Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

149 results about "Spindle oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spindle oils are a type of low-viscosity mineral oil marketed for use in lubrication of high-speed machine spindles. Spindle oil is free from gumming properties. Since the viscosity is so low that the oil runs off the surface of the spindle during shut-down periods, the spindle oil may be doped with additives that prevent rusting. Since the spindle oil often is used in textile factories, it is also important that it doesn't stain the textiles.

Food-grade-lubricant

InactiveUS20040241309A1Increase varietyExtend compassBase-materialsFood preparationGeneral purposePolyolefin

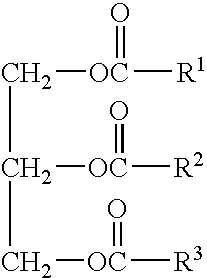

The present invention discloses an improved food-grade-lubricant useful as hydraulic oil, circulating oil, drip oil, general purpose oil, grease base oil, cable oil, chain oil, spindle oil, gear oil, and compressor oil for equipment in the food service industry. The lubricant comprises at least one vegetable oil, at least one polyalphaolefin, and at least one antioxidant. The lubricant has improved properties when subjected to thermal and mechanical stress.

Owner:RENEWABLE LUBRICANTS INC

Compounded rubber racetrack and its processing method

The composite rubber runway is produced with styrene-butadiene rubber, EPDM, natural rubber, silica white, pot clay, stearic acid, spindle oil, naphthenic oil, antioxidant, ultraviolet absorbent, nano particle and promoter, and through weighing materials, cutting rubber materials, mixing, milling, calendering, kneading, sulfurizing in sulfurizing machine, sulfurizing and foaming in tunnel stove, washing, trimming and polishing. The present invention has excellent resilience, toughness and damping effect; is wear resistant, antiaging and ultraviolet resistant, and may be all-weather used.

Owner:绿茵天地体育产业股份有限公司

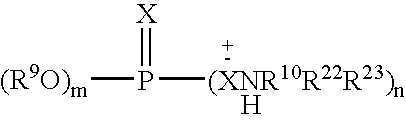

Process for re-refining used oils by solvent extraction

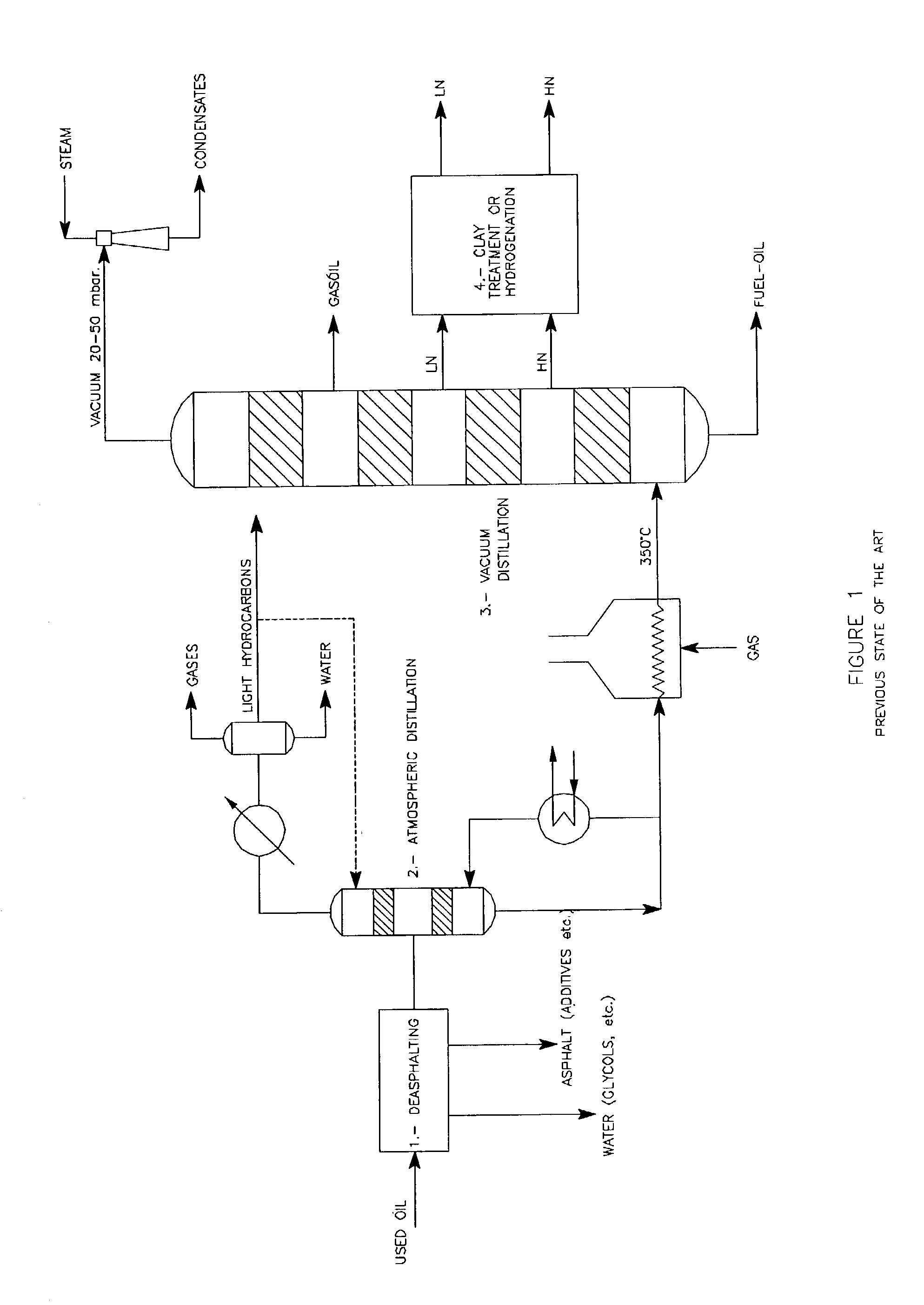

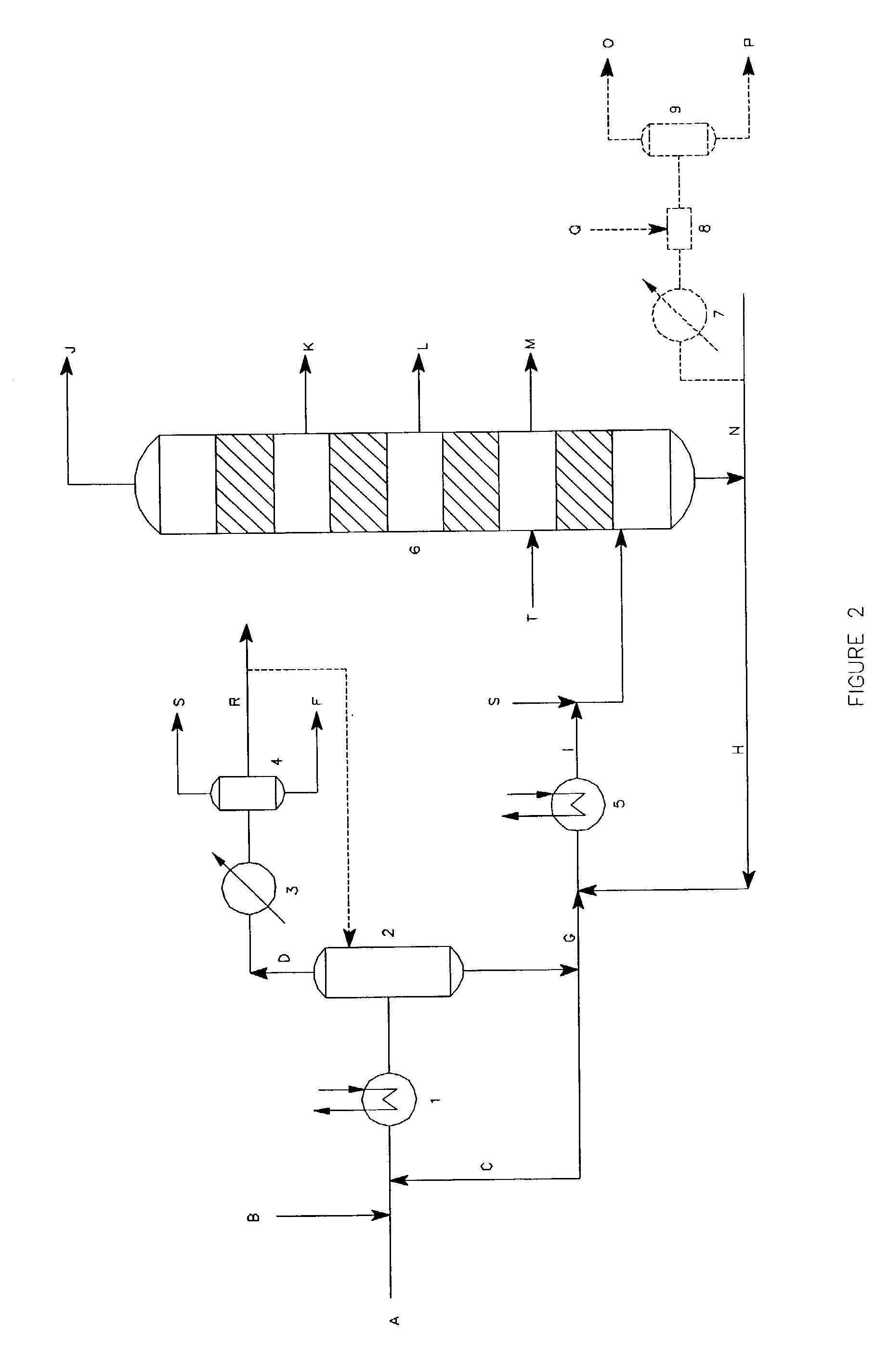

InactiveUS7226533B2No corrosionExpedited distillationWorking-up pitch/asphalt/bitumenTreatment with plural serial refining stagesWaste oilFuel oil

A process to re-refine used petroleum oils by extraction with aliphatic solvents, wherein after eliminating the extract solvent, the process consists of the following treatments, (a) flash, continuous vaporization, at atmospheric pressure or near atmospheric pressure, to separate the light fractions, in the presence of small amounts of a basic compound or a reducing agent or a combination of both and (b) continuous distillation, in a fractionating column, of the bottom liquid obtained in stage (a), under vacuum and moderate temperatures, in the presence of a basic compound or a reducing compound or a combination of both, with recirculation from the bottom of the column to its feed; separating, as lateral extractions, the vacuum gas-oil or spindle oil and the lubricant bases and, as bottom product, a fuel-oil or asphaltic component.

Owner:SENER GRUPO DE ING SA

Rubber shoes with oilproof and antiskid functions

The invention relates to rubber shoes with oilproof and antiskid functions. An oilproof undersole is prepared from the raw materials in parts by weight: 100 parts of nitrile rubber, 1-3 parts of sulfur, 0.5-1.0 part of accelerant DM, 1.0-1.5 parts of accelerant CZ, 3-5 parts of zinc oxide, 1-3 parts of stearic acid, 8-15 parts of liquid coumarone, 10-18 parts of dibutyl phthalate, 30-40 parts of argil, 2-4 parts of pine tar, 45-55 parts of high-wear-resistant carbon black and 0.5-1.5 parts of anti-aging agent. An oilproof edge strip and a toe cap are prepared from the raw materials in parts by weight: 80-95 parts of neoprene, 5-20 parts of standard rubber, 0.3-0.5 part of accelerant DM, 0.3-0.5 part of accelerant NA-220, 3-5 parts of zinc oxide, 3-5 parts of magnesium oxide, 2-4 parts of stearic acid, 0.3-0.5 part of paraffin, 3-5 parts of pine tar, 4-6 parts of dibutyl phthalate, 3-5 parts of spindle oil, 55-65 parts of argil, 20-30 parts of high-wear-resistant carbon black and 0.5-1.5 parts of anti-aging agent. Oilproof rubber paste is prepared from the raw materials in parts by weight: 100 parts of neoprene, 0.4-0.8 part of accelerant DM, 0.4-0.8 part of accelerant NA-220, 3-5 parts of zinc oxide, 3-5 parts of magnesium oxide, 4-8 parts of phenolic resin, 15-25 parts of calcium carbonate and 0.5-1.5 parts of anti-aging agent. The shoes are good in oilproof and antiskid effects, low in cost and high in percent of pass.

Owner:JIHUA 3517 RUBBER PROD

Oil resistant seal ring and preparation method thereof

Belonging to the technical field of rubber products, the invention mainly relates to an oil resistant seal ring for engineering machinery braking devices and a preparation method thereof. The oil resistant seal ring is characterized by containing the following components by weight: 100 parts of nitrile butadiene rubber 220S; 70-75 parts of carbon black N550; 8-10 parts of a plasticizer TP-95; 4.5-5 parts of a promoter; 3-4 parts of an antiager; 4-5 parts of zinc oxide; 1-1.5 parts of active agent stearic acid; 0.5-0.6 part of vulcanizing agent sulfur; and 1-1.5 parts of an operation aid TM-80. Compared with the prior art, the oil resistant seal ring and the preparation method provided by the invention have the advantages that: 1. the oil resistant seal ring has moderate hardness, high strength, large elongation, small compression set, good elasticity, spindle oil resistance, and resistance to DOP3 brake fluid; and 2. the oil resistant seal ring prepared by the method provided by the invention achieves the performance requirements of Japanese industrial standards JIS B 2401 3, and after customer installation use, the oil leakage phenomenon is solved.

Owner:QINGDAO BAOFENGSHENG FUHUA IMPORT & EXPORT SEALS

Viscosespinning oil and preparation method thereof

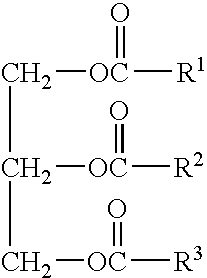

ActiveCN108755141AImprove antistatic performanceGood flexibilityGrip property fibresAlkylphosphatePolyethylene glycol

The invention discloses viscosespinning oil and a preparation methodthereof, and belongs to the technical field of textile assistants. The viscosespinning oil comprises a lubricant, an antistatic agent and an emulsifier, wherein the lubricant is selected from one or more of white oil, liquid paraffin, vaseline, spindle oil, stearate and oleate; the emulsifier is selected from one or more of fattyalcoholpolyoxyethylene ether, polyoxyethylene fatty acid, polyol fatty acid ester, nonylphenolpolyoxyethylene ether and polyethylene glycol; and the antistatic agent is selected from one or more of alkyl phosphate salt, alkyl sulfate, alkyl phosphate and higher alcohol alkyl sulfate. By screening the components of the lubricant, the antistatic agent and the emulsifier of the viscose oil, the prepared product can effectively regulate the friction force of the fiber surface, improve the antistatic performance, has high softness, good smooth feeling, appropriate bundling performance and bundlingcohesion performance, and can effectively improve the fiber spinning processability.

Owner:乌鲁木齐市华泰隆化学助剂有限公司

Automobile power steering pump powder metallurgy inner and outer rotor formula and preparation technology

The invention discloses an automobile power steering pump powder metallurgy inner and outer rotor formula and preparation technology. The formula comprises the following components, by weight percentage, 92-95% of atomized iron powder, 0.6-1.2% of colloidal graphite, 1-5% of electrolytic copper, 0.5-3% of nickel powder, 0.5-3% of molybdenum powder, 0.1-0.6% of manganese sulfide, 0.1-0.6% of sulfur, 0.3-0.7% of micronized waxes, and 5-30ml / 100kg of spindle oil. The preparation technology comprises the following steps of ingredient preparing, powder mixing, compression molding, sintering and alloying, shaping and correcting, machining, steam treating and the like. Utilization ratio of materials is improved effectively, the surface roughness reaches 0.8-1.6Mum, the service life, accuracy class, safety performance of the power steering pump are improved effectively, and production cost is reduced.

Owner:ANHUI HENGJUN POWDER METALLURGY TECH

Copper iron tin powder composition and preparation method thereof

The invention provides a copper iron tin powder composition and a preparation method thereof. The preparation method of the copper iron tine powder composition includes: firstly, mixing copper powder and iron powder, and dispersing mixture to obtain copper and iron pre-alloy powder; and secondly, adding spindle oil after smashing and screening the pre-alloy powder, and then adding tin powder and graphite powder to obtain the copper iron tin powder composition. As content of copper and tin is increased and the spindle oil is added, wear resistance of the powder composition is improved. Meanwhile, iron powder in the copper iron tin powder composition is exposed by smashing during preparation, and accordingly, strength of the powder composition is improved. Therefore, the copper iron tin powder composition is high in strength and wear resistance.

Owner:湖南汇融科技有限公司

Wool oil for production of fibers

The invention discloses wool oil for production of fibers. The wool oil is prepared by components including, by weight, 40-60 parts of spindle oil, 2-4 parts of lauryl polyoxyethylene ether (9), 1-2 parts of cocoyl methyl diethanolamine, 0.5-1 part of dimethyl silicone fluid, -805-10 parts of tweens, 1-2 parts of N,N-dimethyldodecylamine-N-oxide sol, 1-3 parts of sodium oleate, 1-3 parts of triethanolamine, 1-3 parts of glycerol and 0.5-1.5 parts of monododecyl potassium quercetin phosphate. The wool oil for production of fibers is capable of smoothing fibers and enabling the fibers to be soft and antistatic. Fibers treated by the wool oil are not easy to generate static electricity or anti-fuzzing during opening, combing, drawing and spinning, evenness and smoothness during slivering, roving and fine spinning are guaranteed, and further, fabrics knitted by the fibers treated with the wool oil are fine and smooth with neat and clear texture.

Owner:博罗县富得针织有限公司

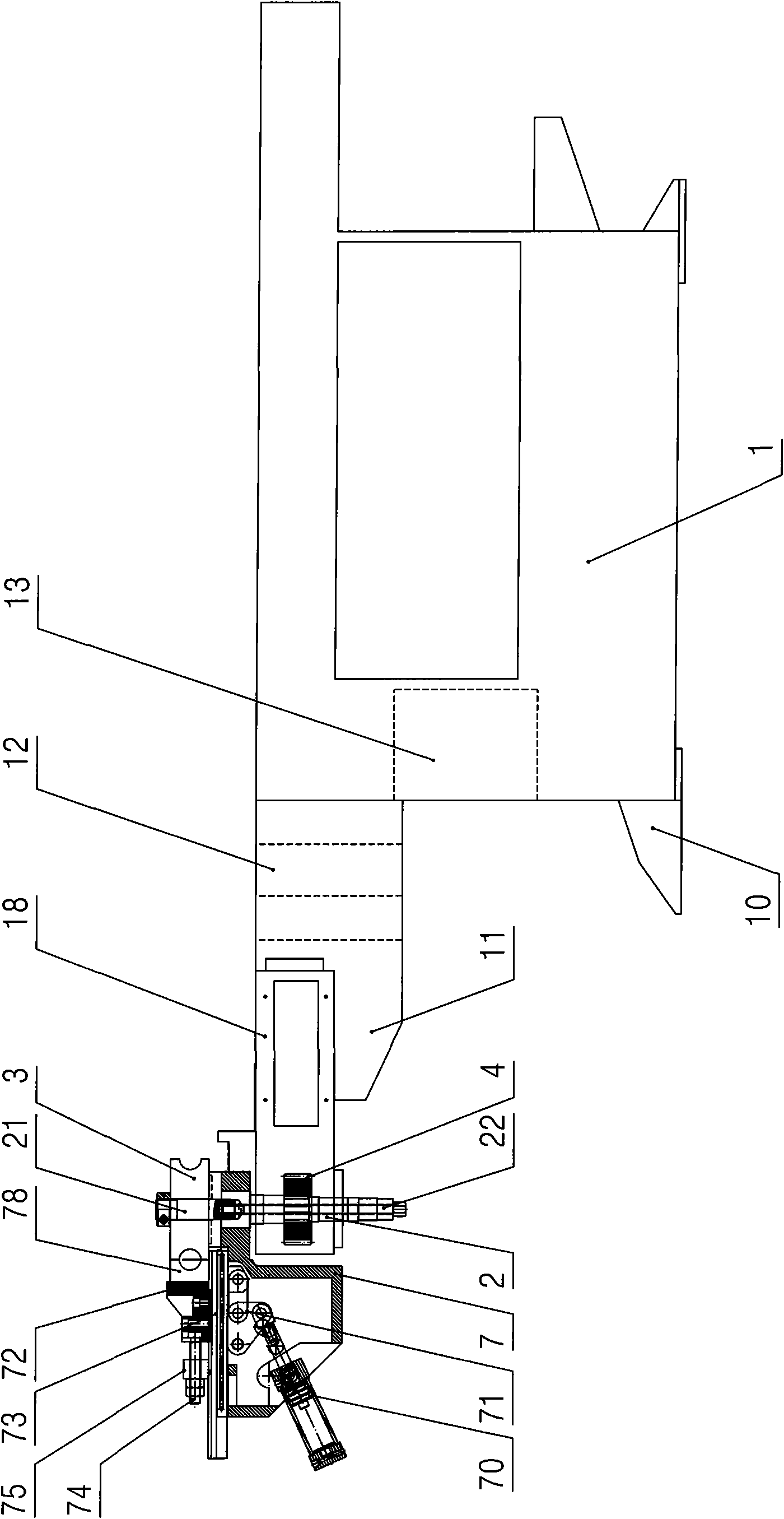

Special pipe bender of chain frame

The invention discloses a special pipe bender of a chain frame, which can integrally mold the chair frame in one step, comprising a bender body. One end of the bender body is provided with an outrigger which is provided with a bender head; the bender head is movably provided with a spindle which is provided with a pipe bending die, a pipe bending arm and a transmission gear; the pipe bending arm is provided with a clamping oil cylinder; a piston rod of the clamping oil cylinder is provided with a clamping die holder which is provided with a clamping die; the bender body is provided with a spindle oil cylinder; a piston rod of the spindle oil cylinder is provided with a transmission rack which is engaged with the transmission gear; the back side of the outrigger is provided with a vertical avoiding groove used for avoiding the chair frame, and the trigger vertically penetrates through the avoiding groove a; and correspondingly, the transmission rack and the spindle oil cylinder are in inclined arrangement. The invention is mainly used for integrally molding chair frames.

Owner:ZHANGJIAGANG MINGHUA MACHINERY MFG

Polyurethane rubber roller

InactiveCN104693411AImprove wear resistanceImprove high temperature resistanceGlycerolWorking environment

The invention discloses a polyurethane rubber roller. The polyurethane rubber roller is prepared from the following materials in parts by weight: 50 parts of polytrimethylene glycol, 20-30 parts of toluene diisocynate, 20-30 parts of methanol, 30-40 parts of diethanol amine, 5-10 parts of glycerol, 15-25 parts of 3,3-dichloro-4,4-diaminodiphenyl-methane, 0.5-1.0 part of titanium dioxide and 10-15 parts of spindle oil. The rubber roller is excellent in wear resistance, high temperature resistance, corrosion resistance and antiaging performance, and can be continuously used for 3-4 months under a high-rotation-speed work environment without any change.

Owner:王东奎

Manufacture method for automobile 5DYA limited block

InactiveCN102198508AReduce consumptionEasy to shapeTurbinesOther manufacturing equipments/toolsManufacturing technologySpindle oil

The invention discloses a manufacture method for an automobile 5DYA limited block. The limited block comprises the following raw materials in percentages by weight: 94.5-94.9 percent of atomized iron powder, 0.7-0.9 percent of graphite, 1.95-2.05 percent of copper powder, 0.9-1 percent of nickel powder, 1 percent of molybdenum disulfide, 0.5 percent of zinc stearate and 0.025-0.05 percent of spindle oil. The process provided by the invention comprises the following steps of: 1, adding the graphite, the copper powder, the nickel powder, the molybdenum disulfide and a proper amount of the spindle oil into the atomized iron powder, and mixing uniformly to prepare a mixed material; 2, loading the mixed material into a mould and performing press forming by an automatic pressing machine to prepare a forming element; 3, loading the forming element into a sintering furnace and sintering in an atmosphere of decomposing ammonia at the temperature of 1160-1165 DEG C for 60-80 minutes; and 4, carrying out following machining by adopting a drilling machine to obtain a finished product. The manufacture method provided by the invention belongs to a powder metallurgy manufacturing technology and is suitable for a product with a complex shape and large quantity.

Owner:XINGTAI HAIBO POWDER METALLURGY

Powder metallurgy formula of full-hydraulic steering gear stator and rotor pair and manufacturing process

ActiveCN103611925AIngredient ratio scienceImprove wear resistanceTurbinesOther manufacturing equipments/toolsAquadagSpindle oil

The invention discloses a powder metallurgy formula of a full-hydraulic steering gear stator and rotor pair. The powder metallurgy formula is characterized in that the powder metallurgy formula comprises, by weight, 90.5% to 94.5% of atomized iron powder, 0.6% to 1.2% of aquadag, 1.0% to 4.0% of electrolytic copper, 0.8% to 2.0% of nickel powder, 0.5% to 2.0% of molybdenum powder, 0.2% to 0.5% of chromium powder, 0.1% to 0.6% of manganese sulfide, 0.3% to 0.7% of micronized wax and balance spindle oil, wherein every 100kg of the powder metallurgy formula contains 5mL to 30mL of spindle oil. The invention further discloses a powder metallurgy manufacturing process of the full-hydraulic steering gear stator and rotor pair. The powder metallurgy manufacturing process includes the dosing step, the powder stirring step, the pressing and forming step, the sintering and alloying step, the shaping and shape correcting step, the machining step, the steam processing step and other steps. By means of the powder metallurgy formula and the manufacturing process, the effects of being scientific in material composition proportion, good in wear resistance, not prone to abrasion, high in machining efficiency, material utilization rate and machining accuracy, good in rust protection performance and the like are achieved, and the market requirements can be completely met.

Owner:ANHUI HENGJUN POWDER METALLURGY TECH

Cotton picker spindle oil and preparation method thereof

InactiveCN101845354AImprove performanceNo damageAdditivesBase-materialsAgricultural engineeringProcess engineering

The lubricating grease prepared by the invention not only is applicable to cotton picker spindle oil, but also has the advantages of good shear reversibility, high and low temperature, extreme pressure wear resistance, rust resistance, compatibility (with other lipid) and the like and thereby has wide scope of application, can realize very good lubrication action under adverse working conditions,can be widely applied to agricultural machinery, building machinery, railways, ball mills and other equipment as well as steel making, cement, power generation, packaging, chemical engineering, automobile and other industrial fields. Lubricating grease products increasingly develop to the direction of high drop point, high efficiency, long service and environmental friendliness. Ti-based composite resin is just adaptable to the trend of the lubricating grease, now has become the focus of attention in the lubricating grease industry, represents the international advanced level of the lubricating grease, and is a development direction of high-performance lubricating grease variety in the world nowadays.

Owner:新疆五家渠现代石油化工有限公司

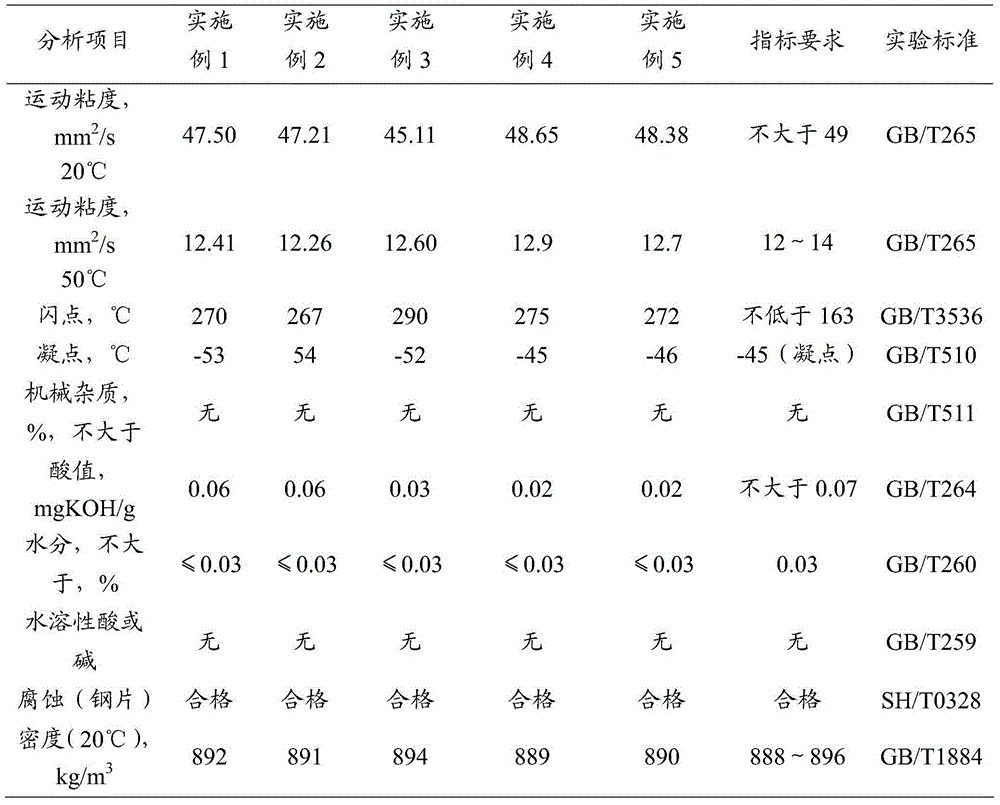

Spindle oil composition

The invention provides a spindle oil composition. The spindle oil composition comprises 43.45-56wt% of aromatic ester oil, 37.45-50wt% of poly(alpha-olefin), 0.1-3wt% of an anti-oxidant, 0.01-0.5wt% of a metal deactivator, 0.1-3wt% of a corrosion inhibitor and 0.0005-0.05wt% of an anti-foaming agent. Compared with the prior art, a preparation method of the spindle oil composition is free of naphthenic mineral oil or alkylbenzene base oil having an unstable source, utilizes poly(alpha-olefin) and aromatic ester oil as base oil of the spindle oil composition. The poly(alpha-olefin) and aromatic ester oil have wide sources, simple synthesis routes and high yields and thus the poly(alpha-olefin) and aromatic ester oil as spindle oil composition preparation raw materials can be supplied stably.

Owner:CHINA PETROLEUM & CHEM CORP

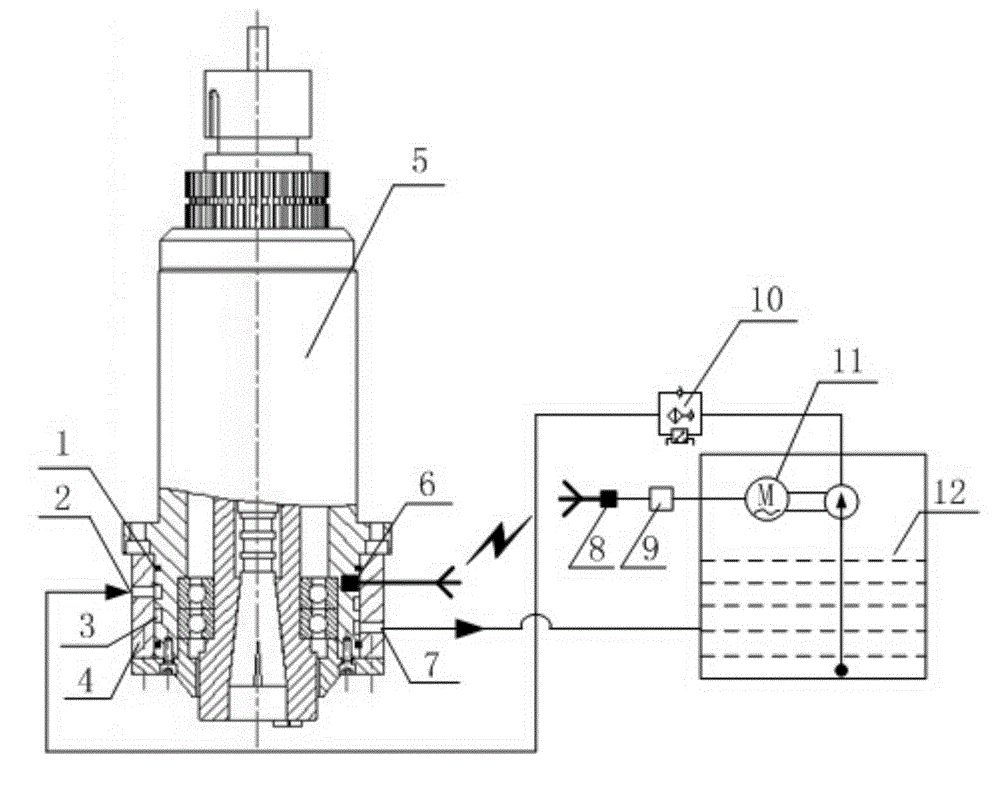

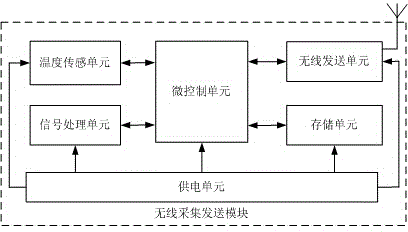

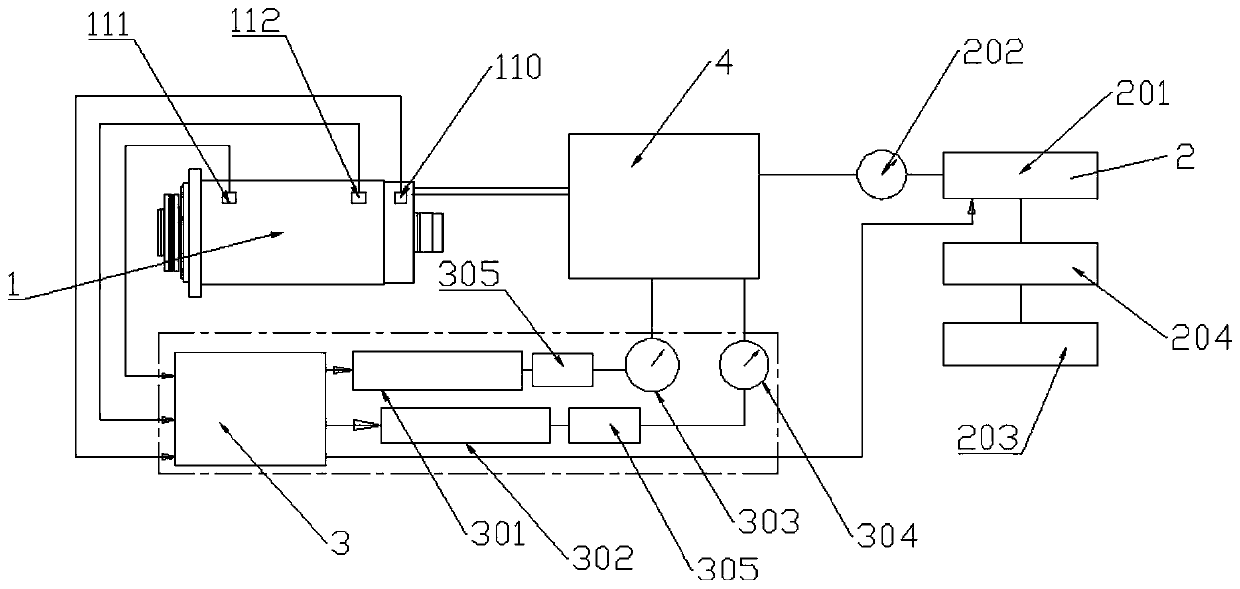

Numerical control machine tool spindle intelligent cooling system and working process thereof

InactiveCN104551850ASolve the problem that the cooling time cannot be adjusted in real time according to the spindle temperatureReduce energy consumptionMaintainance and safety accessoriesNumerical controlComputer module

The invention discloses a numerical control machine tool spindle intelligent cooling system and a working process thereof. The working process includes the steps of (1) performing temperature field simulation analysis on a spindle according to the actual structural size of the spindle to determine a thermosensitive area; (2) machining a spiral cutting groove in the outer surface of the thermosensitive area, forming an oil circulation cavity of an annular groove with a spindle oil cooling sleeve, and arranging a seal ring for sealing; (3) mounting a wireless acquisition transmitting module inside the spindle, and transmitting temperature information to a wireless receiving module outside the spindle; (4) determining through the wireless receiving module according to the received information, and starting an alarm device and an oil pump if the temperature exceeds a set threshold value, wherein the cooling oil enters a spindle oil cooling channel through a filter and finally returns to an oil tank from an oil outlet to form a closed-loop control circulation cooling system. The numerical control machine tool spindle intelligent cooling system and the working process thereof can perform intelligent control of the oil pump opening and closing according to the actually-measured temperature of the thermosensitive area of the spindle to achieve quick and effective cooling of the spindle and have the advantages of being low in energy consumption and high in efficiency and the like.

Owner:NANTONG GUOSHENG INTELLIGENCE TECH GRP CO LTD

Anti-static odorless odor-resistant dithio sponge rubber material as well as preparation method and application thereof

The invention discloses an anti-static odorless odor-resistant dithio sponge rubber material as well as a preparation method and an application thereof. The anti-static odorless odor-resistant dithio sponge rubber material comprises the following components in parts by weight: 90-110 parts of standard rubber, 2-3 parts of sulfur, 1.7-2 parts of vulcanization accelerator, 7-9 parts of nano zinc oxide, 11-15 parts of stearic acid, 80-100 parts of argil, 4-5 parts of odorless foaming agent, 18-22 parts of carbon black with high wear resistance, 4-6 parts of conductive black, 12-17 parts of spindle oil, 8-12 parts of dibutyl phthalate, 2.2-2.8 parts of anti-bacterial and odor-resistant powder and 1-1.5 parts of sanxiang organic guanidine antimicrobial XT-11. The dithio sponge rubber material formula and preparation process disclosed by the invention are searched and screened to obtain the optimal combination, so that a product obtained according to the technical scheme of the invention not only has the anti-static effect, but also can eliminate the peculiar smell of the dithio sponge and effectively inhibit the odor of hong kong feet. The preparation method is simple and easy, wide in material source and low in cost, and the product is good in use effect.

Owner:际华制鞋工业有限公司

Viscose oil agent

InactiveCN101725041AReasonable formulaImprove work performanceVegetal fibresSpindle oilViscose fiber

The invention discloses a viscose oil agent, which is formed by mixing spindle oil, turkey red oil, an emulsifier OP-10, triethanolamine, a softening agent DC and water. The invention is reasonable in formula, good in service performance, convenient in production and use and low in production cost.

Owner:何培祥

Food Grade Compressor Lubricant

ActiveUS20130065805A1Excellent characteristicsIncrease resistanceBase-materialsGeneral purposePolyolester

The invention relates to an improved food-grade-lubricant useful as hydraulic oil, circulating oil, drip oil, general purpose oil, grease base oil, cable oil, chain oil, spindle oil, gear oil, and compressor oil for equipment in the food service industry. Specifically, it relates to a composition comprising at least one polyalphaolefin base fluid, at least one food grade polyolester base fluid, and at least one food grade performance additive.

Owner:THE LUBRIZOL CORP

Multi-stage rotary oil supply joint

InactiveCN102364196AWith multi-channel oil supply capabilityCompact structurePipe elementsMulti pathSpindle oil

The invention provides a multi-stage rotary oil supply joint, which comprises a central spindle and an outer cylinder, wherein the outer cylinder is sleeved outside the central spindle; the central spindle can rotate 360 degrees in the outer cylinder; a support bearing is arranged between the central spindle and the outer cylinder; a gland fixedly connected with the outer cylinder is arranged on the rear parts of the central spindle and the outer cylinder; the central spindle comprises a spindle oil inlet pipeline and a spindle oil outlet pipeline; the spindle oil inlet pipeline is provided with a plurality of spindle oil inlets; the spindle oil outlet pipeline is provided with a plurality of spindle oil outlets; the upper part of the outer cylinder is provided with a plurality of oil outlets, and the lower part of the outer cylinder is provided with a plurality of oil inlets; and the spindle oil inlet pipeline is communicated with the oil inlets, and the spindle oil outlet pipeline is communicated with the oil outlets to form oil supply channels. The multi-pass rotary oil supply joint has the advantages that: an oil circuit of the central spindle and an oil circuit of the outer cylinder are matched to form a multi-stage oil circuit channel, so that the joint has a multi-path oil supplying capacity; and the whole device is compact in structure and convenient to use.

Owner:CHANGZHOU TENT HYDRAULIC MACHINERY

Efficient environment-friendly water-based copper wire-drawing liquor and preparation method thereof

The invention discloses efficient environment-friendly water-based copper wire-drawing liquor. The efficient environment-friendly water-based copper wire-drawing liquor is characterized by being prepared from the following raw materials in parts by weight: 1-2 parts of sodium borate, 2-4 parts of aminosulfonic acid, 2.5-3.5 parts of vinyl carboxylic ester, 5-7 parts of silicon micro powder, 4-5 parts of polyricinoleate, 0.8-1.5 parts of urotropin, 3-5 parts of lithium base grease, 3-4 parts of triethanolamine, 3-5 parts of spindle oil, 3-5 parts of sodium stearate, 2.5-3.5 parts of sodium dioctylsulfosuccinate, 5-7 parts of auxiliaries and 900-950 parts of deionized water. The efficient environment-friendly water-based copper wire-drawing liquor adopts an environment-friendly formula, is efficient and environmentally friendly, and has good wear resistance, dispersion, lubrication and film-forming property due to addition of the auxiliaries; and when the efficient environment-friendly water-based copper wire-drawing liquor and a surfactant constitute a formula, a protective film layer is formed on the surface of the metal to achieve the corrosion inhibition effect. The efficient environment-friendly water-based copper wire-drawing liquor is good in lubricating effect, good in cooling performance, high in heat transfer speed and easy to clean. A copper wire drawn by the efficient environment-friendly water-based copper wire-drawing liquor is bright in surface and not prone to rust.

Owner:ANHUI WANGDA COPPER DEV

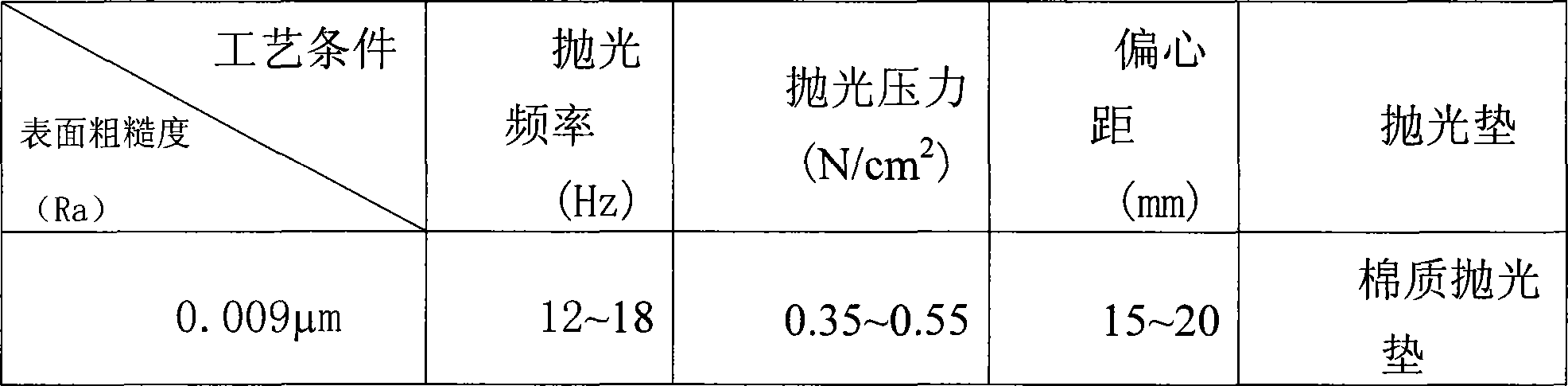

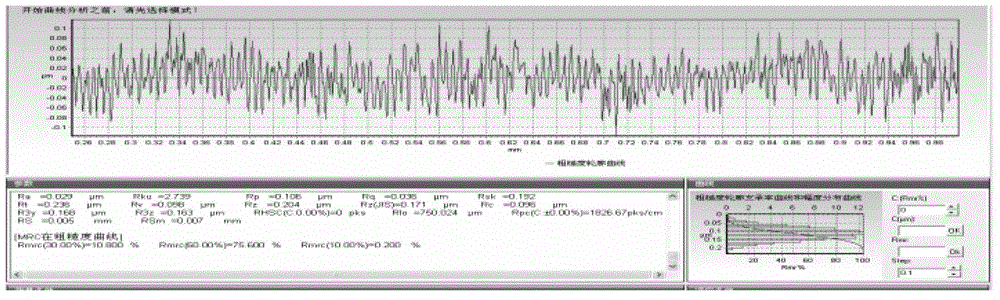

H62 brass polishing liquid and its preparing process

InactiveCN101054499ARelieves mechanical scoringImprove surface qualityPolishing compositions with abrasivesSurface roughnessProcess engineering

H62 brass specific polishing fluid and its producing method belong to precision mechanical polishing field. The common polishing fluid can not well satisfy plastic metal material minuteness mirror face. The polishing fluid is composed of Al2O3 micropowder with a grain diameter of 0.5-1.0 mum, coal oil, lard, plant oil and spindle oil, wherein Al2O3 micropowder is abradant, coal oil is solvent, the mixing liquid of lard, plant oil and spindle oil is as additive; and the polishing fluid is prepared by a mixing liquid which is composed of 2% lard, 2% abraser, 8% plant oil and spindle oil by volume and 88% coal oil. The polishing fluid can produce the H62 brass element with a uniform surface quality and a good surface roughness value up to 0.008 mum, has the characteristics of no eroding elements, effectively relieving mechanical score, good processing surface quality and can be used for decoration of the plastic metal material and surface polishing process before the material metallographic microscope analysis.

Owner:BEIJING UNIV OF TECH

Lubricant for automobile chassis stampings and a preparing method thereof

InactiveCN106350175AExcellent flame retardantGood acid and alkali resistanceLubricant compositionPolybutylene terephthalateFatty acid

The invention relates to a lubricant for automobile chassis stamping. The lubricant is prepared from light spindle oil, soybean oil, polybutylene terephthalate, molybdenum dioxide powder, polypropylene glycol, soya oil acid, sodium fatty acid, polyether silicone oil, dimethylformamide, bromo-geramine, garlic oil, chlorhexidine, potassium sorbate, chlorothalonil, calcium lignosulphonate, aluminum nanopowder, zinc octoate, nanometer active calcium carbonate, polypropylene wax, expanded perlite powder, vanadic anhydride powder, hexamethylene diisocyanate, polyethylene wax, tetraethoxysilane, decabromodiphenyl ethane, hexahydrophthalic anhydride, butyl stearate, gumacacia powder, dioctyl adipate, didecyldimethylammonium chloride, sodium lignosulfonate and graphite powder. The lubricant for automobile chassis stamping has the advantages of excellent flame retardant, acid and alkali resistant and mildew proof, which improve the product performance.

Owner:SICHUAN ZHENGLIANG MACHINERY

Anti-aging polyvinyl chloride cable material

InactiveCN106800722AImprove stabilityImprove toughnessPlastic/resin/waxes insulatorsPolyvinyl chlorideGlass microsphere

The invention discloses an anti-aging polyvinyl chloride cable material which is prepared from the following raw materials in parts by weight: 30-60 parts of polyvinyl chloride, 5-15 parts of modified rice bran fiber, 0.5-1.5 parts of methyl triethoxy silane, 1-2 parts of maleic anhydride, 5-15 parts of smectite, 2-6 parts of glass microsphere, 5-10 parts of quartz powder, 1-4 parts of fly ash, 2-4 parts of nano titanium oxide, 2-4 parts of white clay, 1-5 parts of spherical silicon micropowder, 1-3 parts of lanthanum chloride, 1-2 parts of butyl tin mercaptide, 1-2 parts of dibutyltin dilaurate, 1-3 parts of ethoxylated ammonium alkyl sulfate, 2-6 parts of abietinol, 1-3 parts of copper 8-hydroxyquinoline, 0.5-1.2 parts of microcrystalline wax, 1-2 parts of spindle oil, 1-2 parts of disproportionated rosin and 1-4 parts of polyimide. The anti-aging polyvinyl chloride cable material disclosed by the invention has the advantages of excellent tear resistance, excellent aging resistance, excellent toughness, smooth surface, excellent compactness and long service life.

Owner:ANHUI HUATIAN CABLE

Phosphorization bolt friction coefficient stabilizer and preparation method thereof

The invention relates to a phosphorization bolt friction coefficient stabilizer and a preparation method thereof. The stabilizer comprises the following components in percentage by mass: 10%-20% of base oil, 6%-15% of fatty acid, 8%-12% of triethanolamine, 1%-2% of emulsifying agent, 0.5%-1% of bactericide, 3%-5% of silicone oil and 48%-60% of purified water, wherein various machine oils and spindle oils are selected as the base oil. The preparation method of the stabilizer comprises the following steps of: firstly adding a design amount of base oil, fatty acid and silicon oil to a container, adding the purified water for dissolving, then sequentially adding the triethanolamine, the emulsifying agent, the bactericide and a defoaming agent according to proportioning, stirring, dissolving and filling a volumetric flask, thus the phosphorization bolt friction coefficient stabilizer can be used. The phosphorization bolt friction coefficient stabilizer has good capacity of resisting oxidation, acid gas, discoloration and dampness; a lubricating film formed on the surface of a phosphating film stabilizes the friction coefficient of a fastener to be in the range of 0.06-0.09; and the friction coefficient of phosphorization bolts is controlled in the range of 0.075+ / -0.015, thus the effects of controlling the friction coefficient very well and resisting corrosion are achieved.

Owner:十堰达克罗涂覆工贸有限公司

Electric spindle oil-air lubricating device, control system and control method

ActiveCN109807356AEffective regulationMeasurement/indication equipmentsMaintainance and safety accessoriesElectricityControl system

The invention provides an electric spindle oil-air lubricating device, a control system and a control method, and relates to the technical field of bearing lubricating. The electric spindle oil-air lubricating device comprises an electric spindle assembly with a rotation speed measuring element, an air adjusting mechanism, an oil amount control mechanism and a mixing mechanism; a front bearing anda back bearing are each provided with a temperature measuring element; the electric spindle assembly is provided with a first oil way communicating with the front bearing and a second oil way communicating with the back bearing; the electric spindle assembly, the oil amount control mechanism and the mixing mechanism sequentially communicate with one another to form a circulating loop, and the mixing mechanism communicates with the first oil way and the second oil way; the mixing mechanism is provided with an oil-air mixing valve; the air adjusting mechanism communicates with the mixing mechanism, and the oil amount control mechanism is electrically connected with the air adjusting mechanism; and the oil amount control mechanism is used for controlling the opening degree of the air adjusting mechanism and the flow of lubricating oil introduced into the mixing mechanism according to the measured temperature and rotation speed.

Owner:GREE ELECTRIC APPLIANCES INC

Special polishing fluid for plastic soft metallic materials and method for preparing polishing fluid

The invention relates to special polishing fluid for plastic soft metallic materials and a method for preparing the polishing fluid and belongs to the technical field of the polishing fluid. The polishing fluid is prepared from a ground material, a solvent and additives which are in a certain volume ratio, namely 2% of brightener, 3% of diamond micro powder, 15% of additives and 80% of kerosene. The method comprises the steps of: adding the diamond micro powder into melted lard or vaseline, and stirring uniformly; then, adding the kerosene, and cooling down to room temperature for standby; and adding stearic acid particles (C17H35COOH), vegetable oil and spindle oil into a clean vessel, stirring uniformly, adding the brightener, and uniformly mixing and stirring the solution, thereby obtaining the polishing fluid. The surface of a niobium alloy workpiece processed by the polishing fluid is uniform in mass, is free from polishing lines and can reach a mirror polishing effect. Meanwhile, the polishing fluid can play a role in cooling, lubrication, adsorption and washing during processing and can also be applied to the mirror polishing processing of similar plastic soft metallic materials, the operation is simple, the efficiency is high, the cost is low, and no pollution is caused.

Owner:东莞市硕丰研磨科技有限公司

Machining method for spindle hole oil groove of large diesel engine body

ActiveCN105583449AProtectImprove rigidityWorkpiecesMilling equipment detailsMilling cutterDiesel engine

The invention relates to a machining method for a spindle hole oil groove of a large diesel engine body. The method comprises the following implementation steps that most margins are removed with a short ball milling cutter with the good rigidity; margins of the interference portion are removed with a long ball milling cutter; remaining margins are removed for one time with a three-edge milling cutter, and the groove is finally obtained. The machining method has the advantages that the machining time is short, the machining efficiency is high, the cutters are not prone to be tipped, the using effect is good, and the life is long.

Owner:WEICHAI HEAVY MACHINERY

Heat-resistant ageing-resistant sound-absorbing cotton and preparation method thereof

InactiveCN105220493AReasonable structureGood sound absorptionFibre typesPolyesterAbsorption capacity

The invention discloses heat-resistant ageing-resistant sound-absorbing cotton. The heat-resistant ageing-resistant sound-absorbing cotton is prepared from, by weight, 40-60 parts of polyester fibers, 5-10 parts of polybenzimidazole fibers, 10-15 parts of poly(m-phenylene isophthalamide)fibers, 10-15 parts of ES fibers, 3-5 parts of ceramic fibers, 0.1-0.2 part of butylated hydroxytoluene, 3-5 parts of spindle oil, 2-4 parts of barite powder, 1-2 parts of silane coupling agents KH-550, 0.2-0.4 part of pentaerythritol oleate and 10-15 parts of composite resin. The sound-absorbing cotton has better full frequency sound absorption capacity, the acoustic property is obvious promoted, good heat resistance and ageing resistance are achieved, the use property is good, the service life is long, the application range is wide, and the practicability is high.

Owner:WUHU HUANRUI AUTO INTERIOR DECORATION

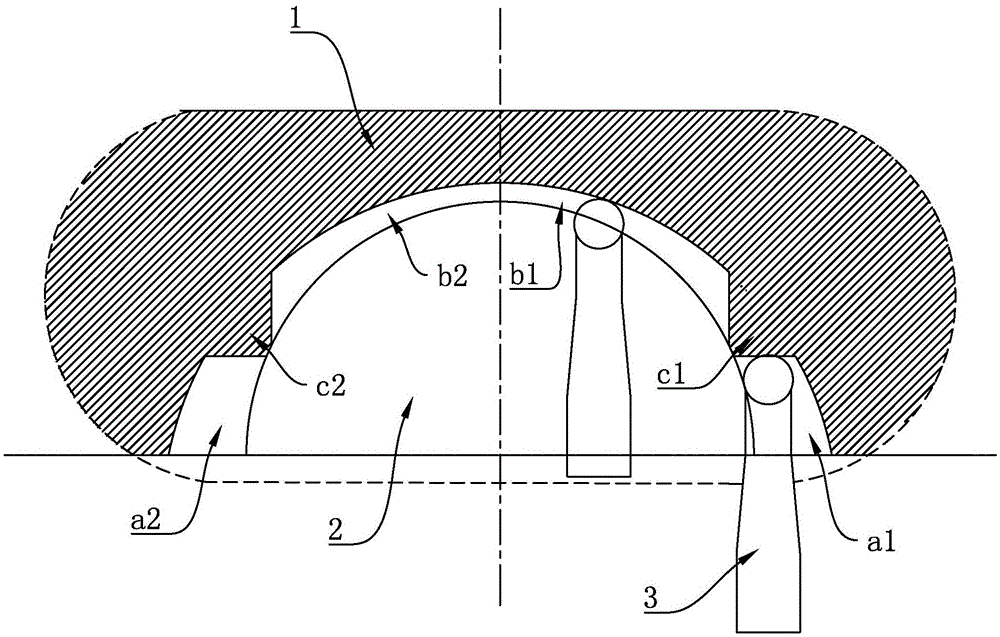

Turning fixture for gleason spiral bevel gear

InactiveCN103084895AGuaranteed unityEnsure consistencyTurning machinesPositioning apparatusGear wheelEngineering

The technology provides a turning fixture for an arc-teeth cone gear. The turning fixture for the Gleason spiral bevel gear can be connected to a lathe and can carry out turn an inner hole and a plane of the Gleason spiral bevel gear to improve the processing efficiency and ensure the processing quality. The turning fixture for the Gleason spiral bevel gear comprises a clamp base used for being connected with a spindle, a clamp is fixed on the clamp arc-teeth cone gear base, and a bearing plate is arranged on the clamp; at least three positioning balls, evenly located on the circumferential direction of the Gleason spiral bevel gear, are arranged on the bearing plate. The Gleason spiral bevel gear is pressed tightly on the positioning balls by three pressing plates sleeved on three pulling bars. Lower ends of the pulling bars are connected with a fork-shaped plate through the clamp; a spherical pair is formed by a center portion of the fork-shaped plate and a movable sliding block; a center screw rod is arranged on the movable sliding block to be connected to a spindle oil cylinder of the lathe; and the pressing plates are connected with the pulling bars by screw pairs.

Owner:JIANGSUSNGCHI GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com