Low-temperature preheating high-strength flux-cored wire and production process thereof

A flux-cored welding wire and production process technology, which is applied in the field of low-temperature preheating high-strength flux-cored welding wire and its production process, can solve the problems of complex high-temperature heating welding process, unguaranteed production process, and high cost, so as to improve welding production efficiency, The effect of improving the quality of welding wire and simplifying the welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1, a low-temperature preheating high-strength flux-cored welding wire, including a steel strip sheath with an O-shaped cross-section and powder packed in the steel strip sheath, the medicine powder includes the following components by mass percentage: C: 0.042%; Si : 0.49%; Mn: 1.56%; P: 0.013%; S: 0.0092%; Ni: 1.18%; Cr: 0.12%; Mo: 0.3%; .

Embodiment 2

[0023] Example 2, a low-temperature preheating high-strength flux-cored welding wire, including a steel strip sheath with an O-shaped cross-section and powder packed in the steel strip sheath, the medicine powder includes the following components by mass percentage: C: 0.04%; Si : 0.47%; Mn: 1.76%; P: 0.015%; S: 0.009%; Ni: 1.38%; Cr: 0.15%; Mo: 0.298%; V: 0.004%; .

Embodiment 3

[0024] Embodiment 3, a low-temperature preheating high-strength flux-cored welding wire, including a steel strip sheath with an O-shaped cross-section and powder packed in the steel strip sheath, the medicine powder includes the following components by mass percentage: C: 0.03%; Si : 0.49%; Mn: 1.87%; P: 0.013%; S: 0.0092%; Ni: 1.52%; Cr: 0.25%; Mo: 0.37%; .

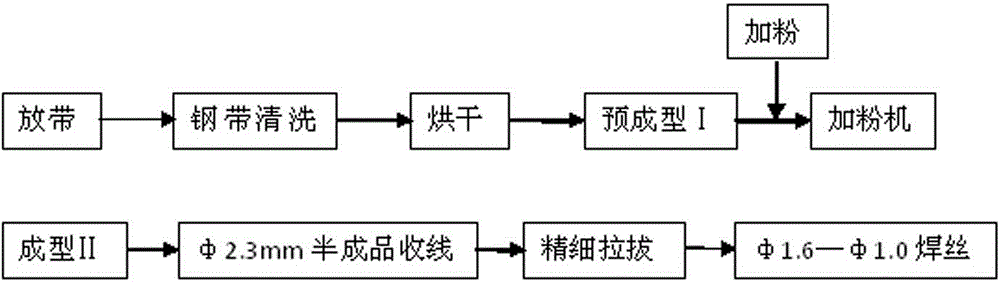

[0025] A production process for low-temperature preheating high-strength flux-cored welding wire, comprising the following steps:

[0026] The first step is the slitting of the steel strip. The raw steel strip is cut into a narrow steel strip of 8-16mm on the steel strip slitting machine, and then the narrow steel strip is wound on the I-shaped wheel by the steel strip layer winding machine for subsequent use. process use;

[0027] In the second step, the welding wire is preformed. After shearing and processing, the narrow steel strip is rolled on the I-shaped wheel. After the steel strip cleaning machine cleans the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com