Hydraulic cylinder with sealing follow-up device

A technology of follower device and hydraulic cylinder, applied in the field of hydraulic cylinder, can solve the problems of poor continuous working ability, low working pressure and short life, and achieve the effect of good sealing effect, increased pressure and enhanced sealing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

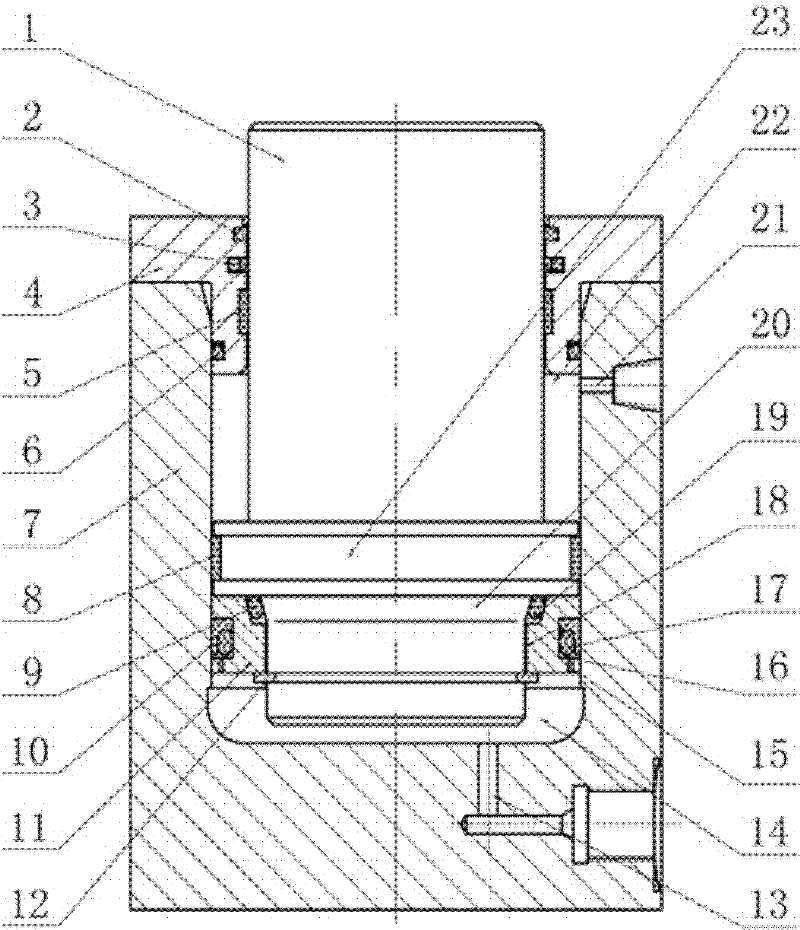

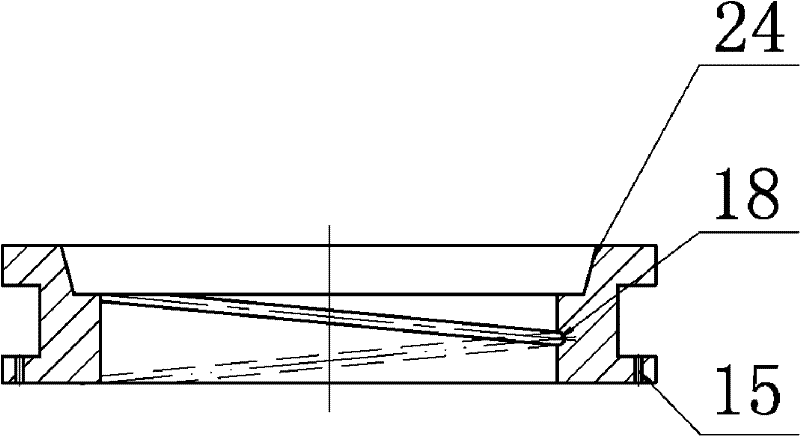

[0023] in Figure 1-Figure 2 In the embodiment shown, the piston guide ring 8 is installed in the piston annular groove 23 on the piston 1, and the seal follower ring 11 is installed on the rodless side of the piston 1, and is fixed with a snap ring 12 to seal the truncated cone hole on the follower ring 11. 24 and the outer conical surface of the piston 1 form the pressure oil chamber 19 in the sealing follower ring, and form a sealing pressure cone angle 28. The sealing pressure cone angle 28 is less than 90 degrees, and the seal will be pressed into the pressure cone angle under pressure. Inside, the positive pressure area will be reduced to protect the seal. Because of the presence of the pressure cone angle, the side pressure will increase, making the seal more effective. At the same time, the design of the pressure cone angle will make the seal be in the alternate process of forward compression and reverse compression when pressurizing and releasing pressure, that is, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com