Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

84results about How to "Realize continuous welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

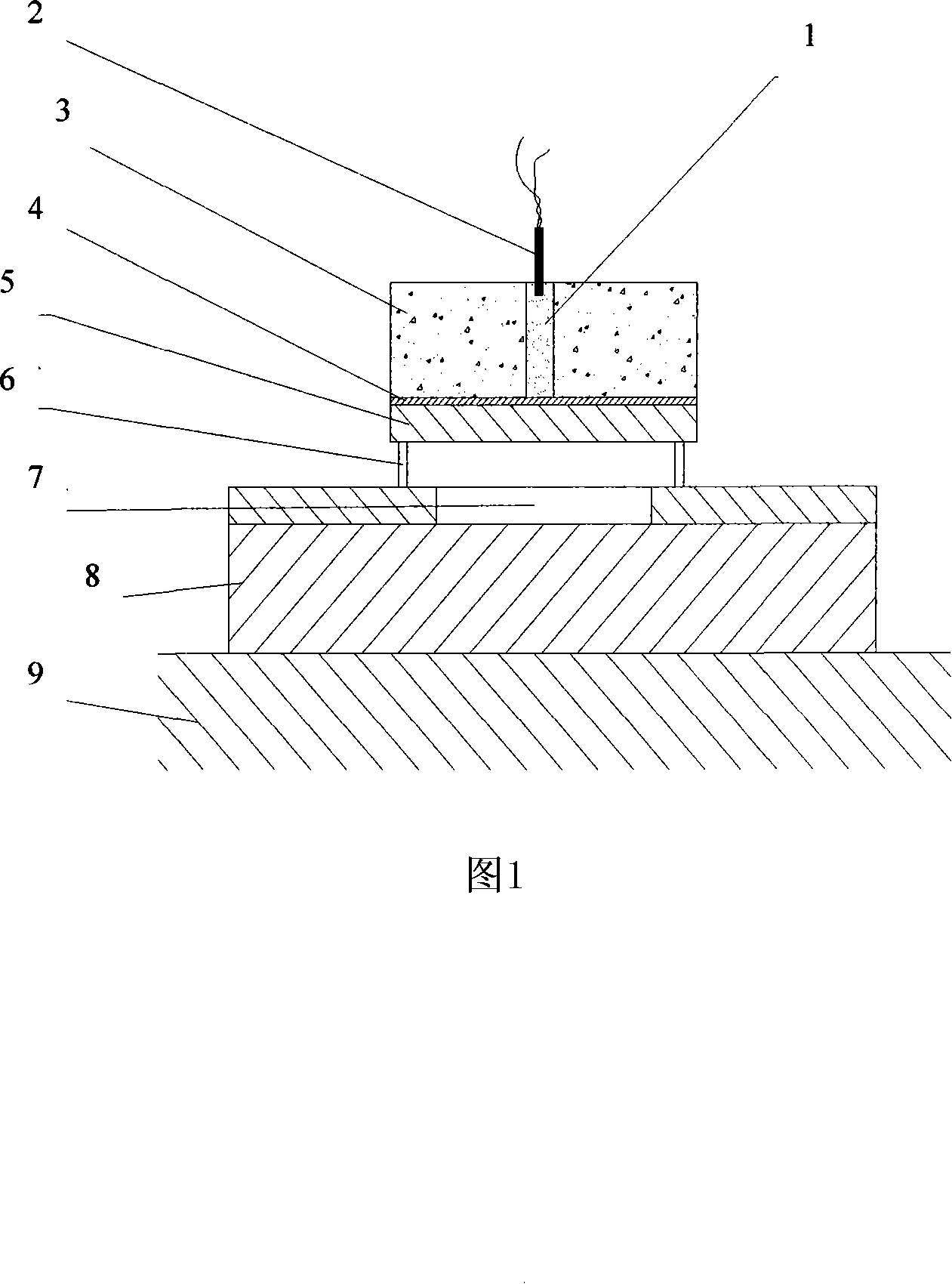

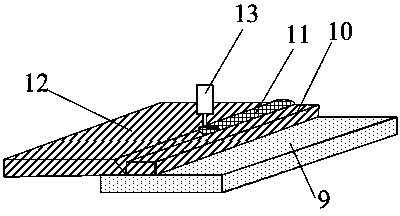

Explosion welding repair method of infusible uncommon metal composite board

InactiveCN101108444ARealize continuous weldingWelding/soldering/cutting articlesMetal working apparatusFire pointExplosion welding

An explode welding repairing method which is hard to dilute metal compound board, firstly, the thickness of hard-diluting metal board is larger than the original board material by 0.5 to 1mm, the area of board material is larger than a defect zone by 20 to 60 mm2; secondly, proceed fine polishing to the compound board at the position under epair; thirdly, put rare metals on the surface under epair, the compound board under epair is made as the lower layer of base board; fourthly, the rare metal board and a placode under epair, the enlarged supporting gas between the two boards adopts edge supporting, the gap is of 7 to 10mm and laid in parallel; fifthly, the rare metal board surface after protecting is distributed with explode evenly, the protecting layer uses lubricate resin adding thinner, the thickness of the protecting layer equals to 0.5 to 1mm; sixthly, the size of the fire point is controlled below the diameter of 15mm; seventhly, after exploding compound, the invention is level to the main material after heat process, flattening and repairing and abrasion of the connection edge.

Owner:南京三邦新材料科技有限公司

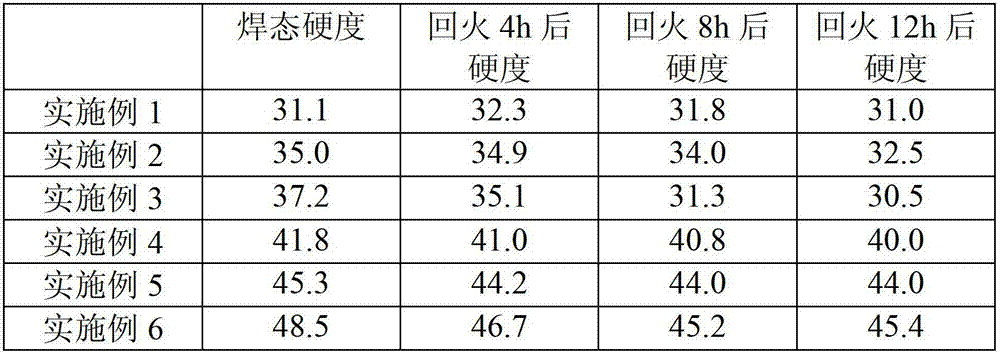

Gas-shielded overlaying flux cored soldering wire for repairing hot-forging mould

ActiveCN102029482ASimple welding processGood welding wire crack resistanceArc welding apparatusWelding/cutting media/materialsCrack resistanceFerrosilicon

The invention discloses a gas-shielded overlaying flux cored soldering wire for repairing a hot-forging mould, which is manufactured by taking SPCC-SD cold-rolling low-carbon steel belts as raw materials of a soldering wire and utilizing a conventional flux cored transient alloy way, a universal flux cored standard and a flux cored soldering wire manufacturing technique. The soldering wire flux core contains fluoride, calcium carbonate, feldspar, magnesia and alloy powder according to a proportion, wherein the fluoride comprises calcium fluoride, sodium fluoride and barium fluoride, and the alloy powder contains iron powder, high-carbon ferrochrome, electrolytic manganese, ferrosilicon, ferromolybdenum, ferrovanadium, nickel powder, tungsten powder and cobalt powder. The invention has the following beneficial effects: because the gas-shielded overlaying flux cored soldering wire takes CO2 or a gas mixture with volume percentage ratio of 80% Ar and 20% CO2 as the protective gas, the gas-shielded overlaying flux cored soldering wire has the advantages of great soldering technique, stable electric arc, less splash, easy deslagging, good crack resistance, great high-temperature hardness and thermal fatigue resistance, continuous soldering and improvement on production efficiency.

Owner:TIANJIN YONGCHANG WELDING WIRES

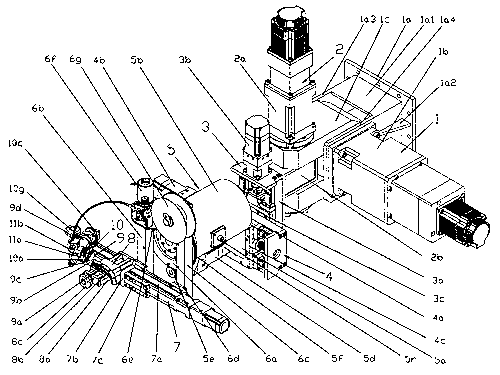

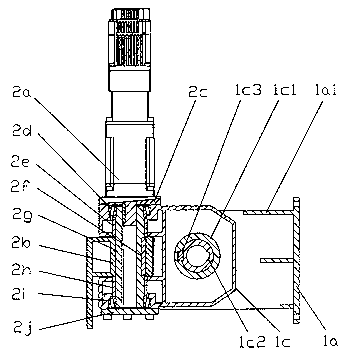

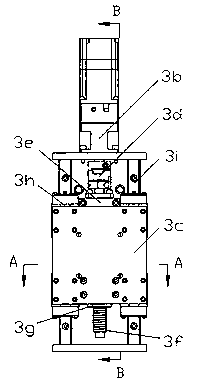

Flange sealing groove inner surface annular all-position TIG (Tungsten Inert Gas) automatic surface welding equipment and welding method thereof

InactiveCN102825368AExcellent surfacing qualityEasy post-weld processingArc welding apparatusElectrical controlElectric control

The invention provides a flange sealing groove inner surface annular all-position TIG (Tungsten Inert Gas) automatic surface welding equipment and a welding method thereof, belonging to the technical field of automatic welding equipments and welding methods. The automatic welding equipment mainly comprises a position regulation mechanism and a TIG rotary welding head, wherein the TIG rotary welding head is used for regulating a surface welding position of a flange sealing groove through the position regulation mechanism. An electric control device is used for setting parameters such as welding current, a wire feed speed, a welding speed and arc voltage control according to the circumferential position located by the welding head and a cycle of 12 preset partitions so as to carry out welding control. The rotational radius of the welding head can be automatically changed inwards or outwards according to set width after a cycle of welding is finished, so that surface welding in the flange sealing groove is realized, and surface welding on the side surface of the flange sealing groove is carried out after an angle of a welding gun is changed until one end surface is piled up. The surface welding surface is smooth, so that the problems of cutter beating and long processing time in the process of processing the flange sealing groove by manual surface welding at a later stage are avoided, surface welding quality is superior to quality of manual surface welding, and the problem that a product is repaired due to defects after manual surface welding is reduced.

Owner:CHINA FIRST HEAVY IND +1

High-hardness high-cracking-resistance gas shielding bead weld flux-cored wire and manufacturing method

ActiveCN103862195AImprove crack resistanceReduce moistureWelding/cutting media/materialsSoldering mediaCrack resistanceAlloy

The invention provides a high-hardness high-cracking-resistance gas shielding bead weld flux-cored wire and a manufacturing method. An SPCC-SD cold rolling low-carbon-steel steel belt serves as welding wire raw materials, and a welding wire flux core comprises fluoride, calcium carbonate, feldspar, rutile, magnesia and alloy powder. The manufacturing method includes the steps of baking, powder blending, belt cutting, padding molding, drawing, conducting winding in a layered mode, packaging and the like. The high-hardness high-cracking-resistance gas shielding bead weld flux-cored wire has the advantages that the welding process is good, electric arcs are stable, splashing is small, residues are easy to remove, welding wires have the high cracking resistance, and the Rockwell hardness HRC is higher than 60. Continuous welding can b achieved, and the production efficiency is improved.

Owner:TIANJIN YONGCHANG WELDING WIRES

Flux-cored wire for welding low-temperature steel and preparation method thereof

ActiveCN104439760AOxygen limitationLimited diffusible hydrogen contentWelding/cutting media/materialsSoldering mediaRare-earth element% diameter reduction

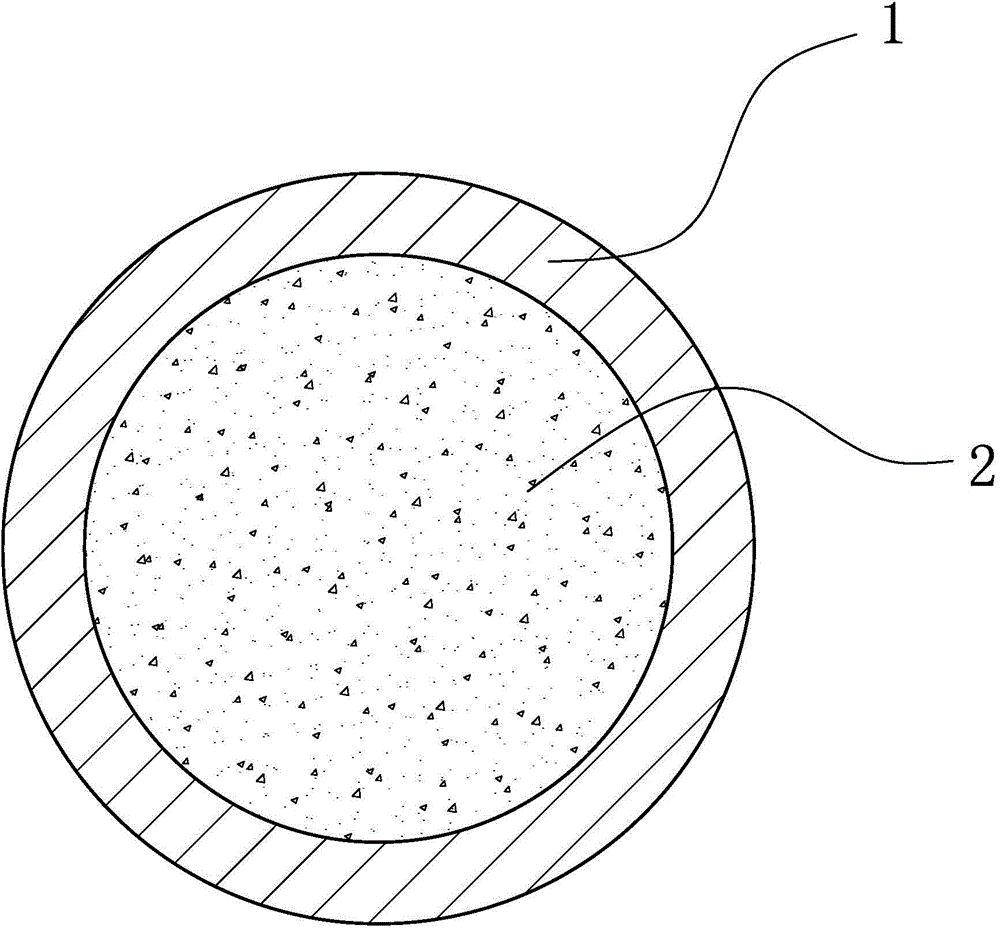

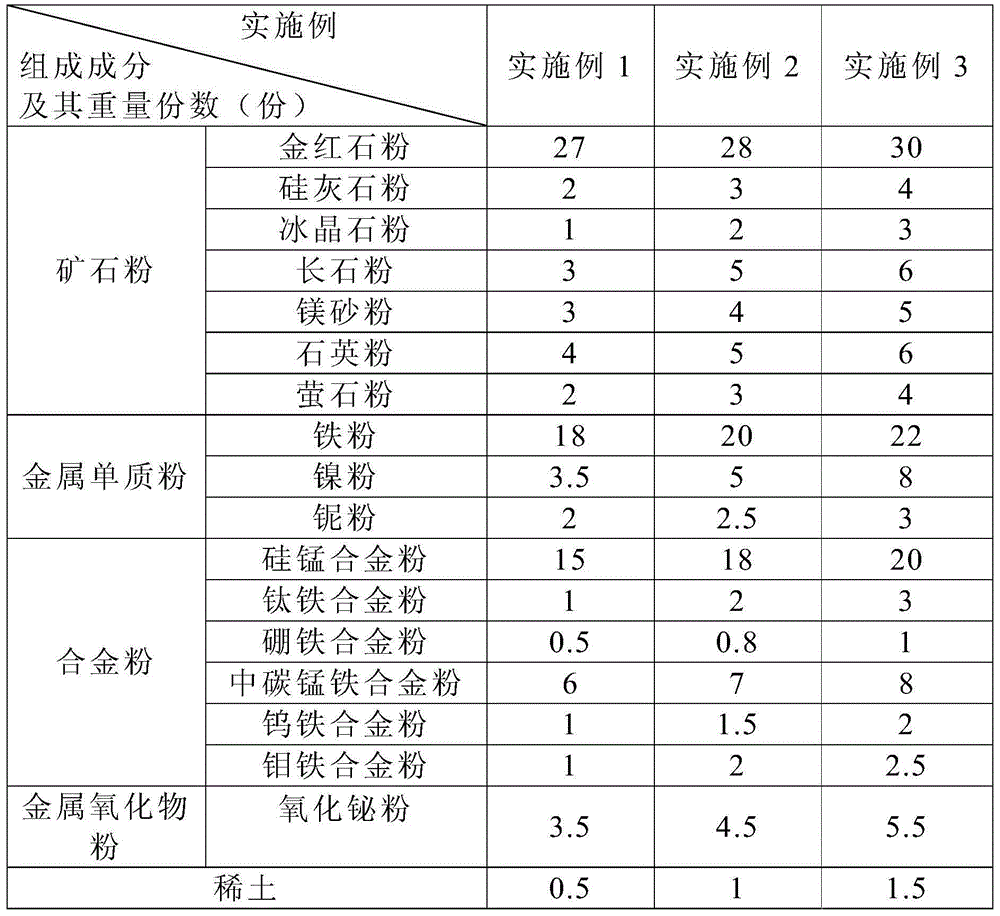

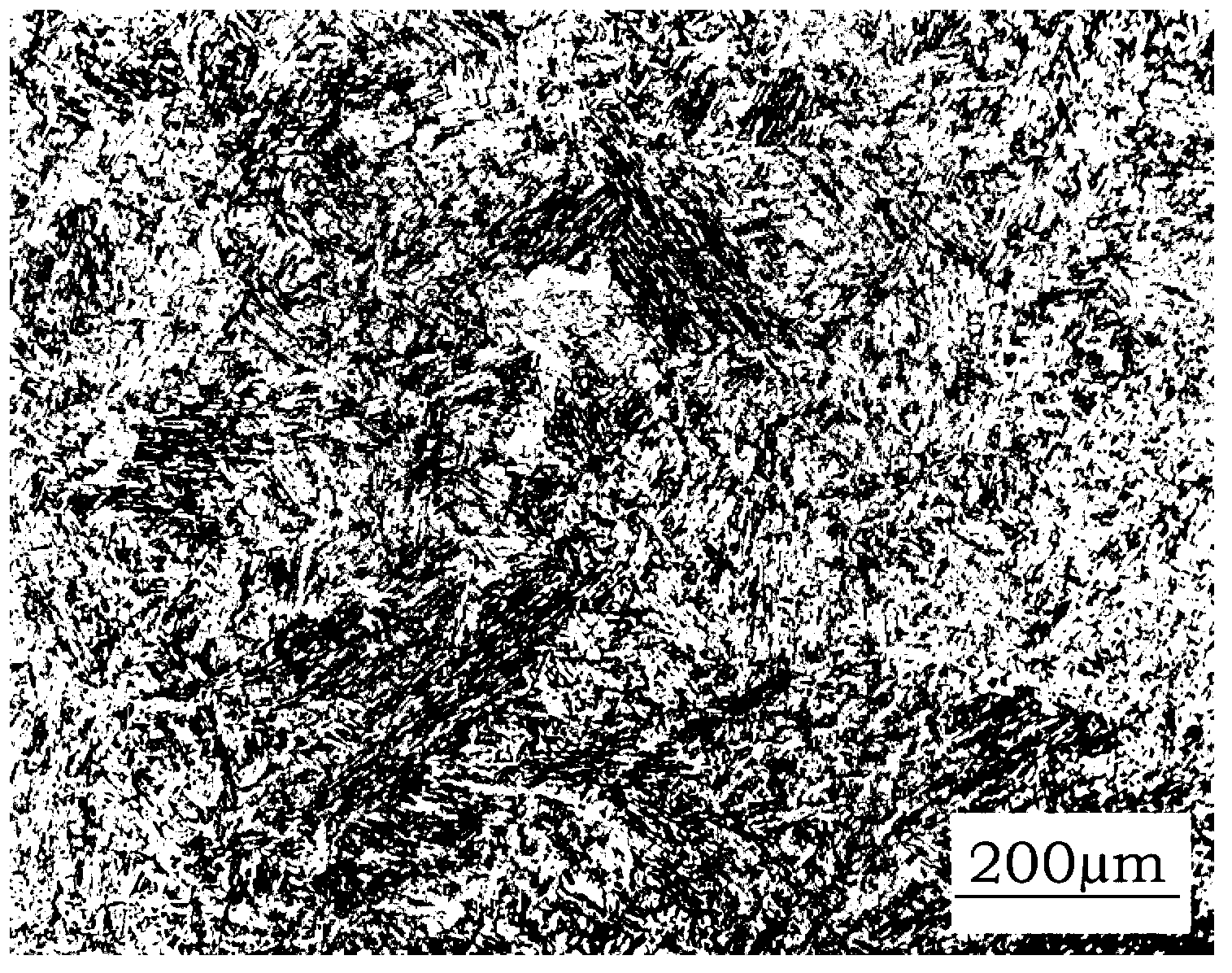

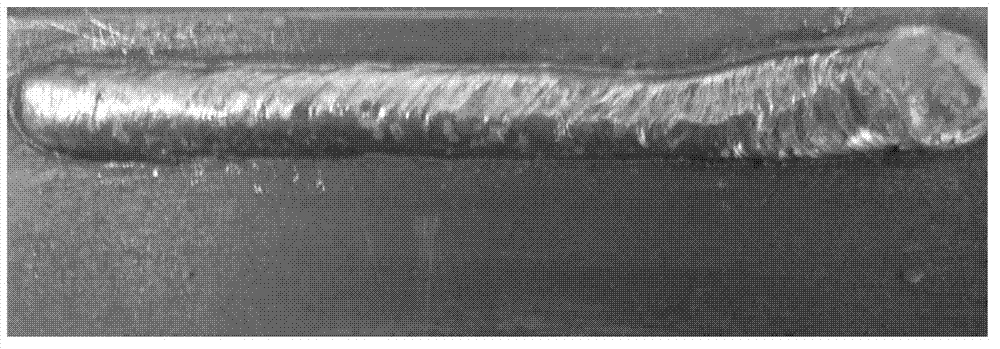

The invention relates to a flux-cored wire for welding low-temperature steel. The flux-cored wire comprises a cylindrical skin, wherein a through hole penetrating through the skin along the axis line is formed in the skin, and the through hole is filled with flux core powder composed of mineral powder, metal simple-substance powder (except rare earth elements), alloyed powder, metal oxide powder and rare earth. According to a preparation method of the flux-cored wire, the flux core powder is prepared first and then added into a U-shaped groove which is formed by drawing a steel belt; next, after an opening of the U-shaped groove is closed, the through hole penetrating through the steel belt is formed in the axial direction of the steel belt, and the flux core powder is arranged in the through hole; lastly, the flux-cored wire is obtained by means of step-by-step drawing and diameter reduction. The flux-cored wire can be welded in all directions, the welding efficiency is high, and weld joints are stable in metal performance and more attractive in appearance; besides, the average impact work of deposited metal at the low temperature of minus 60 DEG C can reach 65 J, so that the properties such as low-temperature impact toughness and low-temperature anti-cracking performance are improved to a higher grade.

Owner:NINGBO LONGXING WELDING CUTTING TECH STOCK

Flux-cored wire for overlay welding of forging die and application thereof

InactiveCN103008924AGood performance of surfacing welding processGood welding wire crack resistanceArc welding apparatusWelding/cutting media/materialsHigh carbonManganese

The invention discloses a flux-cored wire for overlay welding of a forging die and an application thereof, and belongs to the technical field of material processing welding materials. Flux core powder is coated with a carbon steel belt; the filling rate of the flux-cored wire is 30-37 percent; and the flux core powder comprises the following substances in percentage by mass: 4-7 percent of calcium fluoride, 0.5-3 percent of soda ash, 0.5-4 percent of quartz, 2-6 percent of rutile, 13.6-27.2 percent of high-carbon ferro-chrome, 13.9-19.2 percent of pure chromium powder, 2.2-5.7 percent of nickel powder, 1.8-4.3 percent of electrolytic manganese, 6.3-13.2 percent of ferromolybdenum powder, 2.1-5.0 percent of ferrosilicon powder, 0.6-1.9 percent of vanadium iron powder, and the balance of reduced iron powder. The welding wire has very high high-temperature hardness and heat-fatigue resistance, and continuous welding can be realized.

Owner:BEIJING UNIV OF TECH

Bead weld flux-cored wire for repairing hammer forging die and preparation method

InactiveCN102814604AHigh hardnessImprove heat resistanceWelding/cutting media/materialsSoldering mediaIron powderFerrosilicon

The invention provides a bead weld flux-cored wire for repairing a hammer forging die and a preparation method, and belongs to the field of a flux-cored wire. According to the bead weld flux-cored wire, flux-cored powder is wrapped with a carbon steel belt, and a filling rate is of 20 to 35%; and the flux-cored powder comprises the following components in percentage by weight: 4 to 12% of calcium fluoride, 0.5 to 4.5% of soda, 0.5 to 4.5% of quartz, 2 to 12% of rutile, 8.5 to 17% of ferrochrome powder, 5 to 11% of nickel powder, 4 to 11% of electrolytic manganese, 3 to 6.5% of ferromolybdenum, 1.7 to 11% of ferrosilicon, 0.5 to 2.1% of ferrovanadium, and the balance of ferrous powder; and fused alloy elements comprise comprises the following components in percentage by weight: 0.1 to 0.27% of C, 1.2 to 2.2% of Cr, 1 to 2.3% of Ni, 0.74 to 2% of Mn, 0.45 to 1% of Mo, 0.16 to 1.1% of Si, 0.05 to 0.22% of V, and the balance of Fe. The bead weld flux-cored wire has high efficiency, a good technical performance, and high temperature hardness and thermal fatigue resistance performances.

Owner:BEIJING UNIV OF TECH

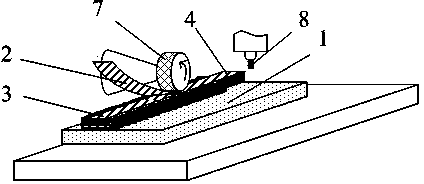

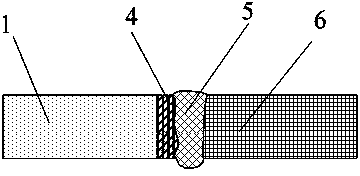

Method for preparing joint made of dissimilar material by firstly ultrasonically prefabricating and secondly welding transition belt

ActiveCN103551721AEasy to implement stacking processRealize subsequent machiningNon-electric welding apparatusMetal foilMilling cutter

The invention discloses a method for preparing a joint made of a dissimilar material by firstly ultrasonically prefabricating and secondly welding a transition belt. The method comprises the main steps of stacking at least one layer of metal foil on the surface of a to-be-connected material through ultrasonic rolling welding to form a stacking layer; after the stacking layer is prepared, cutting off a foil disconnected part at the periphery of the stacking layer by a milling cutter of an ultrasonic rolling welding system, and milling the stacking layer to form the transition belt with a proper shape and a proper size; directly welding the transition belt with another to-be-connected metal by a fusion welding method, a braze welding method or a diffusion welding method so as to obtain the joint made of the dissimilar material with the macrostructure being formed by the to-be-connected material, the transition belt, a welding seam and another to-be-connected material. The technical scheme has the characteristics that through stacking the metal foil on the surface of the to-be-connected material to finally form the transition belt by utilizing the advantage of ultrasonic solid phase connection, welding of dissimilar hard-to-weld materials is indirectly converted into welding of two kinds of materials with metallurgy dissolvability, and then the joint made of the dissimilar material with reliable performance is prepared.

Owner:WEIHAI WANFENG MAGNESIUM IND DEV

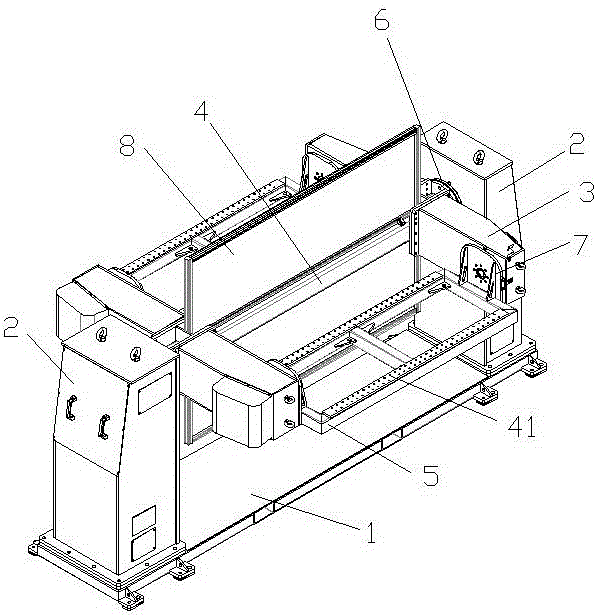

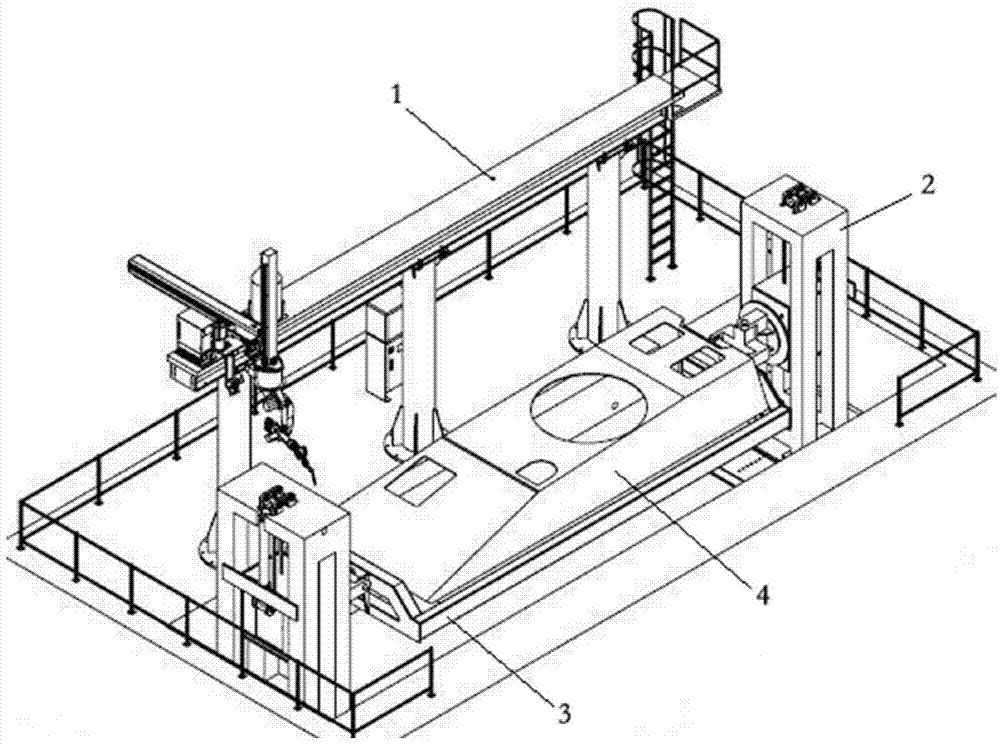

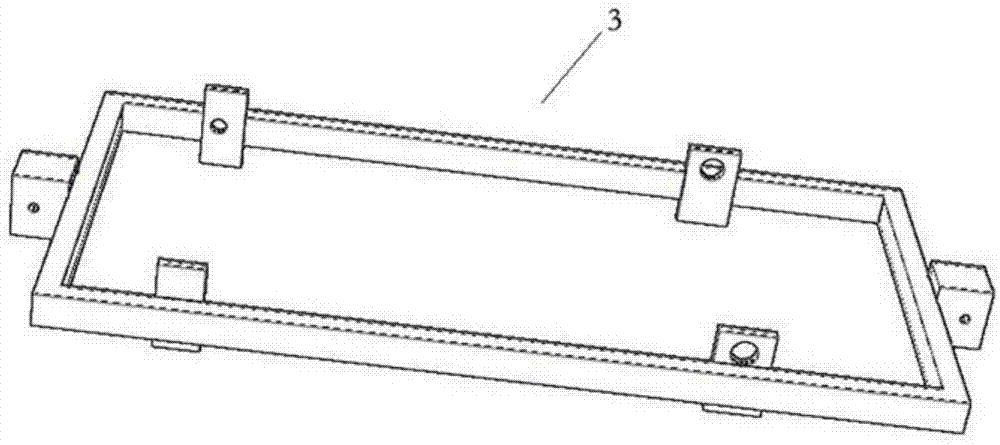

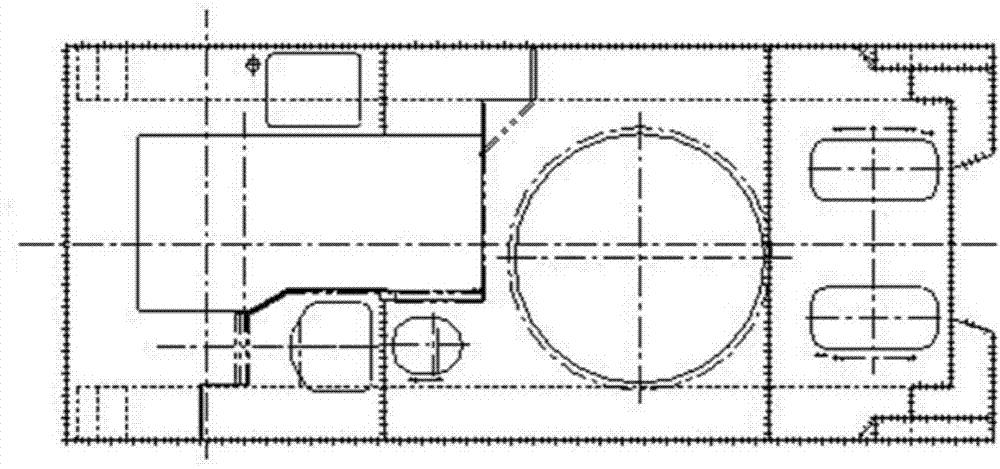

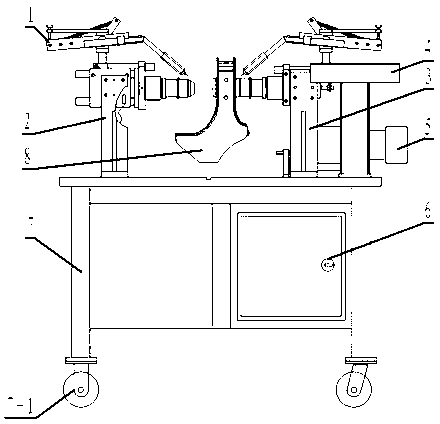

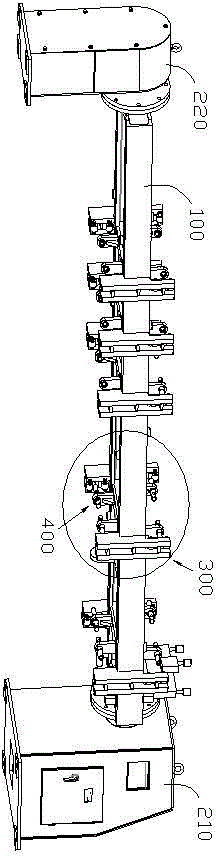

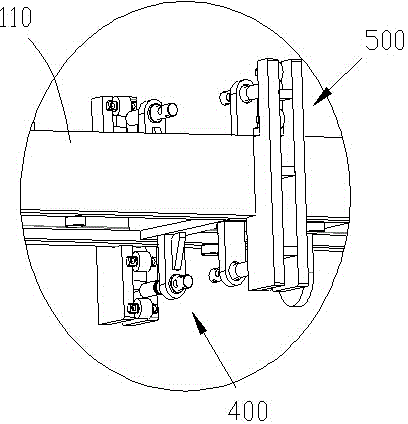

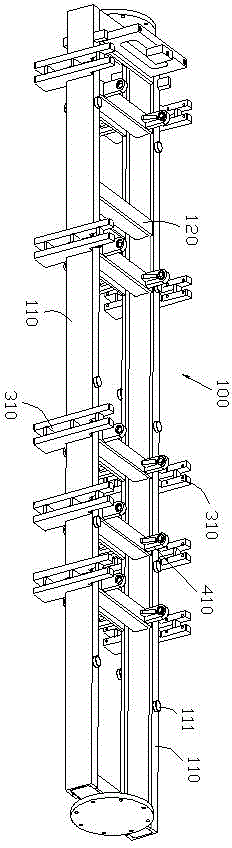

Multi-station universal type robot welding positioner

InactiveCN106346187AEasy to weldRealize continuous weldingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringRobot welding

The invention discloses a multi-station general-purpose robot welding positioner, which comprises a base, columns are arranged at both ends of the base, first turntables are arranged on the two columns, and the first turntable is fixed on the first turntable. There are rotating crossbeams, second turntables are arranged at both ends of the two rotating crossbeams, welding platforms are arranged between the corresponding two sets of second turntables, and each welding platform can rotate relative to the rotating crossbeams. Welding platforms are set at both ends of the rotating beam. When the workpiece on one of the welding platforms is being welded, the workpiece can be clamped on the other welding platform. After the welding is completed, the continuous welding is realized by turning the rotating beam. The welding efficiency is improved, and each welding platform can be turned over relative to the rotating beam, which is convenient for welding the upper and lower surfaces of the workpiece.

Owner:SUZHOU AOGUAN ROBOTIZATION EQUIP

Stainless steel water tank for nuclear power station and welding method

InactiveCN108172313ARealize continuous weldingImprove welding productivityNuclear energy generationArc welding apparatusNuclear powerShielding gas

The invention discloses a stainless steel water tank for a nuclear power station and a welding method. The MIG semi-automatic welding is adopted for the welded weld joints: the electric arc burnt between the continuously-fed welding wire and the workpiece is used as a heat source, the welding wire is molten by the electric arc and is sent into the welding area, and the arc is protected by the protective gas sprayed out by a welding torch nozzle; the diameter of the welding wire is 0.8-1.2mm, the welding current is 42 -90 A, the arc voltage is 18-24 V, and the protective gas flow is 10-15 L / min, and the temperature between the layers is 5 DEGC <=T<=150 DEG C; the protective gas is the mixed gas of argon and helium, and the content ratio of the argon to helium is 15-20:85-80. The stainless steel water tank adopts MIG semi-automatic welding. Meanwhile, the fillet welding joints of the installation of an accessory structure, an anchor rib assembly pair, an anchor rib assembly, a top platepair, welded nails, a shooting plate groove pair, and a cover plate supporting system are welded. Full-position welding can be carried out, the welding speed is high, and the deposition efficiency ishigh.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD +1

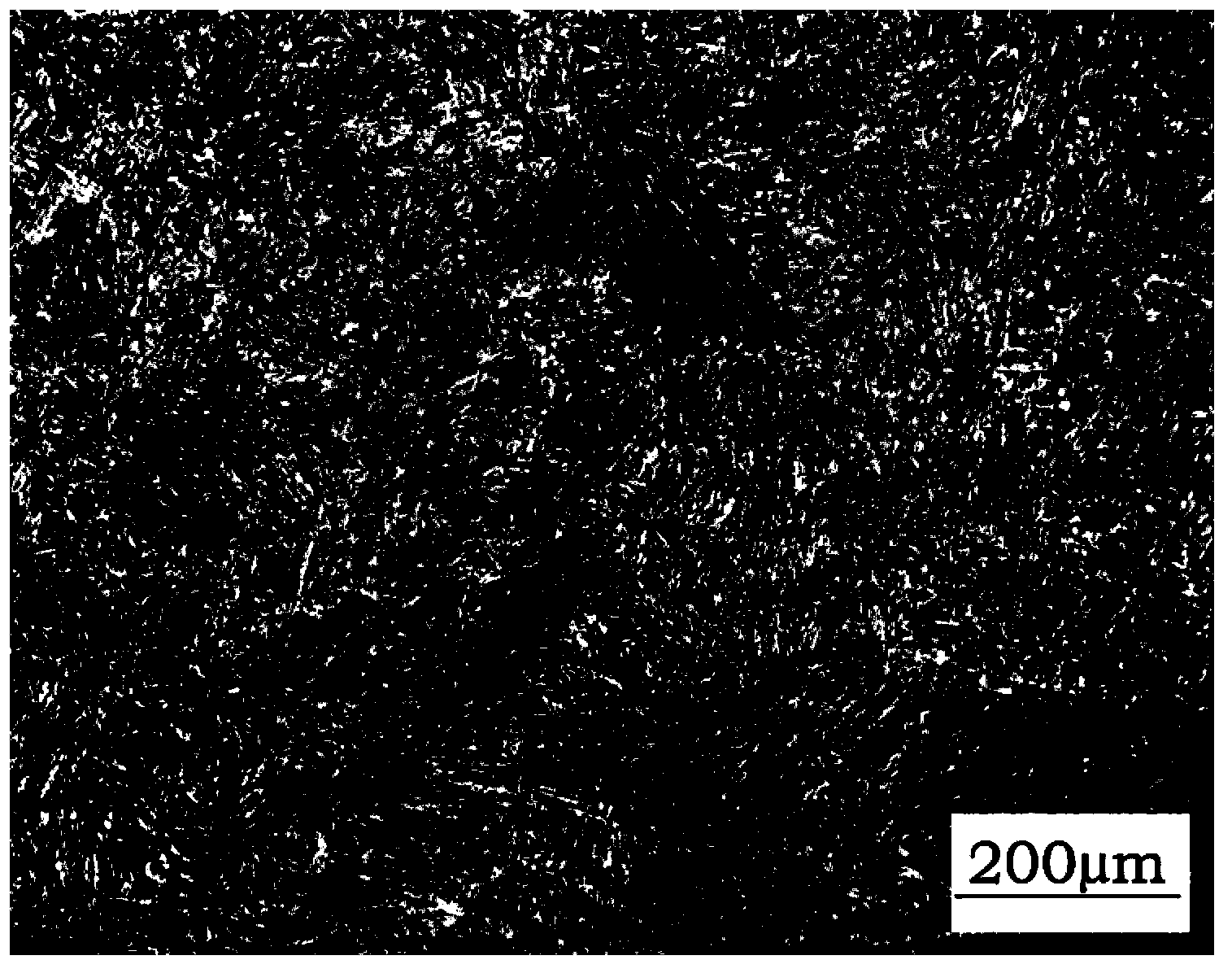

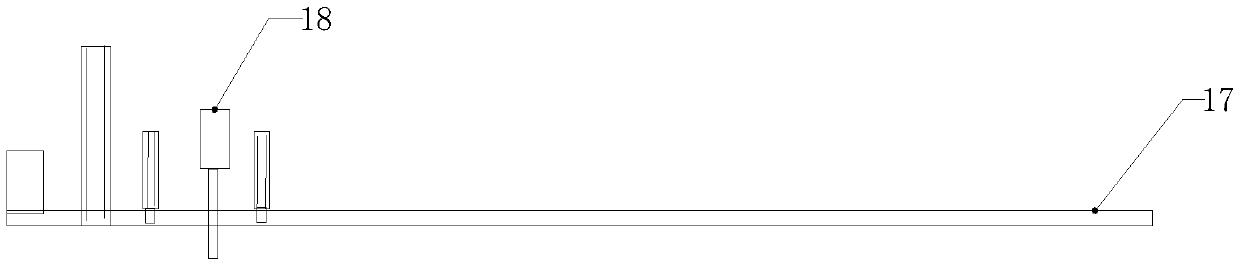

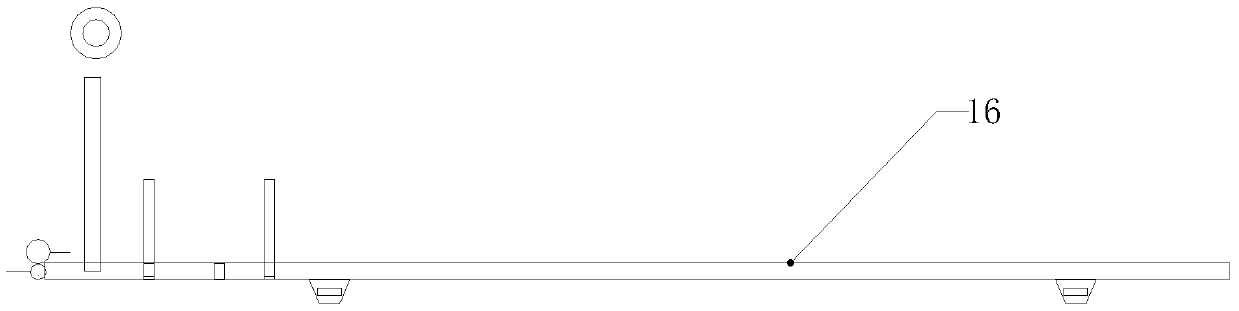

Automatic welding device and automatic welding method for thin-shell car body

InactiveCN103659137ARealize continuous weldingIncrease productivityWelding/cutting auxillary devicesArc welding apparatusThin shellsEngineering

The invention discloses an automatic welding device and an automatic welding method for a thin-shell car body. The device comprises a portal-frame welding robot, elevation-type head-tail frame positioners which is arranged on the side of the welding robot, a reversing frame which is installed between the positioners and a control mechanism which is used for controlling the welding robot and the positioners to work. The method comprises the following steps of back welding a weld seam which is more than 1mm, then filling the weld seam, placing the top / left side / bottom / head / right side / tail part of a car body on a horizontal position by rotating the elevation-type head-tail frame positioner, and welding the corresponding weld seam. The automatic welding device has the beneficial effects that automatic welding of different weld seams in different forms of different car types can be satisfied, the continuous welding of a majority of weld seams outside the car body can be realized, and the production efficiency is greatly improved; by adopting the welding method, not only can the quality of the weld seam be improved, but also the welding speed is high, the heat input is small, the weld deformation is small, and the subsequent assembling can be guaranteed.

Owner:BEIJING NORTH VEHICLE GROUP CORP

Flux-cored wire for overlay welding of forging die and application thereof

InactiveCN103008924BGood performance of surfacing welding processGood welding wire crack resistanceArc welding apparatusWelding/cutting media/materialsManganeseFerrosilicon

Owner:BEIJING UNIV OF TECH

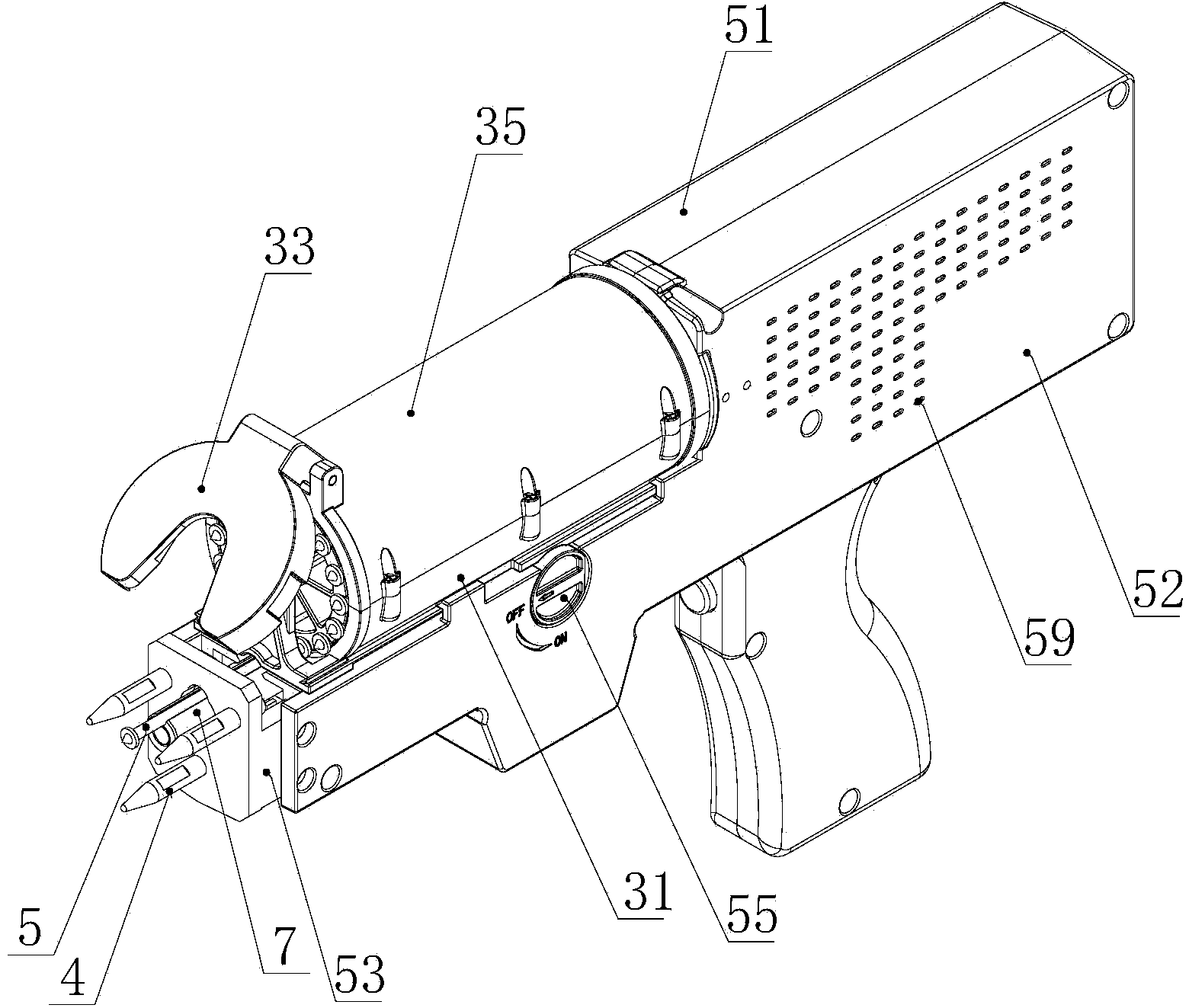

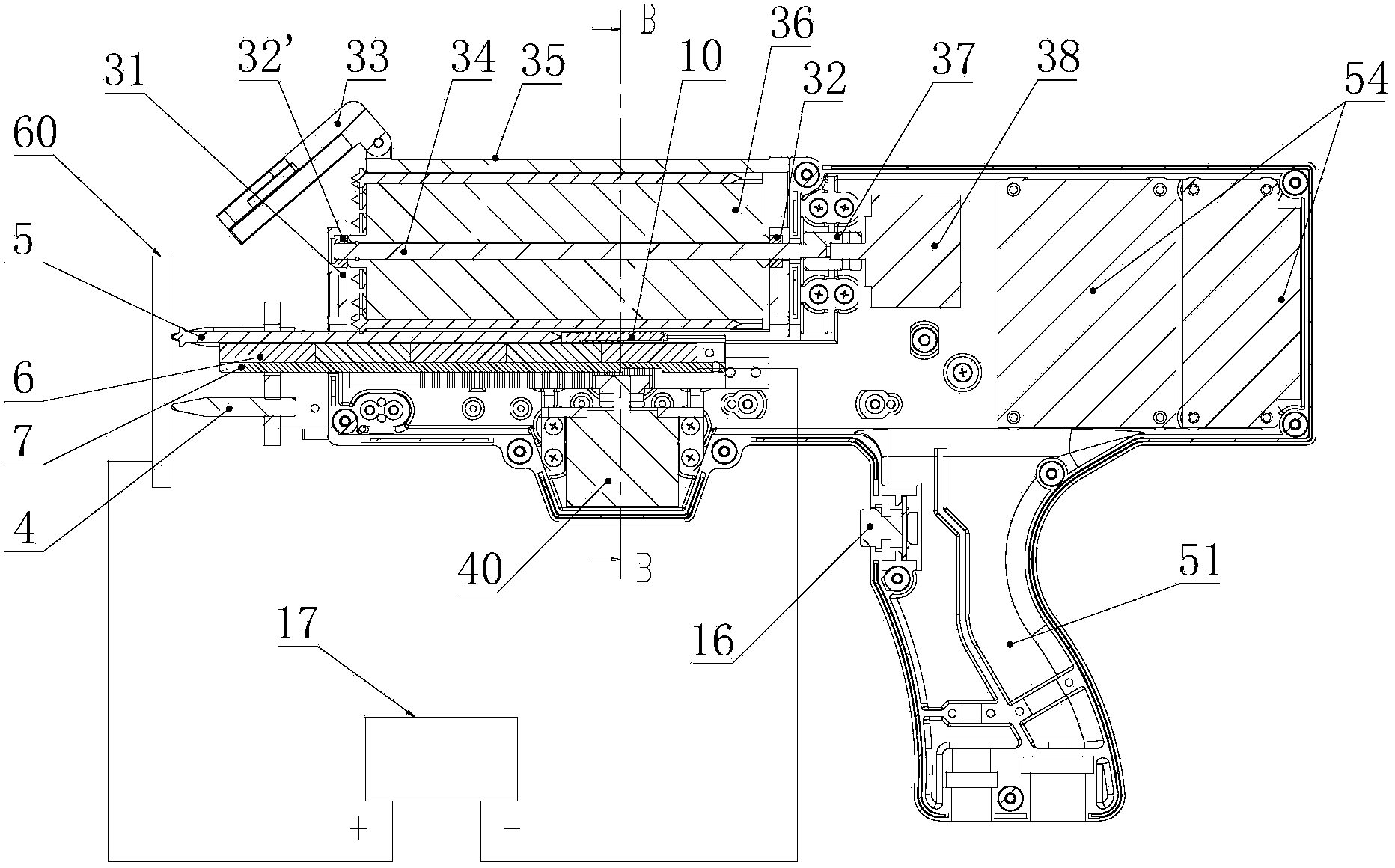

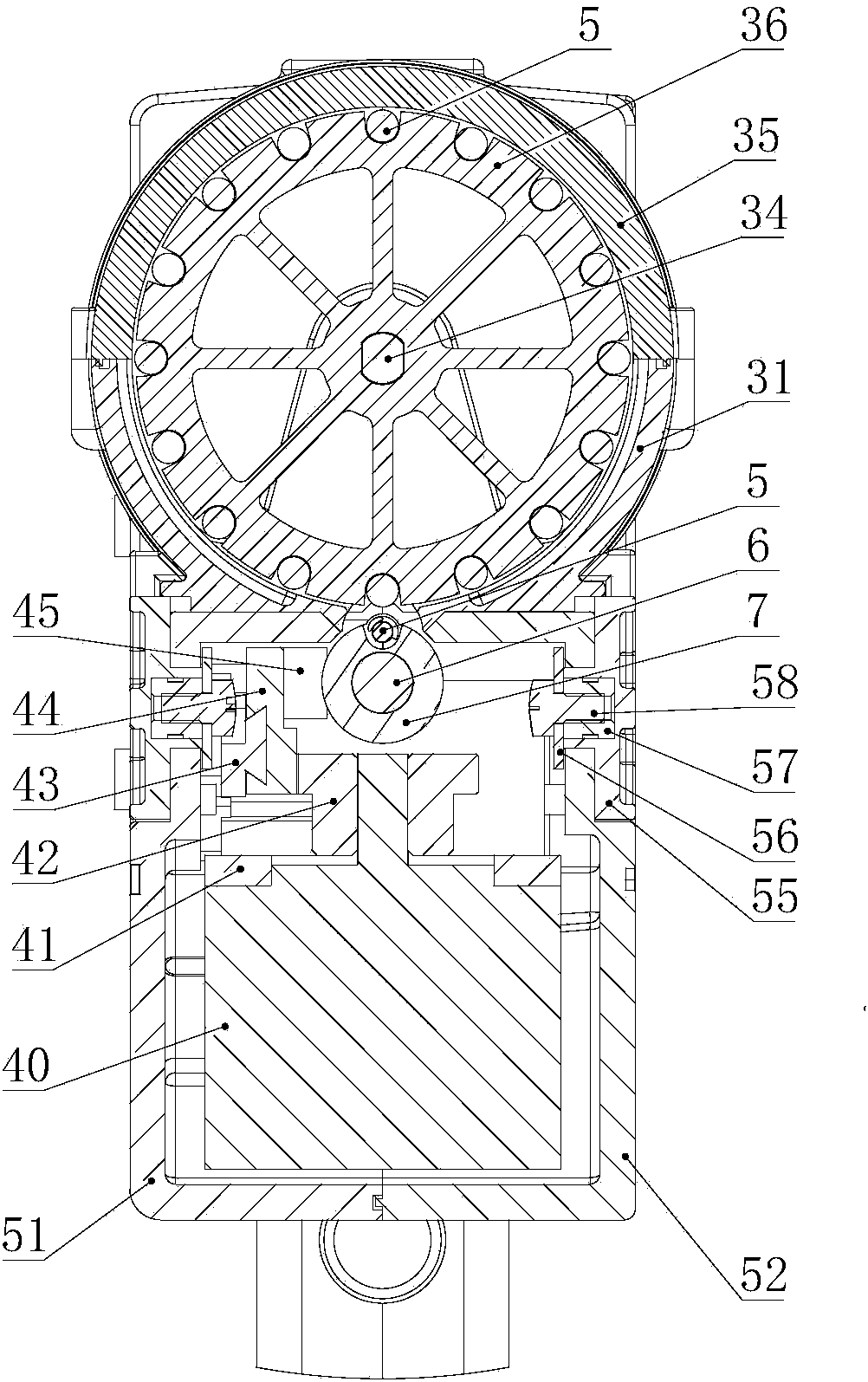

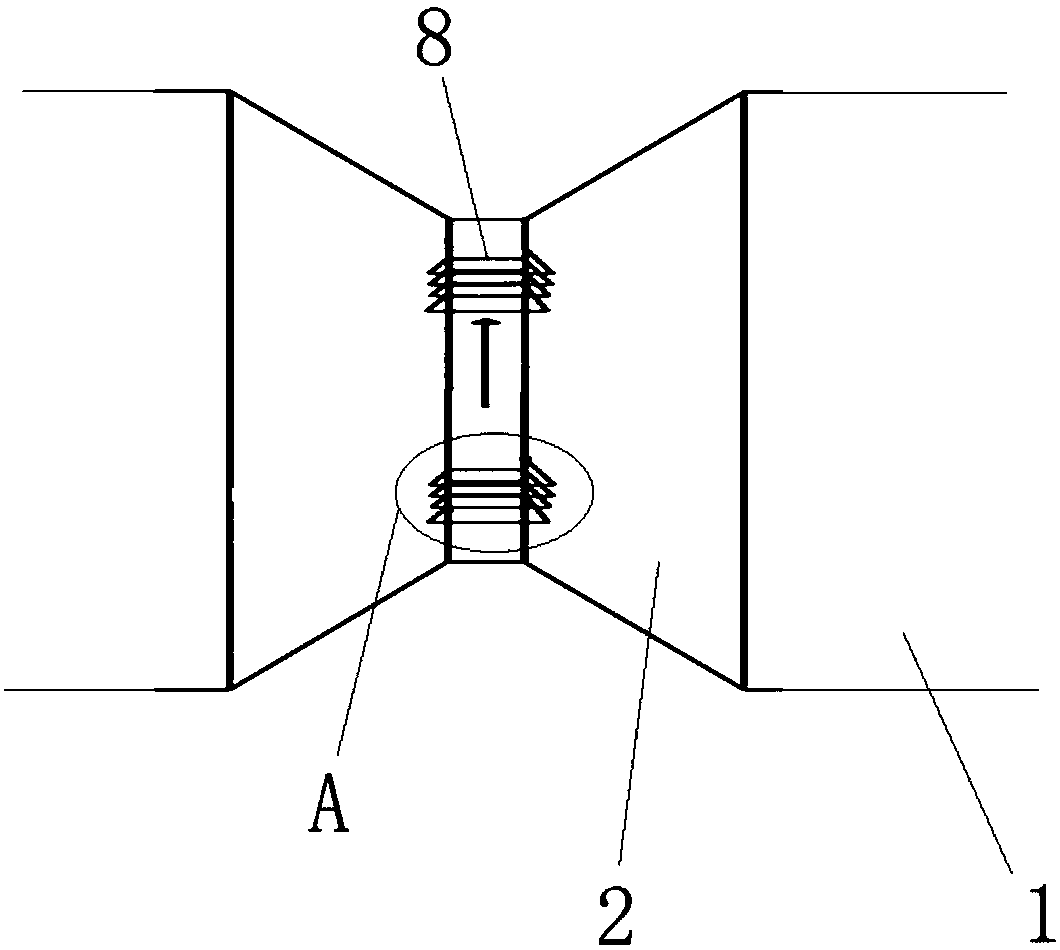

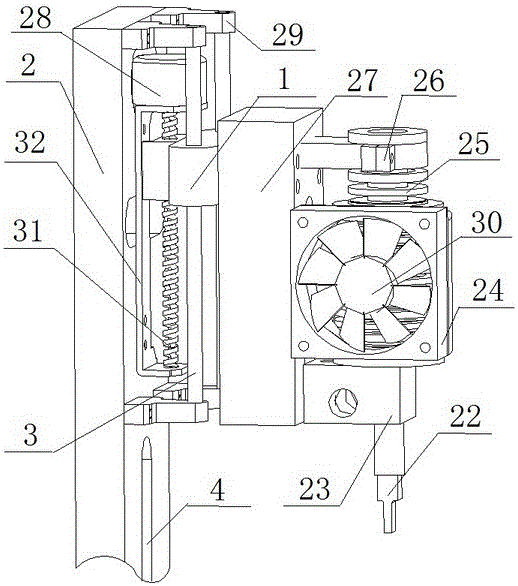

Repeating stud welding torch

ActiveCN103817419ARealize continuous weldingEasy to operateElectrode supporting devicesEngineeringDrive shaft

The invention relates to a repeating stud welding torch, which comprises a torch casing, a rotary wheel mechanism, a first motor, a second motor and a driven shaft, wherein the interior of the driven shaft is coated with a radial magnetic steel or a radial electromagnet, and the top end of the driven shaft is provided with a groove which is matched with the diameter of a welding screw; the driven shaft is connected with the second motor, and the second motor drives the driven shaft to move; the front end of the torch casing is provided with a welding screw positioning mechanism; the rotary wheel mechanism comprises a rotary wheel, a shaft center of the rotary wheel is inserted with a core shaft, one end of the core shaft is connected with the first motor, the other end of the core shaft is rotationally connected with a rotary wheel seat, the periphery of the rotary wheel is provided with a plurality of concave openings at equal intervals, and each concave opening is matched with the diameter of each welding screw; the welding screws are sequentially inserted into the concave openings of the rotary wheel, the first motor drives the rotary wheel to rotate, the concave grooves are sequentially aligned with the groove of the driven shaft, the welding screws are absorbed to fall into the groove, and the driven shaft delivers the welding screws to the welding surface for welding. The welding torch has the advantages that the continuous welding is realized, the operation is convenient, and the welding efficiency is high.

Owner:青岛艾特尔电源科技有限公司

Brush type seal robot welding system based on ultrasonic detection technology

InactiveCN105562929AGuarantee welding qualityGuaranteed fine controlLaser beam welding apparatusWeld seamEngineering

The invention discloses a brush type seal robot welding system based on the ultrasonic detection technology. The brush type seal robot welding system based on the ultrasonic detection technology comprises an ultrasonic detection module. An ultrasonic analysis module is electrically connected with and communicates with the ultrasonic detection module and a robot control module. A laser welding module is fixedly connected with the robot control module. The ultrasonic analysis module scans a welding surface of a row wire root of a brush type seal through ultrasonic flaw detection equipment and sends wave signals obtained after scanning to the ultrasonic analysis module to carry out welding area positioning, welding seam tracking and welding penetration detection. Operation parameters are determined and sent to the robot control module. The robot control module works in cooperation with the laser welding module to complete welding operation. Welding area positioning, welding seam tracking and welding penetration monitoring are carried out through the ultrasonic detection technology, and automatic welding is realized in combination with a robot welding system, so that the welding quality is fully guaranteed, and meanwhile the welding work efficiency is improved.

Owner:江苏拓平密封科技有限公司

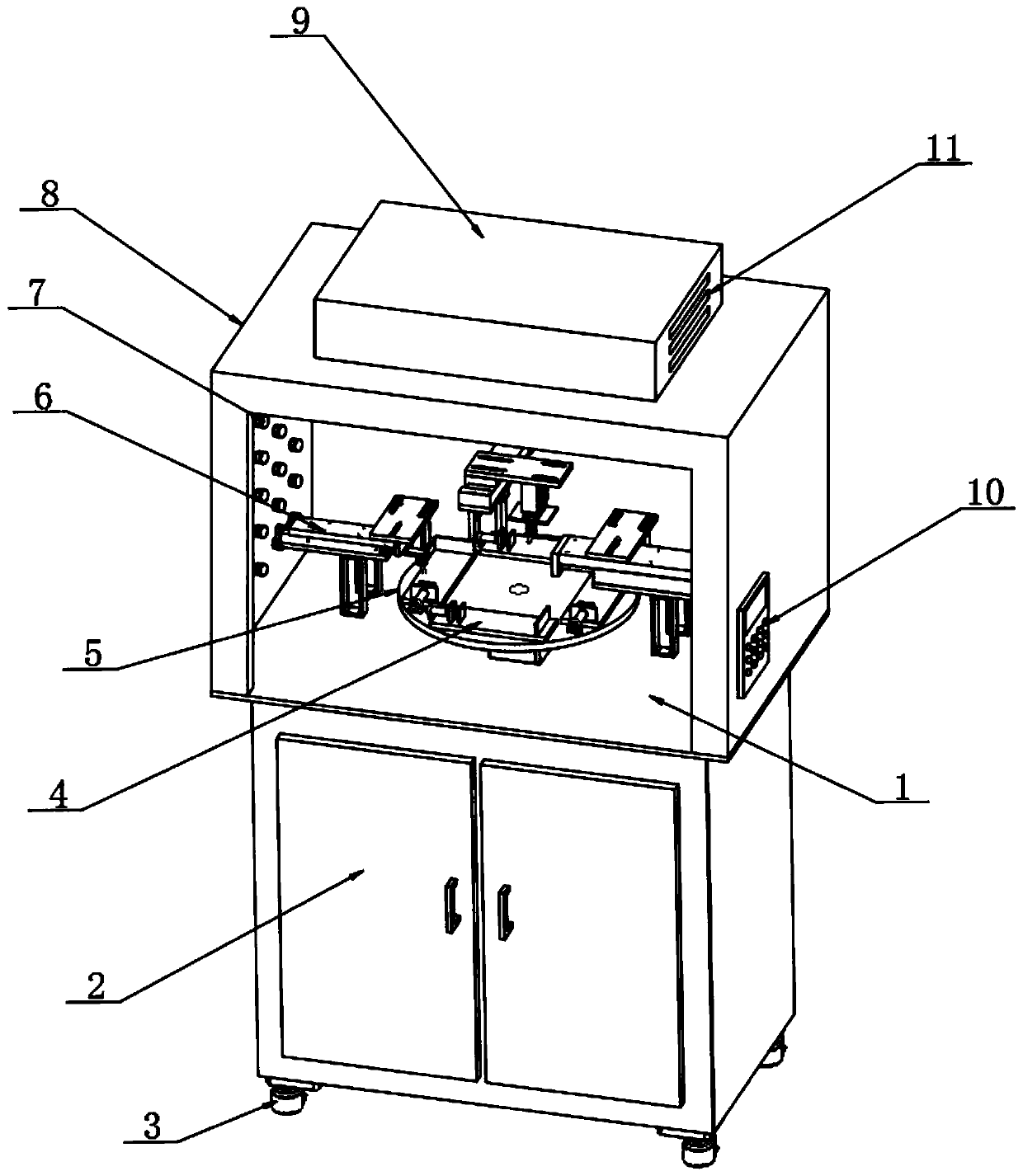

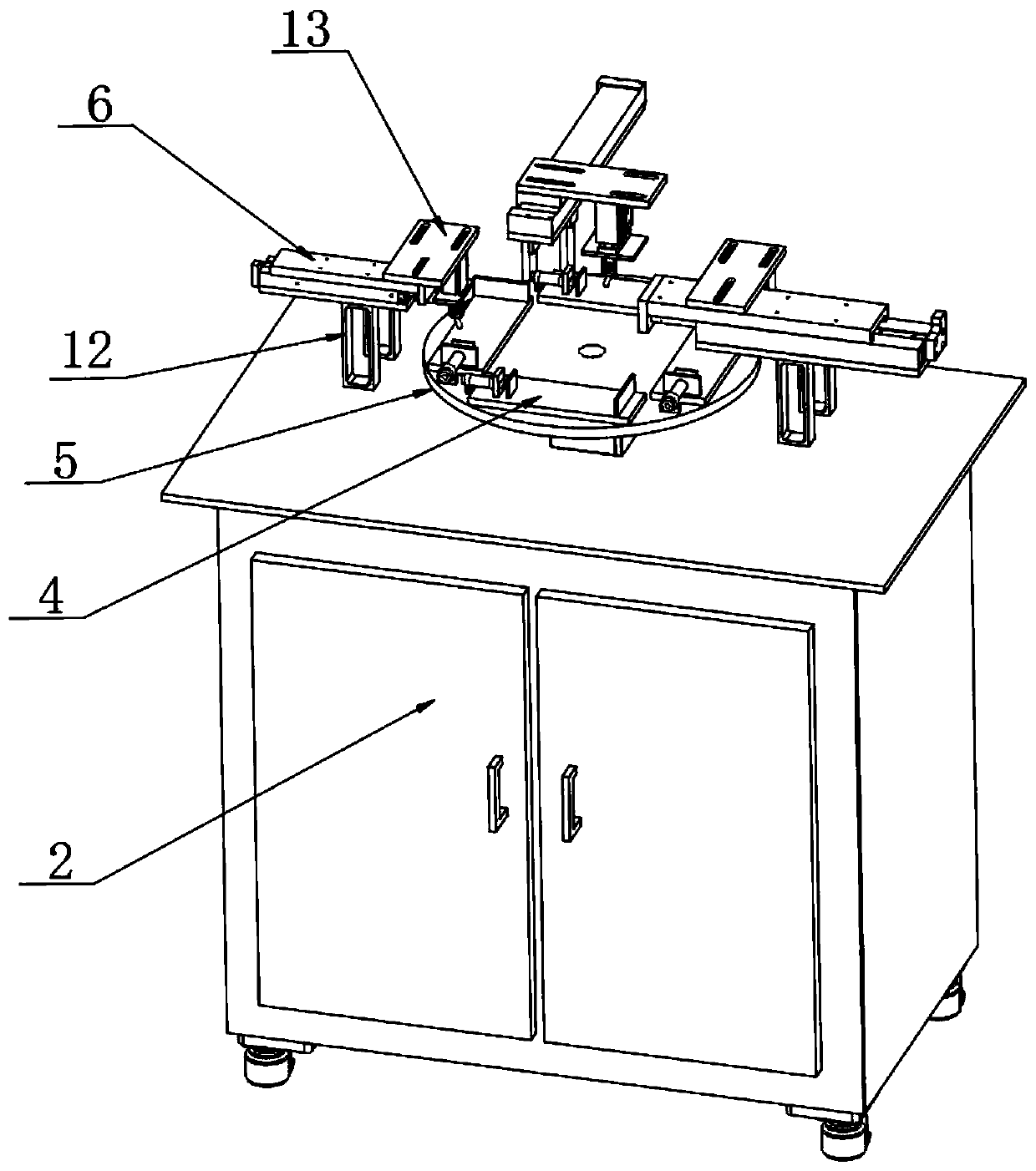

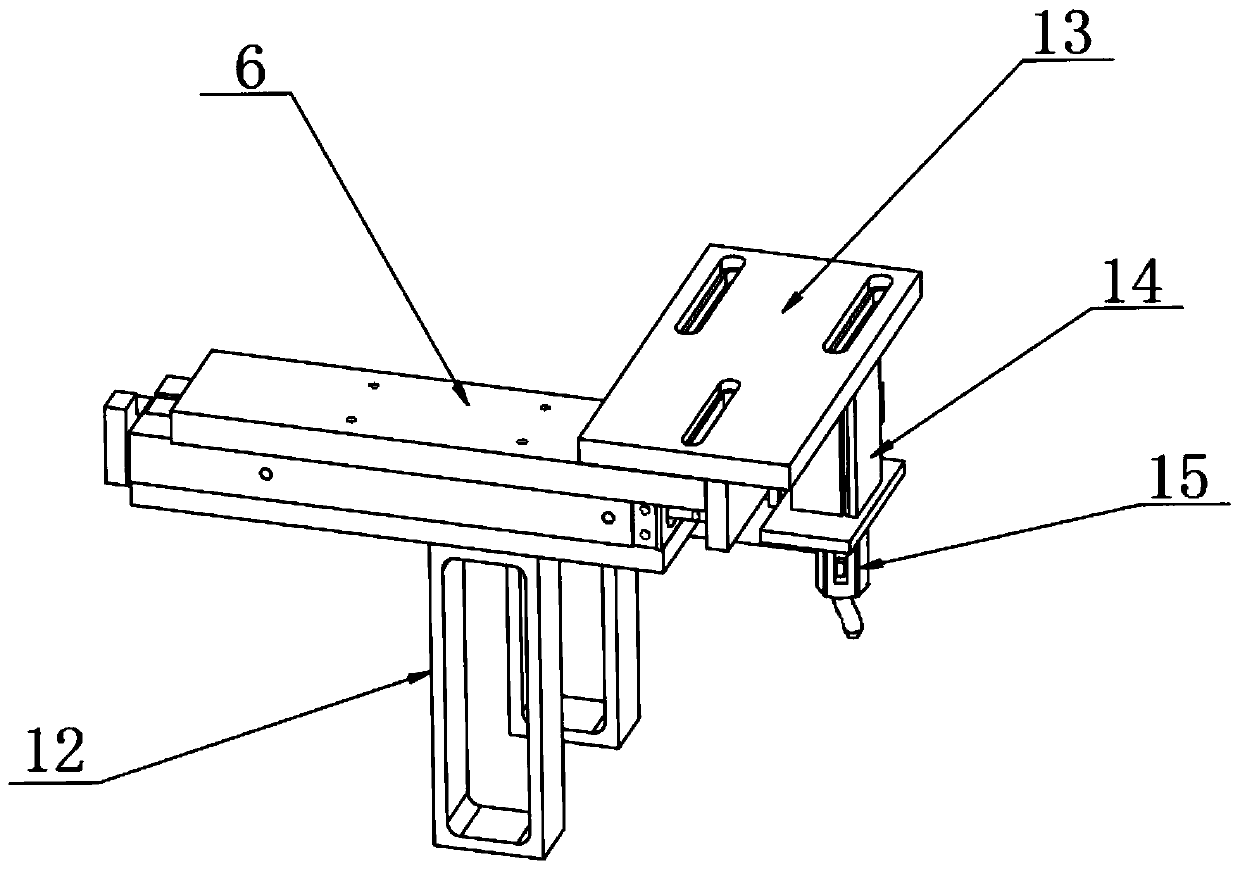

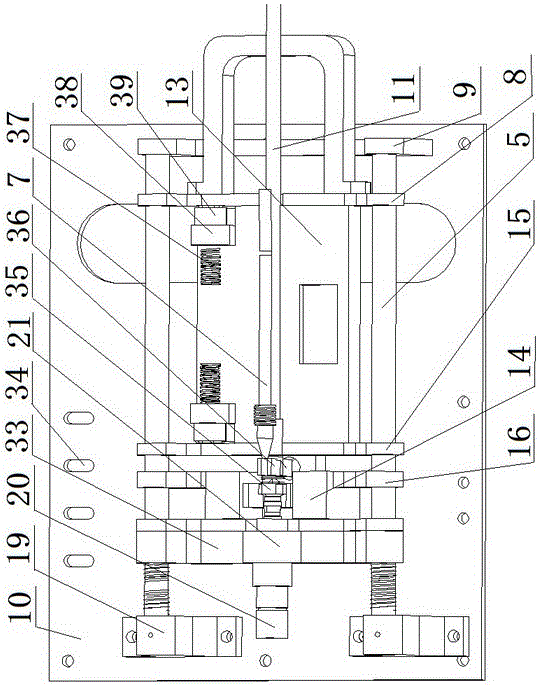

Automatic welding equipment for double annular welding beads

ActiveCN103008940AFulfill welding requirementsRealize continuous weldingWelding/cutting auxillary devicesAuxillary welding devicesAutomatic test equipmentCaster

An automatic welding equipment for double annular welding beads is used for solving problems of high equipment cost, low manual welding efficiency and hardly guaranteed welding quality of a welding robot. The automatic welding equipment comprises a welding gun position switching and welding gun clamping adjusting mechanism, a left side positioning mechanism, a right side positioning mechanism, an operation station, a power output mechanism, a control mechanism and a base stage, wherein the welding gun position switching and welding gun clamping adjusting mechanism comprises a left part and a right part, which are symmetric and respectively mounted together with the left side positioning mechanism and the right side positioning mechanism; the left side positioning mechanism, the right side positioning mechanism and the operation station are all fixed on the base stage; the power output mechanism is mounted together with the right side positioning mechanism; and a caster is arranged at the bottom of the base stage. The automatic welding equipment has the advantages of simple operation, convenient maintenance and low manufacturing cost; the welding efficiency can be increased, the product quality is improved, the welding operation condition is improved and the labor intensities of operators are reduced.

Owner:长城汽车股份有限公司平湖分公司

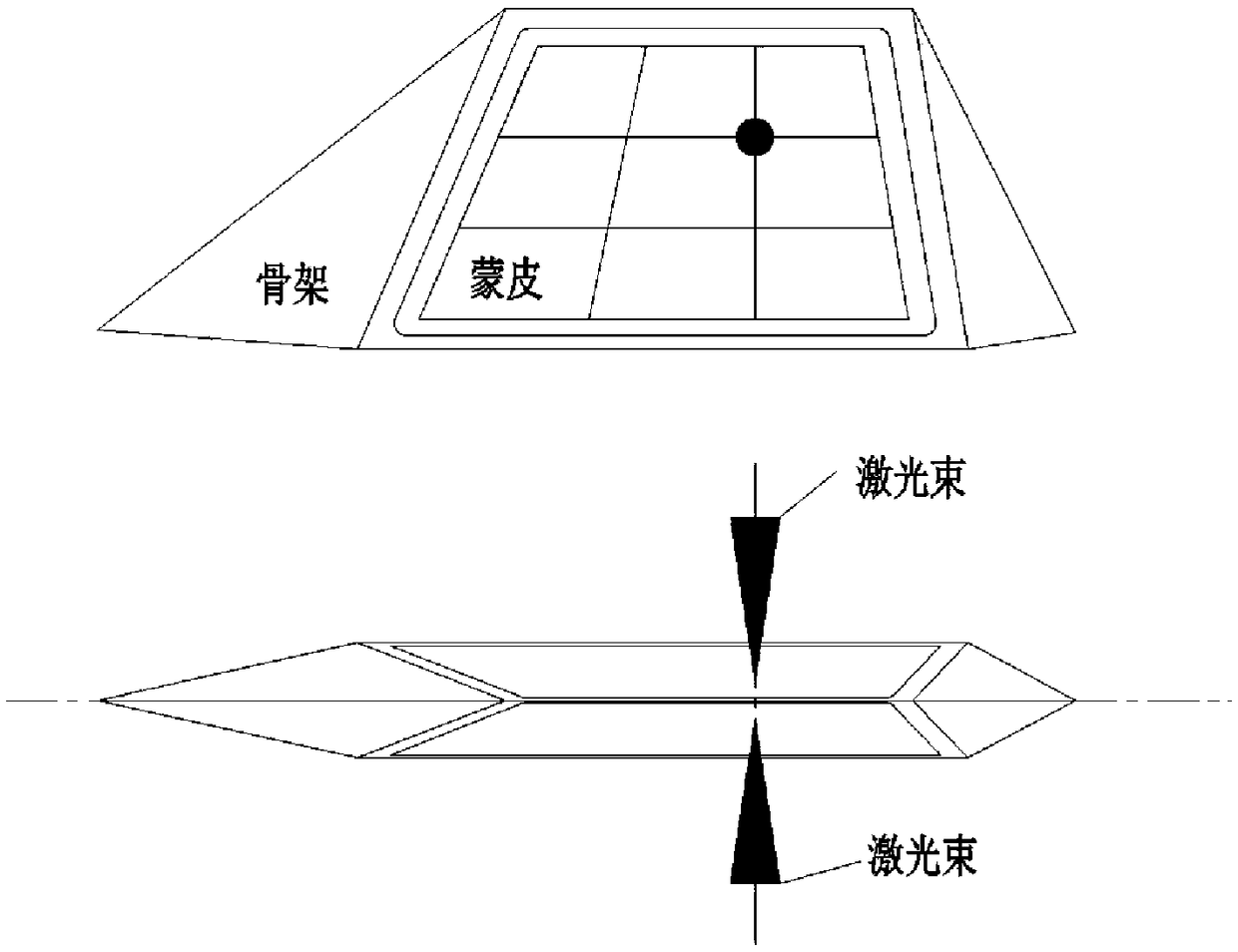

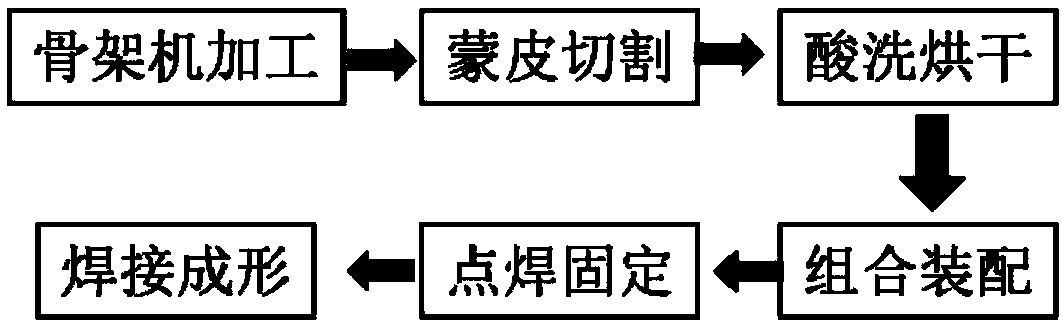

Double-beam laser mirror image welding method

InactiveCN109465547AAvoid workloadImprove welding efficiencyLaser beam welding apparatusRoom temperatureLight beam

The invention provides a double-beam laser mirror image welding method. The method aims at solving the problems that existing welding manufacturing is not high in precision, and low in efficiency, andautomation is not convenient to realize. According to the new assembly, welding and cooling scheme, an assembly method in a vertical position is adopted to replace an assembly method through which welding is conducted while a blocker is pasted, so that a large amount of repeated rudder surface turnover work is omitted; meanwhile, continuous welding after one-time clamping is achieved, the production process is greatly simplified, not only the welding efficiency is greatly improved, but also the automation of the welding process is more convenient to realize. By adopting a double-beam laser mirror image synchronous welding process, single-surface welding of a single heat source is replaced, high symmetry is realized in the heat cycle process, and the welding manufacturing precision can begreatly improved; and after the welding of a rudder surface is completed, the rudder surface of a titanium alloy skin skeleton is vertically placed or hung, the rudder surface is cooled to the room temperature through free radiation, the temperature change symmetry of a heat cycle of the rudder surface is further ensured, and the welding manufacturing precision is further improved.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

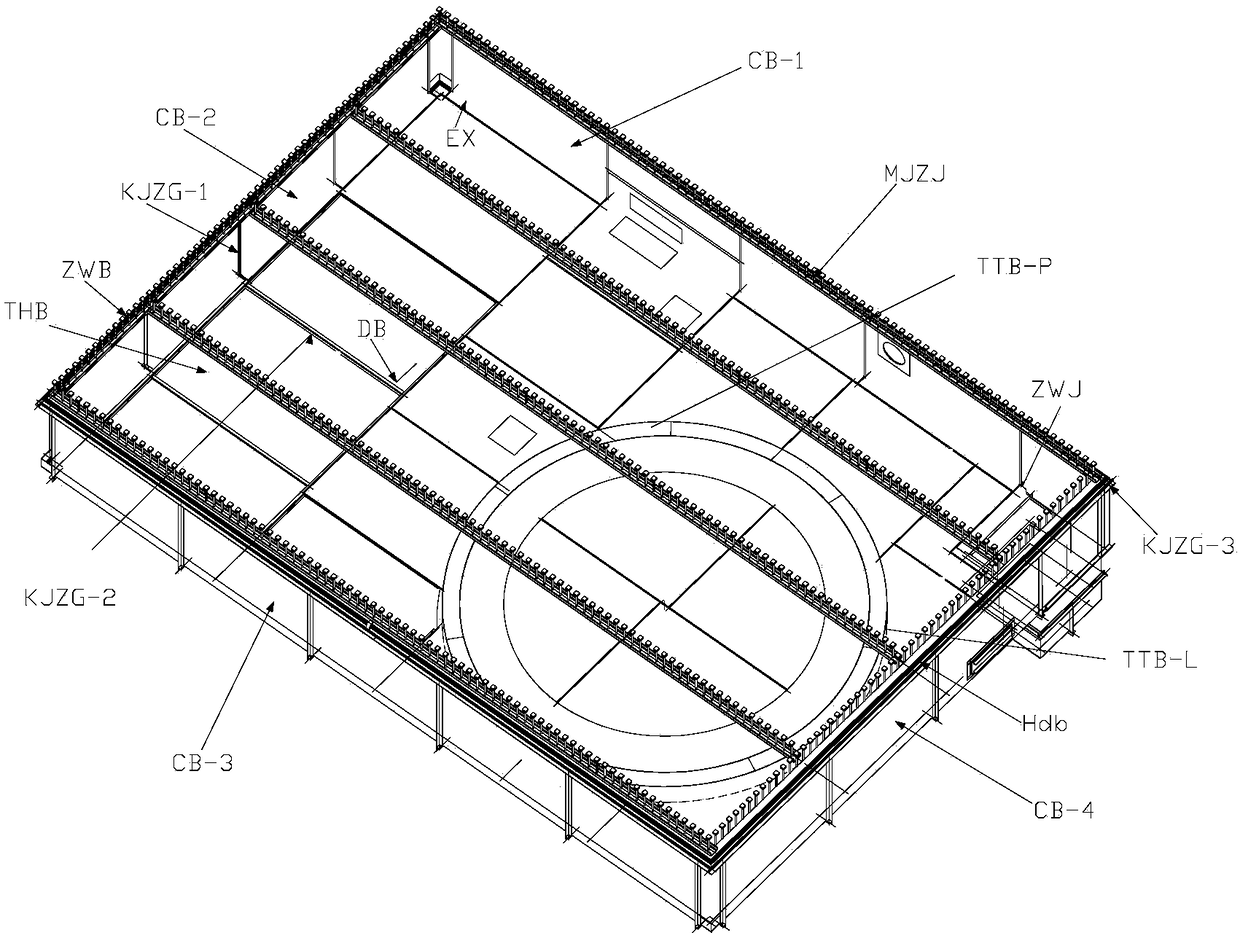

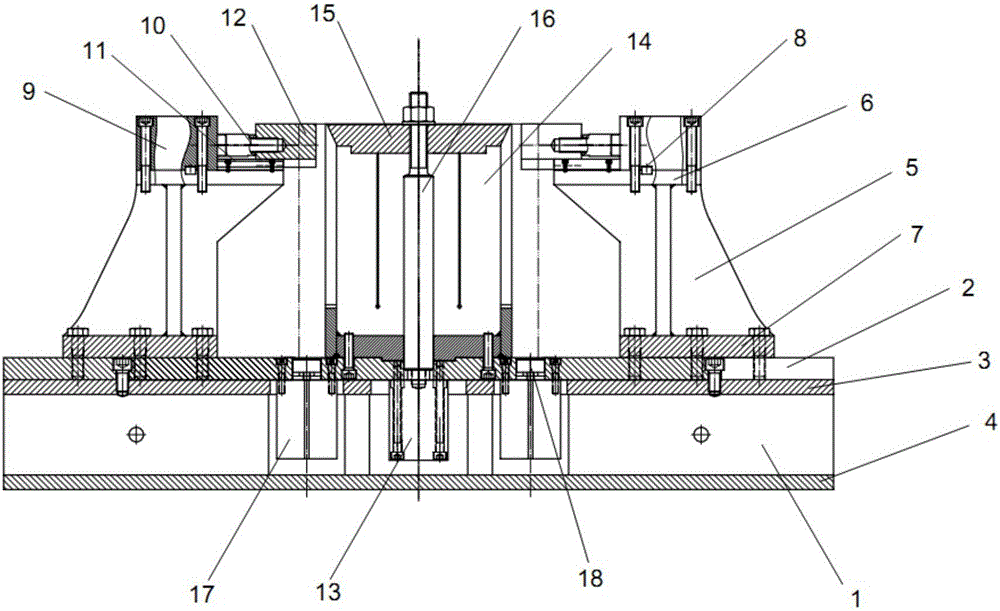

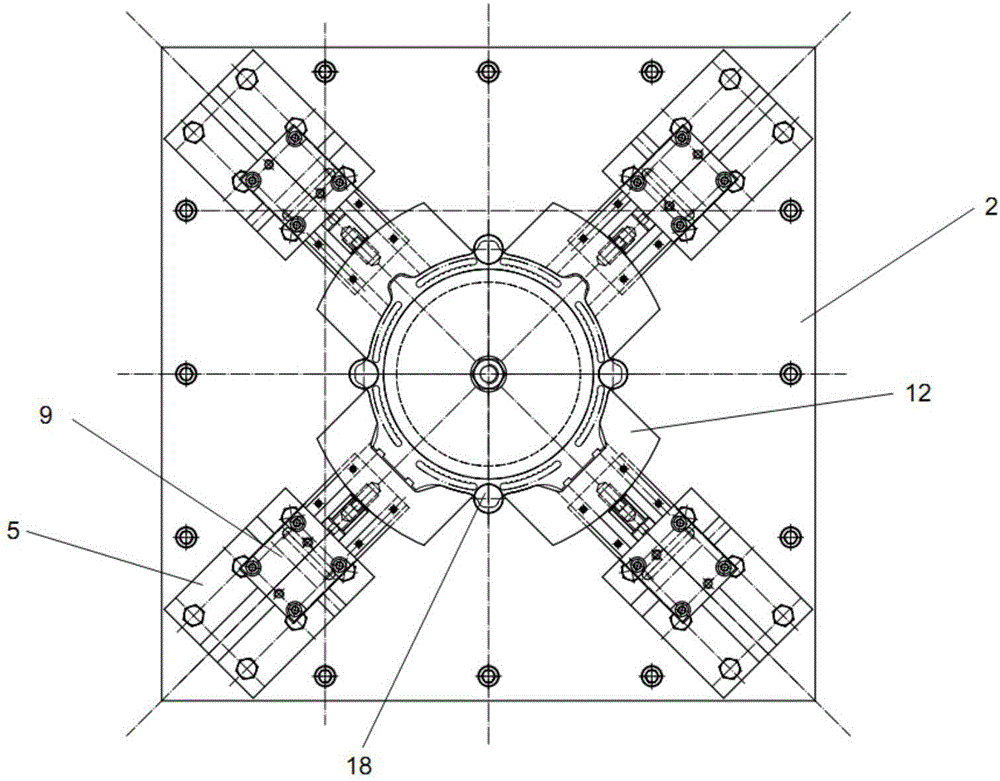

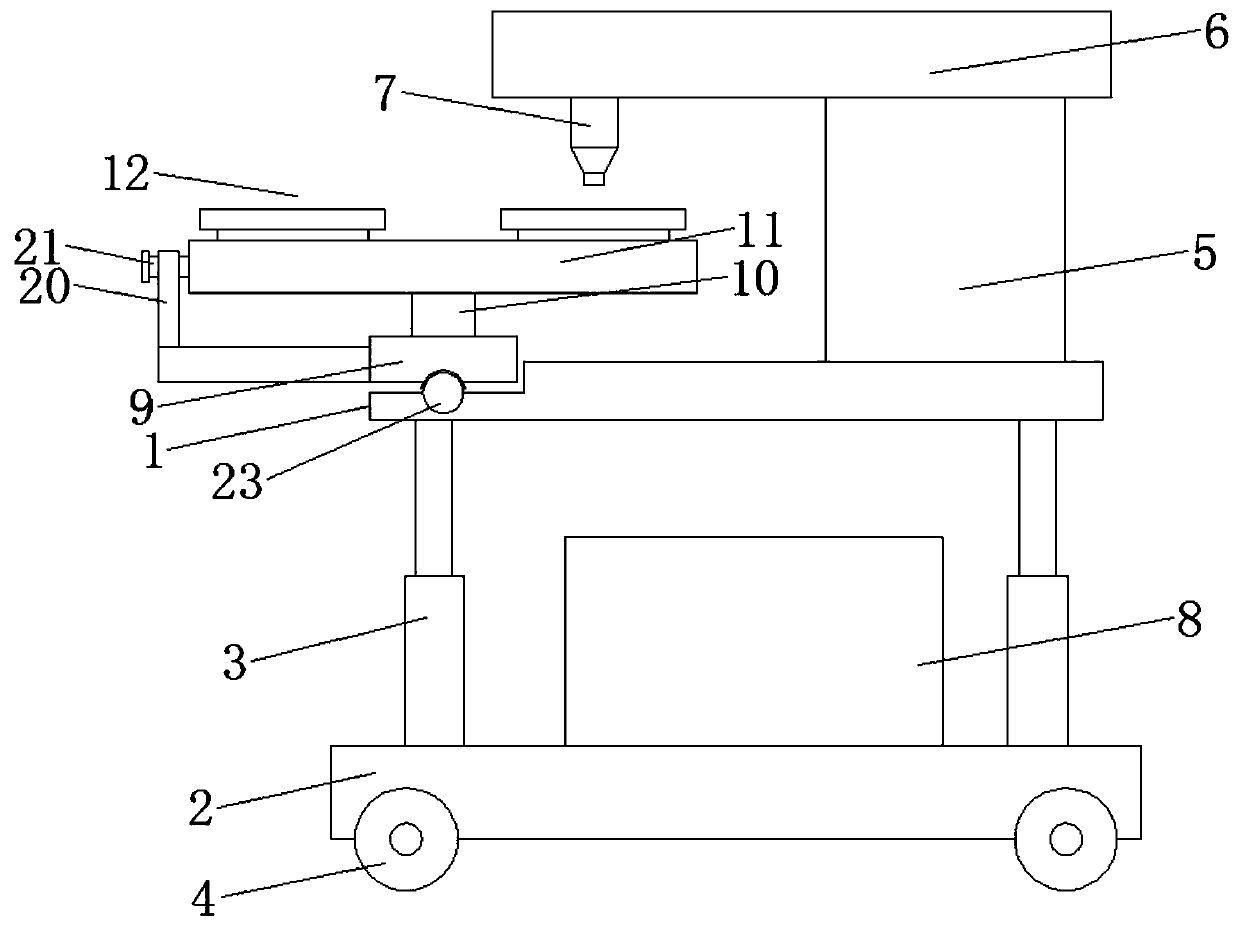

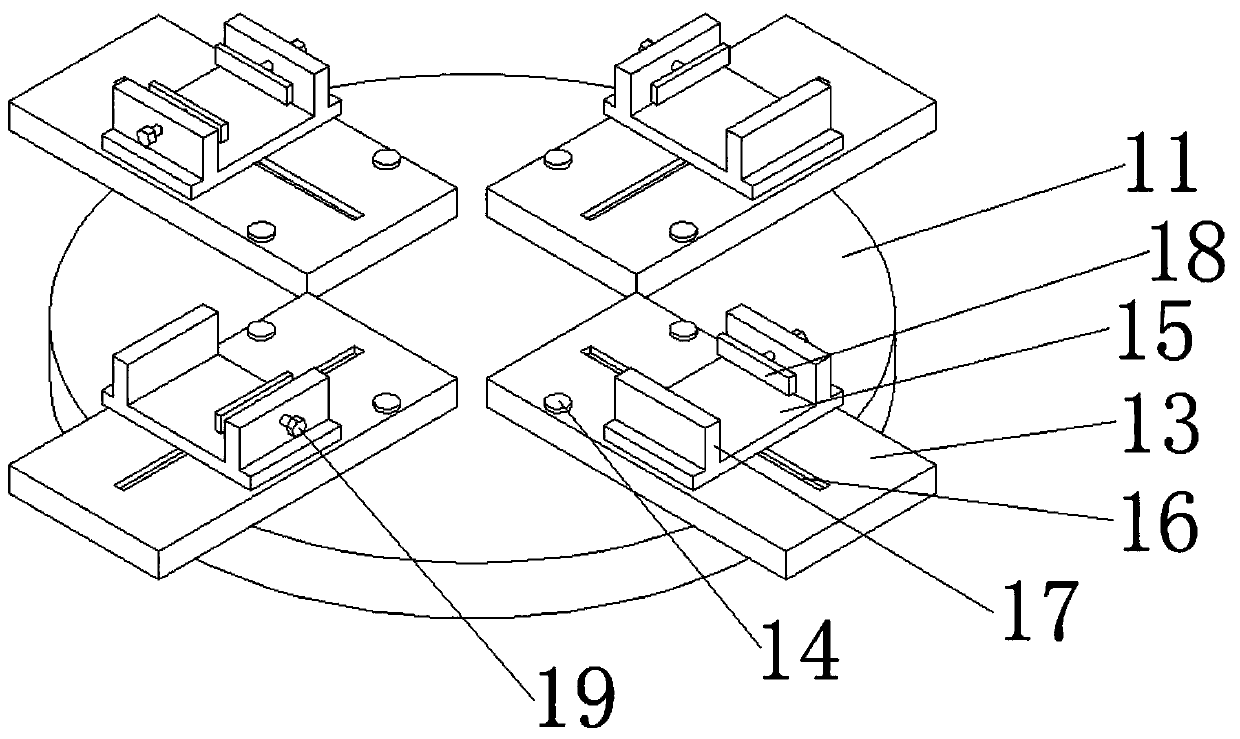

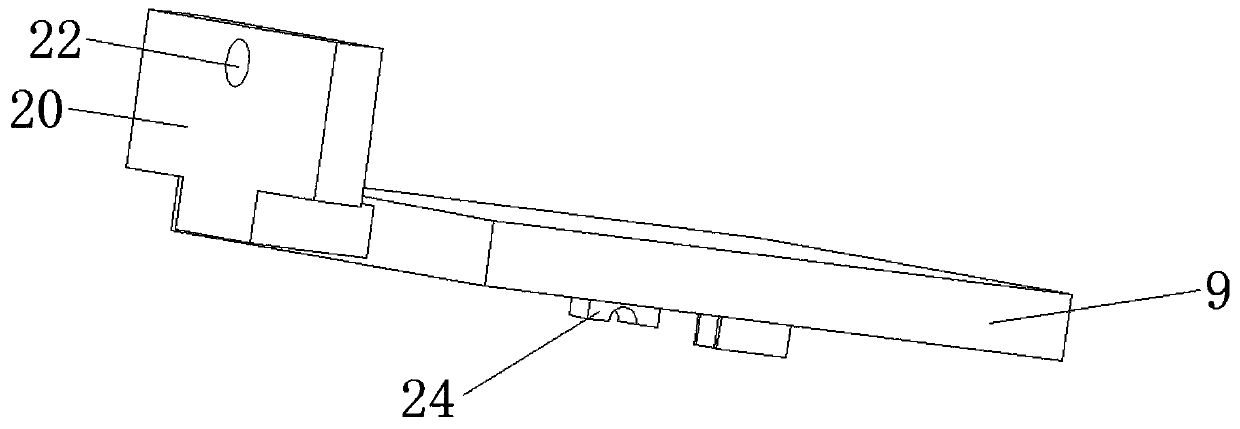

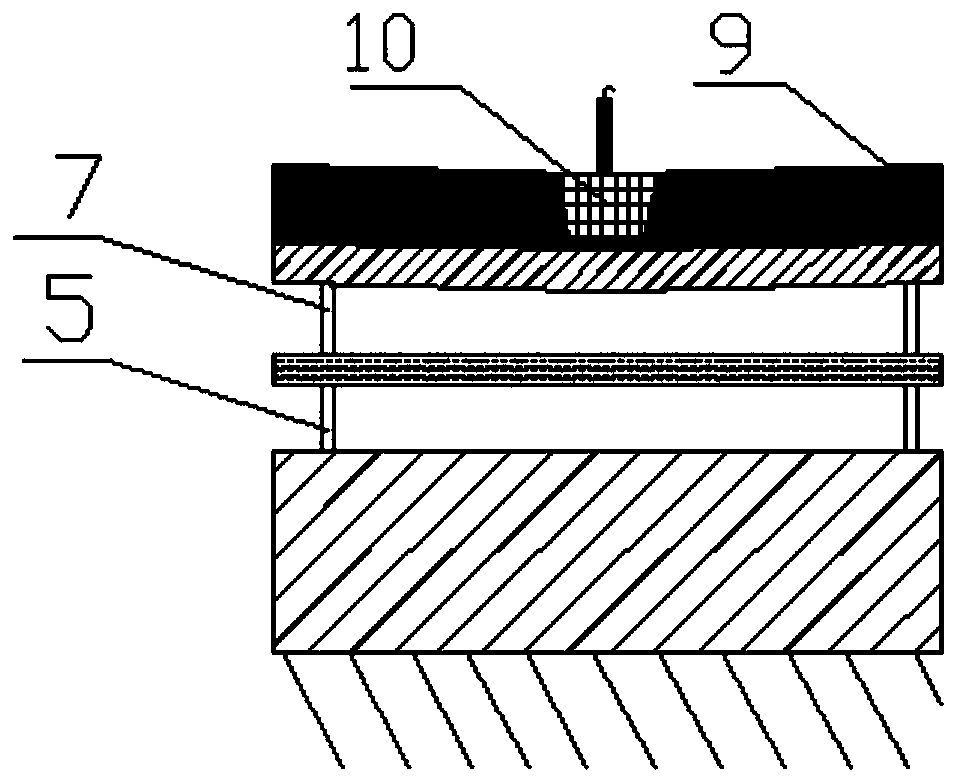

Welding fixture for friction stir welding of water channels of water-cooled motor shell and annular welding technology

ActiveCN105921880ALoading and unloadingFully automatedNon-electric welding apparatusFriction weldingWater channel

The invention relates to a welding fixture for friction stir welding of water channels of a water-cooled motor shell. The welding fixture for friction stir welding of the water channels of the water-cooled motor shell comprises a fixture base, an oil cylinder support mechanism, an ejector block clamping mechanism, a power lock locking mechanism and a PLC system. The ejector block clamping mechanism and the power lock locking mechanism are respectively connected with the PLC system. According to the welding technology, double working tables are alternately used for welding of friction stir welding equipment, by the PLC system, the welding fixture moves along an X-axis guide track of each working table, a stirring head moves along a Y-axis guide track of each working table, and annular continuous welding of the water channels is realized. The welding fixture for friction stir welding of the water channels of the water-cooled motor shell has the beneficial effects that the inner side of a workpiece is locked by an expander sleeve and the center is positioned firmly, an oil cylinder drives an outward ejector block to move along a linear guide track to clamp the outer side of the workpiece, the water-cooled motor shell is ensured not to deform in a clamping process, and the stability of a welding process is also ensured; and the welding fixture moves along the X-axis guide track of each working table and the stirring head moves along the Y-axis guide track of each working table by the friction stir welding equipment through programming, and therefore, annular continuous welding of the water channels is realized.

Owner:中色创新研究院(天津)有限公司

Welding equipment for copper processing

ActiveCN110842402AAchieve feedRealize continuous weldingWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringWeld seam

The invention relates to the field of copper processing and specifically discloses welding equipment for copper processing. The welding equipment for copper processing comprises a platform, a base, lifting supporting legs, rolling wheels, a supporting base, a cross beam, an electric welding spray head and a control cabinet. An adjusting seat swinging around the midpoint is arranged at the left endof the platform. A rotary shaft perpendicular to the surface of the adjusting seat is rotatably connected to the upper surface of the adjusting seat. A rotary disk parallel to the adjustment seat iscoaxially fixed to the upper end of the rotary shaft. A plurality of detachable clamping and moving mechanisms are mounted on the upper surface of the rotary disk. Each clamping and moving mechanism comprises a mounting plate, fixing bolts, a movable seat and a sliding groove. The inclination angle of the electric welding spray head can be changed through the adjusting seat capable of swinging. The welding equipment for copper processing can conduct welding on different positions, especially weld seams in the vertical direction, can conduct continuous welding on workpieces mounted on the clamping and moving mechanisms, has no influence on the welding process during discharging and feeding and can save time and improve the production efficiency.

Owner:苏州铜盟电气有限公司

Convertible welding mold

ActiveCN104097010ARealize continuous weldingImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringMechanical engineering

The invention provides a convertible welding mold. The convertible welding mold comprises a mold body, overturning devices, outer clamping devices and inner clamping devices, wherein the mold body comprises side plates, an upper connecting plate and a lower connecting plate; the side plates are positioned on two sides of the mold body; the side plates are connected with each other by the upper connecting plate and the lower connecting plate; the overturning devices are arranged at two ends of the mold body; the outer clamping devices are arranged on the side plates on two sides of the welding mold; and the inner clamping devices are arranged on the upper connecting plate and the lower connecting plate. A workpiece to be welded is positioned and clamped by the inner clamping devices and the outer clamping devices of the turnover mold body, workpieces with two different crotch sizes can be continuously welded, the welding efficiency and the utilization rate of equipment are improved, the space is saved on overall arrangement of a workshop, the vacancy rate is reduced, and the welding cost is also reduced.

Owner:ANHUI HAOYUN MACHINERY

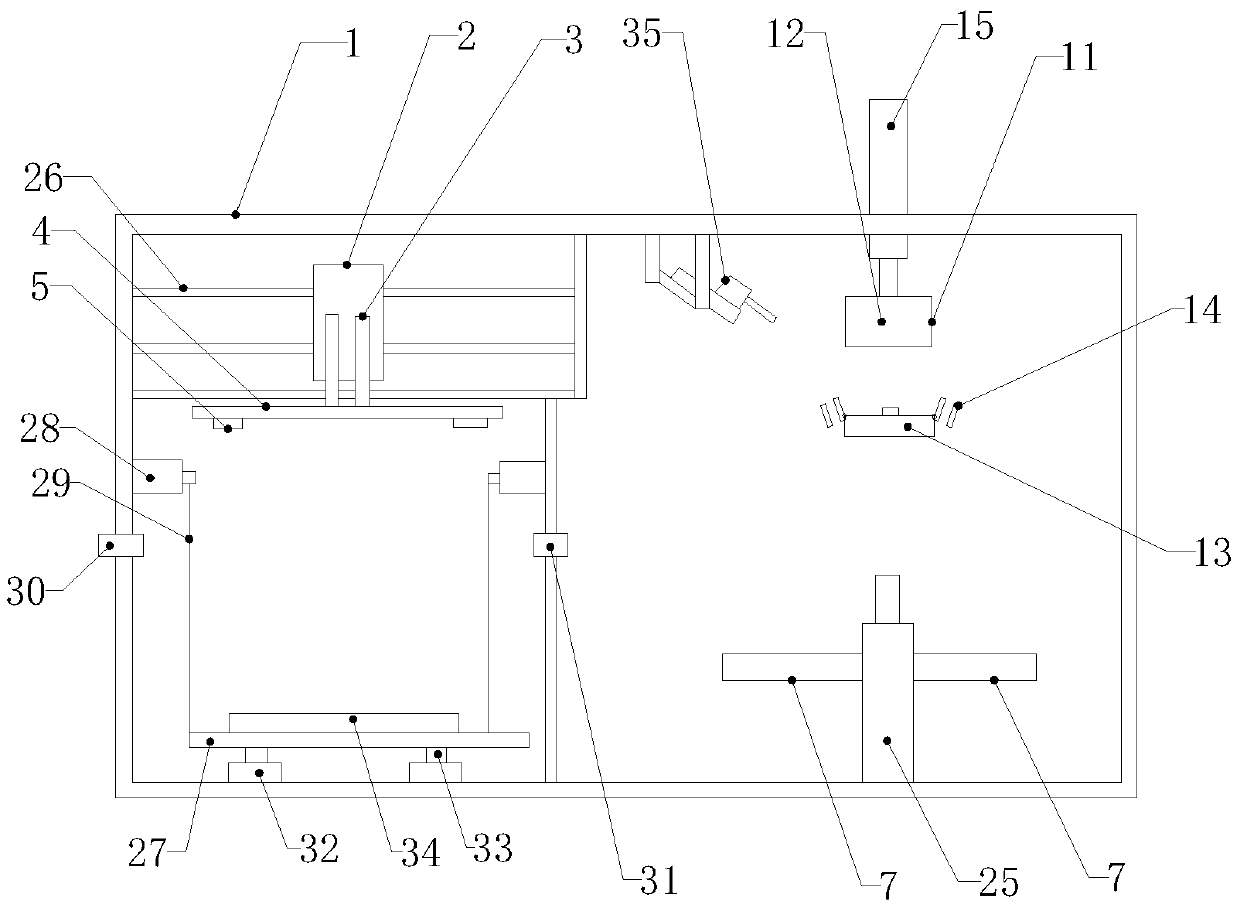

Full-automatic welding machine

ActiveCN105563818AFusion realizationThe fusion splicer is realized by setting the first transportEngineeringAutomation

The invention relates to a full-automatic welding machine through which manual sheet bending is not needed, and the automation degree is high. The full-automatic welding machine comprises an installing frame. A first conveying device, a bending device and a welding device are arranged in the installing frame. The first conveying device comprises a sliding block. The sliding block is arranged on the installing frame in a sliding manner and provided with a first lifting device. The power output end of the first lifting device is connected with a fixing plate, and vacuum suction cups are arranged on the lower surface of the fixing plate. The bending device comprises a base plate. Supporting plates are rotationally arranged on the left side and the right side of the base plate. Installing plates are arranged below the supporting plates. A supporting plate drive air cylinder is arranged between each installing plate and the corresponding supporting plate. A second lifting device is arranged below the base plate, and the power output end of the second lifting device is connected with the base plate. The welding device is arranged above the bending device, and the bending device is used for welding sheets conveyed from the bending device.

Owner:JIANGSU YUANXIANG INTERNET OF THINGS SCI & TECH

Automatic active argon tungsten-arc welding method

InactiveCN107570845AIncreased Penetration and Aspect RatioImprove mechanical propertiesElectrode supporting devicesElectrode accessoriesActive agentWidth ratio

The invention belongs to the technical field of welding and particularly relates to an automatic active argon tungsten-arc welding method. In order to further improve the welding efficiency and welding quality of the current active argon tungsten-arc welding, the invention discloses a novel automatic active argon tungsten-arc welding method. According to the automatic active argon tungsten-arc welding method, a double-layer protective gas welding gun is adopted for carrying out argon tungsten-arc welding, wherein an inner layer gas passage transports inert gas, and an outer layer gas passage transports active agent powder and outer layer gas. With adoption of the automatic active argon tungsten-arc welding method, through changing the elements of the active agent or the variety of the outer layer gas, flow behavior of metal in a furnace hearth can be changed, the fusion depth and depth-to-width ratio of a weld joint are increased in a multiplied manner, the elements and the texture ofthe weld joint are controlled, and the mechanical property of the weld joint is improved to obtain the weld joint with high quality and high fusion depth; and in addition, automatic adding of the active agent can be realized during the welding process, so that automation of the welding operation is realized, and the welding efficiency is improved.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

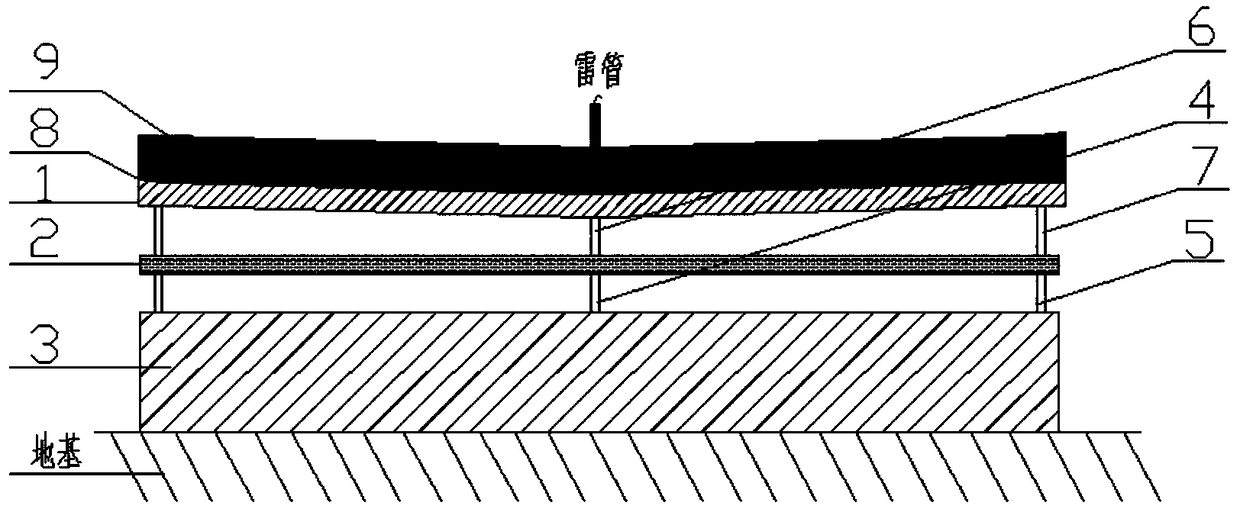

Explosive cladding method used for transition base plate of helicopter deck of drilling platform

InactiveCN109290671AReduce distanceAvoid restraintWelding/soldering/cutting articlesNon-electric welding apparatusDetonatorInitiation point

The invention discloses an explosive cladding method used for a transition base plate of a helicopter deck of a drilling platform. An explosive welding formation method of a composite plate includingan aluminum plate, a titanium plate and a steel plate comprises the following steps that first, the surface of the aluminum plate, the surface of the titanium plate and the surface of the steel plateare cleaned; second, the aluminum plate is used as a first layer in contact with a corrosive medium, the titanium plate is used as a second layer used for transition, and the steel plate is used as athird layer for bearing a load; third, a rock emulsion explosive 1# with the detonation velocity equal to or higher than 2000mm / s is continuously laid on the surface of the aluminum plate, a detonation groove with the width of 20mm is laid on the rock emulsion explosive 1#, and an ammonium oil explosive having the detonation velocity equal to or higher than 2600mm / s is continuously laid in the detonation groove; and fourth, an initiation point is arranged at the center of the aluminum plate, and a detonator is arranged on the initiation point. By adoption of the explosive cladding method, therequirements for the cladding joint rate, the shearing strength and the tensile strength of large-area aluminum plate, titanium plate and steel plate explosion for development of the well-drilling petroleum industry can be met.

Owner:安徽宝泰特种材料有限公司

Butt welding method for thick-wall steel pipes

The invention belongs to the technical field of welding, and particularly relates to a butt welding method for thick-wall steel pipes. The butt welding method for the thick-wall steel pipes comprisesthe following steps that the surfaces to be welded of the two thick-wall steel pipes are machined into a groove; butt welding is carried out on the surfaces to be welded of the two thick-wall steel pipes under the condition of keeping clearance, and the butted groove is positioned and welded; backing welding is carried out on the root of the butted groove, and polishing is carried out on a weldedseam generated after backing welding so that the portion, from the beginning end to the tail end, of the welded seam generated after backing welding can be narrowed in the circumferential direction ofthe thick-walled steel pipes; welded seams generated after positioning and welding are removed; and filling and welding are carried out on the butted groove, wherein in the filling and welding process, arc starting is carried out from the starting end of the welded seam generated after backing welding, and spiral welding is carried out in the circumferential direction of the thick-wall steel pipes by using a trapezoidal strip conveying mode. By the adoption of the method, the quality of the welded seams is improved, continuous welding of the butted welded seams of the thick-wall steel pipes is realized, and the production efficiency is greatly improved.

Owner:CRRC QINGDAO SIFANG CO LTD

Smokeless welding devices for machine manufacturing

InactiveCN111390436AEasy to adjustThe adjustment mechanism is easy to use with the welding gunWelding/cutting auxillary devicesDirt cleaningMachine buildingFlue gas

The invention discloses a smokeless welding device for machine manufacturing, and relates to the technical field of machine manufacturing. The smokeless welding device comprises a workbench, and further comprises an adjusting mechanism, a clamping mechanism, a flue gas purifying mechanism and a welding table located in the middle of the upper end of the workbench, and four placing plates are arranged on the upper surface of the welding table in a rectangular shape. According to the welding device, three welding guns are used in cooperation with a rotary welding table, multiple welding positions on a machined object can be conveniently welded at a time, continuous welding of the machined object can be achieved, meanwhile, the clamping mechanism is designed in cooperation with the placing plates, the machined object can be conveniently clamped and fixed, and influence on welding effect due to movement or shaking of the machined object in welding process is avoided; and in addition, a protective shell is used in cooperation with the flue gas purifying mechanism, flue gas generated in the welding process is conveniently sucked into a purification cavity to be purified and then discharged, and the device is low in cost, high in welding effect and suitable for welding machining of large-batch objects.

Owner:JIANGSU OCEAN UNIV

Magazine type stud welding gun

PendingCN109175624AAvoid painIncreased manual welding efficiencyArc welding apparatusEngineeringTime duration

The invention discloses a magazine type stud welding gun which comprises a welding gun body, a nail containing magazine, a nail rotating barrel and a nail feeding centre. The upper end of the nail rotating barrel is fixedly connected with a main shaft body. The lower end of the nail rotating barrel is fixedly connected with a welding nail chuck. An opening is formed on the inner side face of the nail rotating barrel. The head end of the nail containing magazine penetrates through the opening to be located in an inner cavity of the nail rotating barrel. A nail collection hole communicating withthe welding nail chuck is formed in the lower end of the nail rotating barrel. A nail outlet through hole is formed in the head end of the nail containing magazine, and the tail end of the nail feeding centre can penetrate through the main shaft body and the upper end of the nail rotating barrel to abut against the top of a welding gun located in the nail outlet through hole. The nail containingmagazine is fixedly connected with a tube through a connecting assembly. According to the magazine type stud welding gun, magazine type nail feeding is achieved, multiple welding nails can be loaded easily at a time, automatic nail feeding can be achieved, the pain caused by manual loading to welding workers can be avoided, continuous welding of a certain time duration can be achieved, and the manual welding efficiency is obviously improved.

Owner:浙江上势自动焊接科技有限公司

Pre-feeding gap eliminating device of metal cylinder welding machine

ActiveCN103071952BEliminate gapsReduce lossWelding/cutting auxillary devicesAuxillary welding devicesFriction forceMetal

The invention discloses a pre-feeding gap eliminating device of a metal cylinder welding machine. The device comprises an upper conveying mechanism and a lower conveying mechanism, wherein the upper conveying mechanism and the lower conveying mechanism are fixedly arranged on a fixing seat, the upper conveying mechanism and the lower conveying mechanism respectively comprise two rows of chains and roller wheels, the chains are driven by a driving mechanism to synchronously run, the roller wheels are arranged on the chains and rotate around roller wheel shafts, the roller wheels are driven by the chains to do linear movement and also do radial rotation around the roller wheel shafts, and the roller wheels of the upper conveying mechanism are provided with positioning grooves which are used for positioning the crimping openings of the conveyed cylinders. When the two adjacent cylinders with a gap are conveyed between the upper conveying mechanism and the lower conveying mechanism, the gap between the end surfaces of the two metal cylinders is eliminated under the action of the friction force between the roller wheels and the metal cylinders. The pre-feeding gap eliminating device has the advantage that the continuous welding can be realized by the metal cylinder welding machine, and the arc starting and arc stopping notches are avoided on the continuous middle non-gap end surfaces of the metal cylinders, so the welding efficiency is improved, and the material loss is greatly reduced.

Owner:SHENZHEN PREVAIL TECH

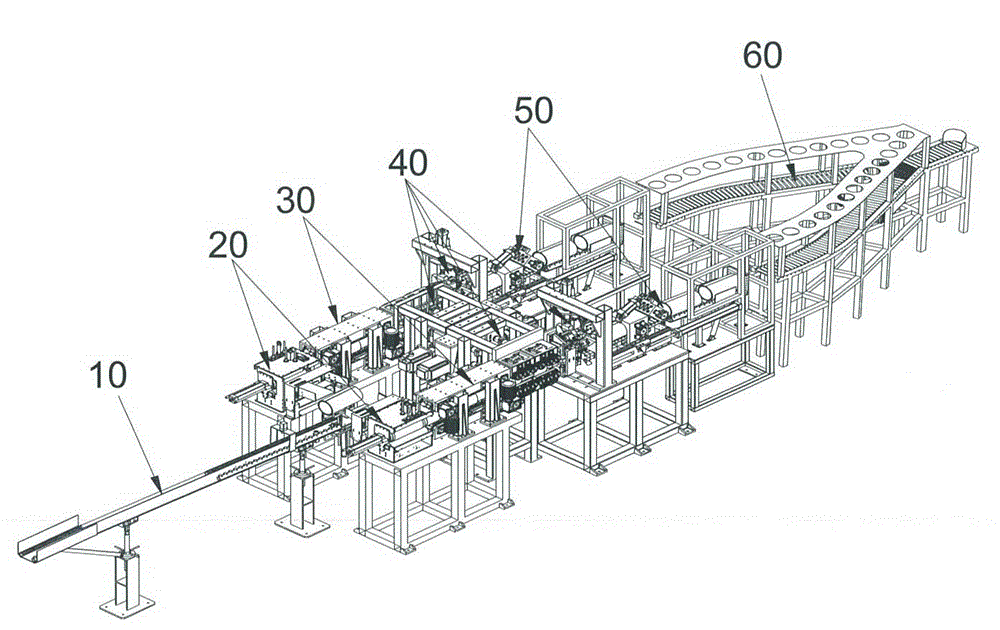

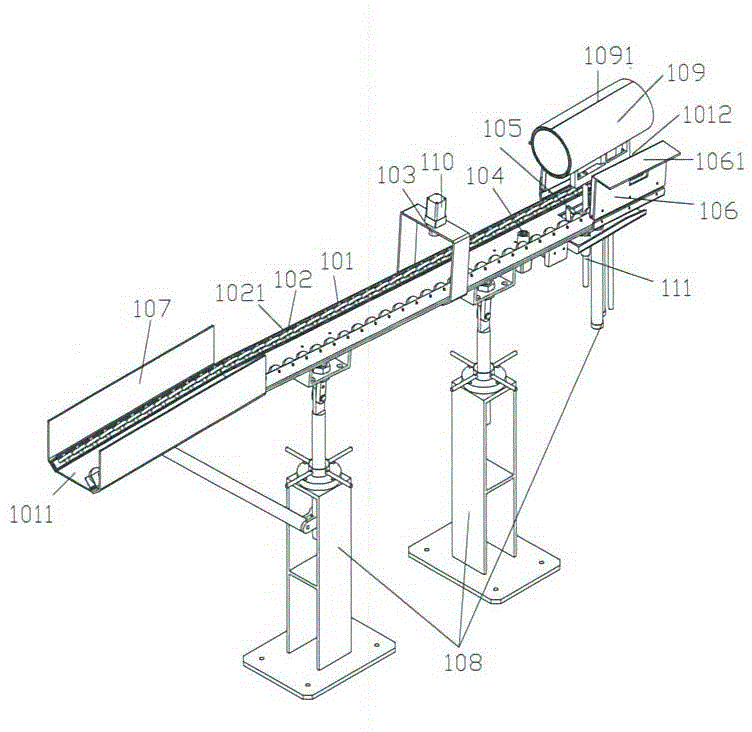

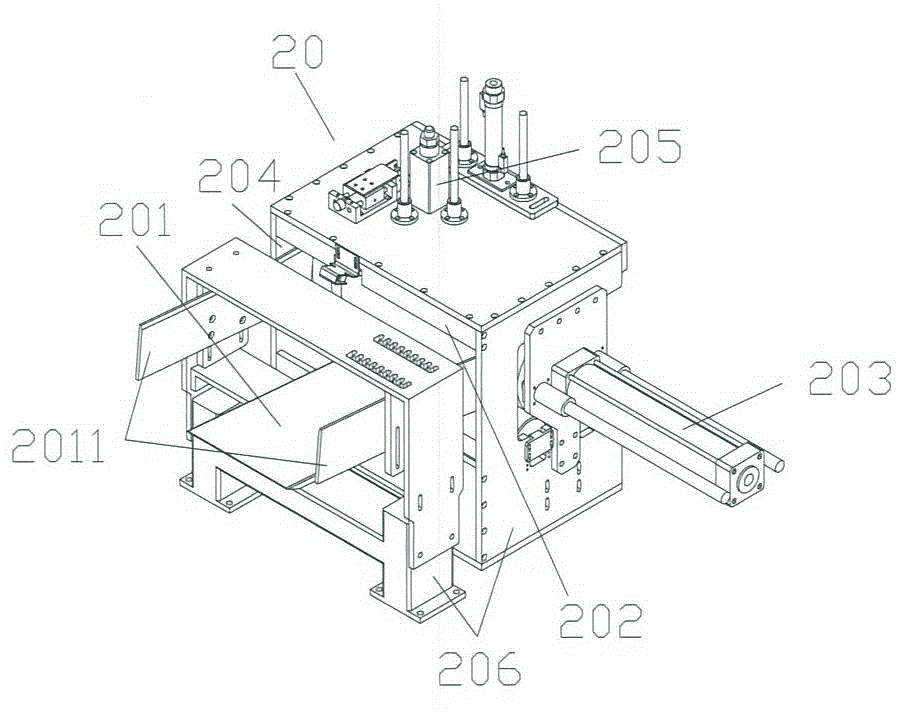

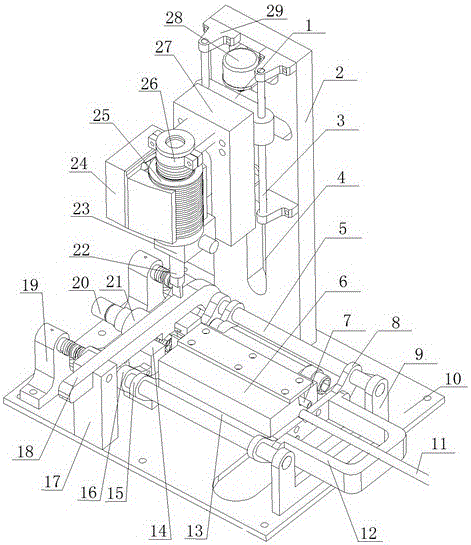

2M head automatic welding device

ActiveCN106378509ARealize automatic productionRealize continuous weldingSoldering ironMetal working apparatusAutomatic controlProduction line

The invention provides a 2M head automatic welding device and belongs to the technical field of welding. Through the 2M head automatic welding device provided by the invention, purely mechanical operation is adopted when a 2M head and a coaxial wire core are welded, and the welding precision is improved. The 2M head automatic welding device comprises a lifting mechanism, a welding mechanism, a tin feeding mechanism, a wire clamping mechanism, a guide rail mechanism, a 2M head fixing mechanism and a detection mechanism. According to the 2M head automatic welding device, the lifting mechanism, the welding mechanism, the tin feeding mechanism and the detection mechanism can be controlled automatically, the welding condition can be observed through a screen, of an inner camera, on a box, continuous welding and production line automatic production can be achieved, most manual labor is replaced, and the production efficiency is improved greatly. The labor intensity can be relieved, and the production efficiency is improved.

Owner:国网吉林省电力有限公司超高压公司 +1

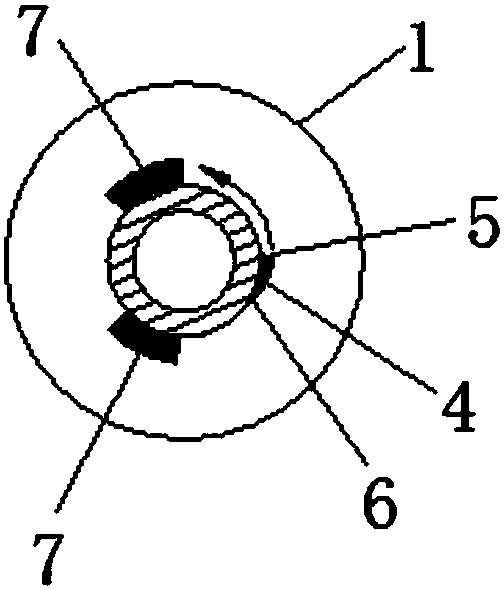

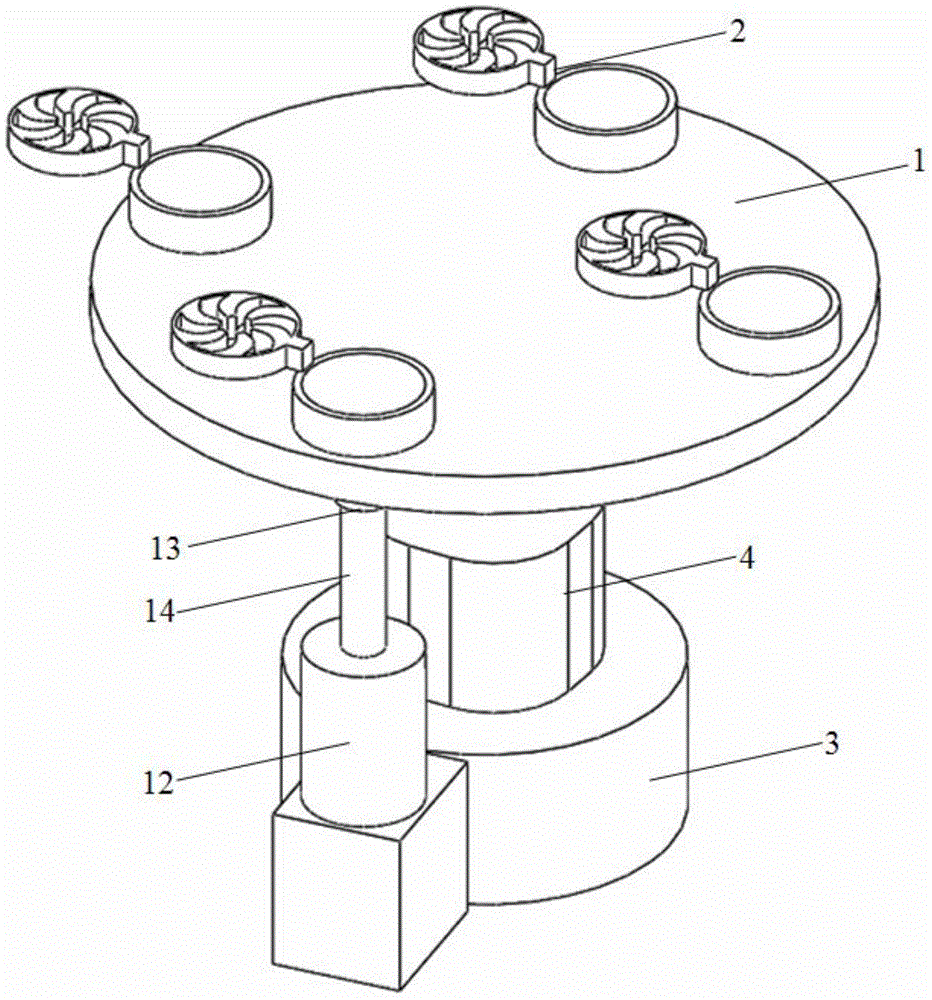

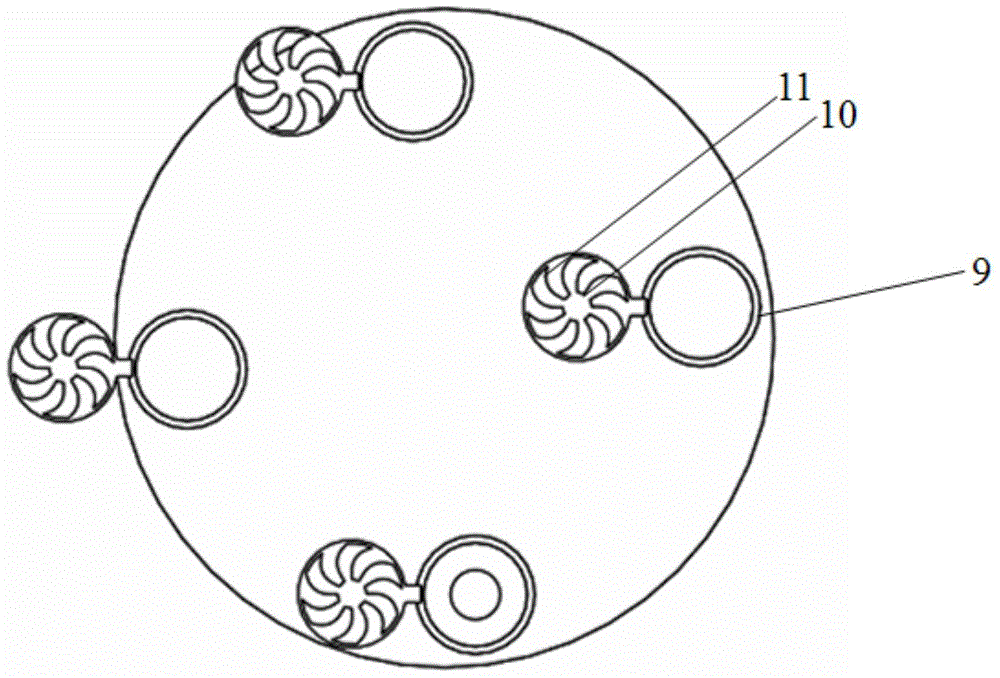

Continuous welding device for laser welder of impeller of water pump

ActiveCN104668773ARealize one-time weldingRealize continuous weldingLaser beam welding apparatusPhysicsElectric machinery

The invention relates to a continuous welding device for a laser welder of an impeller of a water pump. The continuous welding device for the laser welder of the impeller of the water pump comprises an automatic rotating plate and an impeller fixing clamp, wherein the impeller fixing clamp is arranged on the automatic rotating plate; a base is arranged on the lower portion of the automatic rotating plate; a motor is arranged in the middle of the base; a driving gear is arranged on a rotating shaft of the motor; a driven gear is fixed on the automatic rotating plate through screws; the driving gear and the driven gear are gripped with each other; the impeller fixing clamp comprises an impeller base fixing concave die and a blade fixing support; the blade fixing support consists of two concentric rings and an impeller fixing barrier strip welded to the middles of the rings; an ejector is arranged on the bottom of the automatic rotating plate and comprises a cylinder, a foot switch and an ejection lever; and the ejection lever is arranged on a piston of the cylinder. The blade fixing support is made of peek and is connected to the base through hinges. The continuous welding device for the laser welder of the impeller of the water pump is simple in structure, novel in design, convenient to operate and high in production efficiency, and has an automatic continuous welding function.

Owner:ANHUI SHUNYU WATER AFFAIRS CO LTD

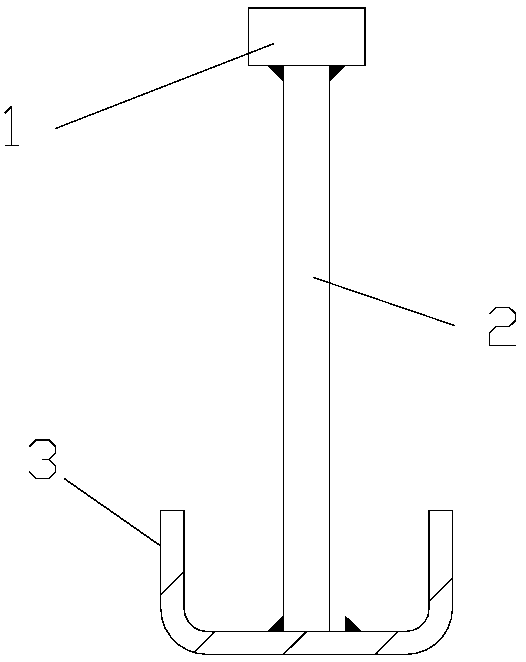

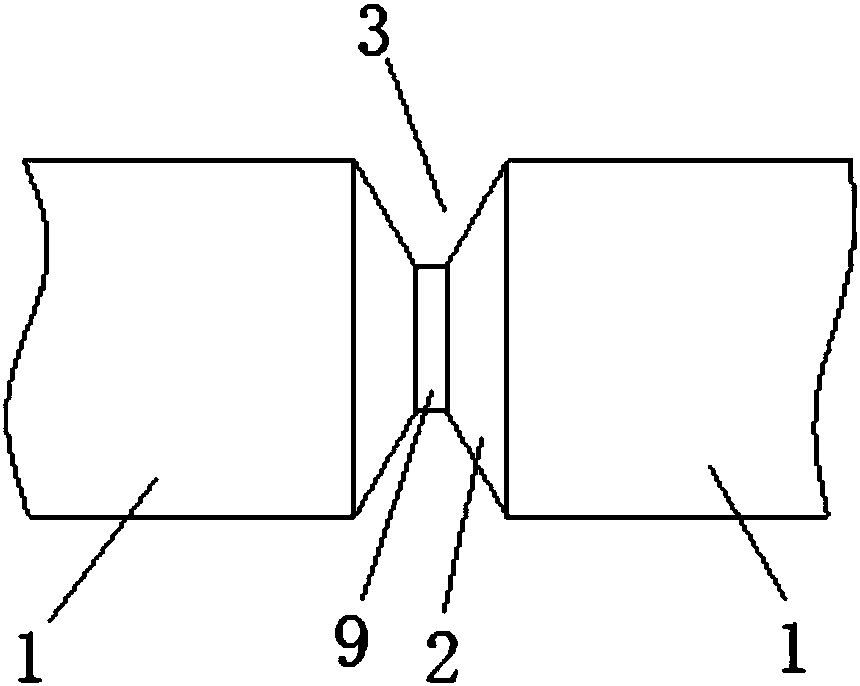

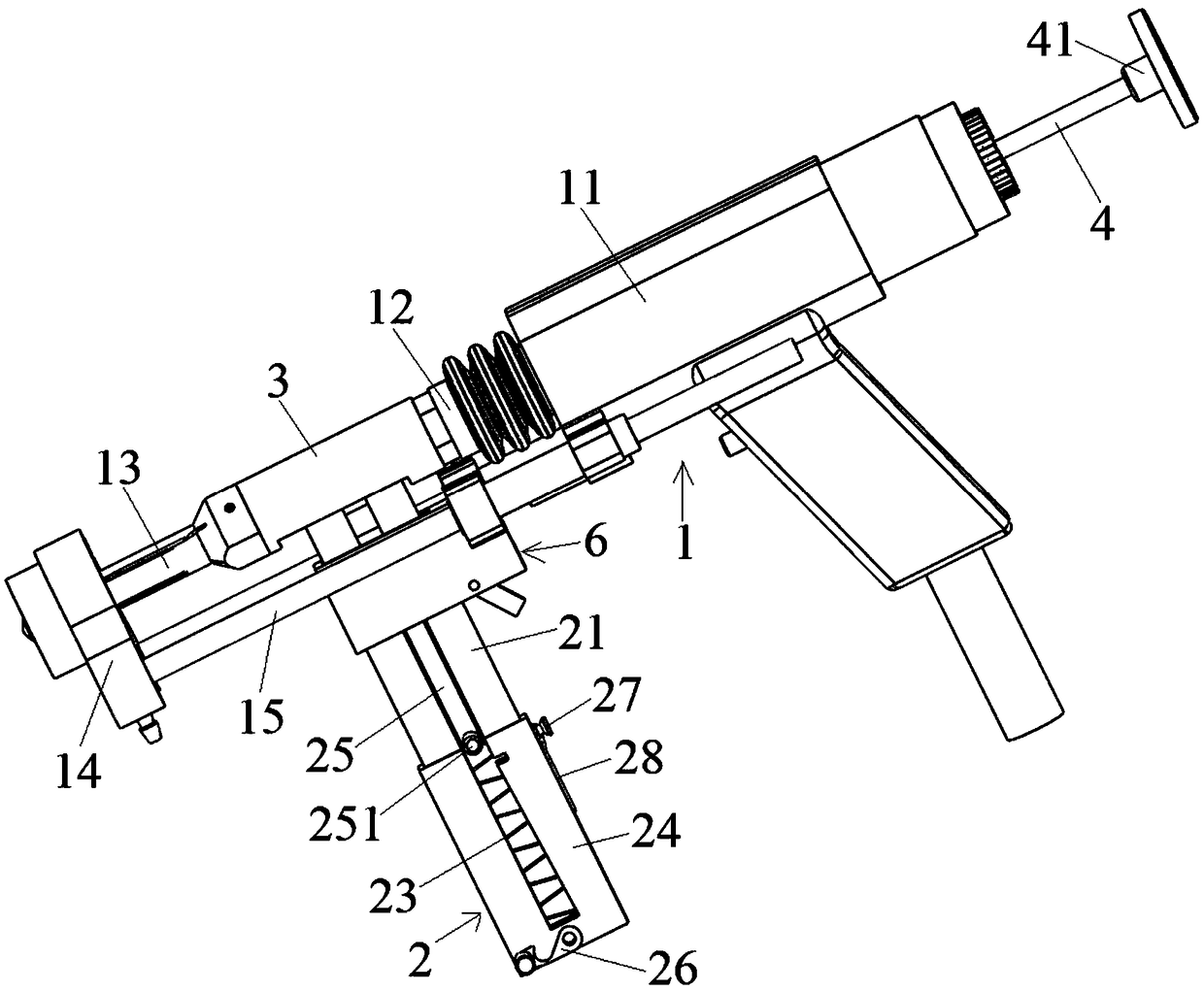

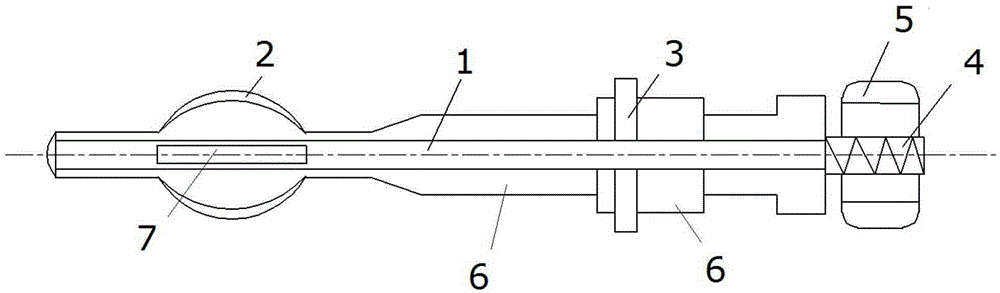

Inner expansion positioning welding central spindle

InactiveCN106695234AWith expansion and contraction functionRealize continuous weldingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWeld seam

The invention belongs to the technical field of aerospace manufacturing, and particularly discloses an inner expansion positioning welding central spindle. The inner expansion positioning welding central spindle comprises a tension bar, an elastic expansion device and a limiting device. A lug is machined on the tension bar. The elastic expansion device is arranged outside the lug. The limiting device is fixedly arranged outside the middle part of the tension bar. The inner expansion positioning welding central spindle further comprises a rotary moving structure arranged at one side of the tension bar. The welding central spindle has an expansion and contraction function. In the welding process, the tension bar can be adjusted through an adjusting nut, radial-direction expansion of an inner bracing structure is realized so that a pipe and a joint can be fixed, and the pipe and the joint are located on the same axis; angular deformation of the pipe and the joint due to welding high temperatures is avoided, the phenomenon that the welding position of the joint is molten due to overtemperature in the welding process, strength is lowered and thus the welded joint is disengaged can be prevented, repeated arc starting and suppressing can be avoided, continuous welding of welding seams is achieved, and the welding percent of pass is increased.

Owner:CAPITAL AEROSPACE MACHINERY +1

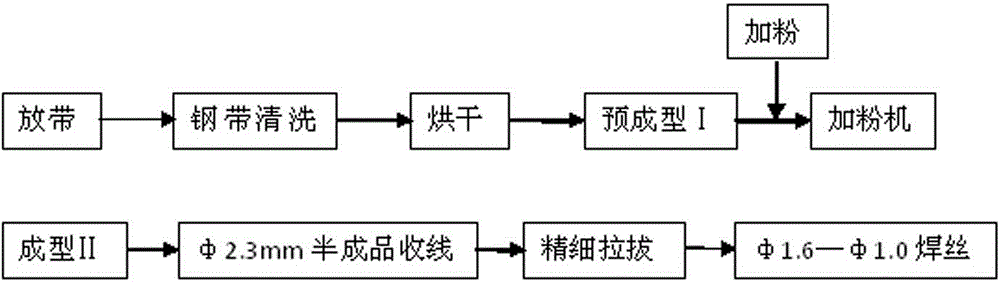

Low-temperature preheating high-strength flux-cored wire and production process thereof

InactiveCN106346166ARealize continuous weldingSimple welding processWelding/cutting media/materialsSoldering mediaSteel beltWelding process

The invention discloses a low-temperature preheating high-strength flux-cored wire and a production process thereof, belongs to the technical field of welding materials and can solve the problems that a high-strength plate high-temperature heating welding process is complicated, long in cycle and high in cost, and product quality cannot be ensured by a production process in the prior art. The low-temperature preheating high-strength flux-cored wire comprises a steel tape sheath and powder, the steel tape sheath is provided with an O-shaped section, and the powder is placed in the steel tape sheath and comprises, in weight percentage, 0.03-0.042% of C, 0.47-0.49% of Si, 1.56-1.87% of Mn, 0.013-0.015% of P, 0.009-0.0092% of S, 1.18-1.52% of Ni, 0.12-0.25% of Cr, 0.298-0.37% of Mo, 0.003-0.004% of V and 0.013-0.014% of Cu. The balance is the steel tape sheath, a steel tape is longitudinally sheared, a welding wire is pre-formed and secondarily formed, and the flux-cored wire is produced by a fine drawing process. The welding process can be simplified, and the quality of the flux-cored wire can be improved.

Owner:JINCHENG JINFEI ELECTROMECHANICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com