A steering support pipe beam structure

A technology of pipe beams and support clips, which is applied to superstructures, subassemblies of superstructures, vehicle components, etc., can solve problems such as high restructuring costs, and achieve the effects of saving restructuring costs, reducing tooling costs, and high generalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

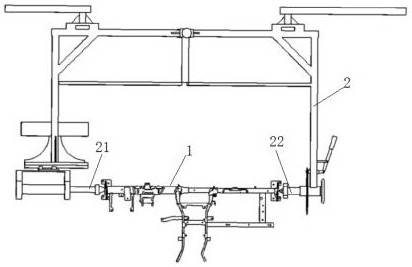

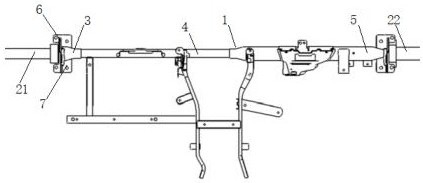

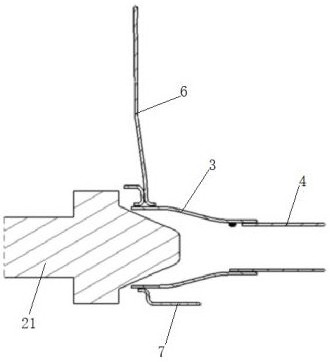

[0036] Example 1, please refer to Figure 6 , the present invention discloses a steering support pipe beam structure, which includes an instrument panel mounting bracket 6, a vehicle body mounting bracket 7, a left rudder steering support left cross tube 8 and a left rudder steering support right cross tube 9, the left rudder steering supports the left The inside of the cross pipe 8 is fixedly provided with a left rudder steering support right cross pipe 9, and one side of the left rudder steering support left cross pipe 8 and the left rudder steering support right cross pipe 9 are all fixedly provided with an instrument panel mounting bracket 6, so The other side of the left rudder steering support left cross pipe 8 and the left rudder steering support right cross pipe 9 are fixedly provided with a vehicle body mounting bracket 7, and the diameter specification of the right end of the left rudder steering support left cross pipe 8 is the same as that of the right rudder steeri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com