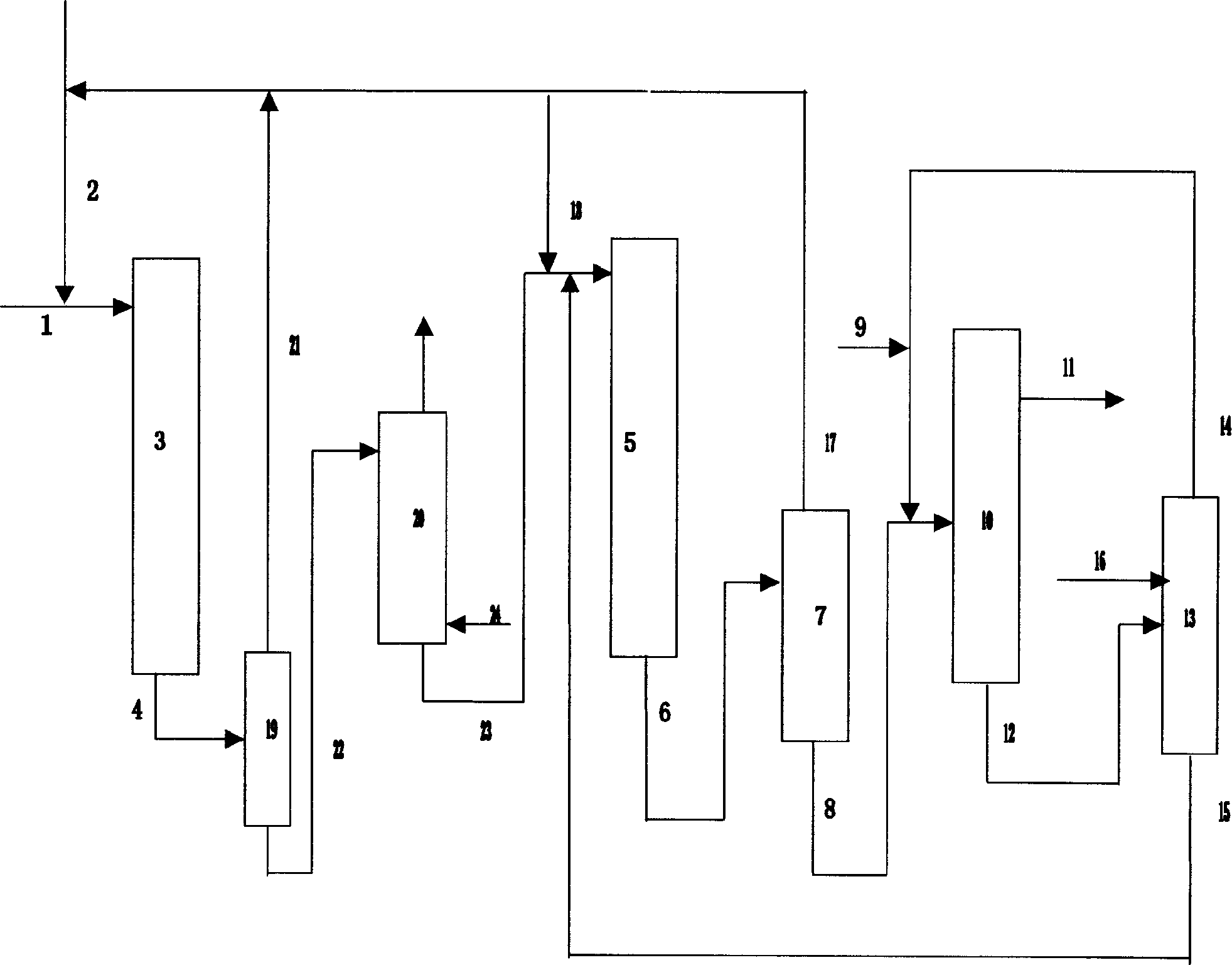

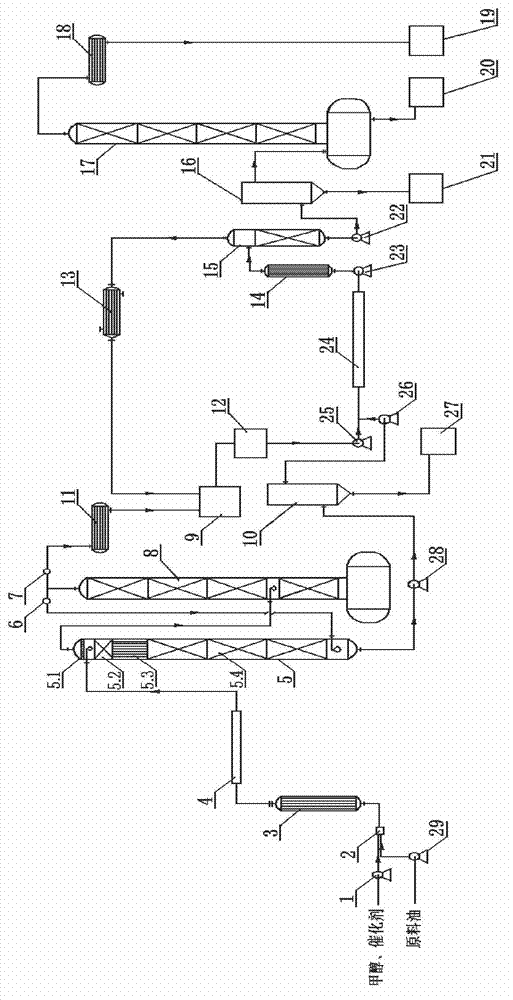

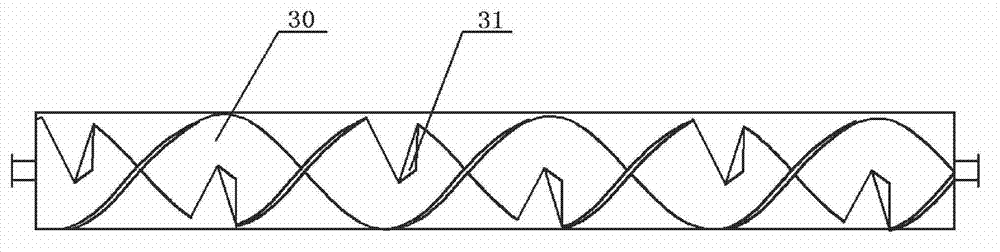

Continuous production device and method of biodiesel

The invention discloses a continuous production device of biodiesel, which comprises a biodiesel reaction device, a connecting pipeline, and a metering pump, a delivery pump and a flow meter, wherein the metering pump, the delivery pump and the flow meter are arranged in the pipeline; the biodiesel reaction device comprises a mixer 2, a heater I3, a pipeline reactor I4, an esterification reaction tower 5, a catalyst separator 10, a methanol storage tank 9, a pipeline reactor II24, a flash column 15, a glycerin separator 16, a distillation tower 17 and a biodiesel storage tank 19. A method for preparing the biodiesel by the continuous production device comprises the steps of: pretreating high acid value raw oil, carrying out first stage esterification reaction and second stage esterification reaction, separating by a catalyst, carrying out transesterification, and finally separating and distilling flash and glycerin which are obtained by heating oil after transesterification to obtain the biodiesel. The method disclosed by the invention is simple in production technology, wide in application scope of equipment for the raw oil quality, low in production energy consumption, higher in conversion rate and more environment-friendly, and more effectively improves the production quality and the yield of the biodiesel.

Owner:GUANGXI HEZHONG ENERGY +1

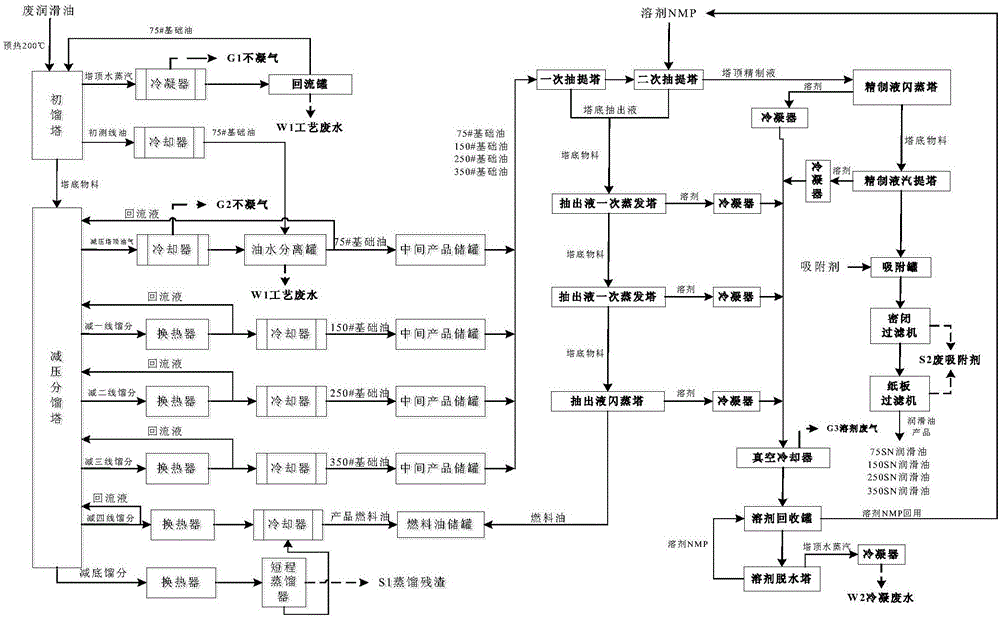

Method for regenerating base oil by waste oil

InactiveCN106833736AAvoid wastingImprove protectionTreatment with plural serial refining stagesLubricant compositionDistillationFuel oil

The invention discloses a method for regenerating base oil by waste oil, belonging to the technical field of waste oil regeneration. The problems that the waste oil regeneration rate is low, the oil quality of regenerated oil is poor, the environment is polluted and the like in the prior art are solved. The method for regenerating the base oil by the waste oil comprises a raw material pretreating part and a solvent refining part; wherein the raw material pretreating part comprises three phases of prefractionation, reduced pressure distillation cutting and molecular distillation; the solvent refining part comprises the steps of extraction, refined solution recovery, extracted solution recovery and solvent recovery; the molecular distillation refers to the process that tower bottom oil of a reduced pressure distillation tower is fed into a short-path distiller, and separating fuel oil and residues through two-stage molecular distillation under the condition that the pressure is 0.001 to 100Pa. The method provided by the invention is suitable for regenerating the base oil by the waste oil.

Owner:山东铂铠环保科技有限公司

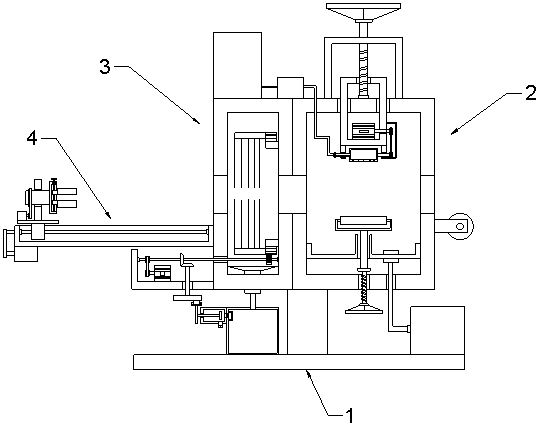

Steel pipe mechanical-oiling equipment

InactiveCN109550640AReduce dosageEfficient dust removalLiquid surface applicatorsCoatingsArchitectural engineeringFuel tank

The invention discloses steel pipe mechanical-oiling equipment which comprises a base, an oiling mechanism, a dust removing mechanism and a feeding mechanism, wherein the oiling mechanism comprises anoiling tank which is fixedly connected with the base; an oiling roll is arranged in the oiling tank; uniformly-distributed overflow holes are formed in the circumferential surface of the oiling roll;the dust removing mechanism comprises a dust removing tank; and a ring-shaped brush is arranged in the dust removing tank. The steel pipe mechanical-oiling equipment disclosed by the invention has the beneficial effects that through the arrangement of the hollow oiling roll provided with the overflow holes as well as a spreading roll capable of rising and falling, the surface of a steel pipe canbe uniformly coated with anti-rust oil, thereby improving the oiling quality when the consumption of the anti-rust oil is reduced; and through the arrangement of the ring-shaped brush, a dust collecting hood and a dust collecting tank which communicates with a suction piston cylinder, the efficient dust removing operation on the to-be-oiled steel pipe can be achieved, thereby guaranteeing the oiling quality; and through the arrangement of a rotating cylinder and a sliding frame which are equipped with a clamping mechanism, the steel pipe can be rotated when fed, thereby facilitating the oilingoperation on the circumferential surface of the steel pipe.

Owner:HUNAN UNIV OF SCI & ENG

Hydrofining process of waste lubricating oil

ActiveCN104611058AHigh compressive strengthExtended service lifeTreatment with hydrotreatment processesHydrogenation reactionReaction temperature

The invention provides a hydrofining process of waste lubricating oil. The process comprises: after pre-treating, dewatering and removing impurities from a raw material, removing pitch and colloid in a propane extraction or wiped film vaporization device, and perfecting the product quality via a two-stage hydrofining reactor, and filling a hydrogenation protective agent and a demetallization agent in a pre-hydrogenation reaction, wherein the reaction temperature is 310-360 DEG C, the pressure is 6-12 MPa, the volume ratio of hydrogen to oil is 100-300, and the liquid volume space velocity is 0.5-1.2h<-1>, the reaction temperature of a main hydrogenation reactor is 320-400 DEG C, the pressure is 6-12 MPa, the volume ratio of hydrogen to oil is 500-1000, the liquid volume space velocity is 0.2-0.6h<-1>, and the used catalyst is Ni-Mo-W-Ce / Al2O3 or Ni-Mo-P-La / Al2O3; no acid or alkali waste is discharged in the production process, thereby being environmentally friendly and pollution-free, the recovery rate of the waste oil is higher than 95%, and the oil quality can be greatly improved to increase the economic benefits.

Owner:WUHAN KELIN FINE CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com