Supporting tool for spraying zinc to surface of fence small assembly of ship deck

A technology for ship decks and small groups, which is applied in the directions of fusion spraying, metal material coating process, coating, etc., can solve the problems of destroying the integrity of the galvanized surface layer, prolonging the production cycle, and investing large auxiliary costs, achieving universal Good performance, reduce usage, reduce the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

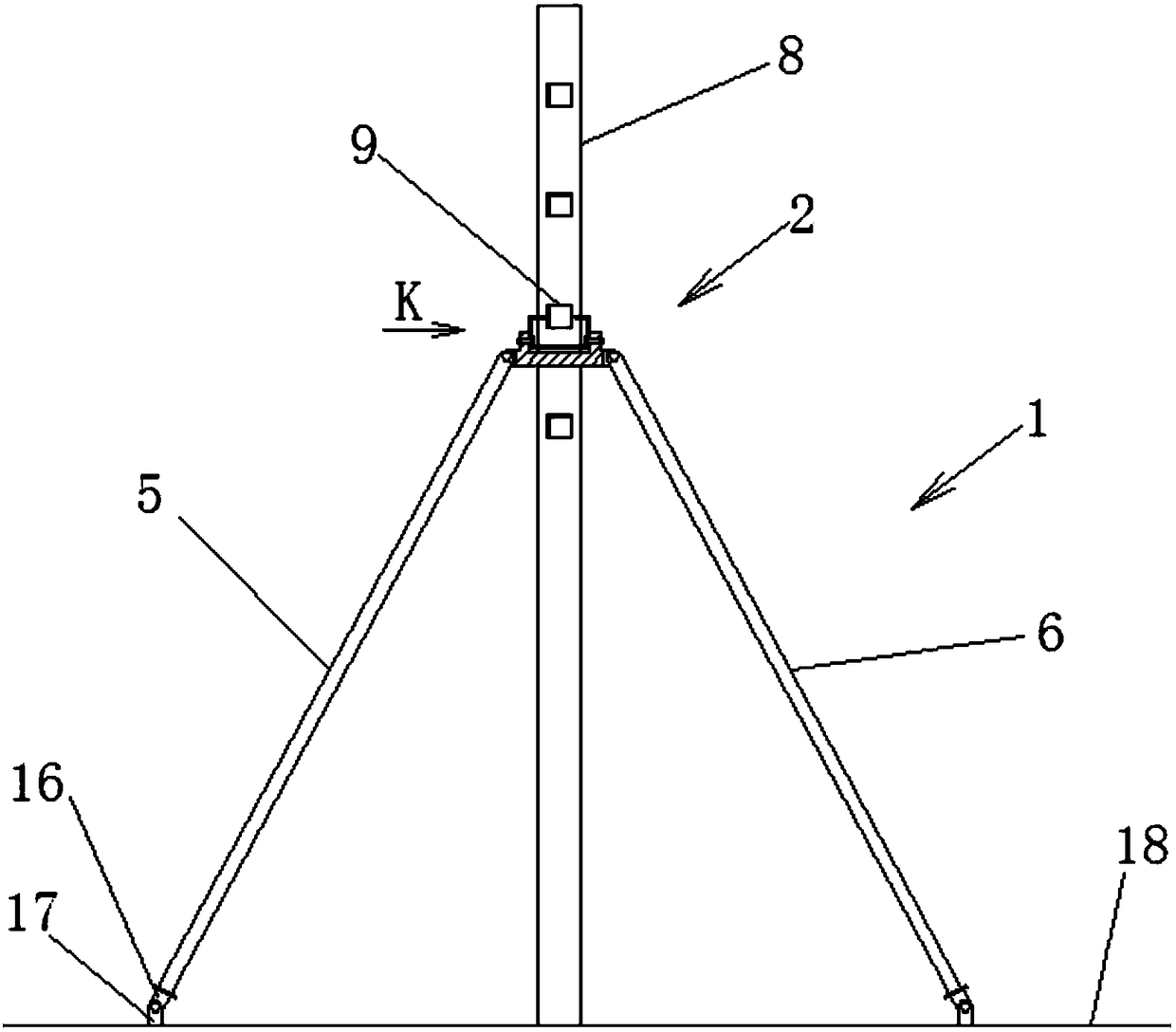

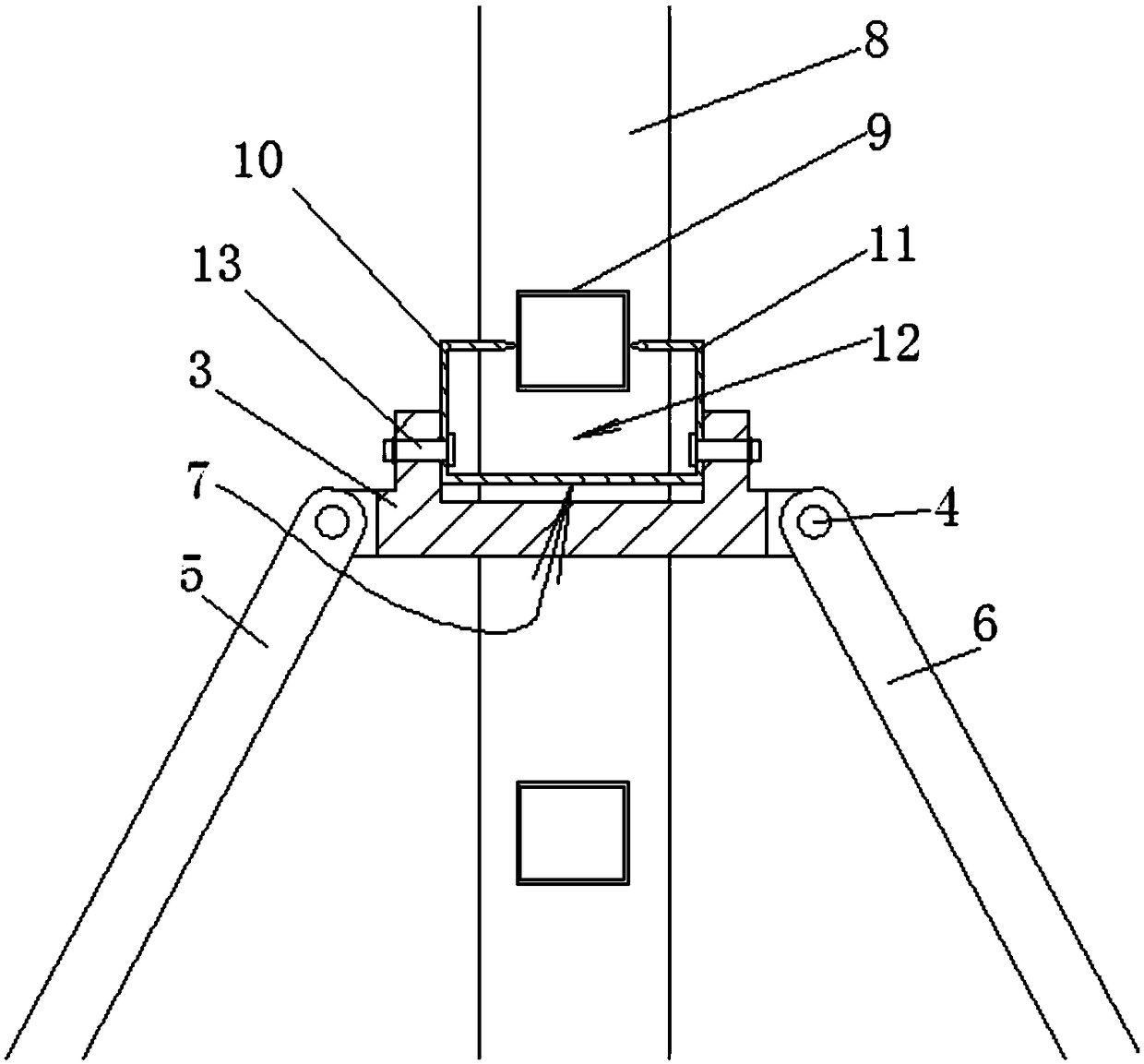

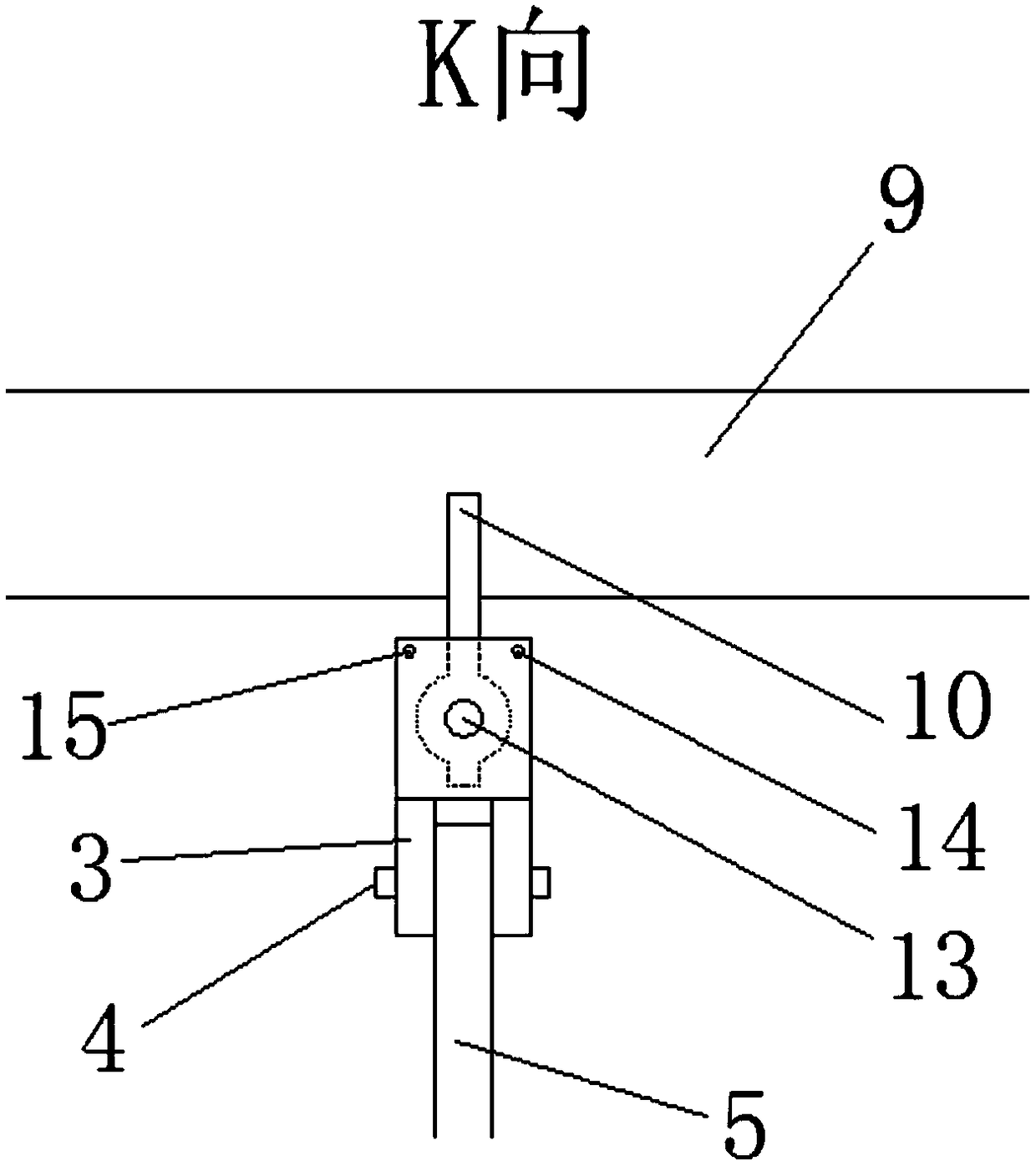

[0035] Such as Figures 1 to 4 Shown is an embodiment of a support tooling for spraying zinc on the surface of a ship deck fence group stand according to the present invention. Positioner 2, the support frame 1 includes a seat block 3, the left and right sides of the seat block 3 are respectively connected with a left support rod 5 and a right support rod 6 through a hinge shaft 4, and the upper end of the seat block 3 is connected with The lateral limiter 2, the lateral limiter 2 includes a connecting arm 7 arranged horizontally, a railing 9 arranged at both ends of the connecting arm 7 and extending upward for the fence group 8 There are left-curved paw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com