Vacuum induction furnace capable of smelting aluminum and aluminum alloy

A vacuum induction furnace and alloy technology, which is applied to furnaces, charge materials, crucible furnaces, etc., can solve the problems of wasted man-hours, troublesome feeding and reclaiming of vacuum induction furnaces, and large engineering volume, and can solve the problems of low magnetic permeability and improve melting Efficiency, small element burnout effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

[0054] The technical scheme of concrete implementation of the present invention is:

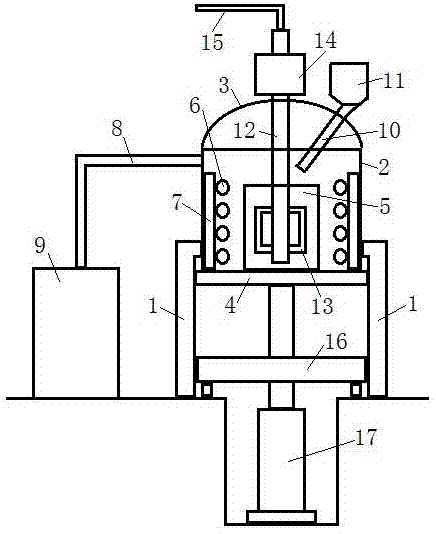

[0055] like figure 1 As shown, a vacuum induction furnace capable of smelting aluminum and its alloys includes:

[0056] Vertical hob 1,

[0057] a vertical cylindrical furnace body 2 erected on the top of the furnace frame 1,

[0058] The furnace cover 3 located at the top of the furnace body 2,

[0059] A horizontal liftable furnace bottom plate 4 arranged at the bottom end of the furnace body 2,

[0060] Place the graphite crucible 5 on the top surface of the furnace floor 4,

[0061] An induction coil 6 arranged in the body of furnace 2 and used for i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com