Pouring gate structure for nut casting

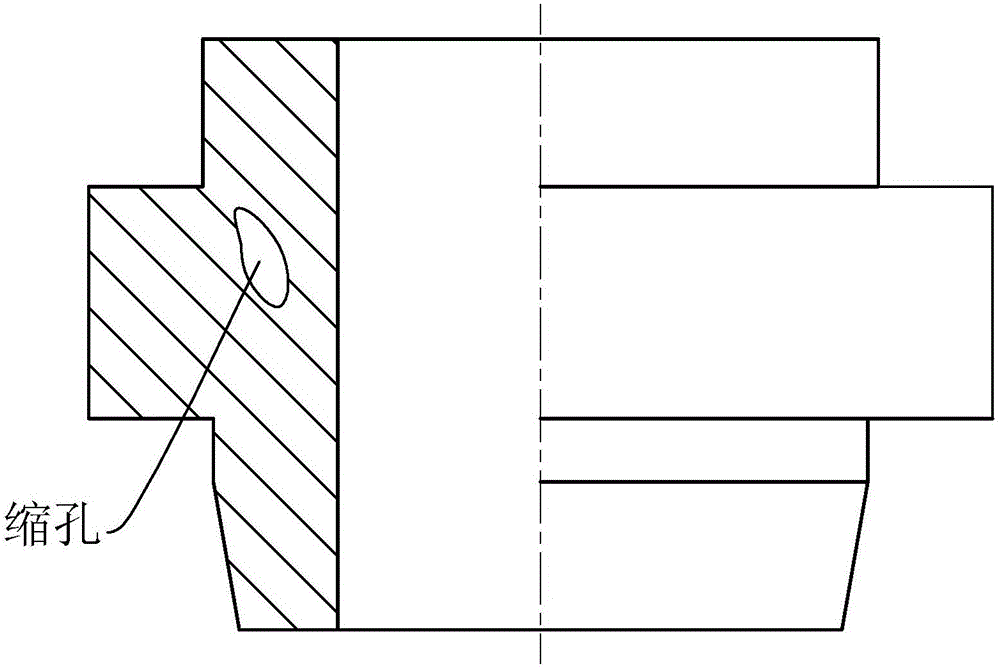

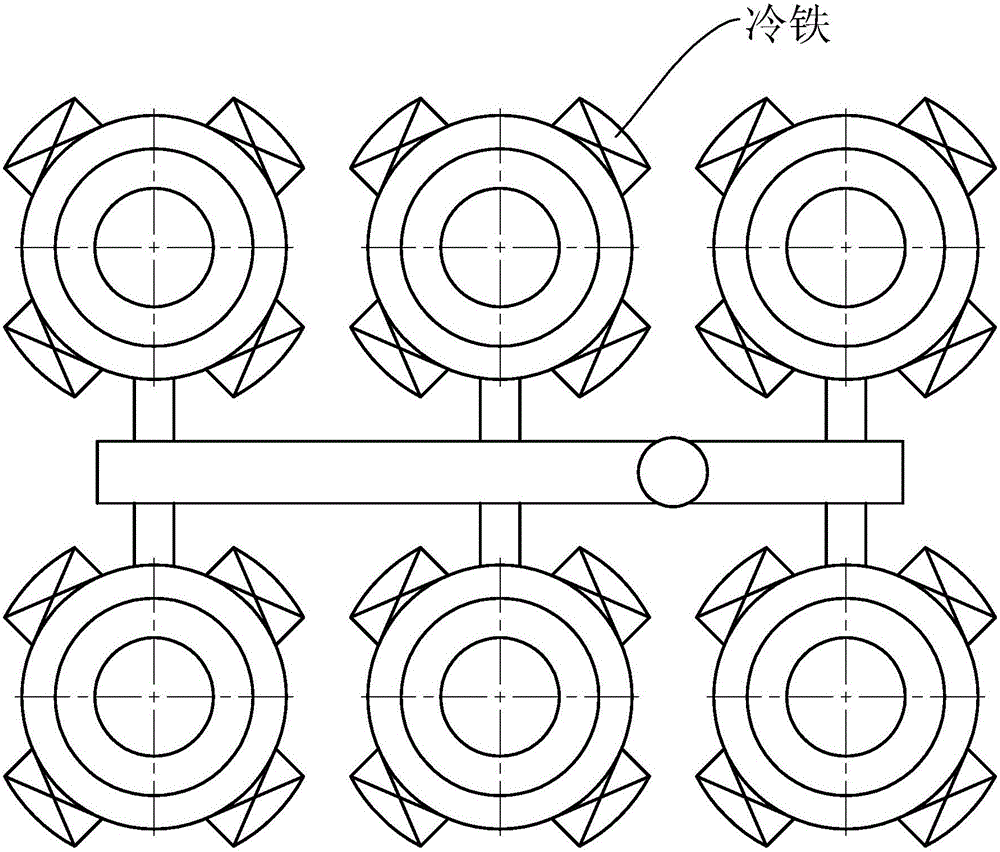

A runner and nut technology, applied in the field of nut casting, can solve problems such as failure to meet process requirements, slow cooling speed, and pore structure defects, and achieve the effects of eliminating pore defects, delaying cooling speed, and saving tooling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

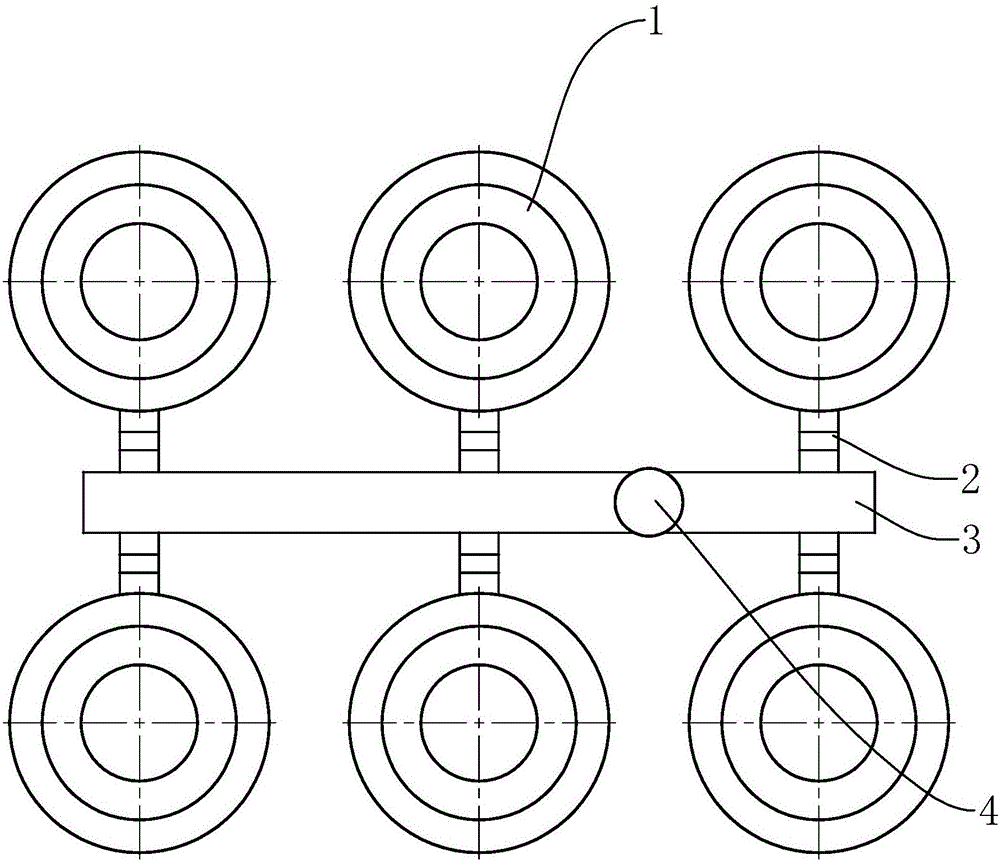

[0020] refer to Figure 3 to Figure 5 , Figure 3 to Figure 5 It is a structural schematic diagram of a specific embodiment of the present invention. As shown in the figure, a runner structure applied to nut casting includes a cavity 1, an inner runner 2, a runner 3, and a sprue 4. During casting, The molten metal enters from the sprue 4, distributes and flows into the runner 3, and then injects the cavity 1 through the inrunner 2. The connection between the cavity 1 and the inrunner 2 is an ingate, and the runner 3. The junction with the ingate 2 is a cross gate, and the cross-sectional area of the cross gate is larger than that of the ingate.

[0021] Preferably, the ingate 2 includes a pouring section 21 connected to the cavity 1 and a liquid inlet section 22 connected to the runner 3, the cross-sectional area of the pouring section 21 is larger than that of the liquid inlet section 22, The volume of molten metal that can be accommodated by the pouring section 21 is g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com