Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about How to "Save tooling costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

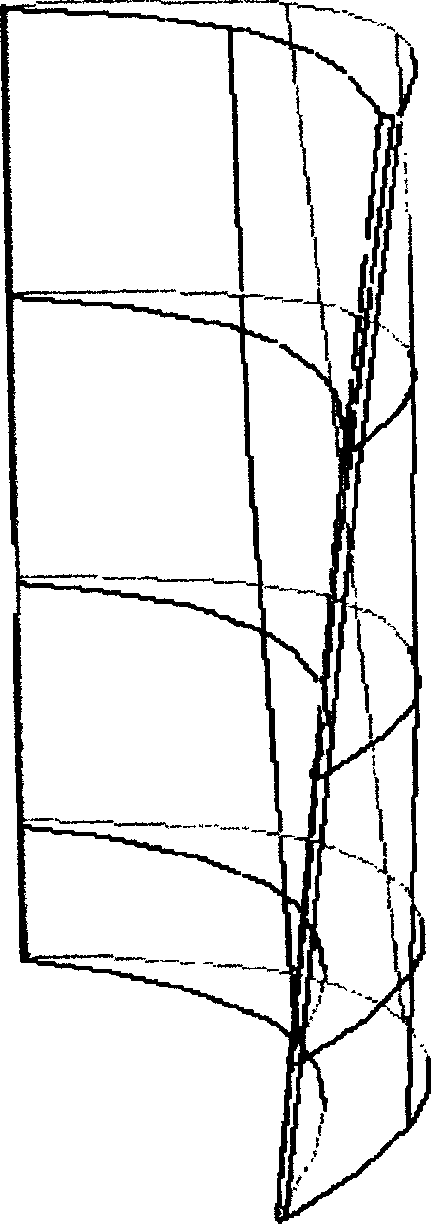

Method and apparatus for turbine blades milling with once clamping

InactiveCN1613590ASimple interfaceEasy to operateMilling equipment detailsNumerical controlSteam turbine blade

A technology for milling the blade of steam turbine by fixing it on the 5-coordinate numerally controlled machine-tool once includes such steps as improving the coarse machining module of Turbsoft program for 5-coordinate numerally controlled machine tool by adding the blade-milling module, fixing the steel blank of blade onto said machine-tool, and milling under the control of said program.

Owner:DONGFANG TURBINE CO LTD

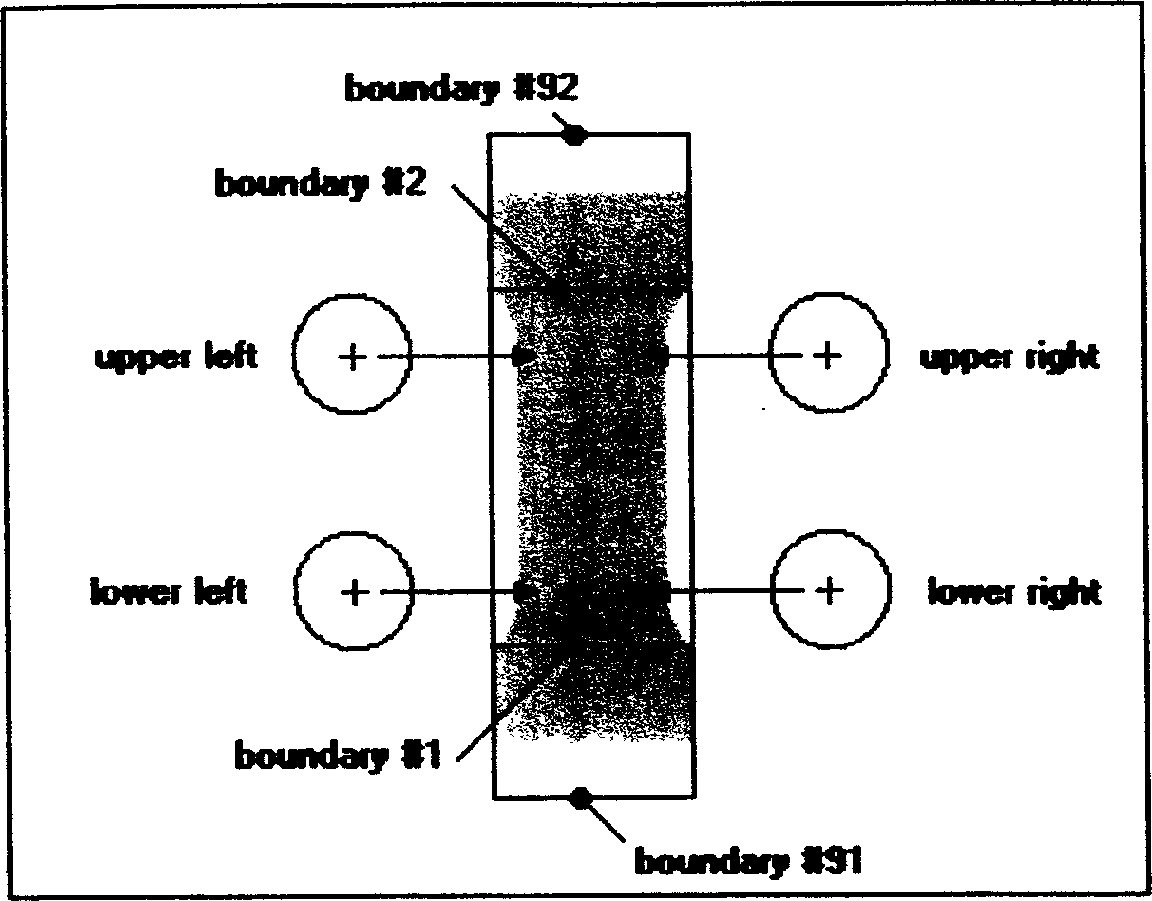

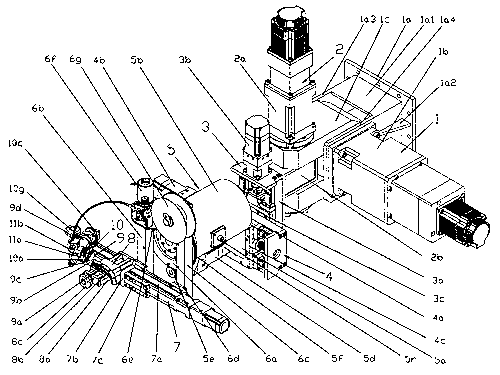

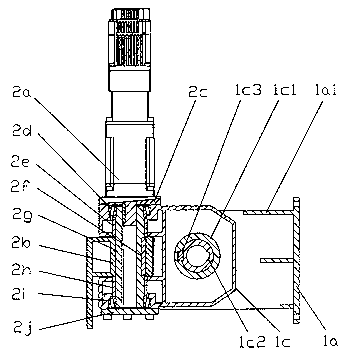

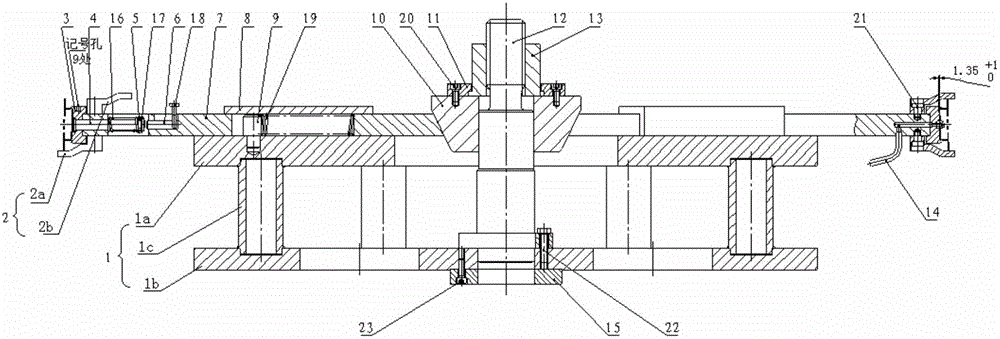

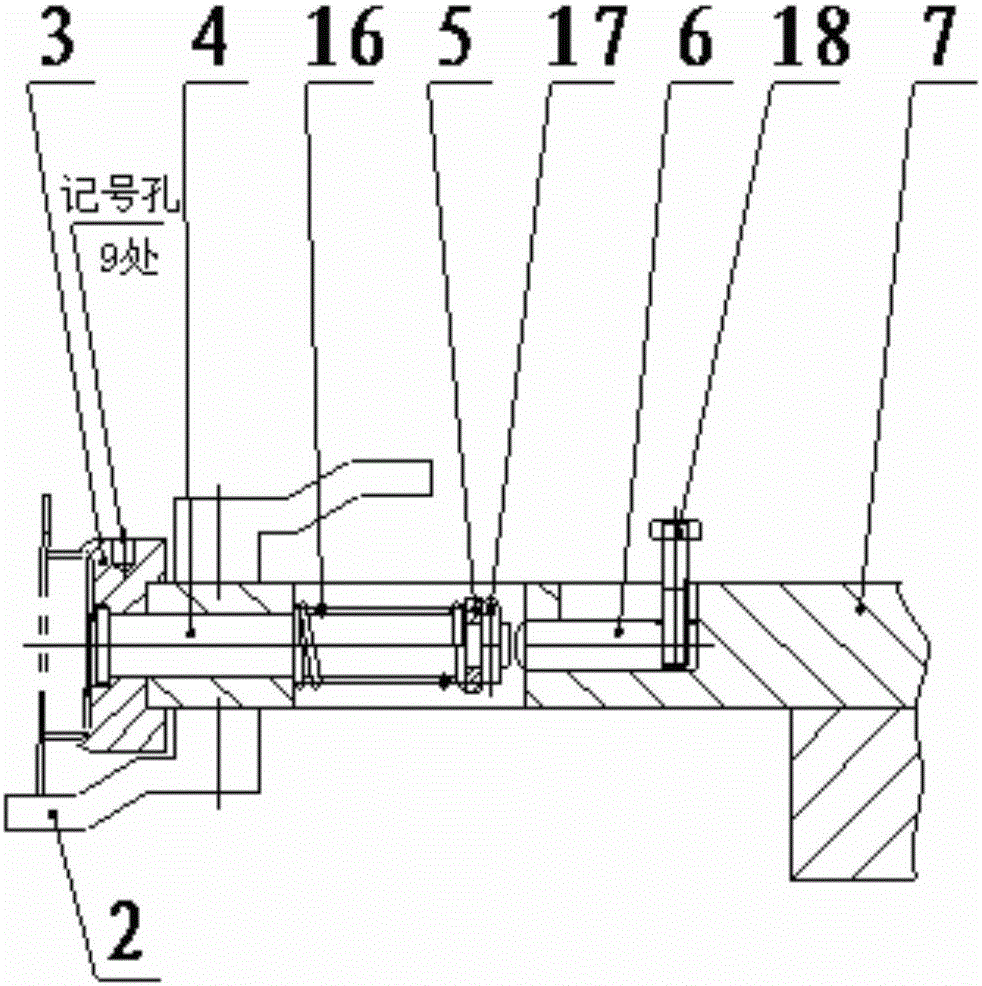

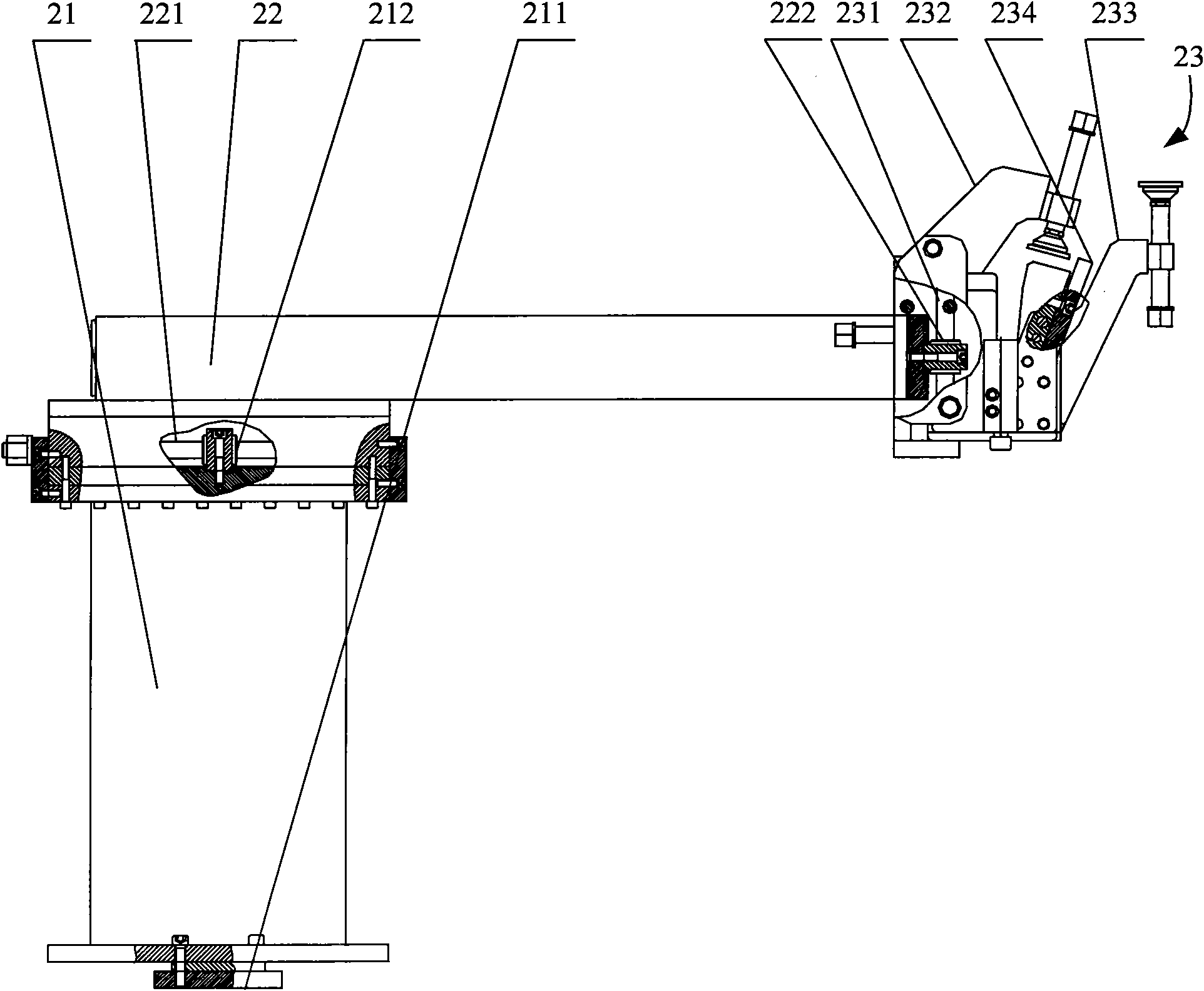

Flange sealing groove inner surface annular all-position TIG (Tungsten Inert Gas) automatic surface welding equipment and welding method thereof

InactiveCN102825368AExcellent surfacing qualityEasy post-weld processingArc welding apparatusElectrical controlElectric control

The invention provides a flange sealing groove inner surface annular all-position TIG (Tungsten Inert Gas) automatic surface welding equipment and a welding method thereof, belonging to the technical field of automatic welding equipments and welding methods. The automatic welding equipment mainly comprises a position regulation mechanism and a TIG rotary welding head, wherein the TIG rotary welding head is used for regulating a surface welding position of a flange sealing groove through the position regulation mechanism. An electric control device is used for setting parameters such as welding current, a wire feed speed, a welding speed and arc voltage control according to the circumferential position located by the welding head and a cycle of 12 preset partitions so as to carry out welding control. The rotational radius of the welding head can be automatically changed inwards or outwards according to set width after a cycle of welding is finished, so that surface welding in the flange sealing groove is realized, and surface welding on the side surface of the flange sealing groove is carried out after an angle of a welding gun is changed until one end surface is piled up. The surface welding surface is smooth, so that the problems of cutter beating and long processing time in the process of processing the flange sealing groove by manual surface welding at a later stage are avoided, surface welding quality is superior to quality of manual surface welding, and the problem that a product is repaired due to defects after manual surface welding is reduced.

Owner:CHINA FIRST HEAVY IND +1

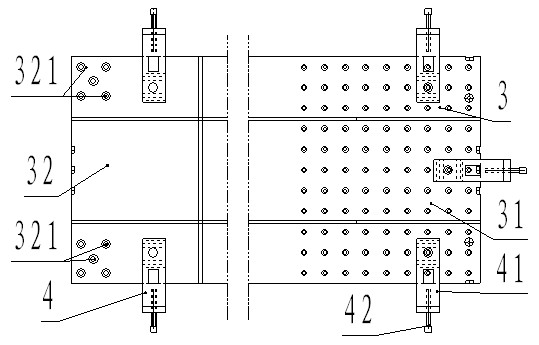

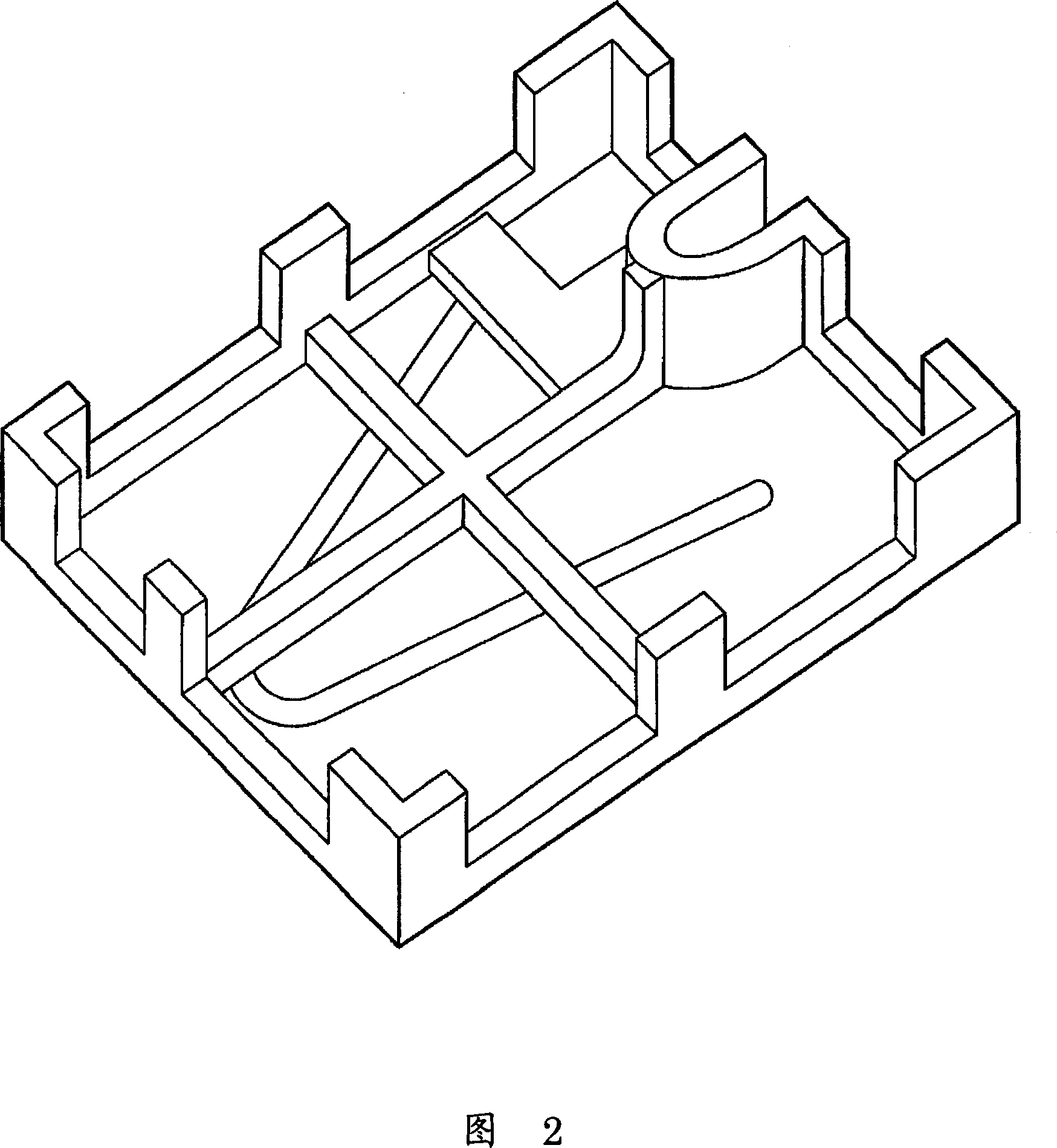

Adjustable multi-point positioning hole making device and hole making method

ActiveCN102632273AGuaranteed hole making accuracyGuaranteed accuracyDrill jigsEngineeringHole making

The invention discloses an adjustable multi-point positioning hole making device, which comprises a hole making template, a regulating template and two bridging plates used for connecting the hole making template and the regulating template, wherein the hole making template comprises a hole making end provided with hole groups and a positioning end used for connecting the bridging plates, the regulating template comprises a hole making end provided with hole groups and a regulating positioning end used for connecting the bridging plates, one ends of the bridging plates are provided with a plurality of groups of connecting holes matched with positioning holes of the hole making template, each group of connecting holes are in arrangement with certain distances between the front and the back, and the other ends of the bridging plates are provided with bridging holes. The adjustable multi-point positioning hole making device adopting the technical scheme has the advantages that the universality is high, the kind and the number of the hole making device can be recued, the tooling manufacture cost is reduced, and the standard production requirement of the hole making in the large-scale manufacture process is met. The invention also discloses a hole making method utilizing the device, the method is simple and feasible, and the hole making is precise.

Owner:中铁宝桥(扬州)有限公司

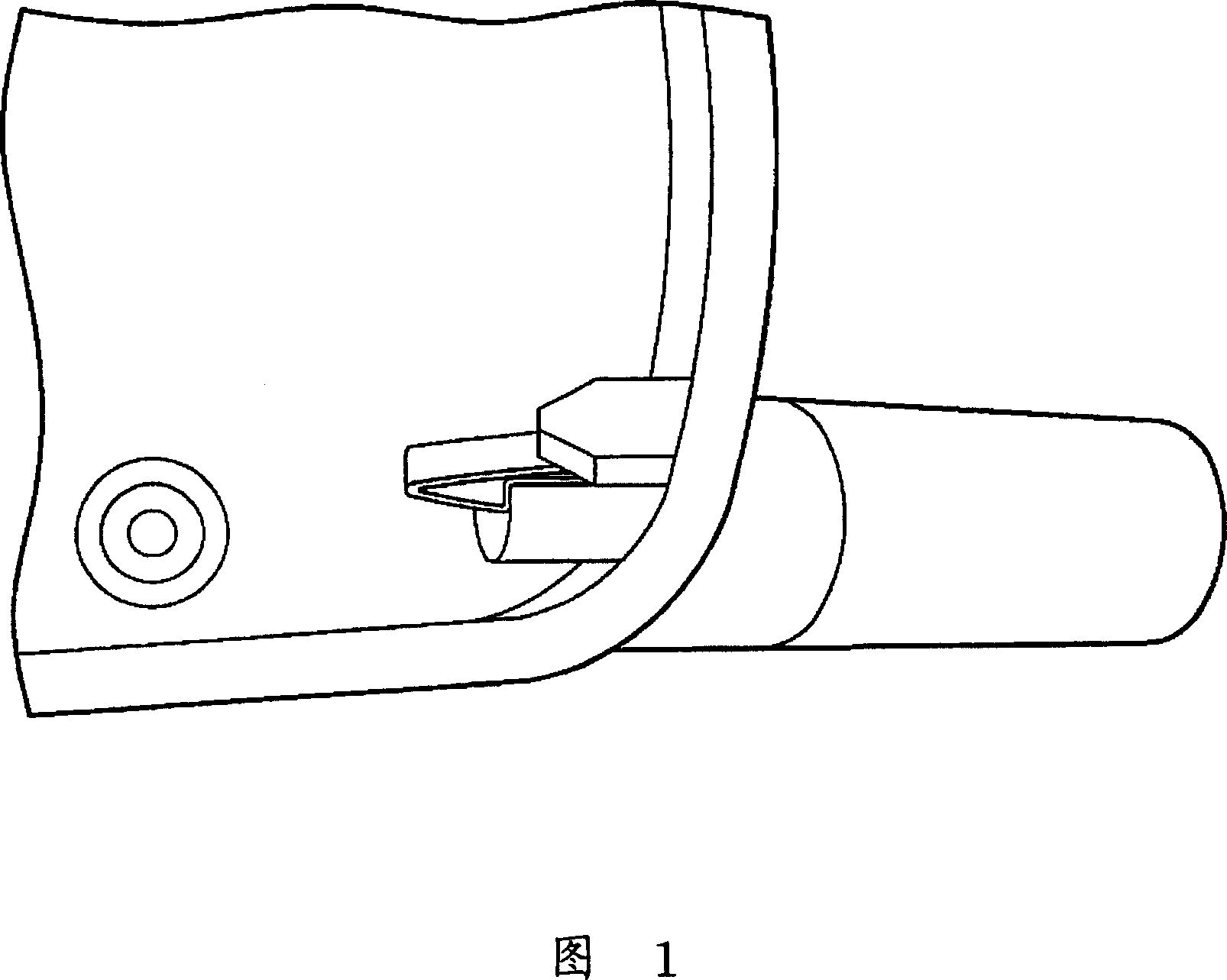

Bidirectional location thin-walled workpiece welding clamp

ActiveCN106425256APrevent oxidationEliminate positioning gapsWelding/cutting auxillary devicesAuxillary welding devicesWeld seamEngineering

The invention discloses a bidirectional location thin-walled workpiece welding clamp. The bidirectional location thin-walled workpiece welding clamp comprises a body base, a clamping plate, overturnable locating blocks, small shafts, gaskets, push pins, expansion blocks, guide plates, stop pins, a conical body, a cover plate, a mandrel, a nut, a ventilation pipe, a locating plug, springs I, split pins, bolts I, springs II, screws I, screws II, bolts II and screws III. By means of the bidirectional location thin-walled workpiece welding clamp, location clearance can be effectively eliminated, welding deformation can be resisted, and a welding seam zone is prevented from metal oxidation; and due to the fact that a locating face can be overturned, a support ring can be welded to a tool, and the number of tools and tool replacement time are reduced. When the bidirectional location thin-walled workpiece welding clamp is used practically, the problems that welding deformation of the support ring is large, and dimensions and angles are out of tolerance are solved; tool cost is saved; labor intensity is lowered; the qualification rate of products is increased; and production efficiency is improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

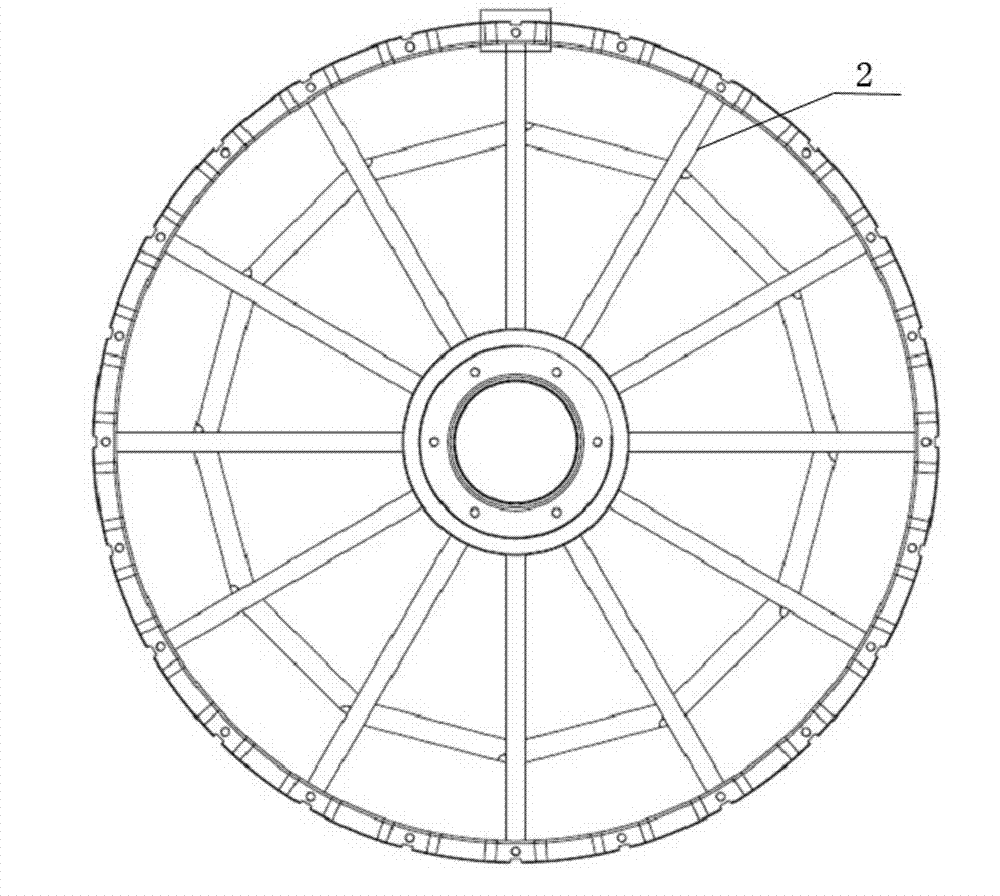

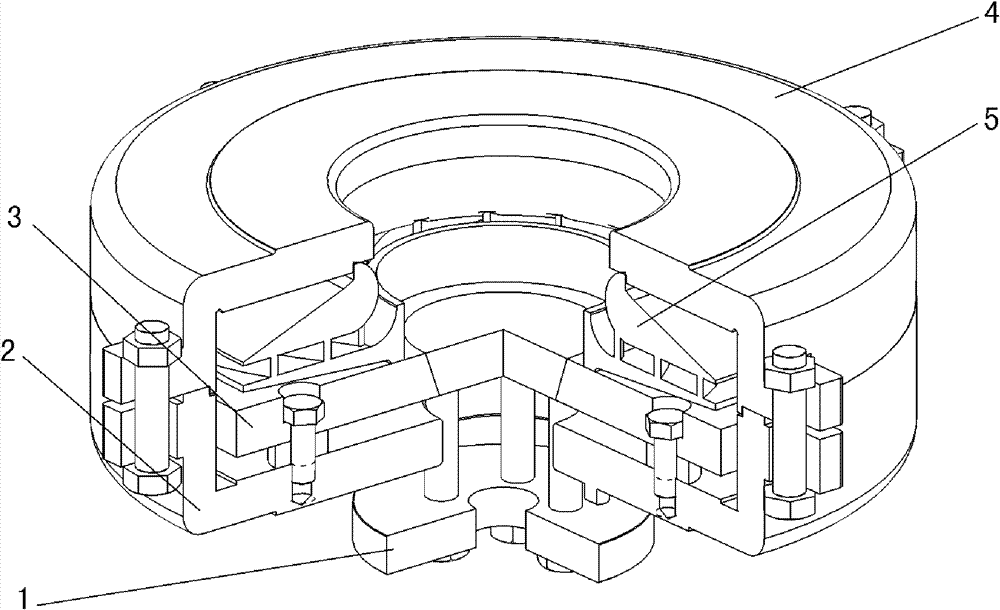

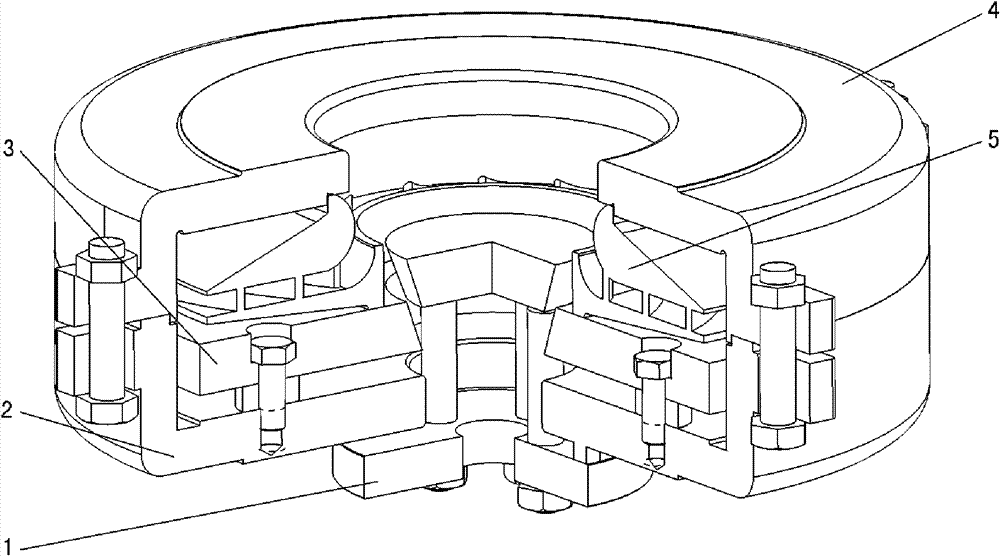

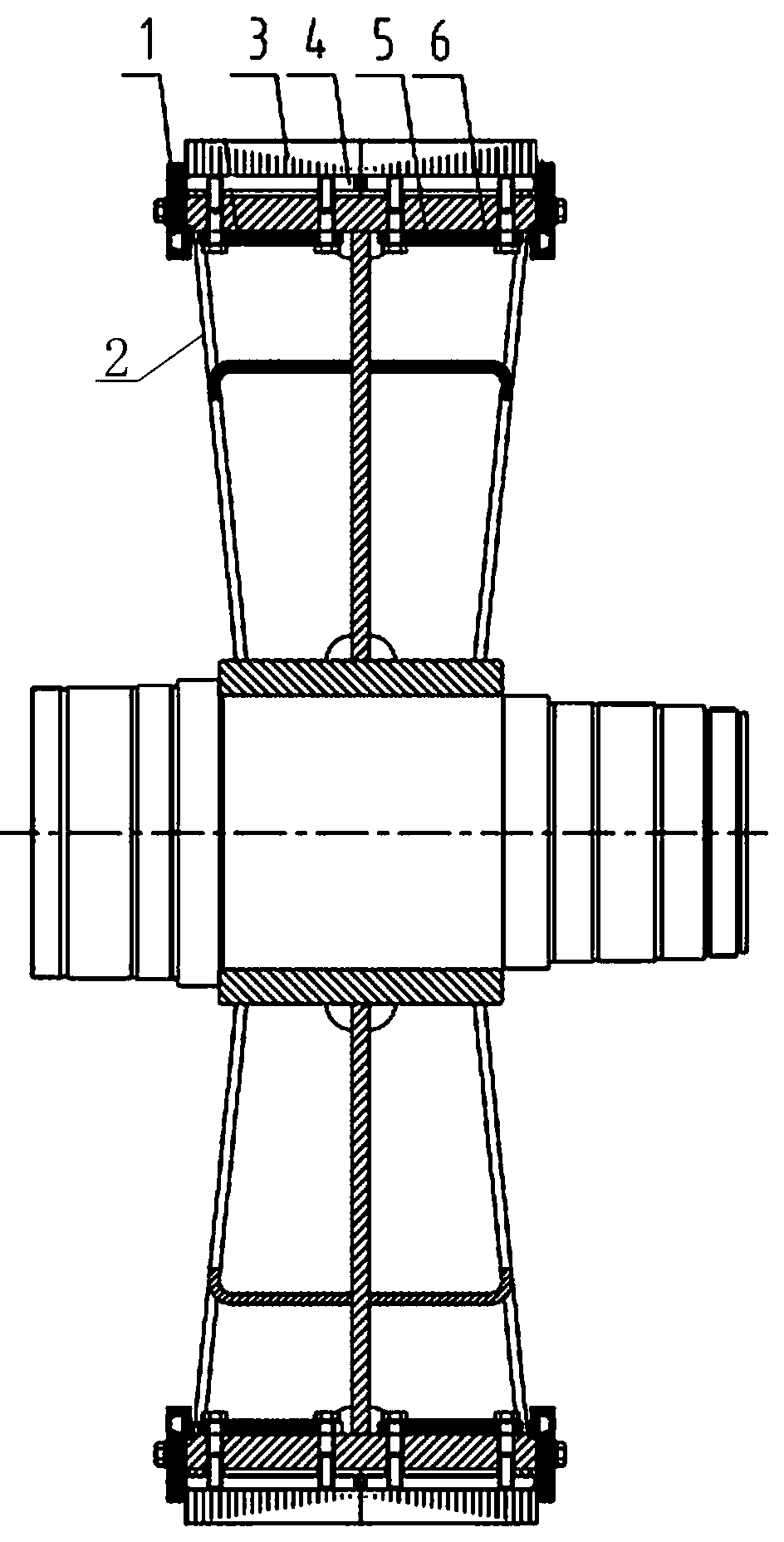

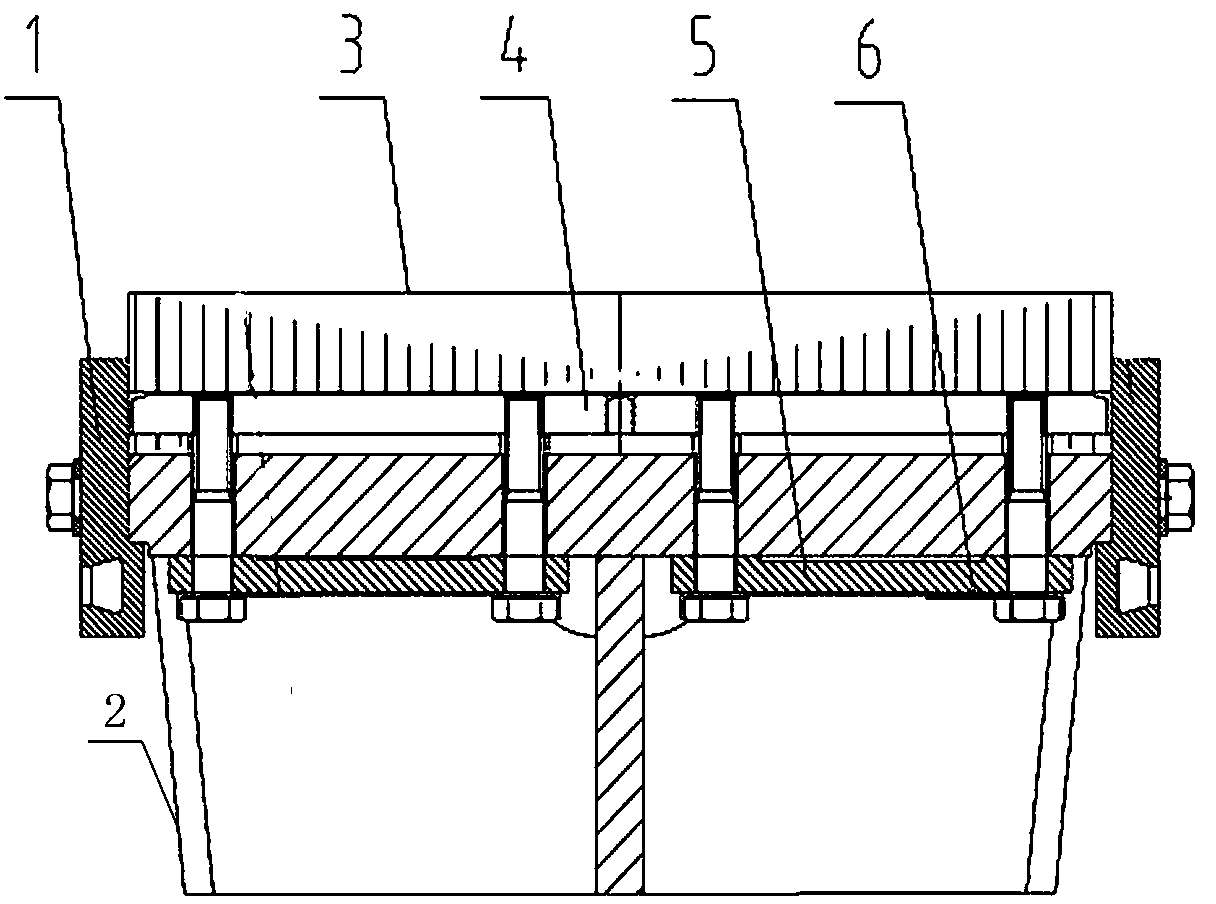

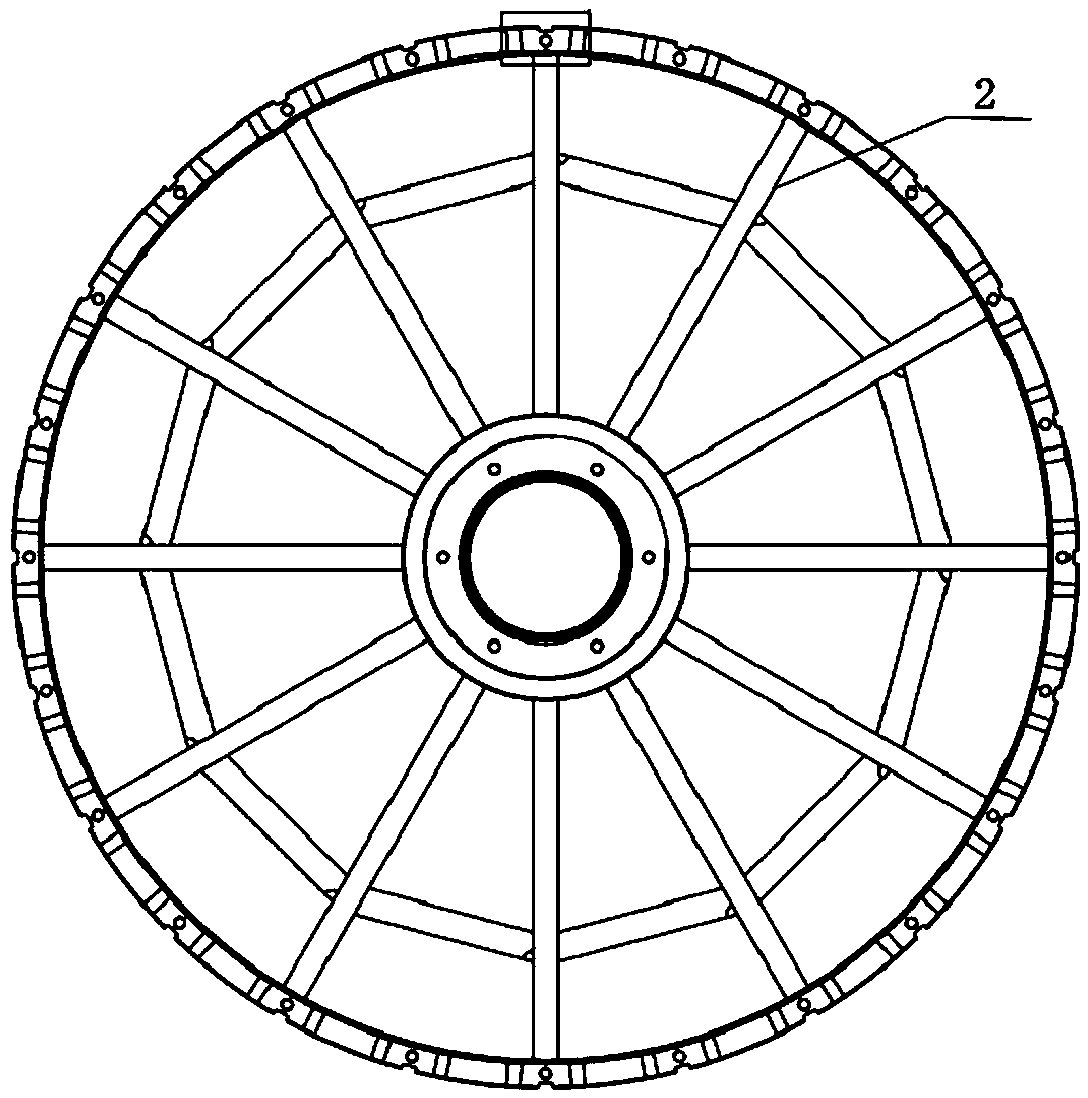

Compact permanent magnet wind generator rotor

ActiveCN102931741AAssembly positioning is accurateImprove ventilation efficiencyMagnetic circuit rotating partsMagnetic polesEngineering

The invention relates to a rotating device inside a permanent magnet wind generator, in particular to a compact permanent magnet wind generator rotor, solving the problem of an unreasonable structure of the permanent magnet wind generator rotor. The compact permanent magnet wind generator rotor comprises a rotor bracket, and a magnetic pole box provided with a permanent magnet mounting hole; magnetic steel is arranged inside the permanent magnet mounting hole; a fixed rod mounting hole is arranged on the magnetic pole box; a bolt perforating hole is arranged on the contact surface of the magnetic pole box and the rotor bracket; the bolt perforating hole is communicated with the fixed rod mounting hole; a locating lug boss is also arranged on the surface contacting a magnet yoke on the rotor bracket on the magnetic pole box; a radial bolt hole and a guide locating groove matched with the locating lug boss are arranged on the magnet yoke on the rotor bracket, and a fixed rod with the bolt hole is arranged inside the fixed rod mounting hole. The compact permanent magnet wind generator rotor is novel in structure; the performance of a motor is improved; the manufacturing cost of the motor rotor is reduced, and the stability of the entire structure of the rotor is improved.

Owner:CRRC YONGJI ELECTRIC CO LTD

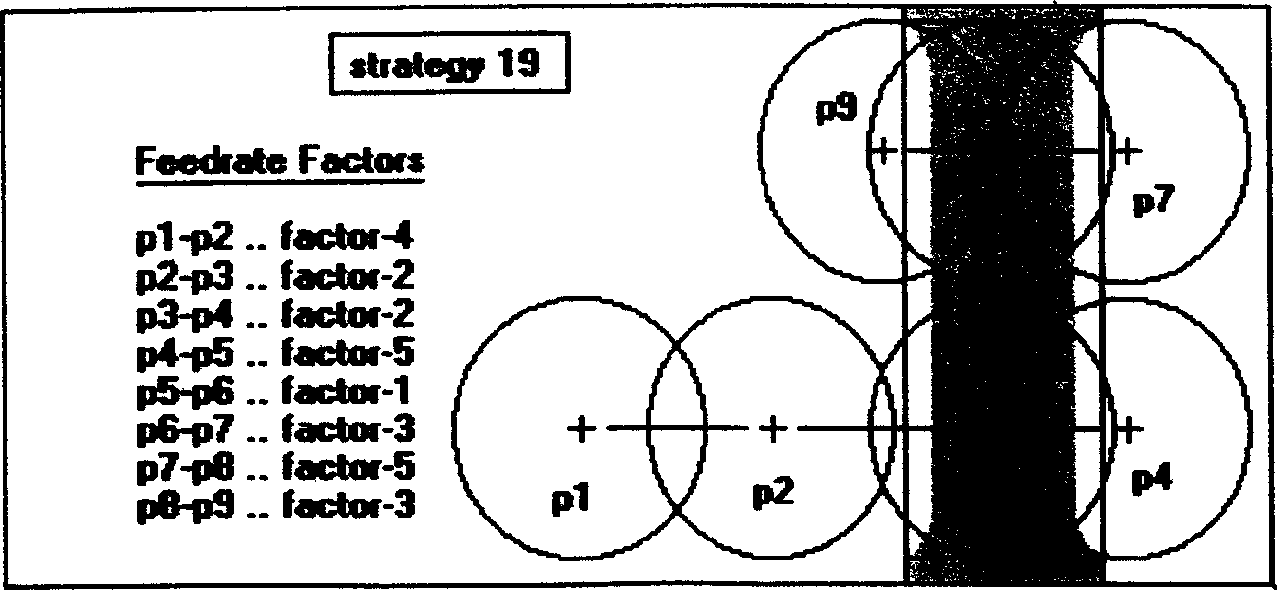

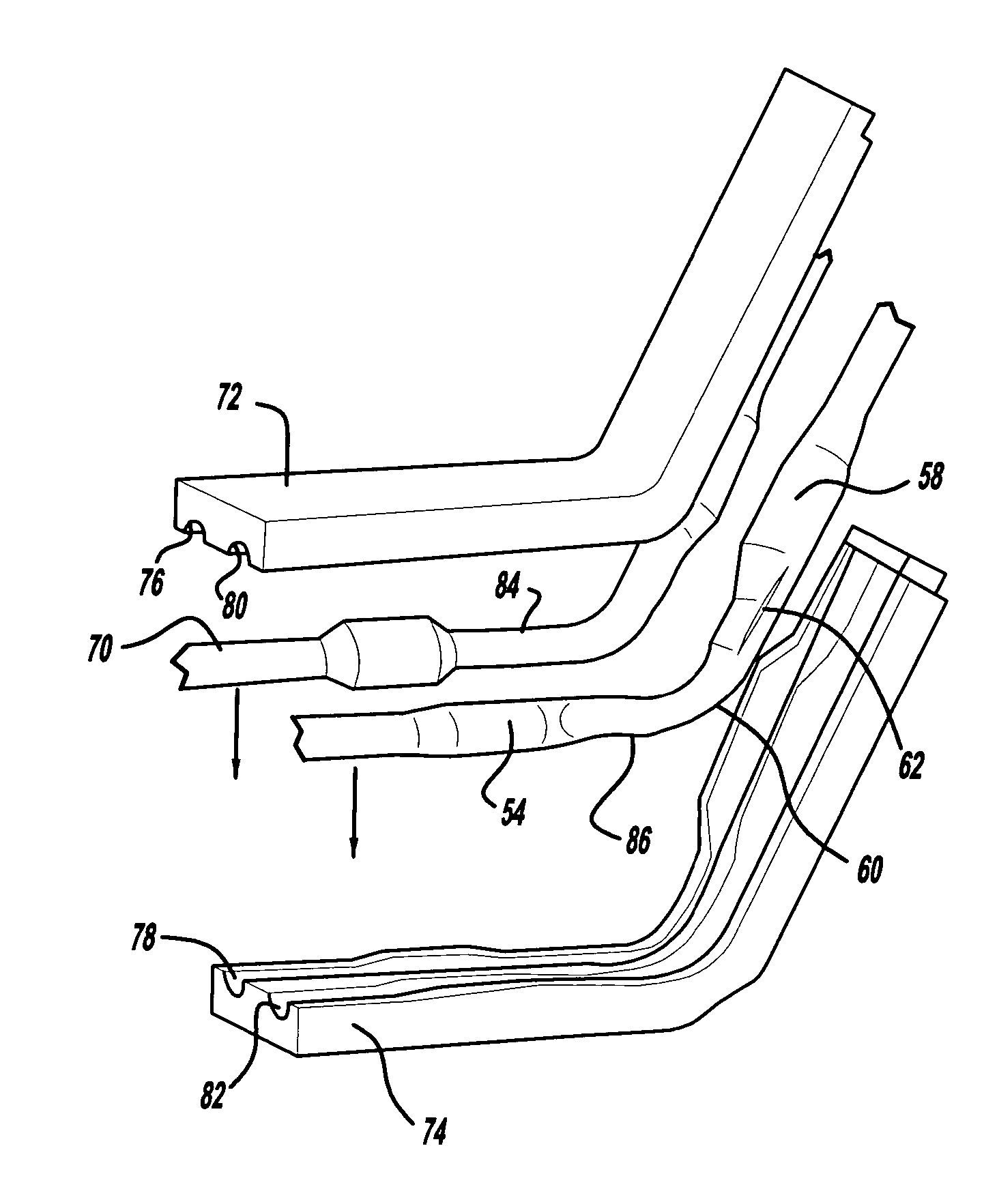

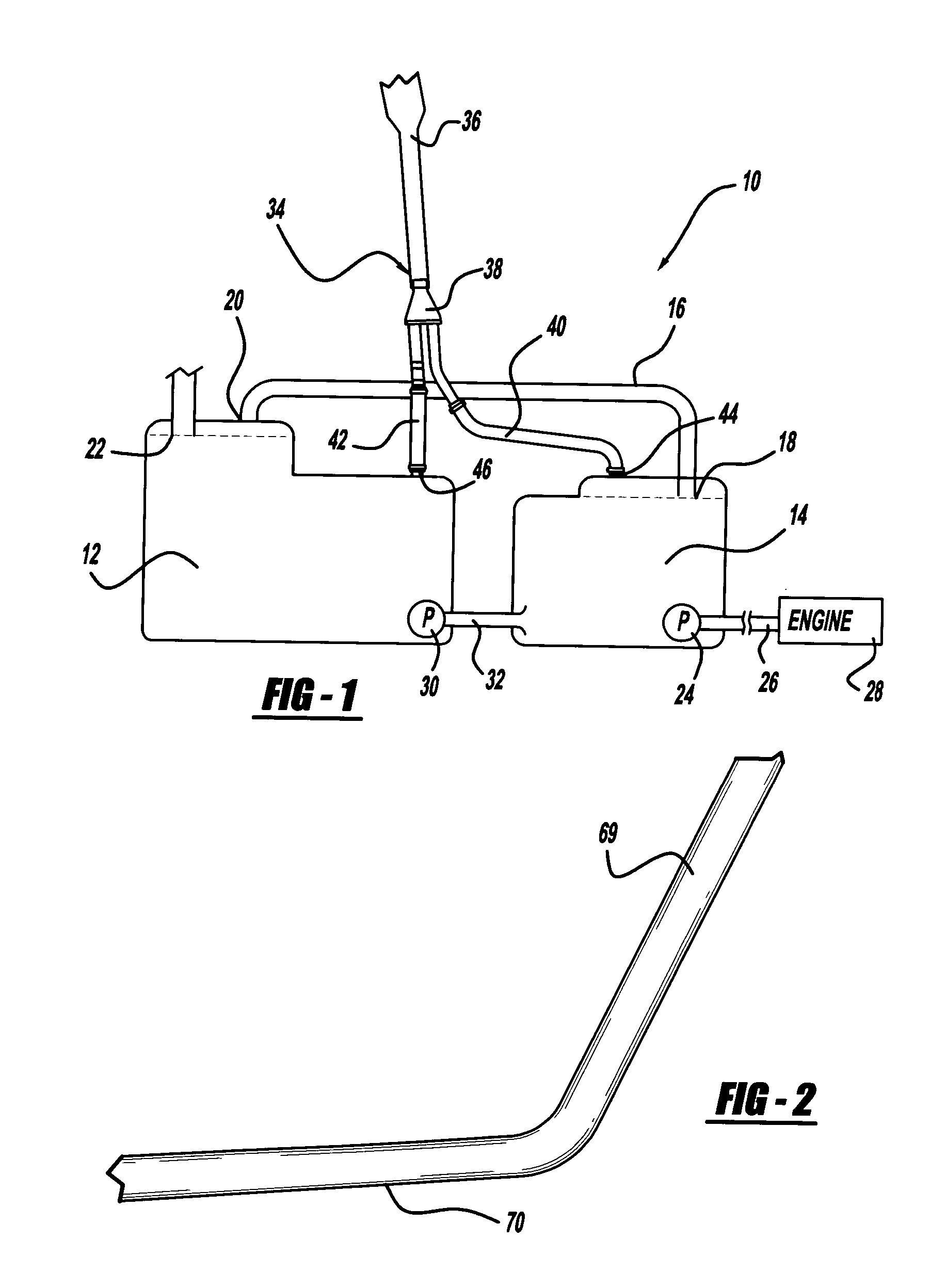

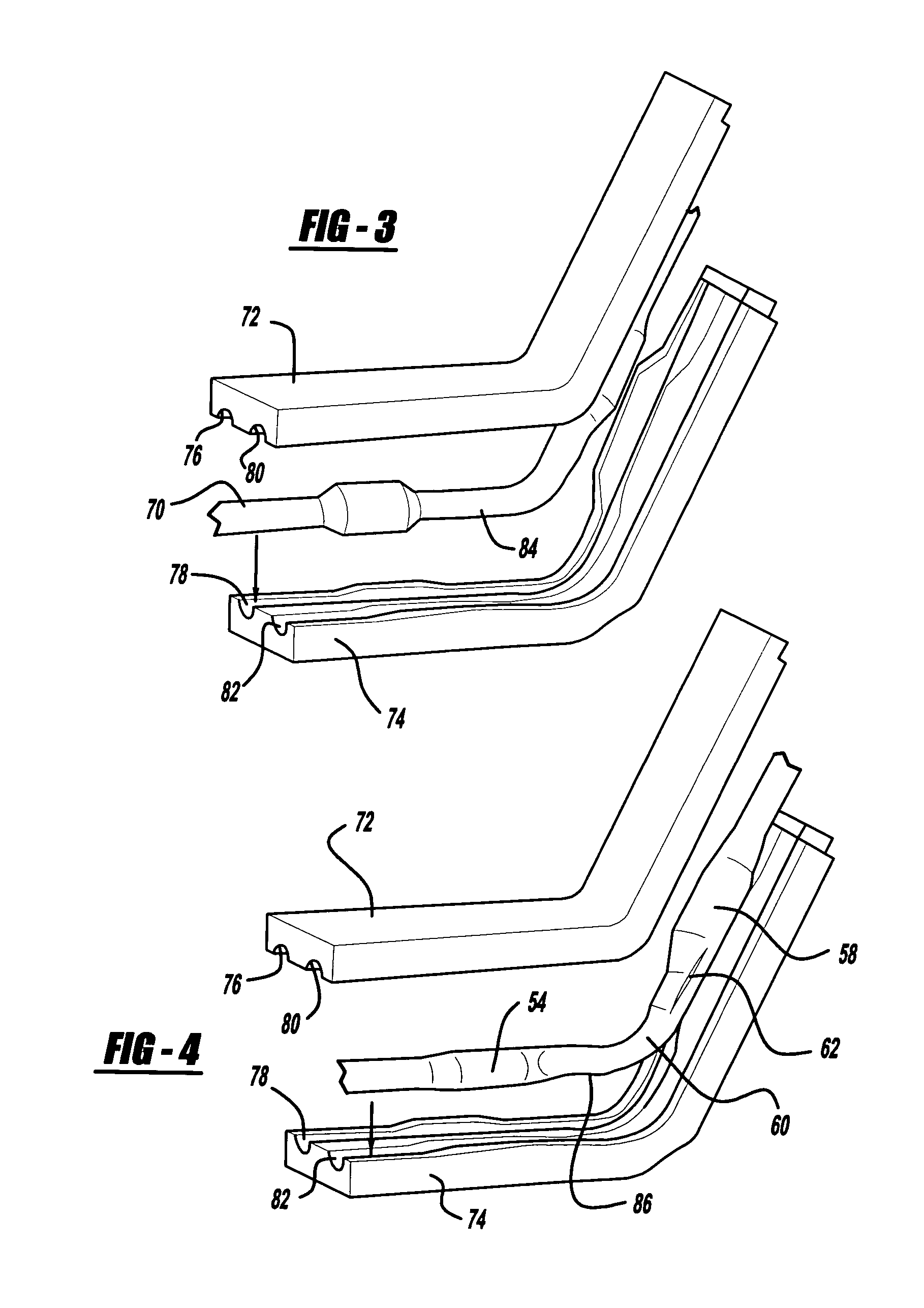

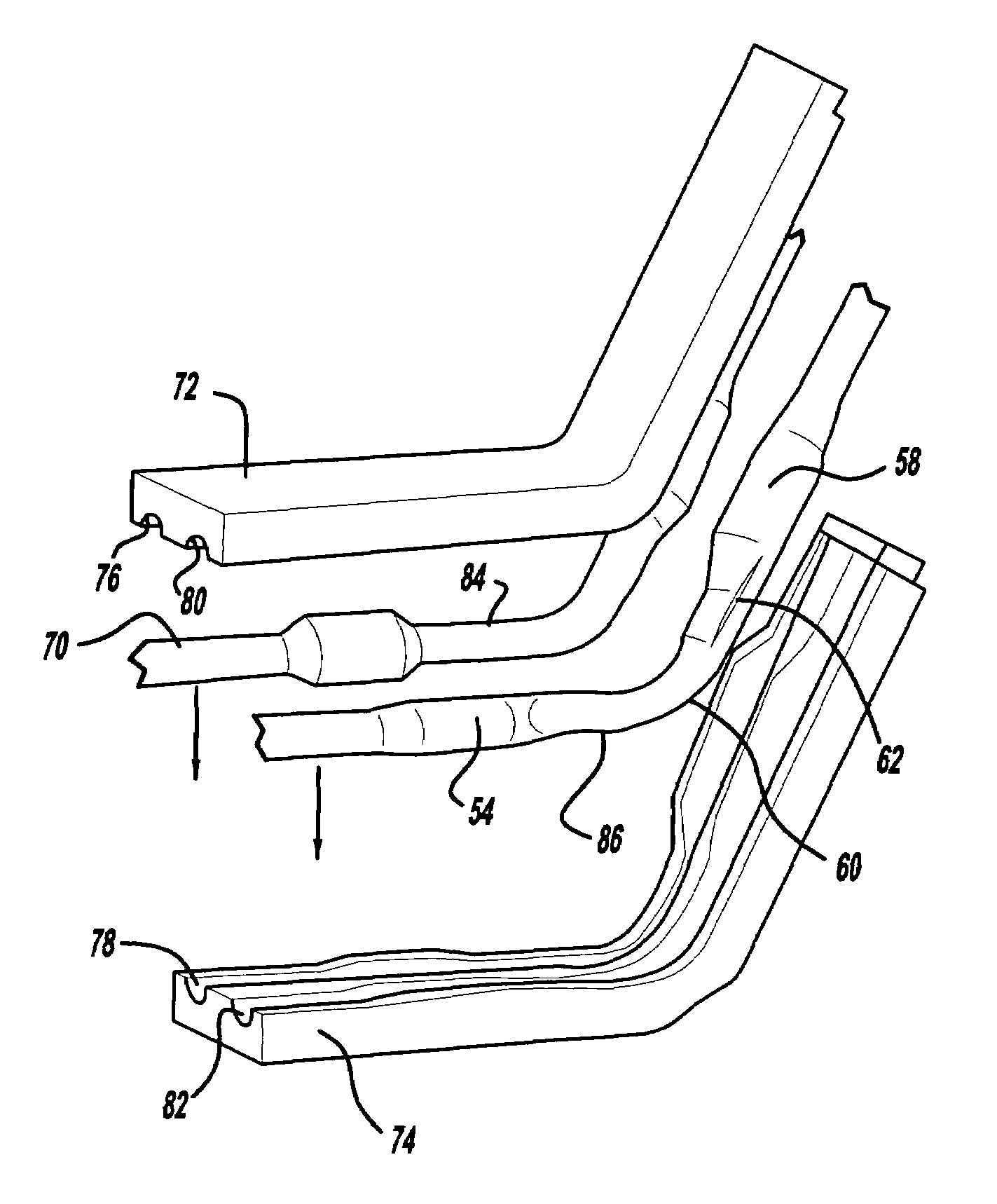

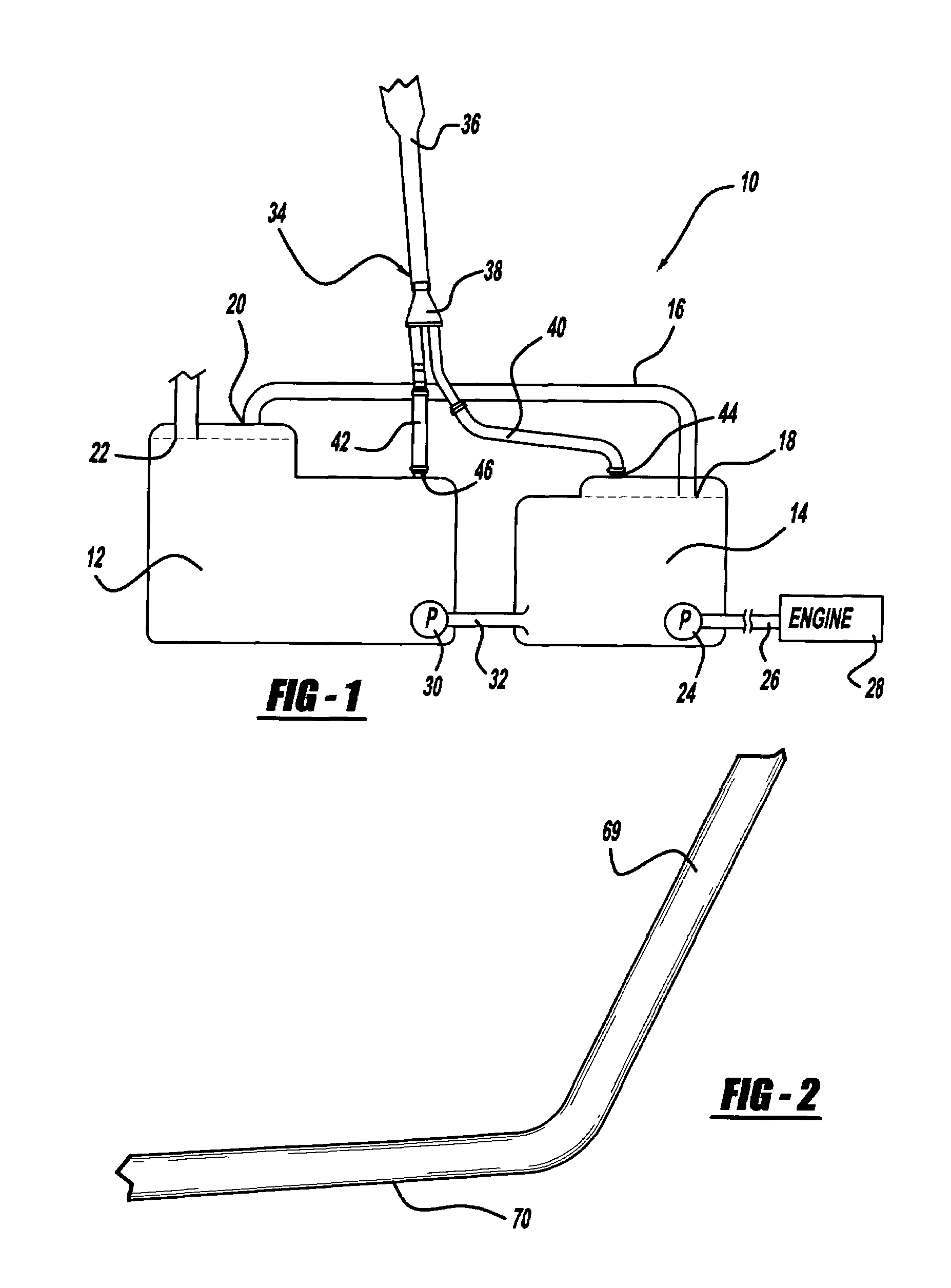

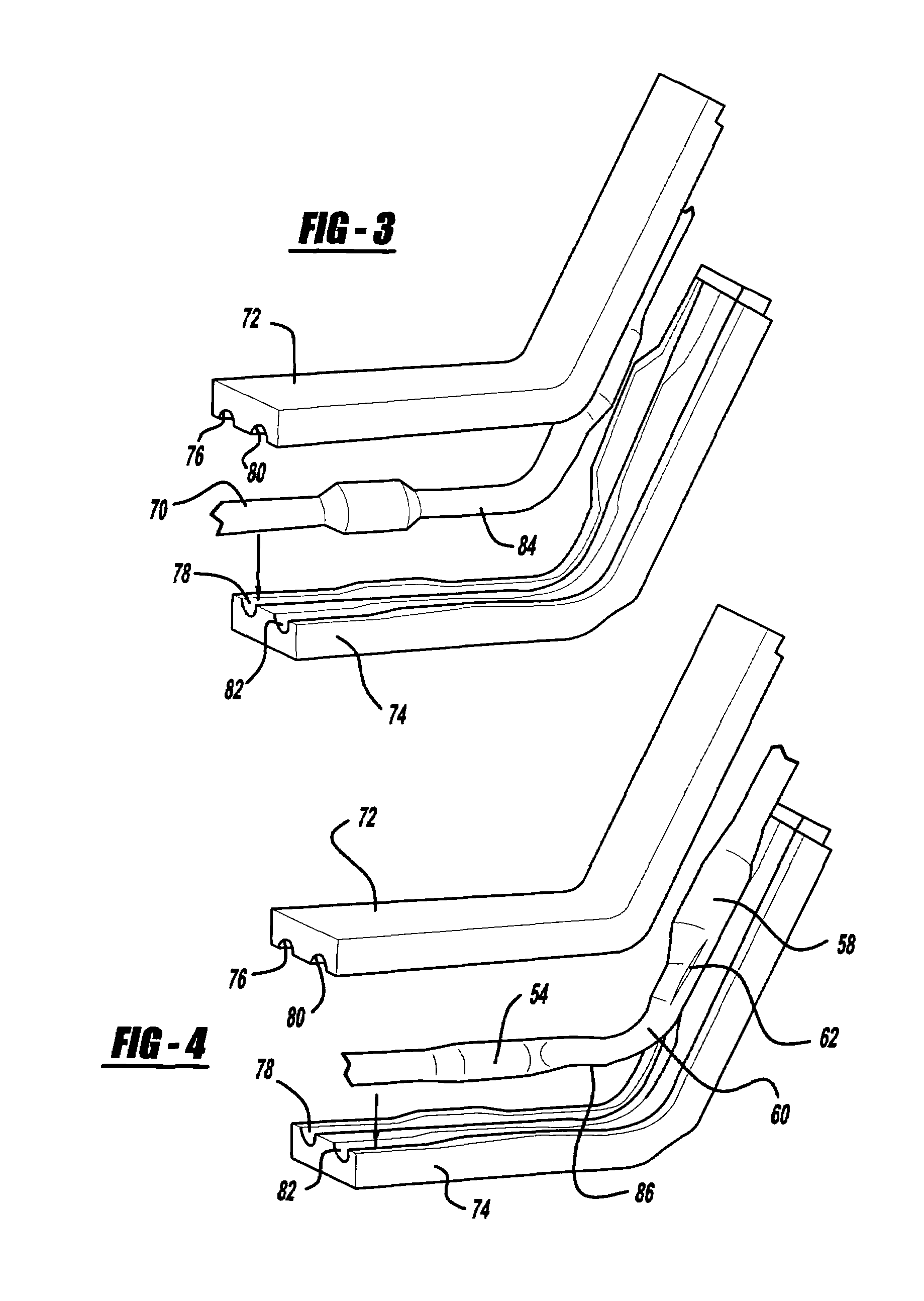

Method of progressive hydro-forming of tubular members

A method of progressive hydro-forming of a tubular member includes the steps of positioning a tubular member between open die halves mating with one another to define a first tubular cavity portion in a first stage. The method also includes the steps of progressively closing the die halves and applying hydraulic pressure to expand and conform the tubular member to the first tubular cavity portion in the first stage. The method includes the steps of positioning the expanded tubular member in a second tubular cavity portion in a second stage and progressively closing the die halves to progressively deform the expanded tubular member within the second tubular cavity portion. The method includes the steps of applying hydraulic pressure to expand and conform the expanded tubular member to the second tubular cavity portion in the second stage.

Owner:GM GLOBAL TECH OPERATIONS LLC

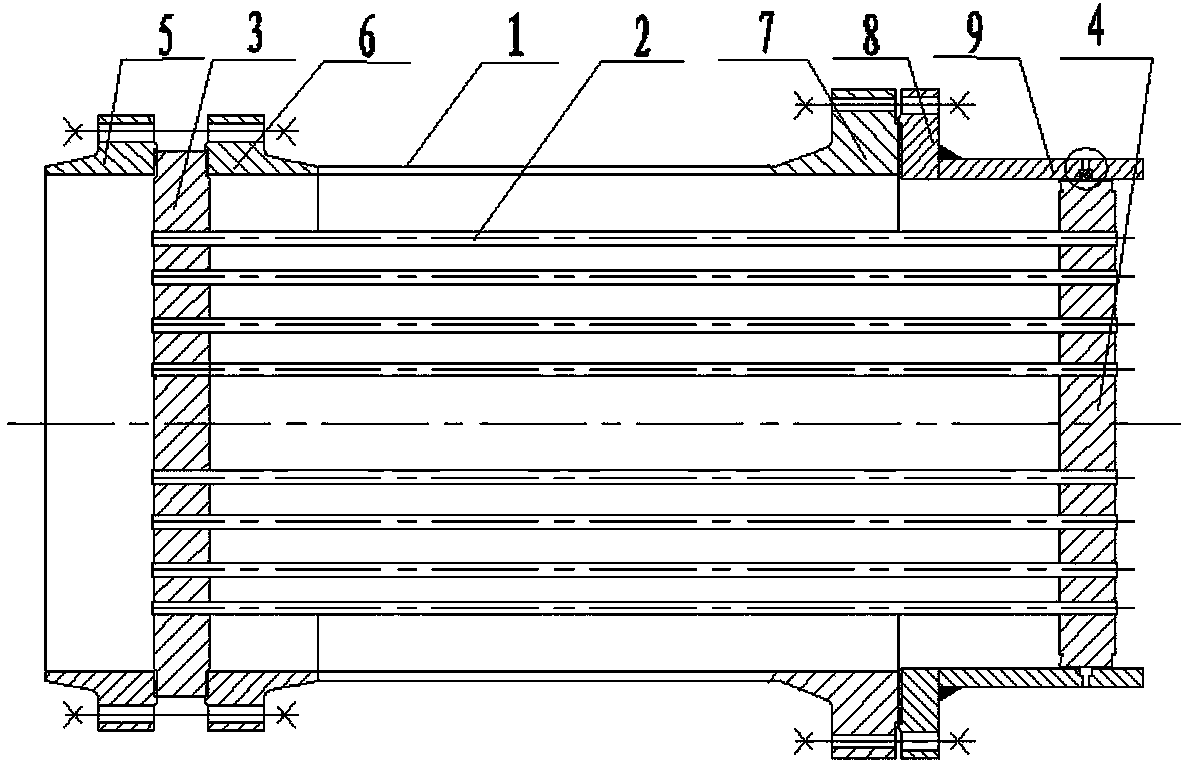

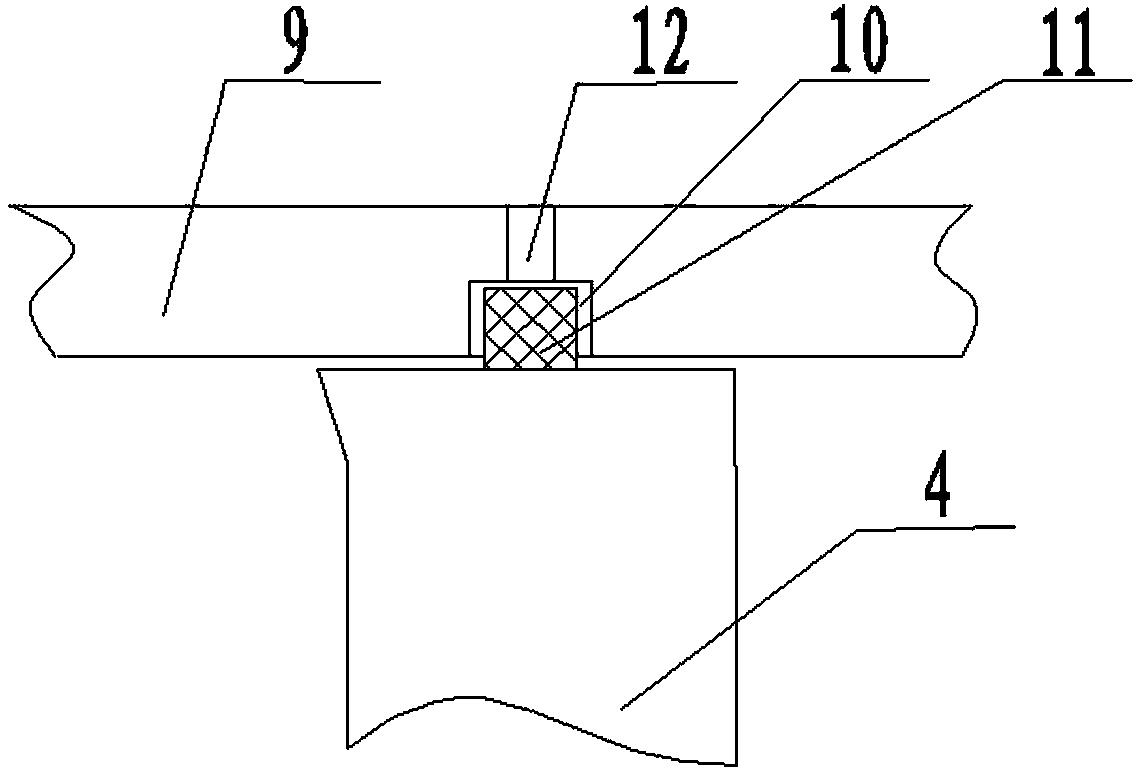

Simple floating heat exchanger pressure test tool

InactiveCN104215410ALong construction periodSave materialMeasurement of fluid loss/gain rateEngineeringFlange

A simple floating heat exchanger pressure test tool comprises a heat exchanger barrel, a fixed tube plate, a floating tube plate and a heat exchange tube bundle. A tube box side flange and an outer head cover side flange are welded at two ends of the heat exchanger barrel respectively, the fixed tube plate and the floating tube plate are welded into an integral structure through the heat exchange tube bundle, the outer head cover side flange and the tube box side flange are matched to fix the fixed tube plate at one end of the heat exchanger barrel, the other end of the heat exchanger barrel is provided with a pressure test barrel section with the floating tube plate fixed in the section, the pressure test barrel section achieves connection of the heat exchanger barrel and the pressure test barrel section by means of matching of the tool flange arranged on the pressure test barrel section and the outer head cover side flange, a sealing gasket matched with an annular cutting groove formed in the inner surface of the pressure test barrel section is arranged on the floating tube plate, and an air hole applying pressing force on the sealing gasket is formed in the pressure test barrel section. The test tool avoids traditional welding connection of the pressure test barrel section and the floating tube plate, facilitates disassembly after pressure test and is good in sealing effect in the pressure test process.

Owner:HENAN UNIV OF SCI & TECH

Method of progressive hydro-forming of tubular members

Owner:GM GLOBAL TECH OPERATIONS LLC

Steering axle of automobile

ActiveCN101618734AImprove mechanical propertiesExtended service lifeSteering linkagesAxle unitsEngineeringTorsional strength

The invention relates to a steering axle of an automobile, comprising an shaft body, a steering joint and a connector, wherein, the connector is connected with the shaft body and the steering joint and enable the steering joint to pivot and rotate around the shaft body, the shaft body integrally comprises an shaft end, an shaft arm and an shaft center part, the shaft end, the shaft arm and the shaft center part are all hollow shaft tubes, a pivot rotation inserting block is arranged in the shaft end, and a containing hole of the connector penetrates through the upper wall face and the lower wall face of the shaft end and the pivot rotation inserting block. The steering axle of the automobile has the advantages of convenient processing and low manufacturing cost and can effectively enhance the mechanical properties of the rigidity, the bending-resistant and torsional strength and the like of an automobile axle.

Owner:GUANGDONG FUWA HEAVY IND

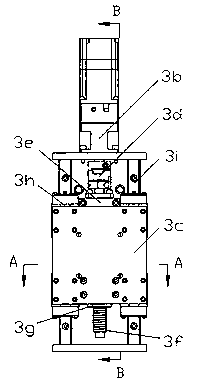

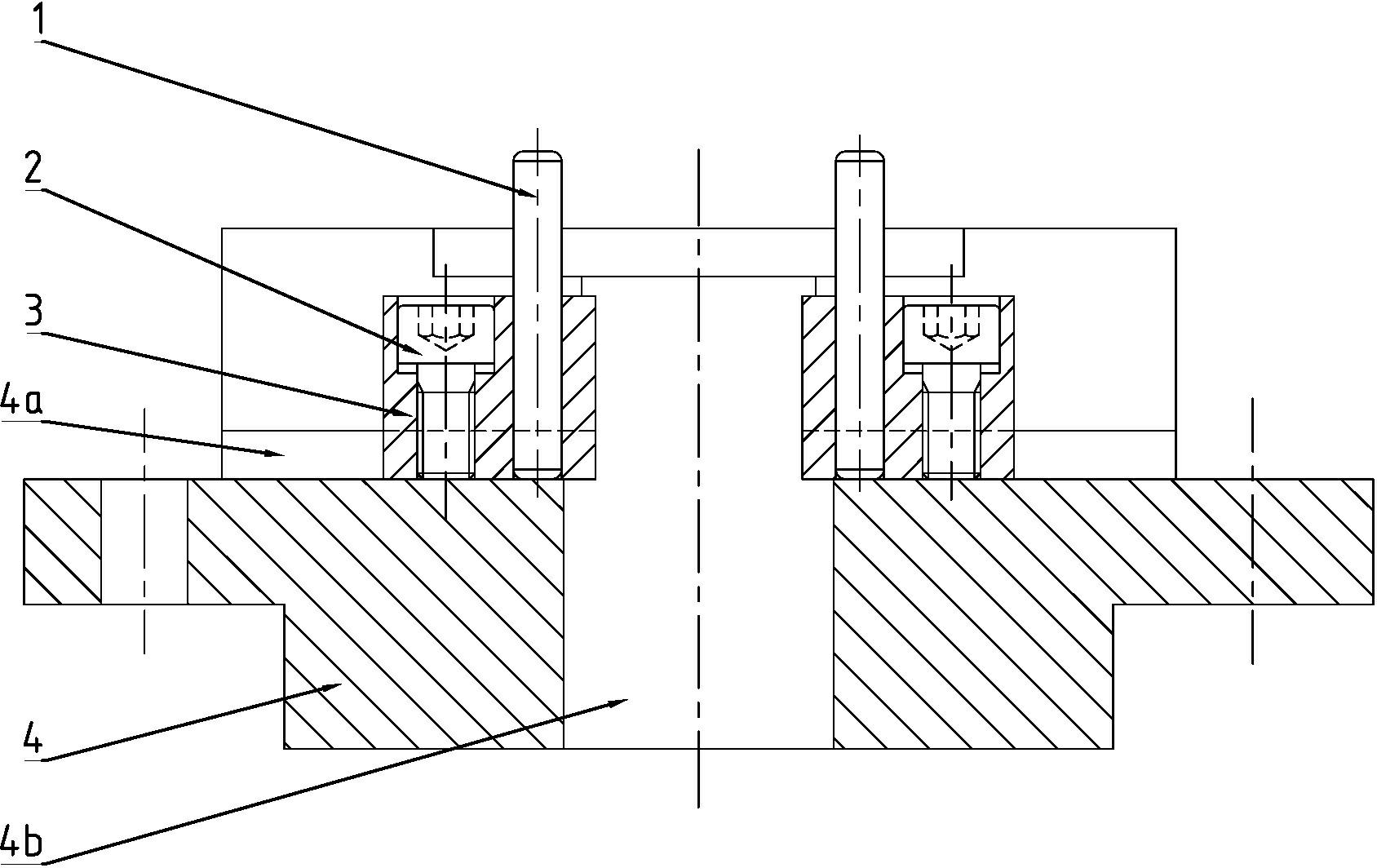

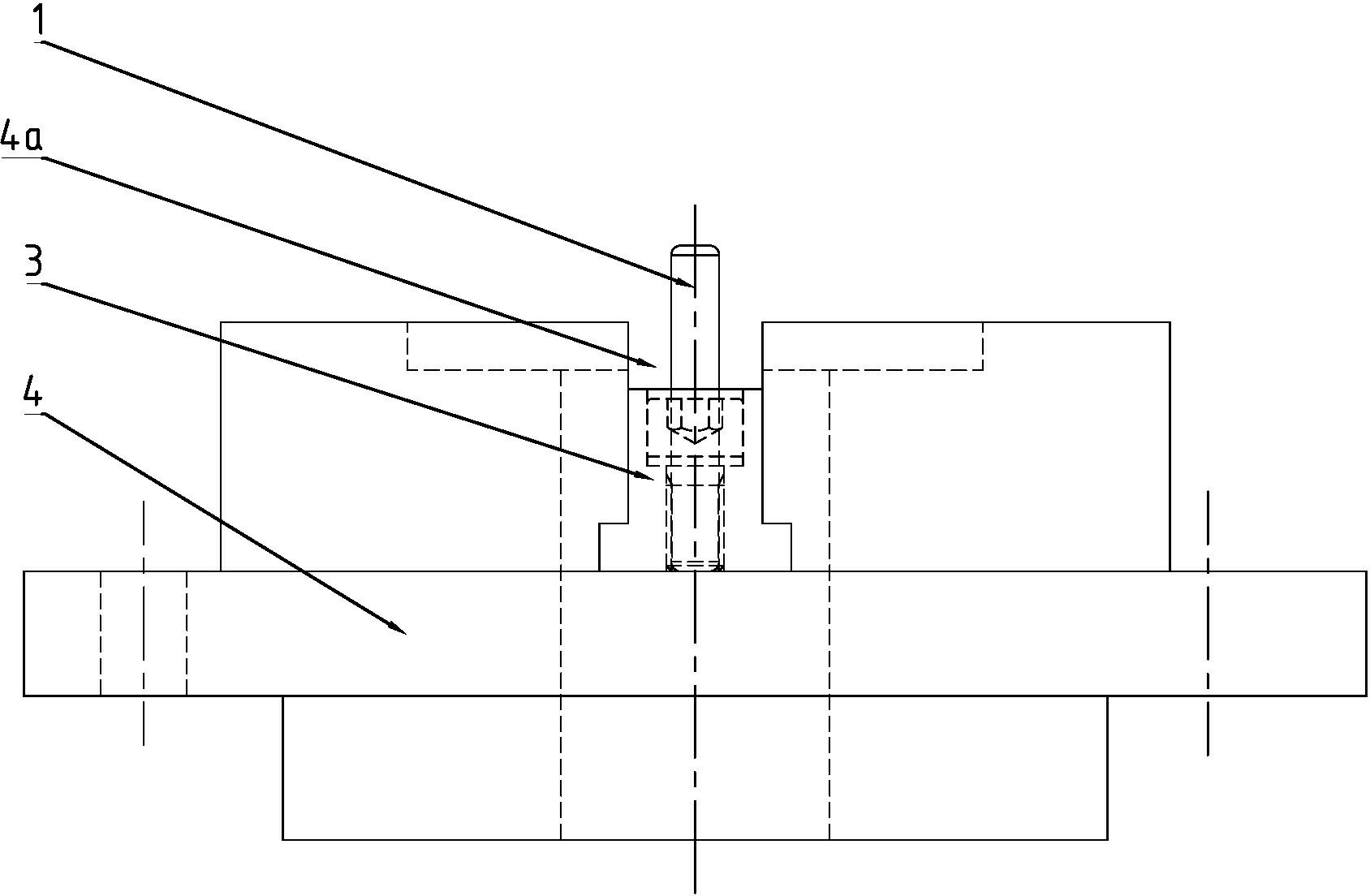

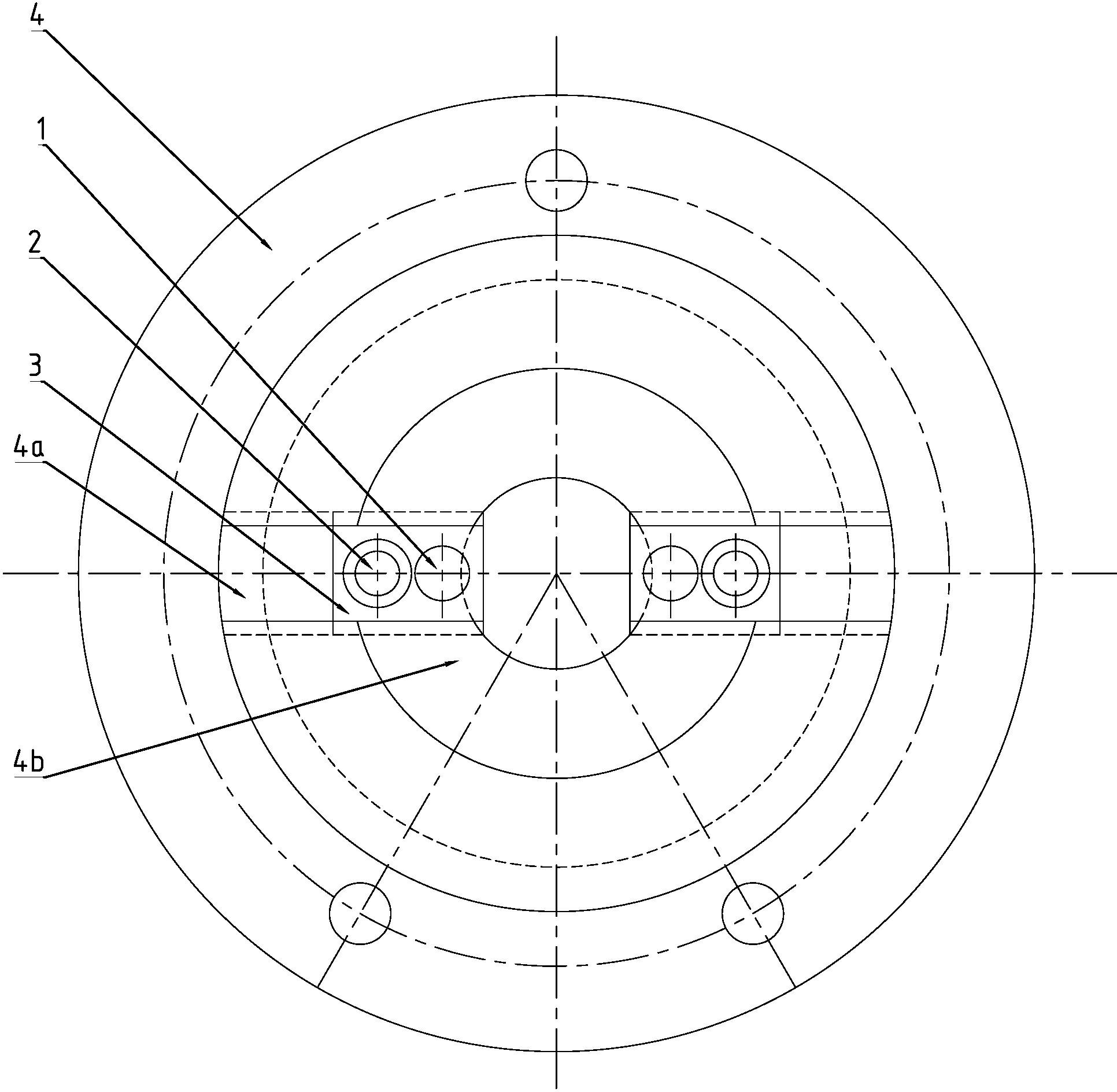

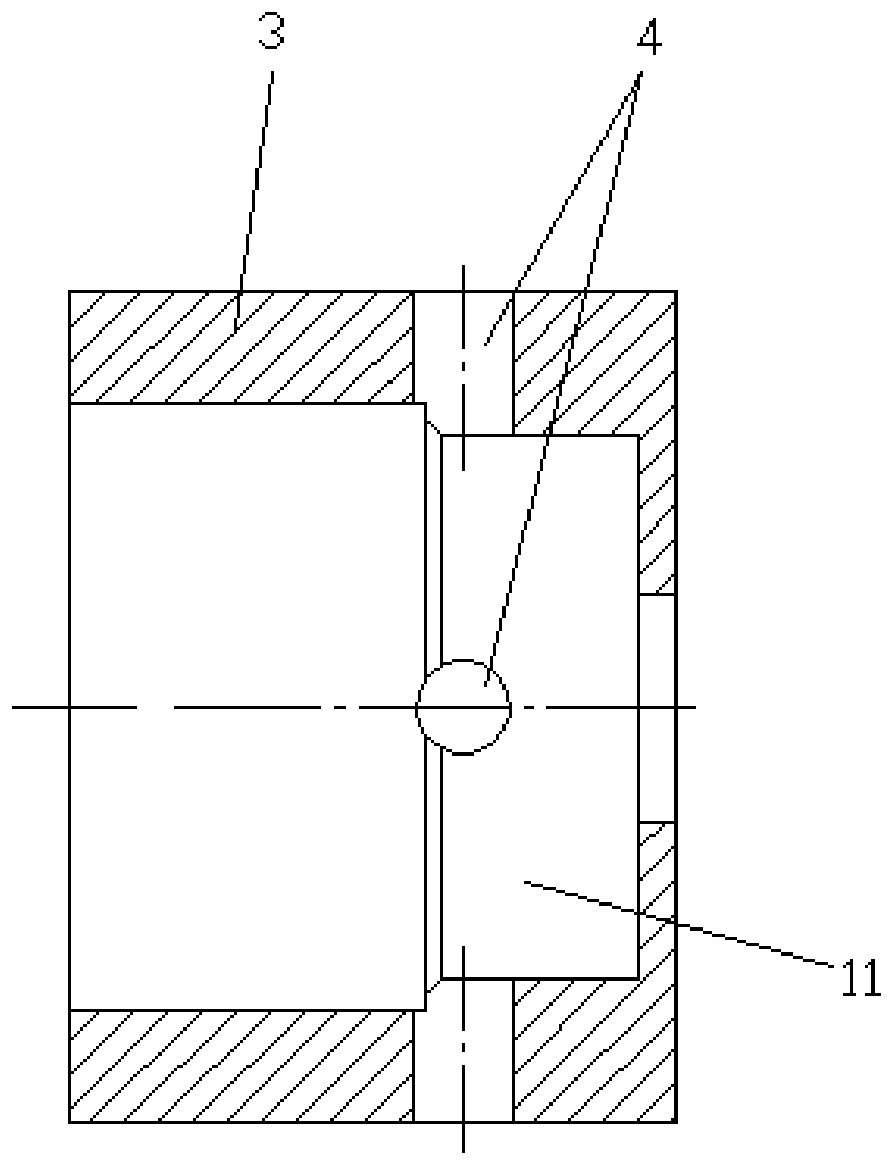

Machining and positioning device for inner bore

InactiveCN102398179AEasy to adjustFor quick replacementThread cutting machinesPositioning apparatusEngineeringInverted-T shape

The invention belongs to the field of machining, and in particular relates to a machining and positioning device for an inner bore. The machining and positioning device comprises a positioning base (4) which is fixed on a workbench of a machine tool, wherein an inverted T-shaped groove (4a) is formed on the upper part of the positioning base (4); two T-shaped positioning slide blocks (3) are arranged in the T-shaped groove (4a); positioning pins (1) are arranged on the positioning slide blocks (3) and are positioned together with the existing symmetrical bores in a workpiece in a matched mode; screw holes which are run through are formed in the positioning slide blocks (3); a screw (2) passes through the positioning slide blocks (3), so that the screw (2) is pressed against a bottom plane of the T-shaped groove (4a) to be fixed; and a through hole (4b) is formed at the central position of the positioning base (4), so that chip removal and cutter back-off are convenient to perform. The positioning device is adjustable; and aiming at different center distances of the symmetrical bores in different products, only the positioning slide blocks are required to be adjusted slightly, so the production efficiency is improved, the management cost is reduced, and the machining and positioning device can be widely applied to the machining of other product parts with similar structures.

Owner:BENGBU JINWEI FILTERS

A kind of preparation method of plain colored high-gloss shell of green home appliances

ActiveCN102294828AImprove environmental protection effectThe process is simple and fastFlat articlesMolding machineUltrasonic welding

The invention discloses a method for preparing a plain high-gloss shell of a green home appliance. The invention comprises the following technical steps: co-extruding recycled plastics and flame-retardant plastics into boards; using a special surface non-contact gas pressure forming machine to form; The semi-finished green home appliance shell is cut in three dimensions; according to the size requirements of the cut shell semi-finished product, the insert is injected; the green home appliance shell semi-finished product after forming and cut is assembled with the injection molded insert; the assembly is performed using an ultrasonic welding machine After welding the inserts; apply glue to the above welded inserts. Adopting the present invention not only satisfies the requirement of high-gloss flame-retardant properties of green home appliances, but also improves the reutilization rate of industrial waste and reduces environmental pollution; the production process is simple and fast, reducing equipment investment; the produced products are plain, reducing the painting process and meeting environmental protection requirements .

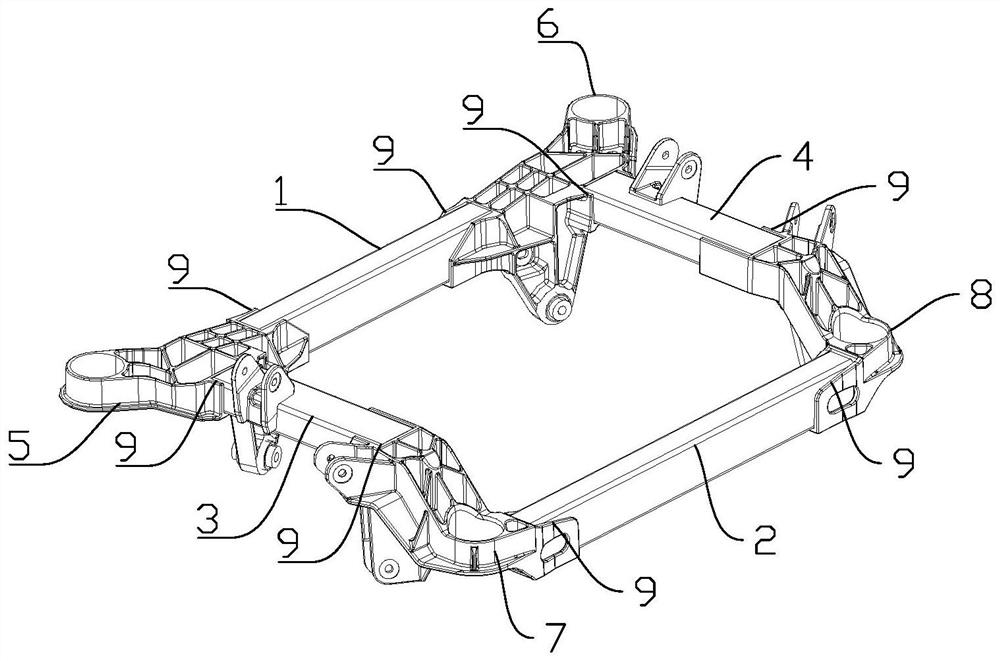

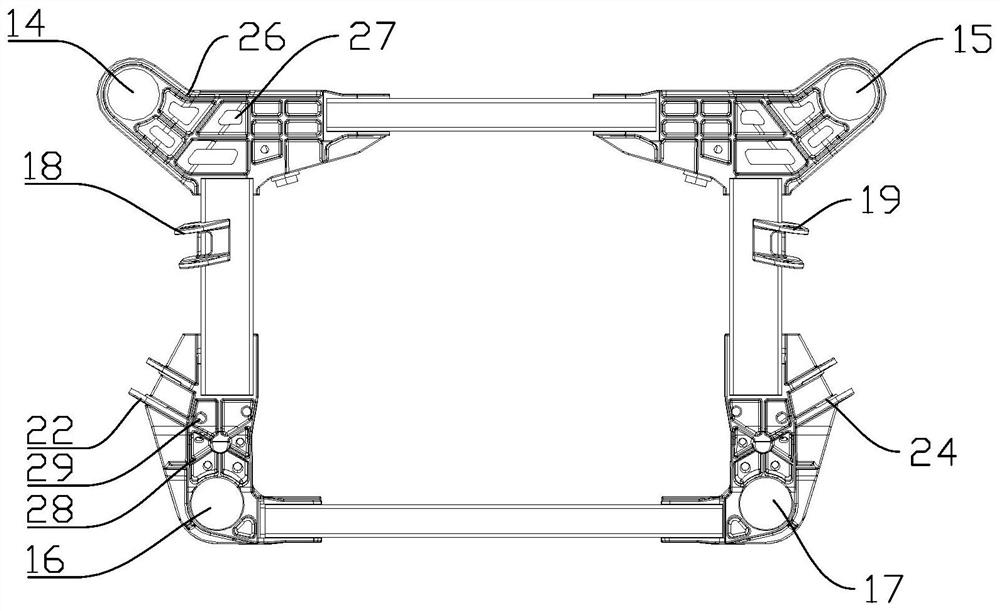

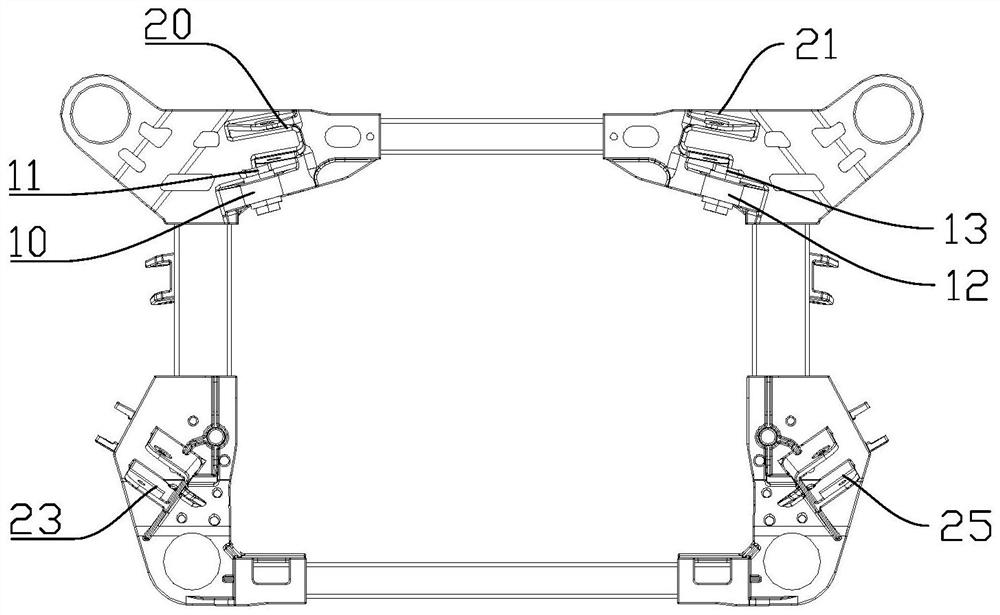

Novel aluminum alloy auxiliary frame

The invention discloses a novel aluminum alloy auxiliary frame which comprises a front cross beam, a rear cross beam, a left longitudinal beam and a right longitudinal beam, and the front cross beam, the rear cross beam, the left longitudinal beam and the right longitudinal beam are all of a hollow tubular structure formed by extrusion forming of aluminum alloy sections. The auxiliary frame further comprises a left front mounting bracket, a right front mounting bracket, a left rear mounting bracket and a right rear mounting bracket; the left front mounting bracket, the right front mounting bracket, the left rear mounting bracket and the right rear mounting bracket are all formed by casting aluminum alloy. According to the novel aluminum alloy auxiliary frame, through the front cross beam, the rear cross beam, the left longitudinal beam and the right longitudinal beam which are formed through extrusion, the weight is light, the yield is high, the cost is low, and welding is easy to control; the left front mounting bracket, the right front mounting bracket, the left rear mounting bracket and the right rear mounting bracket need to be connected with other parts of a vehicle body or a chassis, structural changes are complex, and the mechanical performance of casting parts formed through casting is improved.

Owner:HOZON NEW ENERGY AUTOMOBILE CO LTD

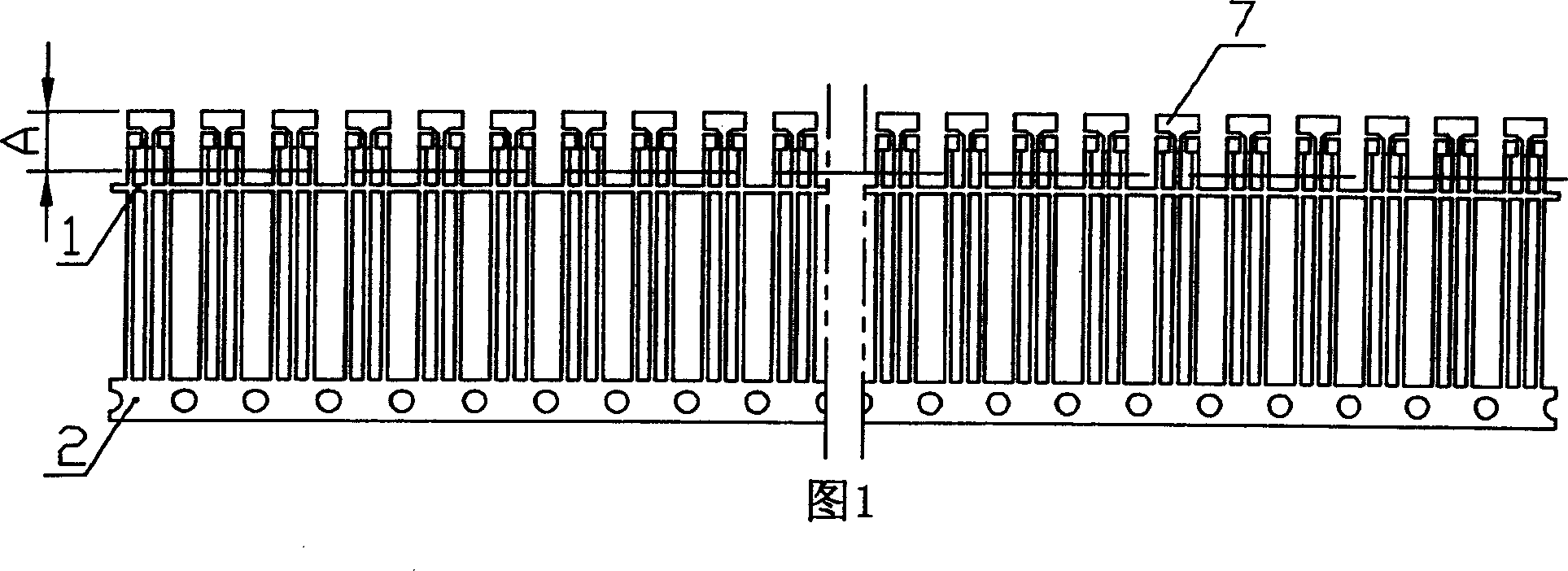

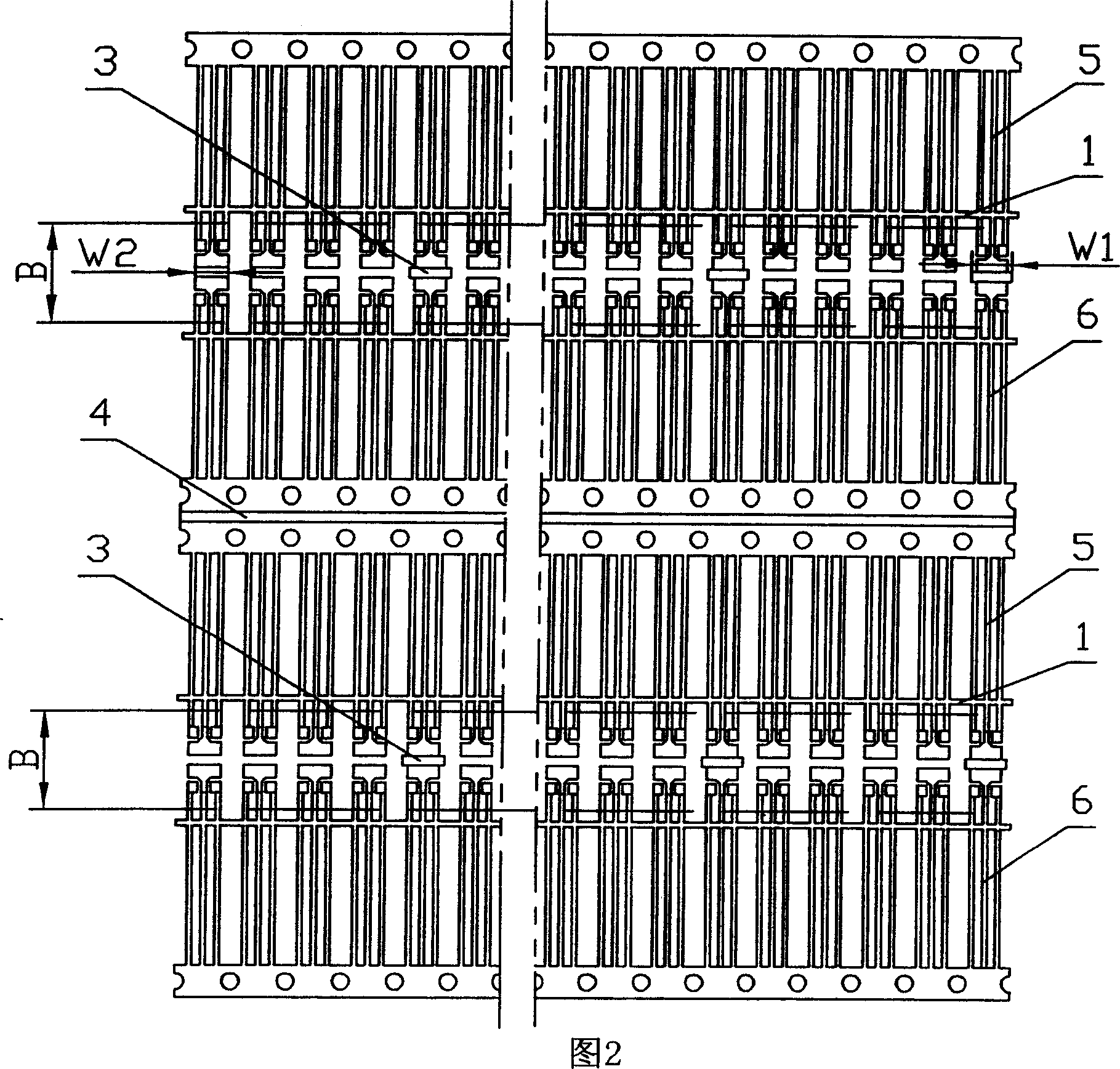

Method for fabricating lead frame of triode

ActiveCN1959945AReduce pollutionIncrease productivitySemiconductor/solid-state device manufacturingPunchingEngineering

The invention discloses method for fabricating lead frame, especially punching method for fabricating lead frame in use for triode. The method includes steps: (1) producing tape coiling of lead frame through punching: fabricating two pieces of tape coiling of lead frame connected through splice bars from same work piece by punching operation, then removing splice bars; the said tape coiling is two rows of single tape coiling of lead frame; through parting cut points on outer edge of head part of tape coiling, two rows of single tape coiling are connected; (2) plating the head parts and the parting cut points; (3) truncating off the parting cut points, and cutting off separated tape coiling of lead frame so as to obtain multiple pieces of lead frame, each piece of lead frame includes multiple lead frames. Features are: high production efficiency, reduced cost, and decreased pollution on environment.

Owner:NINGBO KANGQIANG ELECTRONICS CO LTD

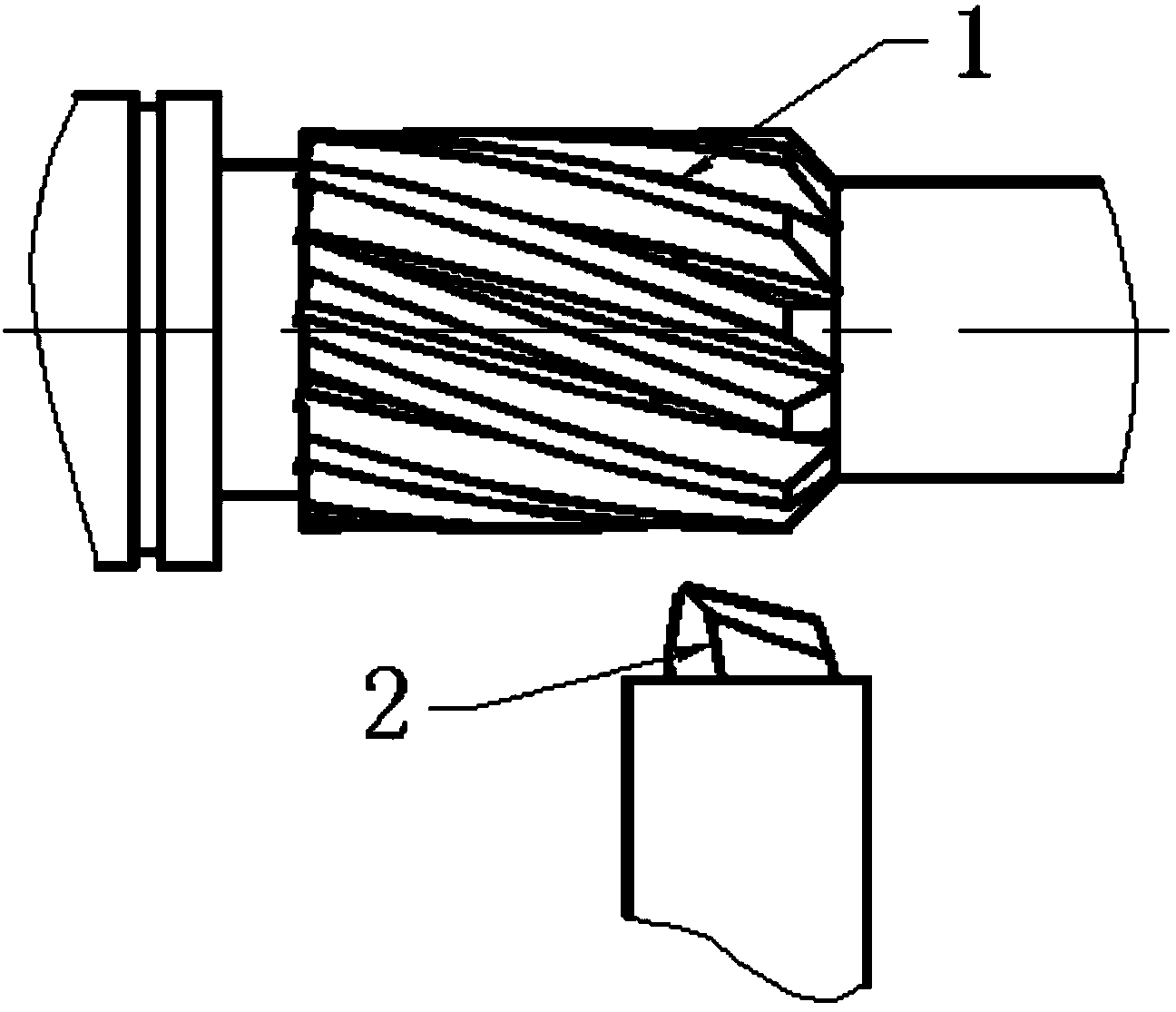

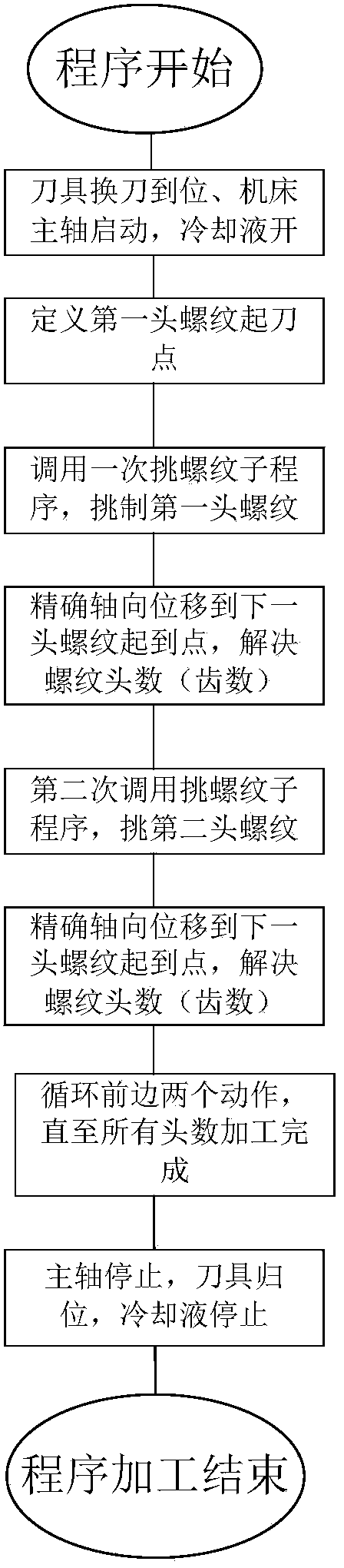

Spiral gear tooth form turning method

InactiveCN104384619AEasy processingStable and reliable processing technologyGear teethNumerical controlGear wheel

The invention provides a spiral gear tooth form turning method. Firstly, a cutter is designed and prepared; then, spiral parameters are determined; and finally, a numerical control lathe thread picking program is programmed according to the spiral parameters, and a numerical control lathe is controlled to use the prepared cutter for circularly picking threads to realize the spiral gear tooth form turning. The spiral gear tooth form turning method has the following beneficial effects: a numerical control turning method is adopted; such special complex forming cutters as tooth form slotting tool, milling cutter, hobbing cutter and broaching tool have no need to be customized; the spiral gear tooth form machining can be finished in a shorter period only by sharpening a single tooth form turning tool; and a convenient and reliable machining process is provided for the gear tooth form machining. The spiral gear tooth form turning method can be applied to a product development stage or a single small-batch production phase, is short in development stage, is much lower in tool cost, and is economic and practical.

Owner:SHAANXI AVIATION ELECTRICAL

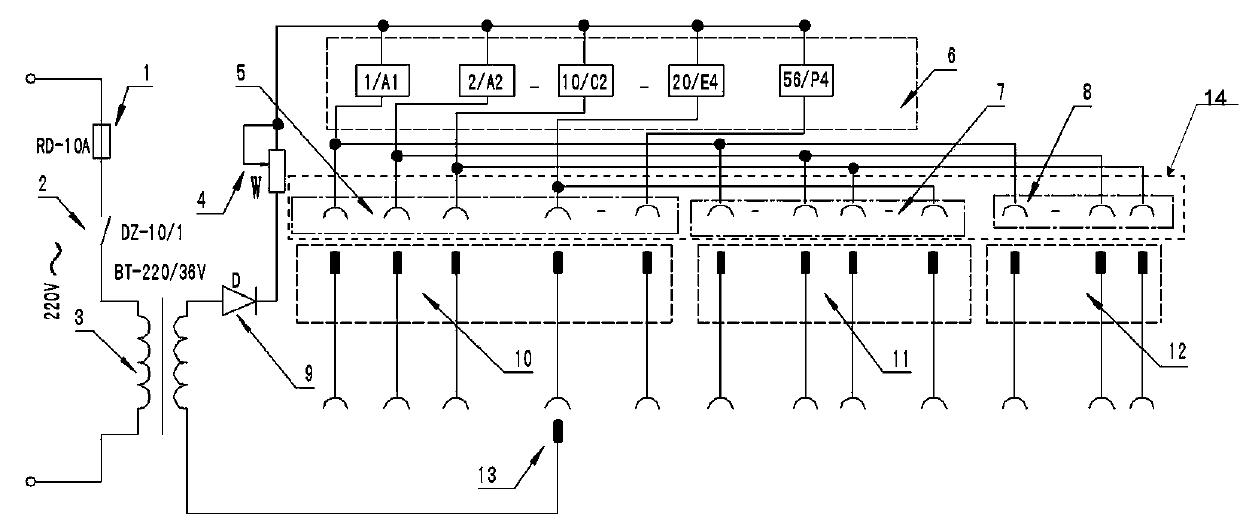

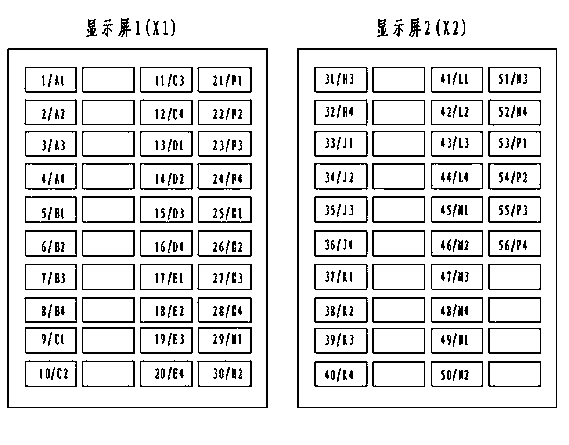

Correction device for wire harness of locomotive connector

ActiveCN103364687ASave tooling costsImprove ergonomicsElectrical testingDisplay deviceRectifier diodes

The invention discloses a correction device for a wire harness of a locomotive connector. The correction device comprises a machine-tool control transformer, a rectifying diode, a display, an electric connector and a test needle, wherein an alternating current is connected into the machine-tool control transformer; one connecting terminal of the machine-tool control transformer passes through an electric wire, subjected to the half-wave rectification by the rectifying diode, and then connected with the display; the electric connector is connected with the display; the other connecting terminal of the machine-tool control transformer is connected with the test needle. The device is capable of rapidly detecting the correctness of the wire size of the wire harness, thus improving the working efficiency.

Owner:CRRC LUOYANG CO LTD

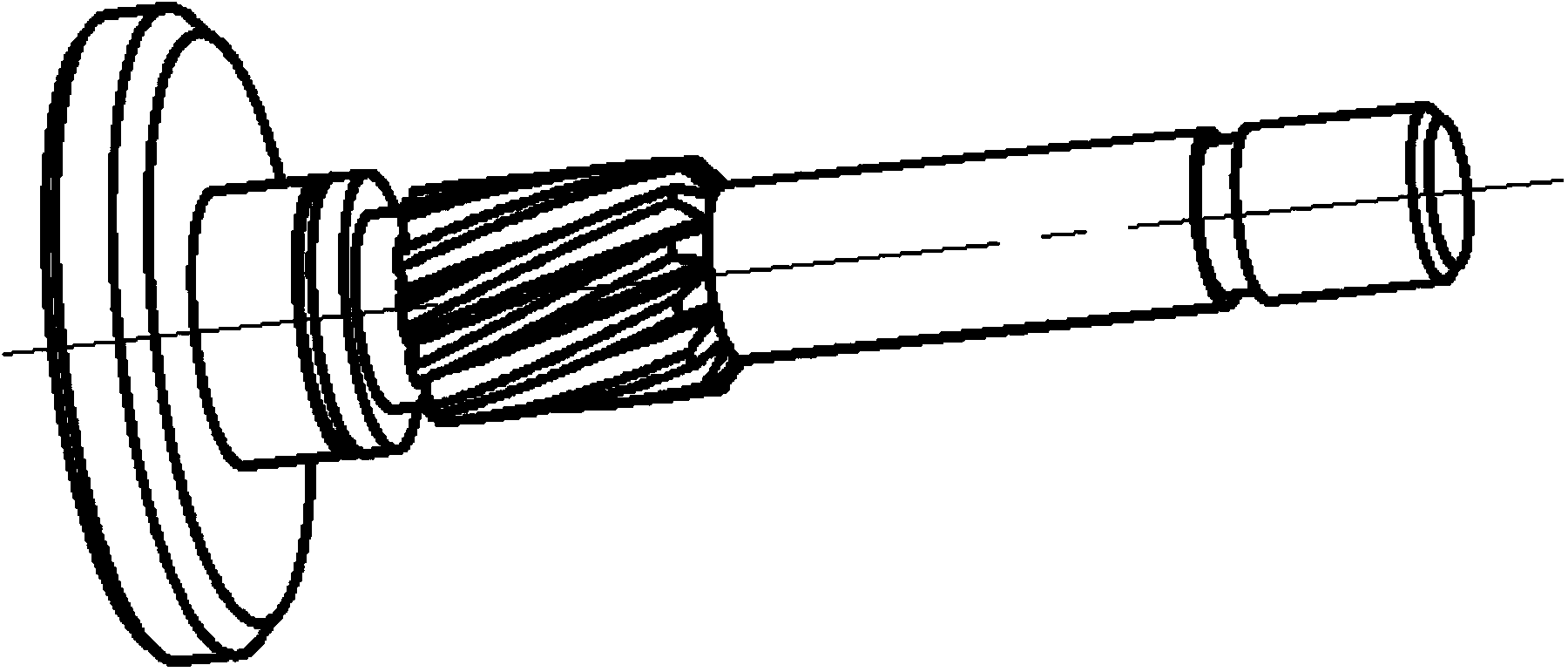

High precision machining method for double-head cross hole in bolt shaft

InactiveCN111390216AImprove versatilitySave tooling costsSoldering ironDrill jigsThermal dilatationEngineering

The invention discloses a high precision machining method for a double-head cross hole in a bolt shaft The method comprises the following steps of (1) drill jig manufacturing: designing and manufacturing a pair of overturn cross hole drill jig with 90-degree overturn surfaces; (2) electric soldering iron reforming: reforming the heads of a pair of electric soldering iron to a positioning shaft; (3) drill jig positioning and clamping; (4) first time drilling: drilling one hole in the double-head cross hole in the bolt shaft by a drill bit separately; (5) electric soldering iron gapless positioning: separating the positioning shafts of the pair of electric soldering iron into drilled holes, separately, and connecting a power supply for thermal expansion gapless positioning; (6) drill jig overturning and clamping; and (7) second time drilling: drilling the other hole in the double-head cross hole by the drill bit, separately; and after drilling, unloading the electric soldering iron and the cross hole drill jig after the electric soldering iron is cooled. The method improves the machining precision of the double-head cross hole and is low in implementation cost.

Owner:CHENGXI SHIPYARD

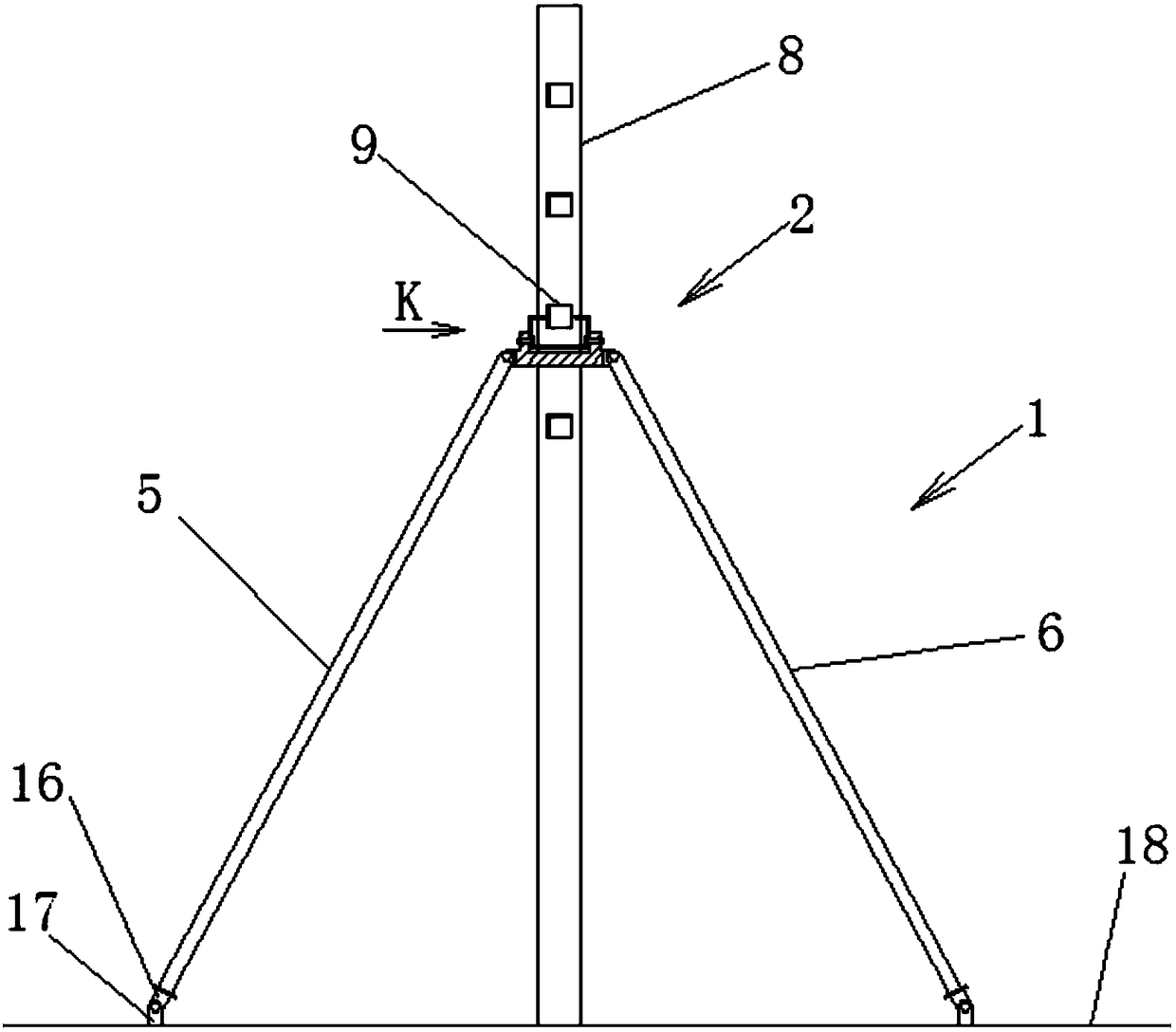

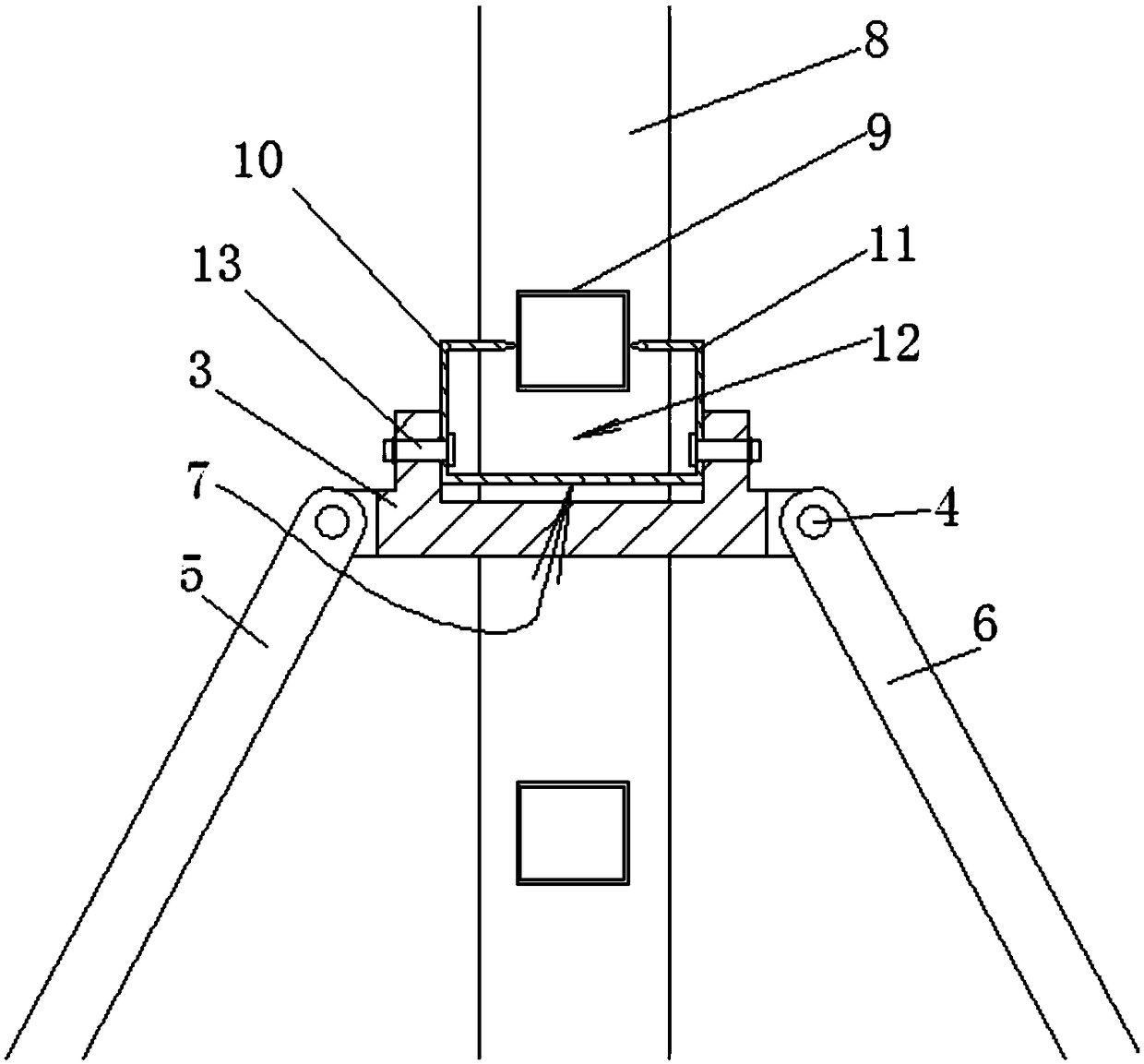

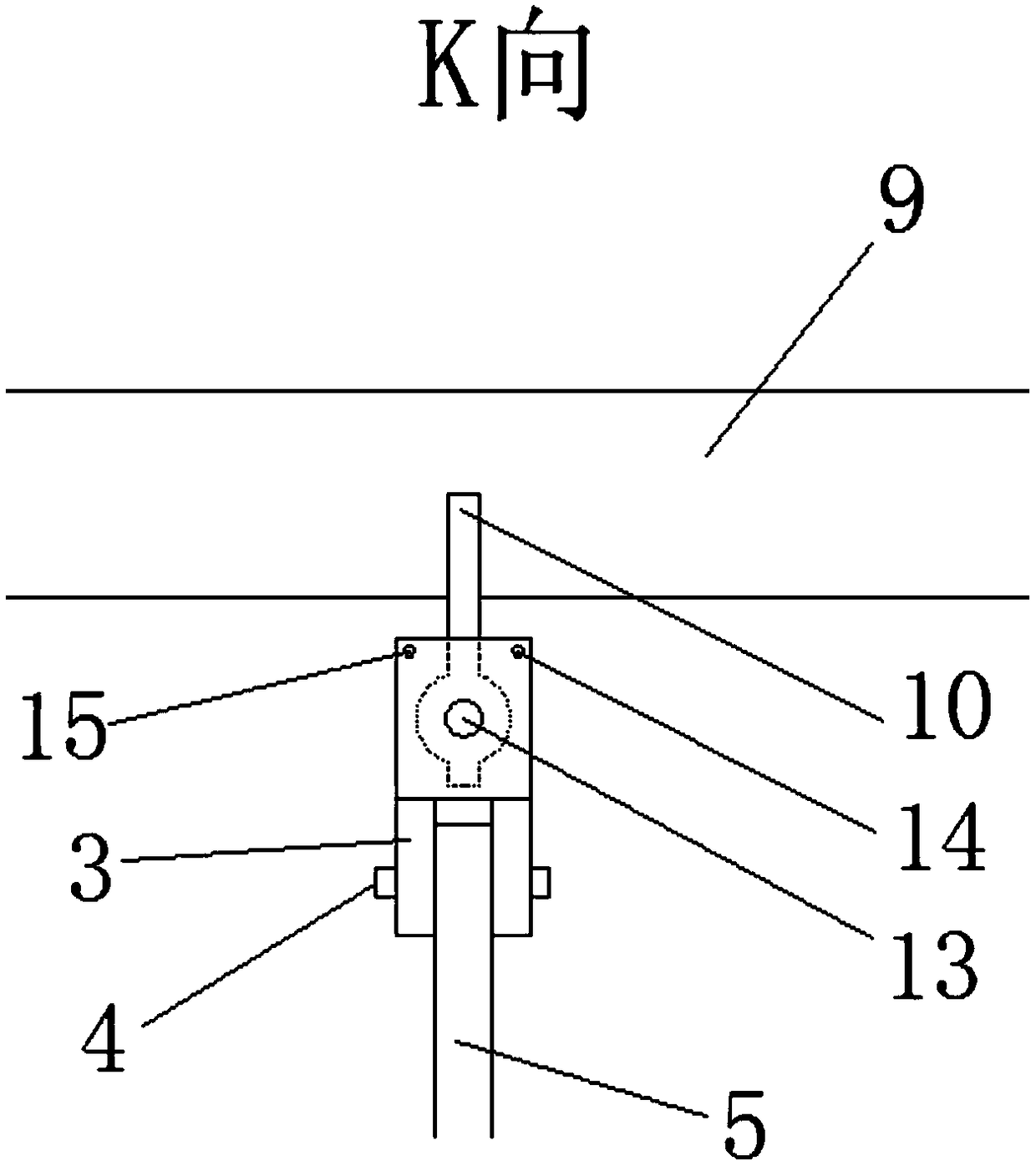

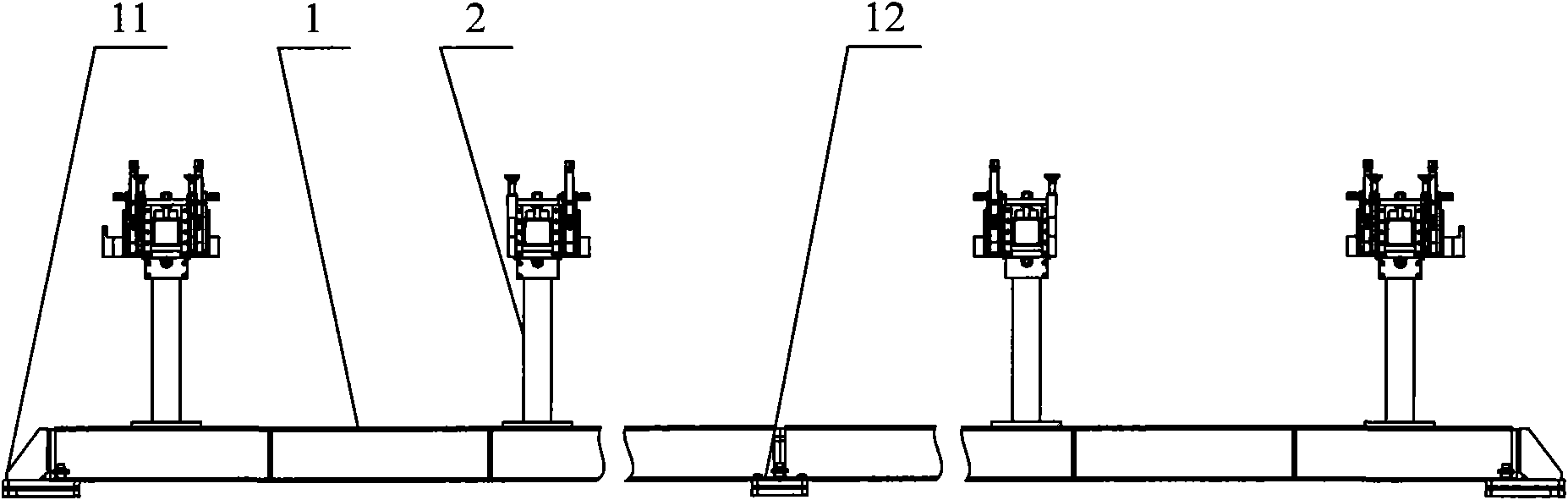

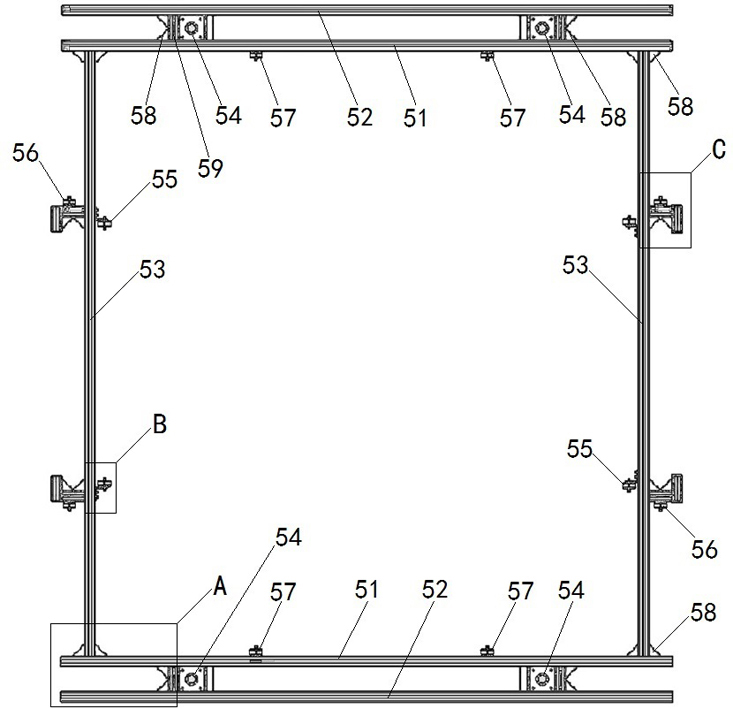

Supporting tool for spraying zinc to surface of fence small assembly of ship deck

The invention relates to the technical field of ship manufacturing, and discloses a supporting tool for spraying zinc to the surface of a fence small assembly of a ship deck. The supporting tool for spraying zinc to the surface of the fence small assembly of the ship deck comprises a supporting rack and a lateral limiting device, wherein the lateral limiting device is arranged on the upper portionof the supporting rack and is used for preventing the fence small assembly from tilting leftwards or rightwards; the supporting rack comprises a seat block; the left side and the right side of the seat block are separately connected with a left supporting rod and a right supporting rod through hinges; the upper end of the seat block is connected with the lateral limiting device; and the lateral limiting device comprises a connecting arm, a left bent catch pawl and a right bent catch pawl, the connecting arm is arranged horizontally, the left bent catch pawl and the right bent catch pawl are arranged at the two ends of the connecting arm, extend upwards and are used for limiting the left side surface and the right side surface of a handrail in the fence small assembly; and a gap for zinc spraying to the handrail is formed between the connecting arm and the handrail. The zinc spraying quality and efficiency are improved, and meanwhile, the cost for supporting auxiliary materials is saved.

Owner:CHENGXI SHIPYARD

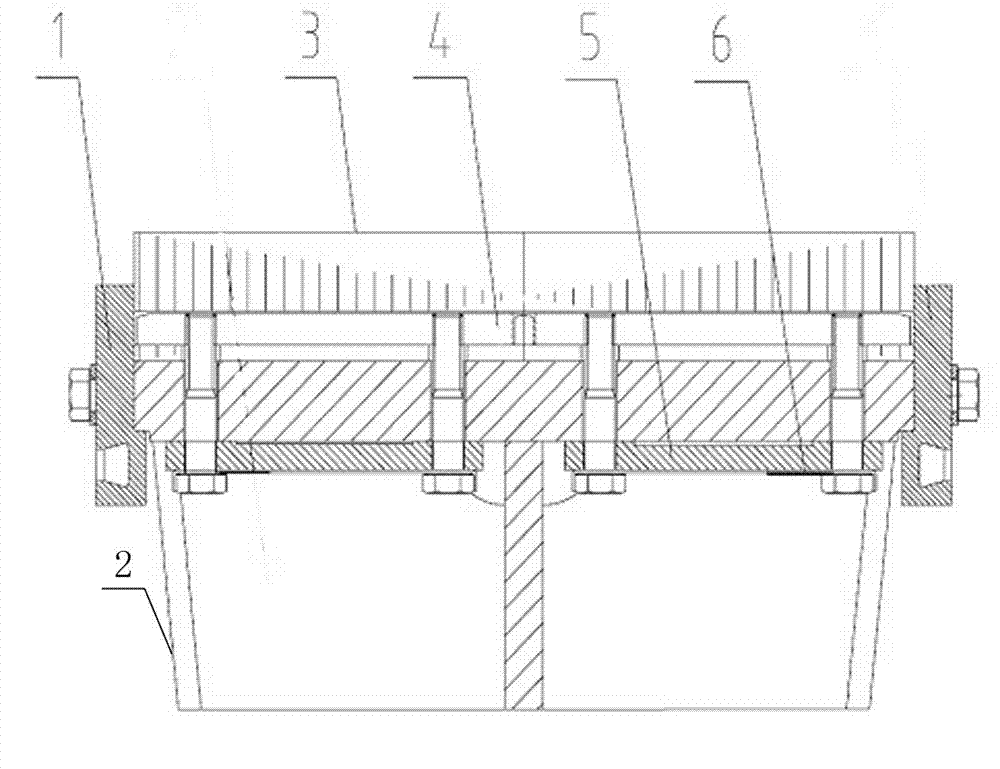

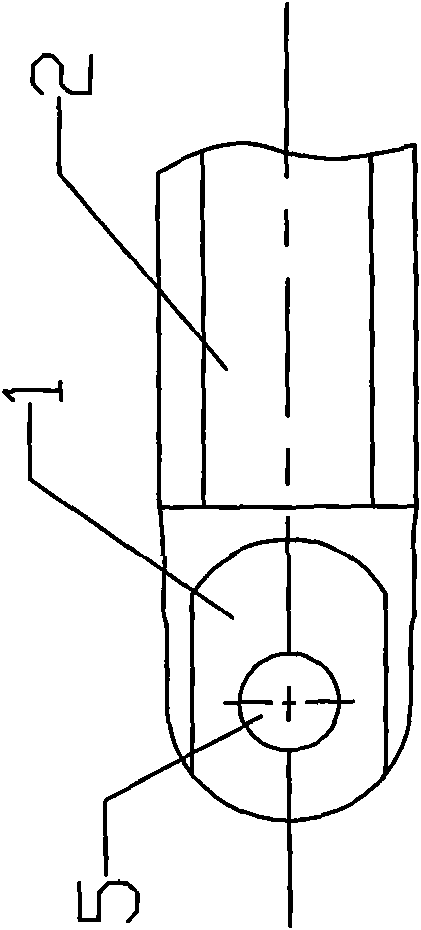

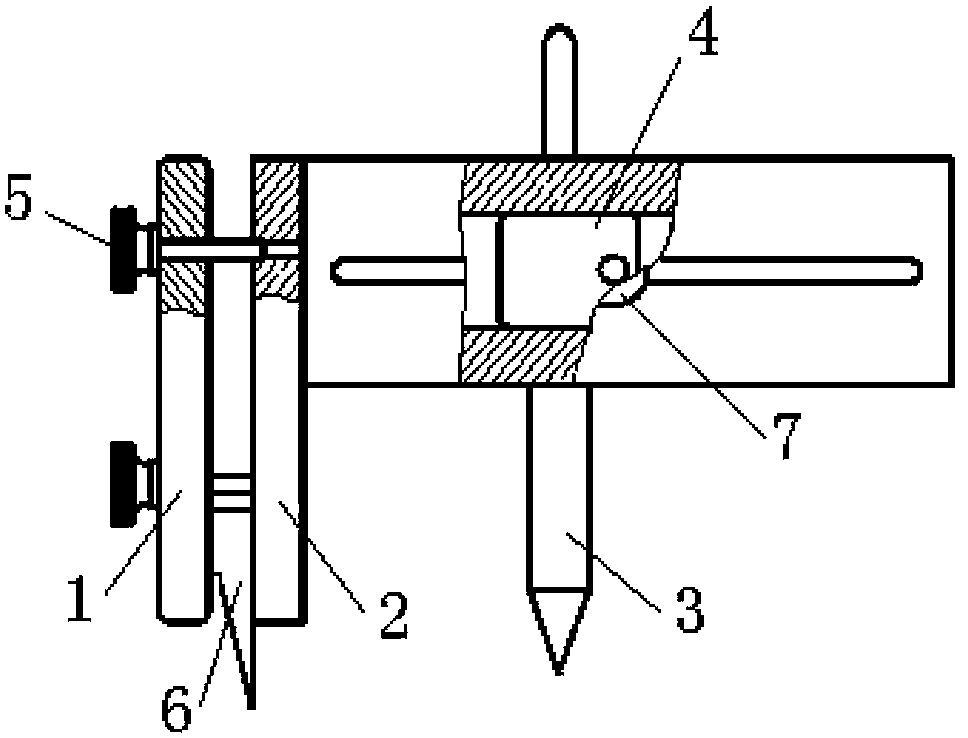

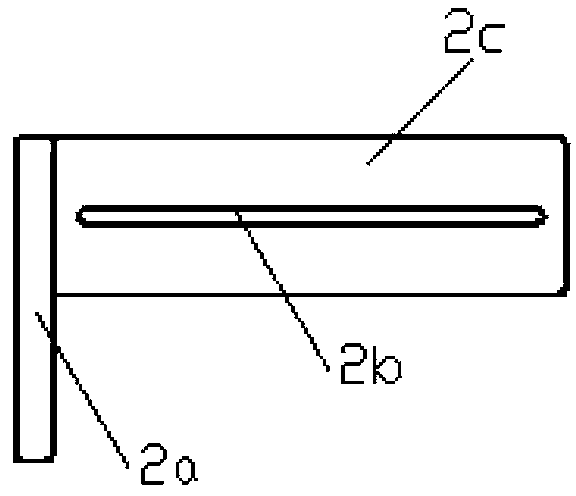

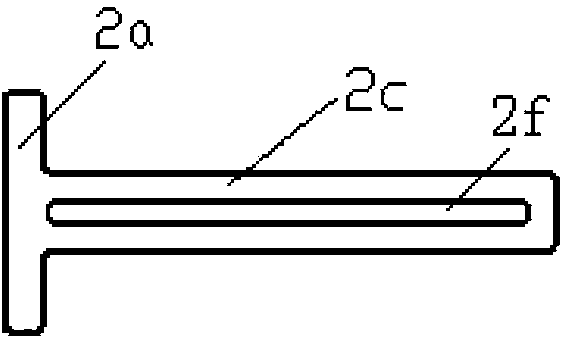

Blanking tool of fluorine coated rubber ring workblank

The invention relates to a blanking tool of a fluorine coated rubber ring workblank, and belongs to the technology of rubber processing. The blanking tool is characterized by comprising a pressing plate (1), a tool rest (2), a central spindle (3), a sliding block (4), three pressing plate screws (5), a blade (6) and a sliding block locking screw (7). The blanking tool of a universal fluorine coated rubber ring workblank, which can be adjusted according to size of a fluorine coated rubber ring, is provided, and a special punching die is not required to be manufactured, so that the tooling expense is saved, and the blanking cost is reduced.

Owner:XINXIANG AVIATION IND GROUP RUBBER PLASTICPROD

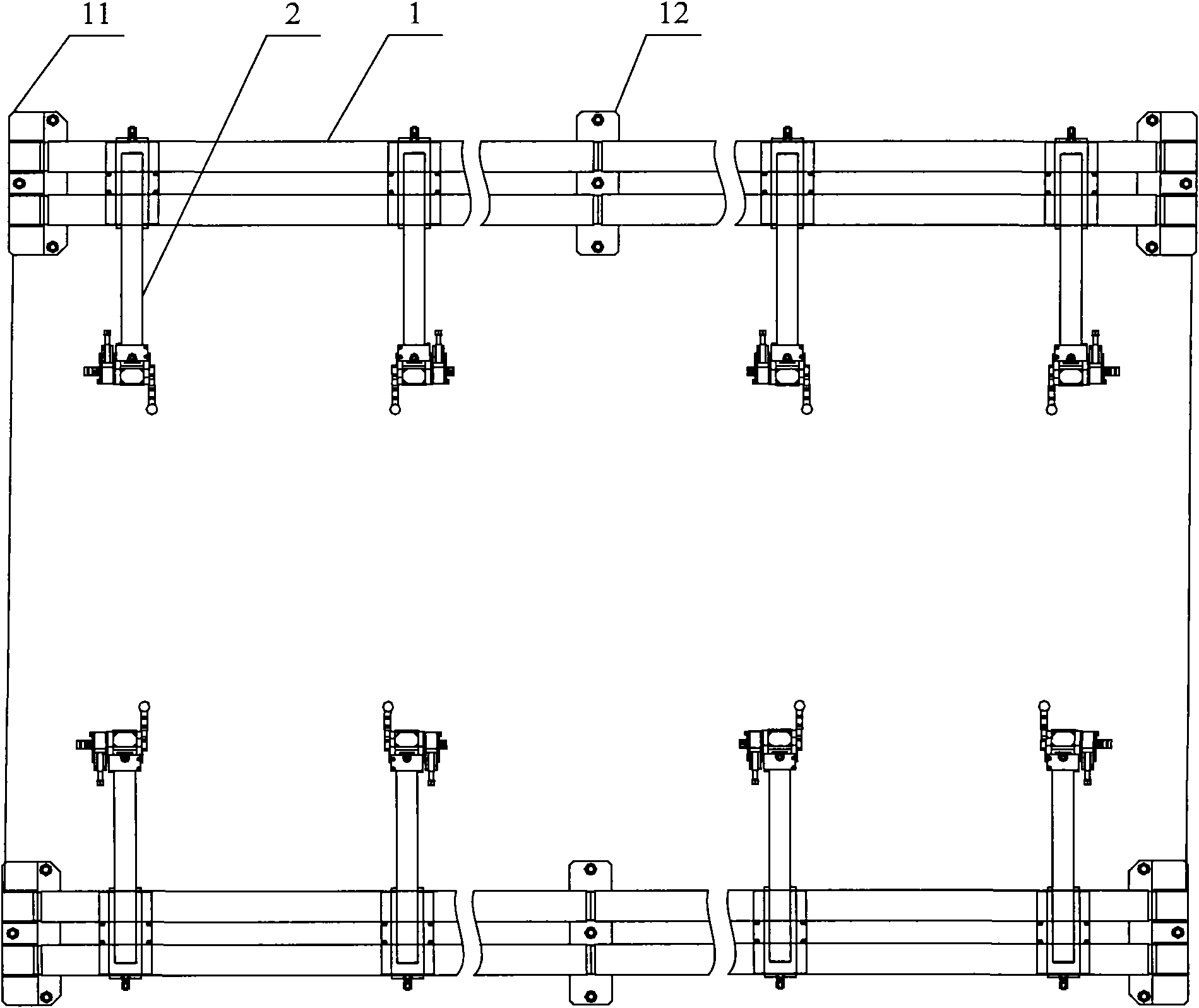

Ceiling welding tool and ceiling welding process

InactiveCN102019498AImprove spot welding qualitySimple structureResistance welding apparatusSpot weldingCantilever

The invention discloses a ceiling welding tool and a ceiling welding process. The ceiling welding tool comprises two symmetrically arranged supporting platforms, a plurality of tool fixtures are arranged at intervals on each supporting platform, the tool fixtures are slidably arranged on the supporting platforms and are used for fixing upper cantilever beams while installing a ceiling. The ceiling welding tool provided by the invention has simple structure, is convenient to realize and can effectively reduce tool expense. Meanwhile, the ceiling welding tool provided by the invention can be used for carrying out double-side single-spot welding on the ceiling and can effectively improve the welding quality of the ceiling.

Owner:CRRC DALIAN CO LTD

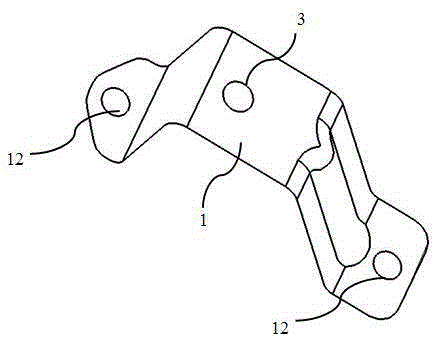

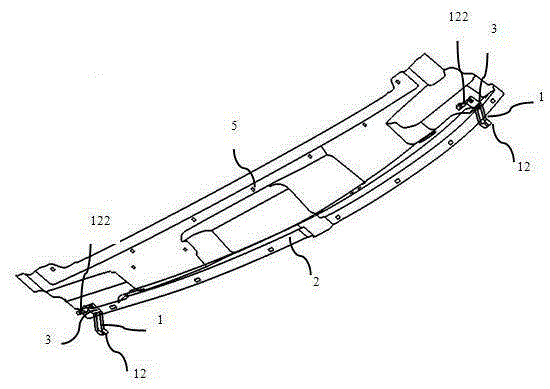

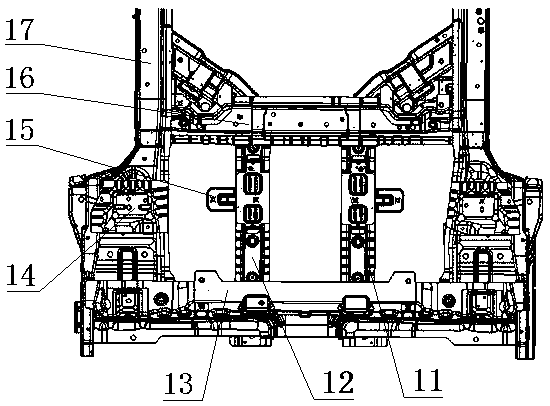

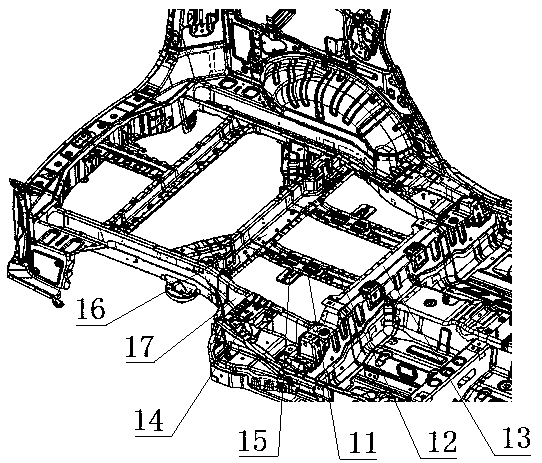

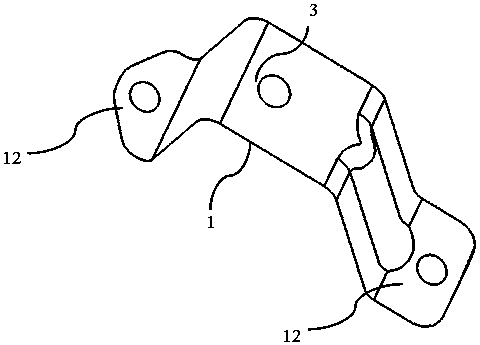

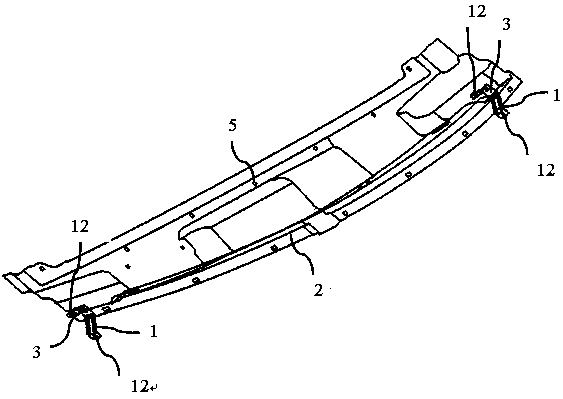

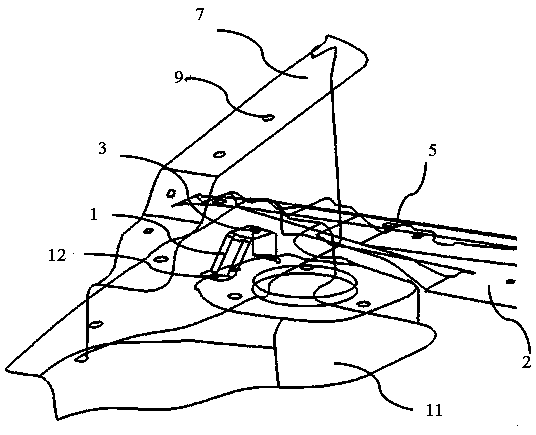

Anti-cracking drain channel structure and mounting method

ActiveCN105235750ASimple structureSmall footprintSuperstructure subunitsNoise, vibration, and harshnessEngineering

The invention discloses an anti-cracking drain channel structure. The anti-cracking drain channel structure comprises front shock absorber seat connecting plates (11), an automobile drain channel main body (2) and pi-shaped brackets (1), wherein plug welding holes (12) are formed in the front ends and the back ends of the pi-shaped brackets (1); mounting screw holes are formed in the top ends of the pi-shaped brackets (1); by using bolts, the two pi-shaped brackets (1) are fixedly connected with the automobile drain channel main body (2) at the two ends of the automobile drain channel main body (2) through the mounting screw holes (3); the two pi-shaped brackets (1) are fixed on the front shock absorber seat connecting plates (11) through respective front and back plug welding holes (12). The anti-cracking drain channel structure disclosed by the invention is advantaged in that the structure of the anti-cracking drain channel structure is simple and practical, the space occupied by the anti-cracking drain channel structure is small, the anti-cracking drain channel structure is convenient to mount and detach and the NVH (Noise Vibration and Harshness) performance of the whole automobile can be improved.

Owner:CHERY AUTOMOBILE CO LTD

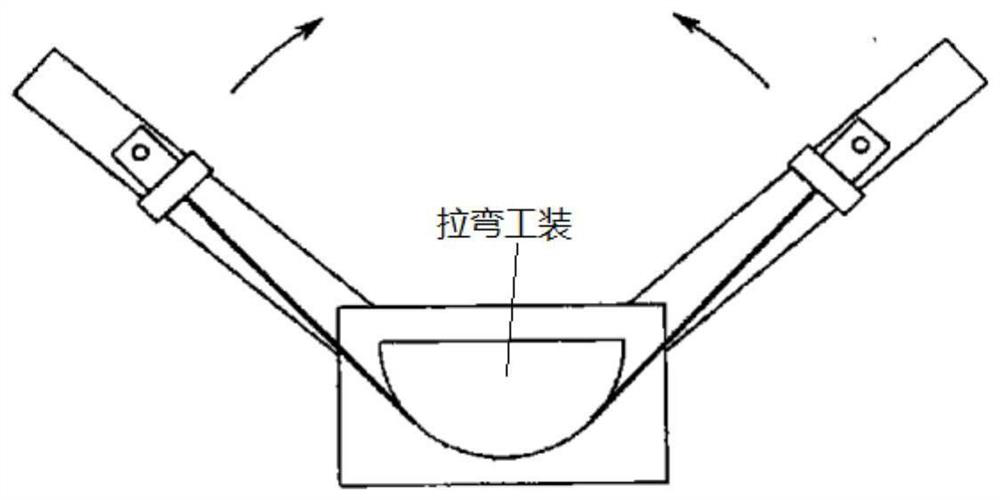

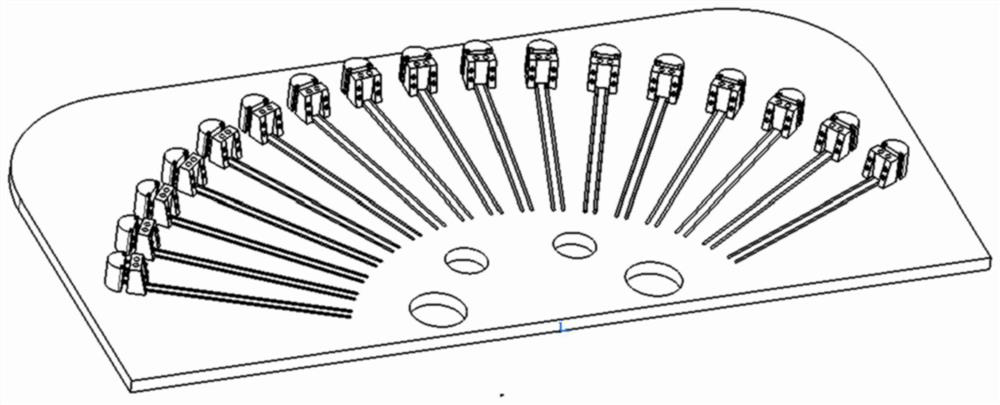

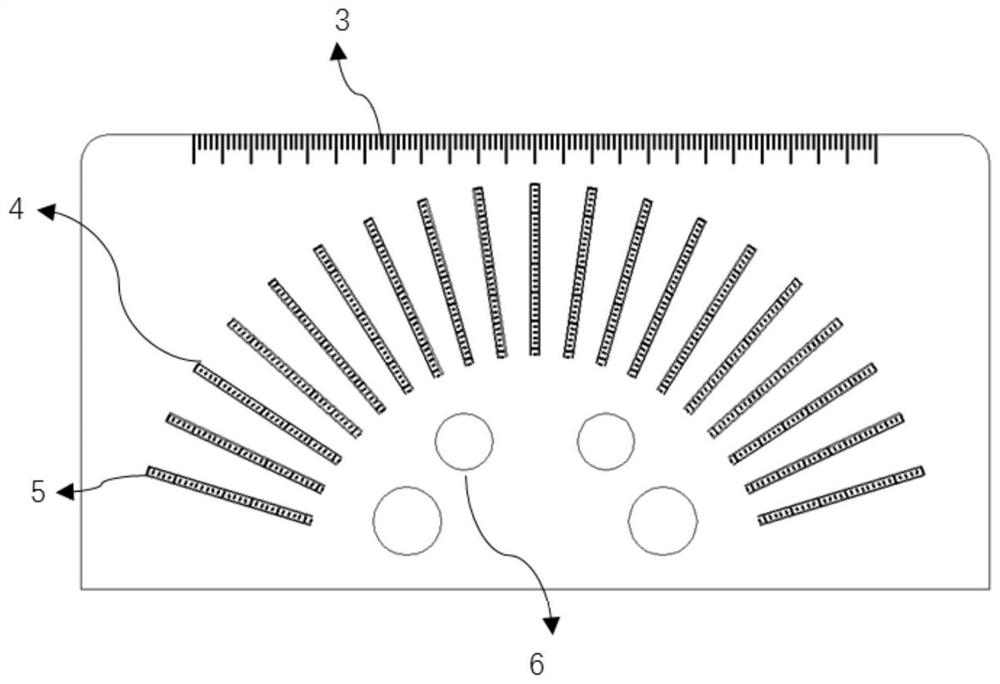

Multifunctional aluminum profile stretch-bending forming die and stretch-bending forming process

The invention relates to a multifunctional aluminum profile stretch-bending forming die and a stretch-bending forming process. The multifunctional aluminum profile stretch-bending forming die comprises a tool bottom plate and multiple radial radian positioning block slideways fixedly installed on the tool bottom plate, radian positioning blocks are installed on the radian positioning block slideways in a sliding manner, and the radian positioning blocks comprise arc-shaped positioning blocks and fine adjustment positioning blocks. Bolt connecting holes are formed in the longitudinal directionsof the fine adjustment positioning blocks, a height adjusting nut is slidably installed in each T-shaped groove in the sides, opposite to the fine adjustment positioning blocks, of the arc-shaped positioning blocks, and screw rods are arranged in the fine adjustment positioning blocks in a penetrating manner. Radian fine adjustment nuts corresponding to the height adjustment nuts are installed atthe positions, on the sides, opposite to the arc-shaped positioning blocks, of the fine adjustment positioning blocks, of the screw rods in a threaded manner, and fastening nuts are installed at thepositions, on the sides, away from the arc-shaped positioning blocks, of the fine adjustment positioning blocks, of the screw rods in a threaded manner. The problems that an existing high-strength aluminum alloy angle aluminum profile stretch-bending tool is simple in design, free of universality, high in tool cost, large in manual mounting and dismounting workload and prone to influencing tool precision are solved.

Owner:CHINA ZHONGWANG

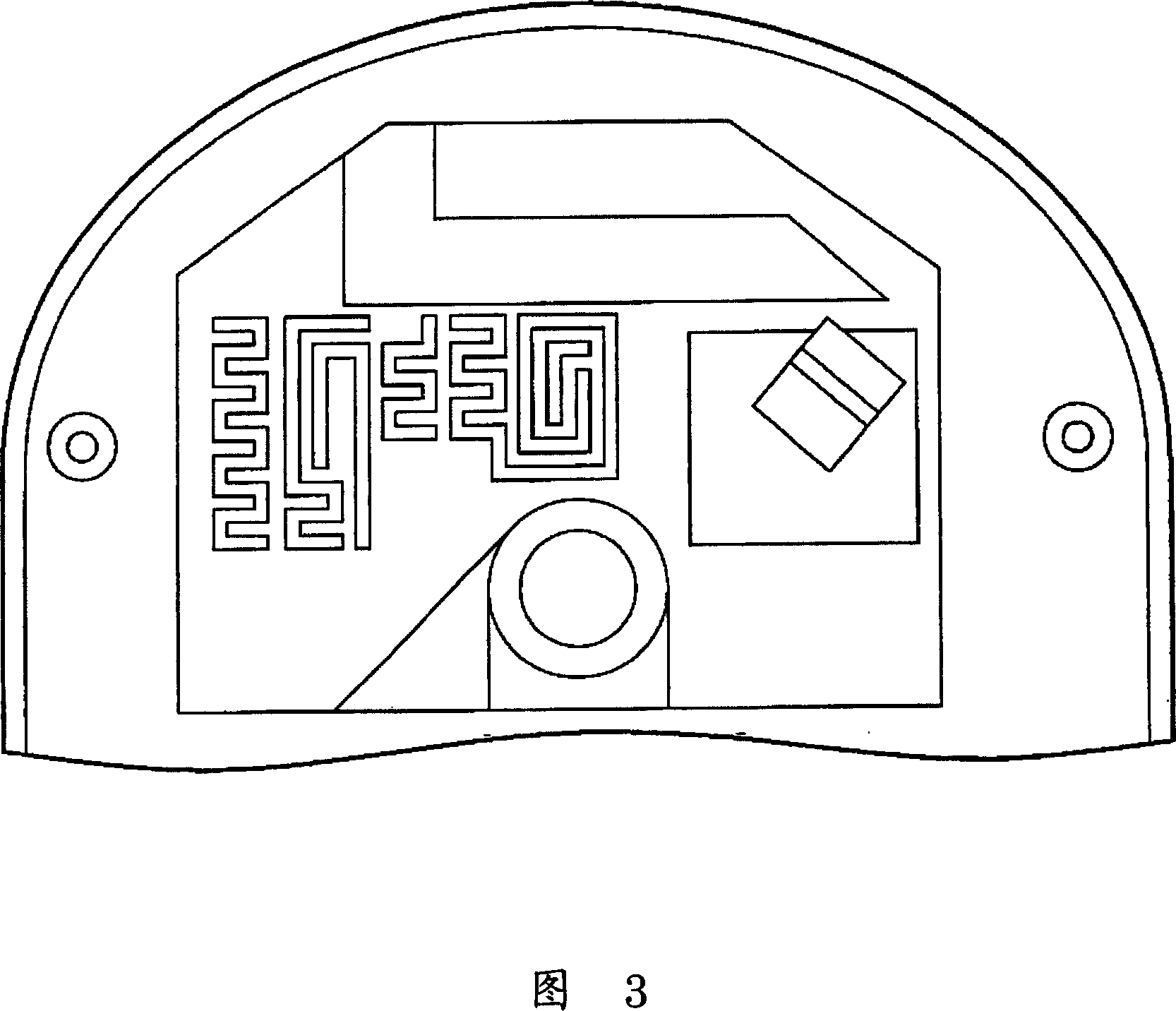

Electronic device and its antenna structure

InactiveCN101064376ACost advantageAdvantages of Mechanism DesignAntenna supports/mountingsRadiating elements structural formsOptoelectronicsElectron

The invention provides an electron device and antenna structure, said antenna structure includes a film layer, an antenna emitting layer and a backing. The antenna emitting layer is formed on the film layer, the antenna emitting layer and the film layer are combined on the backing, and the antenna emitting layer is between the backing and the film layer. Said backing can be the shell of an electron device, and the antenna emitting layer can be combined on the shell of the electron device in emitting in mould mode. The electron device and antenna structure in the invention can decrease the cost of mould and material of metal piece, but also increase the quality ratio and consistency.

Owner:LITE ON TECH CORP

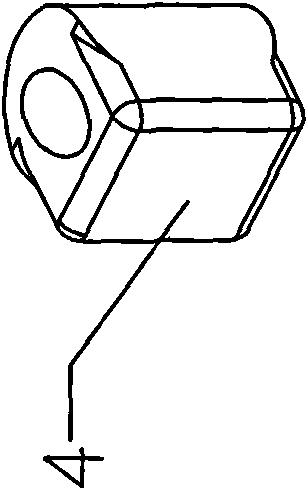

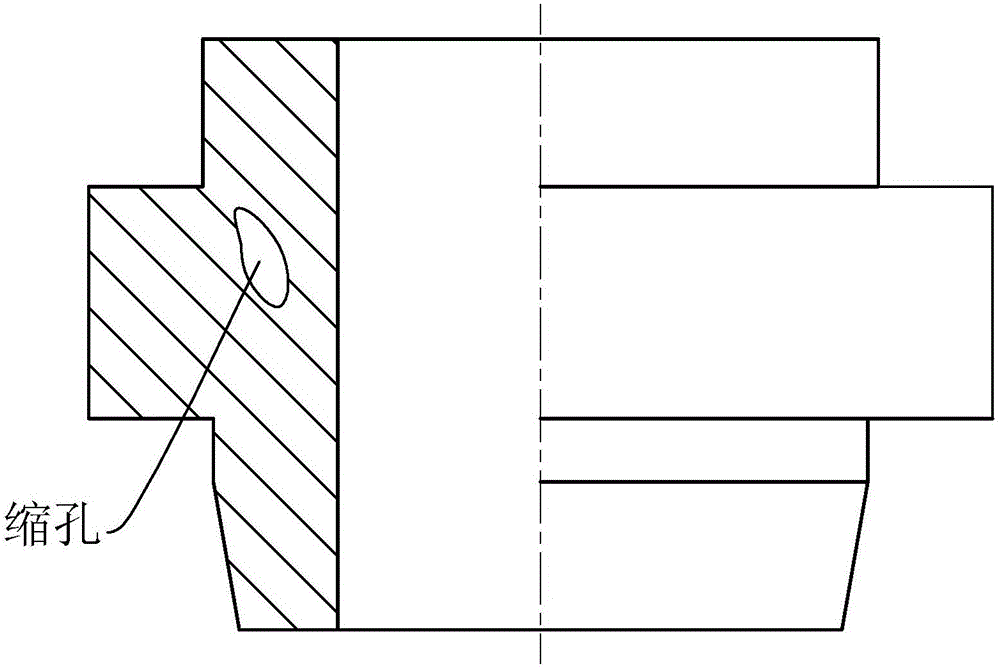

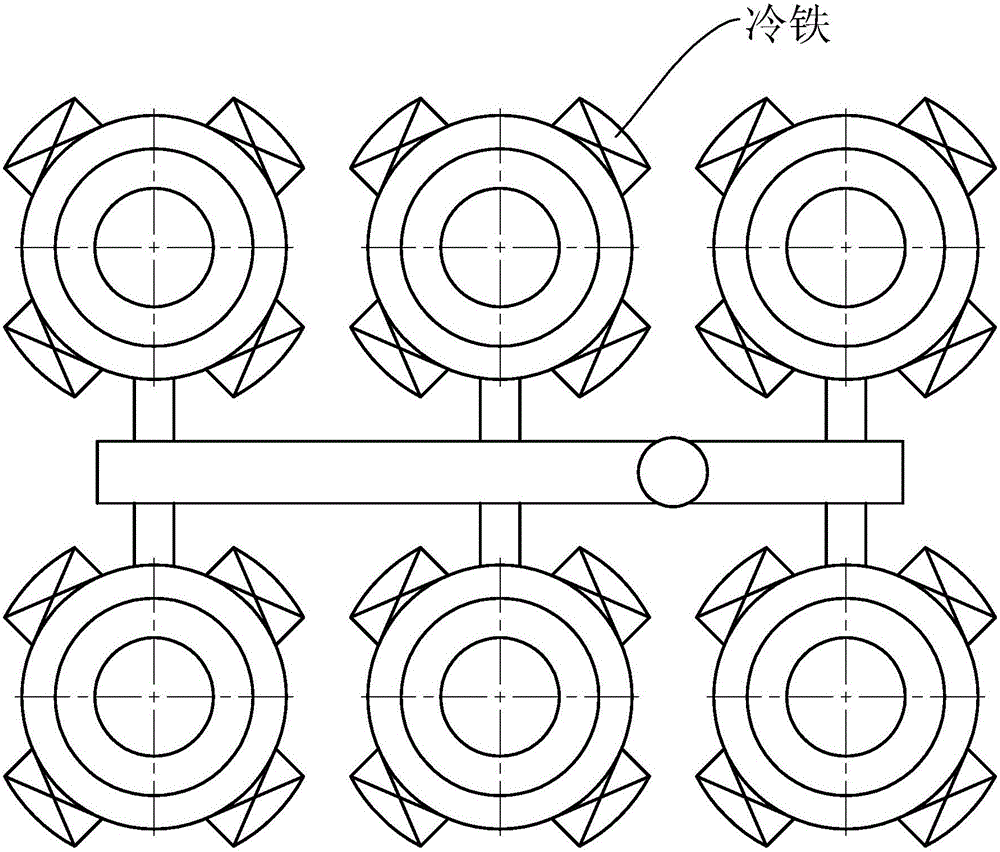

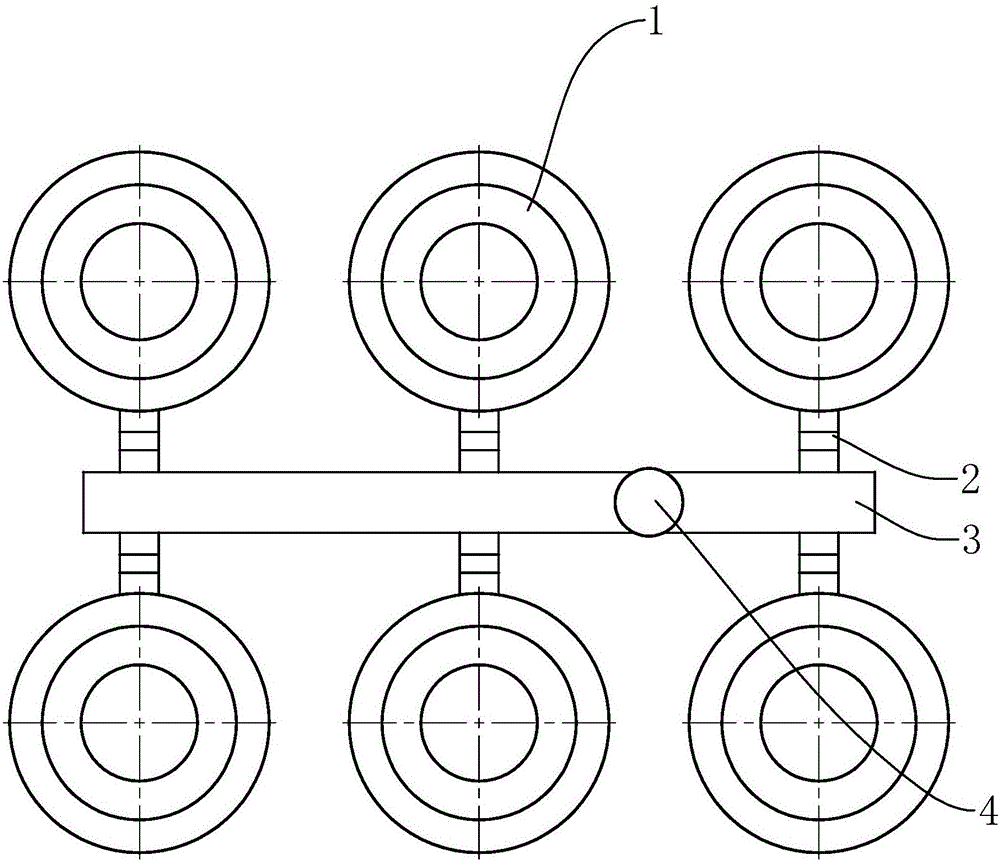

Pouring gate structure for nut casting

InactiveCN105903905ASpeed up coolingEliminate stomatal defectsFoundry mouldsFoundry coresMaterials scienceMolten metal

The invention discloses a pouring gate structure for nut casting. The pouring gate structure for nut casting comprises cavities, ingates, a runner and a sprue. During casting, molten metal enters from the sprue, flows into the runner in a distributed manner, and then is injected into the cavities via the ingates, a position where each cavity is connected with the corresponding ingate is an inner gate, a position where the runner is connected with each ingate is a runner gate, the cross-sectional area of each runner gate is greater than that of the inner gate, the cooling speed of the ingates is slowed, replenishment time is sufficient when liquid in the cavity of a casting is cooled by the molten metal, defects of shrinkage holes and shrinkage porosity are eliminated, chilling block treatment and arrangement are not required, a large amount of costs for tools are saved, pore defects which are possibly caused by chilling blocks are eliminated, and the yield of the casting can reach 100%.

Owner:GUANGDONG HENGCHENG TECH

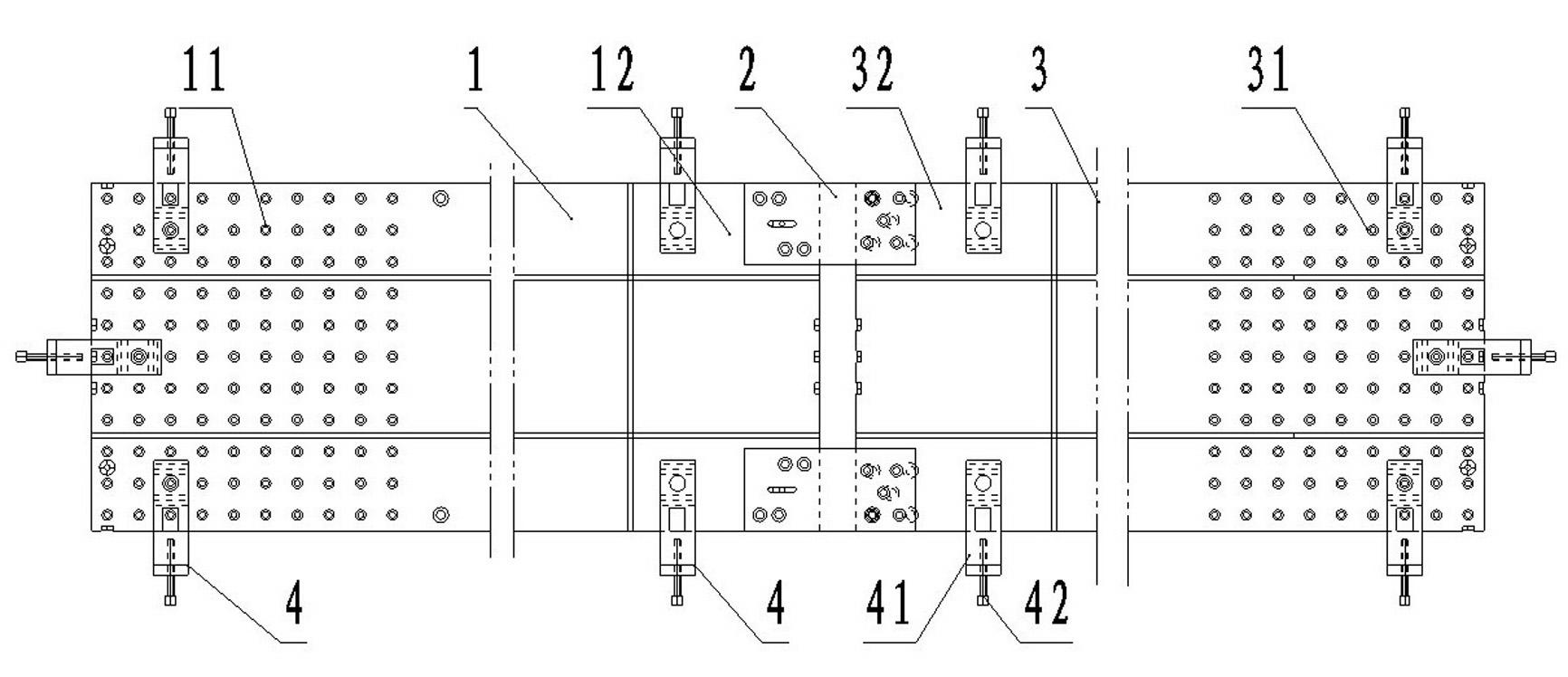

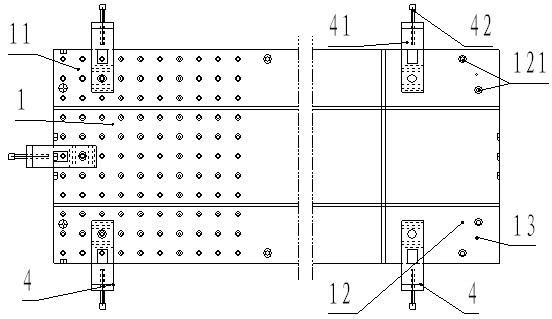

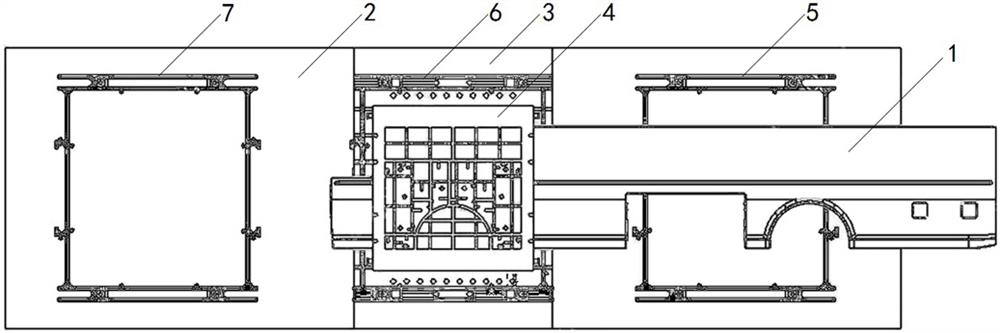

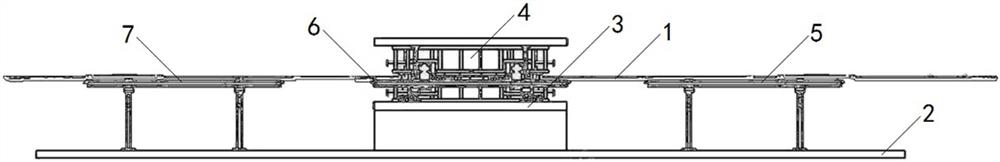

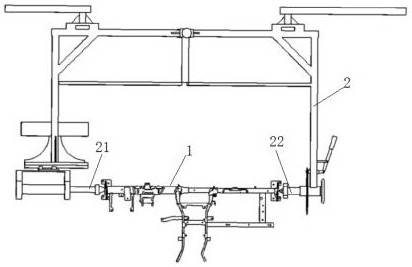

Novel feeding mechanism

ActiveCN113333607AReduce moving frictionReduce labor intensityMetal-working feeding devicesPositioning devicesStringerMechanical engineering

The invention provides a novel feeding mechanism. The novel feeding mechanism comprises a feeding rack; a working rack; a discharging rack; ad the three racks are sequentially arranged left and right, each rack comprises a height-adjustable supporting leg, a cross beam and a longitudinal beam, at least two longitudinal rollers are installed on each longitudinal beam, and the longitudinal rollers are installed on the longitudinal beams through an adjustable structure so that the distance can be adjusted. The novel feeding mechanism provided by the invention has high universality, height adjustment is achieved through a simple profile sleeving structure, the novel feeding mechanism can be matched with stamping dies of different heights and sizes to achieve feeding and discharging of plates, and the novel feeding mechanism is economical and practical; a working rack height adjusting mechanism can realize lifting of the plates so as to be matched with the working process of a die; and the distance between the longitudinal rollers is adjustable, and the novel feeding mechanism can adapt to feeding and discharging of plates of different widths and sizes. Therefore, one set of feeding mechanism can be suitable for the plates of different sizes and the stamping dies of different sizes, multiple sets of feeding mechanisms do not need to be arranged and frequently replaced, the tooling cost can be saved, the labor intensity of workers is reduced, and meanwhile the production efficiency can be improved.

Owner:郑州豫诚模具有限公司

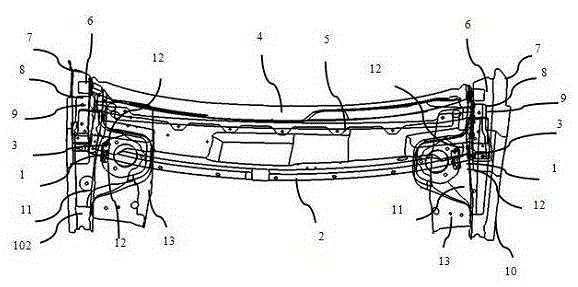

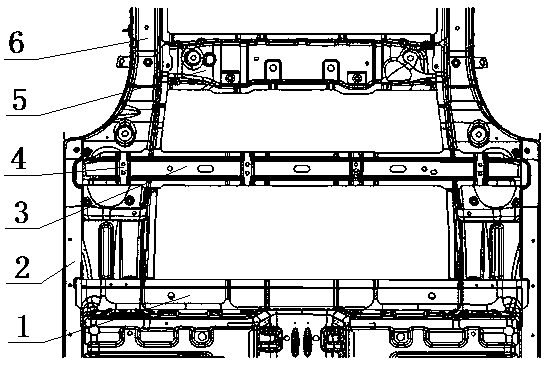

Middle row seat mounting cross beam

InactiveCN110789408AIncrease stiffnessIncreased torsional stiffnessSeat framesSuperstructure subunitsCantileverMechanical engineering

The invention discloses a middle row seat mounting cross beam, and relates to the technical field of automobile manufacturing. The middle row seat mounting cross beam comprises a seat cross beam located between a rear floor front cross beam and a rear floor lower cross beam. The two ends of the seat cross beam respectively penetrate through rear longitudinal beams to be fixedly connected with threshold beams. A plurality of seat mounting supports are arranged on the seat cross beam. Compared with the prior art, according to the middle row seat mounting cross beam, a seat in the middle and seats on two sides are mounted on the seat mounting supports, middle-row seats can be mounted through just two parts, few types of tools for production are required correspondingly, and the production cost is low. The seat mounting supports are arranged on the seat cross beam, a cantilever structure is eliminated, and the rigidity of a seat mounting point is improved. When a vehicle body is subjectedto side collision, through the rear floor front cross beam, the rear floor lower cross beam and the seat cross beam for force transmission, a side collision force transmission path is increased, sideimpact bearing performance is improved, and meanwhile, the torsional rigidity is effectively improved.

Owner:DONGFENG LIUZHOU MOTOR

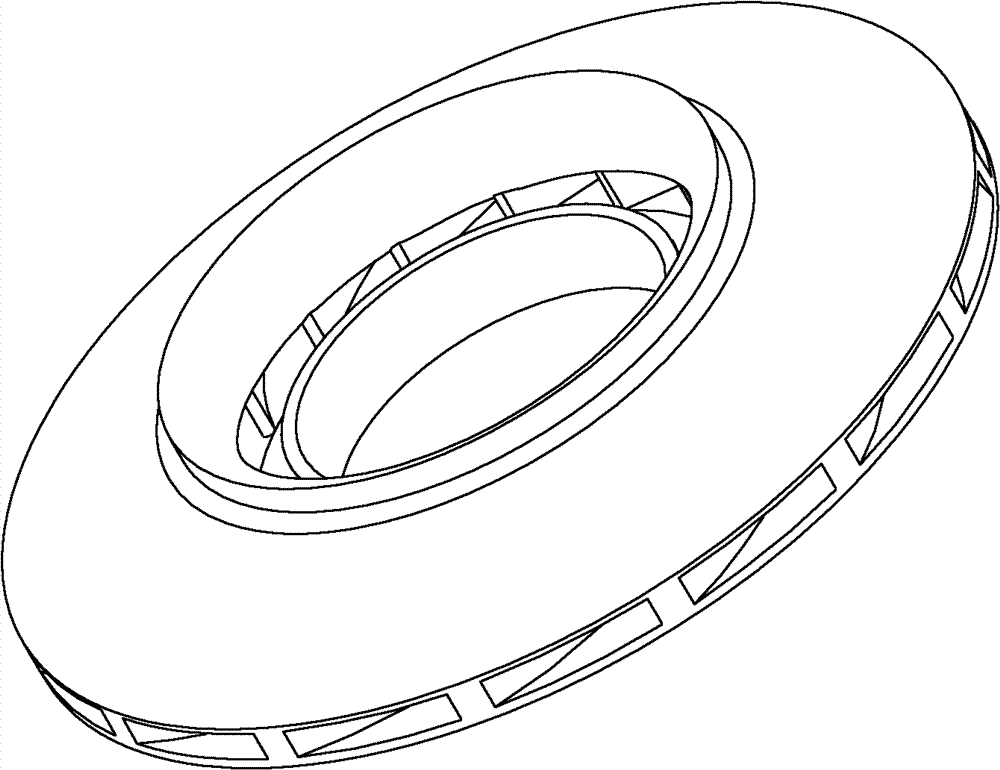

Special clamp for abrasive flow polishing of narrow flow passage closed impeller flow passage

InactiveCN102152244BRealize up and down reciprocating flowAvoid damagePolishing machinesEngine manufactureImpellerCircular disc

The invention discloses a special clamp for abrasive flow polishing of a narrow flow passage closed impeller flow passage. The special clamp comprises an upper mold, a lower mold, a floating lock and a gasket support plate, wherein the upper mold and the lower mold form a cylindrical cavity; the inner diameter of the cylindrical cavity is greater than the diameter of the impellers; the gasket support plate is a round disc having the diameter as the same as the diameter of the impellers; the floating lock consists of an upper round disc and a lower round disc and a double-head stud and a bolt which are used for connecting the two round discs; the mounted floating lock can move between the gasket support plate and the lower mold; the impellers are arranged on the gasket support plate, and are fastened by the upper mold and the lower mold; and the upper mold and the lower mold are positioned through seam allowance, and are fixed by the bolts. The clamp for abrasive flow machining of the narrow plow passage closed impellers can be used for fixing the impellers and can guide abrasive materials to flow through the surface of the impeller flow passage, and keep a given pressure so as to grind and polish the internal part of the impeller flow passage, form a circular loop and realize reciprocating flow of the abrasive materials.

Owner:DALIAN POLYTECHNIC UNIVERSITY

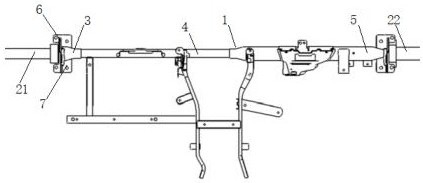

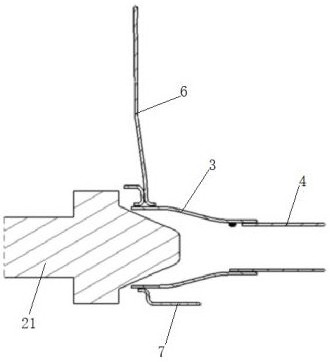

A steering support pipe beam structure

ActiveCN112249168BImprove generalizationSave tooling costsSuperstructure subunitsControl engineeringControl theory

The invention discloses a steering support pipe beam structure, which relates to the technical field of automobiles. Including steering support assembly, steering support fixture tooling, instrument panel mounting bracket and body mounting bracket A right rudder steering support middle transverse tube is fixedly arranged inside the supporting left transverse tube, and a right rudder steering support right transverse tube is fixedly arranged on the surface of the right rudder steering support middle transverse tube. By setting the steering support assembly, steering support fixture, left rudder steering support left cross tube and left rudder steering support right cross tube, the diameter of the right end of the left cross tube of the right rudder steering support and the diameter of both ends of the right cross tube of the right rudder steering support Consistent, so the shrinking tooling can be shared, the tube beam forming tooling is highly generalized, no redevelopment is required, and the tooling cost is reduced. The device has a simple structure, a short development cycle, easy to ensure accuracy, and broad application prospects.

Owner:HEFEI CHANGAN AUTOMOBILE

Compact permanent magnet wind generator rotor

ActiveCN102931741BAssembly positioning is accurateImprove ventilation efficiencyMagnetic circuit rotating partsMagnetic polesPermanent magnet synchronous generator

The invention relates to a rotating device inside a permanent magnet wind generator, in particular to a compact permanent magnet wind generator rotor, solving the problem of an unreasonable structure of the permanent magnet wind generator rotor. The compact permanent magnet wind generator rotor comprises a rotor bracket, and a magnetic pole box provided with a permanent magnet mounting hole; magnetic steel is arranged inside the permanent magnet mounting hole; a fixed rod mounting hole is arranged on the magnetic pole box; a bolt perforating hole is arranged on the contact surface of the magnetic pole box and the rotor bracket; the bolt perforating hole is communicated with the fixed rod mounting hole; a locating lug boss is also arranged on the surface contacting a magnet yoke on the rotor bracket on the magnetic pole box; a radial bolt hole and a guide locating groove matched with the locating lug boss are arranged on the magnet yoke on the rotor bracket, and a fixed rod with the bolt hole is arranged inside the fixed rod mounting hole. The compact permanent magnet wind generator rotor is novel in structure; the performance of a motor is improved; the manufacturing cost of the motor rotor is reduced, and the stability of the entire structure of the rotor is improved.

Owner:CRRC YONGJI ELECTRIC CO LTD

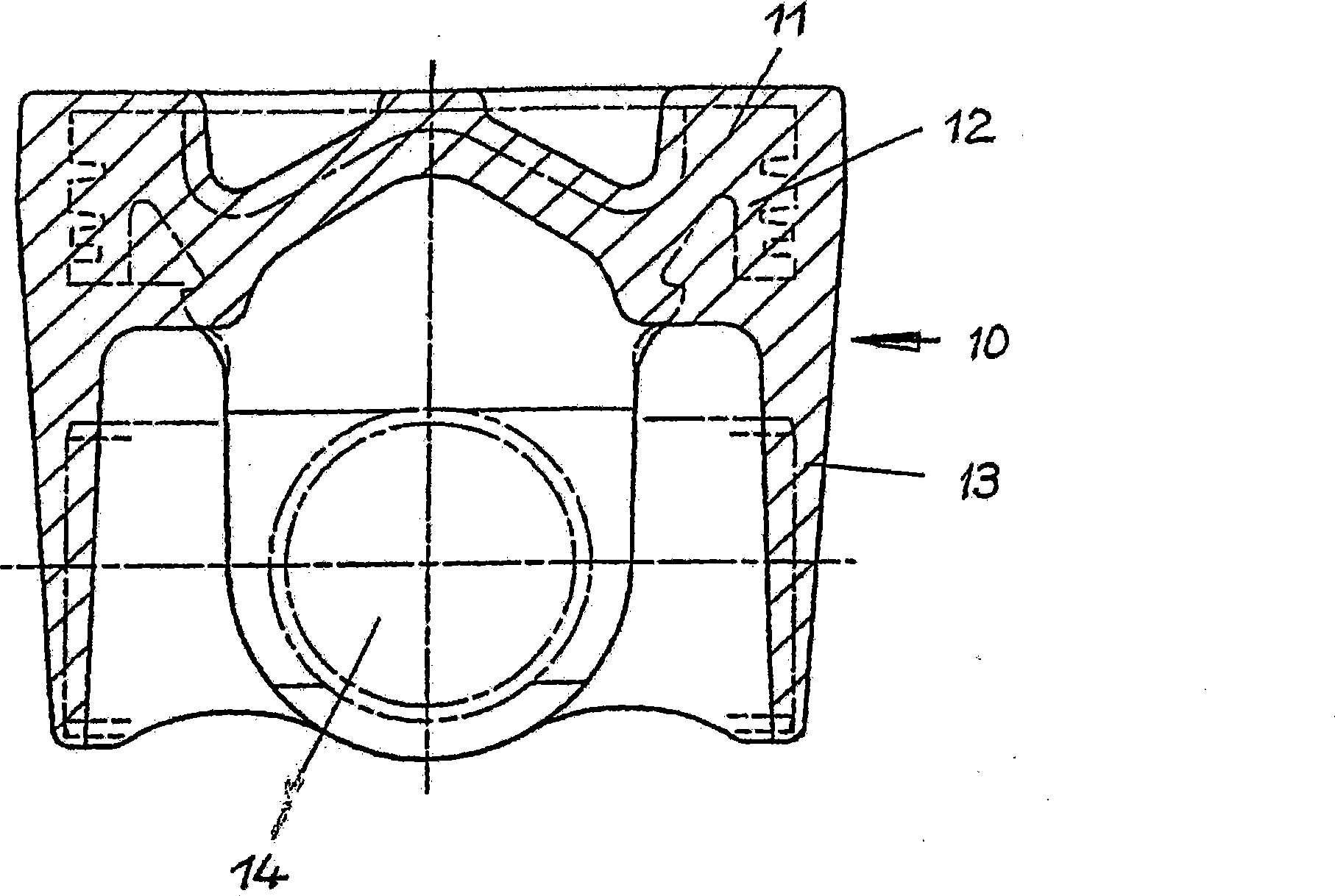

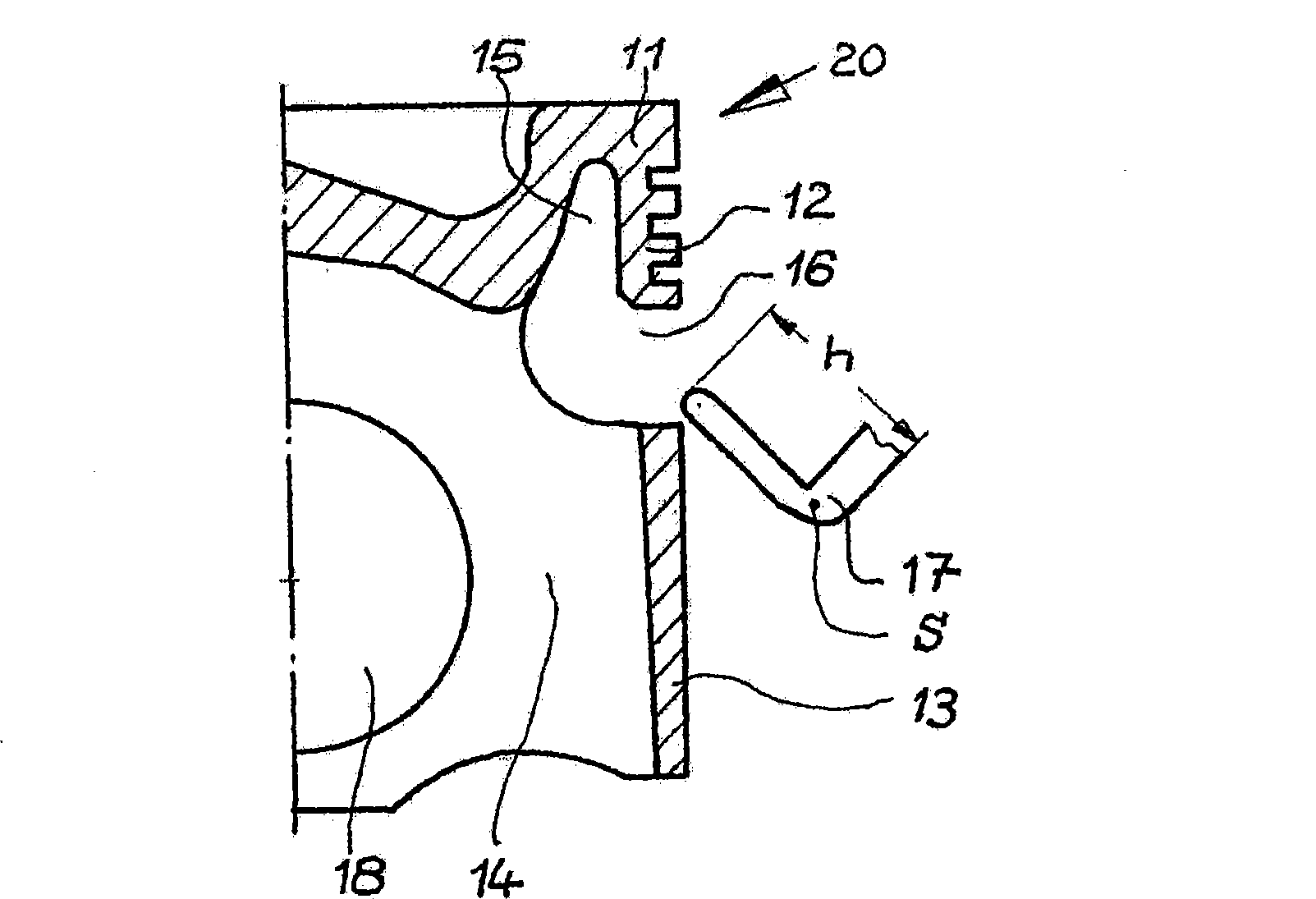

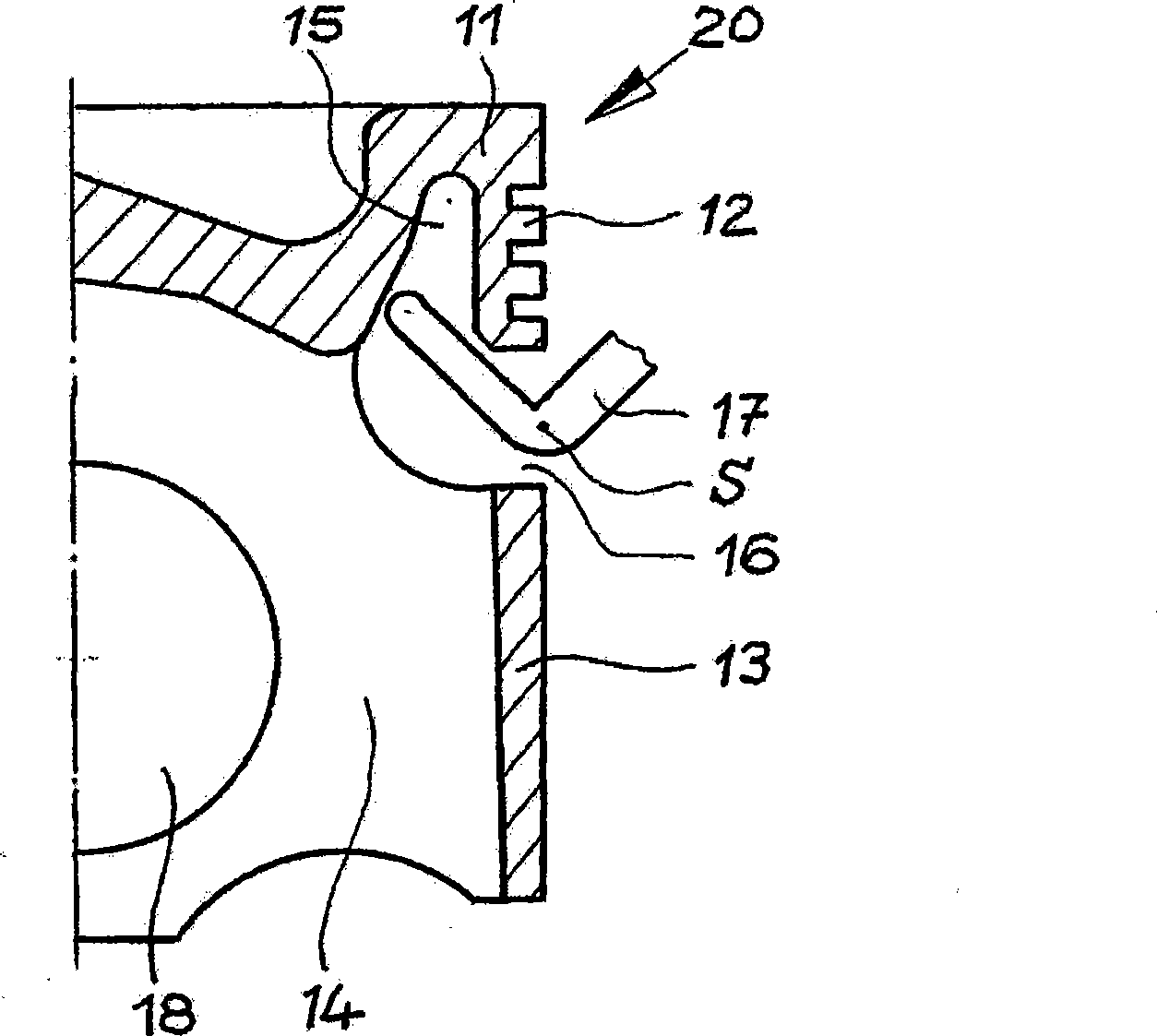

Method for the production of a single part piston and a piston produced by such a method

InactiveCN101472705BSave time at workSave tooling costsInternal combustion piston enginesTurning toolsEngineeringInternal combustion engine

The present invention relates to a method for producing a single part piston (20) for an internal combustion engine from a piston blank (10), with a cooling channel (15) that is open in the downward direction running circularly inside a piston head (11), and an annular recess (16) built between the piston head (11) and a piston shaft (13), wherein the piston head (11) and the piston shaft (13) are connected to each other by means of a piston hub (14), and wherein the annular recess (16) and the cooling channel (15) are machined into the piston blank (10) by means of a cutting operation. According to the invention, it is provided that, for the cutting operation of the cooling channel (15), a tool (17) is moved into the area of the cooling channel (15) in an arc-shaped pivoting movement (A) through the recess (16), and that the cooling channel (15) is cut.

Owner:MAHLE INT GMBH

An anti-cracking vehicle water tank structure and its installation method

ActiveCN105235750BSimple structureSmall footprintSuperstructure subunitsNoise, vibration, and harshnessEngineering

The invention discloses an anti-cracking drain channel structure. The anti-cracking drain channel structure comprises front shock absorber seat connecting plates (11), an automobile drain channel main body (2) and pi-shaped brackets (1), wherein plug welding holes (12) are formed in the front ends and the back ends of the pi-shaped brackets (1); mounting screw holes are formed in the top ends of the pi-shaped brackets (1); by using bolts, the two pi-shaped brackets (1) are fixedly connected with the automobile drain channel main body (2) at the two ends of the automobile drain channel main body (2) through the mounting screw holes (3); the two pi-shaped brackets (1) are fixed on the front shock absorber seat connecting plates (11) through respective front and back plug welding holes (12). The anti-cracking drain channel structure disclosed by the invention is advantaged in that the structure of the anti-cracking drain channel structure is simple and practical, the space occupied by the anti-cracking drain channel structure is small, the anti-cracking drain channel structure is convenient to mount and detach and the NVH (Noise Vibration and Harshness) performance of the whole automobile can be improved.

Owner:CHERY AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com