Acid-proof type microalgae DHA oil microcapsule powder and preparation method thereof

A technology of microcapsules and oils, applied in the directions of food preparation, food ingredient function, food forming, etc., can solve the problems of microalgae DHA oil microcapsule structure damage, affecting product quality, attenuation and deterioration, etc., to achieve odor characteristics and stability. Good properties, low moisture and surface oil content, anti-spill and oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

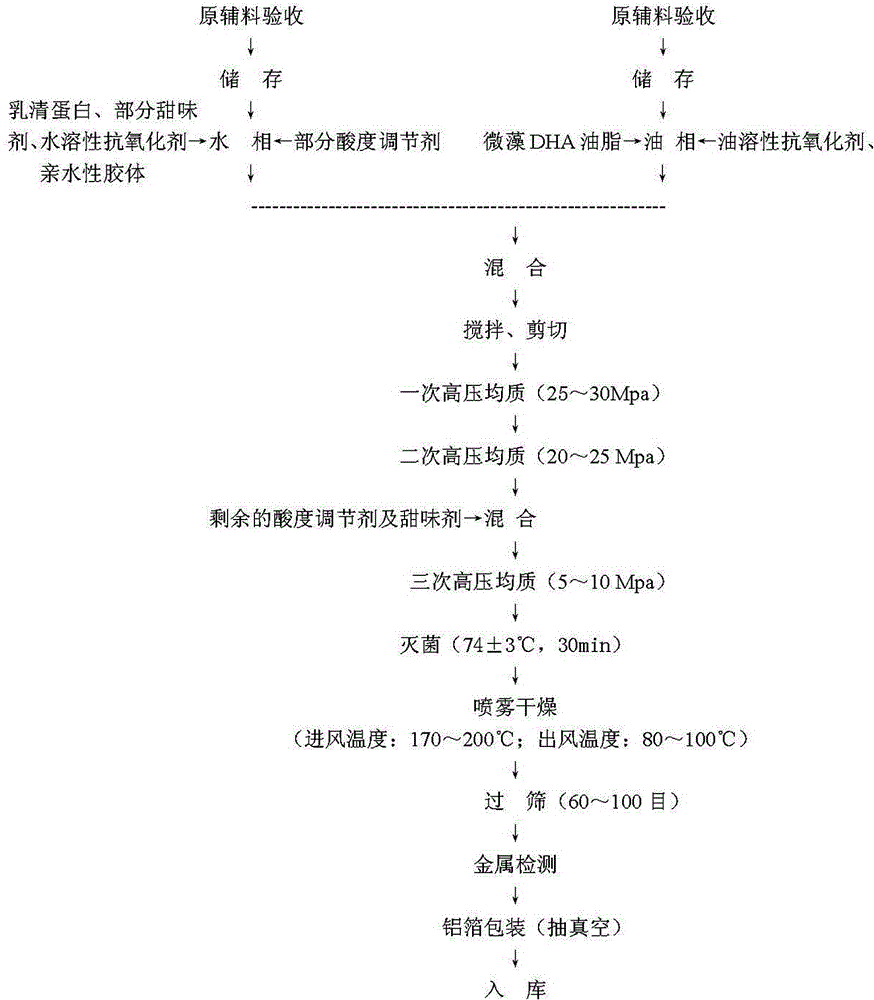

Method used

Image

Examples

preparation example Construction

[0059] (1) Put whey protein, hydrophilic colloid, food emulsifier, water-soluble antioxidant in antioxidant, part of chelated salt in acidity regulator and part of sweetener into water at 70-75°C, keep warm Dissolve for 30 minutes, then stir until completely dissolved and then cool down to 50-55°C to obtain an aqueous phase liquid;

[0060] (2) First use a small amount of microalgae DHA oil to mix the oil-soluble antioxidant in the antioxidant, then stir the remaining microalgae DHA oil at a temperature of 65-70°C and add it to the mixed antioxidant , and continue to stir, until the core material is obtained after uniformity;

[0061] (3) Put the core material obtained in step (2) into the aqueous phase liquid obtained in step (1), and continuously stir for 20-30 minutes, and then perform shearing operation at a speed of 5000-7000 rad / min for 3-5 minutes , for the first embedding to obtain an emulsion;

[0062] (4) Homogenize the emulsion obtained in step (3) twice, the firs...

Embodiment 1

[0068] The above substances are weighed or measured according to the required amount, and then prepared according to the following steps:

[0069] (1) Whey protein, pectin, carboxymethylcellulose sodium (CMC-Na), sodium alginate, hydroxypropyl methylcellulose (HPMC), monoglyceride fatty acid ester, sodium caseinate, lemon Sour fatty acid glycerides, D-sodium erythorbate, potassium dihydrogen phosphate, maltodextrin and part of glucose were put into water at 75°C, kept warm and dissolved for 30 minutes, then stirred until completely dissolved and then cooled to 50°C to obtain an aqueous phase liquid;

[0070] (2) First use a small amount of microalgae DHA oil to mix L-ascorbyl palmitate and vitamin E, then stir the remaining microalgae DHA oil at a temperature of 70°C and add it to the mixed antioxidant. And continue to stir, after being uniform, the core material is ready for use;

[0071] (3) Put the core material obtained in step (2) into the aqueous phase liquid obtained i...

Embodiment 2

[0086] The above substances are weighed or measured according to the required amount, and then prepared according to the following steps:

[0087] (1) Whey protein, pectin, carboxymethylcellulose sodium (CMC-Na), sodium alginate, hydroxypropyl methylcellulose (HPMC), monoglyceride fatty acid ester, sodium caseinate, lemon Sour fatty acid glycerides, D-sodium erythorbate, potassium dihydrogen phosphate, maltodextrin and part of glucose were put into water at 70°C, kept warm and dissolved for 30 minutes, then stirred until completely dissolved and then cooled to 55°C to obtain an aqueous phase liquid;

[0088] (2) First use a small amount of microalgae DHA oil to mix L-ascorbyl palmitate and vitamin E, then stir the remaining microalgae DHA oil at a temperature of 65°C and add it to the mixed antioxidant. And continue to stir, after being uniform, the core material is ready for use;

[0089] (3) Put the core material obtained in step (2) into the aqueous phase liquid obtained i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com