Bidirectional location thin-walled workpiece welding clamp

A welding fixture and two-way positioning technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of support ring size and angle out of tolerance, low support ring manufacturing pass rate, large welding deformation, etc. Achieve the effect of eliminating positioning gap, reducing tooling replacement time, and solving large welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

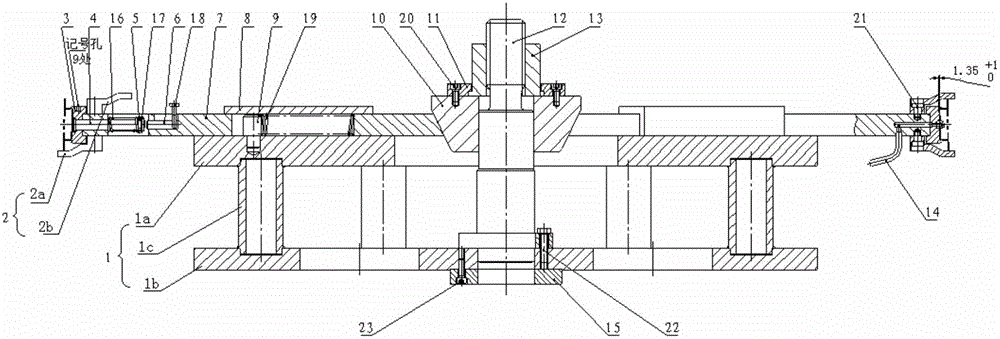

[0021] Such as Figure 1-4 As shown, a two-way positioning thin-walled welding fixture includes: a body 1, a splint 2, a reversible positioning block 3, a small shaft 4, a gasket 5, a push pin 6, an expansion block 7, a guide plate 8, a stop pin 9, Cone 10, cover plate 11, mandrel 12, nut 13, vent pipe 14, positioning plug 15, spring I16, cotter pin 17, bolt I18, spring II19, screw I20, screw II21, bolt II22, screw III23;

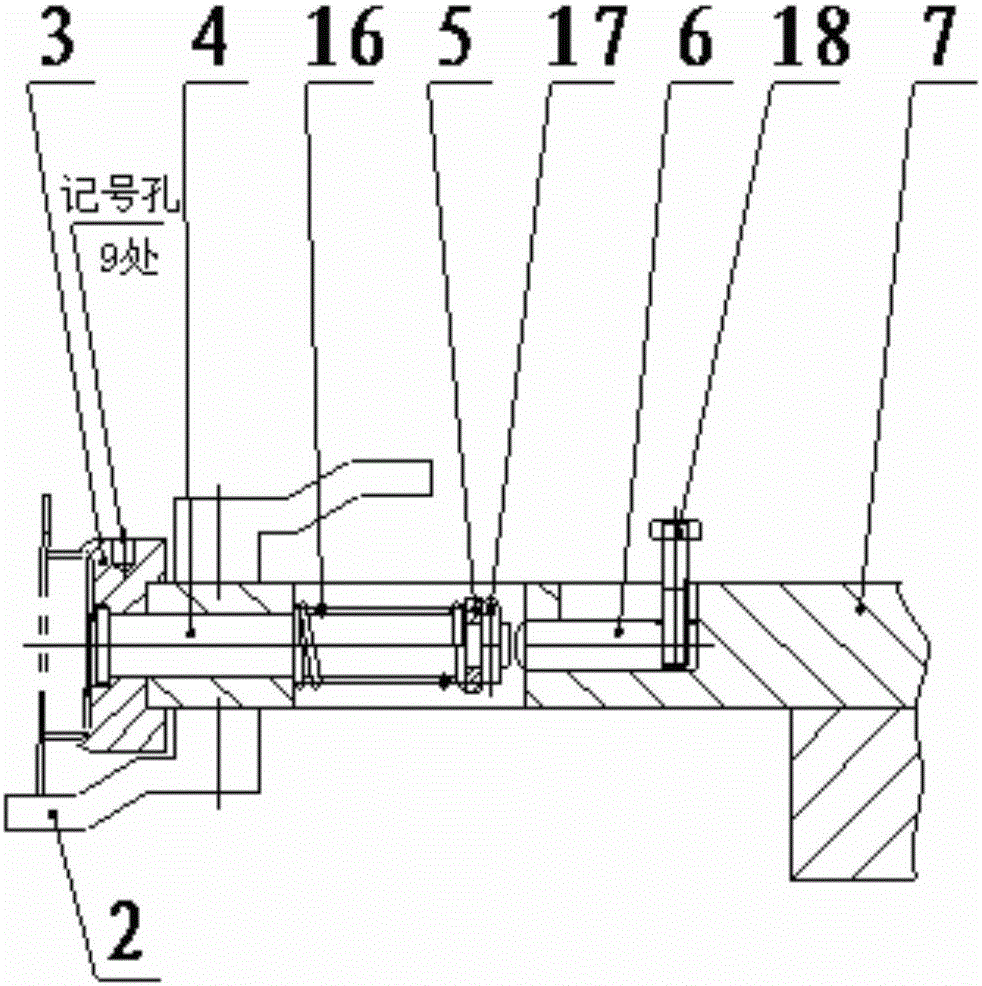

[0022] One, reversible positioning block 3 (see image 3 )

[0023] The reversible positioning block 3 is a fan-shaped block, which is divided into 9 pieces that are evenly distributed on the circumference, and the radial size is the same as that of the swelling block 7 ( figure 1 middle), the inner groove R570H7 cooperates with the expansion block 7R570f7, and the two sides are closely attached, so as to ensure the accurate pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com