Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

662results about How to "Improve melting efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

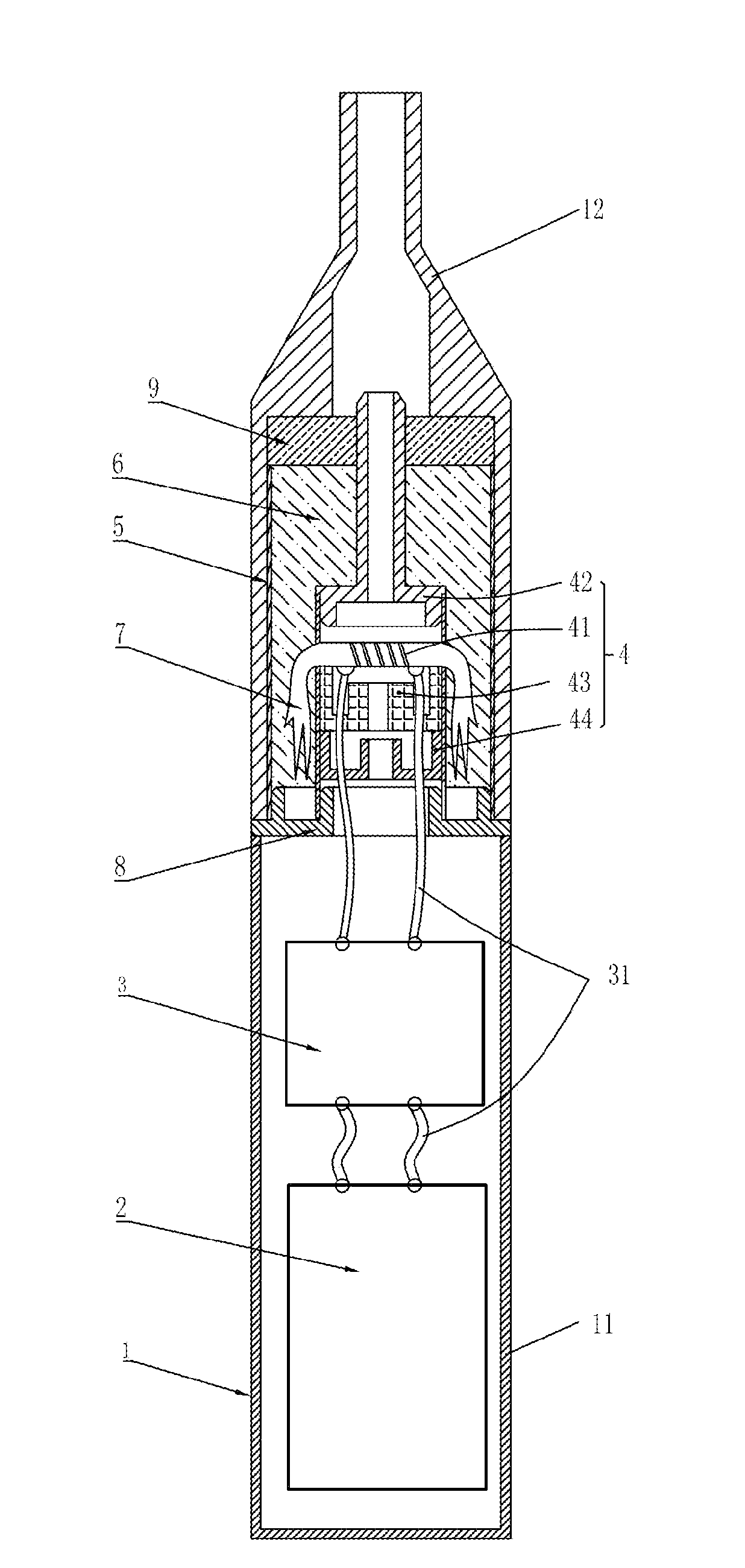

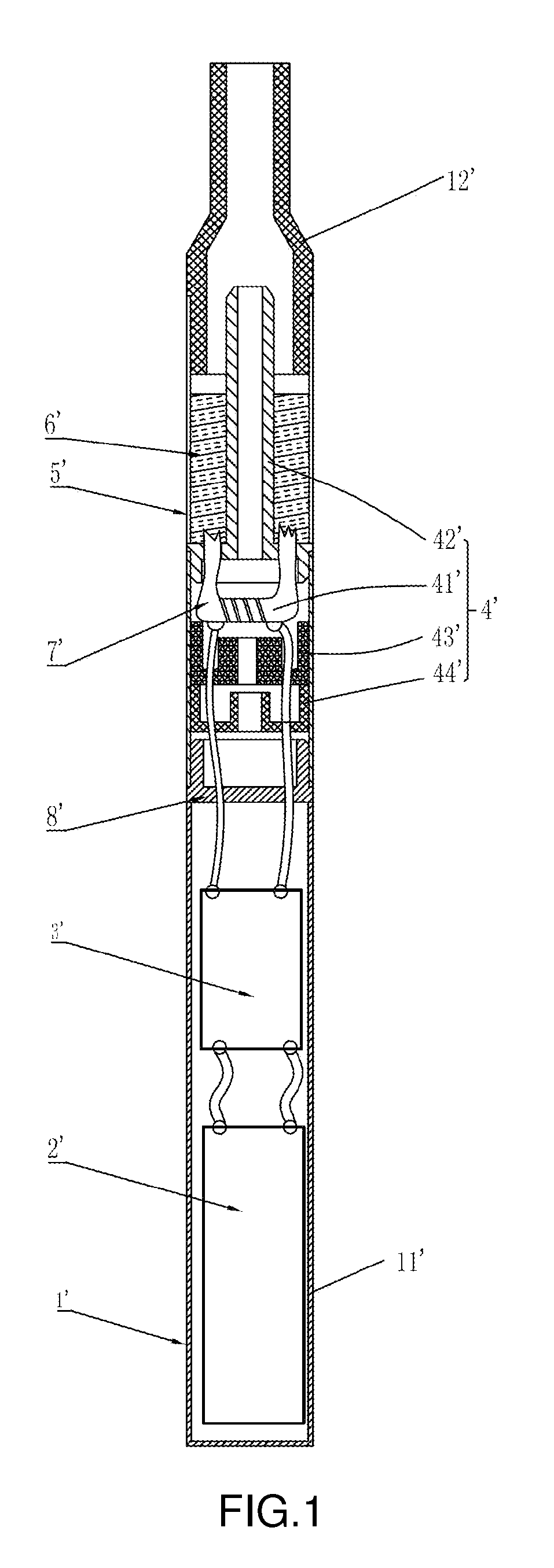

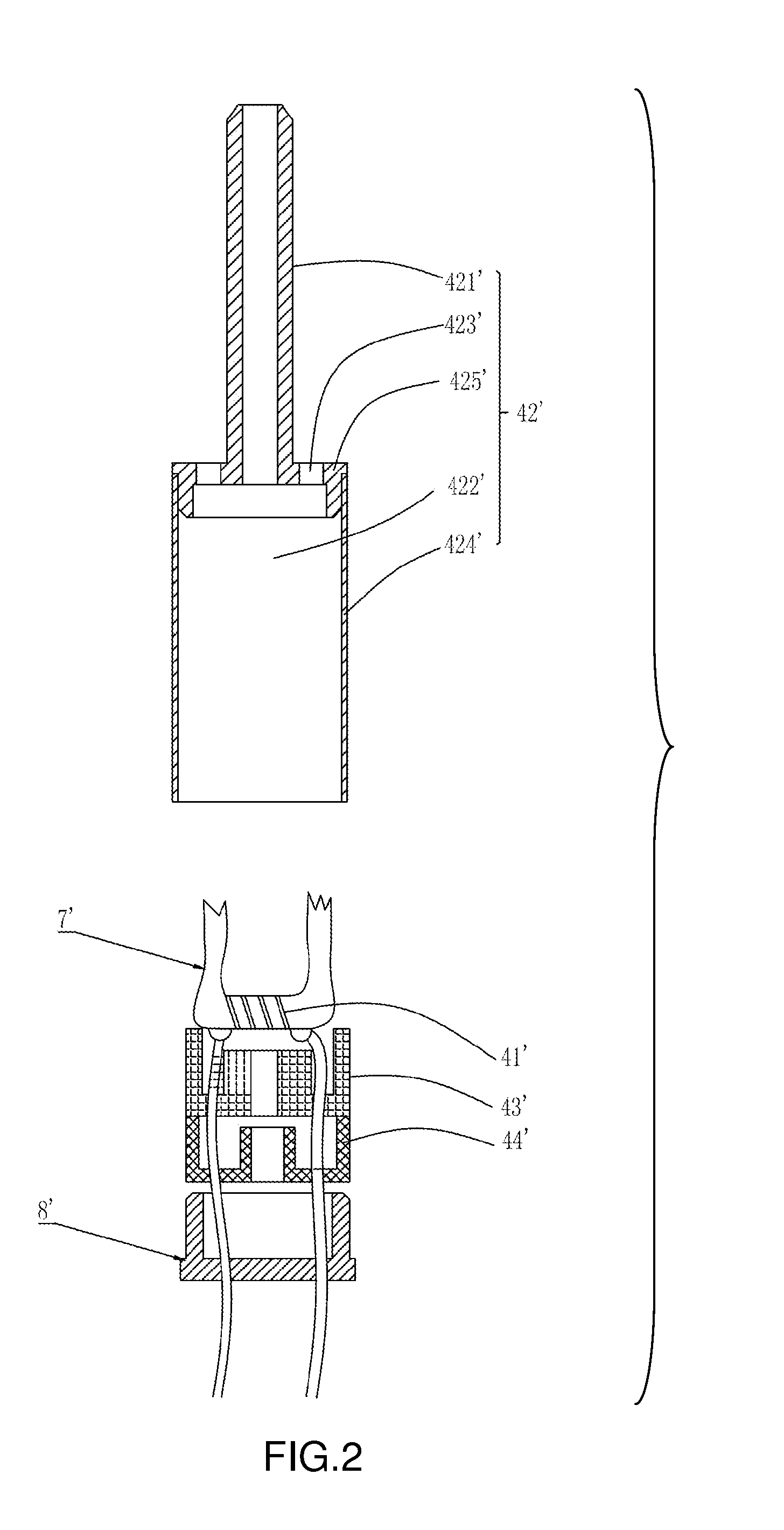

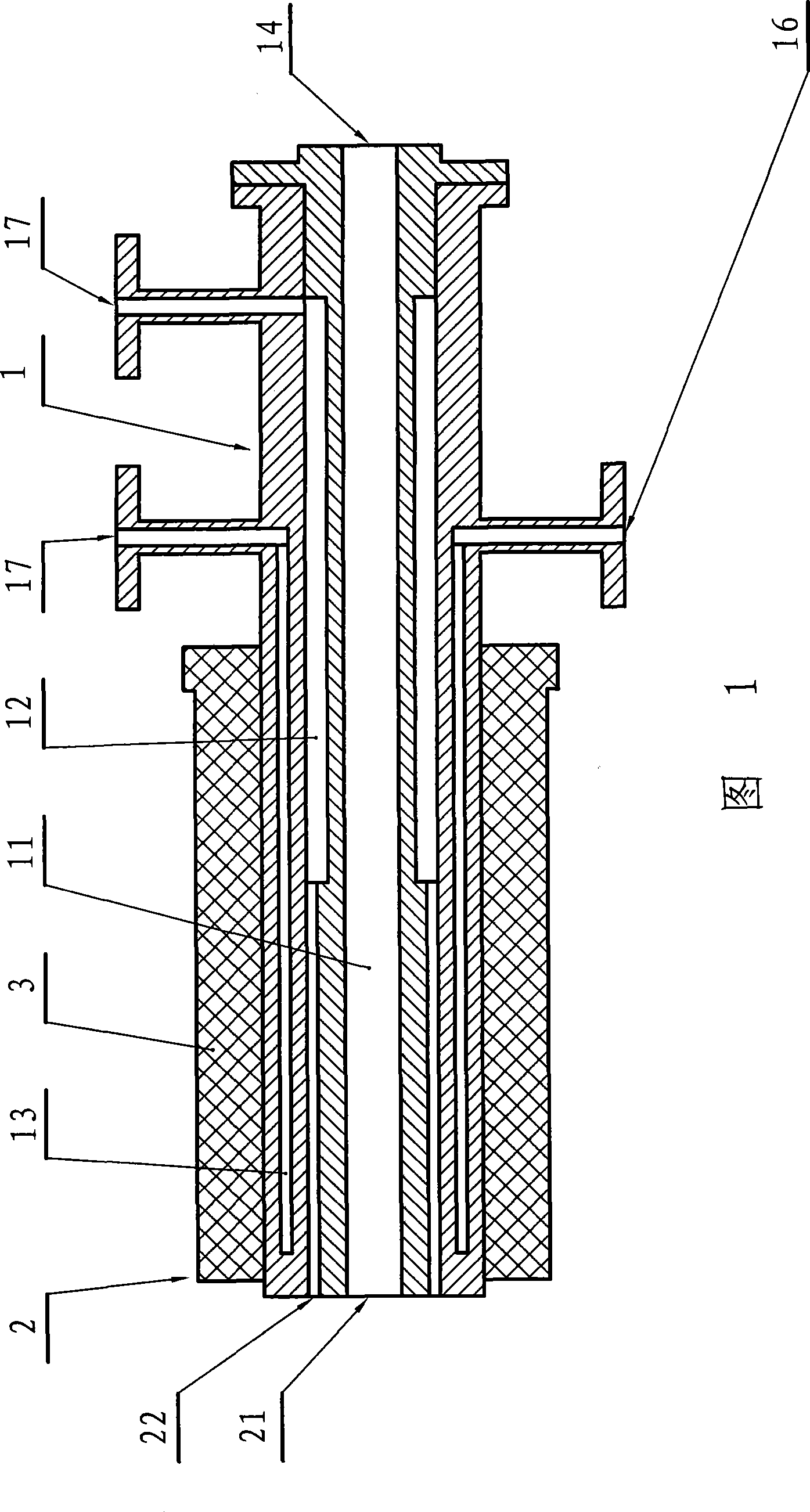

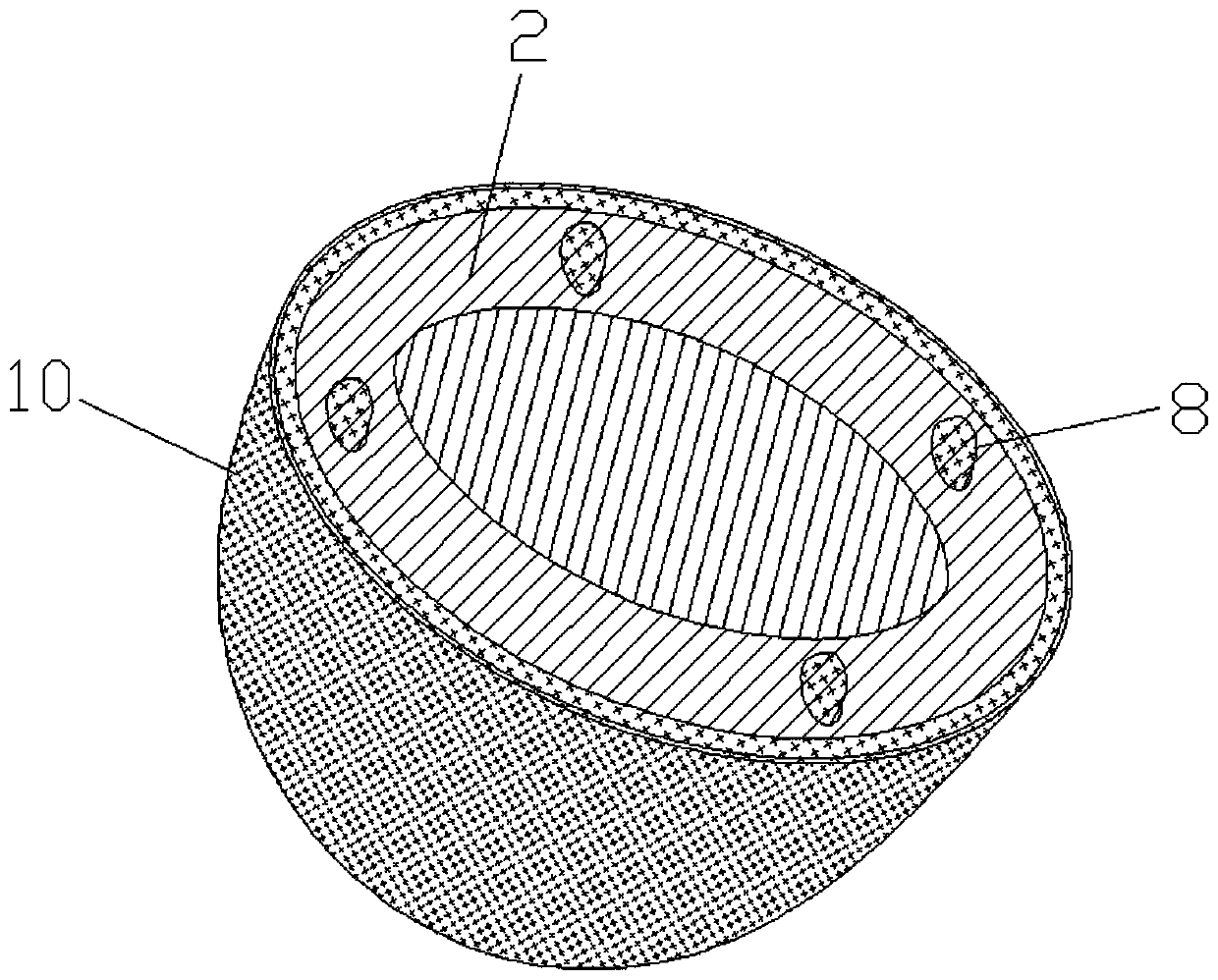

Electronic cigarette with solid tobacco substance

InactiveUS20130167853A1Reduce the amount of solutionImprove melting efficiencyTobacco pipesTobacco devicesEngineeringElectronic cigarette

The present invention relates to an electronic cigarette with solid tobacco substance, which includes a shell with a mouthpiece at one end; a reservoir in the shell for storing tobacco substance; an atomizing device in the shell having an atomizing cup, an atomizer in the atomizing cup for vaporizing tobacco substance; and an aerosol passage connecting the mouthpiece with the atomizing cup; and a guiding unit for drawing tobacco substance from the reservoir to the atomizing device. The atomizing cup is accommodated in the reservoir, the guiding unit penetrates sidewall of the atomizing cup and extends in the reservoir, and solid tobacco substance encases the atomizing cup and guiding unit therein. The present invention solves the problem of solid tobacco substance melting slowly and uneasy assembly of the cigarette; and obtains to improve the melting efficiency of solid tobacco substance and facilitate the assembly.

Owner:KIMREE HI TECH

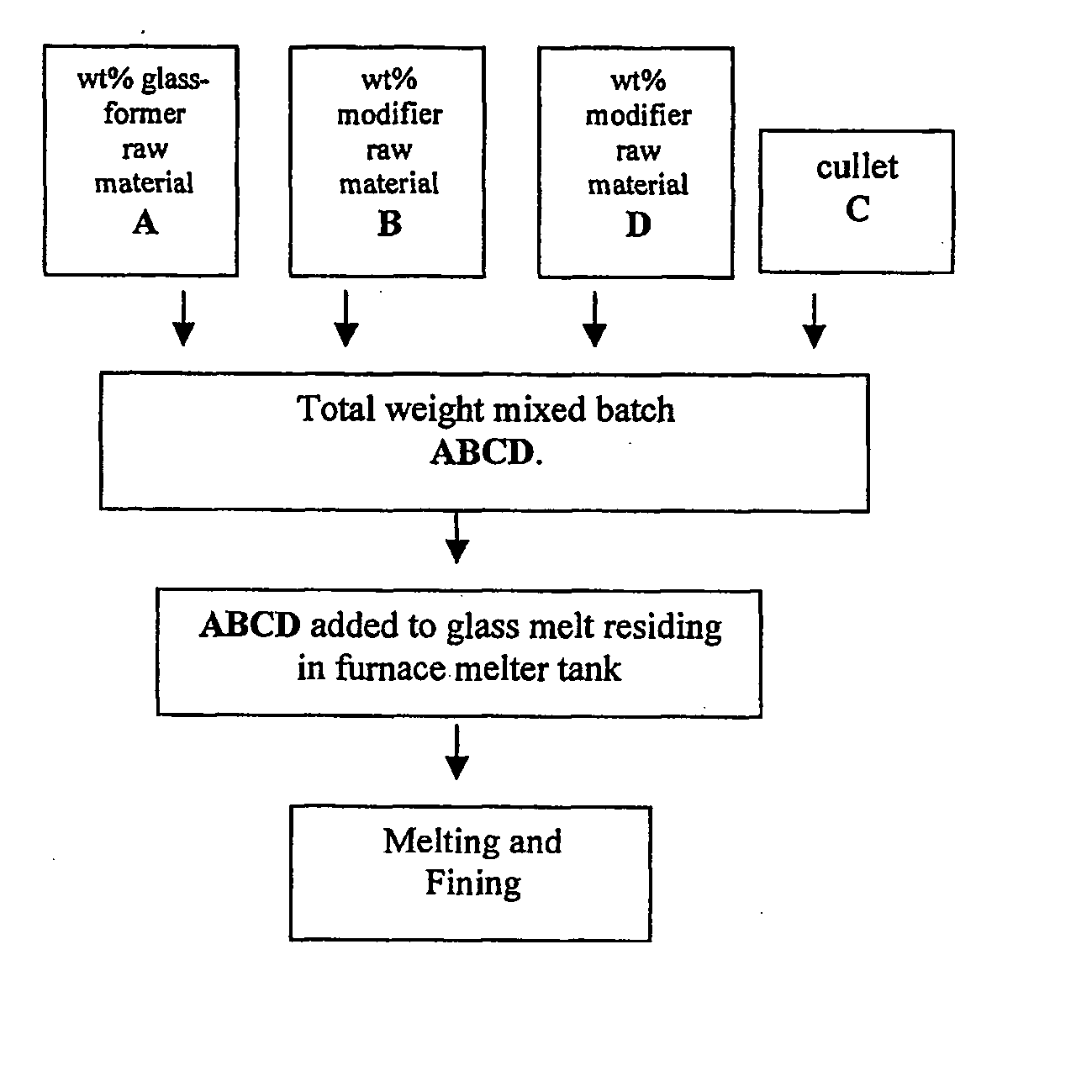

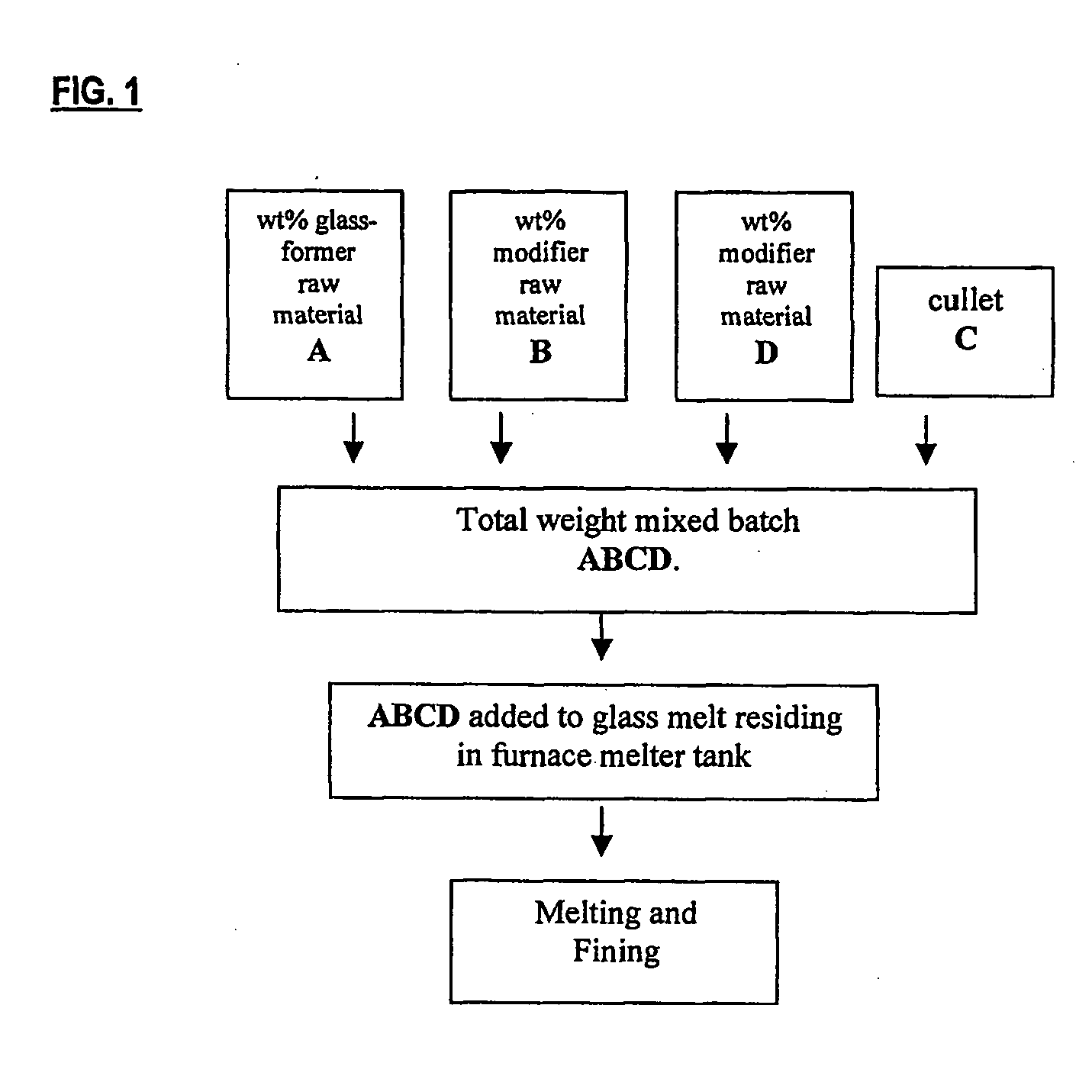

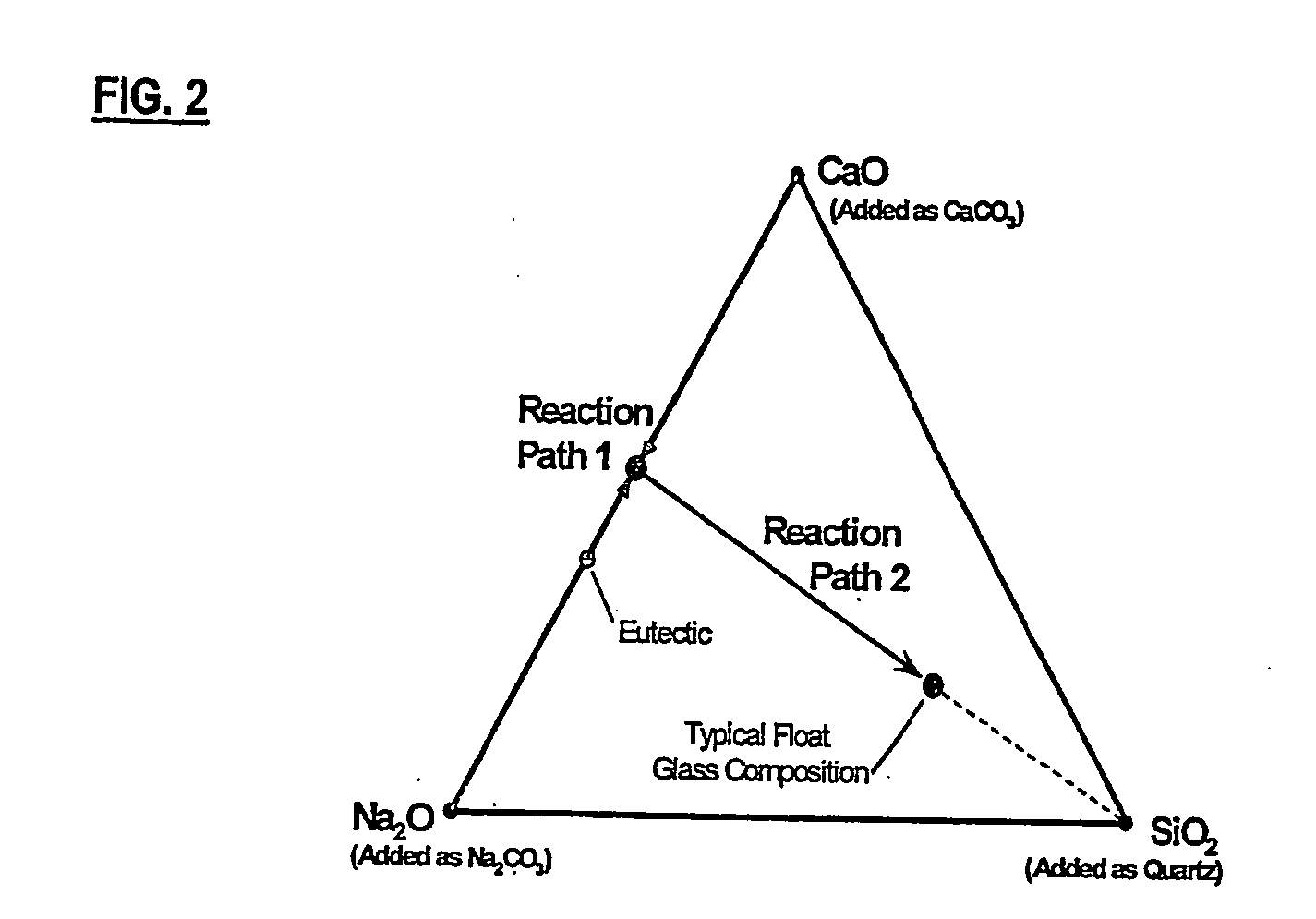

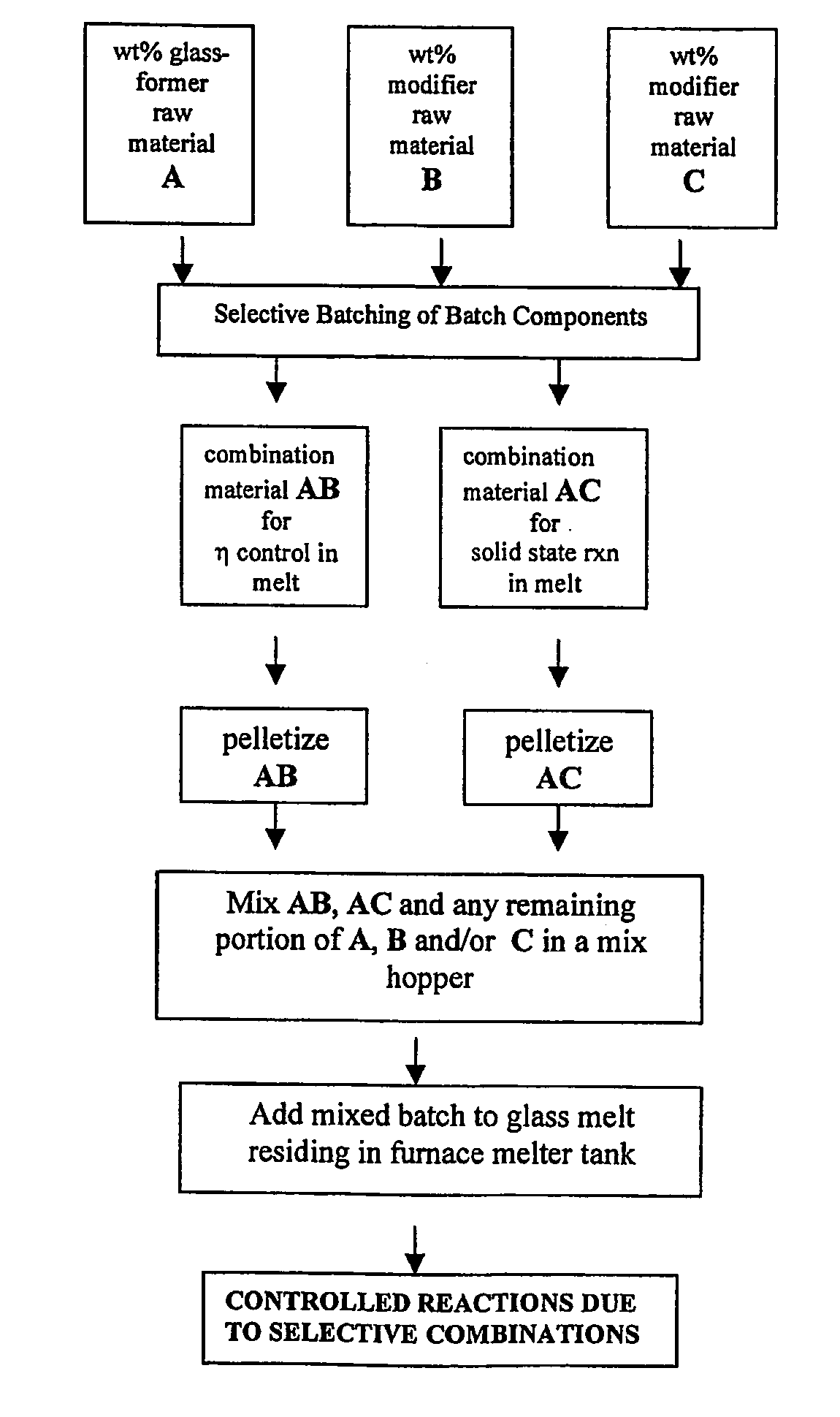

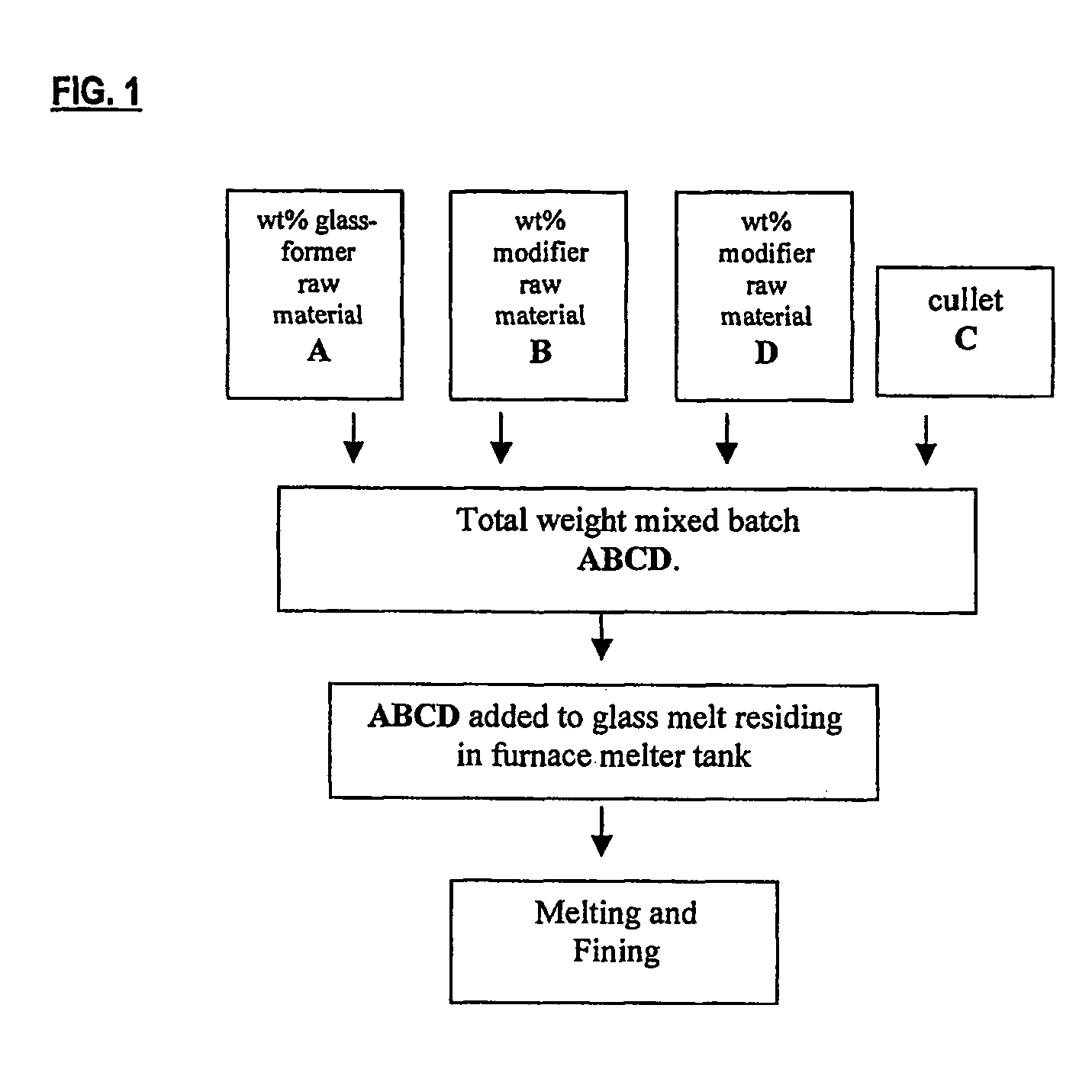

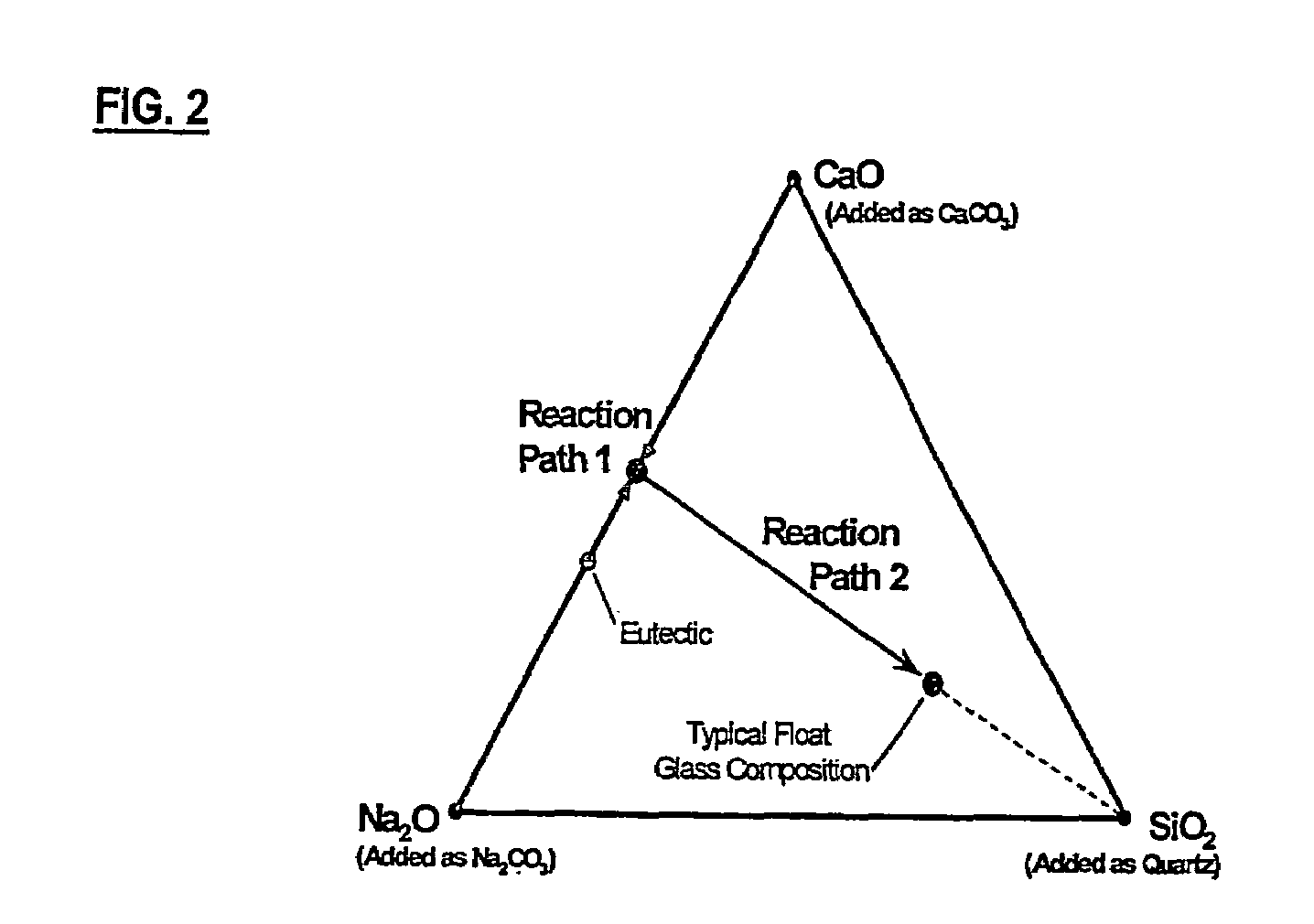

Selective glass batching methods for improving melting efficiency and reducing gross segregation of glass batch components

ActiveUS20050022557A1Improve melting efficiencyOvercomes drawbackCharging furnaceGlass furnace apparatusMelt viscosityMelt temperature

A method of controlling reaction paths of glass batch components added to a resident glass melt is provided, including the steps of providing a plurality of raw material batch components according to a batch recipe, selectively combining a portion of the batch components into a first combination material having a melting temperature in a range of 60 to 90% of a resident melt temperature (K) and a viscosity3 a melt viscosity / 100, and selectively combining another portion of the batch components into a second combination material having a reaction temperature in a range of 60 to 100% of the resident melt temperature, the second combination material being capable of forming an intermediate compound via a solid state reaction before reacting with the glass melt. The first and second combination materials and any remaining batch components are mixed and introduced into a glass melter.

Owner:ALFRED UNIVERSITY

Environment friendly low-gas-content aluminum alloy ingot and production method thereof

The invention discloses an environment friendly low-gas-content aluminum alloy ingot which comprises the following components in percentage by weight: 1.6-3.3 percent of Cu, 9.8-11.8 percent of Si, 0-0.29 percent of Mg, 0-0.08 percent of Zn, 0-0.8 percent of Fe, 0-0.48 percent of Mn, 0-0.48 percent of Ni, 0-0.1 percent of Ti, 0-0.1 percent of Pb, 0-0.2 percent of Sn, 0-0.25 percent of other trace elements and the balance of aluminum. Meanwhile, the invention also discloses a production method of the environment friendly low-gas-content aluminum alloy ingot. The environment friendly low-gas-content aluminum alloy ingot has the advantages of low gas and dreg content, high aluminum liquid cleanness and good mechanical and machining properties. The production method has the advantages of low production cost and high efficiency and effectively solves the pollution problem of the secondary aluminum industry.

Owner:YE CHIU METAL RECYCLINGCHINALTD

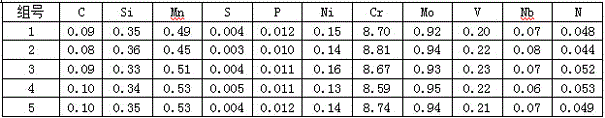

Method for smelting martensitic stainless steel P91 for boiler pipe

ActiveCN106636953AImprove melting efficiencyReduce consumptionElectric arc furnaceMartensitic stainless steel

The invention belongs to the technical field of smelting, and mainly relates to a method for smelting martensitic stainless steel P91 for a boiler pipe. The technological process of an electric arc furnace / medium-frequency induction furnace, an argon-oxygen refining furnace, an LF refining furnace, vacuum degassing, LF and continuous casting is adopted. Components for smelting the martensitic stainless steel for the boiler pipe comprise, by mass percent, 0.08%-0.12% of C, 0.30%-0.50% of Si, 0.30%-0.60% of Mn, not larger than 0.015% of P, not larger than 0.010% of S, not larger than 0.40% of Ni, 8.5%-9.5% of Cr, 0.90%-1.10% of Mo, 0.18%-0.30% of V, not larger than 0.30% of Cu, 0.03%-0.07% of N, 0.05%-0.10% of Nb, not larger than 0.020% of Al, not larger than 0.015% of [As], not larger than 0.010% of [Sn], not larger than 0.010% of [Pb], not larger than 0.010% of [Sb], not larger than 0.010% of [Bi] and the balance Fe and a small quantity of other elements. The method for smelting the martensitic stainless steel P91 for the boiler pipe aims to be low in inclusion content and delta-ferrite content and capable of achieving continuous casting production.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

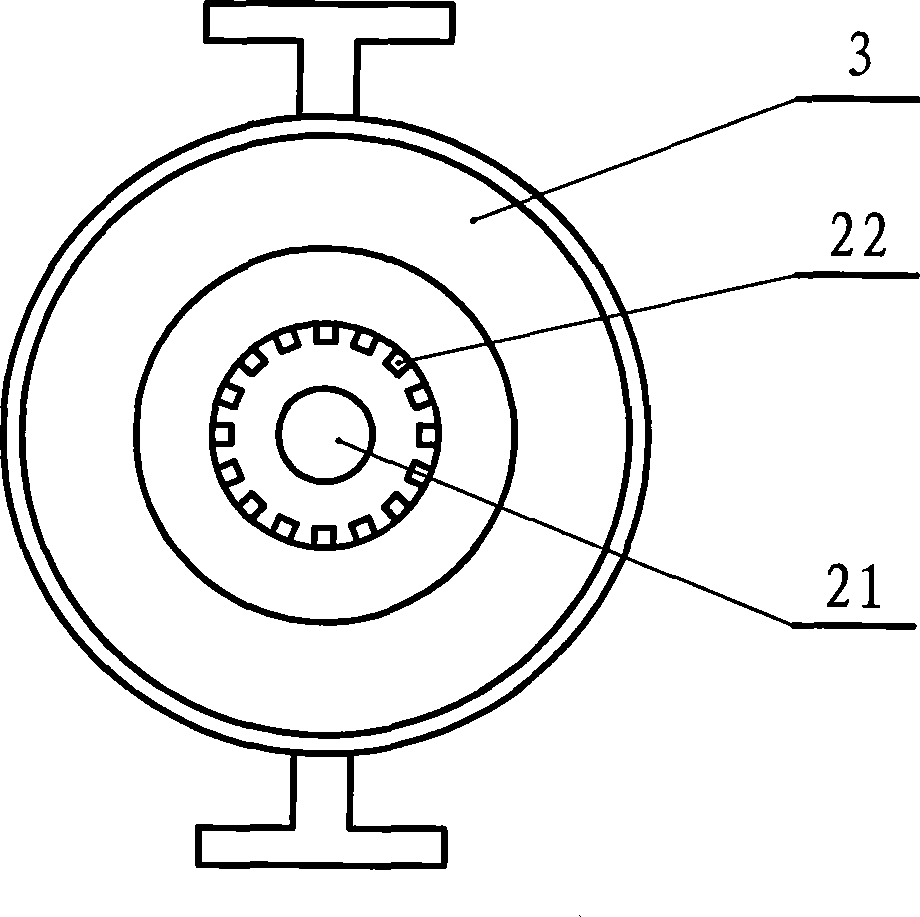

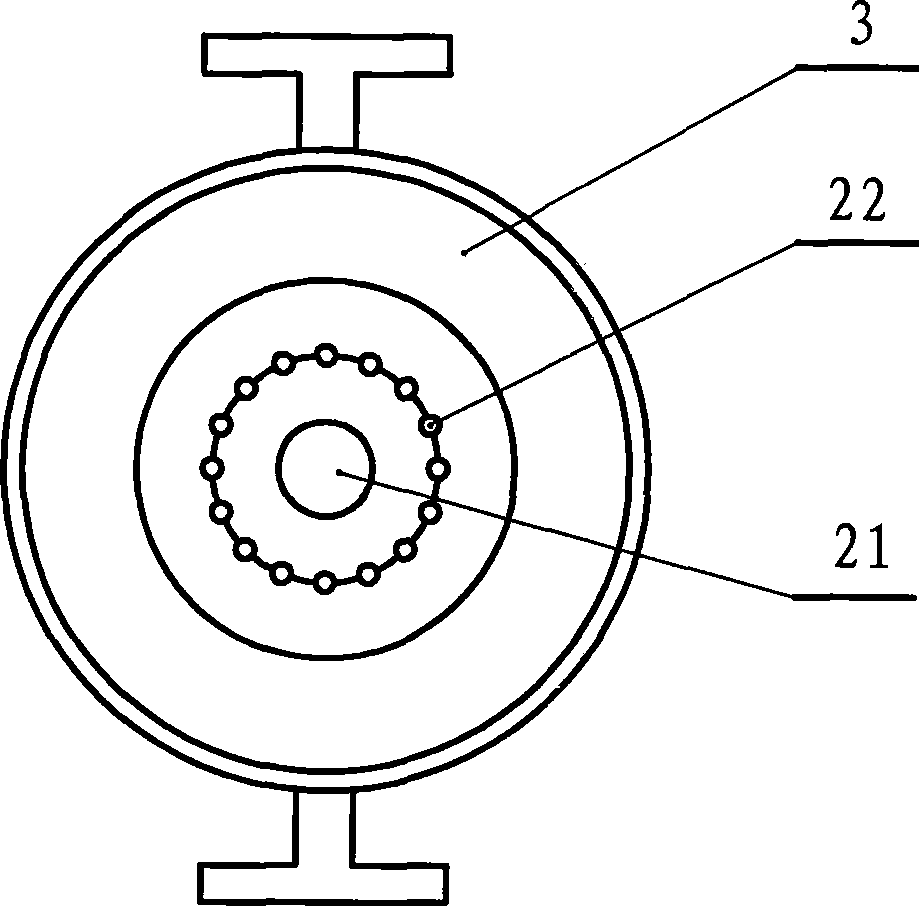

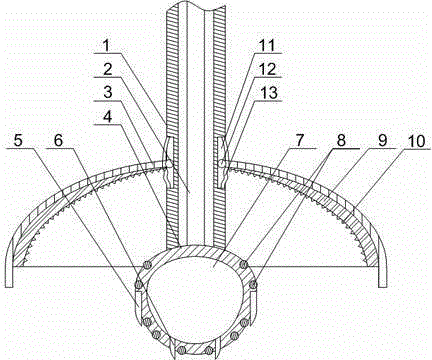

Spray gun of side-blown converter for smelting non-ferrous metal

ActiveCN101382387AImprove combustion performanceSpeed up redox reactionsCharge manipulationCombustionNonferrous metal

The invention discloses a novel side-converter spray gun for smelting nonferrous metals, comprising a spray gun body with a sleeve structure and a spray gun head at the front end of the spray gun body; a central pipeline of the sleeve structure is provided with a connecting interface connected with a fuel conveyor; a sandwich ring channel of the sleeve structure is provided with a connecting interface connected with combustion-supporting gas; the spray gun head is provided with a fuel nozzle which is matched with the central pipeline and a combustion-supporting gas nozzle which is matched with the sandwich ring channel; and the combustion-supporting gas nozzle is provided with a through hole nozzle array.

Owner:CHINA ENFI ENGINEERING CORPORATION

Abrasive surface electrode of efficient high-hardness

InactiveCN101073861AImprove melting efficiencyImprove deposition efficiencyWelding/cutting media/materialsSoldering mediaHigh carbonBoron carbide

The invention is concerned with wear-resisting build up deposited electrode with high efficiency and high rigidity. It relates to Phi4 H08A cored wire, covering with Phi9 outer diameter. The compose of covering is 3 to 5 percent of silver-graphite, 2 to 6 percent of Boron carbide, 2 to 3 percent of carborundum, 3 to 5 percent of ferromolybdenum, 3 to 5 percent of ferrovanadium, 5 to 10 percent of tungsten carbide, 8 to 16 percent of high carbon ferrochrome, 2 to 3 percent of manganese and 72 percent of iron powder. It changes the existing covering structure by adding lots of iron powder, some kinds of alloy element without adding any ore powder. This method increases the melting efficiency and deposition efficiency with buildup deposited metal rigidity of HRC65 to 68 and certain obdurability and without knocking the sediment in the middle of the multi-pathway and multi-layer to continuous build up deposited welding. This is fit for carbon construct ional steel, the buildup deposited welding to low alloy steel and some middle, high alloy steels, and the wear-resisting situation to the abrasion of milling grain.

Owner:XIANGTAN UNIV

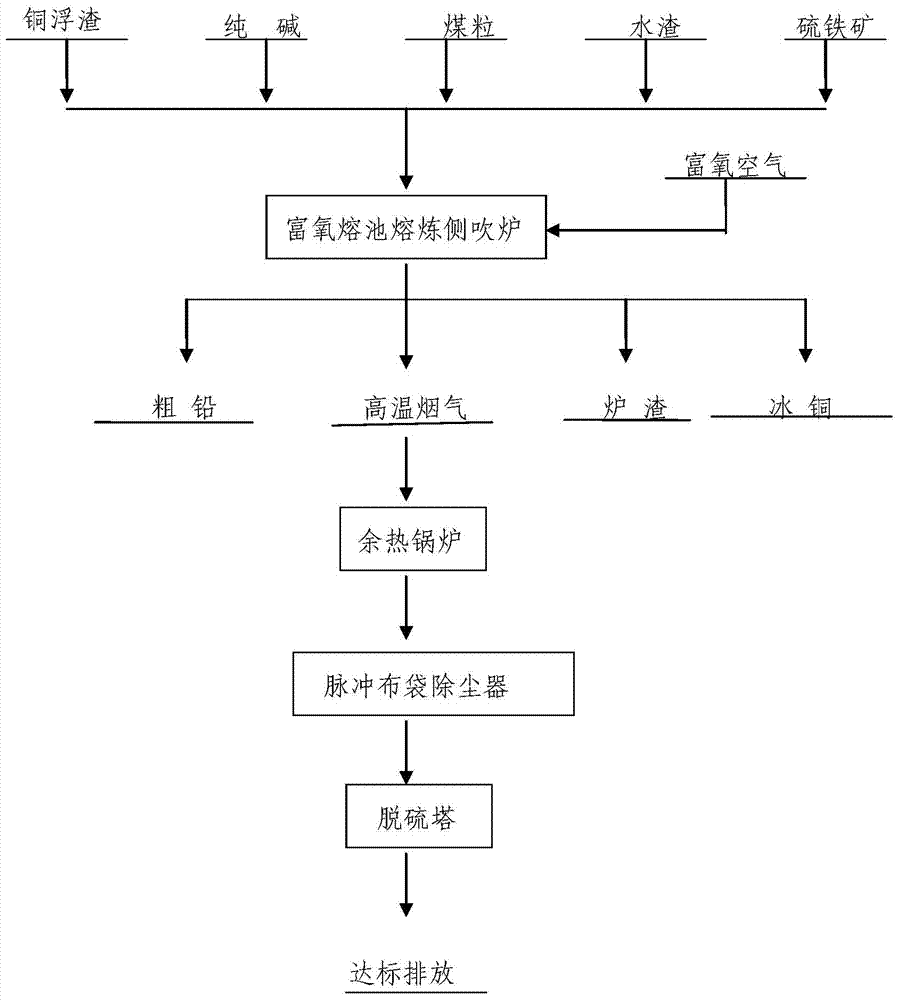

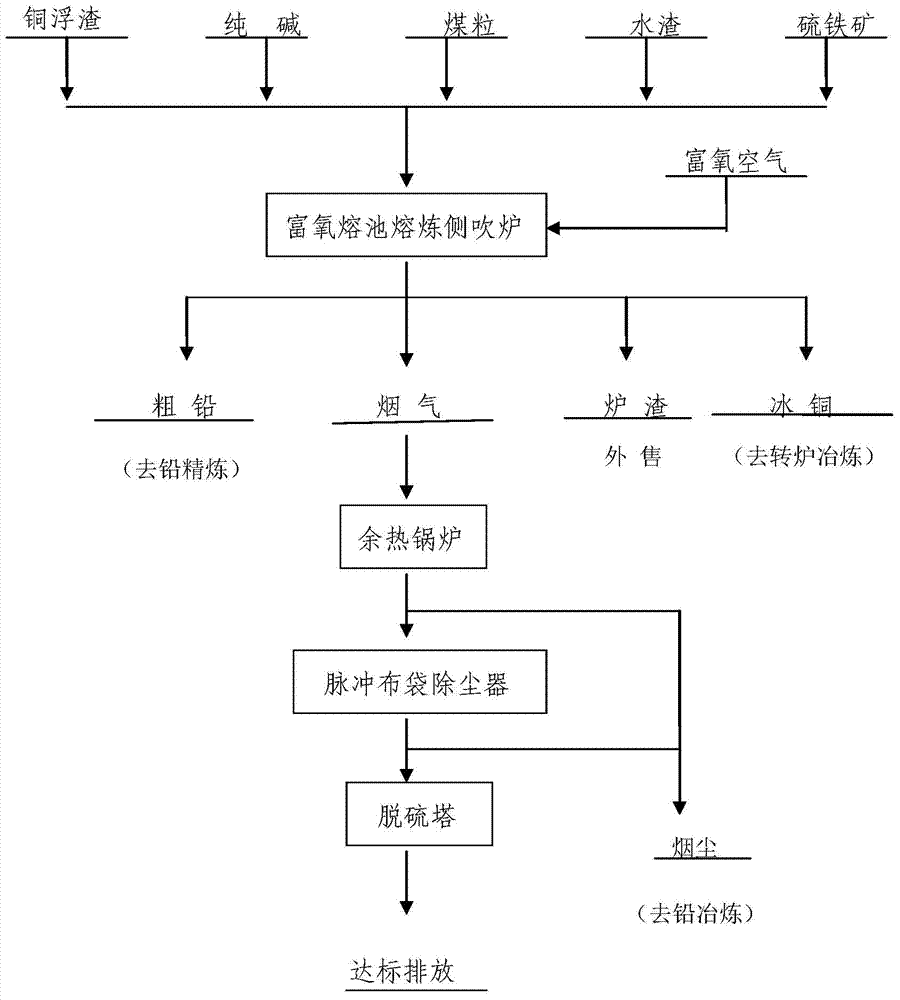

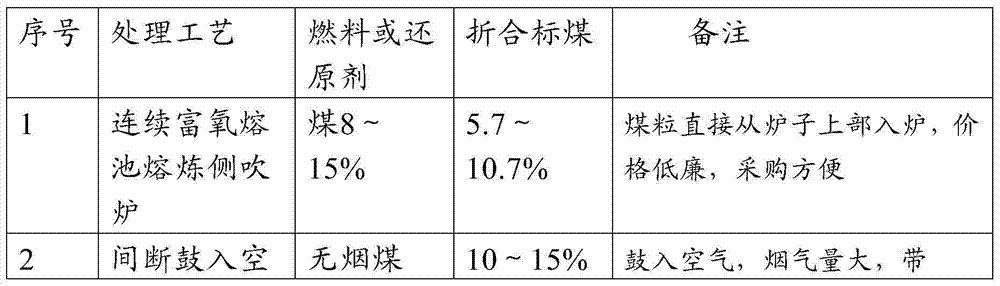

Method for treating copper dross

ActiveCN103924094AImprove melting efficiencyHigh direct metal recovery rate and recovery rateProcess efficiency improvementAutomatic controlPyrite

The invention provides a method for treating copper dross. According to the method, copper dross is treated by using an oxygen enrichment molten pool smelting side blowing furnace, coal granules are adopted as a reducing agent and fuel, copper dross, pure alkali, pyrite and water granulated slag are adopted for blending, together with the coal granules, are fed into the furnace from the feeding hole of the oxygen enrichment molten pool smelting side blowing furnace through a belt, and are blown into an oxygen enrichment air smelting pool for smelting so as to obtain crude lead, copper matte, furnace slag and high-temperature flue gas. By adopting the method provided by the invention, continuous feeding is achieved; due to adoption of a DCS automatic control technique, the working intensity of operators is low, the flushing and casting environment is good, the side blowing treatment bed is high in capacity, the efficiency of the smelting pool is high, the metal recycling rate is high, and the smelting energy consumption is low.

Owner:JIYUAN WANYANG SMELTING GROUP

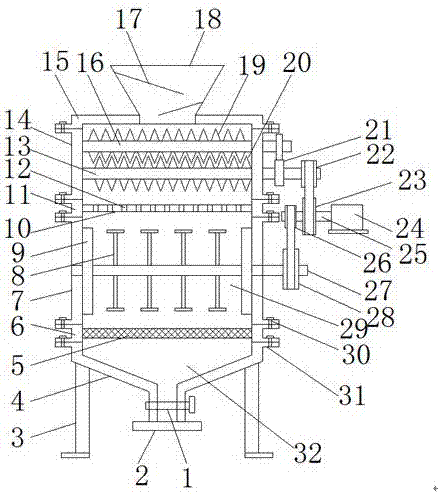

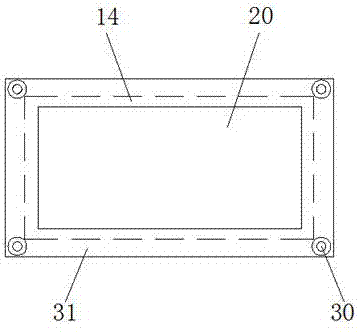

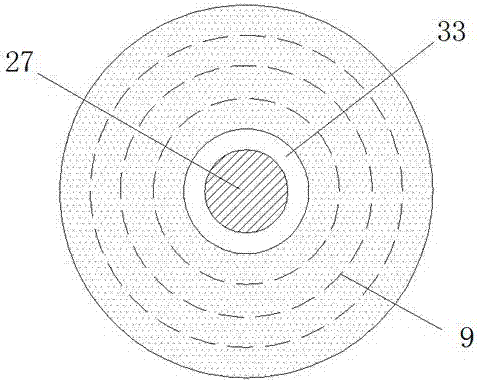

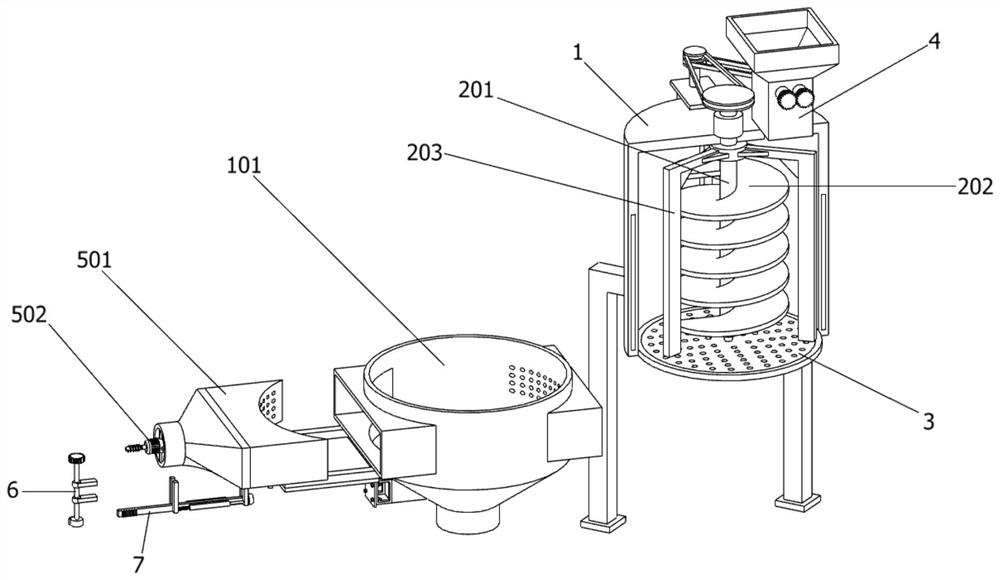

Chemical fiber raw material grinding and melting device

ActiveCN106914306ACompact structureEasy to assemble and disassembleFilament forming substance formingTransportation and packagingFiberEngineering

The invention discloses a chemical fiber raw material grinding and melting device. The device comprises a feed liquor collecting box, a stirring box, a grinding box, and a feed hopper. A discharge pipe is welded on the bottom of the feed liquor collecting box. The upper end of the feed liquor collecting box is connected to a melt filtering box. A filter screen is arranged in the melt filtering box. The upper end of the melt filtering box is connected to the stirring box. A melting and stirring chamber is arranged in the stirring box. A heating disc is arranged on the internal wall of the stirring box. The heating disc is in an annular disc shape. A shaft hole is arranged in the middle of the heating disc. A stirring shaft is arranged in the shaft hole. Multiple stirring rods are vertically welded on the stirring shaft. The provided chemical fiber raw material grinding and melting device has the advantages that the structure is compact, the assembly and disassembly are convenient, the raw materials can be easily added, the grinding is convenient and fast, the screening effect is good, the heating is carried out during stirring process, the raw material melting efficiency is improved, the melt is filtered so as to improve the quality of chemical fiber products, and the raw materials can be fully melted.

Owner:温岭市旗亮鞋业有限公司

Electromagnetic continuous casting apparatus for materials possessing high melting temperature and low electric conductance

InactiveUS20060037733A1Efficient heatingEfficiency of materialMelt-holding vesselsPolycrystalline material growthCrucibleMetallic materials

Disclosed is an electromagnetic continuous casting apparatus for a material having a low electric conductivity. The casting apparatus includes a crucible having a vertical axis. The crucible comprises an upper hot crucible and a lower cold crucible. The crucible is surrounded with an induction coil. The hot crucible is formed of a non-metallic material having a high electric conductivity and is not water-cooled. The cold crucible has a cooling structure and is formed of a metallic material having a high thermal conductivity and a high electric conductivity.

Owner:KCC CORP CO LTD

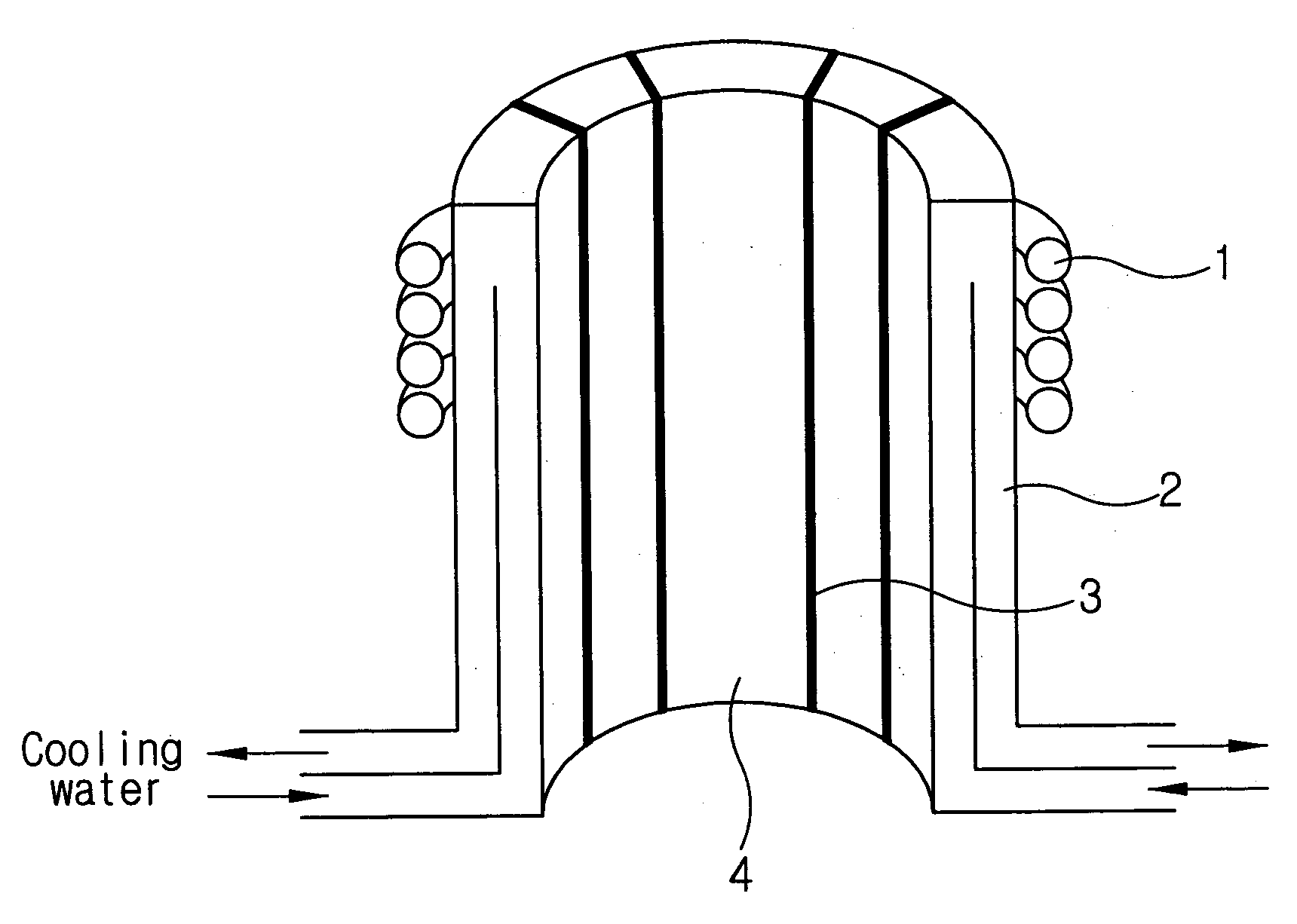

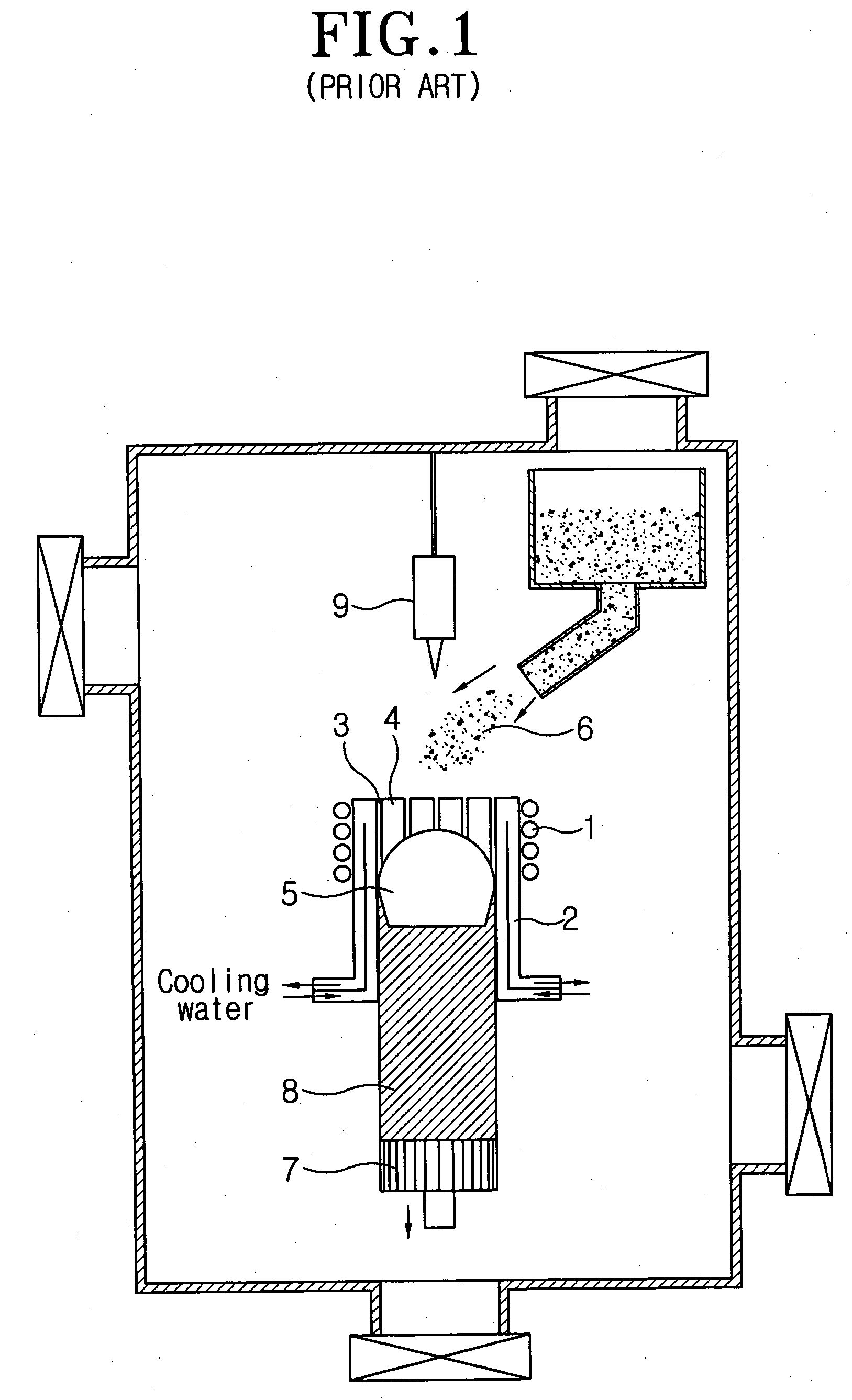

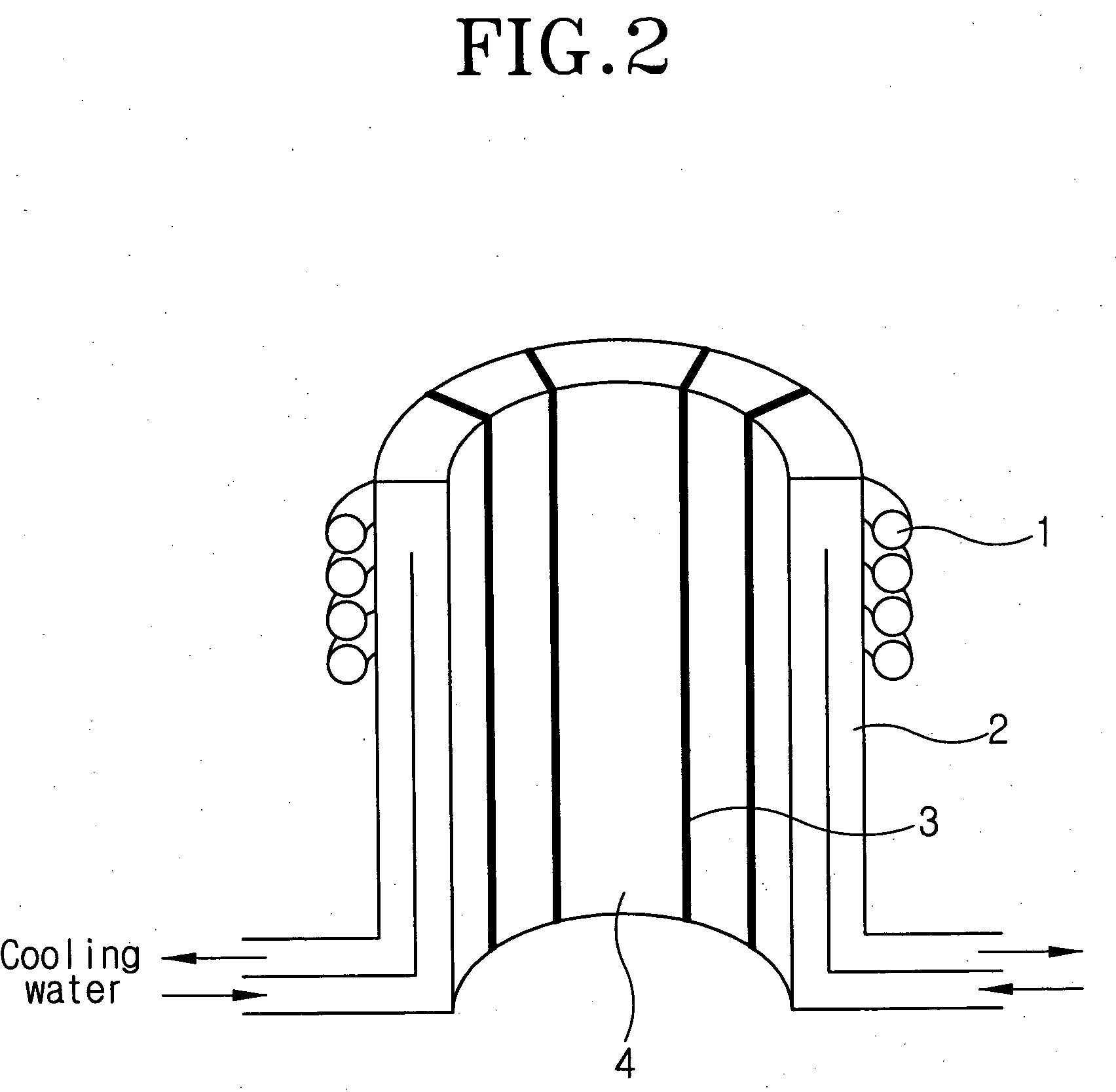

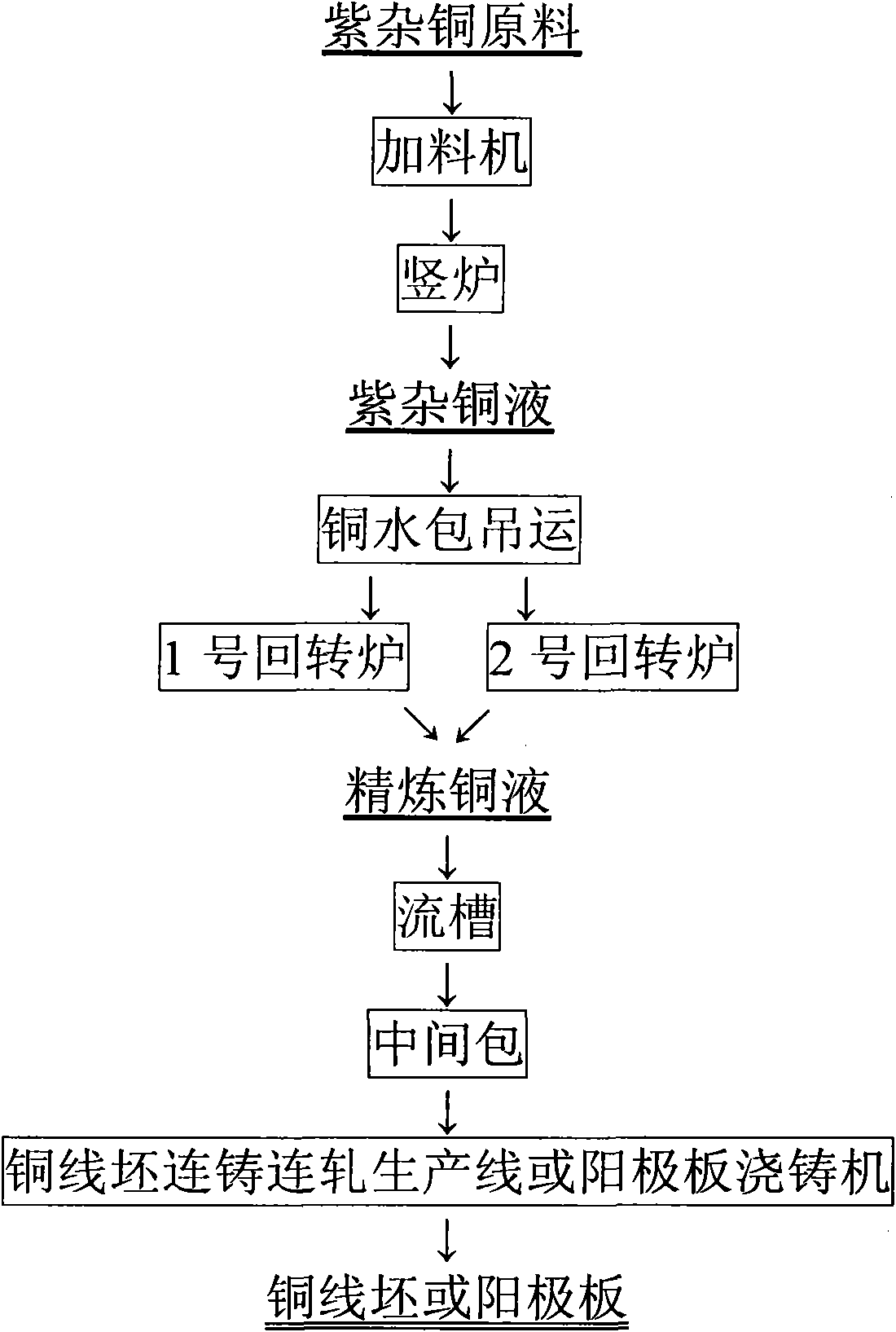

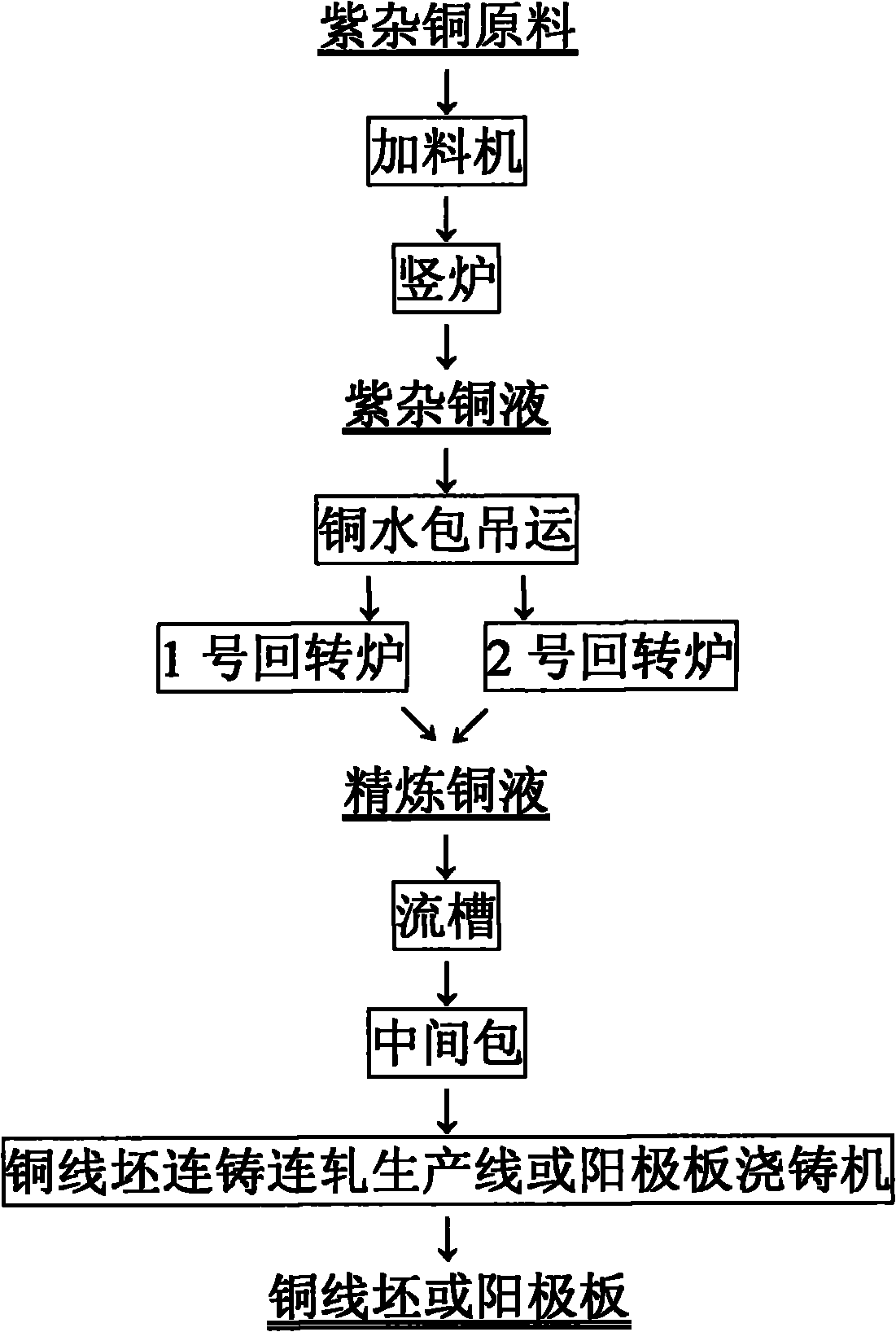

Shaft furnace, copper water bag and rotary furnace combined type fire refining process for raw red copper

InactiveCN101845557AImprove melting efficiencyIncrease profitFurnace typesOxidation-Reduction AgentHigh energy

The invention relates to a fire refining process for raw red copper. The process is characterized by adopting a shaft furnace, a copper water bag and at least one rotary furnace and comprising the following steps of: 1) charging the raw material of the raw red copper into the shaft furnace by using a charging machine and smelting the raw red copper in the shaft furnace into raw red copper liquid; 2) lifting and charging the raw red copper liquid smelted and produced from the shaft furnace into the rotary refining furnace by using the copper water bag to perform redox refining to obtain the refined copper liquid; and 3) allowing the refined copper liquid to directly enter a tundish through a launder to finish the subsequent procedures. According to the fire refining process, a holding furnace is saved, so the fire refining process has the advantages of high energy utilization ratio, high production continuity and good labor condition.

Owner:GANZHOU JIANGWU NEW TYPE ALLOY MATERIAL

Full penetration welding process

InactiveCN105436674AImprove the force characteristicsImprove welding qualityArc welding apparatusMetal working apparatusFillet weldStructural engineering

The invention relates to a full penetration welding process. On the condition that the angle of an assembly bevel is 47 degrees, deep penetration welding backing welding is carried out at the downhand position through an arc-gathering pulse deep penetration welding machine by adopting solid wires, and then cosmetic welding is carried out at the downhand position or the boat-shaped position by adopting flux-cored wires. The process has the advantages of mainly realizing full penetration welding of fillet welds of U-shaped ribs with the thickness being 8 mm and being of great significance in improving the mechanical characteristics of the fillet welds of the U-shaped ribs, improving the weld quality of the U-shaped ribs and prolonging service life of bridges. The arc-gathering pulse deep penetration welding machine is mainly adopted for the full penetration welding process, arc permeation can be obviously improved, the power of penetrating the root of the assembly bevel can be improved, and formation of the weld roots can be guaranteed.

Owner:SHANGHAI ZHENHUA HEAVY IND

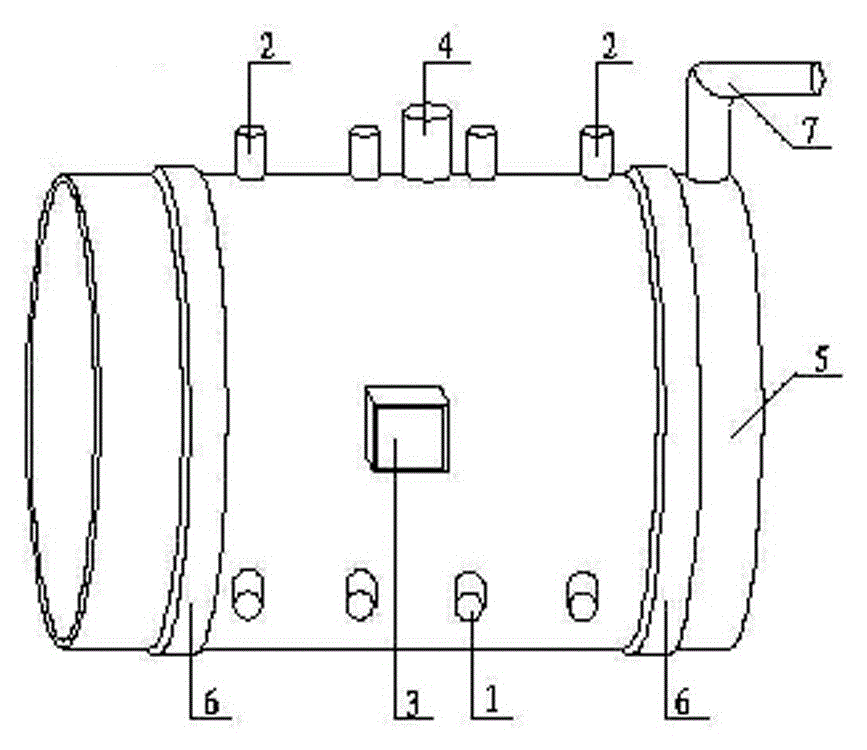

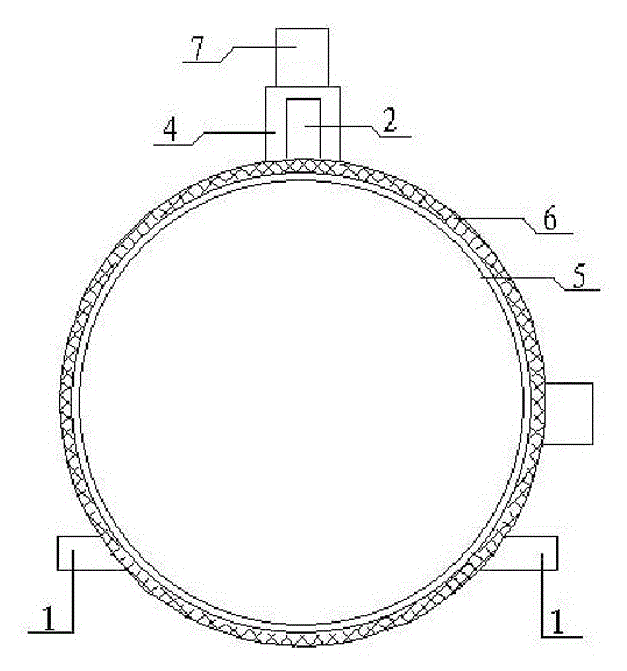

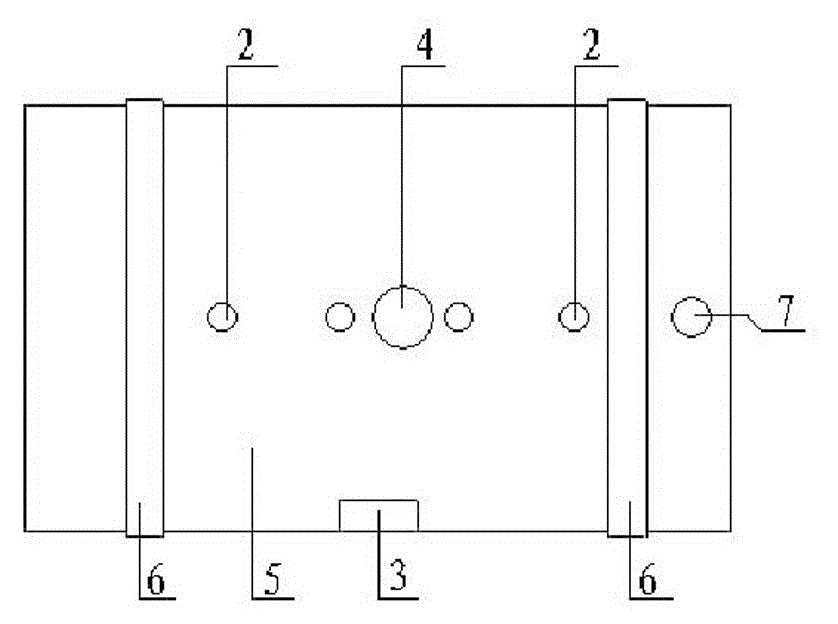

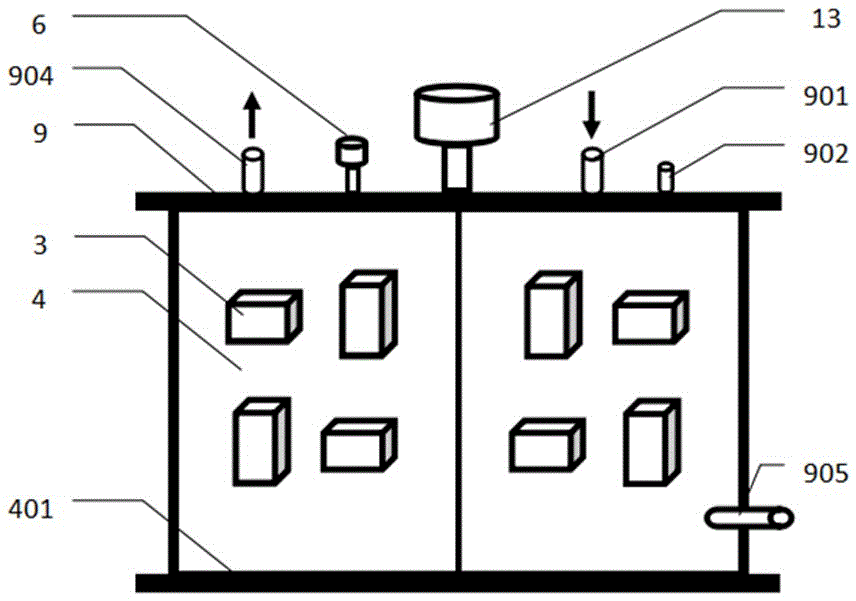

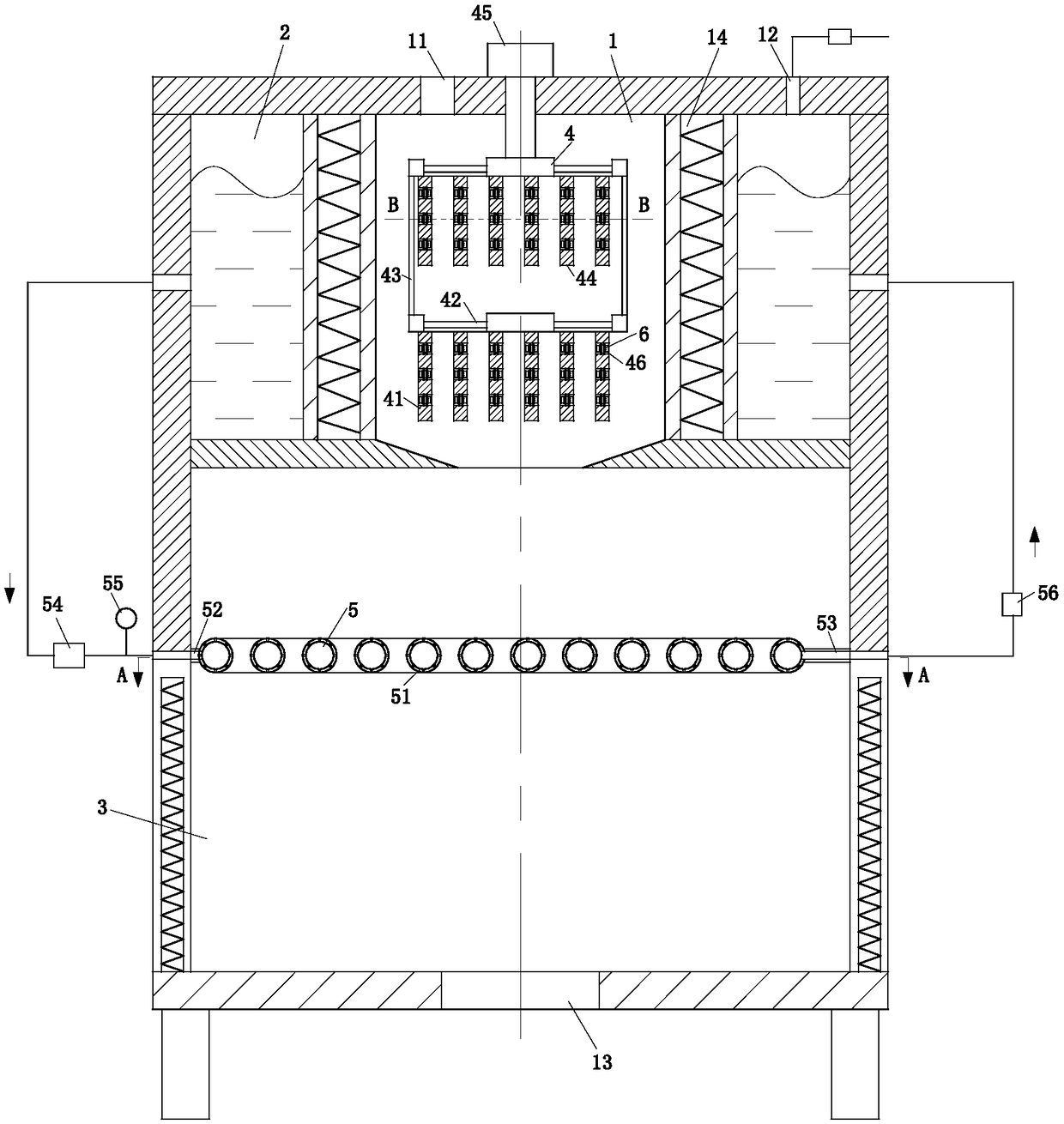

Method and device for preparing crude silver alloy through anode slime

ActiveCN105063363AReduce moistureReduce soot rateProcess efficiency improvementAlloyEnergy consumption

The invention discloses a method and device for preparing crude silver alloy through anode slime. According to the method for preparing crude silver alloy through anode slime, the anode slime is used as the raw material, and the crude silver alloy with the silver content being 80-95 wt% is obtained after the steps of pelletizing, charging and melting, slagging and emission, oxidizing slagging and crude silver alloy discharging. The device is a side-top-combined smelting converter which comprises a plurality of side blowing spray guns (1), a plurality of top blowing spray guns (2), a discharging opening (3), a feed inlet (4), a converter body (5), two rotating racks (6) and a smoke duct (7). According to the method for preparing the crude silver alloy through the anode slime, reduction smelting and oxidizing refining are finished through the side-top-combined smelting converter; compared with traditional two furnaces, the heat efficiency is good, energy consumption is lowered by 20-40%, and cost is reduced; smelting time is shortened to be within 4 days from 6.5 days, and the smelting efficiency is improved; the crude silver alloy can be prepared without additional reducing agents and flux, operation is simple and convenient, and cost is reduced.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

Steel rail surface alloy layer welding method and its material

InactiveCN1803370AGood welding performanceImprove corrosion resistanceWelding with roller electrodesWelding/cutting media/materialsMetallic materialsAlloy

The invention discloses a self-melting alloy powder material in the metal welding and railway signal control method, which comprises the following steps: polishing the railway surface to obtain fresh metal surface; proceeding resistance seam welding through resistance seam welding equipment; producing the needed alloy; coating alloy powder on the metal surface at 1000-1130 deg C fusing point. The powder displays NiCrBSi system self-melting alloy powder or NiCrBSiCu alloy system with HRC20-HRC45 welding layer hardness. The weight percentage of NiCrBSiCu alloy system is 0.2-0.5 percent C, 0.5-5.0 percent B, 1.0-5.0 percent Si, 3.0-15 percent Cr, 2-12 percent Fe, 3-20 percent Cu and Ni. The invention improves the bonding surface of metal and steel, which solves the problem of big rail damage and low production efficiency.

Owner:阴生毅

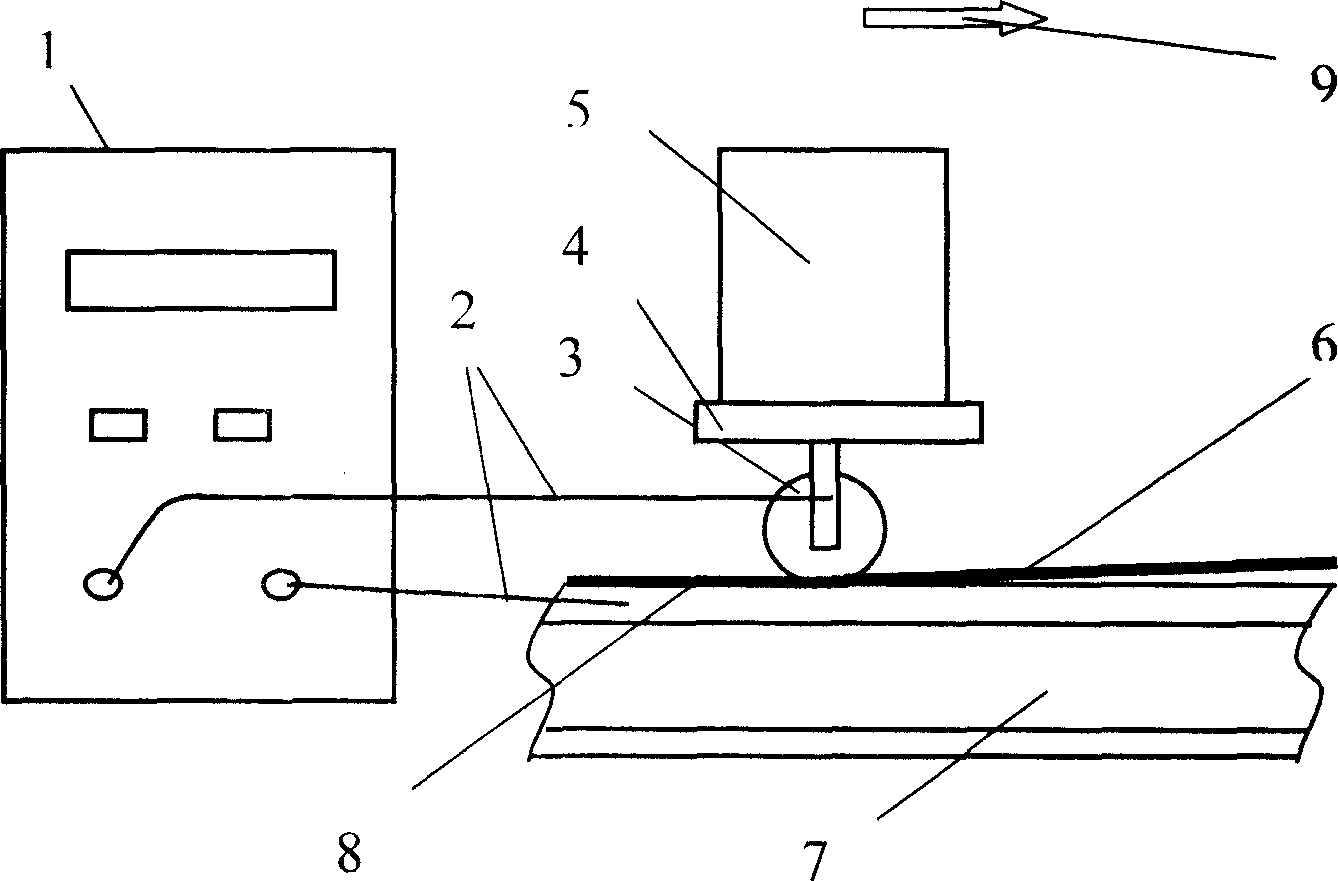

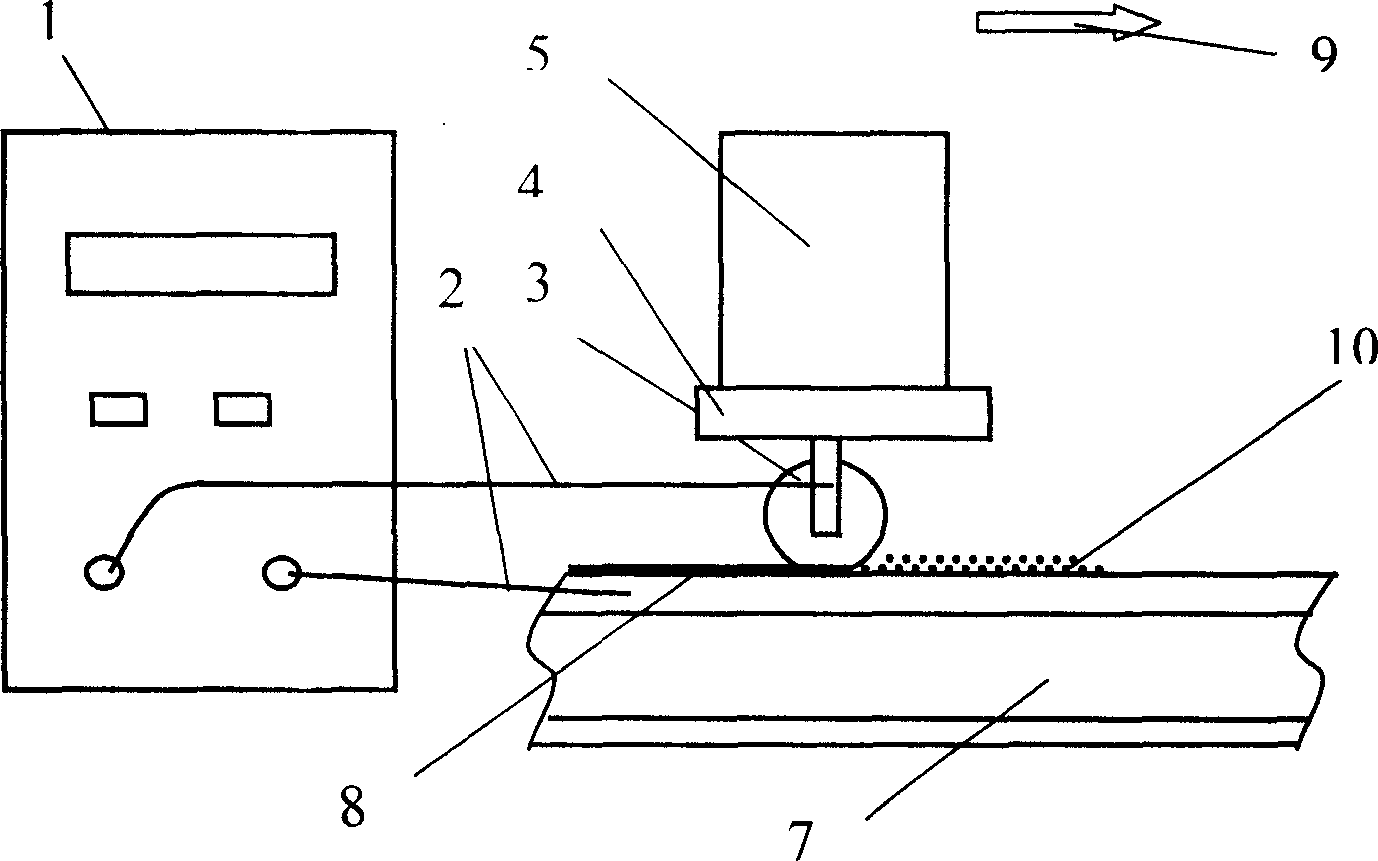

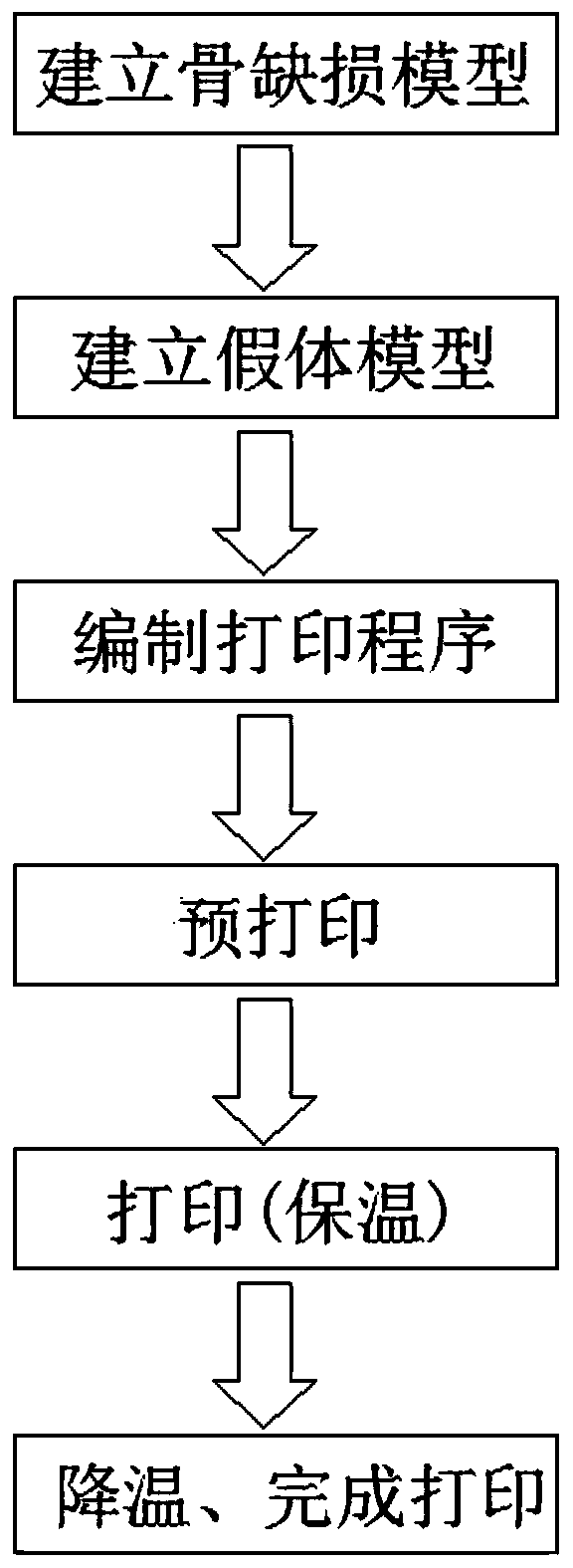

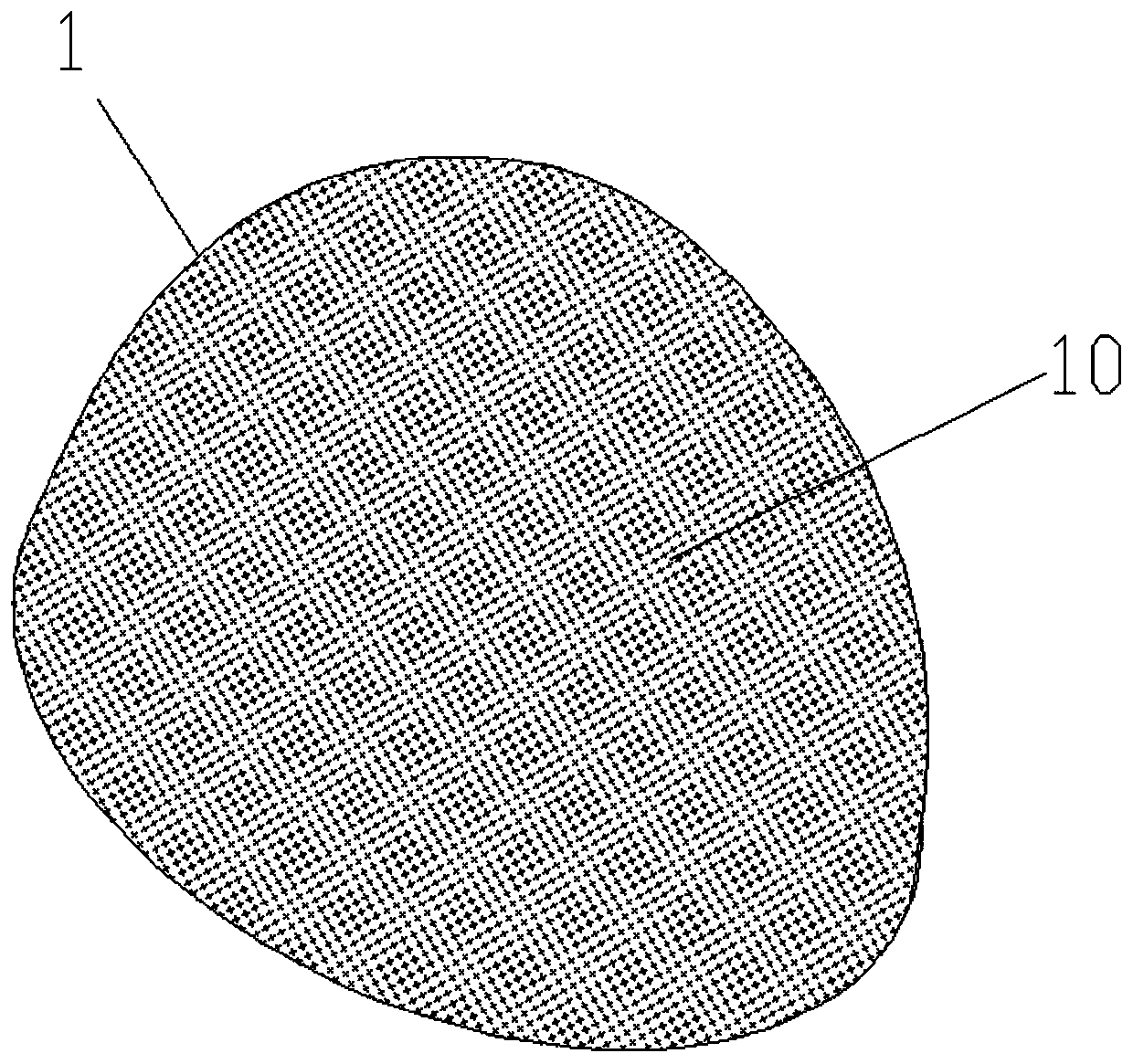

3D printing method of bone defect prosthesis

ActiveCN110575289AHigh bonding strengthFixed and reliableJoint implants3D printingBone prosthesisNatural bone

The invention relates to a 3D printing method of a bone defect prosthesis, and belongs to the technical field of making of a bone prosthesis. The 3D printing method comprises the steps of establishinga bone defect model: constructing a three-dimensional mathematical model for bone defect through a CT or MRI technique; establishing a prosthesis model; compiling a printing program; performing pre-printing: performing printing, and performing layer-by-layer printing of the prosthesis; switching on a heat insulation device in a printing table, and keeping the temperature of the surface being in contact with the prosthesis, of the heat insulation device consistent with the temperature of the prosthesis; reducing the temperature: after printing is completed, rotating the printing table for aircooling and reducing the temperature; and taking down the prosthesis to end printing. According to the 3D printing method disclosed by the invention, through a gradient structure of a supporting framework layer and a merging layer, on one hand, the structural strength is guaranteed, the functionality is realized, on the other hand, through combination of the merging layer and a natural bone, the combining strength can be increased, through the gradient design, the purposes of saving the cost and reducing the weight are realized easily through selection of materials, and help is provided for promoting clinical application of bone prosthesis.

Owner:THE FIRST AFFILIATED HOSPITAL OF ARMY MEDICAL UNIV +1

Selective glass batching methods for improving melting efficiency and reducing gross segregation of glass batch components

ActiveUS7260960B2Improve melting efficiencyOvercomes drawbackCharging furnaceGlass furnace apparatusMetallurgyReaction temperature

A method of controlling reaction paths of glass batch components added to a resident glass melt is provided, including the steps of providing a plurality of raw material batch components according to a batch recipe, selectively combining a portion of the batch components into a first combination material having a melting temperature in a range of 60 to 90% of a resident melt temperature (K) and a viscosity3 a melt viscosity / 100, and selectively combining another portion of the batch components into a second combination material having a reaction temperature in a range of 60 to 100% of the resident melt temperature, the second combination material being capable of forming an intermediate compound via a solid state reaction before reacting with the glass melt. The first and second combination materials and any remaining batch components are mixed and introduced into a glass melter.

Owner:ALFRED UNIVERSITY

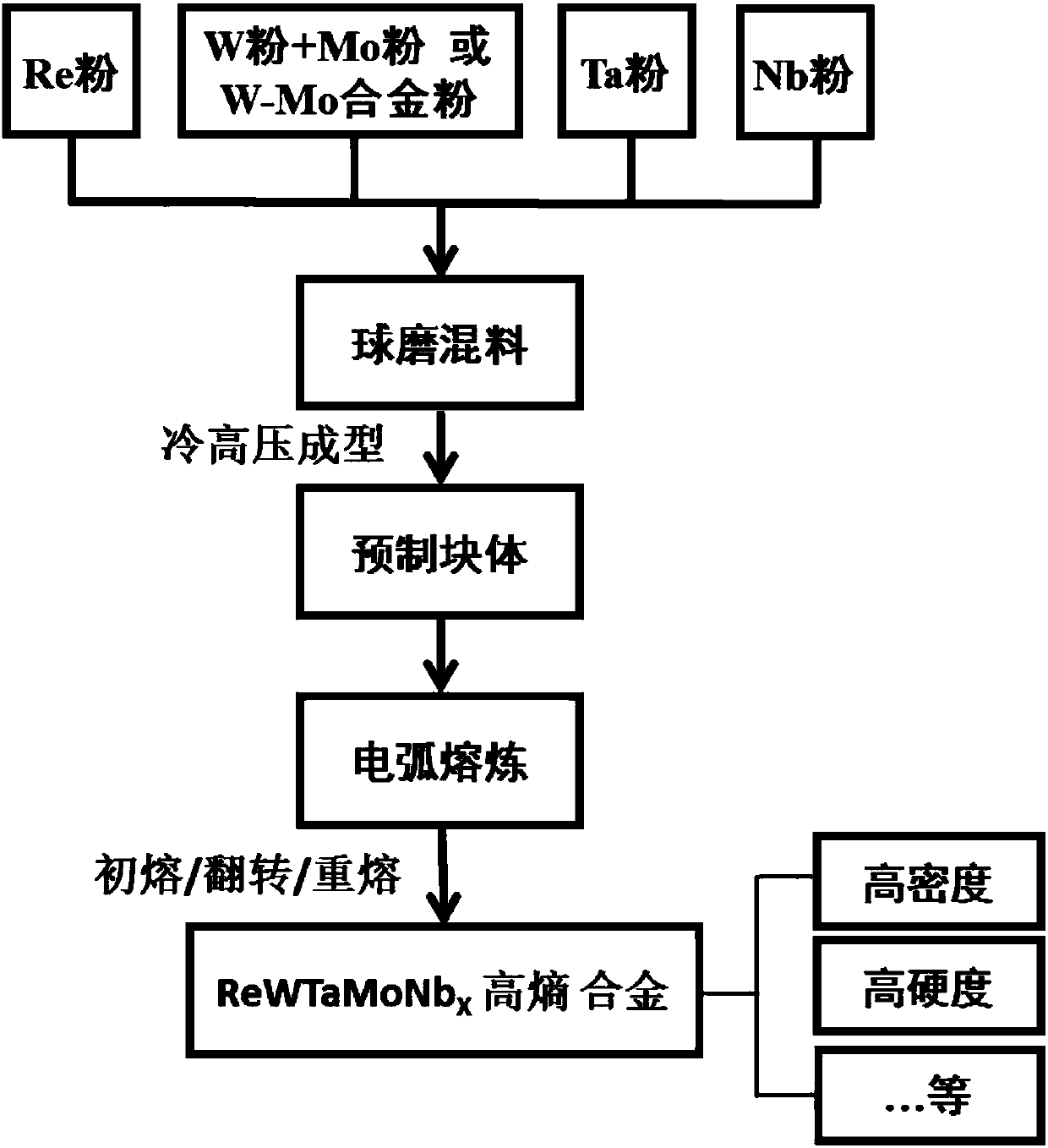

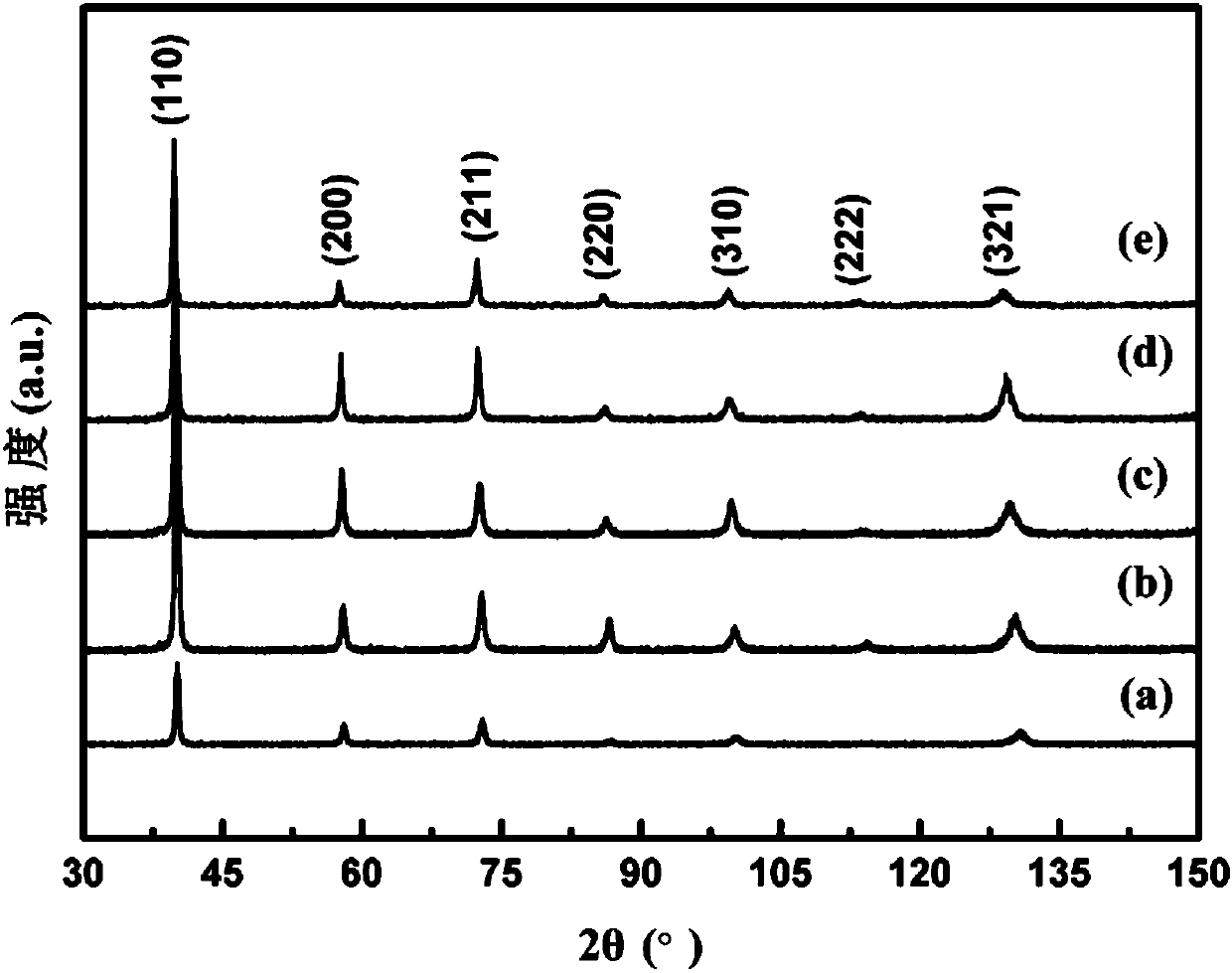

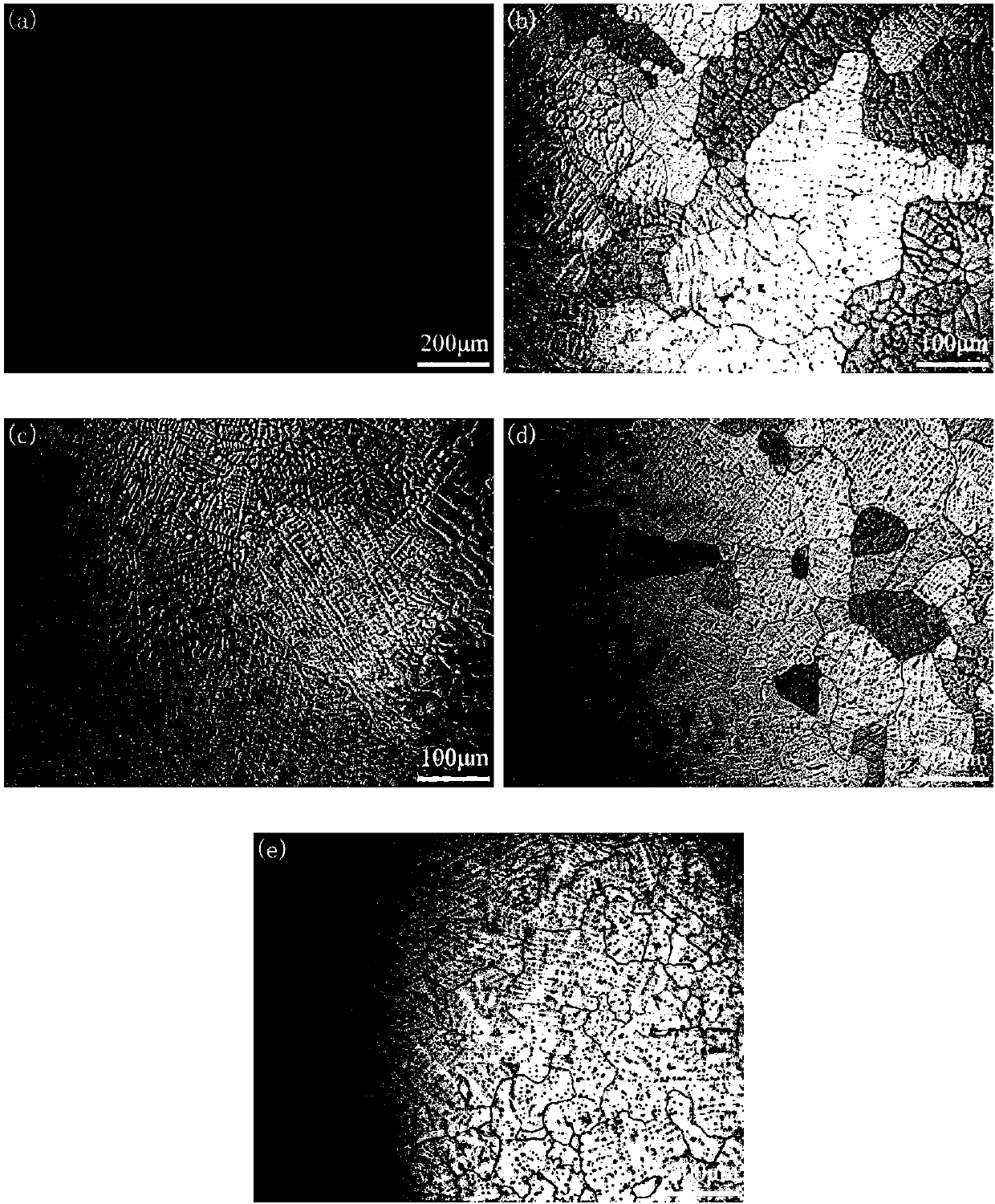

Re-containing high-density ReWTaMoNbx high-entropy alloy material and preparing method thereof

The invention discloses a Re-containing high-density ReWTaMoNbx high-entropy alloy material and a preparing method thereof. The alloy material is composed of ReWTaMoNbx, the molar ratio of any two elements in Re / W / Ta / Mo elements in the alloy is 0.95-1.05, and the molar ratio of the Nb to any element is x=0-1. The preparing method includes the following steps that material mixing is carried out, wherein Re, W-Mo, Ta and Nb metal powder is weighed, and ball milling is carried out to achieve even mixing; precast blocks are prepared, wherein cold high-pressure molding technology is adopted, mixedpowder prepared in the step one is prepared into the precast blocks; and electric arc melting is carried out to prepare a high-entropy alloy, wherein a high vacuum nonconsumable arc smelting furnace is adopted for smelting the precast blocks into master alloy pigs under high-purity argon shielding. The obtained high-entropy alloy material has high density and high hardness, the density is not lower than 15 g / cm<3>, the hardness is not lower than 5700 MPa, and the material can be applied to the field of nuke industry, aerospace, high pressure physics and the like.

Owner:WUHAN UNIV OF TECH

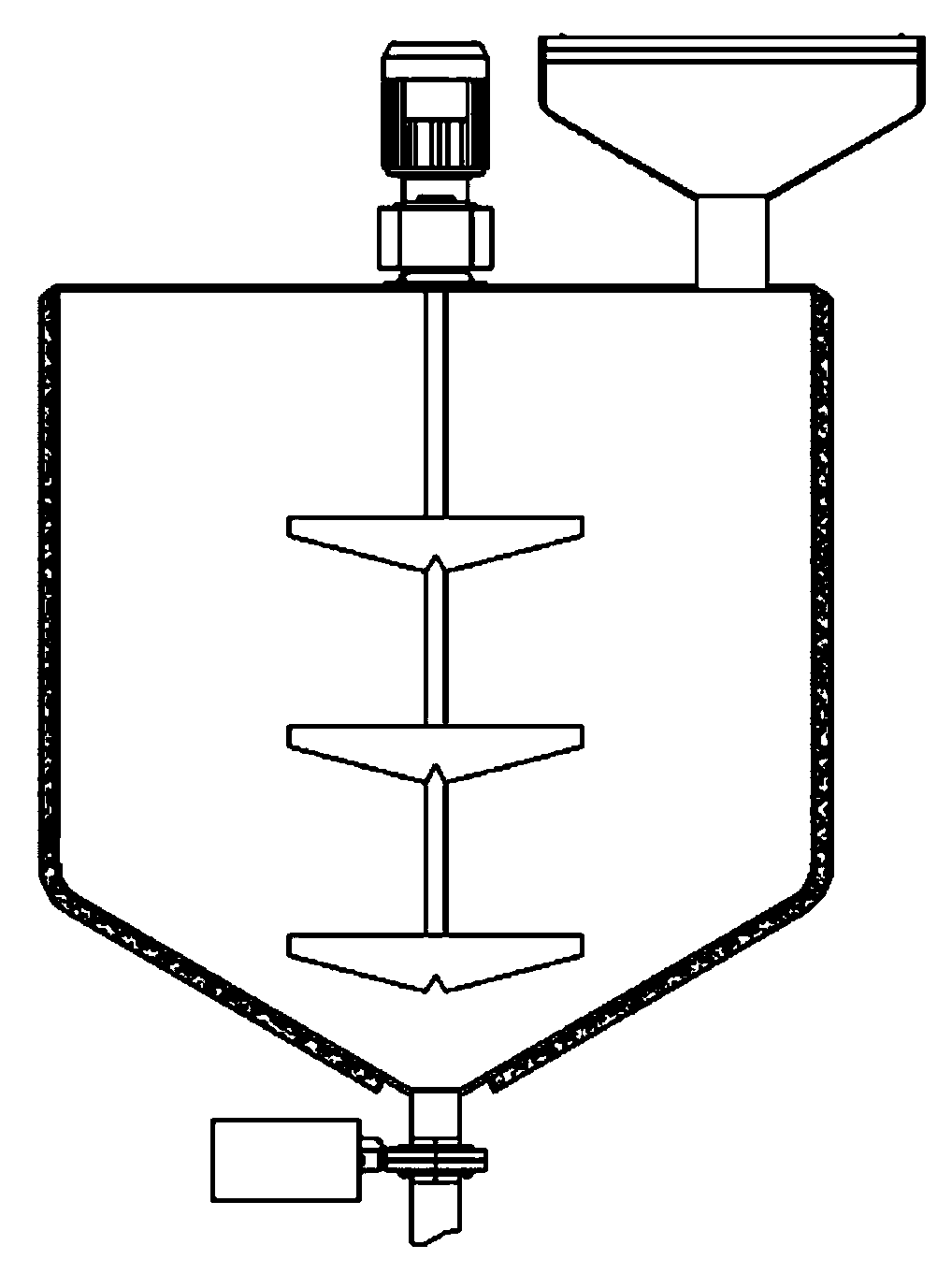

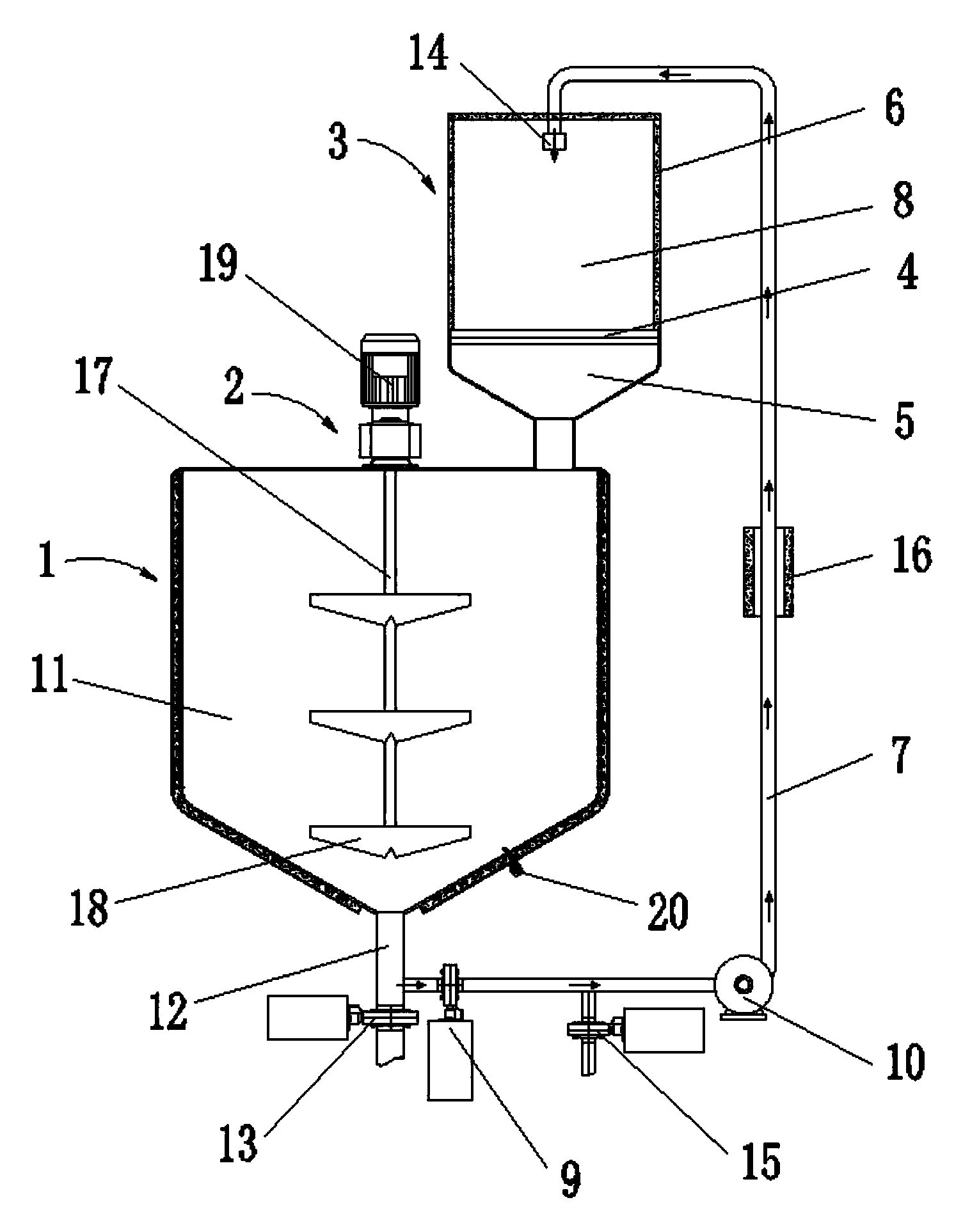

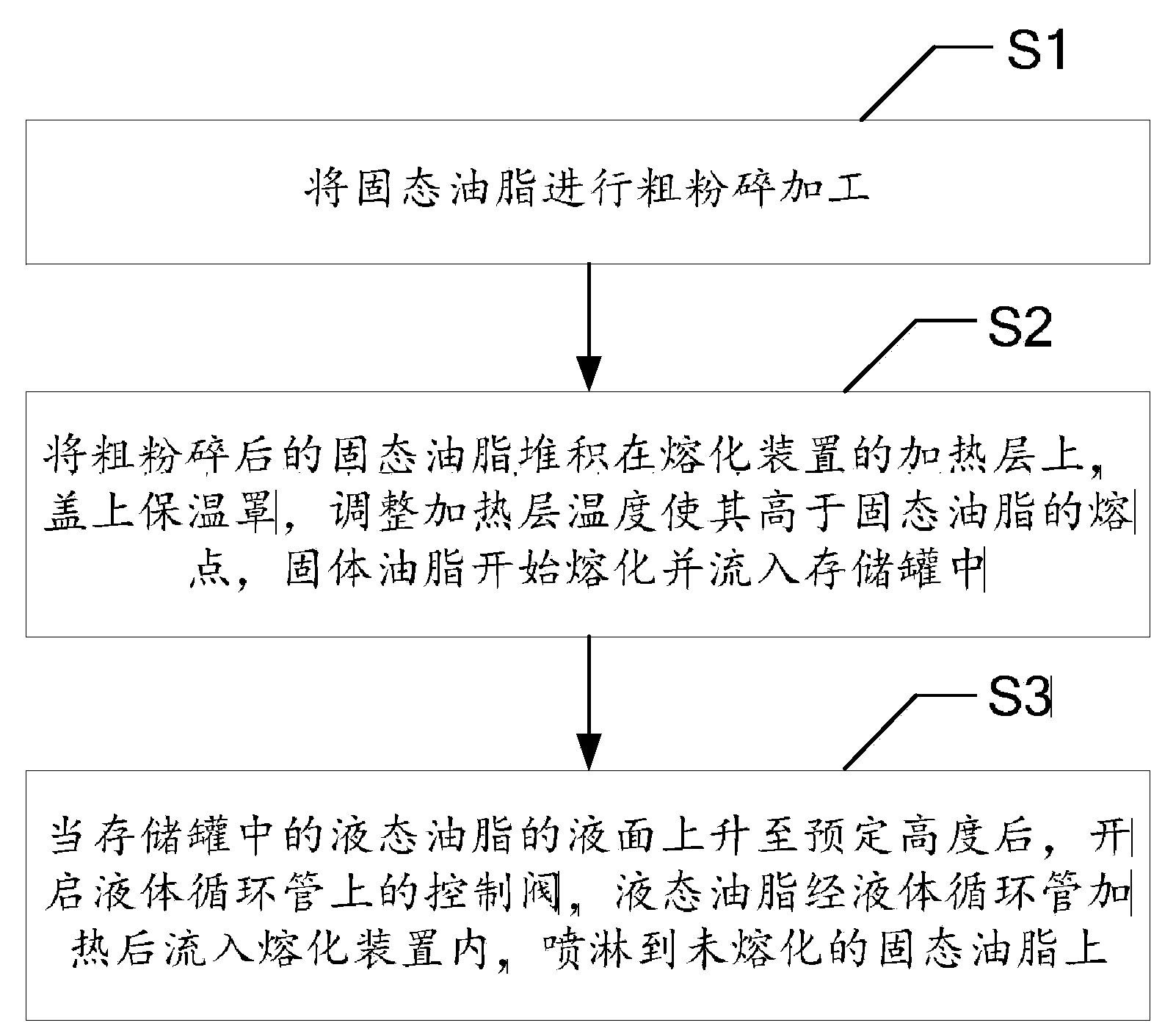

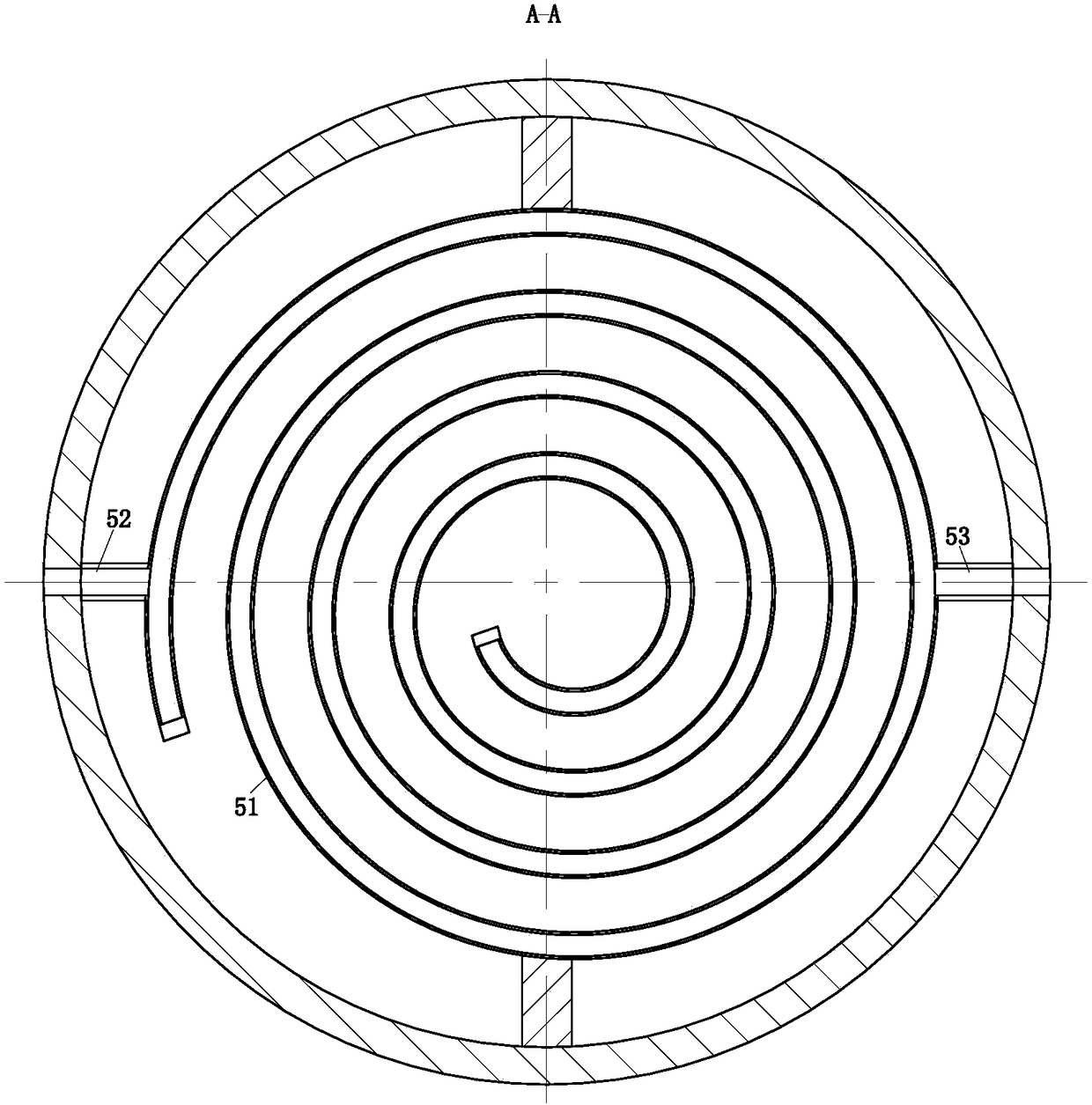

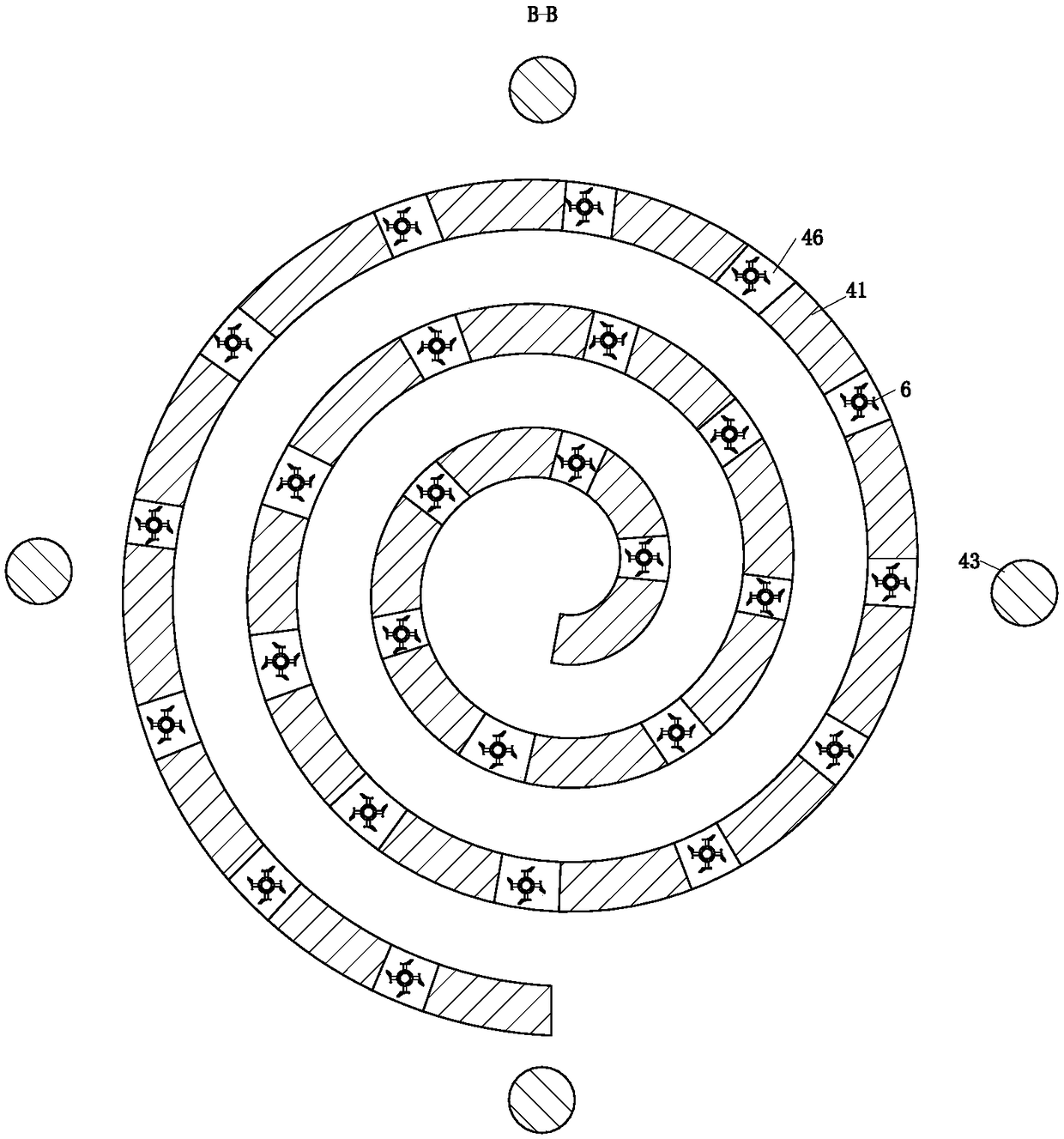

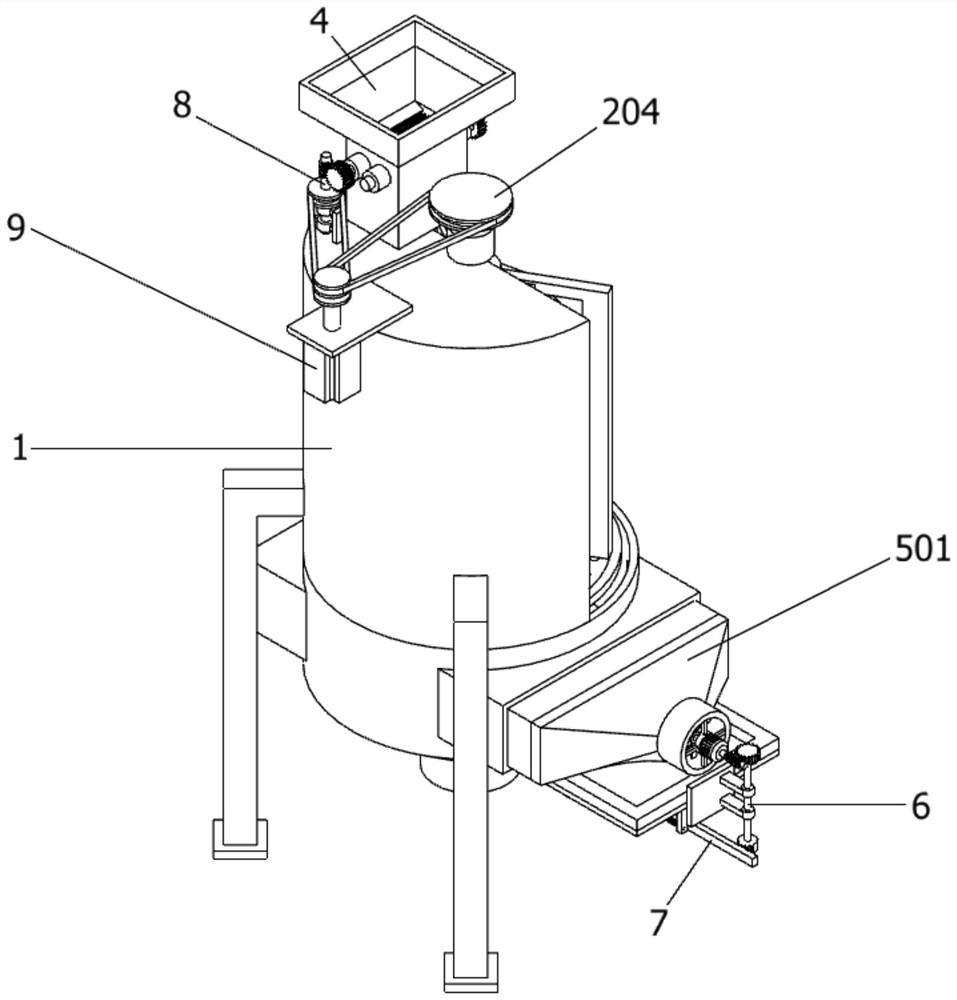

Grease melting stirring system and oil grease melting processing method

ActiveCN104107669AReduce heat lossFast meltingHeat treatmentsRotary stirring mixersOil and greaseControl valves

The invention relates to the technical field of grease processing, particularly to an grease melting stirring system which comprises a liquid grease storage tank, a stirring device, a melting device and a liquid circulation pipe, wherein the melting device comprises a heating layer and a stock bin communicated with the storage tank; the heating layer is arranged on the stock bin; a gap from which melted grease can flow into the stock bin is formed in the heating layer; the melting device further comprises a heat preservation cover; the heat preservation cover is arranged on the stock bin and a heating cavity is formed between the heating layer and the heat preservation cover; one end of the liquid circulation pipe is connected with the storage tank; the other end of the liquid circulation pipe passes through the top of the heat preservation cover to enter the heating cavity; a control valve for controlling liquid to flow and a circulation pump for supplying power for liquid circulation are arranged on the liquid circulation pipe. The invention further provides a grease melting processing method. Compared with the prior art, the grease melting stirring system has the advantages of being simple in structure, convenient to use, high in melting efficiency and convenient to clean.

Owner:SUZHOU DAODAXIN ENG TECH

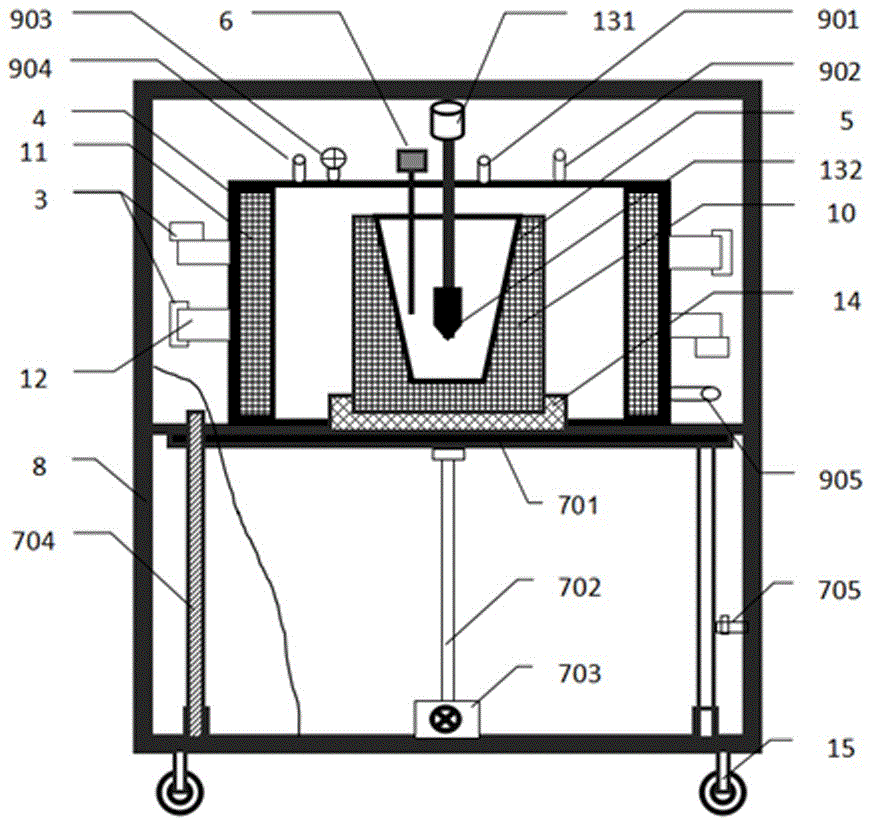

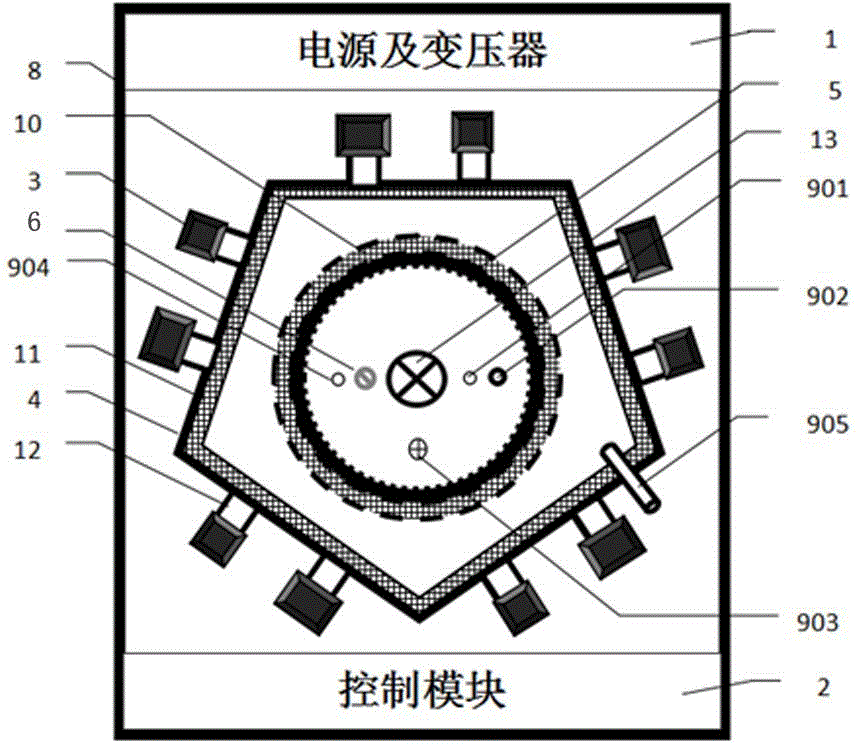

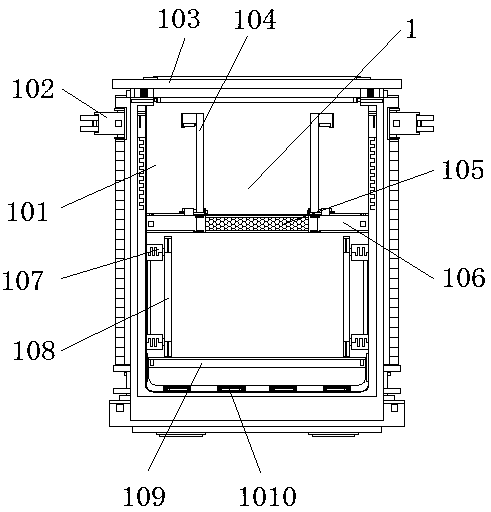

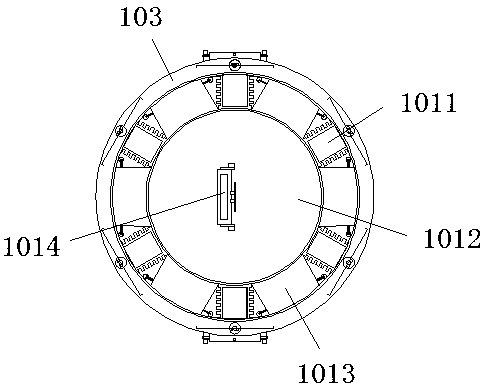

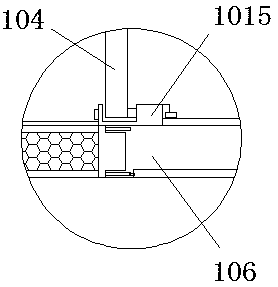

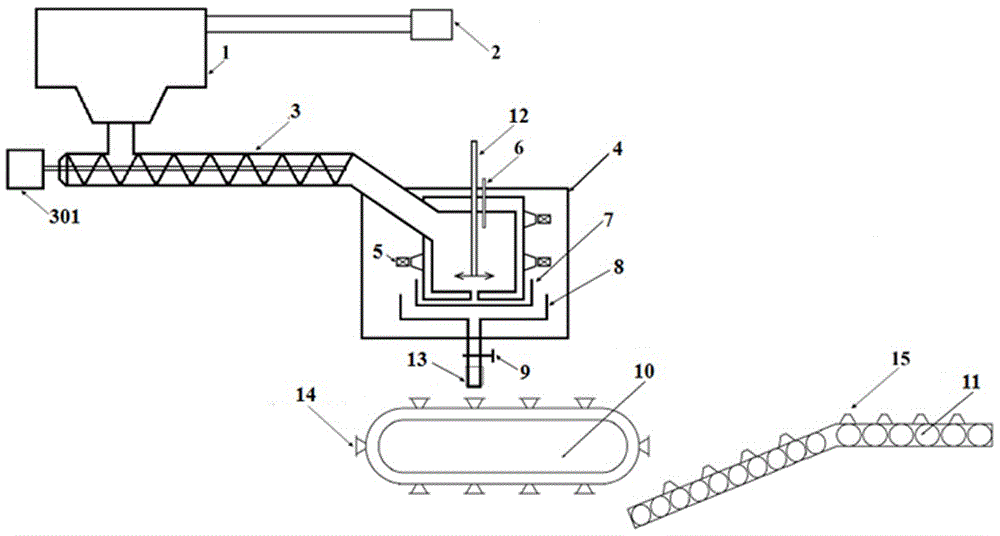

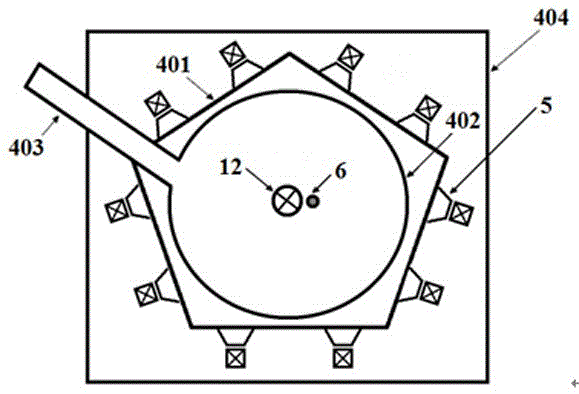

Multifunctional high-temperature microwave metal smelting equipment

InactiveCN106524758AImprove efficiencyReduce processCharge treatment typeCrucible furnacesHeating efficiencyMultiple function

The invention discloses multifunctional high-temperature microwave metal smelting equipment. The multifunctional high-temperature microwave metal smelting equipment comprises a power supply system, a control module, microwave sources, a microwave reaction cavity, a microwave heating container, a temperature measuring device and a discharging device. The wave-absorbing reaction cavity is of an odd number metal structure with not less than five faces and is fixedly connected to a frame of the equipment; the microwaves are arranged on the side walls of the microwave reaction cavity; the microwave sources are connected to the power supply system through the control module; a sealing furnace lid is arranged on the top of the microwave reaction cavity; the temperature measuring device in signal connection to the control module is arranged on the furnace lid; a cavity bottom plate fixedly connected to the microwave reaction cavity is arranged in the bottom of the microwave reaction cavity; a through hole is formed in the center position of the cavity bottom plate and a lifting base of the discharging device is arranged on the lower part; and the wave-absorbing reaction cavity is arranged in the through hole penetrating through the cavity bottom plate and is placed in a wave-transmitting insulating sleeve on the lifting base. The multifunctional high-temperature microwave metal smelting equipment disclosed by the invention has the characteristics of being simple in structure, high in heat efficiency and heating rate, good in heating uniformity, wide in applicability and energy-saving and consumption-reducing.

Owner:KUNMING UNIV OF SCI & TECH

High-intensity wear-resisting complex copper alloy and preparation method thereof

The invention discloses a high-intensity wear-resisting complex copper alloy material and a preparation method thereof. The alloy material comprises the following components in percentage by weight: 63-66% of Cu, 4.5-6.0% of Al, 7.0-8.5% of Mn, 1.0-2.0% of Si, 0.5-1.5% of Fe, 0.3-0.8% of Pb, less than 0.5% of Ni, less than 0.5% of Sn and the balance of Zn. The alloy material has the advantages that good comprehensive mechanical property is achieved, a gear ring made of the alloy material is excellent in abrasion property, the preparation cost of the alloy material is relatively low, the strength of the alloy material is enhanced through metal Al, and the high-hardness wear-resisting Mn5Si3 strengthening phase is formed by metal Mn and Si, so that the wear-resisting property is improved; the cutting machining property of cast brass is effectively improved through adopting the metal Pb, so that the wear resistance is improved; as the quaternary intermediate alloy is subjected to alloying, the melting point of the alloy is lower than the melting point of a high melting point element, so that the melting efficiency is improved.

Owner:武汉泛洲中越合金有限公司

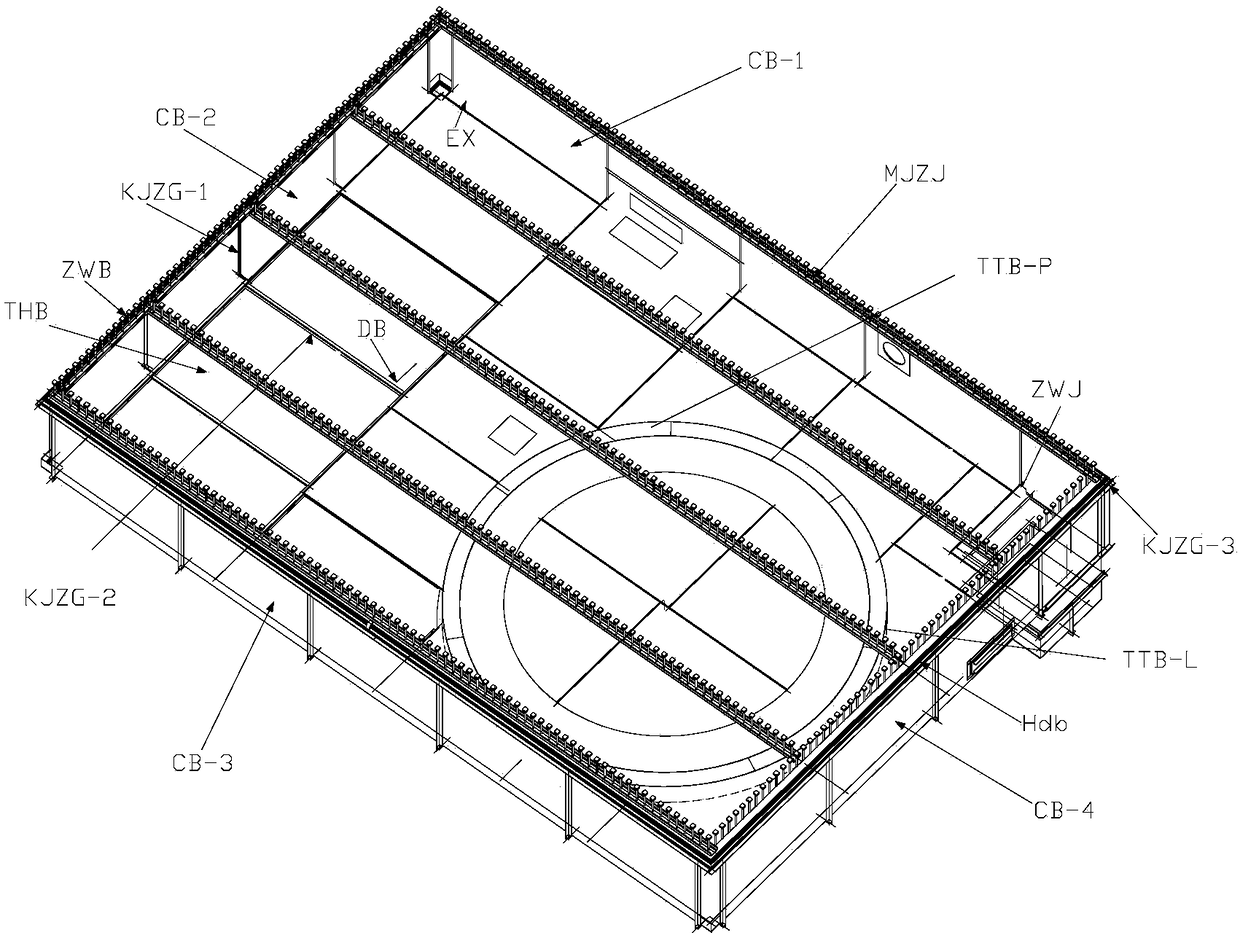

Crystal glass production and manufacturing assembly line

ActiveCN107555763AWell mixedAvoid confusionCharging furnacePolishing machinesAssembly lineGlass melting

The invention relates to a crystal glass production and manufacturing assembly line. A crystal glass dosing device doses different material components of crystal glass proportionally, the dosed material components of the crystal glass are dosed, taken out and conveyed to a feed port of a crystal glass melting device to be heated and melted, a heated and melted crystal glass liquid enters a fixingring of a bubble clarifying device through a discharge port, the crystal glass liquid is heated, a bubble of the crystal glass liquid is clarified, the crystal glass liquid with the bubble clarified enters a pressing forming machine through a glass liquid outlet to be preliminarily pressed and formed, a preliminarily pressed and formed crystal glass plate is conveyed through a grinding groove to acrystal glass polishing device, the surface of the crystal glass plate is grinded and polished, the crystal glass plate is conveyed to a working platform after being grinded and polished, and the edge of the crystal glass plate is finished through a crystal glass edge finishing device.

Owner:石家庄冀超玻璃科技有限公司

Non-protective bottoming welding technology with solid core welding wire for back of staniless steel pipe

InactiveCN1491771AImprove visibilityLess clean upArc welding apparatusWelding/cutting media/materialsShielding gasEngineering

The present invention belongs to the field of welding in material processing engineering, and is used mainly in welding austenic stainless steel in petroleum, chemical, medicine, ship building, food production and other fields. The present invention features that the solid core welding wire ER308L-Si or ER316L-Si is matched with the mixed gas of He 85-94 vol%, Ar 5-10 vol% and CO2 1-5 vol% for the bottoming welding. The present invention needs no back side protecting gas and this simplifies the preparation, lowers the cost and raises the production efficiency. The present invention is especially suitable for welding construction of large and long stainless steel, and in-situ overhead welding operation.

Owner:BEIJING UNIV OF TECH

Methane hydrate collecting device for shallow stratum

The invention discloses a methane hydrate collecting device for a shallow stratum. The device comprises a gas pumping tube and a central rod; a moving block is fixed to the tail end of the central rod; a plurality of heating tubes which are connected in parallel are fixed on the outer wall of the moving block. The device further comprises a collecting cover with an arc-shaped cross section; an annular groove is formed in the outer wall of the gas pumping tube; a plurality of balls are mounted on the inner wall of a through hole; the upper side and the lower side of the collecting cover are respectively connected with the inner walls of two sides of the annular groove through elastic rubber rings; a reflecting plate is mounted on the inner wall of the collecting cover; the thickness of the reflecting plate is gradually increased from the center to two ends; a plurality of reflecting bulges with triangular longitudinal sections are arranged on the inner wall of the reflecting plate. According to the device, combustible ice can be decomposed by grades through the collecting cover and the moving block, so that the heat of the combustible ice can be slowly diffused, the combustible ice cannot be overflowed due to excessively fast decomposing while continuously pumping methane through the gas pumping tube, the influence of production of combustible ice on the environment can be avoided, and as a result, the purposes of increasing the production rate and improving the safety and reliability can be achieved.

Owner:CHENGDU LAIBAO PETROLEUM EQUIP

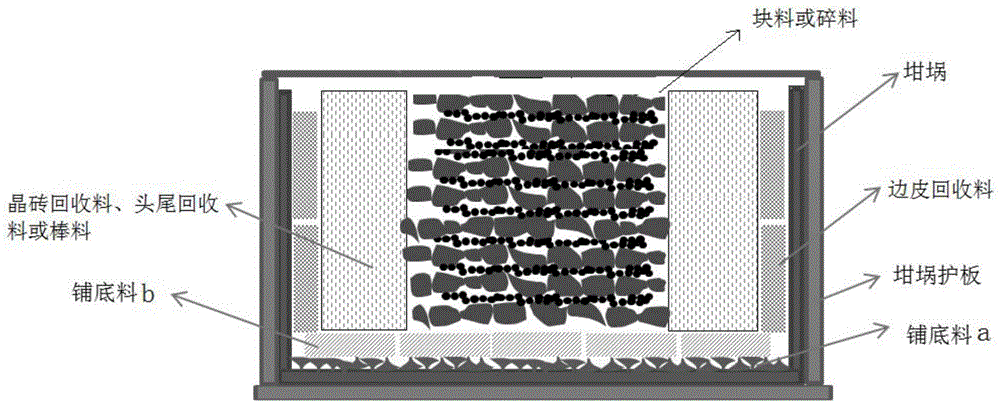

Loading method of high-efficiency crucible for producing polycrystalline silicon

InactiveCN104593862AImprove the role of the crucibleImprove melting efficiencyPolycrystalline material growthSingle crystal growth detailsPolycrystalline diamondCrystallite

The invention provides a loading method of a high-efficiency crucible for producing polycrystalline silicone. The loading method comprises the following steps: (A) selecting a broken silicon material in the size of 3mm to 12mm, pickling the broken silicon material, then rinsing the broken silicon material until no acid remains, drying the silicon material, and packing the silicon material in a splitting manner to obtain a grate-layer material a; selecting a recycled material with the thickness of 3cm to 5cm and the size of 156mm*156mm, placing every five blocks into one package to obtain a grate-layer material b; (B) spraying a layer of grate-layer material a and a grate-layer material b on the bottom of the high-efficiency crucible; (C) laying the leftover recycled material on the periphery of the high-efficiency crucible, stacking a crystal-tile-shaped silicon material and a rod-shaped silicon material at the inner side of the leftover recycled material, and filling a space formed by the crystal-tile recycled material with the blocked silicon material and other smaller silicon materials, and sequentially laying the materials from bottom to top until the loading is ended. The crucible is loaded by utilizing the method, in the ingot casting process, the cold-shock chilling nucleation is not needed, and the high-quality polycrystalline silicon ingots which are uniform and consistent in small grains can be easily obtained.

Owner:YANGZHOU RONGDE NEW ENERGY TECH

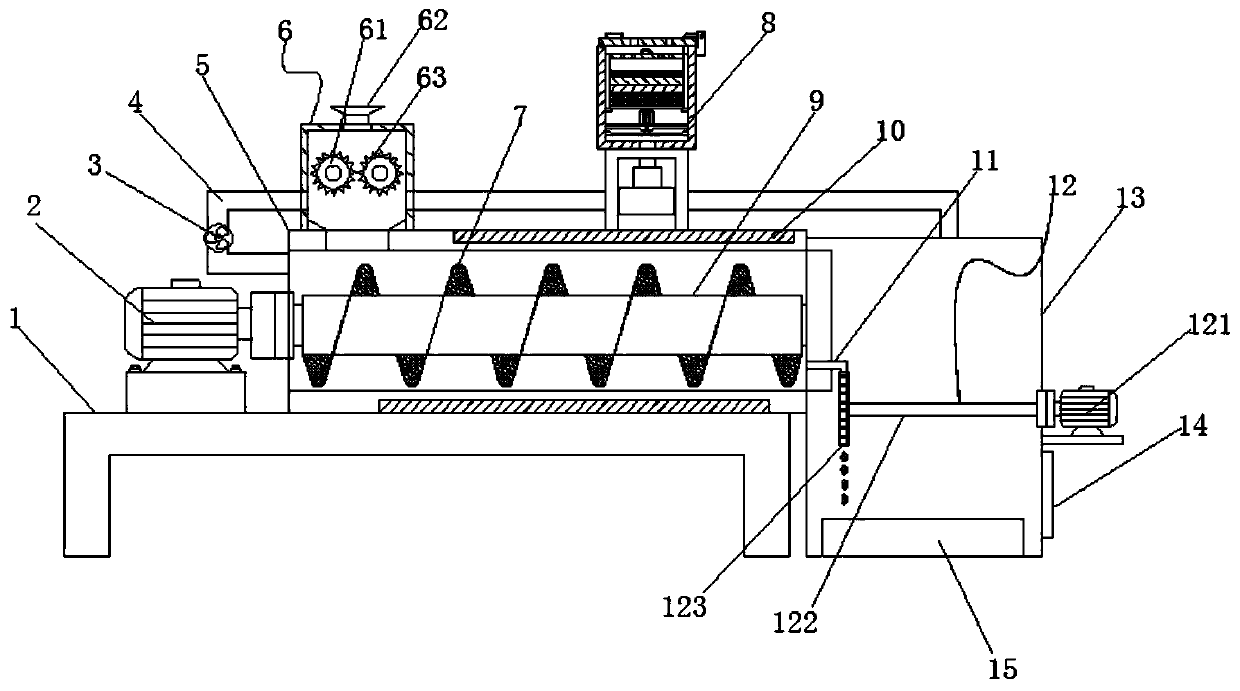

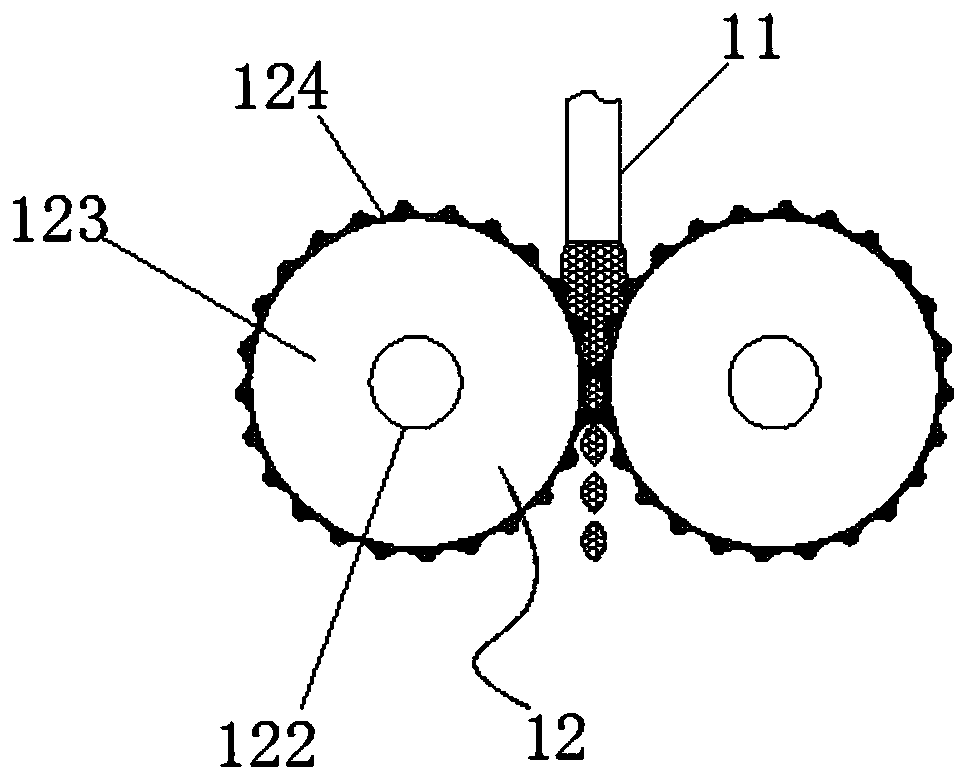

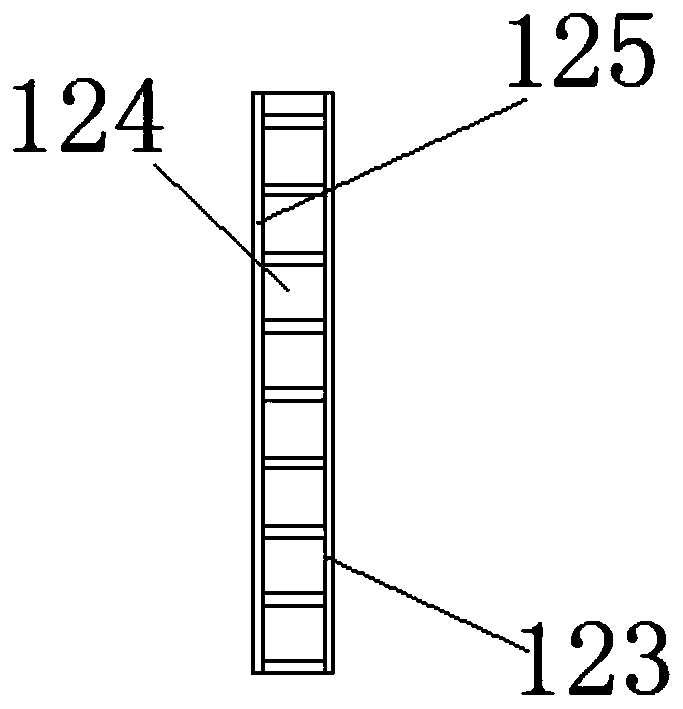

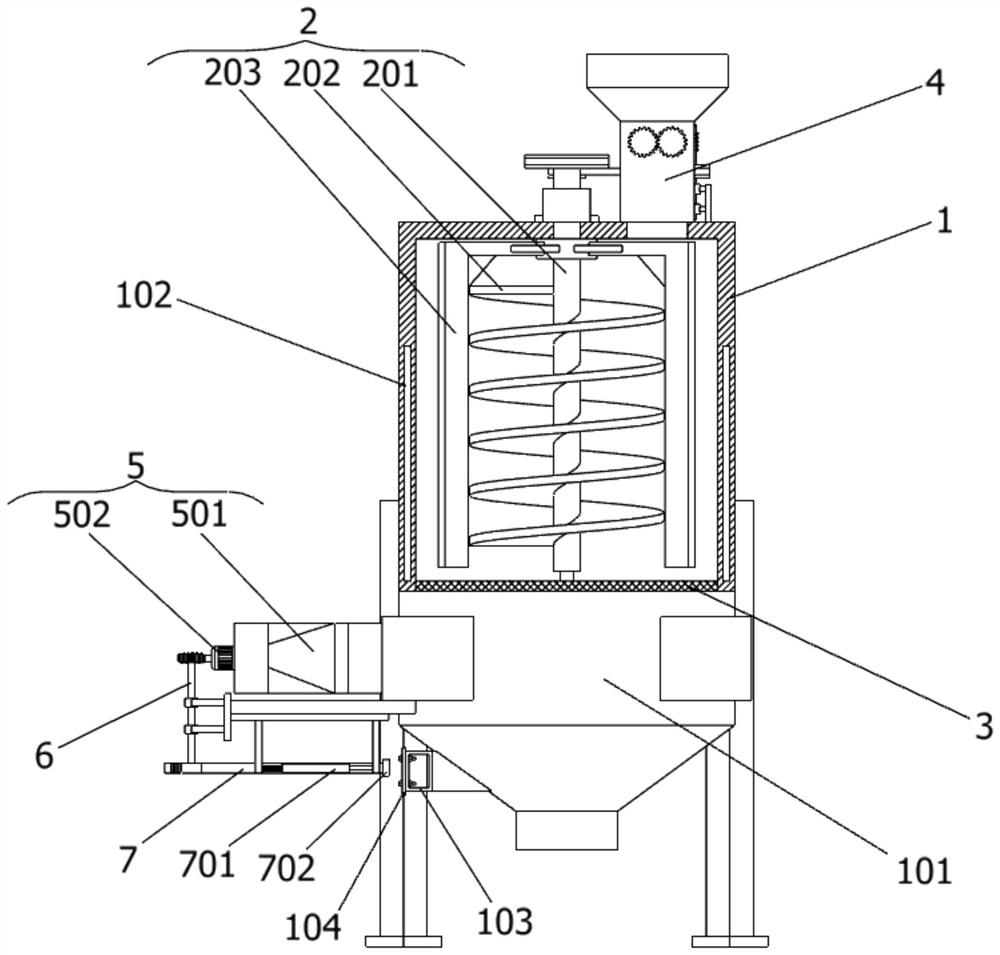

Device for processing polyethylene particles by using waste double-wall corrugated pipe

InactiveCN110682472ASpeed up meltingImprove melting efficiencyDispersed particle filtrationPlastic recyclingActivated carbonGlass fiber

The invention discloses a device for processing polyethylene particles by using a waste double-wall corrugated pipe, and belongs to the technical field of recycling. The device comprises a screw extruder, wherein a connected crushing box is arranged at the upper end of the screw extruder, and a heating tube is arranged on the inner side wall of the screw extruder. The device filters exhaust gas inthe production process through a filter cartridge in a purification filter assembly and then discharges the exhaust gas to the environment. A glass fiber mat layer, a metal sintered mesh layer, a glass fiber filter layer and an activated carbon layer inside filter cartridge effectively adsorb and filter the exhaust gas, ensuring the cleanness of the exhaust gas and avoiding pollution to the environment. At the same time, the filter cartridge is simple and convenient to install and dismantle, and is convenient to clean, and the internal filter net layer is convenient to replace. The polyethylene melt stream is formed first and then cooled by a forming component, which reduces a series of steps such as the traditional thin strip cooling and then coiling, and disadvantages such as the thin strip breaking during the coiling process, thereby improving production efficiency.

Owner:安徽超星新材料科技有限公司

Stainless steel water tank for nuclear power station and welding method

InactiveCN108172313ARealize continuous weldingImprove welding productivityNuclear energy generationArc welding apparatusNuclear powerShielding gas

The invention discloses a stainless steel water tank for a nuclear power station and a welding method. The MIG semi-automatic welding is adopted for the welded weld joints: the electric arc burnt between the continuously-fed welding wire and the workpiece is used as a heat source, the welding wire is molten by the electric arc and is sent into the welding area, and the arc is protected by the protective gas sprayed out by a welding torch nozzle; the diameter of the welding wire is 0.8-1.2mm, the welding current is 42 -90 A, the arc voltage is 18-24 V, and the protective gas flow is 10-15 L / min, and the temperature between the layers is 5 DEGC <=T<=150 DEG C; the protective gas is the mixed gas of argon and helium, and the content ratio of the argon to helium is 15-20:85-80. The stainless steel water tank adopts MIG semi-automatic welding. Meanwhile, the fillet welding joints of the installation of an accessory structure, an anchor rib assembly pair, an anchor rib assembly, a top platepair, welded nails, a shooting plate groove pair, and a cover plate supporting system are welded. Full-position welding can be carried out, the welding speed is high, and the deposition efficiency ishigh.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD +1

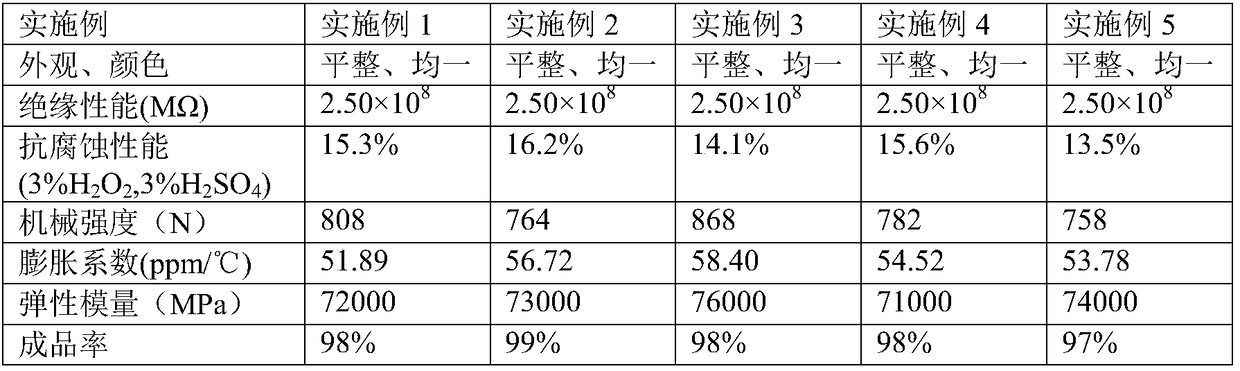

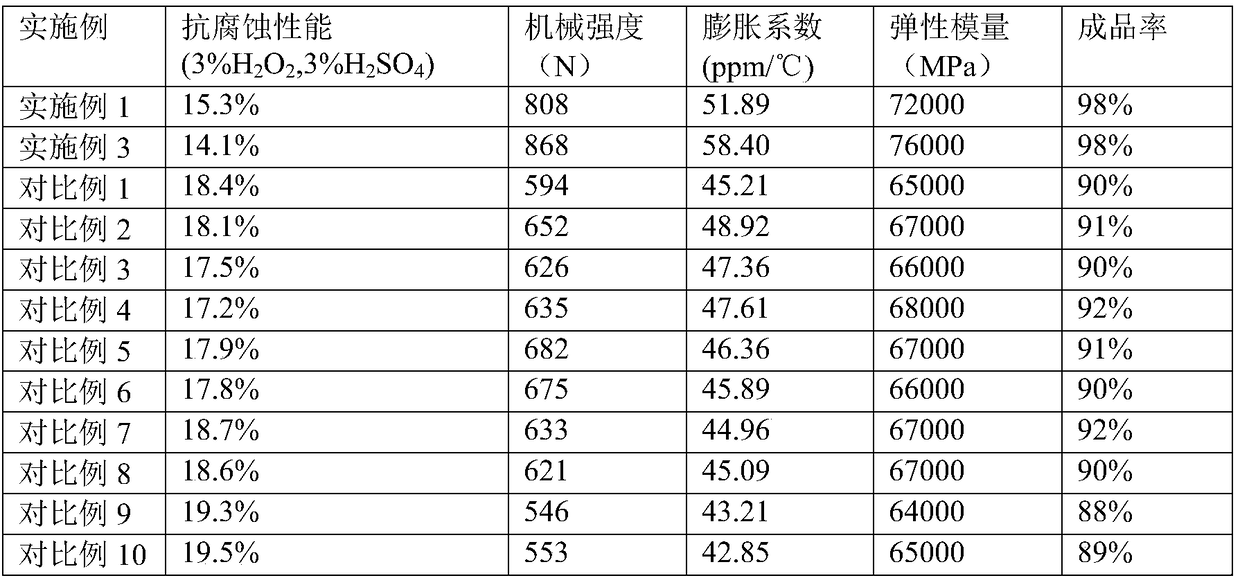

High strength glass fiber, and preparation method thereof

ActiveCN109180009AGuaranteed contentImprove protectionGlass fibre drawing apparatusGlass fiberPyrophyllite

The invention discloses a high strength glass fiber. The high strength glass fiber mainly comprises, by weight, silica sand, kaolin, calcite, fluorite, calciborite, mirabilite, and sodium carbonate. The invention provides a glass fiber raw material formula can be used for replacing pyrophyllite. Glass material preparation uniformity is increased obviously through reasonable control on the mass ratio of a plurality of raw materials, melting efficiency is increased, glass fiber finished product rate is increased, the prepared glass fiber is better in mechanical properties, and production cost isreduced. The invention also provides a preparation method of the glass fiber. No stirring is needed; glass liquid is mixed to be uniform by heat convection in a bath tank, and is used for preparationof glass fiber. The glass fiber prepared based on the formula and the preparation method is high in finished product rate, and excellent in corrosion resistance.

Owner:清远忠信世纪电子材料有限公司

Polyurethane foaming system

The invention belongs to the technical field of polyurethane production equipment and particularly discloses a polyurethane foaming system. The polyurethane foaming system comprises a dual stirring unit and a water control unit, wherein a heating cylinder is fixedly mounted on the upper surface of an upper bottom plate II; a stirring bin is located in the heating cylinder; a water storage bin is located between the outer wall of the heating cylinder and a side plate I; a foaming bin is located between the upper bottom plate II and a lower bottom plate I; the dual stirring unit is located in the stirring bin; the water control unit is located in the foaming bin; a spiral plate I is fixedly mounted at the lower end of a connection rod I through a mounting rack I; the upper end of the connection rod I is fixedly connected with a mounting rack II; a spiral plate II is fixedly mounted on the lower surface of the mounting rack II. The invention discloses a processing method of dual stirringtype polyurethane heat insulation boards. The polyurethane foaming system is mainly used for producing the polyurethane heat insulation boards and is capable of rapidly and uniformly mixing the raw materials, accelerating the melting of the raw materials and improving the foaming quality of the raw materials.

Owner:于泽

Environment-friendly granulator for recycling waste plastics

InactiveCN112917751AImprove melting efficiencyShort melting timePlastic recyclingGrain treatmentsElectric machineryProcess engineering

The invention provides an environment-friendly granulator for recycling waste plastics, belongs to the technical field of granulators, and aims to solve the problem that when the granulator downwards extrudes molten plastics, the extruded molten plastics have relatively high viscosity and easily adhere to the inner wall of a discharging receiving hopper. The environment-friendly granulator for recycling the waste plastics comprises a barrel body, wherein a rotary driving mechanism is arranged at the upper end in the barrel body, and a screen is mounted at the lower end in the barrel body; and a crushing hopper is arranged on the right side of the top end surface of the barrel body, and a cooling mechanism is arranged on the lower portion of the left side of the barrel body. Through the arrangement of the cooling mechanism, an air blowing motor is started, a double-end rotating shaft of the air blowing motor drives air blowing fan blades and a second worm to rotate correspondingly, external air is blown into an air blowing cover through the rotating air blowing fan blades, then air is evenly blown away to the granular molten plastics in the cut-off and falling process through air blowing holes in the air blowing cover, so that the granular molten plastics are rapidly cooled, and the granular molten plastics are not prone to adhering to the inner wall of the discharging receiving hopper.

Owner:田峰

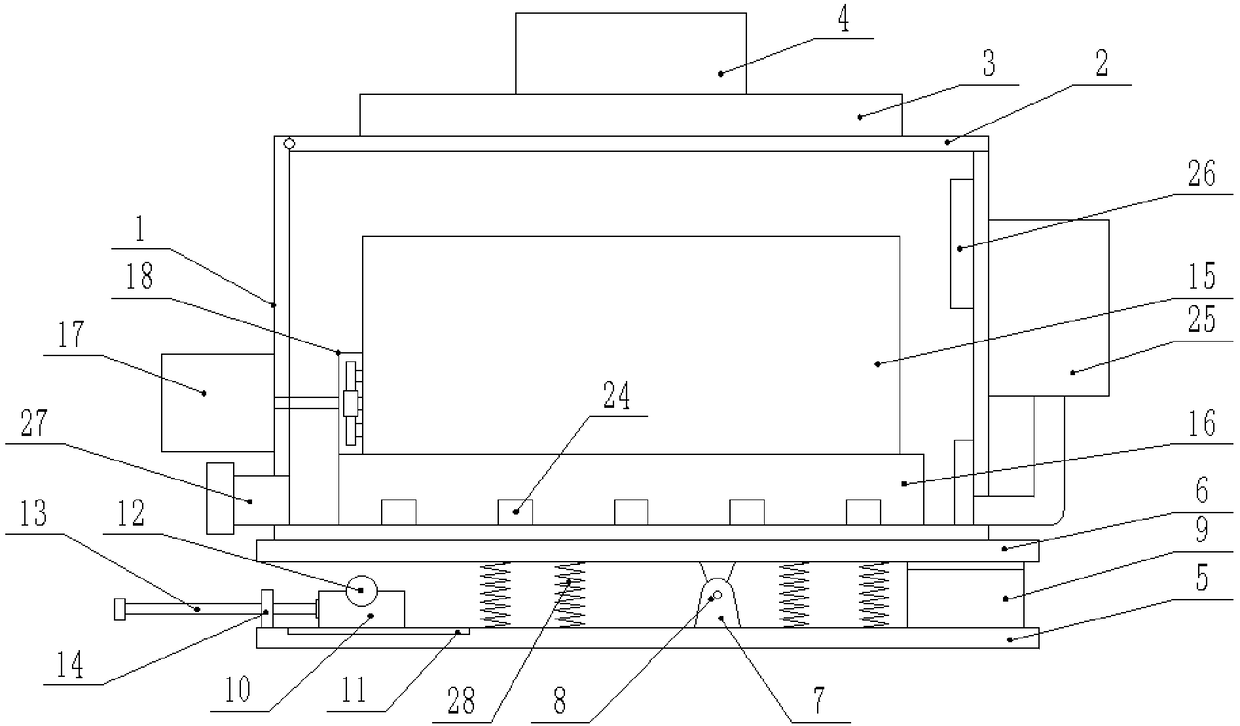

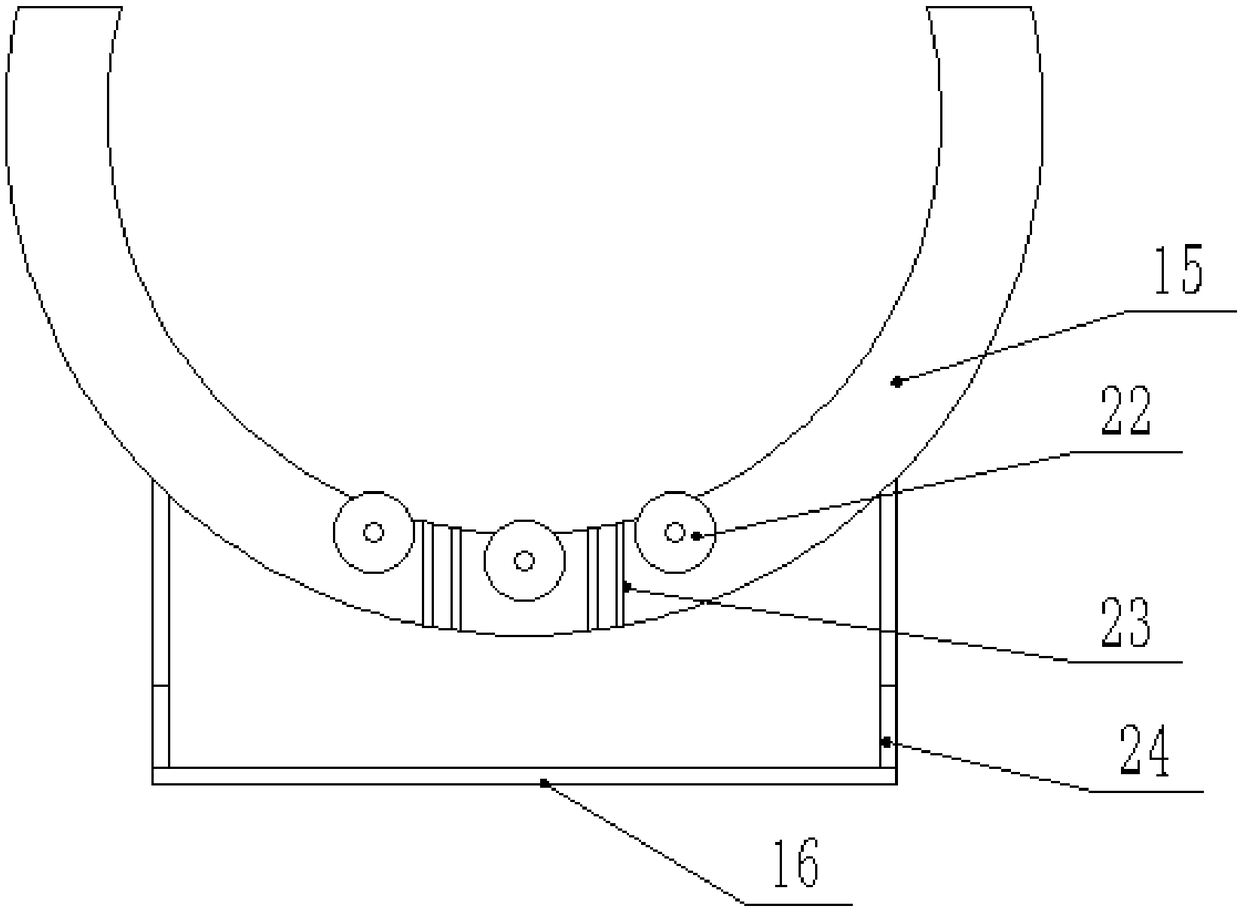

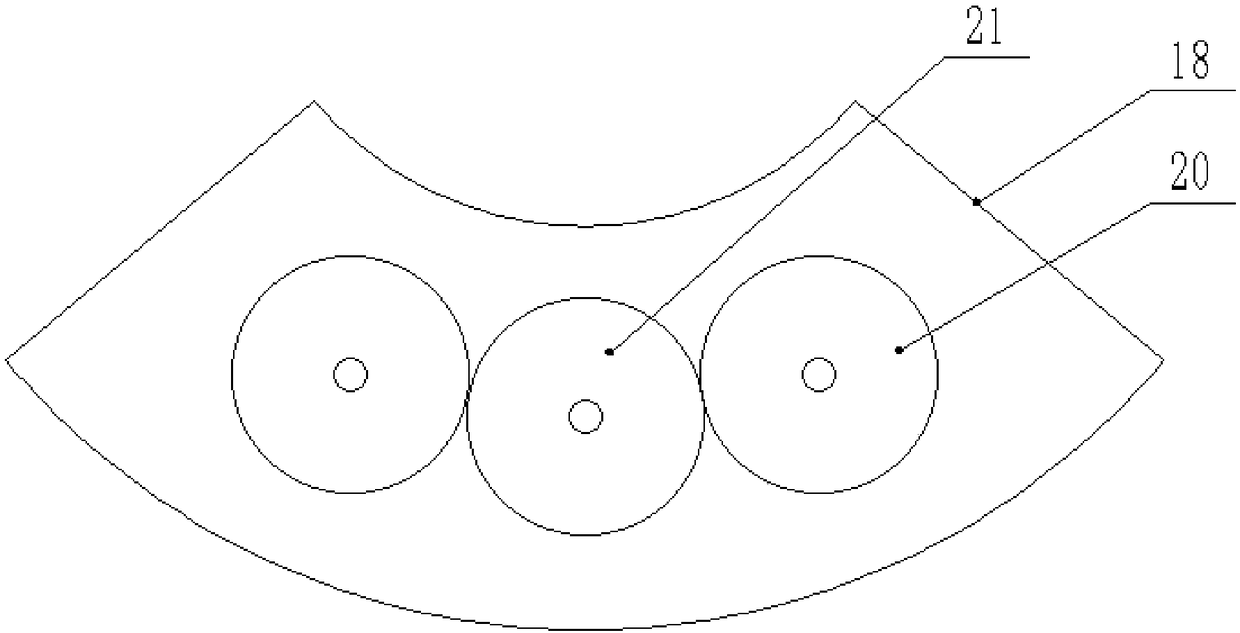

Rotary type rapid thawing device for frozen food

InactiveCN108056359AImprove melting efficiencyImprove thawing efficiencyFood preservationGear wheelElectric machinery

The invention discloses a rotary type rapid thawing device for frozen food. The rotary type rapid thawing device comprises a shell, an upper cover, a heating box, a fan, a base plate and a mounting plate; the base plate is connected to the mounting plate in a rotating mode; a supporting rubber block and an angle adjusting supporting mechanism are arranged between the base plate and the mounting plate; a supporting box is fixedly arranged at the bottom of the interior of the shell; a horizontal frozen food placing groove is fixedly arranged at the top of the supporting box; a transmission box is connected to an output shaft of a motor; horizontal stirring rollers are connected to the positions, corresponding to a driven gear and a driving gear, in the frozen food placing groove; and the bottom of the interior of the shell communicates with a circulating pump through a pipeline. The rotary type rapid thawing device has the advantages that the frozen food is placed in the frozen food placing groove for thawing, the stirring rollers at the bottom of the food are driven to rotate by the motor, the food is driven to rotate, the different surfaces of the food are enabled to face upwards,so that hot air can directly act on the different surfaces of the food, and therefore the thawing efficiency of the food is improved.

Owner:黄利伟

Microwave equipment capable of continuously smelting metal powder

InactiveCN106524759AImprove melting efficiencyReduce processMaintainance of heating chambersCrucible furnacesMicrowave cavityCrucible

The invention discloses microwave equipment capable of continuously smelting metal powder. A microwave cavity of a microwave furnace is of an odd-number-hedron metal structure with no less than five planes; a microwave generator is installed on each of the side walls of the microwave cavity; the microwave generators are connected with a power source system through controlling units; a smelting crucible is installed in the microwave cavity; a temperature detection device is installed at the top of the microwave cavity; the temperature detection device extends to the smelting crucible and is connected with the controlling units in a signal mode; a conveying pipe communicating with a discharging port of a spiral feeder is installed on the smelting crucible; a feeding port of the spiral feeder communicates with a carrying bin; the carrying bin is of a closed bin capable of being opened and closed and communicates with an air supplying pipe of an atmosphere protection system; an unloading port is formed in the bottom of the smelting crucible and communicates with an overflow channel in the lower portion of the smelting crucible; a pouring trough is formed in the lower portion of the overflow channel, and the edge of the pouring trough is larger than that of the overflow channel; a pouring port is formed in the bottom of the pouring trough; a pouring control valve is installed on the pouring port; and an ingot casting machine is installed at the lower end of the pouring port. The microwave equipment capable of continuously smelting the metal powder has the characteristics that the production efficiency is high, energy consumption is low, the metal recovery rate is low, and the application range is wide.

Owner:KUNMING UNIV OF SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com