Low-viscosity high-toughness biodegradable pc/pla alloy and preparation method thereof

A biodegradable, high-toughness technology, applied in the field of polymer materials, can solve the problems of high brittleness, low toughness, and no environmental protection effect, and achieve the effect of not easy to deform, easy to process, and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

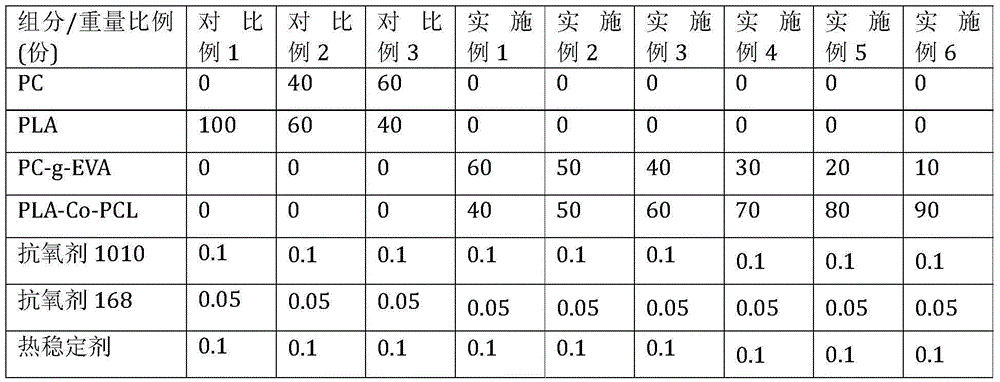

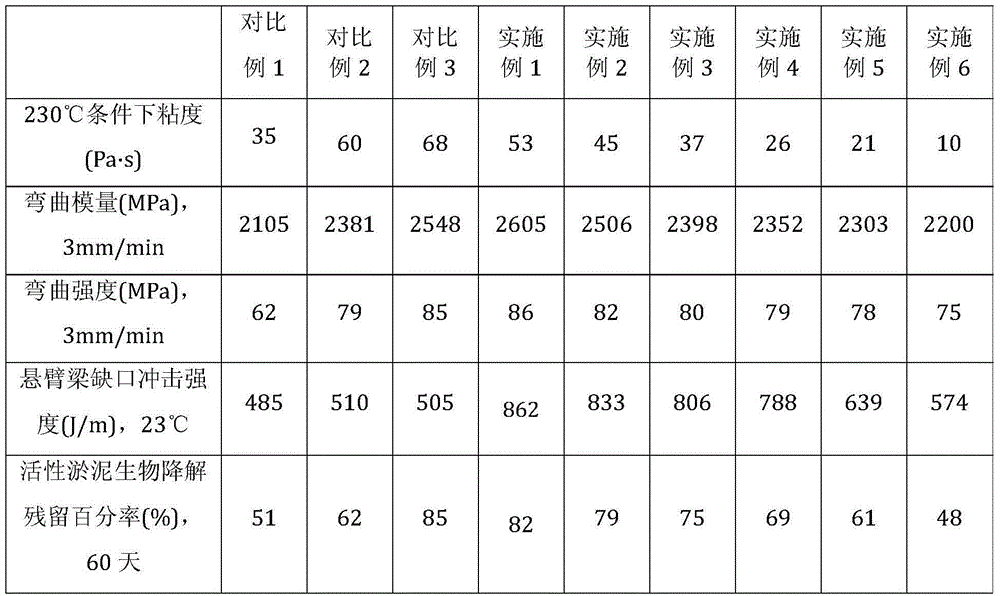

[0031] The components involved in this series of embodiments are specifically as follows:

[0032] The weight ratio of PC and EVA in the PC-g-EVA graft polymer is 80:20.

[0033] The weight ratio of PLA and PCL in the PLA-Co-PCL graft polymer is 90:10.

[0034]

[0035] In the above example series: PC, EVA, DBTO, additives high-speed blending: 100-200r / min blending 5min; melt blending reaction extrusion to prepare PC-g-EVA extrusion temperature is 200-260 ° C, screw speed It is 200‐300r / min.

[0036] The above extrusion process adopts nine-stage extrusion at different temperatures, and the specific temperature settings are as follows:

[0037] Extrude each temperature range

section

second stage

Three sections

Four paragraphs

Five sections

Six paragraphs

Seven paragraphs

eight paragraphs

Kuduan

temperature / ℃

200

220

230

240

245

250

255

260

255

[0038] In the above series of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com