Inner expansion positioning welding central spindle

A technology of positioning welding and mandrel, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of falling off, angular deformation, easy softening of small-diameter aluminum alloy conduit joints, etc., to avoid angular deformation, The effect of improving the welding qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

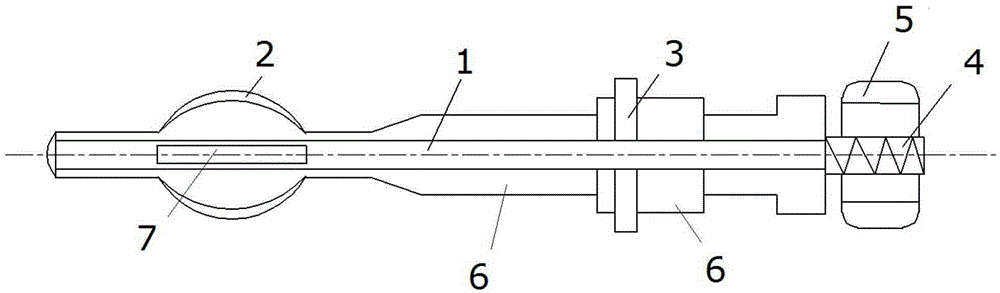

[0016] Such as figure 1 As shown, the stretching rod 1 is a long rod, a protrusion 7 is processed on the long rod, and a limit ring 3 is sheathed in the middle of the stretching rod 1. One end of the stretching rod 1 is connected to the screw 4.

[0017] The stretching rod 1 is installed in the outer sleeve 6. The above-mentioned limit ring 3 divides the outer sleeve 6 into two. The outer sleeve on one side of the limit ring 3 is divided into two sections with different sizes and diameters. The elastic expansion ring 2 is integrally processed, and two sections with different sizes and diameters are connected by a tapered surface. The protrusion 7 of the above-mentioned stretching rod 1 is located in the elastic expansion ring 2.

[0018] The outer sleeve on the other side of the limit ring 3 is wrapped around the outside of the stretching rod 1, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com