System and method for monitoring liquid oil quality

A quality monitoring and liquid oil technology, applied in the electronic field, can solve the problems of oil pollution, viscosity drop, viscosity rise, etc., to achieve the effect of reducing consumption and pollution, improving service life, and improving life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

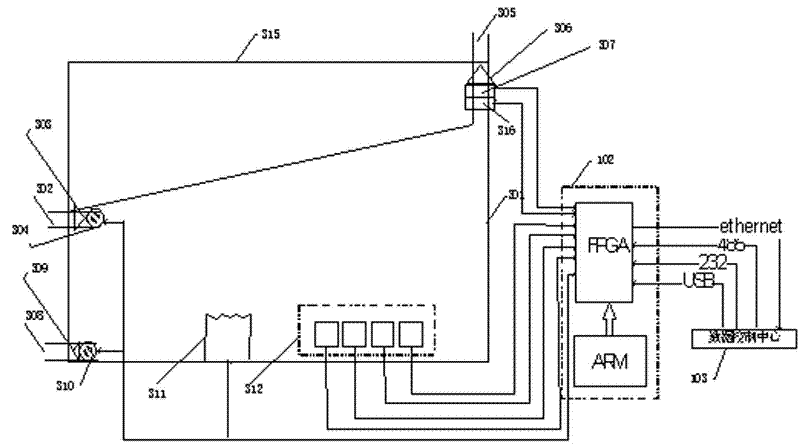

[0044] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

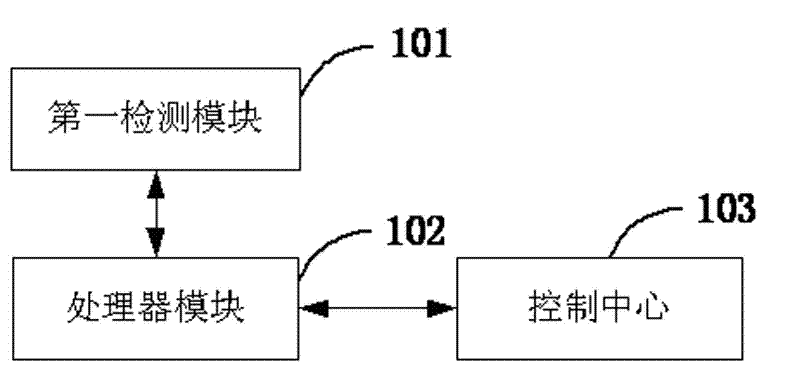

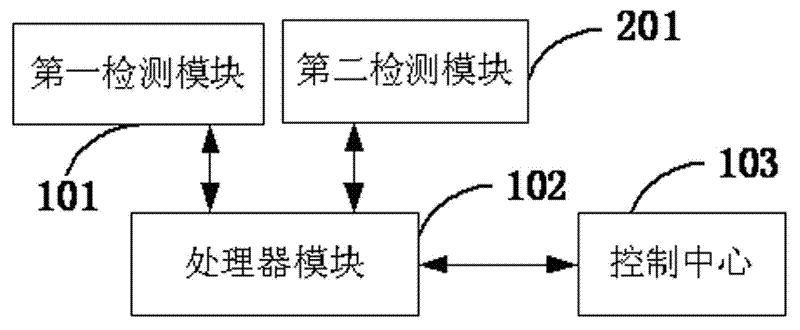

[0045] An embodiment of the present invention provides a liquid oil quality monitoring system, figure 1 It is a logical structural block diagram of the system implementation mode 1 in the embodiment of the present invention, such as figure 1 As shown, the system includes:

[0046] The first detection module 101 is used to detect the liquid oil to obtain various physical and chemical parameters reflecting the quality of the detected liquid oil;

[0047] The processor module 102 is used to compare various physical and chemical parameters of the detected liquid oil obtained by the first detection module 101 with standard values, so as to determine whether the quality of the detected liquid oil meets the standards.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com