Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

760results about How to "Excellent flame retardant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Room-temperature cured phenyl silicon resin conformal coating

The invention discloses a room-temperature cured phenyl silicon resin conformal coating which comprises components A) a segmented copolymer of phenyl silicon resin and linear polyorganosiloxane or methyl phenyl silicon resin and linear polyorganosiloxane, B) alkoxy silane, C) a silane coupling agent containing amino or epoxy group, D) an organic titanium compound, E) organic phosphate flame retardant synergist, and (F) an organic hydrocarbon solvent or low molecular weight siloxane, wherein the organic hydrocarbon solvent is one or multiple of methylbenzene, dimethylbenzene, petroleum ether, cyclohexane and normal heptane; and the low molecular weight siloxane is a mixture of octamethyl-trisiloxan, octamethyl cyclotetrasiloxane or methyl cyclosiloxane. A product produced by the cured resin conformal coating of the invention has the advantages of very high transparency, good elasticity, tough and wearable surfaces as well as excellent high / low temperature performance, waterproofing, heat resistance, cold resistance, weathering resistance, ultraviolet ray resistance, medium resistance, irradiation resistance, flame retarding and the like.

Owner:MIANYANG WELLS ELECTRONICS MATERIAIS

Preparation method of inner decoration material for automobile

ActiveCN1966265AOvercome the shortcoming that some functions are easily weakenedSoft touchLamination ancillary operationsFibre treatmentMetallurgySlurry

The invention relates to a method for producing decorates material of vehicle, wherein it comprises that: (1), pretreating base cloth, while the base cloth is immerged with disinfection and flameproof, dried, cooled and coiled; (2), wet solidifying coat that rolling the base cloth, scraping on coating machine, while the slurry amount is 100-300g / m2, drying, solidifying in solidifying groove, washing, drying and shaping, cooling and coiling; (3), dry transfer surface shaping that special paper transfer adhering; (4), rolling and drying the semi-product, coiling and packing. The inventive product has water resistance, etc.

Owner:HAININ JINDA COATING

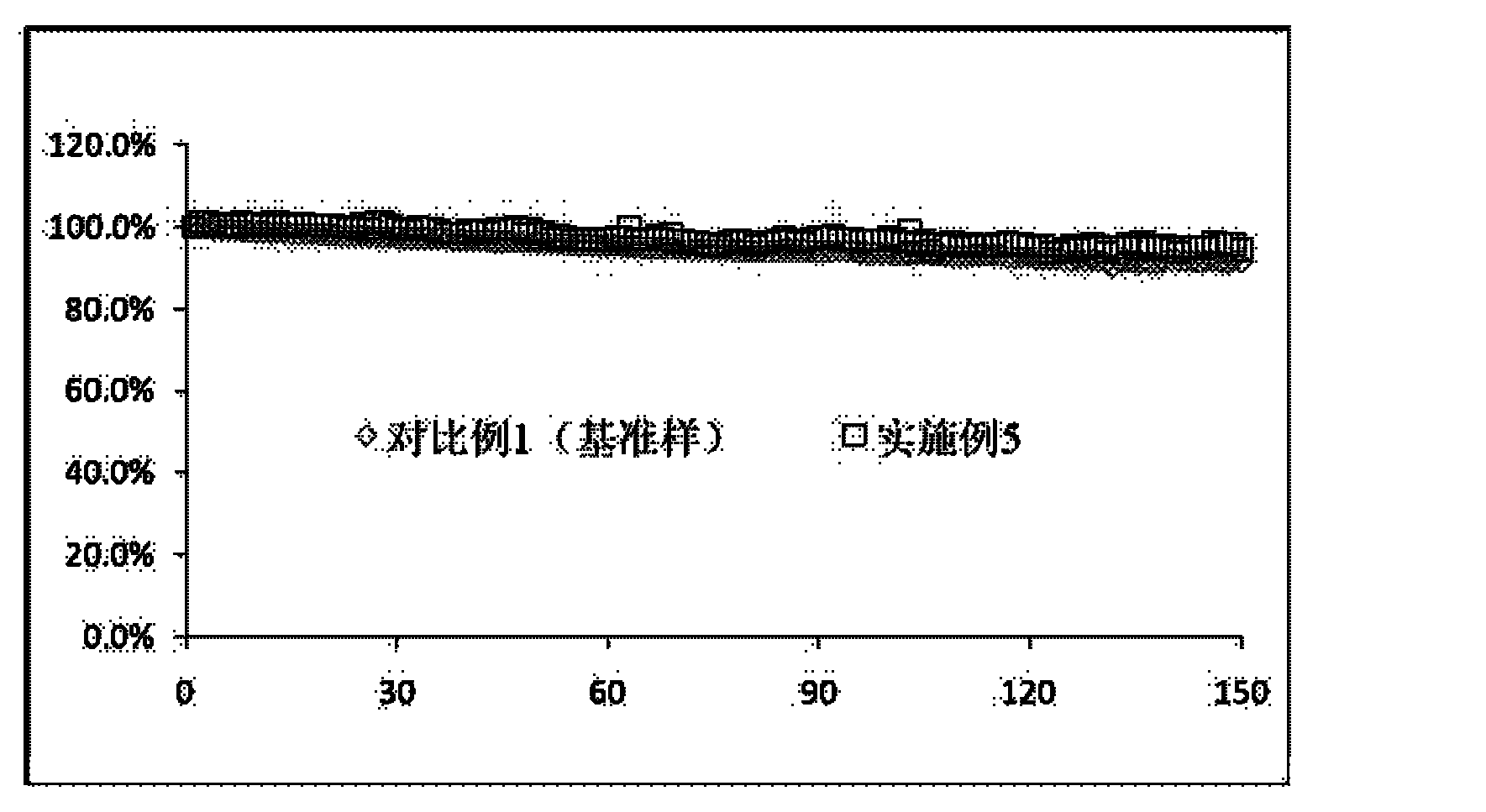

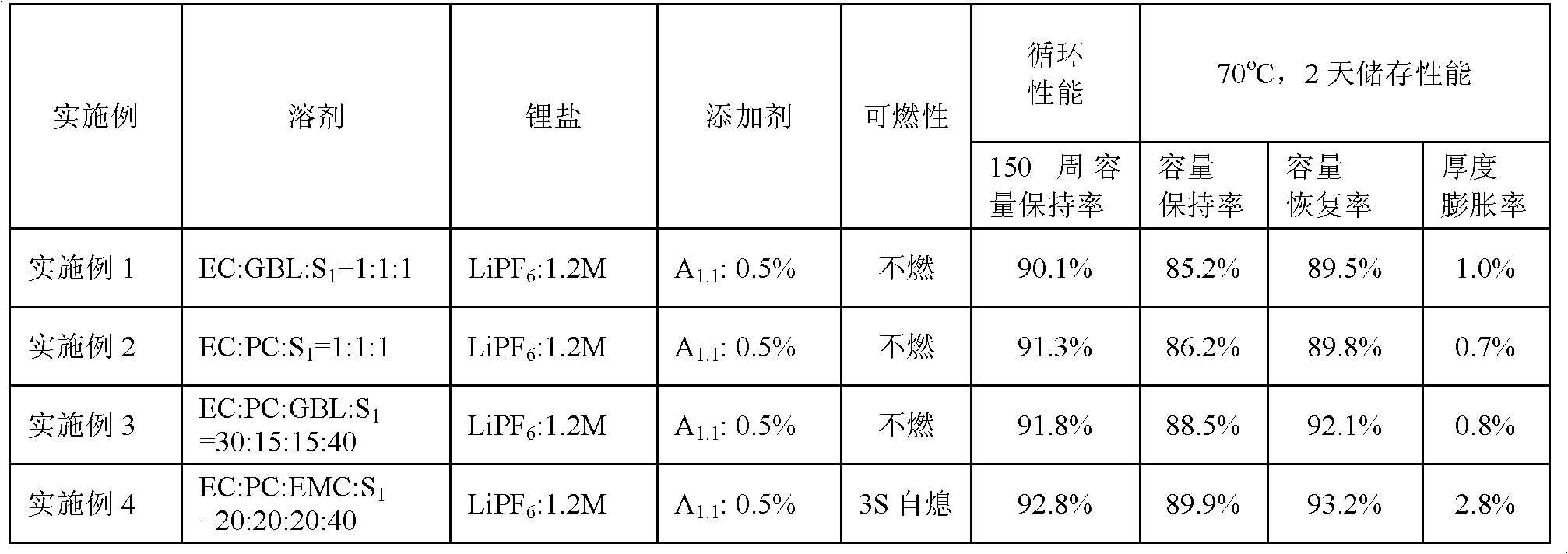

Flame retardant type non-aqueous electrolyte solution and battery thereof

InactiveCN102306833AImprove securityImprove electrochemical performanceSecondary cellsPhysical chemistrySolvent

The invention relates to an organic composition, in particular to a flame retardant type non-aqueous electrolyte solution and a lithium ion battery prepared by the electrolyte solution. The flame retardant type non-aqueous electrolyte solution comprises electrolyte salt, a non-aqueous solvent, 10 to 50 mass percent of flame retardant and 0.001 to 2 mass percent of surfactant, wherein the non-aqueous solvent comprises cyclic carbonic ester and / or cyclic carboxylic ester; the flame retardant comprises an isoflurane organic matter; and the surfactant comprises fluorocarbon surfactant. The electrolyte solution can greatly improve the safety performance of the lithium ion battery; simultaneously, the electrochemistry performance such as cycle performance and high-temperature preservation performance of the lithium ion battery can be obviously improved.

Owner:SHENZHEN CAPCHEM TECH CO LTD

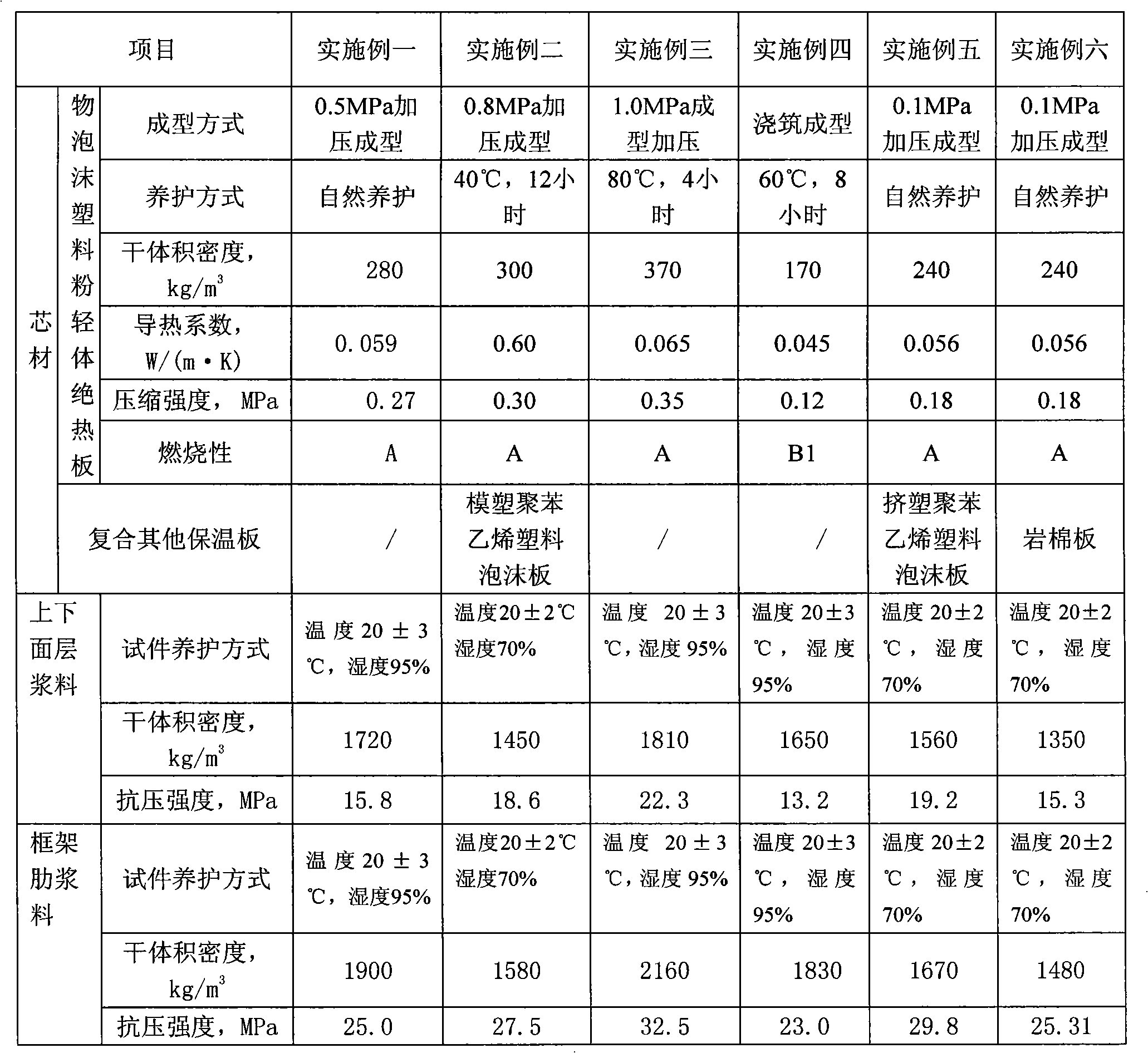

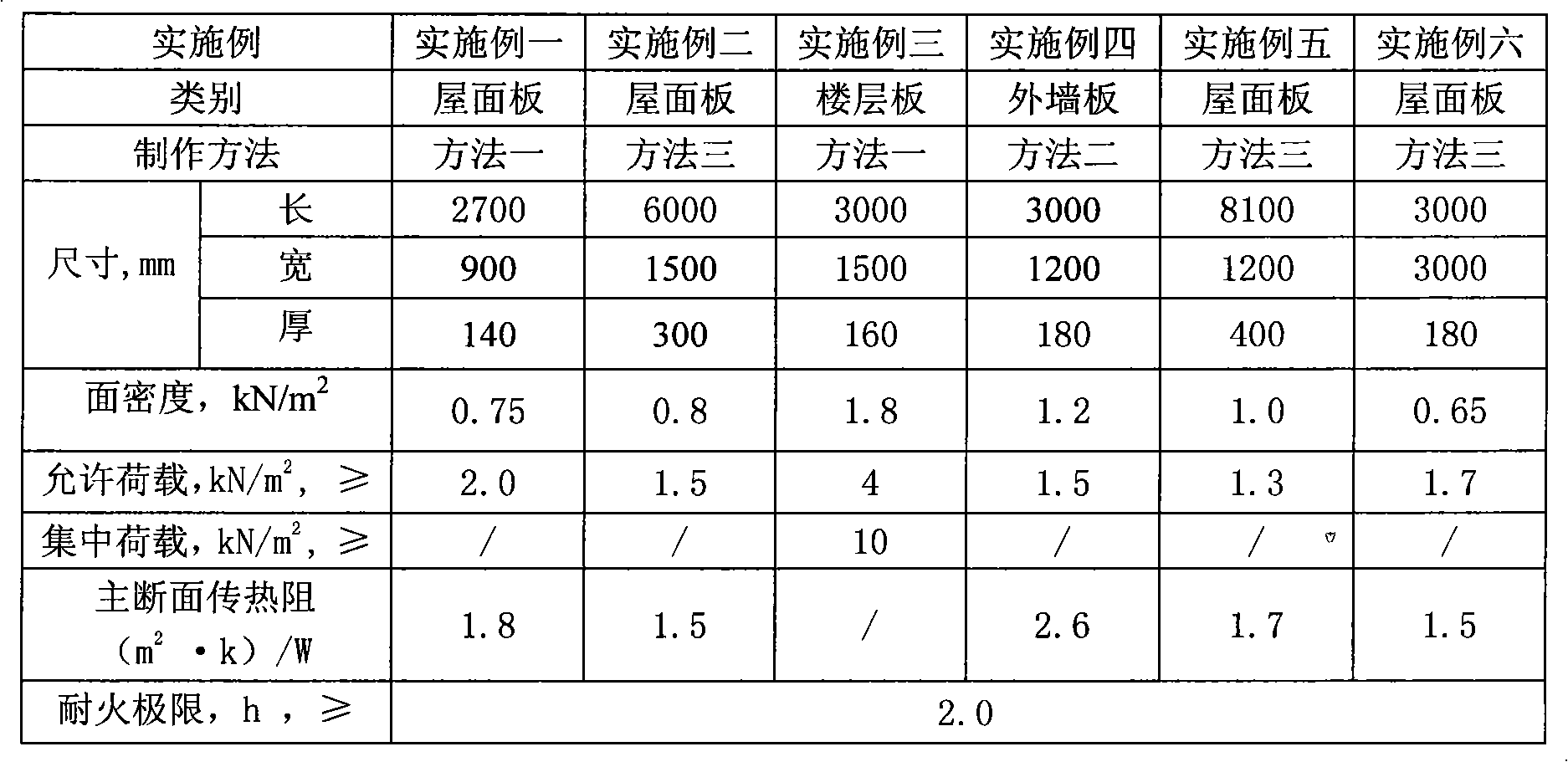

Environmentally-friendly, energy-saving and fireproofing lightweight roof panel, floor plate or wallboard

ActiveCN101914977AStable chemical propertiesGood insulation performanceRoof covering using slabs/sheetsConstruction materialCrack resistancePolystyrene

The invention relates to an environmentally-friendly, energy-saving and fireproofing lightweight roof panel, floor plate or wallboard, which comprises an upper surface layer, a lower surface layer and frame ribs. Insulating layers are arranged between the upper surface layer and the lower surface layer, and are cement polymer foamed plastic powder lightweight insulating plates or are formed by compounding the cement polymer foamed plastic powder lightweight insulating plates and any one of molded polystyrene foam plates, extruding-molded polystyrene foam plates and rock-wool slabs respectively; fiberglass alkaline-resistant mesh fabric is arranged in the upper surface layer and the lower surface layer; the frame ribs are fixedly connected to the lower surface layer; and an anticorrosion steel reinforcement frame is arranged in the frame ribs. In the environmentally-friendly, energy-saving and fireproofing lightweight roof panel, floor plate or wallboard of the invention, the lightweight insulating plates and lightweight surface layer mortar are manufactured by foamed plastic powder; the foamed plastic powder and heat-preservation foamed plastic form particles are applied to lightweight concrete; and materials for the upper and lower surface layers and the frame ribs are enhanced by two or more assorted fibers so as to fulfill the aims of lightweight, high strength, energy saving, sound insulation, fireproofing, crack resistance and durability.

Owner:辽宁际洲环保节能建材有限公司

Polysiloxane acid imide foam and method for preparing same

The invention relates to polysiloxane-imide foam and a preparation method thereof. The polysiloxane-imide foam is made by the steps: one or more than one sort of aromatic dianhydride is composed with one or more than one sort of aromatic diamine according to a certain proportion to get polyimide acid solution, then certain content of silicon-containing blocking agent, polysiloxane precursor and foam stabilizer are added sequentially, then the mixture is heated to remove small molecule volatiles so as to obtain polysiloxane precursor powder, then the powder is filled in a mould and frothed at high temperature to make soft elastic, semi-rigid and rigid polysiloxane-imide foam materials with a density of 0.01g / cm3-1.0g / cm3 and a glass transition temperature of 280 DEGC -350 DEG C. The polysiloxane-imide foam materials of the invention have good performances of high temperature resistance, low temperature resistance, flame retardancy, heat insulation and noise reduction and mechanical properties.

Owner:SHENZHEN HIFUTURE ELECTRIC

Preparation method for wood-bamboo reinforced resin composite material based on high-pressure densification

ActiveCN108772922AIncrease productivityPromote greenWood treatment detailsReed/straw treatmentStress concentrationHigh pressure

The invention relates to a preparation method for a wood-bamboo reinforced resin composite material based on high-pressure densification, and belongs to the field of composite materials and artificialboards. The preparation method for the wood-bamboo reinforced resin composite material based on the high-pressure densification comprises the steps that lignin and hemicellulose are partially removedfrom wood veneers, wood boards or bamboo sheets by a chemical reagent, the chemical reagent is removed by water, and the water is replaced by ethanol or acetone; the wood veneers, the wood boards orthe bamboo sheets with lignin and hemicelluloses removal are put into a mixed solution of a resin system or a resin solution and a flame retardant, a diluent and / or a toughening agent additive, or sequentially put into the resin system or the resin solution and the mixed solution of the additive, so that the resin and additive penetrate into cells and cell pores of the wood or the bamboo; and semi-finished products are assembled into blanks, and high-pressure densification and high-temperature curing are carried out to prepare the high-strength composite material. The preparation method for the wood-bamboo reinforced resin composite material based on the high-pressure densification overcomes the stress concentration problem caused by the pores and the like in an existing artificial board,and the prepared novel structural composite material has good mechanical properties and flame retardancy, so that the application of wood in the structural fields of airplanes, high-speed trains, buildings and the like are greatly promoted.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

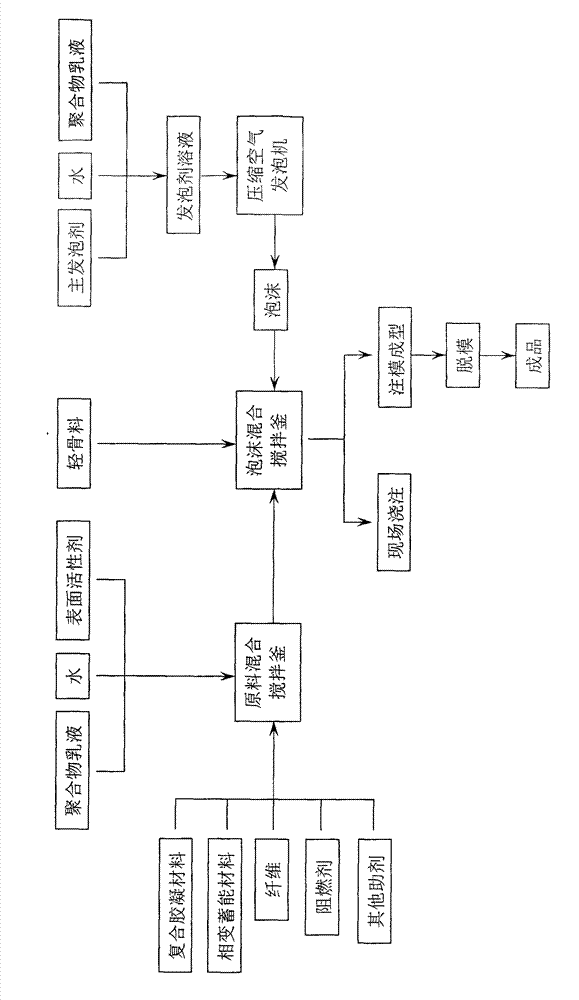

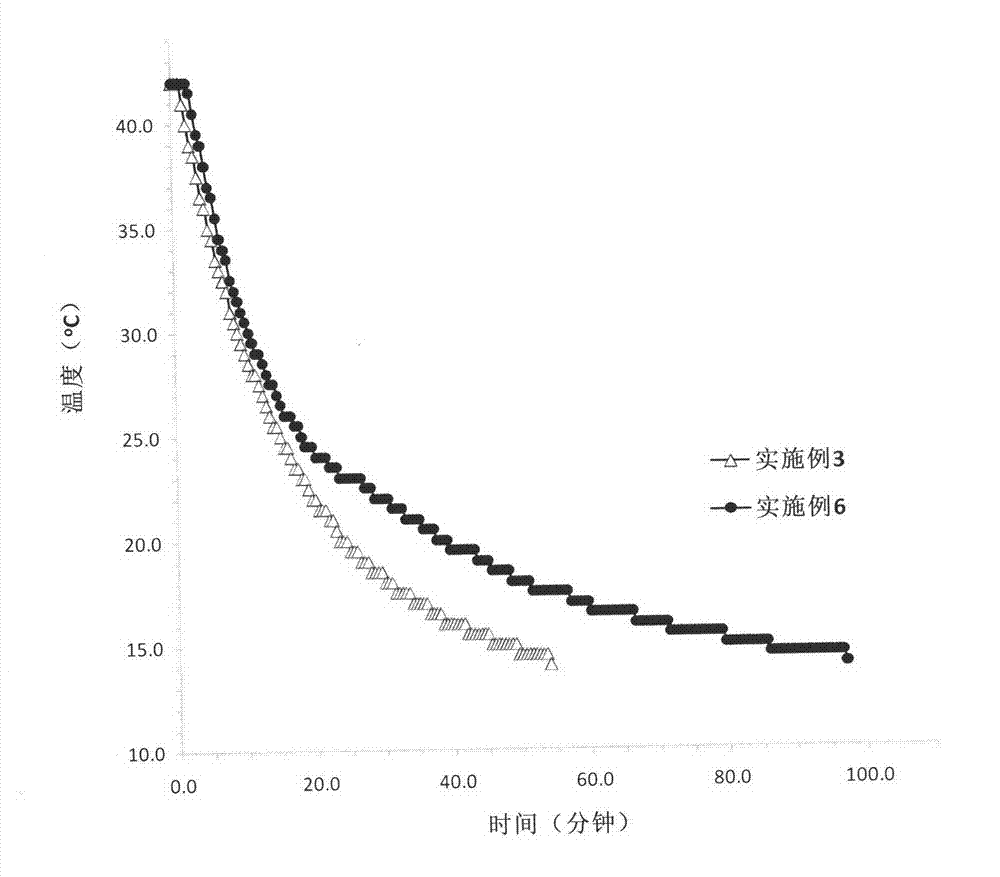

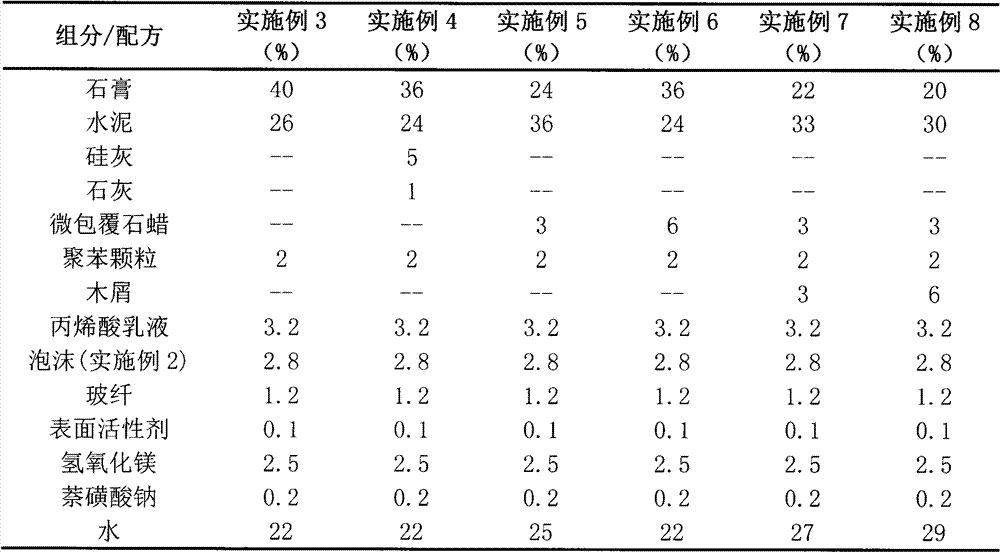

Energy storage energy-efficient foam gypsum cement composite material and preparation method thereof

ActiveCN102765959AImprove fire performancePrevent high temperature penetrationCeramicwareInsulation layerThermal insulation

The invention relates to an energy storage energy-efficient foam gypsum cement composite material and a preparation method thereof. The formula thereof is composed of a composite cementing material, lightweight aggregate, a phase change energy storage material, polymer latex, foam and a foaming agent. The composite cementing material is mainly composed of semi-hydrated gypsum and cement. The preparation method thereof comprises the steps of: preparing a foaming agent solution to prepare stable foam; thoroughly mixing water, polymer emulsion and other liquid state components with the composite cementing material, the phase change energy storage material and other additives such as solid-state components; and sending the solid-liquid mixed slurry to a foam-mixing kettle filled with the lightweight aggregate, while introducing the foam, to prepare the foam gypsum cement composite slurry. The inorganic composite foam material of the present invention has an energy storage function absorbing heat during the day and radiating heat at night, so as to effectively maintain a comfortable indoor temperature, is fire-proof, heat preservative, humidity-adjustable, good in water-resistance, and high in strength, and can be used for manufacturing fireproof insulation layers or fireproof insulation zones for interior and exterior walls of buildings, heat insulation, fire proof and heat preservation wallboards, door panels and core materials, steel structure fireproof cladding materials and the like.

Owner:南京依科国特新材料科技有限公司

Begin-color flame-proof antistatic polyolefin master batch

The invention discloses a natural color, flammable and antistatic polyolefin master batch, pertaining to the field of the preparation technology of master batches for the engineering plastic modification. The master batch comprises matrix resins, nano-silicate, coated red phosphorous agents, antistatic agents, polysiloxane silicone surface surfactants and boride charring agents. The weight percentages of the components are as follows: 5 percent to 20 percent of matrix resins, 3 percent to 5 percent of nano-silicate, 20 percent to 50 percent of coated red phosphorous agents, 10 percent to 20 percent of antistatic agents, 1 percent to 2 percent of polysiloxane silicone surface surfactants, and 10 percent to 15 percent of boride charring agents. The polyolefin is used as the matrix resins, and after a plurality of repeated tests and study the component percentages and technique of the flammable antistatic polyolefin master batch are reasonably determined, therefore the production of the master batch with three efficacies, namely, natural color, flammable and antistatic properties is realized; the problem of single color (black) of the flammable antistatic polyolefin master batch series can be solved and colorful plastic products can be prepared to enrich the environmental senses.

Owner:ZHEJIANG QISELU MASTERBATCH

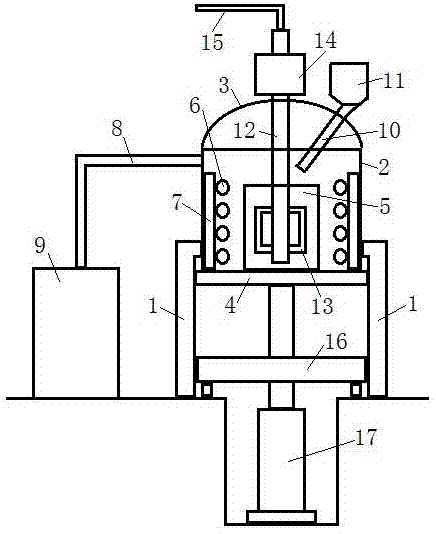

Vacuum induction furnace capable of smelting aluminum and aluminum alloy

PendingCN106871638AEasy to moveFast meltingStirring devicesCharge composition/stateAluminiumVacuum induction furnace

The invention discloses a vacuum induction furnace capable of smelting aluminum and aluminum alloy. The vacuum induction furnace comprises a furnace body erected at the top of a furnace frame, a liftable furnace bottom plate arranged at the bottom end of the furnace body and bearing a graphite crucible, an induction coil arranged in the furnace body, an air suction pipe arranged on the side wall of the furnace body, a charging pipe penetrating through a furnace cover, a stirring shaft penetrating through the furnace cover, a stirring frame arranged at the bottom of the stirring shaft, a through hole formed in the stirring shaft, an argon blowing pipe penetrating through the through hole and extending to the bottom of an inner cavity of the graphite crucible, an argon supply device connected with the argon blowing pipe, a trolley arranged under the furnace body and capable of bearing the furnace bottom plate, and a lifting driving mechanism used for driving the furnace bottom plate to rise and fall vertically. The graphite crucible of the vacuum induction furnace is borne by the liftable furnace bottom plate, thereby entering and going out of the furnace body conveniently. The furnace bottom plate and the graphite crucible can be transported by the trolley, and moving is convenient. The stirring mechanism can conduct stirring during smelting of the aluminum and the aluminum alloy, argon can be led into aluminum liquid during stirring, and a purification effect can be achieved.

Owner:SUZHOU ZHENHU ELECTRIC FURNACE

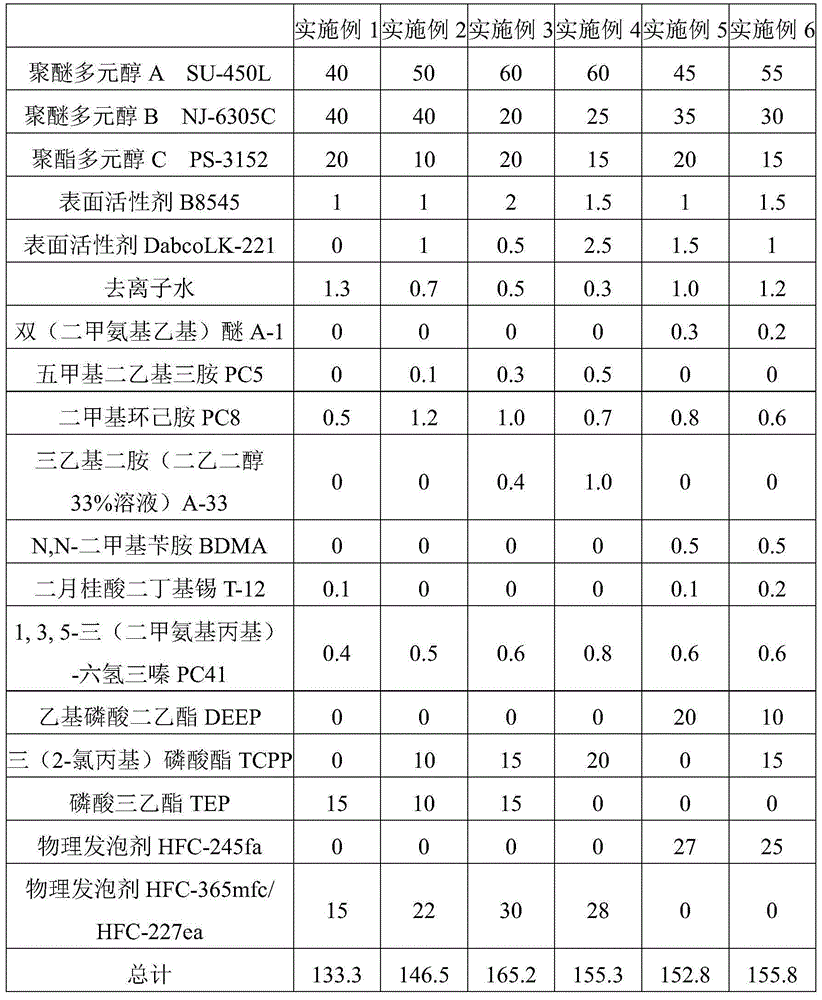

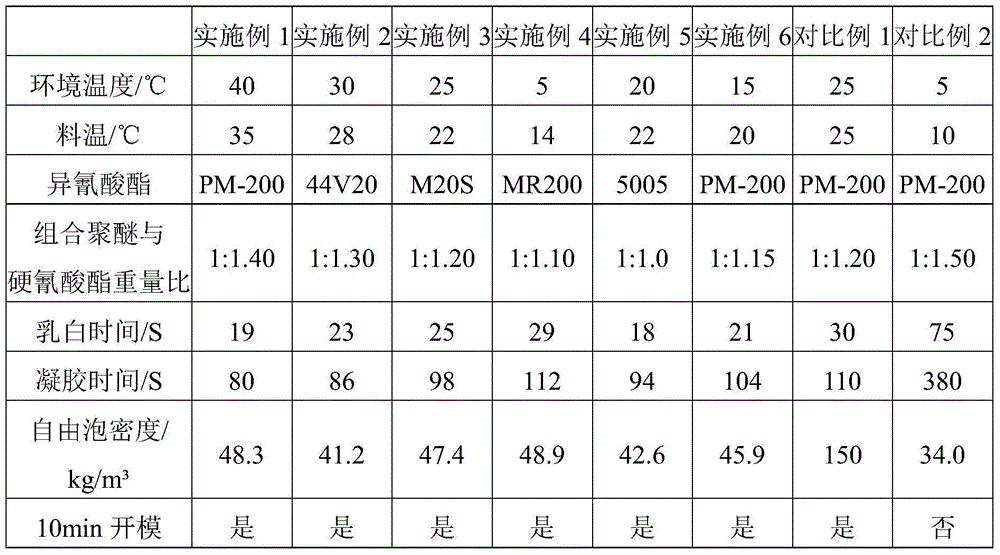

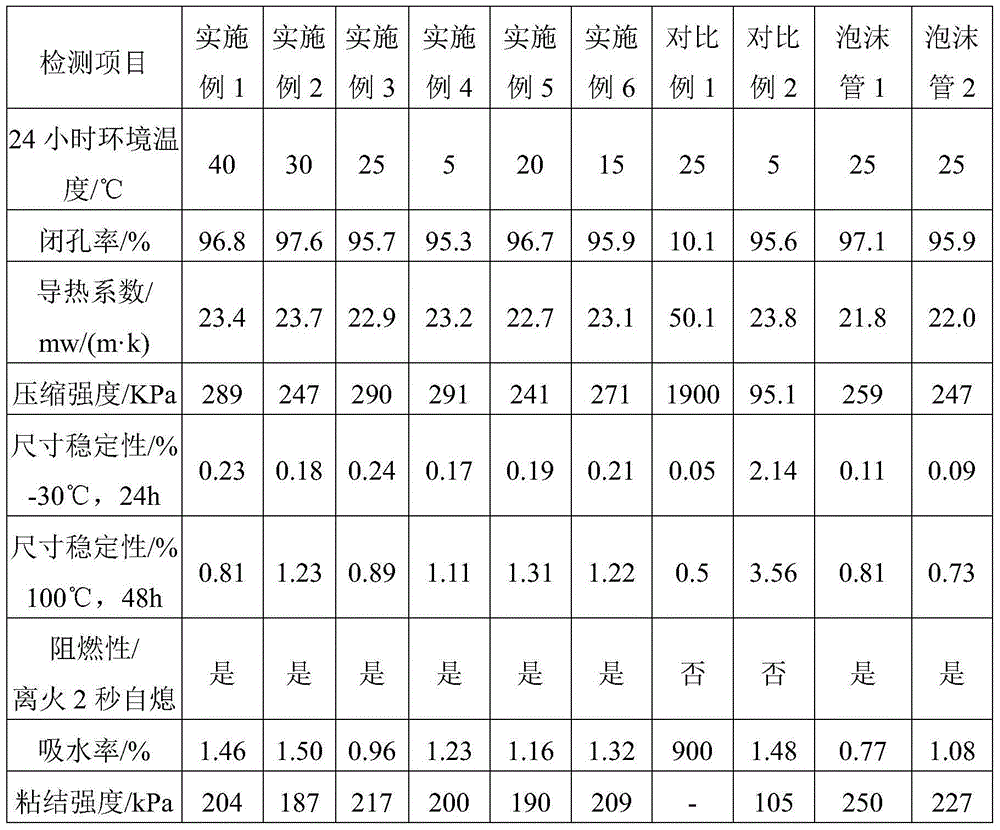

Combined polyether, raw material composition, polyurethane foam as well as preparation method and application thereof

ActiveCN104592471ALow thermal conductivityHigh compressive strengthThermal insulationPipe protection by thermal insulationPolyesterPolyol

The invention discloses combined polyether, a raw material composition, polyurethane foam as well as a preparation method and application thereof. The combined polyether comprises the following components in parts by weight: 100 parts of polyol, 1-4 parts of a surfactant, 0.3-1.3 parts of a chemical foaming agent, 1-3 parts of a catalyst, 15-30 parts of a flame retardant and 15-30 parts of a physical foaming agent, wherein polyol is a mixture of 40-60 parts of polyether polyol A, 20-40 parts of polyester polyol B and 10-20 parts of phthalic anhydride polyol. The foam has the advantages of excellent comprehensive property, low cost, a certain thermal insulation fire-retardant property and is simple in preparation method, safe to operate and wide in application range, high in construction and foam curing speed and short in time from mixing to foam molding curing ( only 10 minutes) and can be used in high-temperature, wind, cold and other 5-40 DEG C terrestrial environments.

Owner:SHANGHAI DONGDA POLYURETHANE

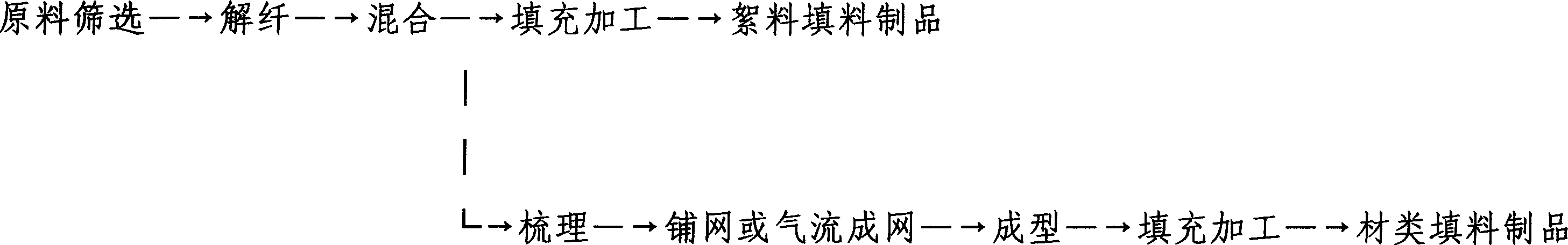

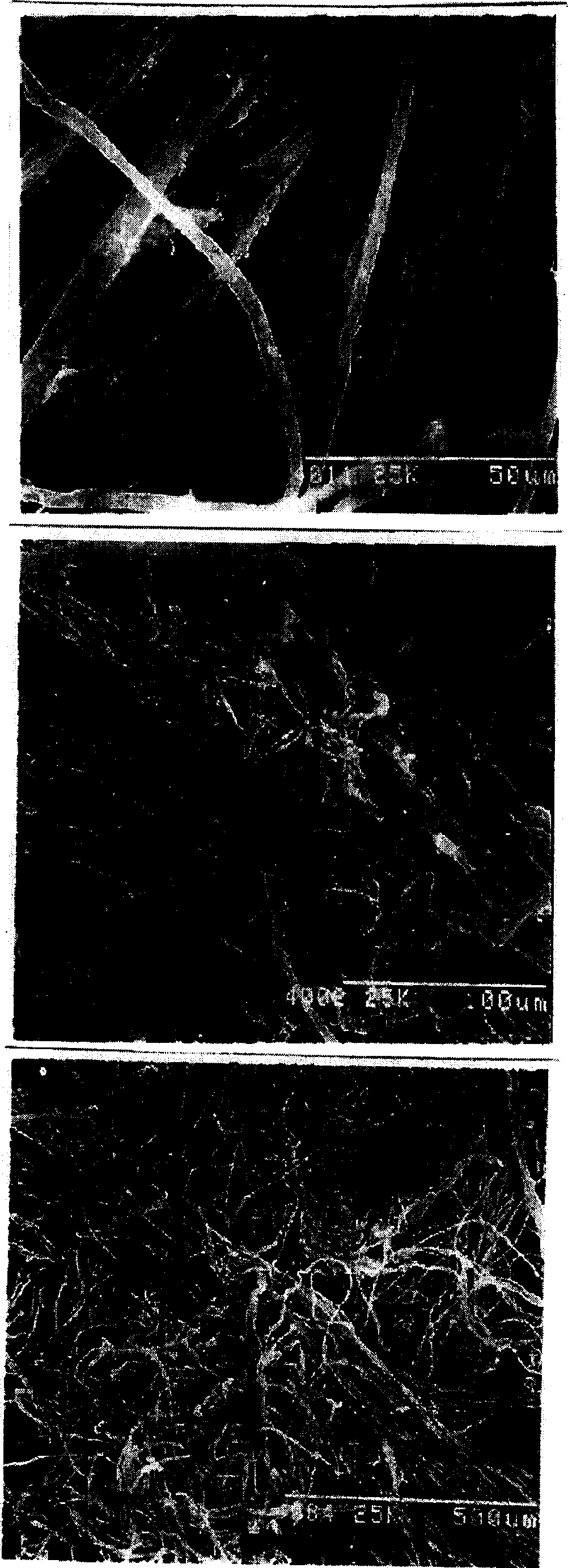

Collagen fiber stuffing product and processing method thereof

ActiveCN1730376AHigh heat retention rateHigh static stabilityMonocomponent protein artificial filamentUpholstery fillingTextile fiberEngineering

The invention provides a collagen fiber stuffing product which comprises 50%-100% collagen fiber in the stuffing and its Process for preparing. The said stuffing is oakum stuffing mixed collagen fiber deliberating from animal hide with at least another textile fiber; or materials stuffing arise from teasing, bedding web and modeling. The stuffing product in the invention is provided with advantages of well puffy, well rebound, well warming, flameproof and sound absorbing which the current stuffing can not get because it uses collagen fiber as main stuffing. The stuffing produced in the process provided in the invention has no peculiar smell, without putrefaction, without mouldy, and can be used in practice. The product is low cost and settles the problem of leftover bits and pieces of industrial material, so it is environment friendly.

Owner:GUANGZHOU WUYUAN NEW MATERIAL CO LTD

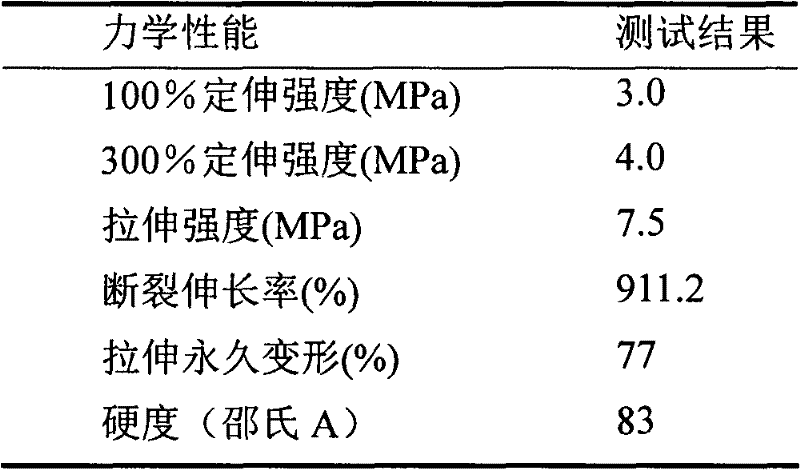

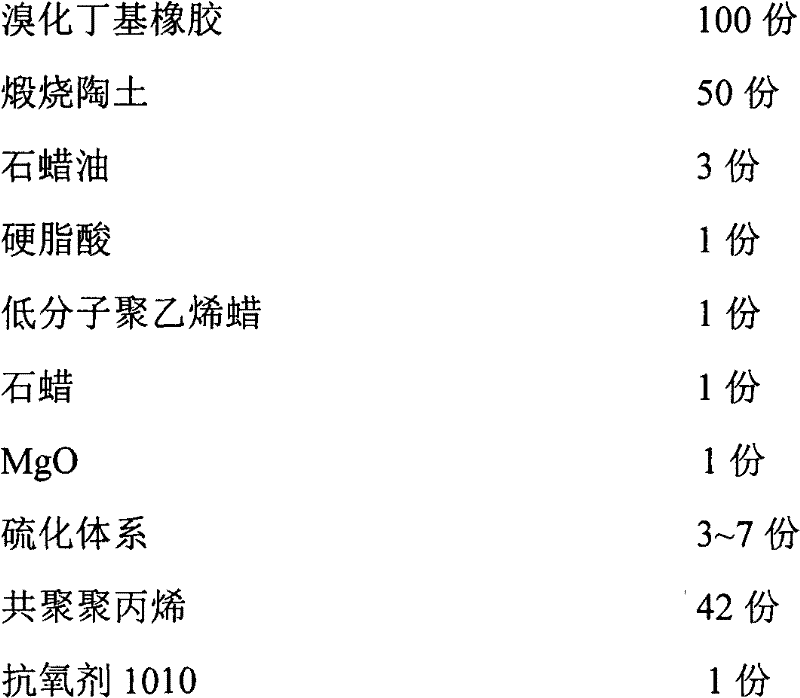

Vulcanizing system of brominated butyl rubber/ polypropylene thermoplastic elastomer sealing material and preparation method for sealing material

InactiveCN102585319APlay a role in vulcanizationHigh elongation at breakOther chemical processesCross-linkPolymer science

The invention provides a vulcanizing system of a brominated butyl rubber / polypropylene thermoplastic elastomer sealing material and a preparation method for the sealing material. The vulcanizing system comprises a vulcanizing agent, a catalyst and an active agent. The vulcanizing agent is a sulfur-free vulcanizing system, is granular and dustless, and is easy to weigh, calculate and disperse and safe in operation. The preparation method is a dynamic vulcanizing blending method, and can comprise injection and extrusion molding; the cross-linked rubber phase is dispersed uniformly in a plastic phase; and the preparation method has the advantages of simple process, a small amount of waste, high production efficiency and the like. The performance of the prepared sealing material meets the requirement of national standard YBB00232004. The vulcanizing system can substitute brominated butyl vulcanized rubber and can be applied in various fields.

Owner:EAST CHINA UNIV OF SCI & TECH

Light diffusion material

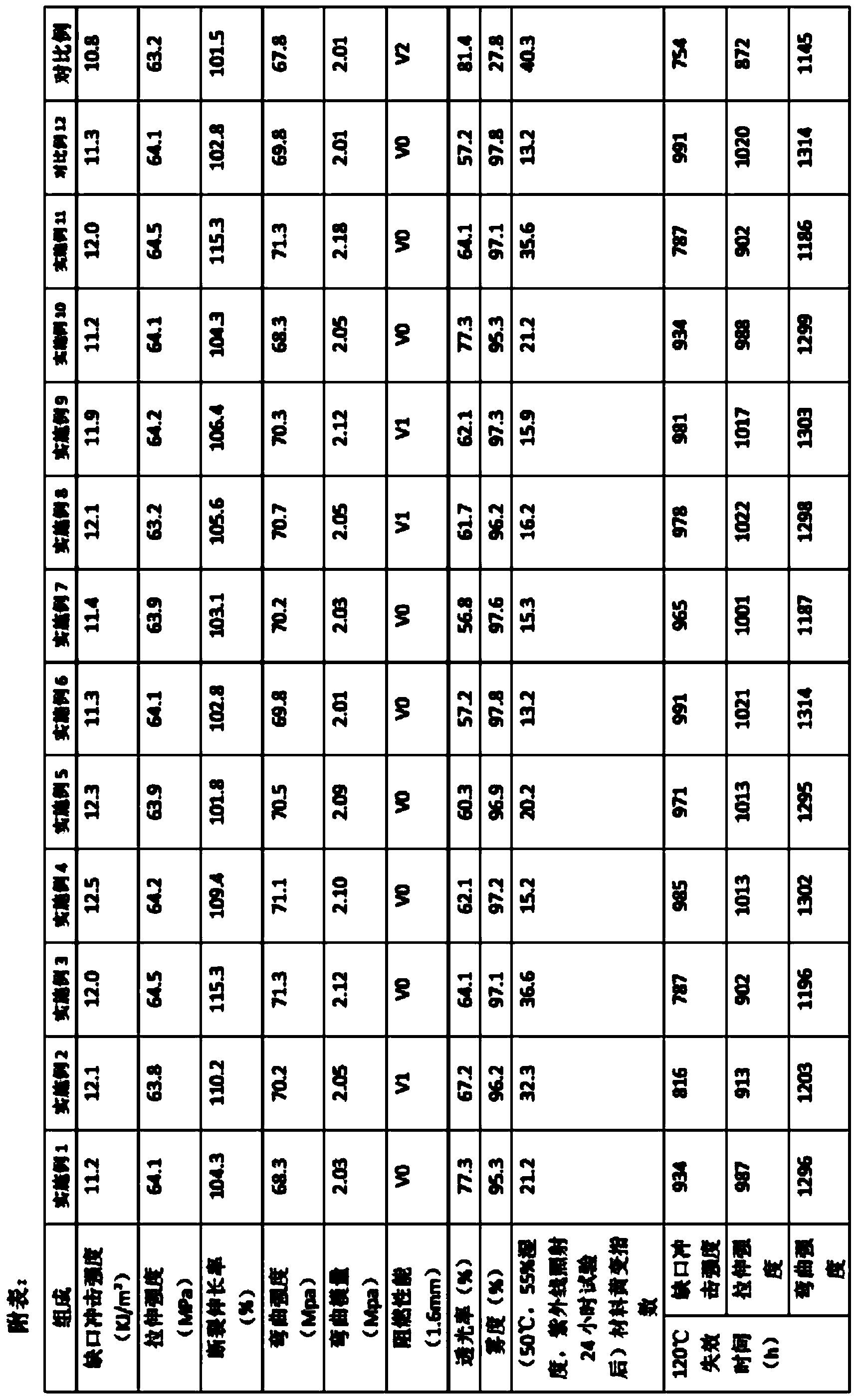

ActiveCN103709713AGood physical and mechanical propertiesGood aging resistanceAntioxidantAging resistance

The invention belongs to the technical field of high molecular materials and particularly relates to a light diffusion technique. A light diffusion material is prepared by the step of with polycarbonate resin as a matrix material, matching a light diffusant, a composite antioxidant, a composite flame retardant and other auxiliary agents by virtue of a melt extrusion process. The light diffusion material at least comprises the following materials in parts by weight: 100 parts of polycarbonate resin, 2-10 parts of the light diffusant, 0.2-6 parts of light stabilizers, 0.3-9 parts of the composite antioxidant and 0.5-10 parts of the composite flame retardant. The light diffusion material has the advantages of good physical and mechanical properties, fire resistance, excellent ageing resistance, high light transmissivity and good light diffusion performance, thermal stability and manufacturability, and the failure time is remarkably prolonged, so that the service life is effectively prolonged; the light diffusion material is suitable for the machining forming of lamp products of lamp tubes and the like and particularly suitable for thin-wall abnormal-shaped lamp tubes of which the wall thickness are less than 3mm.

Owner:余姚中国塑料城塑料研究院有限公司

Heat-resistant halogen-free flame-retardant polylactic acid multi-element composite material and preparation method thereof

The invention discloses a heat-resistant halogen-free flame-retardant polylactic acid multi-element composite material and a preparation method thereof. The composite material is prepared from the following raw materials: modified polylactic resin, aromatic polycarbonate resin, aliphatic polyster resin, a cross-linking agent, a halogen-free flame retardant, white oil, a dispersing agent, an antioxygen, and a processing aid. The preparation method comprises the following steps: a, drying the modified polylactic resin; b, uniformly mixing the dried modified polylactic resin and the white oil; c, uniformly mixing the cross-linking agent and the dispersing agent; d, continuously mixing the halogen-free flame retardant, the antioxygen, the processing aid and the mixed materials in step b and step c; and e, putting the mixed material in step d into a twin-screw extruder, and performing melt extrusion for granulation. The invention provides a composite material having the advantages of heat resistance, flame retardancy and good impact resistance, and a method for preparing the composite material, which has the advantages of simple production process, convenient operation and low cost.

Owner:SHENZHEN KEJU NEW MATERIAL

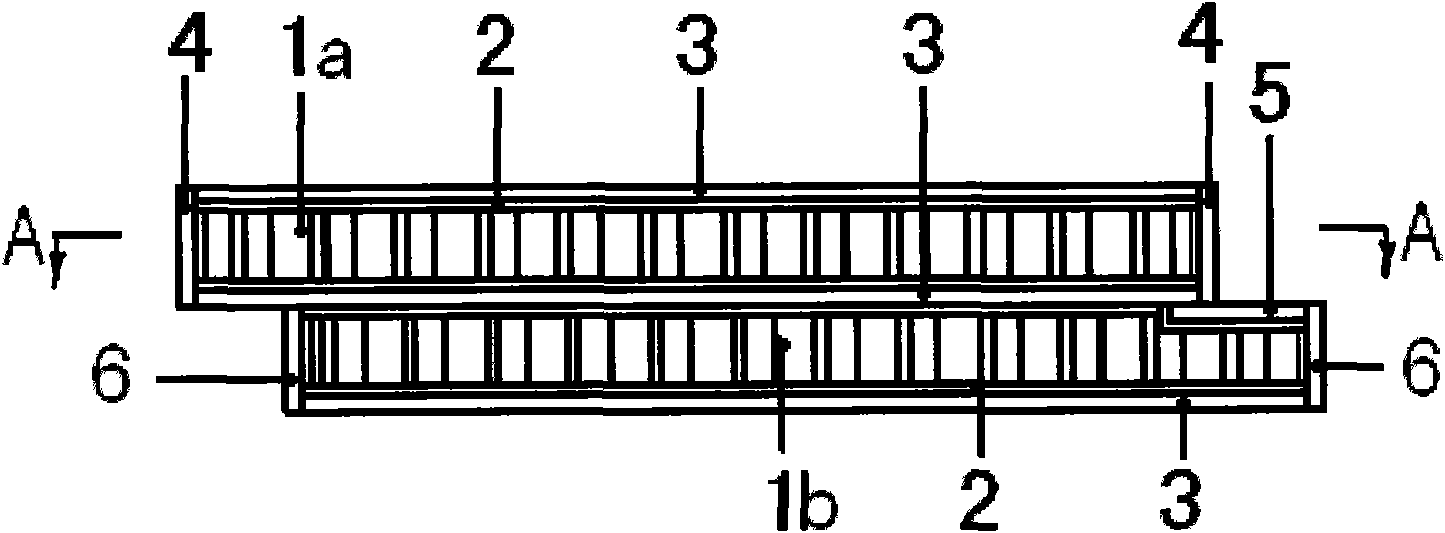

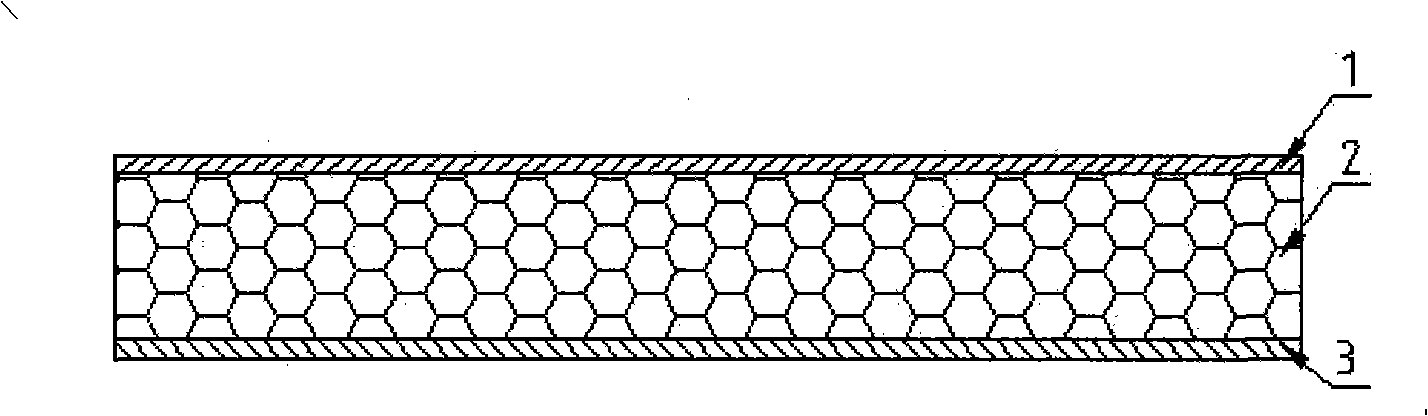

Flexible honeycomb sound-insulating and heat-insulating composite board

InactiveCN101608477AImprove insulation performanceGood flame retardantHeat proofingSound proofingCardboardHoneycomb

The invention relates to a flexible honeycomb sound-insulating and heat-insulating composite board having good performance in heat insulation and heat preservation, water resistance and flame resistance and belonging to the field of functional panels for building and decoration. In the invention, at least two double-layer board sound-insulating structures are formed by using the combination mode that two honeycomb cardboard filling core materials (1a, 1b) are sandwiched between an upper composite panel and a middle composite panel and between the middle composite panel and a lower composite panel respectively, wherein, the upper and the lower honeycomb cardboard filling core materials (1a, 1b) constitute hermetic air cavities between the two boards of the two double-layer board sound-insulating structures. Therefore, the honeycomb sound-insulating and heat-insulating composite board which integrates the characteristics of a single honeycomb cardboard and a single composite panel has the advantages of low density, low per-unit specific gravity, sound insulation, heat insulation, water resistance, flame resistance, high durability and the like.

Owner:耿忠平

Macromolecular flame-retardant elastomer environment-friendly material and preparation method thereof

The invention provides a macromolecular flame-retardant elastomer environment-friendly material and a preparation method thereof. The macromolecular flame-retardant elastomer environment-friendly material consists of thermoplastic styrene elastomer, polypropylene, polyethylene octene co-elastomer, a phosphorus nitrogen series composite flame retardant, a flame-retardant synergist, a compatilizer, white oil, an antioxidant and a coloring agent. The preparation method comprises the following steps of: mixing the raw materials in a ratio, extruding, drawing, granulating, and thus obtaining the material. The material has good physical property, and is suitable for making low-voltage wires such as electronic wires, earphone wires, audio wires, universal serial bus (USB) wires, computer flat cables and signal wires on the premise that good flame-retardant performance is ensured.

Owner:HUIZHOU CITY YIJIA ELECTRIC WIRE & CABLE MATERIALCO

Flame-retardant rubber material capable of protecting high-risk chemicals and method for preparing same

ActiveCN102977478AEffective protectionSolve the problem of large polarity differenceRubber materialDecabromodiphenyl ether

The invention discloses a flame-retardant rubber material capable of protecting high-risk chemicals and a method for preparing the same, belongs to the technical field of rubber and solves the problems of single function and poor quality due to single rubber type, and difficult formation of homogeneous phase while compounding a plurality of types of rubbers of the existing rubber. The flame-retardant rubber material capable of protecting high-risk chemicals is composed of the following components according to parts by weight: 30-80 parts of chlorinated butyl rubber, 30-10 parts of butadiene styrene rubber, 40-10 parts of neoprene, 2.0 parts of sulfur, 0.8-1.2 parts of accelerant TT, 0.8-1.2 parts of accelerant DM, 30 parts of high abrasion proof carbon black, 8-15 parts of decabromodiphenyl ether, 8-20 parts of antimonous oxide, 5-15 parts of chlorcosane, 5.0 parts of zinc oxide, 2.5 parts of stearic acid and 2.0 parts of antiager D. The flame retardant rubber material effectively overcomes the shortcomings of single function and poor quality of single rubber type; the product is capable of effectively protecting high-risk chemicals and highly corrosive materials, and thus can be widely applied to effectively protecting the feet, the head and the skin.

Owner:SHANXI XINHUA CHEM +1

Method for manufacturing plant fibre composite wall plate

InactiveCN101168263ALarge amount of resourcesExcellent flame retardantFlat articlesDomestic articlesPlant fibrePolystyrene

Provided is a process for preparing a plant fiber composite wall plate, belonging to wall material field. The invention resolves the shortages that the raw material of the existing architectural wall material is large in consumption, the manufacture cost is high and the distribution of the raw material is non-uniform. The process steps of the invention are that crop straw is cleaned and cut into pieces and is ground by a fiber re-chipper, and then is dried after dust and big lump material are screened. The prepared raw material is sent into a glue blend machine and is added with adhesive agent of 10-16%. After being uniformly stirred, the raw material and the added adhesive agent are taken out, added with fire retarding agent and paved, and then are cut in standard size after being pre-pressed, hot-press-molded and cooled. The plate in standard size is combined with polystyrene plates via different layers and thicknesses, the surfaces thereof are stuck with melamine fireproof plates, and then the plant fiber composite wall plate is formed via the combination. The product obtained by the process has the advantages of low density, light weight, perfect insulation, simple technology, large raw material source, low manufacture cost, waste utilization and environment protection. The invention can be used to produce building separating walls, framed wood structural buildings, mobile movable dwellings, and buildings in tourist spots and the like.

Owner:NORTHEAST FORESTRY UNIVERSITY

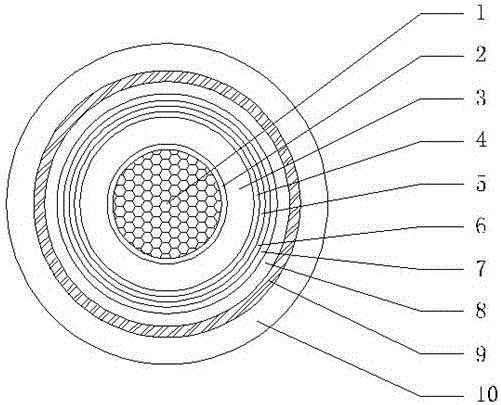

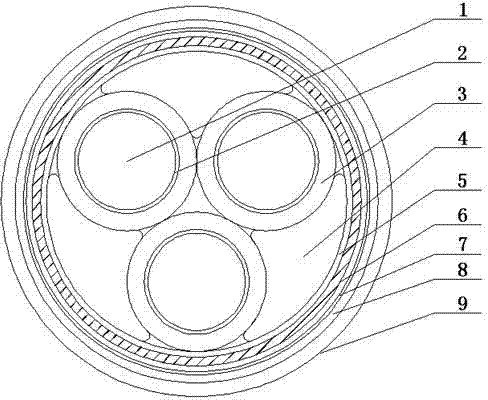

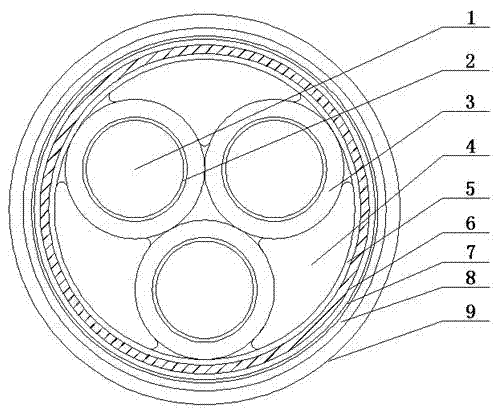

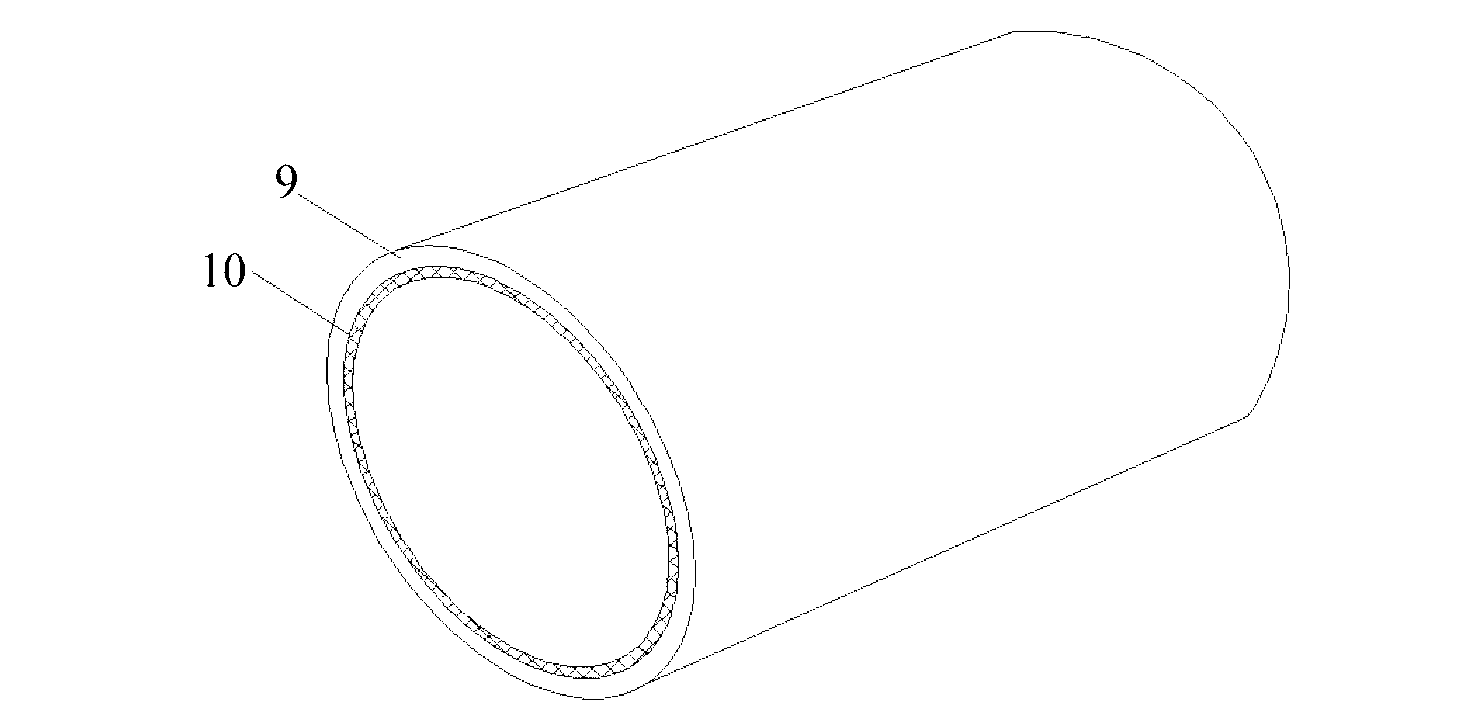

Graphene composite shielding anti-interference power cable for environment-friendly intelligent high-speed rail and fabrication method of graphene composite shielding anti-interference power cable

InactiveCN106098173AAccelerated corrosionImprove tensile propertiesPower cables with screens/conductive layersFlexible cablesCopper conductorInsulation layer

The invention discloses an environment-friendly intelligent high-speed rail graphene composite shielding anti-interference power cable and a preparation method thereof. The insulation layer and the insulation shielding layer form an insulated wire core; the outer layer of the insulating wire core is overlapped and wrapped with a metal inner shielding layer; The aluminum-plastic composite tape layer wrapped longitudinally is extruded with a polyethylene moisture barrier layer; the outer gap of the moisture barrier layer is wrapped with a double-layer tantalum steel alloy tape armor layer, and the outermost layer of the cable is extruded with an outer sheath. The invention has good insulation properties, mechanical properties, power transmission, anti-magnetic interference, lightning protection, flame retardant, halogen-free, low-smoke environmental protection, waterproof, corrosion resistance, radiation resistance and other properties; the structure is reasonable, the comprehensive performance is superior, and the product The performance index is superior to the requirements of international standards; and can produce good social and economic benefits.

Owner:WUXI CITY HENG HUI CABLE

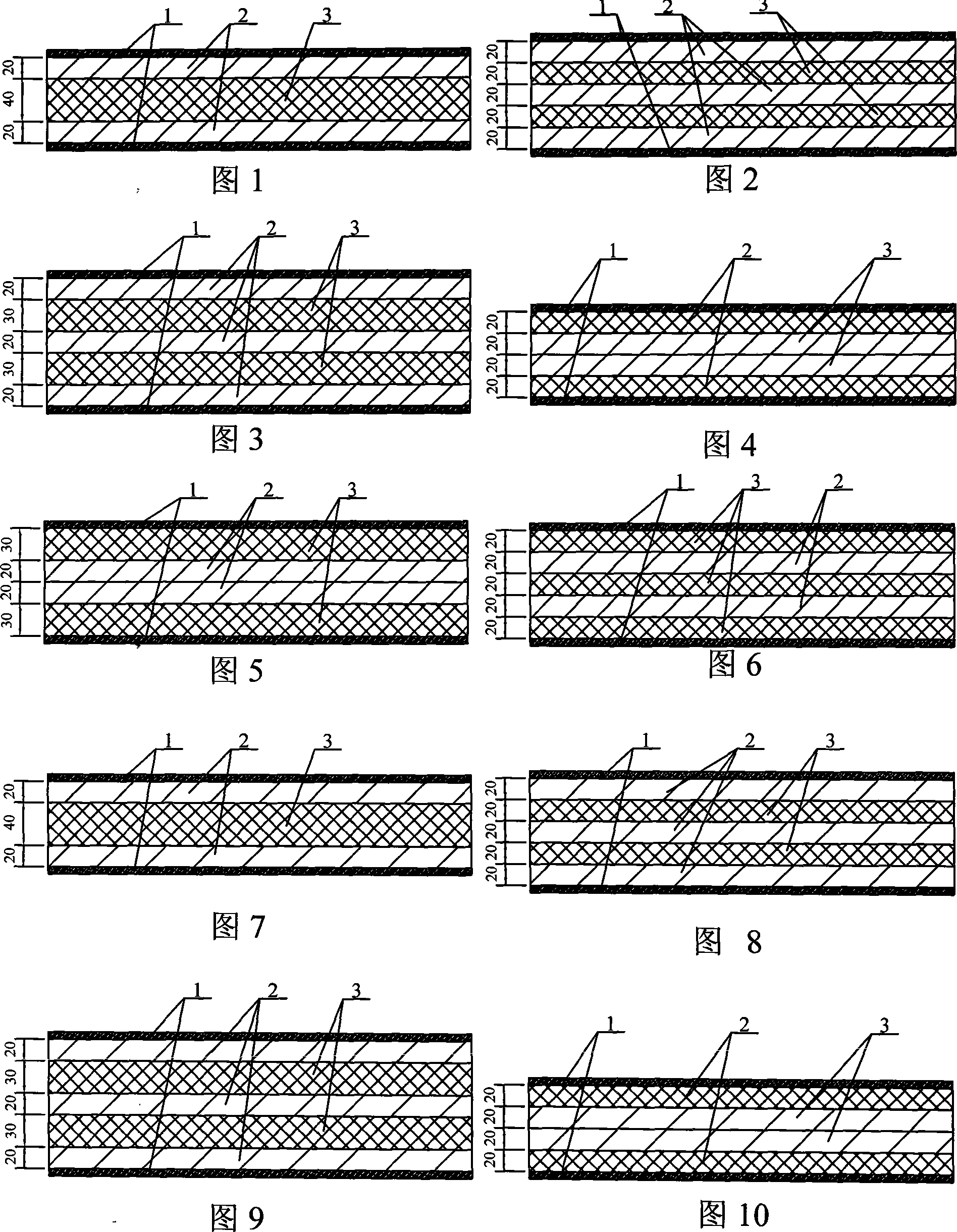

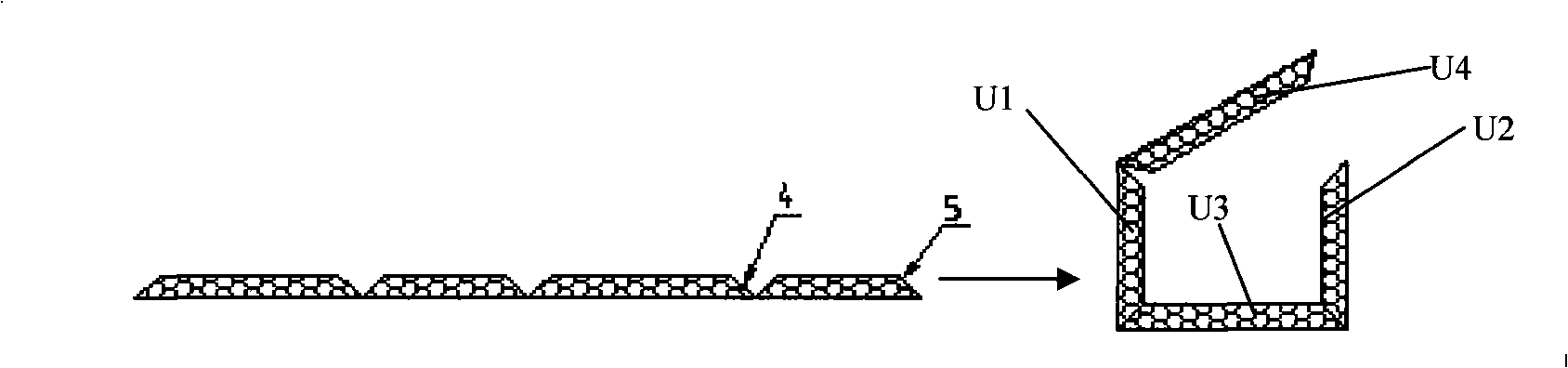

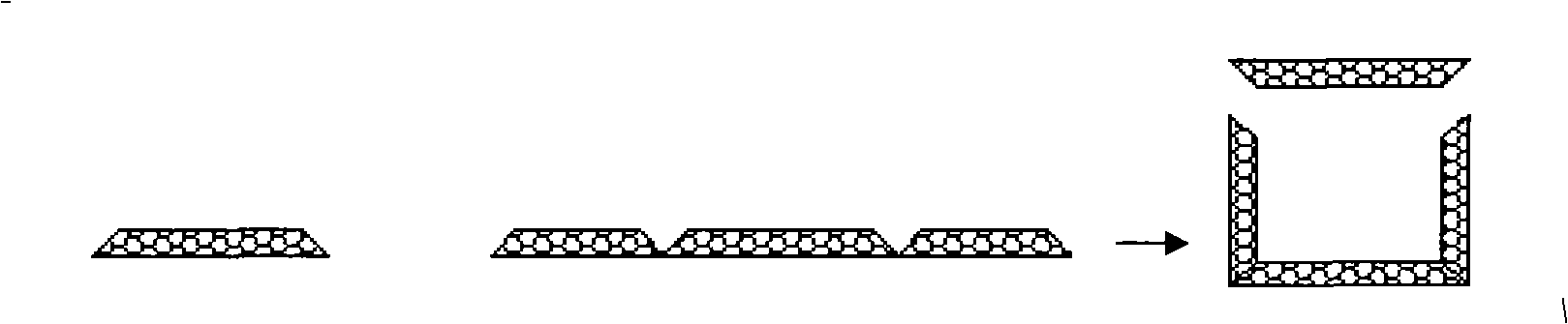

Steel surface type composite air duct and manufacturing method thereof

InactiveCN101329008AOperableNo noiseThermal insulationSpace heating and ventilation detailsSurface layerEngineering

The invention relates to a steel face type composite wind pipe and a manufacturing method thereof, which relates to a wind pipe, in particular to a steel face type composite wind pipe used for building ventilation and an air-conditioning system, and the manufacturing method thereof. The invention provides the steel face type composite wind pipe and the manufacturing method thereof that combine the advantages of the traditional galvanized iron sheet wind pipe and the composite wind pipe, not only have an anti-collision external surface layer, but also have an internal heat insulating layer with good heat preservation effect. The composite wind pipe is provided with a steel face type surface layer, an intermediate foam heat insulating layer and an internal protecting layer which are all bonded by glue. The manufacturing method comprises the following steps: first, a steel face type composite wind pipe plate is prepared, treated with pipe section division and cutting according to the requirements of the size specification, then bonded for molding after pipe section division and cutting, and connected, sealed and blocked.

Owner:厦门高特高新材料有限公司

Cable and production process thereof

ActiveCN105968698AImprove performanceExcellent flame retardantFlexible cablesCable/conductor manufactureElectrical conductorWaterstop

The invention relates to the technical field of cable processing, and particularly provides a cable which comprises multiple insulating wire core groups. A wrapping strap is arranged on the periphery of the insulating wire core groups, a flame-retardant layer, a shielding layer, a lining and an outer jacket are sequentially are outside the wrapping strap, each insulating wire core group is formed by winding multiple insulating wire cores, each insulating wire core is composed of a conductor, an insulating layer and a waterstop strap, each insulating layer and the corresponding waterstop strap wrap the outside of the corresponding conductor in an extruded manner, and fillers are arranged in gaps among the insulating wire cores. The cable is good in comprehensive performance, resistant to flame, wear, water, high temperature, oil and tension and high in flexibility. A production process provided is simple to manufacture and convenient to operate, production efficiency is improved for enterprises, and production cost is lowered.

Owner:ANHUI AICS SCI & TECH GROUP

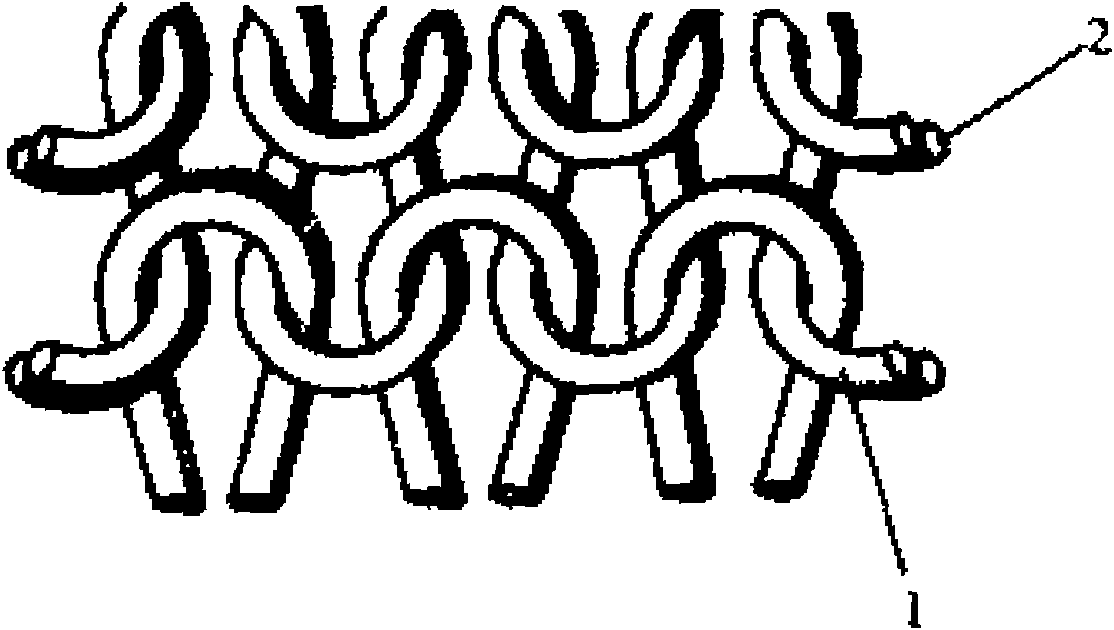

Aramid 1414 fiber/spandex coated wire and multifunctional protective socks using same

InactiveCN101597823AExcellent flame retardantImprove cut resistanceWeft knittingWarp knittingYarnCombing

The invention discloses an aramid 1414 fiber / spandex coated wire and multifunctional protective socks using same. The aramid 1414 fiber / spandex coated wire comprises coated wire and yarn which take plating stitch structures, the coated wire uses spandex wire as core wire and aramid 1414 fiber as outer coated wire, and the yarn uses combed cotton yarn or aramid 1313 / flame retardant viscose blended yarn. In the invention, the coated wire using spandex wire as the core wire and aramid 1414 fiber as the outer coated wire is adopted, and is used to weave socks with combed cotton yarn or aramid 1313 / flame retardant viscose blended yarn by plating stitches, therefore, the aramid 1414 fiber / spandex coated wire has the good performances of anti-cutting, fire retarding, wear resistance, health care, comfortable wear, and the like, and can be widely applied to special industrial workers such as loggers, mining machine operators, firefighters, armed polices, soldiers and the like.

Owner:ZHEJIANG QINGYI SOCKS IND

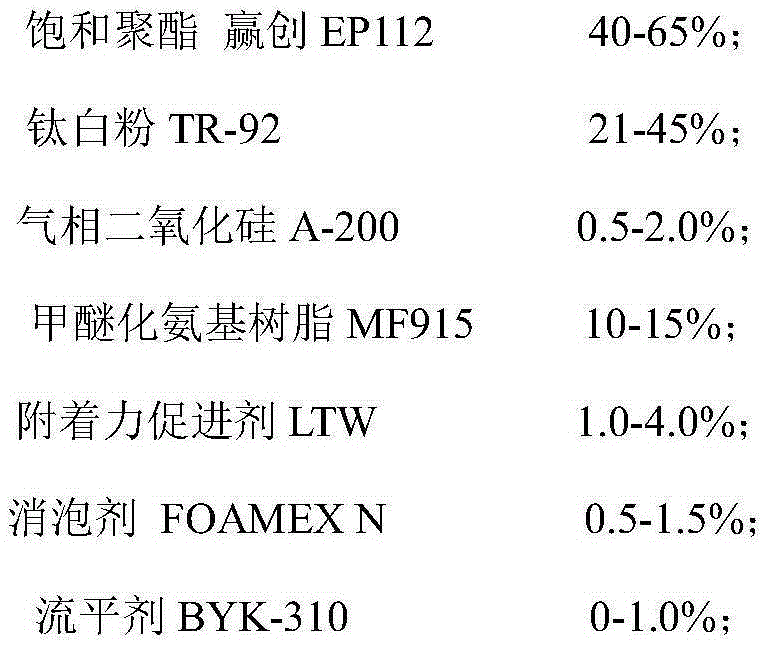

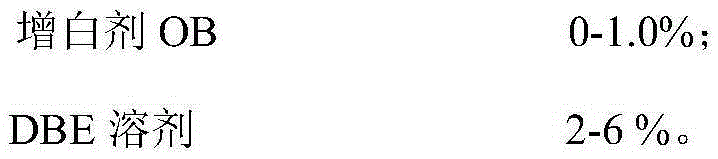

Thermosetting type glass screen printing ink and preparation method thereof

The invention discloses thermosetting type glass screen printing ink. The thermosetting type glass screen printing ink includes, by weight, 40%-65% of Evonik EP112 saturated polyester, 21%-45% of titanium dioxide TR-92, 0.5%-2.0% of fumed silica A-200, 10%-15% of methylated amino resin MF915, 1.0%-4.0% of adhesion promoters LTW, 0.5%-1.5% of antifoaming agents FOAMEXN, 0-1.0% of flatting agents BYK-310, 0-1.0% of brightening agents OB and 2%-6% of DBE solutions. A preparation method of the thermosetting type glass screen printing ink includes the steps that the saturated polyester, the titanium dioxide and the fumed silica are firstly stirred evenly, then the methylated amino resin, the adhesion promoters, the antifoaming agents, and / or the flatting agents, and / or the brightening agents are added into the mixture, and the DBE solutions are added finally. The thermosetting type glass screen printing ink has good adhesion, water resistance, acid and alkali resistance, cold and hot impact resistance, butanone dissolution resistance, fast yellowing resistance, high temperature yellowing resistance, flexibility, constructability and ultraviolet resistance.

Owner:WUHU CHUNFENG NEW MATERIAL

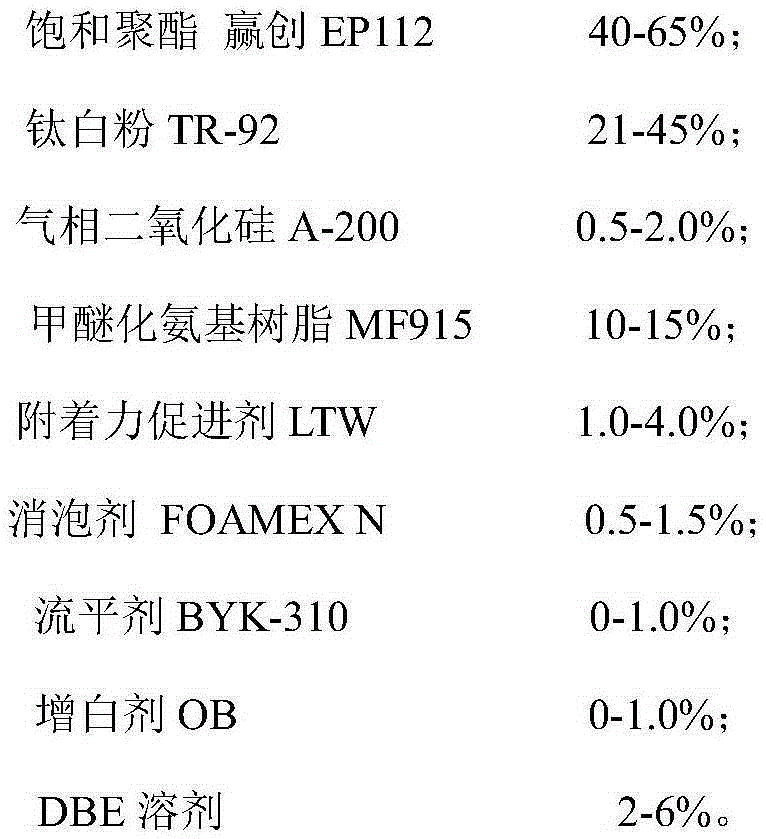

Multifunctional super-hydrophobic textile finishing agent, and preparation method and applications thereof

ActiveCN107326651AReduce usageSimple manufacturing processStain/soil resistant fibresBiochemical fibre treatmentHydrolysisSkin protection

The invention discloses a multifunctional super-hydrophobic textile finishing agent, and a preparation method and applications thereof. The preparation method comprises following steps: a precursor of an oxide sol and a graphite oxide aqueous dispersion are dispersed in deionized water, an anionic surfactant is added, a catalyst is added for hydrolysis and condensation reaction after uniform dispersion so as to obtain a mixed reaction system, and the mixed reaction system is heated to 30 to 50 DEG C for 3 to 12h of reaction so as to obtain a hydrosol; a functional agent is added into the hydrosol so as to obtain the multifunctional super-hydrophobic textile finishing agent. The multifunctional super-hydrophobic textile finishing agent is safe, is friendly to the environment, is excellent in effect, is used for super hydrophobic and multifunctional finishing of textile, is capable of providing textile with six functions including super-hydrophobic property, flame resistance, antibacterial property, stain resistance, ultraviolet resistance, and skin protection performance, is capable of eliminating adverse effect of the plurality of functions, improving the synergistic effect; the preparation method is simple and convenient, is easy to control, and is suitable for large scale production.

Owner:石狮市杰立纺织科技有限公司

Flexible solar power generation cell

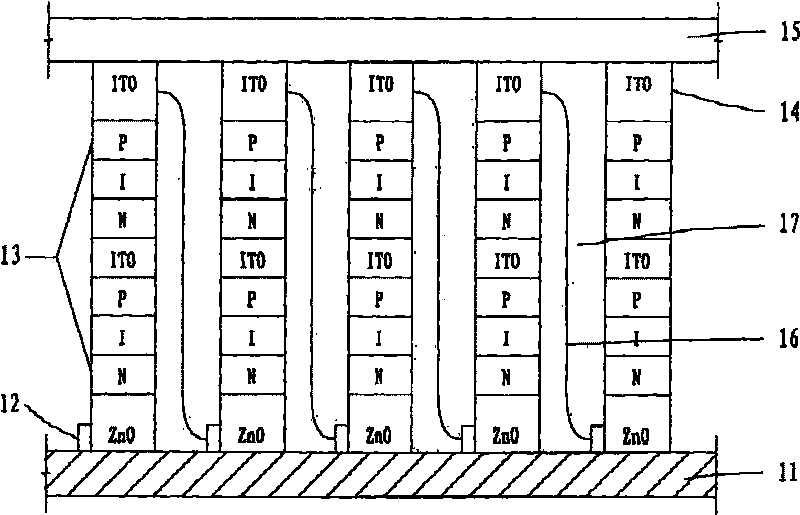

InactiveCN101699634ALight in massEasy to paste and installPhotovoltaicsPhotovoltaic energy generationTectorial membraneGas phase

The invention relates to a flexible solar power generation cell which consists of a plurality of thin film cell units, a flexible substrate, a connecting circuit, a positive electrode and a negative electrode of the cell and a transparent protective film. The thin film cell units are grown on the flexible substrate by the methods of magnetron sputtering and chemical vapor deposition, produced by laser scribing and arranged like an array, the thin film cell units are connected in parallel and connected on the positive electrode and the negative electrode of the cell, and the transparent protective film is bonded on the surface of the solar power generation cell by heating. The thin film cell units consist of a plurality of thin film cell subunits, the structure of each subunit consists of the flexible substrate, a lower electrode, a solar power generation electrode, an upper electrode and the transparent protective film sequentially, and the upper electrodes and the lower electrodes of the adjacent subunits are series-connected by a printed circuit for constituting the thin film cell units. Gaps between the solar cell units and the thin film cell subunits are filled by protective insulating paint. The flexible solar power generation cell is significantly characterized by light weight, ability of winding and convenient carry and installation, and the structure with the combined series connection and the parallel connection can not only ensure a certain output voltage, but also not affect the overall situation when one part is damaged and prolong the service life of the cell.

Owner:SUZHOU ZHONGZE OPTOELECTRONICS TECH

Low-carbon environment-friendly cellular light composite wallboard

InactiveCN102155054AGood sound and heat insulation performance and pressure bearing capacityIncreased load carrying capacity and durabilityCovering/liningsHeat proofingCarbon dioxideEngineering

The invention discloses a low-carbon environment-friendly cellular light composite wallboard, comprising cellular paperboard inner core material, a waterproof heat-resisting adhesive layer, environment-friendly panels and a reinforced edge banding connecting and fastening strip. A cellular paperboard with a stable hexagon structure is used as the inner core material and has good sound insulation, heat-shielding performance and loading capacity. The waterproof heat-resisting adhesive layer firmly adheres an upper environment-friendly panel, a middle environment-friendly panel and a lower environment-friendly panel of the cellular paperboard inner core material together so as to form two double-board sound insulation structures, and the double-board sound insulation structures are also reliable heat insulation structures. The environment-friendly panels have the functions of sound insulation, heat insulation, antiflaming and appearance keeping and protecting and can improve the bearing capacity and durability of the cellular light composite wallboard. The reinforced edge banding connecting and fastening strip can exert sealing, moistureproof and supporting protective effects on the four sides of a single composite wallboard and also can exert connection function in wall surface combination and assembly during the installation of the composite wallboards. The prepared cellular light composite wallboard has low density and light weight and has the advantages of good sound insulating, heat insulating, waterproof, antiflamming performances and good durability. By applying the environment-friendly cellular light composite wallboard, the running time of a heating and ventilating equipment system can be reduced, thus consumption of energy source and discharge of carbon dioxide gas can be reduced, and a low-carbon environment-friendly pleasant environment is created.

Owner:YUNNAN JUHE CONSTR GROUP

Electrostatic flocking fabric made of alginate fiber and preparation method of electrostatic flocking fabric

ActiveCN103407215AGive full play to quality advantagesGive full play to the unique and excellent quality advantages of seaweed fiberLiquid surface applicatorsCellulosic plastic layered productsEpoxyPolymer science

The invention discloses electrostatic flocking fabric made of alginate fiber. The electrostatic flocking fabric comprises a flock layer, an adhesive layer and a base cloth layer, and is characterized in that the flock layer is the alginate fiber; the base cloth layer is aramid plain woven cloth; the middle adhesive layer is an organic silicon modified epoxy resin adhesive. The invention also discloses a preparation method of the electrostatic flocking fabric made of the alginate fiber. The preparation method is characterized by comprising the following steps of cutting alginate fiber strands into alginate fiber flock, and performing electric conduction and coloring treatment; pre-coating and mainly coating adhesives on flocking base cloth, wherein the total thickness of the adhesives is 0.2 to 0.25mm; performing flocking in an electrostatic flocking room to obtain flocked cloth; and performing baking to firmly composite the flock with the base cloth so as to obtain the electrostatic flocking fabric. The electrostatic flocking fabric has good flame resistance and is applicable to army combat uniforms, warship and submarine combat uniforms, bedding equipment, airman training combat uniforms, second artillery training combat uniforms and the like.

Owner:山东领潮新材料有限公司

Industrial protection non-woven material and manufacturing method thereof

ActiveCN103526454AImprove breathabilityExcellent flame retardantFlame-proof filament manufactureNon-woven fabricsPolyesterEngineering

The invention discloses an industrial protection non-woven material and a manufacturing method of the industrial protection non-woven material. The industrial protection non-woven material comprises a PP spunbond non-woven fabric layer, an ES-mixed non-woven fabric layer and a PP melt-blown non-woven fabric layer sandwiched between the PP spunbond non-woven fabric layer and the ES-mixed non-woven fabric layer. Fire retardant mixtures of a first component are added to the PP spunbond non-woven fabric layer, and fire retardants of second components of different types are added to the PP melt-blown non-woven fabric layer. Mixed fibers of ES fibers, polyester fibers and viscose fibers are combed into a net to form the ES-mixed non-woven fabric layer. The industrial protection non-woven material has the moisture percentage similar to the moisture percentage of a human body, good gas permeability and soft and fluffy hand feelings, is comfortable to wear, has high tension stress and morphological stability in all directions, protects the structure of the melt-blown non-woven fabric layer and has the good inflaming retarding characteristic and the environment protection effect, and a guarantee is provided for the protection performance of the industrial protection non-woven material.

Owner:东营俊富净化科技有限公司

Heat-resistant shielded power cable for nuclear power stations

ActiveCN102332336ASmall expansion coefficientHigh dielectric strengthNon-insulated conductorsPower cables with screens/conductive layersAluminiumNuclear power plant

A heat-resistant shielded power cable for nuclear power stations comprises a combined cable core, three power cable cores are stranded to form the combined cable core, filler is arranged on the combined cable core, the periphery of the filler is sequentially wrapped by an isolating layer, a composite shielding layer, a flame-retardant tape, an oxygen barrier and an outer sheath, the filler is a low-smoke halogen-free flame-retardant polyolefin material, a polyester film is lapped to form the isolating layer, tinned copper wires are woven and lapped to form the inner layer of the composite shielding layer, an aluminium-plastic composite tape is overlapped to form the outer layer of the composite shielding layer, a glass fiber tape is lapped to form the flame-retardant tape, irradiation cross-linked low-smoke halogen-free flame-retardant polyethylene is extruded to form the wrapping oxygen barrier, and the outer sheath is made of ceramic fire-resistant silicon rubber; the three power cable cores respectively consist of a cable core conductor, an liner layer and an insulating layer which are arranged sequentially from the inside to the outside, wherein a synthetic mica tape is lappedto form the liner layer, and heat-resistant silicon rubber is extruded to form the insulating layer, and is then vulcanized. The heat-resistant shielded power cable has excellent heat resistance, shielding property and electric insulativity.

Owner:ZHONGGUAN CABLE CO LTD

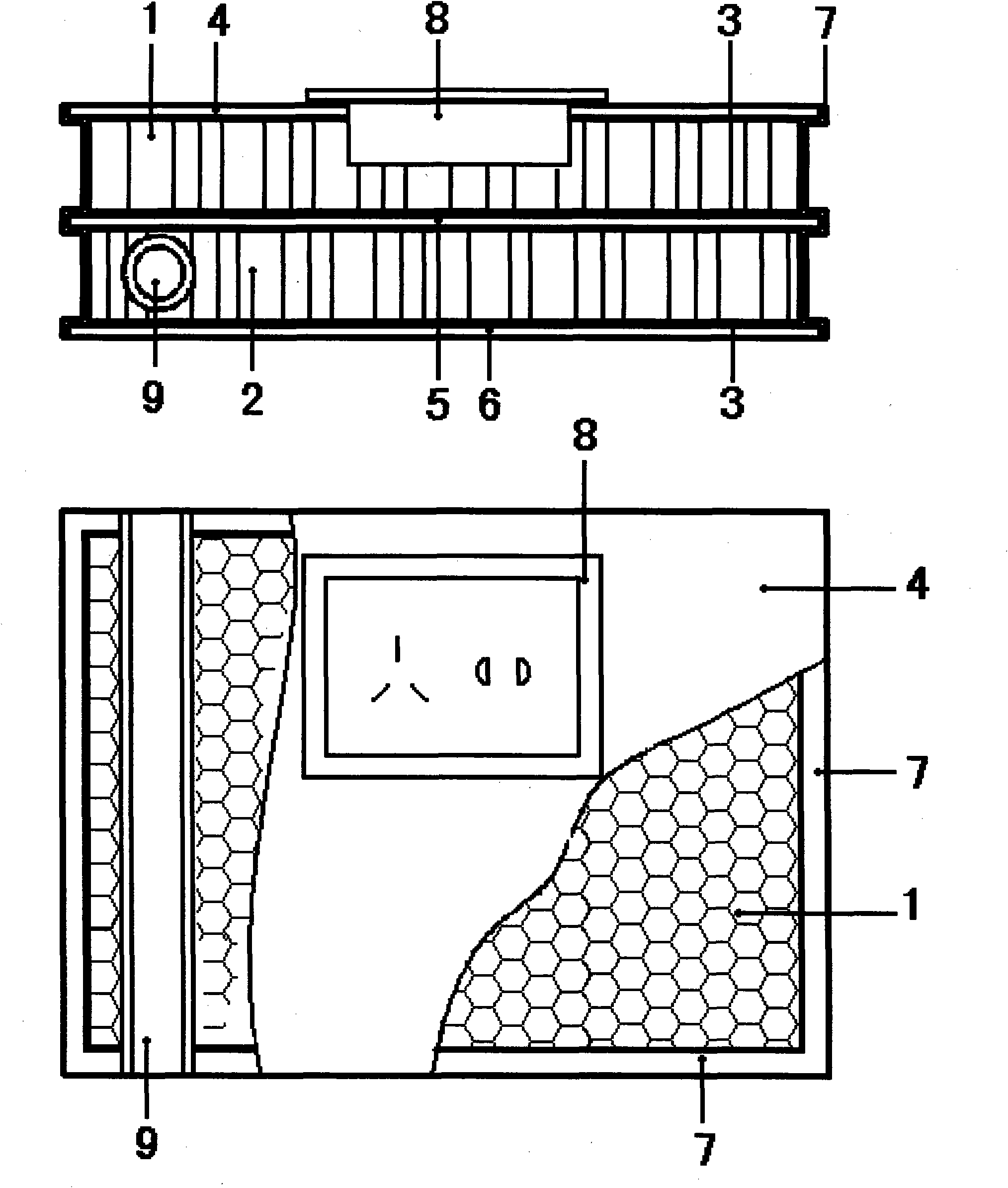

Membrane humidifier for fuel cells

The invention discloses a membrane humidifier for fuel cells, which comprises a cylindrical shell, humidification tubes, a first baffle and a second baffle plate, wherein each humidification tube adopts a two-layer structure; the outer layer of the humidification tube is an aramid paper tube; the inner layer of the humidification tube is a stainless-steel screen stencil; and the two ends of the humidification tube are respectively fixed on the first baffle and the second baffle plate and are sealed in the cylindrical shell, so as to form a tube side and a shell side. The invention further discloses a fuel cell device comprising the membrane humidifier. According to the membrane humidifier for fuel cells, two different gases are conveyed to the tube side and the shell side, and humidity exchange and temperature exchange are carried out through the tube walls of the humidification tubes, so that inlet air of the fuel cells can be humidified and heated effectively and the performance of the fuel cells can be played better; and the membrane humidifier is simple in preparation technology, excellent in performance, lower in cost and long in service life.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com