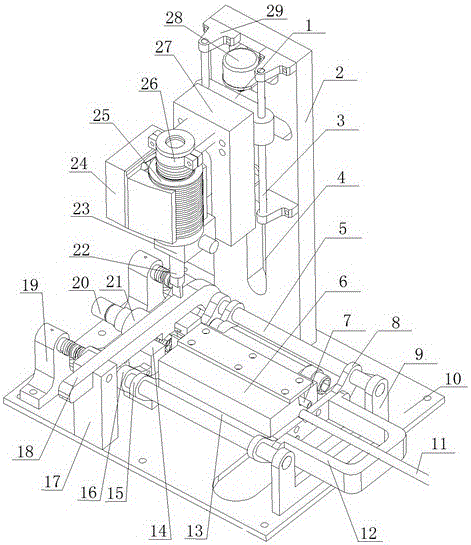

2M head automatic welding device

An automatic welding and detection head technology, applied in tin feeding devices, auxiliary devices, welding equipment, etc., can solve the problems of high labor intensity and low production efficiency, reduce labor intensity, improve production efficiency, and realize automatic assembly line production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

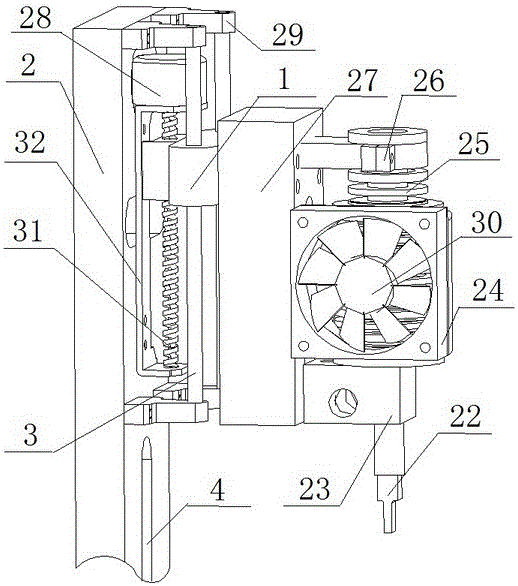

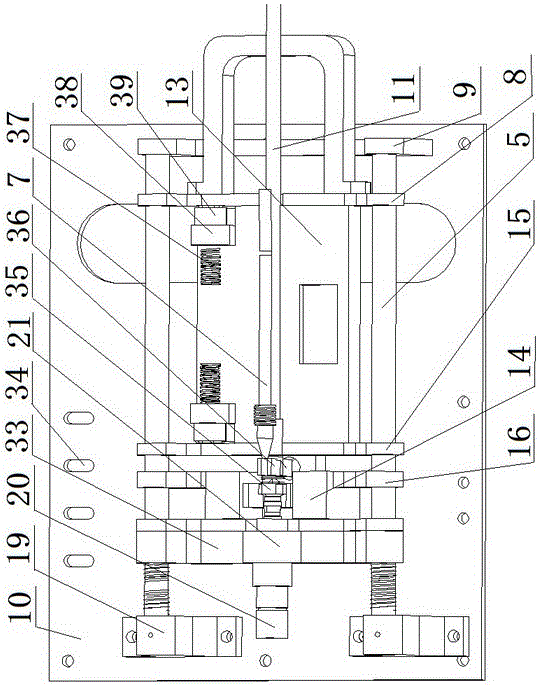

[0013] The lifting support plate 2 of the present invention is installed on the base 10 through the mounting hole 34. The lifting support plate 2 mainly controls the lifting of the tip of the soldering iron. A lifting guide rail seat 29 is installed on the lifting support plate 2. Elevating guide rail 3, screw support 32 is fixedly installed on the lifting support plate 2, leading screw motor 28 is installed on the leading screw support 32, and lifting lead screw 31 is installed on the shaft of leading screw motor 28, and lifting slide block 1 front end cover On the lifting guide rail 3, the rear end is matched with the thread of the lifting screw 31, and a soldering iron seat 27 is installed on the lifting slider 1, and a hanging clip 26 is installed on the soldering iron seat 27, and the hanging clip 26 is clamped on the soldering iron device 25, and the soldering iron device The lower end of 25 is stuck on the soldering iron bracket 23, and the fan 30 is installed through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com