Automatic active argon tungsten-arc welding method

A welding method and argon tungsten arc technology, which are applied in welding equipment, welding accessories, arc welding equipment, etc., can solve problems such as poor welding effect, achieve improved mechanical properties, avoid stability, avoid pollution and burning damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Example 1, the automatic active tungsten argon arc welding method of the present invention is used to carry out direct current positive surface fusion welding on an austenitic stainless steel plate SUS304 with a thickness of 8 mm.

[0056] Among them, the active agent powder is SiO 2 , the particle size is 100 mesh, the motor speed of the powder feeder is 30r / min, that is, the delivery amount of the active agent powder with the outer gas is 0.62g / min. The inner layer gas is argon, and the outer layer gas is argon. The welding process parameters are: welding current 180A, welding speed 80mm / min, arc length 3mm, inner layer gas flow rate 10L / min, outer layer gas flow rate 6L / min.

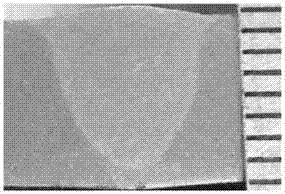

[0057] Before the welding operation, the appearance of the tungsten electrode is as follows: figure 2 Shown; During the welding process, the shape of the arc is as follows image 3 As shown; after welding is completed, the front side of the weld is obtained as Figure 4 As shown, the cross...

Embodiment 2

[0058] In Example 2, the same method as in Example 1 was used to carry out direct current positive surface fusion welding on an austenitic stainless steel plate SUS304 with a thickness of 8 mm. The only difference is that the welding current is 200A, the gas flow rate of the inner layer is 12L / min, and the gas flow rate of the outer layer is 8L / min.

[0059] After welding is completed, obtain the front side of the weld as Figure 7 As shown, the backside of the weld is obtained as Figure 8 As shown, the cross-section of the obtained weld is as Figure 9 shown.

Embodiment 3

[0060] In Example 3, the same method as in Example 1 was used to carry out direct current positive surface fusion welding on an austenitic stainless steel plate SUS304 with a thickness of 8 mm. The only difference is that the active agent powder is made of TiO 2 .

[0061] After welding is completed, obtain the front side of the weld as Figure 10 As shown, the cross-section of the obtained weld is as Figure 11 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Penetration | aaaaa | aaaaa |

| Penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com