Flange sealing groove inner surface annular all-position TIG (Tungsten Inert Gas) automatic surface welding equipment and welding method thereof

A flange sealing and automatic surfacing technology, applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems of long production cycle and increase production cost, achieve excellent surfacing welding quality, save costs, and avoid processing The effect of knife

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

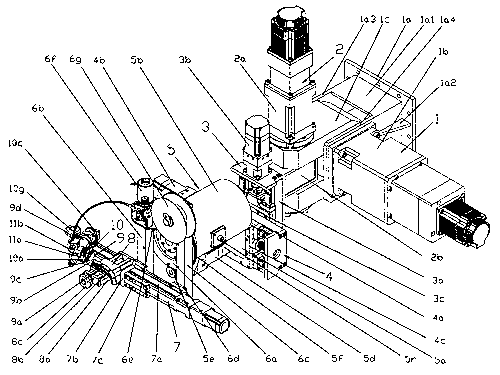

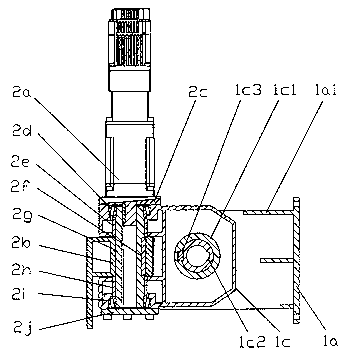

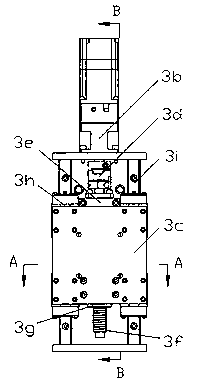

[0036] figure 1 It shows a structural diagram of a circumferential all-position TIG automatic surfacing equipment for the inner surface of a flange sealing groove. exist figure 1 , 2 Among them, the tilting mechanism 1 is composed of a connecting seat 1a, a tilting motor reducer 1b, and a tilting rotating body 1c. The connecting seat 1a includes a connection and fixing surface, and on the left and right sides of the connecting surface, there are respectively a left bearing side plate 1a3 and a bearing seat. The right support side plate 1a4 of the bearing block has a left inclined bearing chamber 1a5 on the left support side plate. There is a right inclined bearing chamber 1a6 on the right support side plate, a rib plate 1a1 is arranged in the middle of the left and right support side plates, and a reinforcement plate 1a2 is arranged on the outside. The tilt motor reducer 1b is installed on the right side of the right tilt bearing chamber 1a6. The output shaft of the reducer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com