Continuous production device and method of biodiesel

A biodiesel and production equipment technology, applied in biofuel, petroleum industry, liquid carbon-containing fuel, etc., can solve the problems of low utilization rate of methanol, low production efficiency, long reaction time, etc., and achieve strong continuity and high utilization rate , the effect of high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

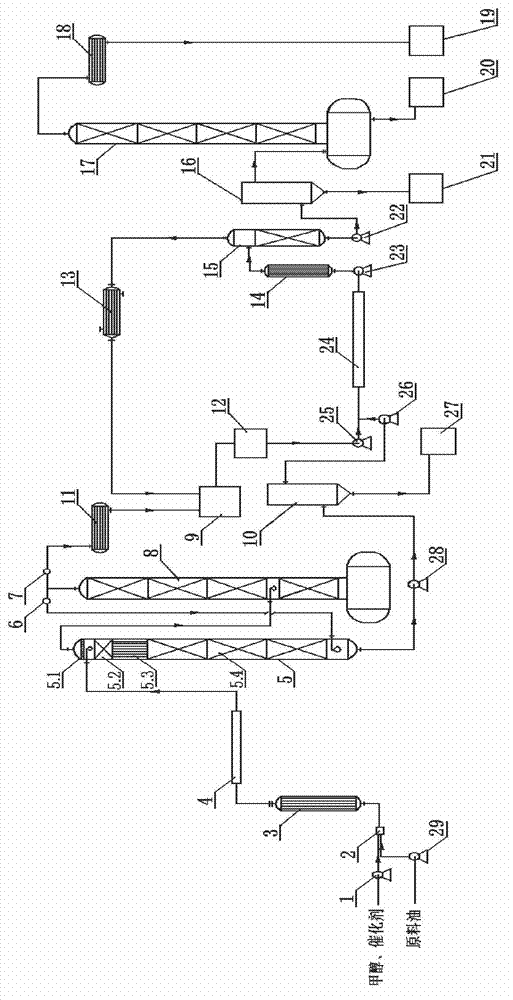

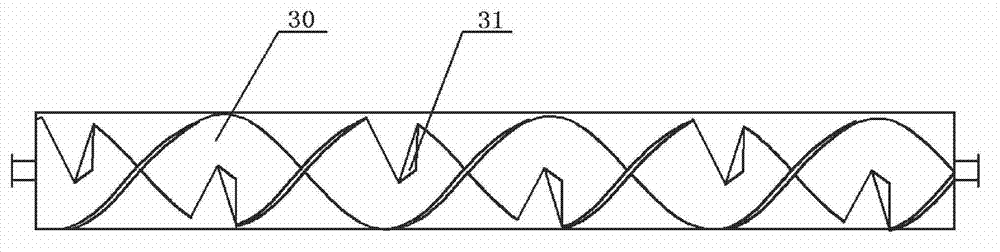

[0044] A continuous biodiesel production equipment, including biodiesel reaction device, methanol recovery device, connecting pipelines and metering pumps, transfer pumps and flowmeters in the pipelines, the biodiesel reaction device includes mixer 2, heater I3, pipeline reaction Device I4, esterification reaction tower 5, catalyst separator 10, methanol storage tank 9, methanol lye tank 12, pipeline reactor II24, flash tower 15, glycerin separator 16, distillation tower 17 and biodiesel storage tank 19, The outlet of the mixer 2 is connected to the pipeline reactor I4 through the heater I3, the outlet pipeline of the pipeline reactor I4 is connected to the upper inlet of the esterification reaction tower 5, the bottom outlet of the esterification reaction tower 5 is connected to the catalyst separator 10, and the bottom outlet of the catalyst separator 10 The pipeline is connected with an acid catalyst recovery tank 27; the outlet of the methanol storage tank 9 is connected wi...

Embodiment 2

[0049] The difference from Example 1 is that the packed tower 5.4 is a packed tower made of fibers.

Embodiment 3

[0051] The difference from Example 1 is that the packed tower 5.4 is a packed tower made of wire mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com