Meat ball making and forming device for food processing

A forming device and food processing technology, applied in the direction of processed meat, meat processing equipment, applications, etc., can solve the problem of slow meatball production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

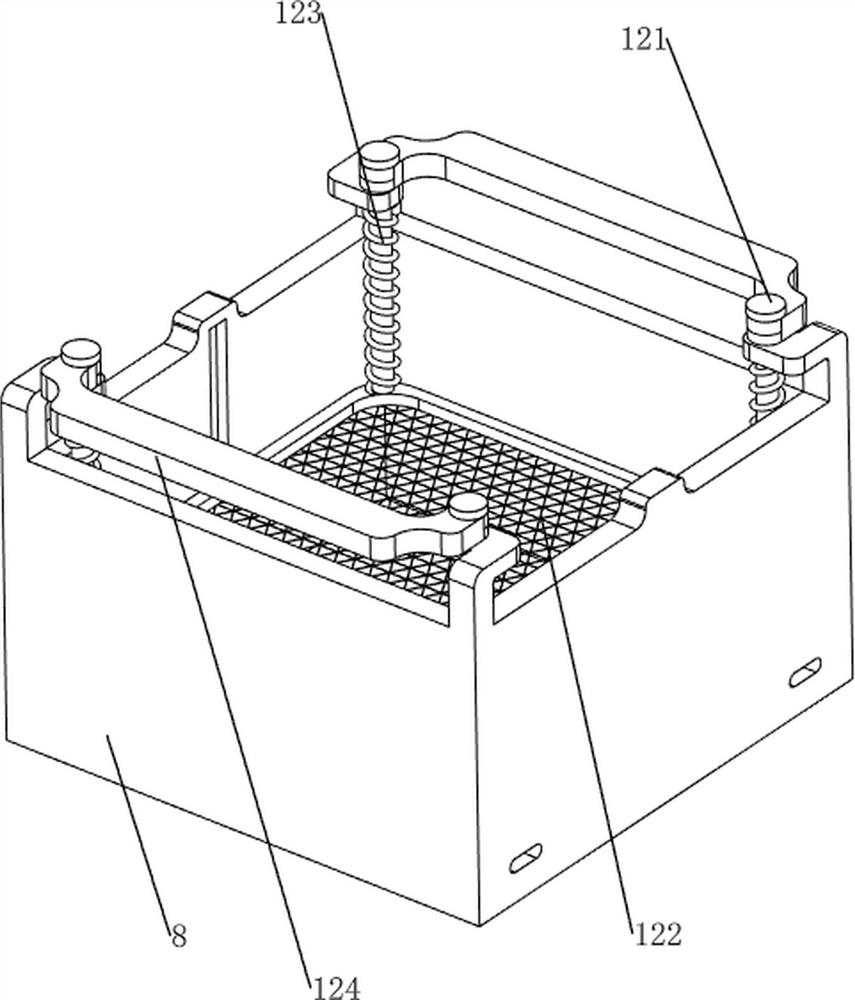

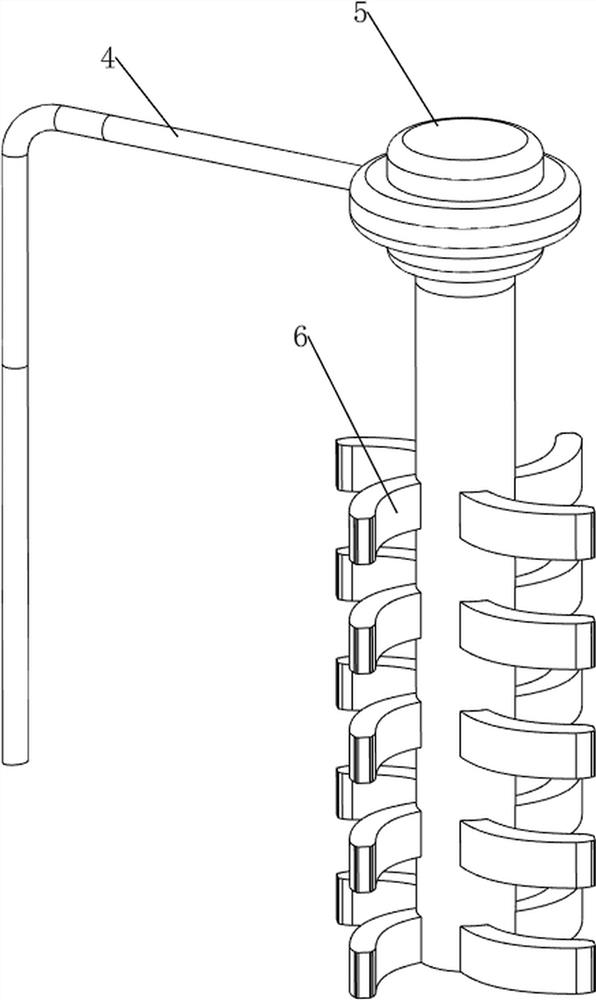

[0027] A kind of meatball making molding device for food processing, such as Figure 1-2 As shown, it includes a supporting plate 1, a first supporting frame 2, a first charging frame 3, a second supporting frame 4, a motor 5, a crushing rod 6, a discharging frame 7, a second charging frame 8, a cutting material Mechanism 9 and manual extrusion mechanism 10, a first support frame 2 is provided on the left side of the top of the support plate 1, a first loading frame 3 is provided on the upper side of the first support frame 2, and a second support frame is provided on the top of the first support frame 2 frame 4, a motor 5 is provided on the second support frame 4, a crushing rod 6 is provided on the lower side of the motor 5, the crushing rod 6 is located in the first charging frame 3, and a second charging frame is provided in the middle of the top of the support plate 1 8. A discharge frame 7 is provided on the rear side of the top of the support plate 1, a material cutting...

Embodiment 2

[0030] On the basis of Example 1, such as figure 1 , image 3 with Figure 4 As shown, the material cutting mechanism 9 includes a first slide rail 91, a blade 92 and a first spring 93, the front and rear sides of the right side of the discharge frame 7 are provided with a first slide rail 91, and the bottom of the first slide rail 91 slides The formula is provided with a blade 92, and a first spring 93 is connected between the blade 92 and the first slide rail 91.

[0031] After the meat stuffing is extruded from the bottom of the discharge frame 7, the user can move the blades 92 on both sides to the inside, and the first spring 93 is compressed, so that the blade 92 can cut the meatball. When a force is applied, the blade 92 moves outward and resets under the reset action of the first spring 93 .

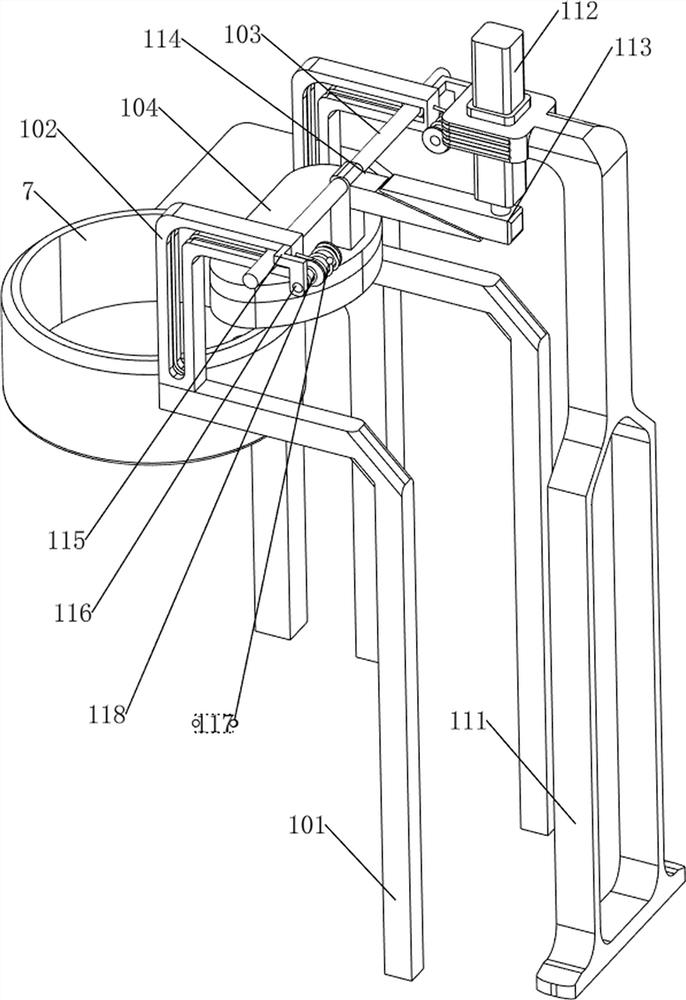

[0032] The manual extruding mechanism 10 includes a third support frame 101, a second slide rail 102, a first movable bar 103 and an extruding plate 104, and the front and rea...

Embodiment 3

[0035] On the basis of Example 2, such as figure 1 with Figure 4-7 As shown, an automatic extrusion mechanism 11 is also included, and the automatic extrusion mechanism 11 includes a fourth support frame 111, a cylinder 112, a first wedge block 113, a second wedge block 114, a fixed block 115, a winding wheel 116, a pulley Rope 117 and torsion spring 118, support plate 1 top right side is provided with the 4th bracing frame 111, and the 4th bracing frame 111 is positioned at the 3rd bracing frame 101 right sides, and the 4th bracing frame 111 top is provided with cylinder 112, and the expansion and contraction of cylinder 112 A first wedge-shaped block 113 is provided on the rod, a second wedge-shaped block 114 is provided on the right side of the extruding plate 104, and a fixed block 115 is provided on the outer position of the right side of the second slide rail 102, and a fixed block 115 is provided on the fixed block 115 in a rotating manner. A reel 116, a torsion sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com