Spiral gear tooth form turning method

A technology of helical gears and tooth shapes, applied in the direction of gear teeth, components with teeth, belts/chains/gears, etc., can solve the problems of long cycle, long production preparation cycle, and less preparation content for milling teeth, and achieve the development cycle Short, tooling cost reduction, reliable processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Describe the present invention below in conjunction with specific embodiment:

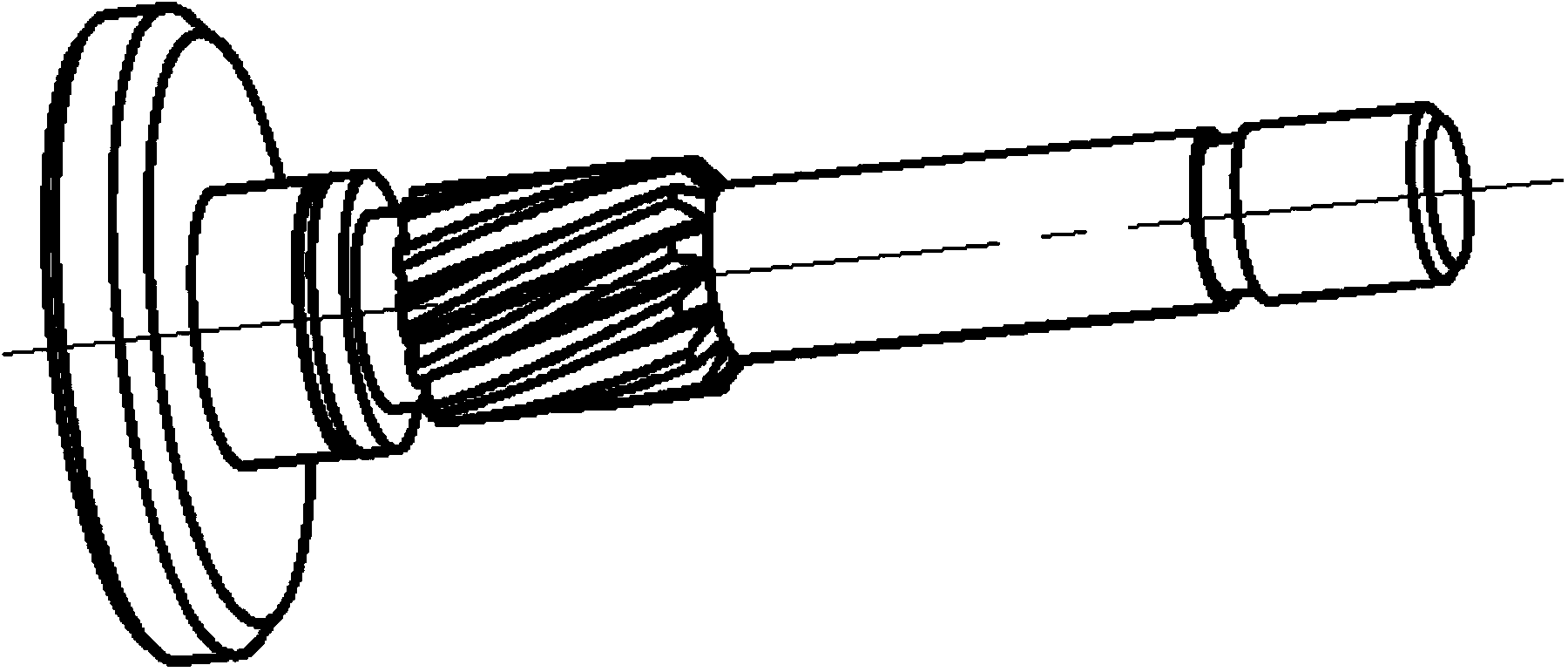

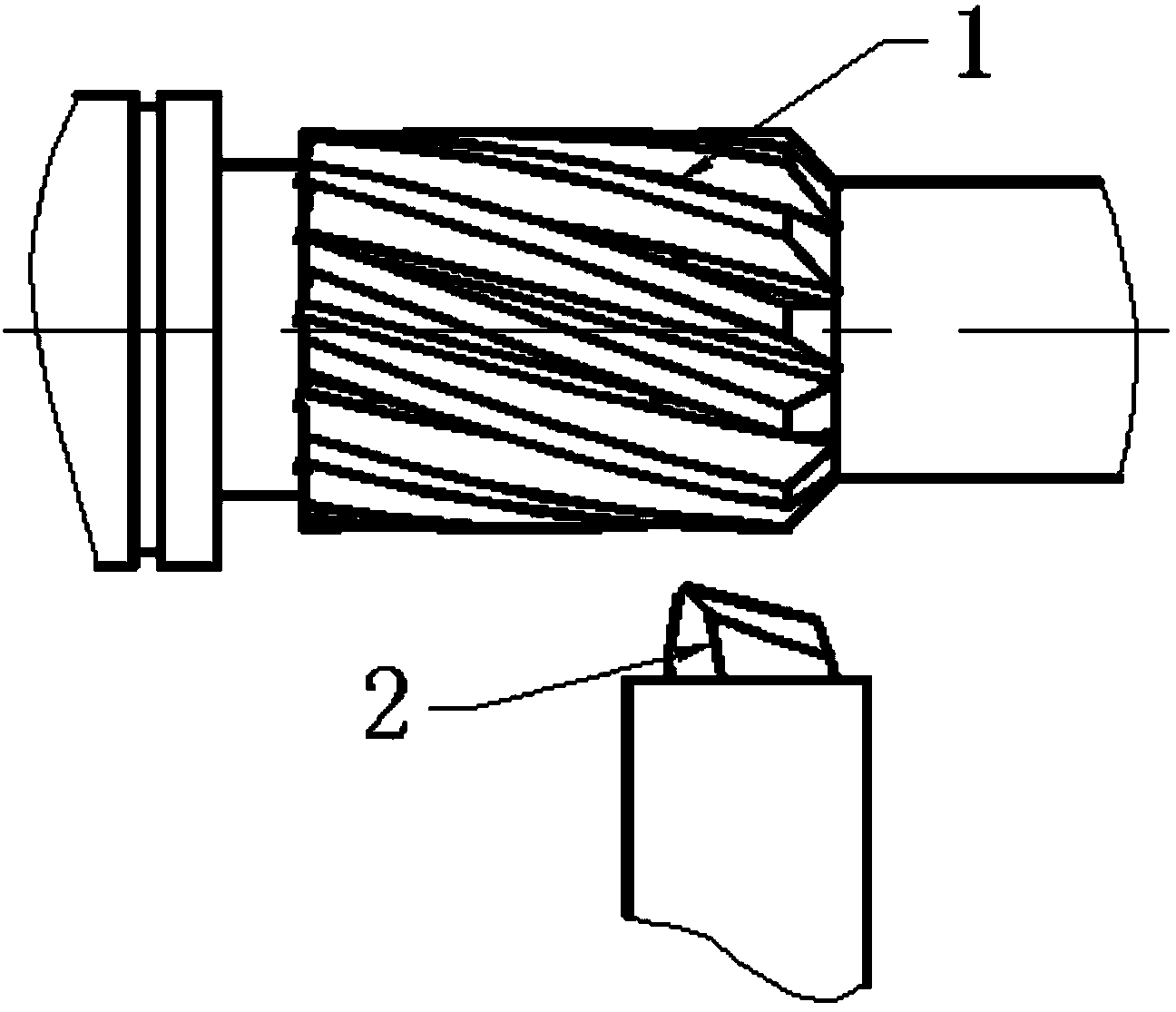

[0024] Such as figure 1 As shown, there is a helical gear in the middle section of the workpiece to be processed in this embodiment, which is right-handed, the number of teeth Z=12, the tooth profile angle is 40°, the pressure angle is 20°, the pitch circle diameter is Φ15, the tooth height coefficient ha=1, and the helical gear The rising angle is 18°, the normal modulus Mn=1.25, and the precision grade is 8-GB / T10095.1-2001.

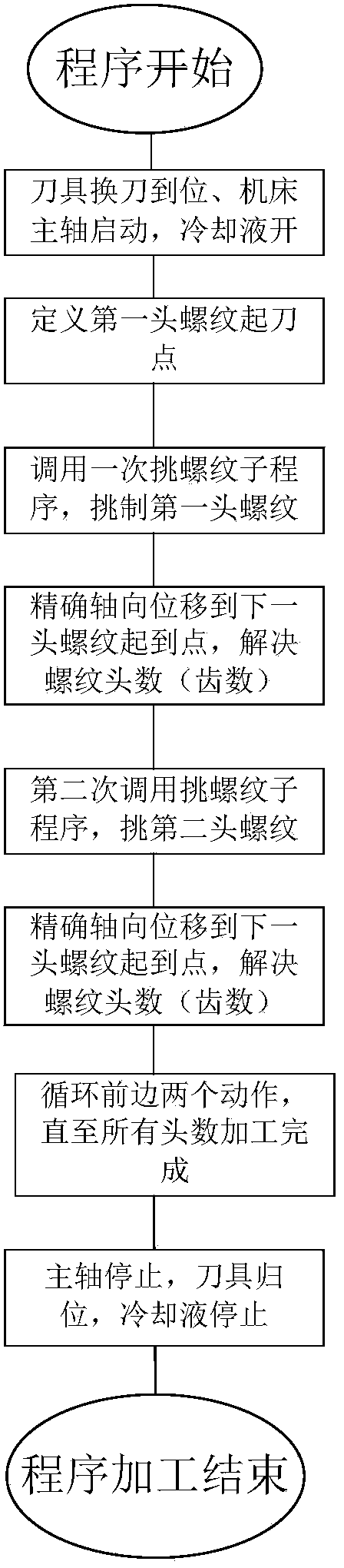

[0025] The steps of implementing the helical gear tooth profile turning method are:

[0026] Step 1: Design and prepare the knife.

[0027] Considering the large amount of material to be removed, the large impact force during cutting, and the large thread lead, the cutters are divided into two sets, which are used for rough turning and finishing turning of the helical gear tooth profile respectively. For the tool, it is required that the shape of the tool tip of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com