Blanking tool of fluorine coated rubber ring workblank

A technology of fluorine-coated rubber rings and blanks, which is applied in the field of blanking tools for fluorine-coated rubber rings, can solve the problems of large number of tooling, high cost of blanking, and large number of punching dies, so as to reduce the cost of blanking and save tooling The effect of fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

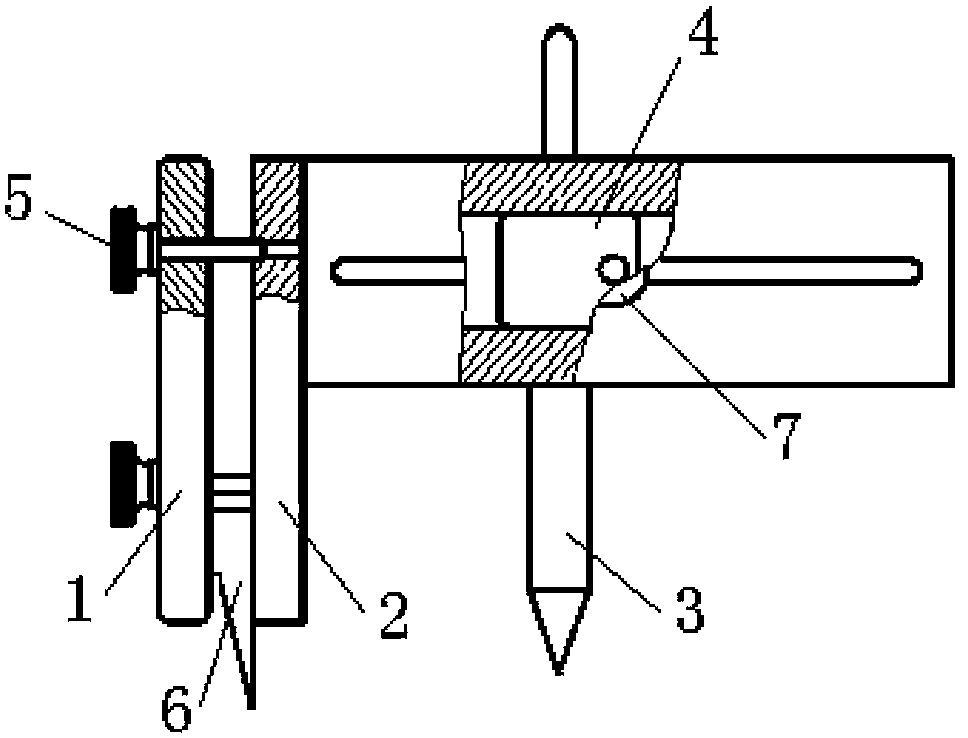

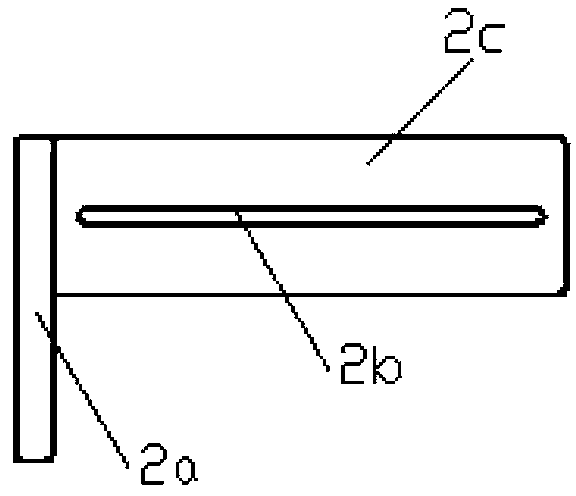

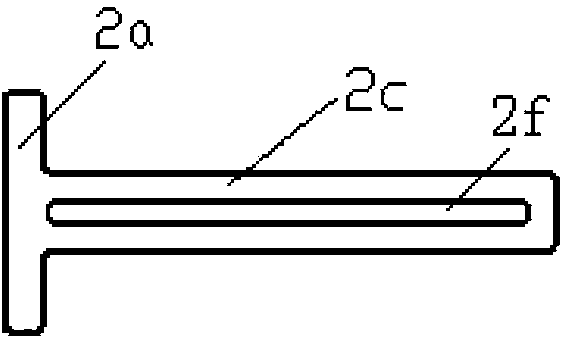

[0011] The present invention will be described in further detail below. see Figure 1 to Figure 5 , a fluorine-coated rubber ring blank blanking tool is characterized in that it consists of a pressing plate 1, a tool holder 2, a mandrel 3, a slider 4, 3 pressing plate screws 5, a blade 6 and a slider locking screw 7; the tool holder 2. It consists of a rectangular blade mounting plate 2a connected to a rectangular slider mounting plate 2c. One short side of the slider mounting plate 2c is vertically connected to the upper part of the right side of the blade mounting plate 2a as a whole. The slider mounting plate 2c The plate surface is parallel to the long side of the blade mounting plate 2a. There are three threaded holes 2d in a triangular distribution on the plate surface of the blade mounting plate 2a. The horizontal relief groove 2b of the slider locking screw extending in the length direction of the board and penetrating the board surface, the distance between the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com