Anti-cracking drain channel structure and mounting method

A flow trough structure and technology of the flow trough, which are applied in the directions of the superstructure, the sub-assembly of the upper structure, the vehicle parts, etc., can solve the problems such as the difficulty of punching the lap joints at both ends of the flow trough, the poor universality of the flow trough, and the increase of the body weight, etc. Achieve the effect of avoiding the difficulty of stamping of abrasive tools, simple and practical structure, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the drawings.

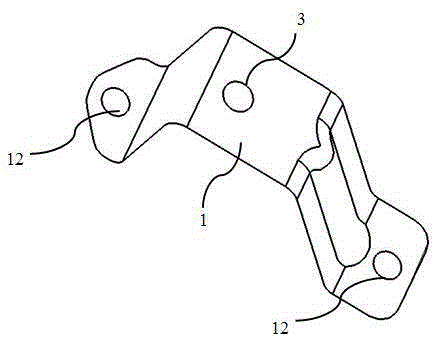

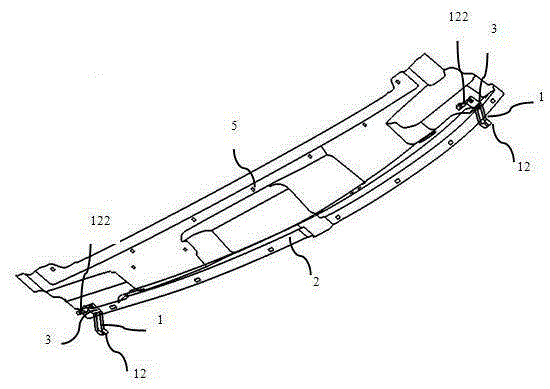

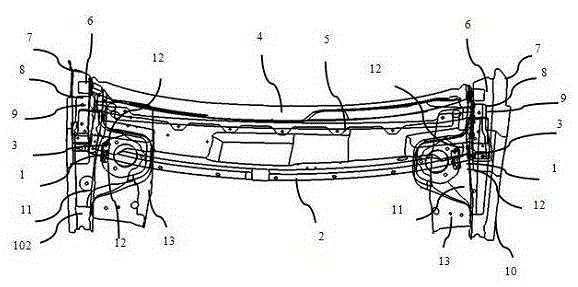

[0029] figure 1 , figure 2 , image 3 It is a partial schematic diagram of the structure of the "Ji"-shaped bracket and the water tank using the "Ji"-shaped bracket. The "Ji"-shaped bracket is fixed on the front shock absorber base connecting plate 11 through two plug welding holes 12 at the front and rear for installation. And easy to disassemble, the car runner body 2 and the "ji"-shaped bracket 1 are connected and fixed by bolts through the mounting screw holes 3. The two ends of the runner body 2 are not overlapped with the hinge mounting plate 7, which avoids stamping difficulties or stamping deformation. At the same time, the weight of the vehicle body can be reduced, and the "several"-shaped bracket 1 has a simple and practical structure, is easy to manufacture and realizes, is reliable in connection and has strong versatility, can be applied to improve the performance of pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com