Rotary type rapid thawing device for frozen food

A frozen food, rotating technology, applied in the field of rotating frozen food rapid thawing device, can solve the problems affecting food processing, long thawing time, food heating, etc., to achieve the effect of improving melting efficiency, ensuring integrity, and improving thawing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

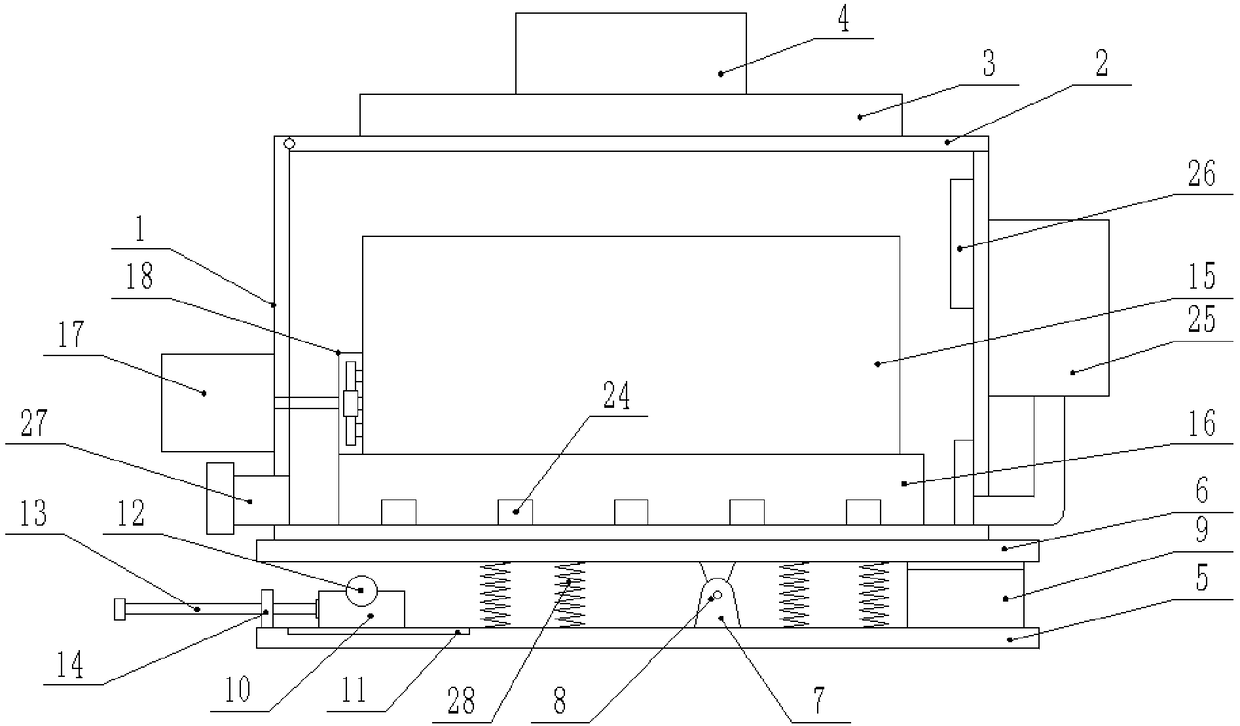

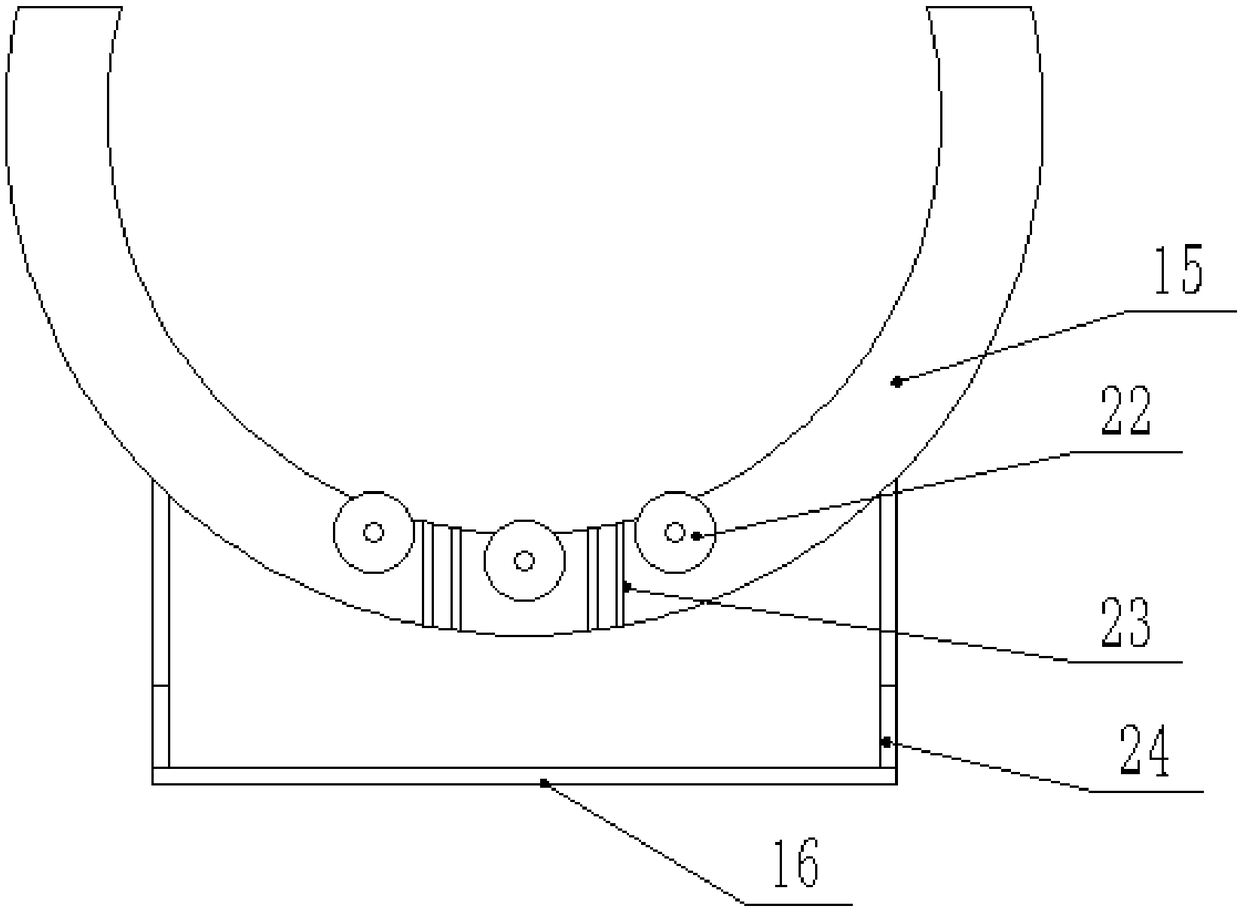

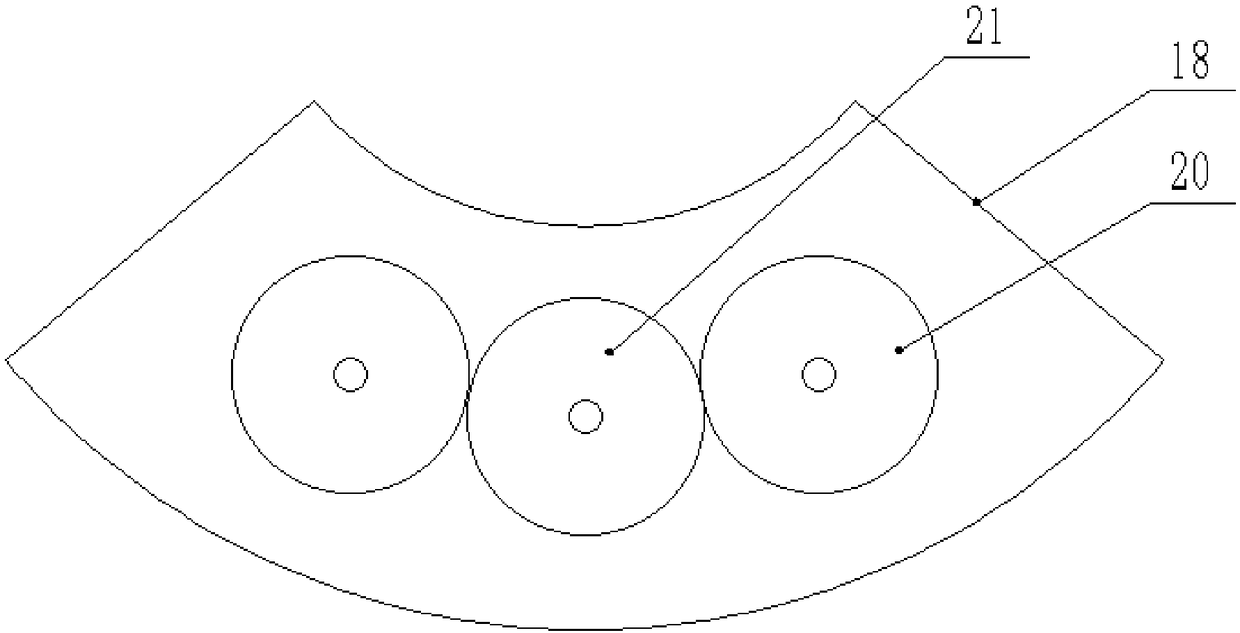

[0018] Please refer to the figure, in the embodiment of the present invention, a rotary frozen food quick thawing device includes a housing 1, an upper cover 2, a heating box 3, a fan 4, a bottom plate 5 and a mounting plate 6; The page is rotatably connected to the housing 1, the housing 1 is fixed on the mounting plate 6, the bottom plate 5 and the mounting plate 6 are arranged in parallel, a bearing seat 7 is fixedly installed on the mounting plate 6, and a rotating shaft 8 is pierced in the bearing seat 7. The rotating shaft 8 is fixed on the mounting plate 6, so that the base plate 5 and the mounting plate 6 are connected in rotation, and the bearing seat 7 is located on the right side of the midpoint of the base plate 5, so that the center of gravity on the mounting plate 6 is located on the left side of the bearing seat 7; A supporting rubber block 9 and an angle adjustment support mechanism are arranged between the base plate 5 and the mounting plate 6, the height of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com