Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

144results about How to "Fully emulsified" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

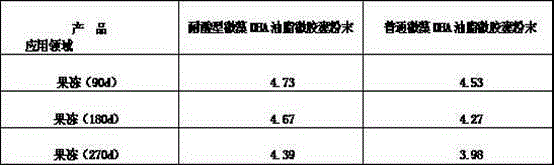

Beauveria bassiana oil suspending agent and method for producing the same

InactiveCN101502272AExtended shelf lifeGood adhesionBiocideAnimal repellantsBiotechnologyVegetable oil

The present invention discloses a beauveria bassiana oil suspension agent which is composed of the following components by weight: 5-15% of beauveria bassiana spore powder, 2-12% of dispersing agent, 1-3% of stabilizing agent and 75-85% of inert mineral oil or vegetable oil. The beauveria bassiana oil suspension agent of the invention has the advantages of long storing period of spore and 80.8% of active spore rate after storing for 1.5 years. The adhesion rate of spore on the body surface of insect is increased. Furthermore the selected dispersing agent and stabilizing agent are extraordinarily safe to the crop and has no chemical injury. After water adding for dilution, the beauveria bassiana oil suspension agent has a transparent or semi-transparent emulsion through slightly mixing. The emulsifying is total and no tall oil, deposition or oil deposition deposits. The stability of beauveria bassiana oil suspension agent is excellent. The beauveria bassiana oil suspension agent accords with the routine medicine taking habit and further has the advantages of convenient use in field, simple preparing method, extensive raw material source of product, and suitability for large-scale production.

Owner:INST OF PLANT PROTECTION HEBEI ACAD OF AGRI & FORESTRY SCI

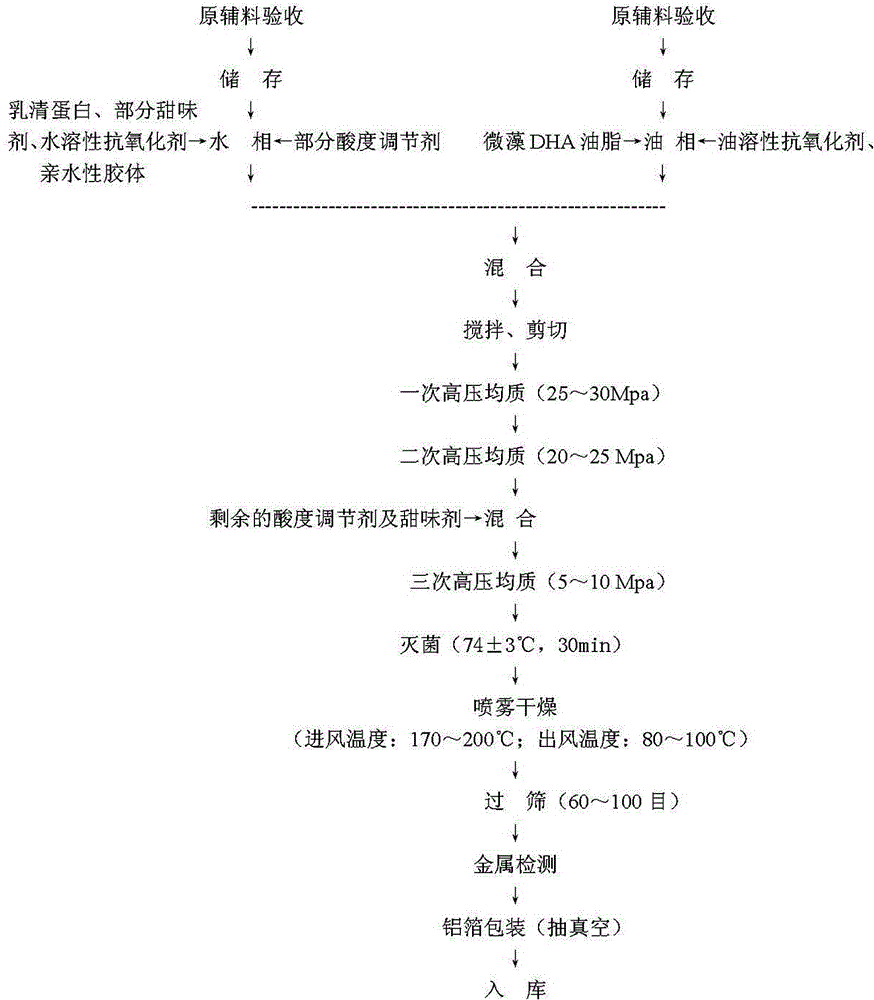

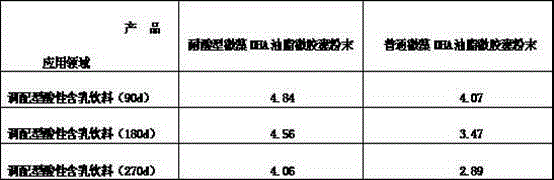

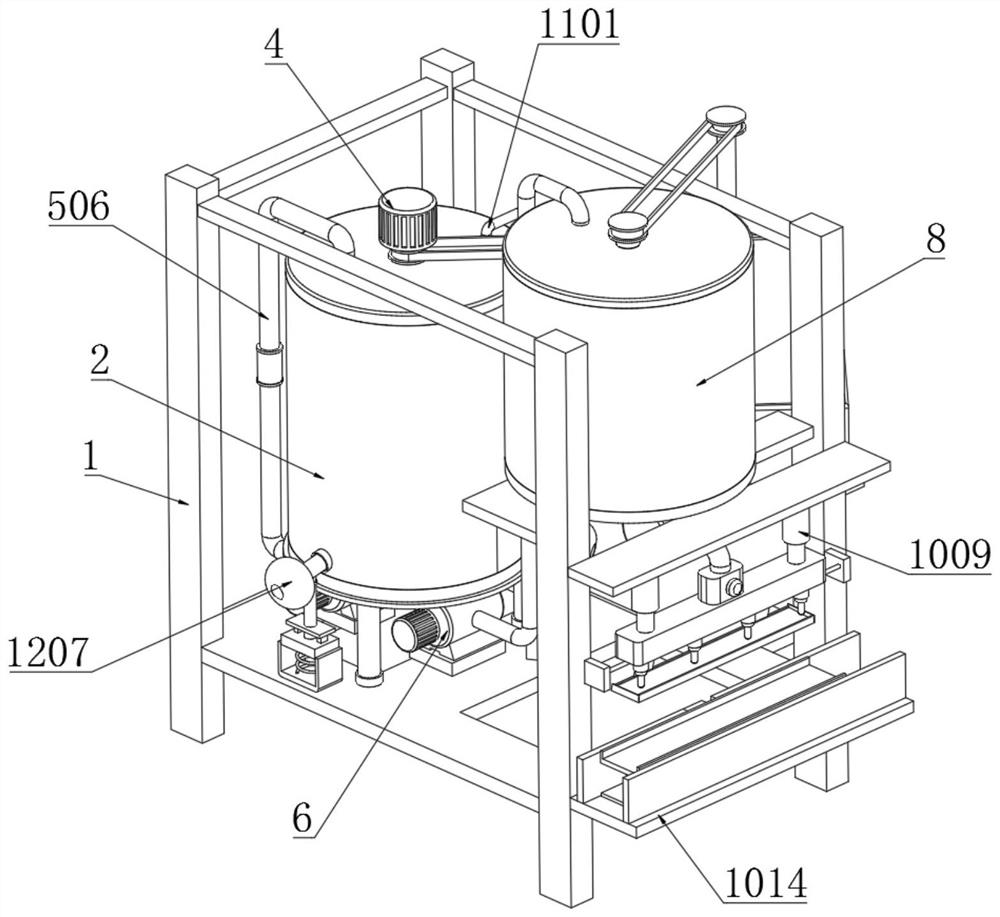

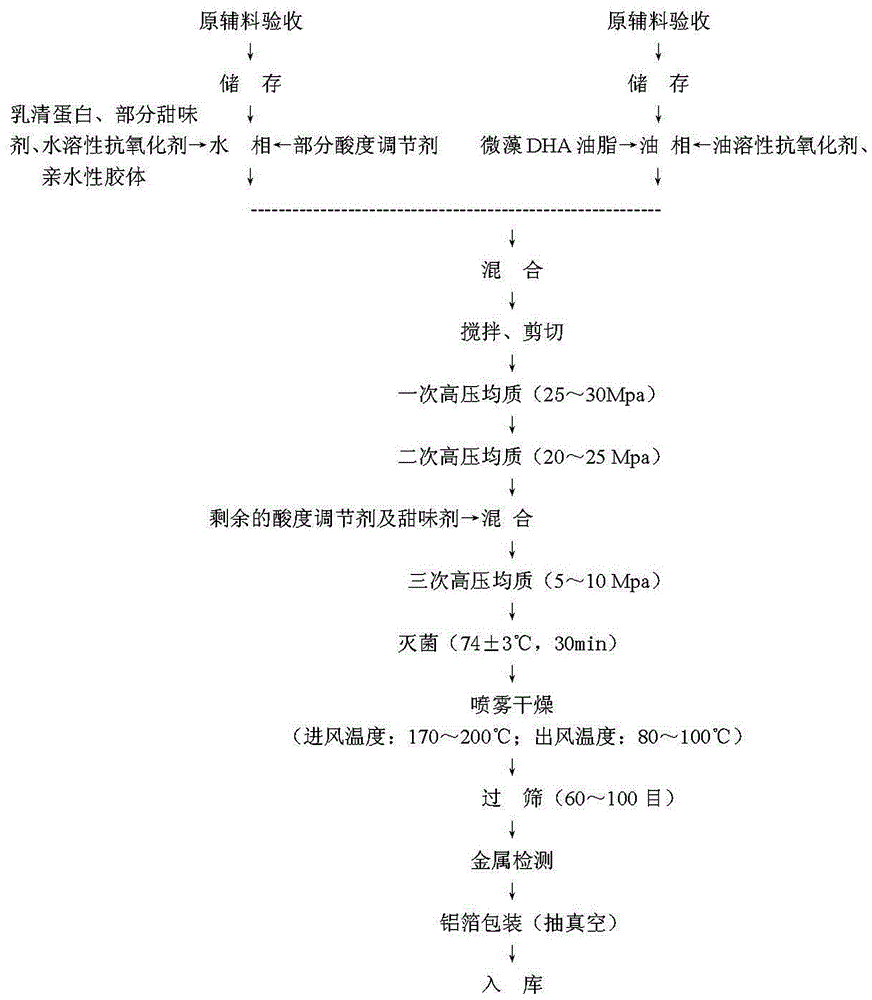

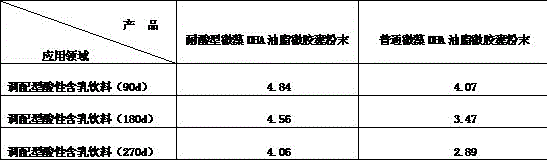

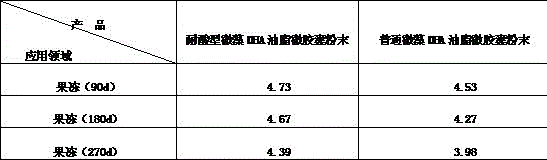

Acid-proof type microalgae DHA oil microcapsule powder and preparation method thereof

ActiveCN104432059AImprove stabilityNo flocculationSugar food ingredientsFood shapingBiotechnologyAcid water

The invention relates to an acid-proof type microalgae DHA oil microcapsule powder and a preparation method thereof. The acid-proof type microalgae DHA oil microcapsule powder is prepared from 12.6%-30.3% of core materials and 69.7%-87.4% of wall materials, concretely comprising the following active ingredients in percentage by weight: 12.5%-30.0% of microalgae DHA oil, 0.1%-0.3% of antioxidant, 25.0%-50.0% of whey protein, 3.0%-8.0% of food emulsifier, 20.0%-54.4% of sweetener, 4.40%-8.0% of hydrophilic colloid, and 0.60%-1.20% of acidity regulator. The prepared acid-proof type microalgae DHA oil microcapsule powder has good acid-proof property, and can be applied in a food system of an acid water system with pH of more than or equal to 3.5, the oxidization speed of microalgae DHA can be effectively reduced and delayed, the activity of the microalgae DHA can be maintained, the stability of microalgae DHA in acid water system food can be enhanced, and the shelf life of the acid water system food with microalgae DHA can be prolonged.

Owner:RUNKE BIOENG FUJIAN

Beauveryia bassiana pesticide suspoemulsion and preparation method thereof

InactiveCN102067886APromote commercializationFast production process requirementsBiocideAnimal repellantsSporeEcological farming

The invention relates to a beauveryia bassiana pesticide suspoemulsion and a preparation method thereof. The invention is characterized in that the beauveryia bassiana pesticide suspoemulsion includes the following materials in part by weight: 20 to 80 parts of beauveryia bassiana spore powder; 10 to 60 parts of emulsified dispersant; 10 to 30 parts of thickening agent; 10 to 30 parts of suspension stabilizer; 10 to 30 parts of spreader; 10 to 60 parts of sugar; and 1 to 10 parts of peptone. The activity of spores is increased, the variety of chemical aids in use is small, moreover, the suspoemulsion can be easily dissolved in water and degraded so that the environmental pollution can be reduced, the adhesion rate of the spores on the body surfaces of inserts is increased, the infection process of the suspoemulsion is quicker than the infection process of raw powder, the requirement of the formulation production process is low, the method is quite simple, and the application in fields is simple. After being diluted by water, the suspoemulsion is in the form of milky, translucent liquid, emulsification is complete, no sediments exist, the stability is high, and the suspoemulsion does not have foreign odor. The dilution factor is high, the packaging and transportation cost is saved, and the transportation of the pesticide is safe. The invention promotes the popularization and commercialization of bassiana and the development of the rural ecological agriculture in China.

Owner:JILIN ACAD OF AGRI SCI

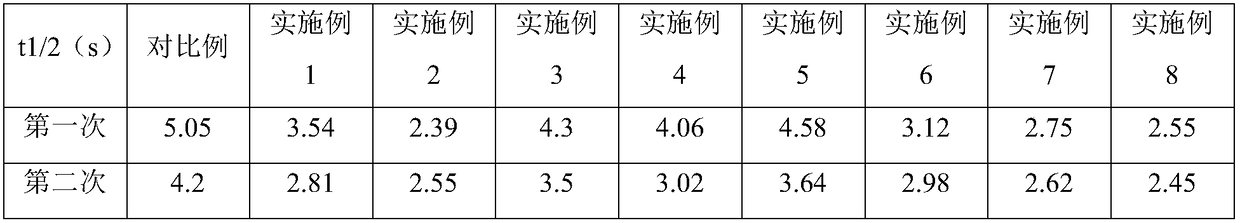

Automatic pressure soybean milk machine and method for producing soybean milk

ActiveCN101485422AControl pressure valueFully emulsifiedBeverage vesselsFood preparationAdditive ingredientDrive shaft

The invention provides an automatic pressure soybean milk machine, and belongs to the technical field of household food cuisine. The machine comprises a machine seat provided inside with a driving motor supplying power, blades arranged at the tail end of a driving shaft of the motor, a cup body, a cup cover arranged above the cup body, a heating element, a temperature detecting device and a circuit board of a control circuit; the cup cover and the mouth of the cup body are provided with sealing elements; under the state of closed cover, a sealed cavity is formed in the cup body, the continuous rise of pressure in the sealed cavity is allowed after heating, and a pressure relief device is also arranged; and air can be discharged by the pressure relief valve when the pressure in the cup body is higher than the preset pressure P0. The temperature for cooking the soybean milk can reach more than 106 DEG C; when the soybean milk is continuously cooked in the sealed cavity, the overflow phenomenon cannot happen so as to shorten the process of cooling the soybean milk and saving time; moreover, the cooked soybean milk is fully emulsified and well cooked; and due to the continuous and quick heating, the loss of the nutrient contents in the food is inhibited in the heating process, so that the cooked soybean milk is fragrant and pure, and tastes good.

Owner:ZHEJIANG SUPOR ELECTRICAL APPLIANCES MFG CO LTD

Method for processing food stick

The invention relates to a method for processing a food bar. The method comprises the following steps of mixing syrup and grease to carry out high-pressure homogenization emulsion; evenly blending and doughing with other components and incising the components into the bar. The process of the high-pressure homogenization emulsion is added in the method, so that the mixture of the syrup and the grease is more even and the emulsion is more sufficient, thereby the product has more delicate quality and better taste.

Owner:BEIJING COMPETITOR SPORTS SCI & TECH +2

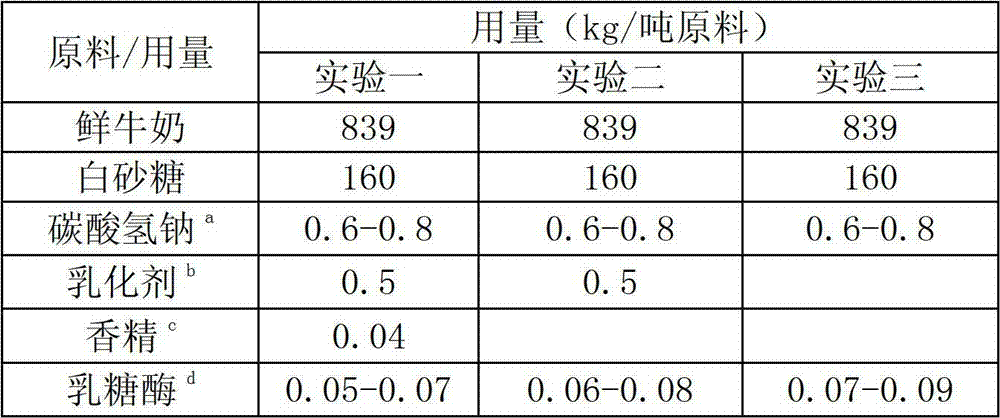

Caramel condensed milk and preparation method and application thereof

ActiveCN102870883ARetain nutrientsSatisfy taste needsMilk preparationPre-extraction tea treatmentFine structureMaillard reaction

The invention discloses caramel condensed milk and a preparation method and application thereof. The caramel condensed milk comprises more than or equal to 1.5 percent of fat, more than or equal to 4.6 percent of protein and less than 30 percent of water, has the titratable acidity of less than or equal to 48 and the sugar degree of 68.5 to 69.5Brix, is uniformly milky yellow, is a glossy viscous semi-solid and has a fine structure, uniform texture, milk aroma and scorch aroma. The preparation method comprises the following steps of: 1) taking a liquid milk raw material with the milk solid content of not more than 70 percent; 2) adding white granulated sugar and sodium bicarbonate into a system obtained in the step 1); 3) heating the system obtained in the step 1) to 95 to 105 DEG C until the system is boiled, continuously boiling, performing Maillard reaction, evaporating water until the sugar degree is 68.5 to 69.5Brix, stopping heating, and cooling; and 4) filling a product obtained in the step 2), sealing a can, sterilizing under high pressure, and cooling. The caramel condensed milk can be applied to food.

Owner:ZHEJIANG PANDA DAIRY GRP COMPANY

Viscosespinning oil and preparation method thereof

ActiveCN108755141AImprove antistatic performanceGood flexibilityGrip property fibresAlkylphosphatePolyethylene glycol

The invention discloses viscosespinning oil and a preparation methodthereof, and belongs to the technical field of textile assistants. The viscosespinning oil comprises a lubricant, an antistatic agent and an emulsifier, wherein the lubricant is selected from one or more of white oil, liquid paraffin, vaseline, spindle oil, stearate and oleate; the emulsifier is selected from one or more of fattyalcoholpolyoxyethylene ether, polyoxyethylene fatty acid, polyol fatty acid ester, nonylphenolpolyoxyethylene ether and polyethylene glycol; and the antistatic agent is selected from one or more of alkyl phosphate salt, alkyl sulfate, alkyl phosphate and higher alcohol alkyl sulfate. By screening the components of the lubricant, the antistatic agent and the emulsifier of the viscose oil, the prepared product can effectively regulate the friction force of the fiber surface, improve the antistatic performance, has high softness, good smooth feeling, appropriate bundling performance and bundlingcohesion performance, and can effectively improve the fiber spinning processability.

Owner:乌鲁木齐市华泰隆化学助剂有限公司

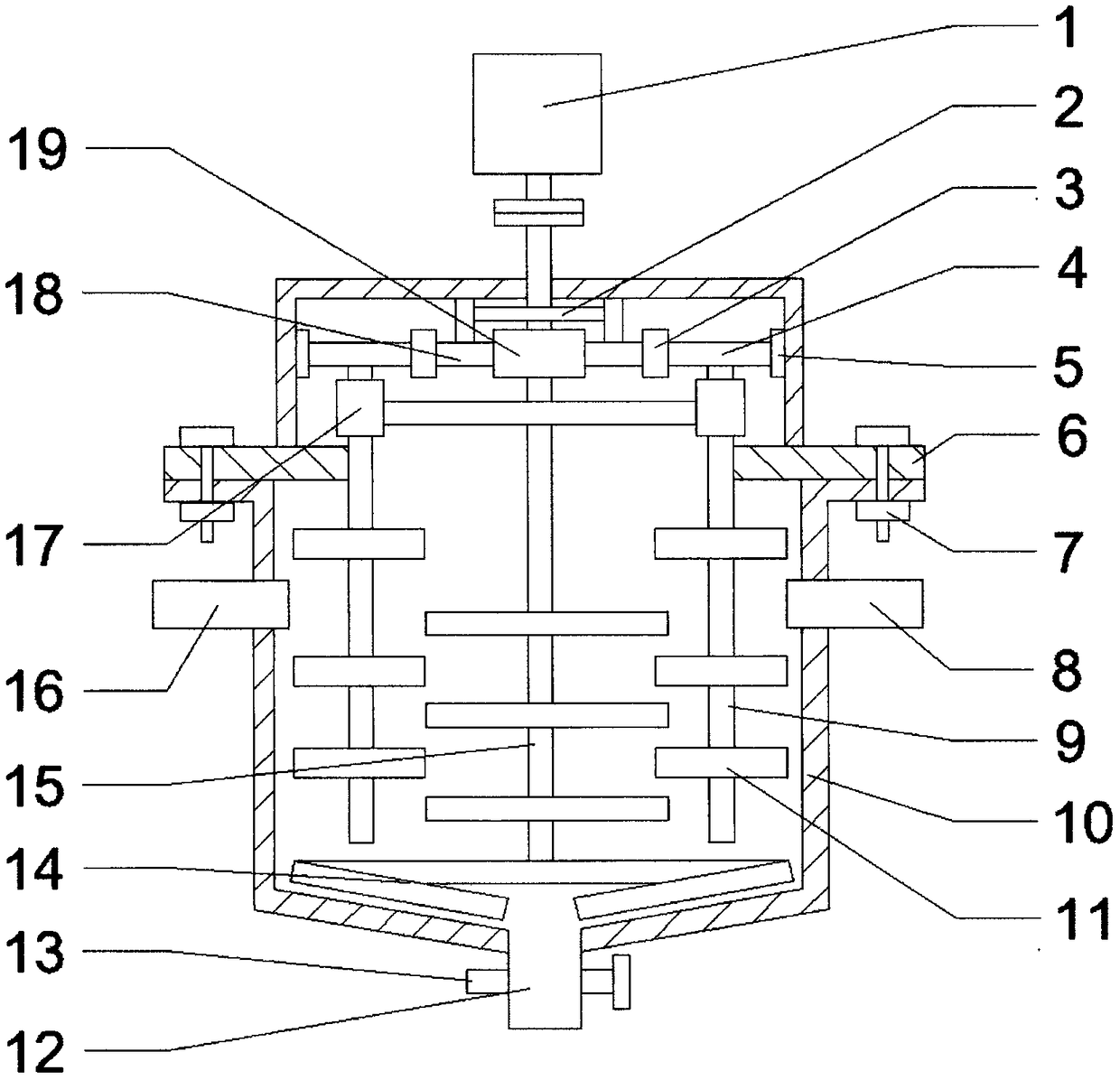

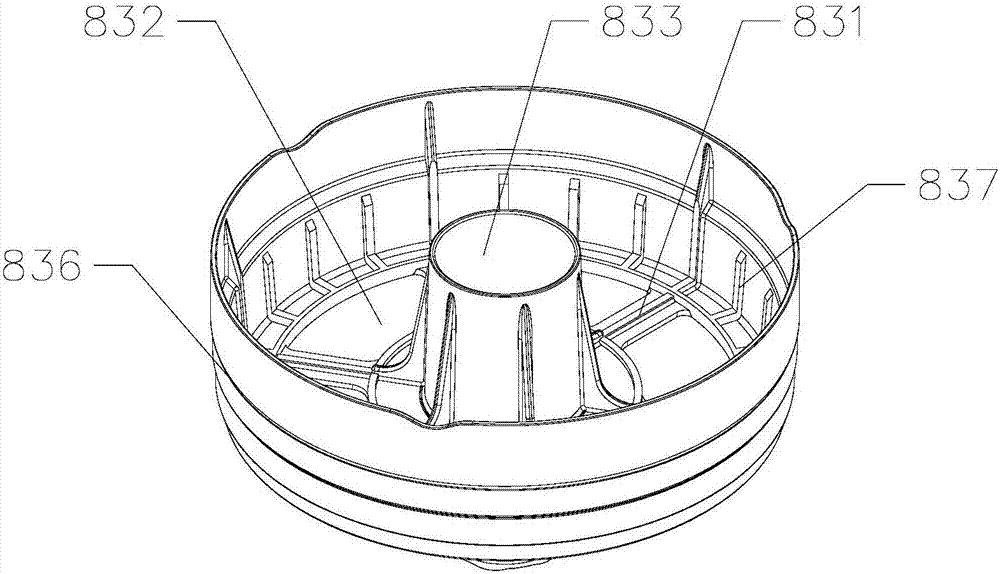

High-low-speed shear emulsifying mixer

InactiveCN108211875APrevent precipitationSimple structureTransportation and packagingMixing methodsLow speedDrive shaft

The invention discloses a high-low-speed shear emulsifying mixer. The high-low-speed shear emulsifying mixer comprises a tank body and a cover body, wherein a discharge opening is formed in the bottomcentral position of the tank body; a first feed opening and a second feed opening are formed in the upper part of the side face of the tank body; a big gear ring is fixed on the inner wall of the cover body and is meshed with a second planet gear inside the big gear ring; a driven shaft is arranged on the second planet gear; the second planet gear is meshed with a small gear ring at the central position of the big gear ring; the small gear ring is meshed with a first planet gear inside the small gear ring; the first planet gear is meshed with a sun gear at the central position of the small gear ring; a driving shaft is arranged on the sun gear; a scraper is arranged at the bottom of the driving shaft. By gear train transmission, the driven shaft rotates and revolves around the driving shaft, so that uniformity and sufficiency in mixing are realized; by transmission of two gear trains, opposite rotating directions of the driving shaft and the driven shaft are realized; meanwhile, the speed difference between the driving shaft and the driven shaft is increased, and uniformity and sufficiency in emulsifying are realized; the scraper arranged at the bottom of the driving shaft can effectively prevent the settlement of materials.

Owner:余姚市滨腾电器有限公司

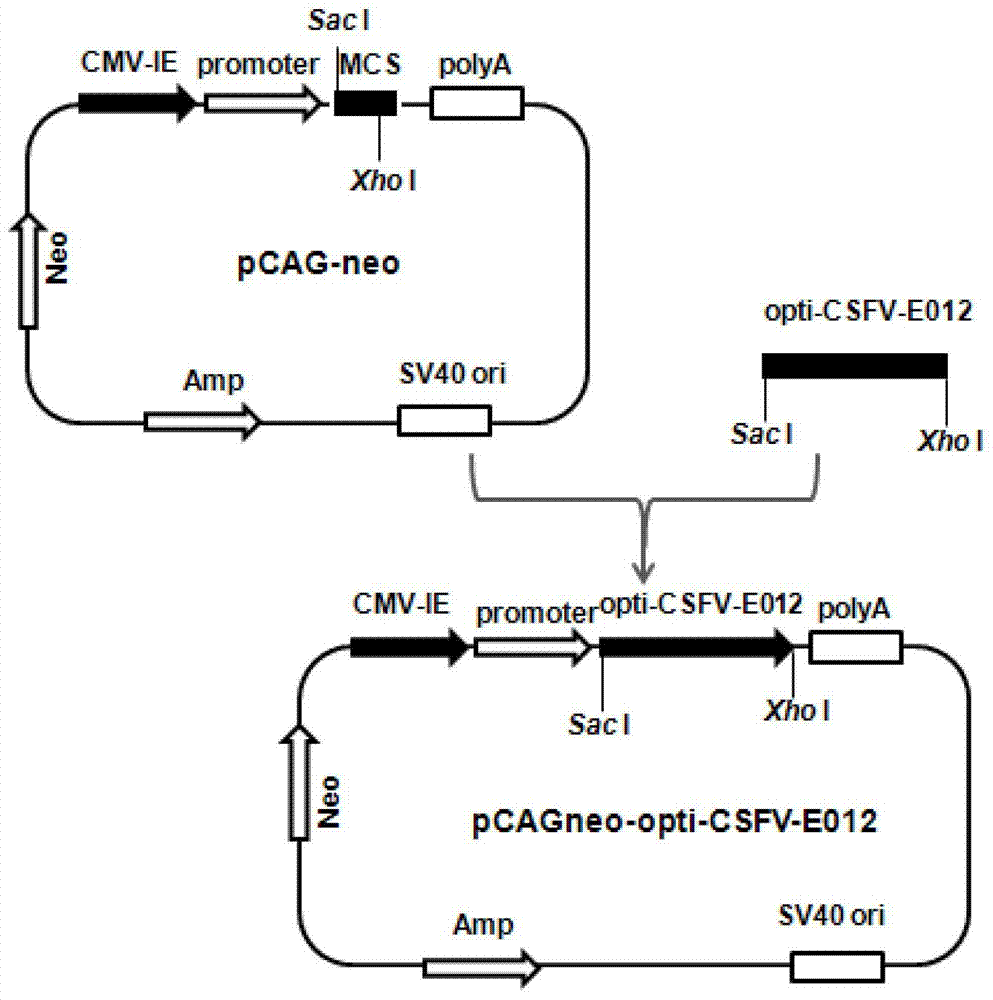

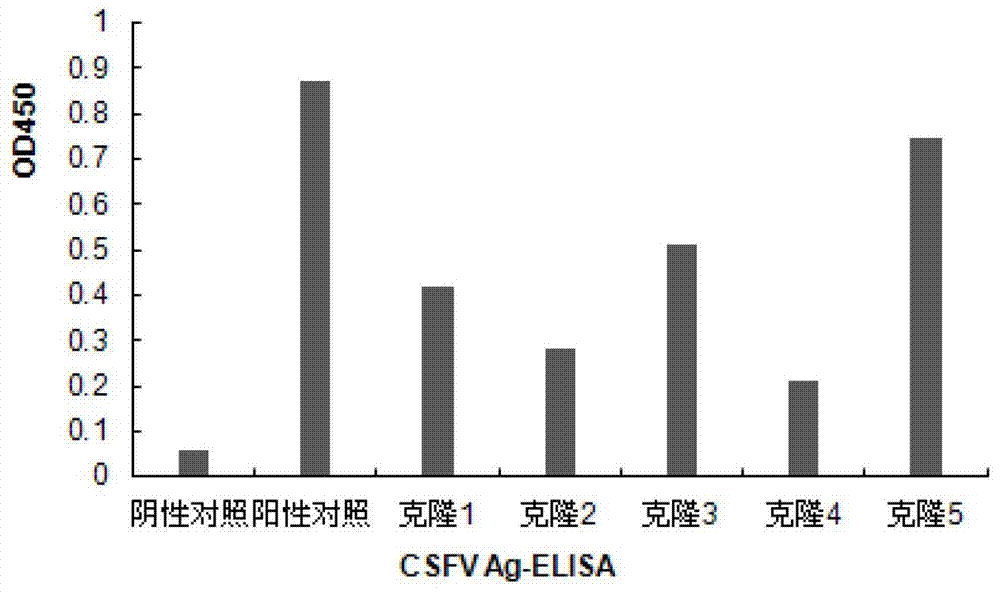

Recombinant BHK cell line for stably expressing classical swine fever virus E0-E1-E2 protein, and applications of the same in preparation of vaccines and diagnosis reagents of classical swine fever

ActiveCN103751773AFully emulsifiedAvoid infectionAntiviralsBiological testingStructural proteinMicrobiological culture

The present invention discloses a recombinant cell line for stably expressing classical swine fever virus E0-E1-E2 protein, and applications of the recombinant cell line in preparation of vaccines and diagnosis reagents of classical swine fever, wherein the recombinant cell line is BCSFV-E012, is preserved in the China General Microbiological Culture Collection Center, and has the preservation number of CGMCC No.7720. In addition, the present invention further discloses an establishment method for the cell line for stably expressing classical swine fever virus E0-E1-E2 protein, and a method for preparing a classical swine fever prevention vaccine composition by using the cell line. The present invention further discloses applications of the E0-E1-E2 protein stably expressed by the recombinant cell line in preparation of classical swine fever prevention vaccines and diagnosis reagents. The classical swine fever vaccine prepared by using the recombinant cell line has characteristics of high safety, good immunization effect, easy mass production, less being susceptible to exogenous virus pollution or influence of antibodies, and no classical swine fever virus non-structural protein antibody production so as to identify the vaccinated animal and the virus infected animal.

Owner:HARBIN WEIKE BIOTECH DEV +1

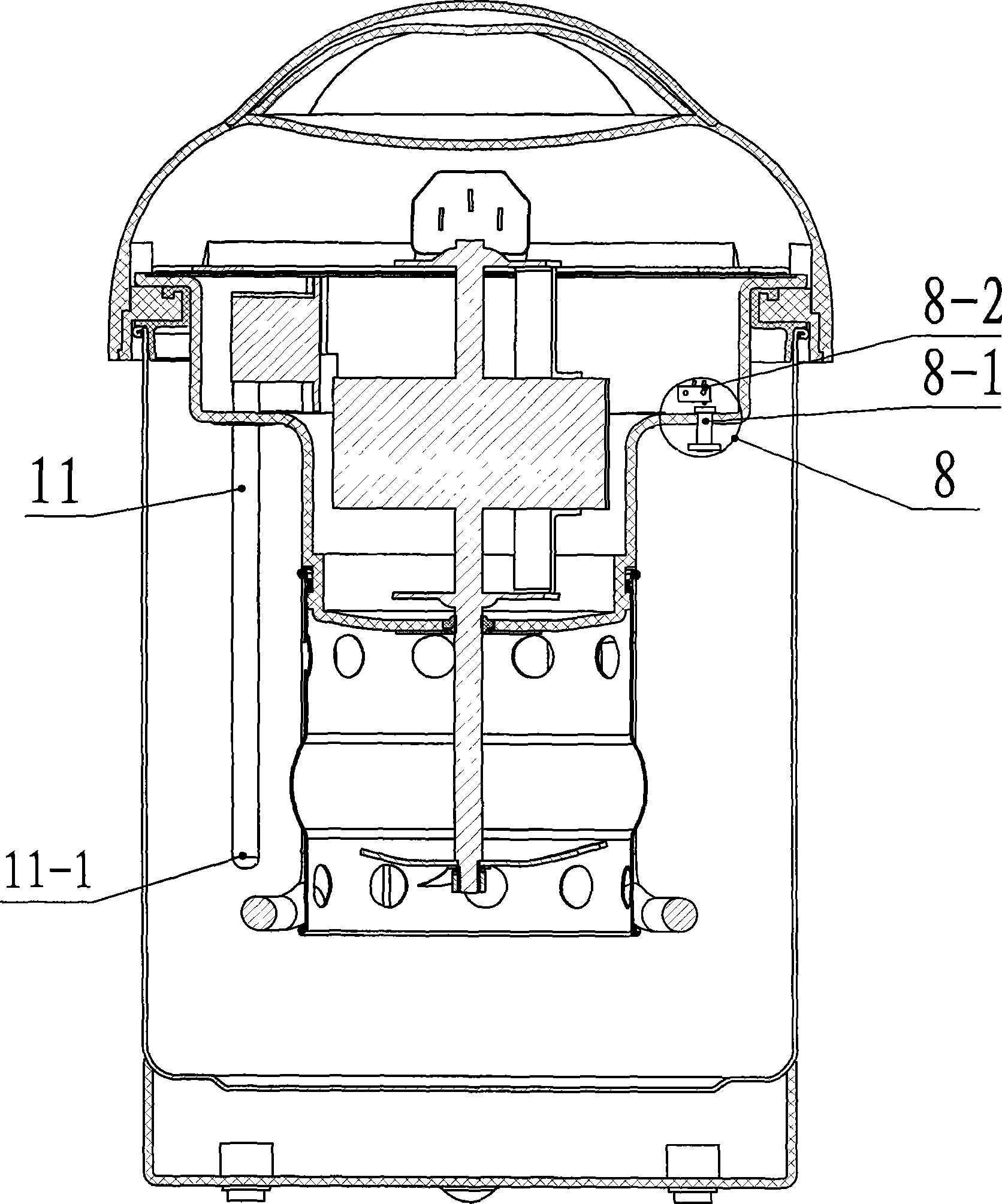

Pressure soymilk grinder and pressure soymilk boiling method

ActiveCN101637242BFully emulsifiedCurb churnBeverage vesselsVessels with intergral heatingElectric machineryEngineering

The invention relates to a pressure soymilk grinder which belongs to the technical field of processors for grinding and processing home food. The pressure soymilk grinder comprises a base, a base inner cover (4), a cover, a material cup (5), a motor (6), a cutter (9), a heating element (11), a sensor (7) attached on the material cup and a control circuit board (1), wherein the motor (6) and the control circuit board (1) are arranged in the base inner cover (4); and the cutter (9) fixed at the tail end of a drive shaft of the motor is extended into the material cup. The pressure soymilk grinder is characterized in that inwards or outwards turned pot teeth capable of buckling the material cup (5) and the cover are arranged between the material cup (5) and the cover; the material cup (5) is a sealing cavity in a closed cover state, and in the process of heating, the pressure of the cavity is maintained for 20-100kPa; the grinder cover is provided with a pressure release valve and a safe open-stop valve; and when pressure in the material cup exceeds preset pressure P0, gas in the cup is released. The invention has high soymilk boiling efficiency, high quality of soymilk dairy products, fully boiled soymilk, concentrated and fragrant soymilk taste and simpler structure.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

Heavy oil reservoir cold production huff-puff self-emulsifying corrosion inhibition viscosity reducer and preparation method and application thereof

ActiveCN111004616ASustained effective viscosity reduction abilitySustained Effective CorrosionFluid removalDrilling compositionOil viscosityDioxyethylene Ether

The invention provides a heavy oil reservoir cold production huff-puff self-emulsifying corrosion inhibition viscosity reducer as well as a preparation method and application thereof, belongs to the technical field of oilfield chemistry, and can solve the technical problems that an existing heavy oil viscosity reducer does not have continuous and effective viscosity reduction capacity, corrosion resistance, or the like. The mass concentration of fatty acid polyoxyethylene ether in the viscosity reducer is 15-70%, the mass concentration of fatty alcohol-polyoxyethylene ether sodium sulfate is 5-20%, the mass concentration of a mixed system composed of organic oxomolybdate, sodium gluconate and sodium polyacrylate is 5-10%, and the balance is water. The method can be applied to exploitationof thick oil at 40-90 DEG C, the viscosity of reservoir crude oil can be effectively reduced, and the stratum crude oil recovery rate is increased.

Owner:SHANDONG XINGANG CHEM

Emulsifying machine

The invention relates to an emulsifying machine which comprises a motor, a connecting body, a cavity, a discharge outlet and a feed inlet, wherein the cavity is internally provided with a fixed gear and a moving gear driven by a spindle of the motor, and the fixed gear and the moving gear are mutually engaged; 2-6 rows of annularly distributed rectangular teeth are arranged on the end faces of the moving gear and the fixed gear, and the gap between each row of adjacent rectangular teeth is 30-50mm; the rectangular teeth of the moving gear and the rectangular teeth of the fixed gear are just inserted into the gaps of the adjacent rows of teeth of each other, and the fixed gear and the moving gear are coaxial; and the cavity is internally provided with 2-5 sets of fixed gears and moving gears which are mutually engaged. The emulsifying machine has good emulsifying effect, smooth surfaces of generated carriers and adhesion phenomenon reduction.

Owner:张再明

Method of making milky coffee drink with capsule drink machine

The invention provides a method of making a milky coffee drink with a capsule drink machine. The capsule drink machine comprises a base, a brewing chamber, a control panel, a brewing head, an inflow piercing needle, an extraction piercing needle, a liquid supply mechanism and a brewing cup for receiving milky coffee capsules; each milky coffee capsule includes a capsule body and a membrane and also includes a separator for liquid passage, the separator is arranged in the capsule body and divides an inner cavity of the capsule body into a first cavity and a second cavity, milk powder is arranged in the first cavity, and coffee powder is arranged in the second cavity; the method comprises the steps of emulsifying, extracting and mixing; sequentially, the milk powder is emulsified and brewed, the coffee powder is extracted and filtered, and milk and coffee liquids are mixed into a milky coffee drink; in the method, the milk and coffee liquids are mixed well, the milk liquid never floats on the surface of the coffee liquid, the taste of the milky coffee drink is enhanced, and the milky coffee drink has good color and appearance.

Owner:HONGYANG HOME APPLIANCES

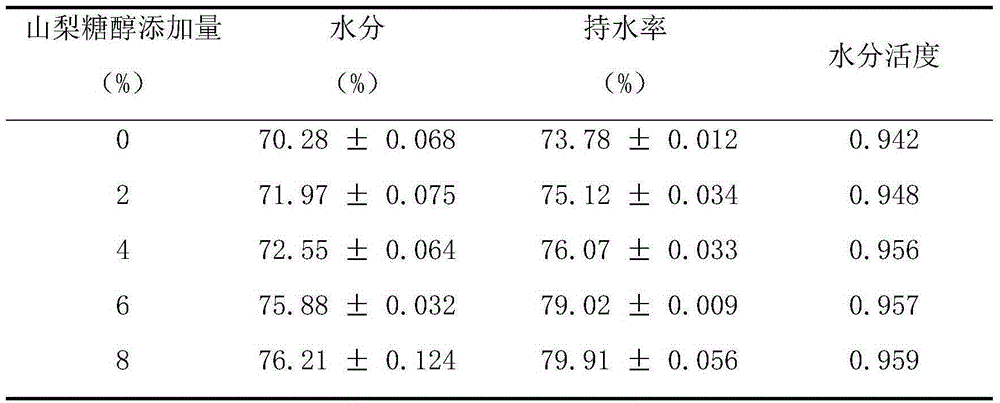

Sugarless steamed eggs with high water retention and preparation method of sugarless steamed eggs

The invention discloses a preparation method of sugarless steamed egg serial products with high water retention. According to the products, eggs and milk are used as main raw materials, other healthy food materials are assisted, and the main raw materials and the other healthy food materials are made into thermal coagulation seasoning egg products in a conventional steaming manner. According to the sugarless steamed eggs disclosed by the invention, water retention rate and sensory indexes are used as evaluation criterions; in the formula, sorbitol, modified soybean lecithin and the like are added, so that the water retention of the products is promoted, a stable product system is formed, a drainage problem during a preserving process is solved or retarded, and the shelf life is prolonged; besides, the products also have function characteristics, the sorbitol is not transformed into glucose in blood, a metabolic process is free from control of insulin, and lecithin has the efficacies of reducing cholesterol, preventing fatty liver, invigorating the brain and the like. According to the sugarless steamed eggs disclosed by the invention, the water retention of the products is jointly optimized from the formula and the technology, the quality guarantee period of the produced steamed eggs is as long as 6 months, the stability is good, the drainage problem does not exist on the steamed eggs during the shelf life, and the steamed eggs also have the function characteristics.

Owner:SICHUAN UNIV

Production method of water-soluble fertilizer containing trace elements

The invention discloses a production method of a high-tower type water-soluble fertilizer containing trace elements. The production method comprises the steps: adding an ammonium nitrate raw material and ammonium phosphate salts into water, melting with the melting temperature of larger than or equal to 135 DEG C and less than 150 DEG C, then mixing the co-molten material slurry after melting with fertilizers needed for production of the compound fertilizer, adding water-soluble trace element-containing compounds, after uniformly mixing, emulsifying to form an emulsion material slurry, granulating, and cooling to obtain the water-soluble fertilizer. The content of zinc is controlled in 500-700 ppm. The water-soluble fertilizer produced by the method has the advantages of uniform nutrients, smooth and round appearance, rapid dissolving speed and good water solubility, and allows water insoluble substances to be within 3.0%. The production method belongs to a novel, environmental-protection and low-energy-consumption production method for high-tower production of particle water-soluble fertilizers.

Owner:GUIGANG BATIAN ECOLOGY

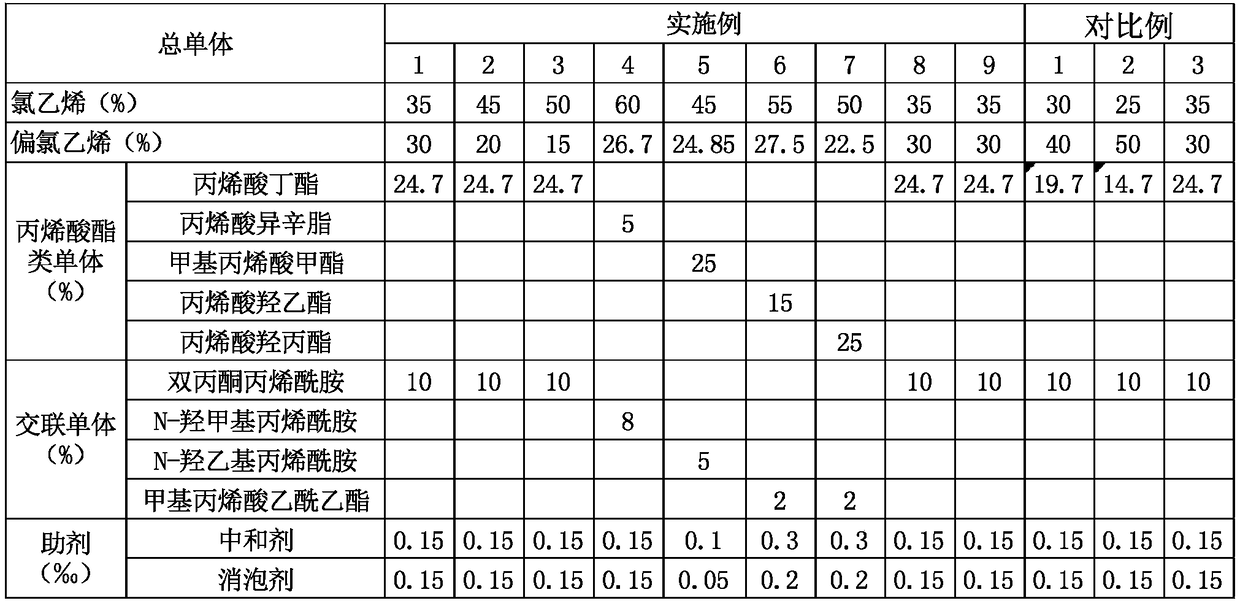

Self-crosslinking type vinyl chloride copolymer emulsion and preparation method thereof

The invention belongs to the technical field of industrial coatings, and relates to self-crosslinking type vinyl chloride copolymer emulsion. The self-crosslinking type vinyl chloride copolymer emulsion is prepared from the following raw materials in parts by weight: 100 parts of a total monomer, 1-5 parts of an emulsifier, 0. 5-2 parts of a pH buffer, 0.05-0.5 part of an initiator and 80-230 parts of deionized water, wherein the total monomer consists of the following components in percentage by weight: 35-60% of vinyl chloride, 15-30% of vinylidene chloride, 5-25% of an acrylate monomer, 2-10% of a cross-linking monomer and 015-0.5% of an auxiliary. The invention provides a preparation method for preparing the self-crosslinking type emulsion by copolymerizing the vinylidene chloride, theacrylate and the crosslinking monomer with vinyl chloride as a main monomer; and according to the method, a polymer structure is adjusted through optimizing an emulsifier system and a polymerizationprocess so as to obtain the vinyl chloride copolymer emulsion which can effectively replace alkyd resins to be used in industrial anticorrosive coatings.

Owner:WUXI HONGHUI NEW MATERIALS TECH

Yellowing-resistant water-based polyurethane emulsion and preparation method thereof

The invention discloses an yellowing-resistant water-based polyurethane emulsion and a preparation method thereof. The yellowing-resistant water-based polyurethane emulsion comprises the following components in parts by mass: 115-125 parts of polypropylene carbonate polyol containing carboxyl in side chain, 18-63 parts of aliphatic diisocyanate, 0.06-0.36 part of a catalyst, 12 parts of a neutralizing agent, 5-20 parts of acetone, 332-460 parts of deionized water, and 0.6-1.2 parts of a chain extender. The preparation method is characterized in that the yellowing-resistant water-based polyurethane emulsion is prepared by adding the chain expander to polypropylene carbonate polyol containing carboxyl in side chain and aliphatic diisocyanate in the presence of the catalyst. With the adoptionof the method, the prepared yellowing-resistant water-based polyurethane emulsion is uniform in blocks, uniform in distribution of soft and hard sections, stable in quality, and free from yellowing in case of long-term storing; the improved preparation method is safe and environmentally friendly; the adopted raw materials are environmentally friendly, and low in cost; the preparation processes are simple; and the actual application value is high.

Owner:HUIZHOU DAYAWAN DAZHI FINE CHEM

Mask and preparation method thereof

InactiveCN106727158AImprove uniformityGood dispersionCosmetic preparationsToilet preparationsHydroxyprolineCHAMOMILE FLOWERS

The invention relates to a mask which is prepared from the following raw materials in parts by weight: 10-25 parts of water, 5-15 parts of propylene glycol, 3-7 parts of xanthan gum, 2-5 parts of PEG-40 hydrogenated castor oil, 5-10 parts of phyllostachys bambusoides root and stem extract, 5-10 parts of aloe extract, 5-10 parts of chamomile flower extract, 3-6 parts of PG-propyl methylsilanediol, 7-13 parts of cucumber extract, 1-4 parts of bisabolol, 3-6 parts of dipotassium glycyrrhizinate, 1-5 parts of vitamin E, 0.5-0.8 part of gold, 7-15 parts of hyaluronic acid, 1-4 parts of phenoxyethanol, 0.9-1.3 parts of dipalmityl hydroxyproline, 3-7 parts of collagen, 1-4 parts of hyaluronic acid and 0.7-3 parts of hexapeptide. The invention also provides a preparation method of the mask. The mask provided by the invention has very good moisturizing and water-replenishing and whitening effects to skin.

Owner:张东洋

Manufacturing technique and method for refining petroleum aqueous emulsion

InactiveCN101283682AStrong emulsificationStrong decontaminationBiocidePlant growth regulatorsInsect pestSolvent

The invention relates to a production process of refined petroleum emulsion in water and belongs to the field of pesticide manufacturing process. The refined petroleum emulsion in water is made from refined petroleum, film-forming agent, emulsifiers, plant nutrients, defoaming agent, stabilizers, antifreezing agent and deionized water, by uniform dispersion using a high-speed shear mixing emulsifier. The refined petroleum emulsion is innoxious and non-irritant or low-toxic or low-irritant to animals and human beings, is harmless to crops, has environmental affinity, enhances the resistance of crops, and can promote the growth of crops. The refined petroleum emulsion can kill main insect pests, regulate the growth of crops, enhance resistance to cold and diseases and increase the yield of crops. The invention has the advantages of use of water as solvent, reduced waste of resources, no discharge of three wastes, environmental friendliness, scientific formulation, advanced process, low cost and good effect.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation process for additive-free dried yoghourt and yoghourt powder

The invention discloses a preparation process for additive-free dried yoghourt and yoghourt powder. The preparation process is provided directed at technical problems in the prior art and is implemented in strict accordance with related standards in China. The preparation process comprises the following steps: selection of dairy yak; hand milking and mechanical milking; milk filtering; stirring and heating of milk; separation of the milk; stirring and heating; stirring and cooling; filtering and dehydration; seasoning; cooling and solidification; trituration into small blocks; blow-drying with a drying box; and timely filling into a food vacuum bag and packaging and sealing through vacuum-pumping (wherein a vacuum machine is an internal-pumping type DZD series vacuum package machine and a food-grade vacuum bag is adopted as a packaging bag for the dried yoghourt). No antiseptic is added into the bag, and the dried yoghourt has a shelf-life of 180 d when kept in a dark place and can retain unchanged taste; and the dried yoghourt is directly eaten in the dry state.

Owner:赵石才

Pretreatment method of hazardous waste materials

ActiveCN110079275AFulfil requirementsImprove liquidityOther chemical processesBulk chemical productionSolubilityLiquid waste

The invention relates to the technical field of waste liquid treatment, in particular to a pretreatment method of hazardous waste materials. According to the treatment method, to-be-treated materialsand an emulsifier A with HLB (hydrophile-lipophile balance) being 3-5 are sufficiently mixed, water is added, the mixture is sufficiently mixed, an emulsifier B with HLB being 7-8, an emulsifier C with HLB being 11.5-12.5 and a thickening agent are added, the mixture is sufficiently mixed, and finally, the calorific value of the materials is adjusted to be 4.2-4.5 MJ / kg with water. The materials are sequentially mixed with emulsifiers with different HBL values, so that the materials are sufficiently emulsified and have good flowability and water solubility, and the feeding requirements of a supercritical water oxidation treatment system can be met.

Owner:廊坊新奥龙河环保科技有限公司

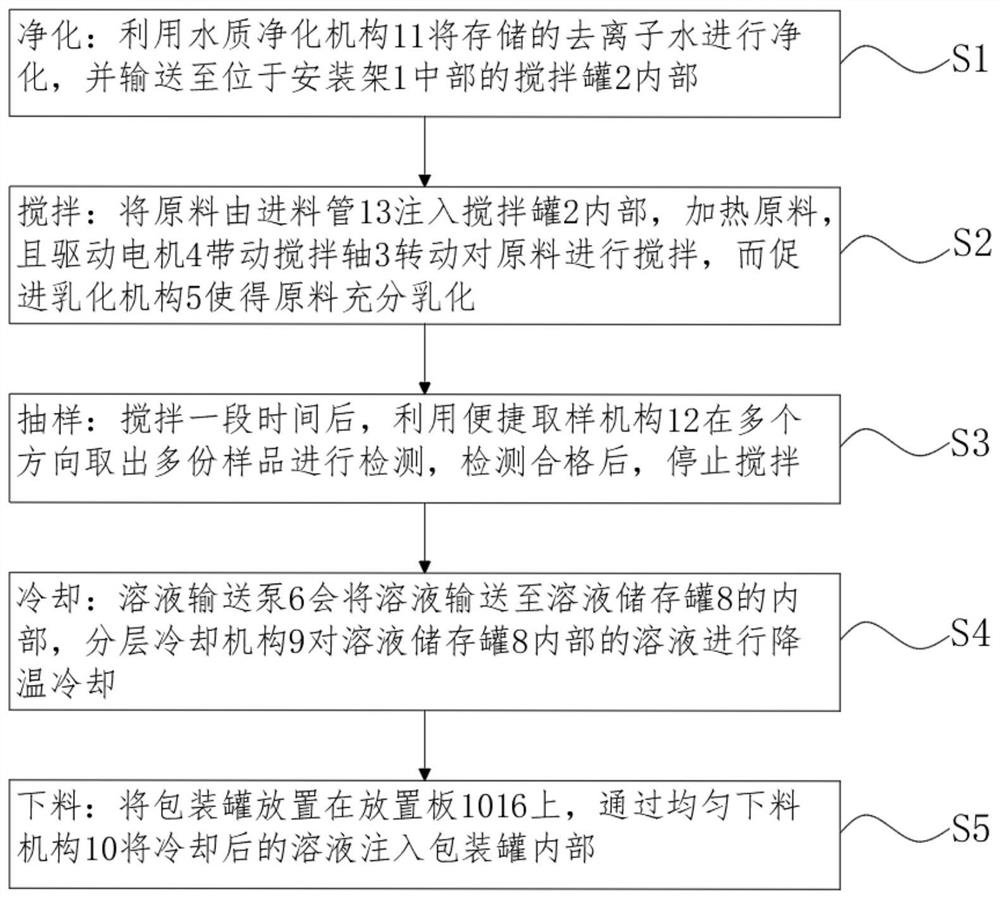

Preparation method of decontamination type laundry detergent

InactiveCN112169610AStir wellWell mixedWater/sewage treatment by irradiationFlow mixersProcess engineeringDrive motor

The invention discloses a preparation method of a decontamination type laundry detergent. The method comprises the following steps of: purification: purifying stored deionized water by using a water quality purification mechanism, conveying the purified deionized water into a stirring tank in the middle of a mounting frame; stirring: injecting raw materials into the stirring tank through a feedingpipe, heating the raw materials, and driving a stirring shaft to rotate by a driving motor so as to stir the raw materials, and fully stirring the raw materials through an emulsification promoting mechanism. The raw materials in the stirring tank can be fully mixed through the emulsification promoting mechanism, the raw materials can be fully mixed, and the situation that the quality of the prepared laundry detergent is unqualified due to uneven mixing of the raw materials is avoided, and meanwhile, through cooperative use of a circulating pump and a circulating conveying pipe, the mixed solution at the bottom of the stirring tank is pumped out and then re-injected into the stirring tank, the problem that the solution is deposited at the bottom of the stirring tank and cannot be fully mixed is avoided, raw materials are fully emulsified, raw material mixing is promoted, and the activity of the raw materials can be improved.

Owner:周燕芳

Paint emulsifying device

InactiveCN104415690ARelieve pressureFully emulsifiedRotary stirring mixersMixing methodsElectric machineEngineering

The invention discloses a paint emulsifying device, which comprises a rack, wherein a lifting device is fixedly arranged on the rack, a positioning cross beam is arranged on the lifting device, a rotating shaft is arranged below the positioning cross beam and is connected with a stirring motor on the positioning cross beam, a spiral auger used for stirring paint is arranged on the rotating shaft, a screw is arranged in the positioning cross beam, a driving motor for driving the screw to rotate is arranged on one end of the positioning cross beam, and the stirring motor is connected with the screw through a slider. The paint emulsifying device is simple in structure, strong in practicability, and low in cost, the pressure of enterprises can be lightened; while the working stability is guaranteed, not only can the working efficiency be improved, but also the paint is thoroughly emulsified.

Owner:中泰致远(天津)涂料有限公司

Livestock blood wine soaked cooking sausage and processing method thereof

ActiveCN103815428AImprove food safetyHigh nutritional valueSugar food ingredientsAlcoholic food ingredientsBiotechnologyHeme

The invention relates to a livestock blood wine soaked cooking sausage and a processing method thereof, and solves the problem that the existing livestock blood is difficult to apply in food processing due to the fact that a blood smell is greater, heme iron is easy to oxidize and becomes brown, and the livestock blood is poor in palatability. On the other hand, the invention provides a sausage without an artificial color and with high safety. A red color of the livestock blood wine soaked cooking sausage is the livestock blood, and the addition of the blood accounts for 12-20% of the total raw material mass of the sausage. In order to prevent ferrous iron from being oxidized into ferric iron, the livestock blood wine soaked cooking sausage also comprises at least 0.01% of a reducer to cover the blood smell, and comprises 8-10% of Sanhua Liquor and 0.2-0.4% of beta-cyclodextrin, and can further comprise 2-3% of soy isolate protein according to the total raw material mass of the sausage. The natural color of the blood serves as the color of the sausage, and the edible safety of the sausage is improved. An appropriate amount of the reducer is added into the sausage and can effectively prevent Fe<2+> in heme from being oxidized into Fe<3+>, and the sausage becomes important food for supplementing available Fe.

Owner:GUANGXI UNIV

A kind of acid-resistant microalgae dha oil microcapsule powder

ActiveCN104432059BImprove stabilityImprove acid resistanceSugar food ingredientsFood shapingAcid waterAntioxidant

Owner:RUNKE BIOENG FUJIAN

Power plant desulphurization defoamer and preparing method thereof

ActiveCN105126394AThe formula is reasonable and effectiveReduce surface tensionDispersed particle separationFoam dispersion/preventionDefoamerSiloxane

The invention discloses a power plant desulphurization defoamer and a preparing method thereof and relates to the technical field of desulfuration treatment. The power plant desulphurization defoamer contains siloxane-oxyalkylene copolymer, modified polyether, monostearin, fumed silica, compound emulsifier, simethicone emulgator, dimethyl dichloroethane, polyethylene glycol 6000 distearate and deionized water. The power plant desulphurization defoamer is specially used for thermal power plant smoke desulphurization and can reduce the surface tension of liquid, prevent the generation of foam and reduce the amount of original foam, and then foam breaking and foam inhibition are achieved at the same time and a stable and remarkable defoaming effect is realized.

Owner:河北恩赛环保科技有限公司

Environment-friendly multi-functional agricultural soil surface nutrient film and preparation method thereof

InactiveCN102146209ASimple structureReduce churnBuilding insulationsPlant protective coveringsSprayerEarth surface

The invention relates to an environment-friendly multi-functional agricultural soil surface nutrient film and a preparation method thereof. The environment-friendly multi-functional agricultural soil surface nutrient film consists of the following components in percentage by weight: 55 to 70 percent of mark asphalt, 0.5 to 0.8 percent of polymeric emulsifier and 22.5 to 44.2 percent of water; and the preparation method for the environment-friendly multi-functional agricultural soil surface nutrient film comprises the following steps of: 1) heating the mark asphalt in an asphalt heating barrel of an emulsifying machine to the temperature of between 130 and 170DEG C; 2) heating liquid soap prepared by mixing the polymeric emulsifier and the water in an emulsifier heating barrel of the emulsifying machine to the temperature of between 85 and 120DEG C, and regulating the pH value to be 7.5-9.0; 3) fully mixing the asphalt and the liquid soap by using a high speed pump of the emulsifying machine, and preparing film stock solution in a mixing pump; and 4) during application, dissolving the film stock solution and water in a ratio of 1:4 for mixing, uniformly stirring, and spraying the film on the earth surface by using a film sprayer to obtain the agricultural soil surface film.

Owner:INST OF AGRI RESOURCES & REGIONAL PLANNING CHINESE ACADEMY OF AGRI SCI

Acrylic ester high molecular type surfactant and preparation of porous resin

InactiveCN101302258AImprove performanceFully emulsifiedTransportation and packagingMixingVacuum dryingChemistry

The invention relates to acrylic macromolecular surfactant and a method for making the porous resin of the same, belonging to the organic macromolecular compound field. The acrylic macromolecular surfactant comprises 93 to 97 percent of acrylic substance, 3 to 7 percent of vinyl ion reagent and 0.5 to 1 percent of initiator. The substances are added in a reactor containing an amount of water, and are reacted at a temperature controlled between 57 and 80 DEG C for 6 to 24 hours; then, the reactants undergo acetone deposition, ether scrubbing and deposition and vacuum drying. The porous resin is made through adopting the following steps that: the acrylic macromolecular surfactant, monomer, initiator and a crosslinking agent are added in water, cyclohexane or the mixed solution of water and cyclohexane; and round porous resin is made by means of emulsion polymerization under the action of the initiator. The method makes the porous resin by means of the acrylic macromolecular surfactant, wherein the surfactant has excellent performances and full emulsification; and the porous resin is round in shape with the diameter ranging between 50 and 500 micron. The porous resin made by the method contains active epoxy group, and can be used in the fields of enzyme immobilization, antibody adsorption and purification and blood pathogen or toxin cleaning, etc.

Owner:黄东东 +1

Preparation method of composite silica aerogel

PendingCN110127706AWide range of applicationsShort production processAerogel preparationSilicon compoundsSolventChemistry

The invention relates to the technical field of aerogels, and especially relates to a preparation method of a composite silica aerogel. The preparation method of the composite silica aerogel comprisesthe following steps: 1, mixing and stirring methyltrimethoxysilane, an aqueous hydrochloric acid solution, a cationic detergent and glass fibers, and hydrolyzing the obtained mixture to obtain a mixed solution; 2, performing ultrasonic treatment on the mixed solution to obtain a wet gel; 3, soaking the wet gel in a solvent, and drying and ageing the soaked wet gel; and 4, modifying, drying and modifying the aged wet gel to obtain the composite silica aerogel. The preparation method of the composite silica aerogel, provided by the invention, solves the technical problem of unsatisfactory poredistribution and particle size of the aerogel prepared by existing preparation methods.

Owner:GUANGDONG UNIV OF TECH

Production process for producing germ nutrition powder by virtue of enzymolysis

ActiveCN104585779AImprove absorption rateStrong absorptionFood ingredient functionsFood preparationBiotechnologyCellulose

The invention discloses a production process for producing germ nutrition powder by virtue of enzymolysis, and belongs to the technical field of food processing. The production process comprises the following steps: mixing and micro-grinding wheat germs, peanut germs and soybean germs, adding water and homogenizing by homogenizers; carrying out an enzymolysis treatment for five times, carrying out the fourth times of enzymolysis with an animal bone mixture, and sequentially homogenizing by five homogenizers. Due to the earlier homogenization of the soybean germs and the wheat germs, the soybean germs and the wheat germs are adequately enzymolysed; small peptides, polypeptides and large peptides generated by enzymolysis, 5% maltodextrin, starch, oligosaccharide and polysaccharide fine celluloses generated by enzymolysing celluloses are adequately emulsified, and coat the animal bone micro-powder grains with diameters of less than 15 microns; a microencapsulation effect is good, absorption is facilitated, in particular, the absorption rate of calcium is also greatly increased, immunity and bone mineral density can be improved, and bone losses can be reduced; moreover, germ oil and VE are basically isolated from oxygen, deterioration and peculiar smell generation are not liable to occur, and an expiration date is long.

Owner:广州萃取生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com