Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2002results about How to "Reduce splash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pulse welder and method of using same

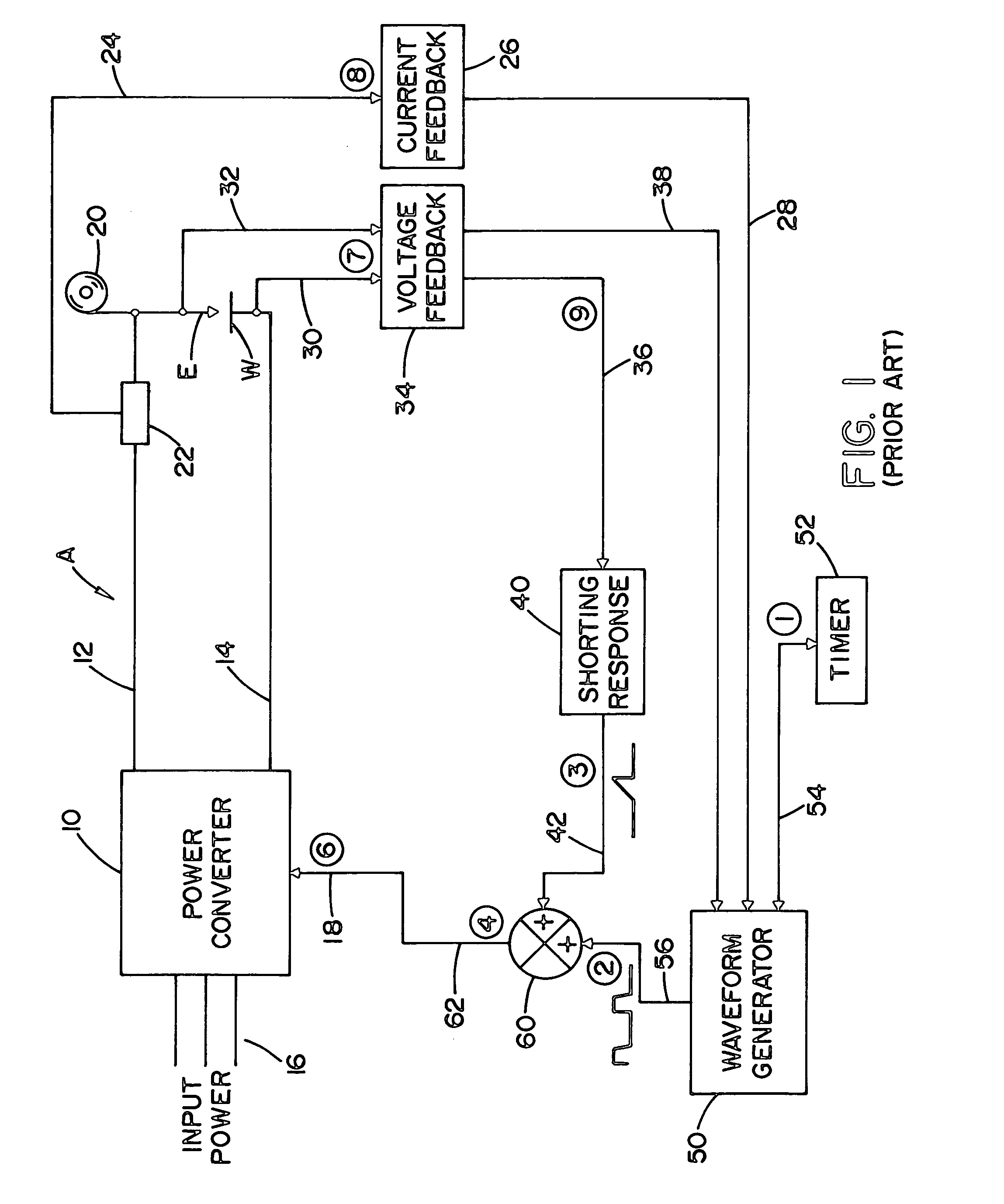

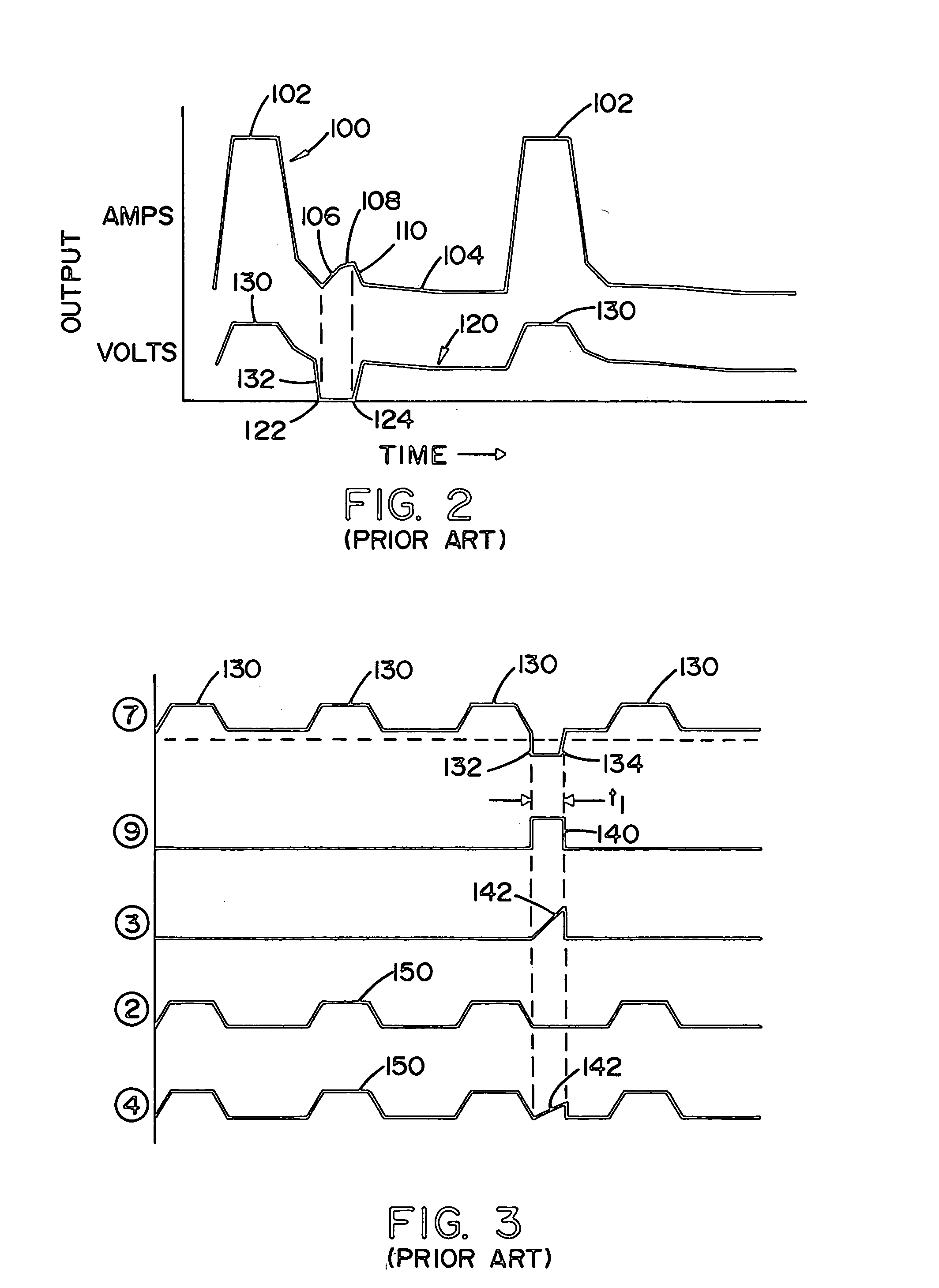

ActiveUS7304269B2Reduce arc forcePromote shorting eventsCoin-freed apparatus detailsArc welding apparatusPower flowEngineering

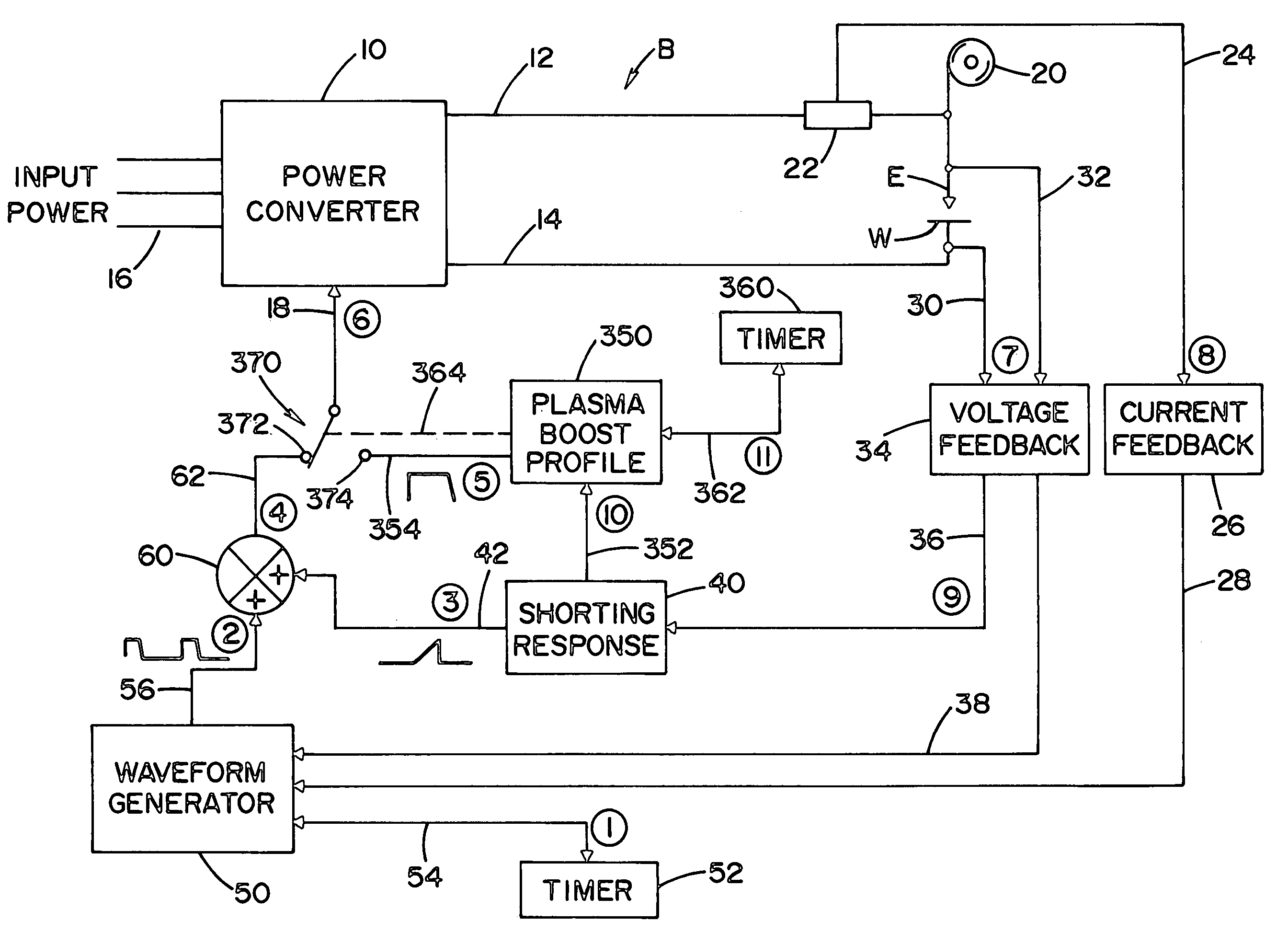

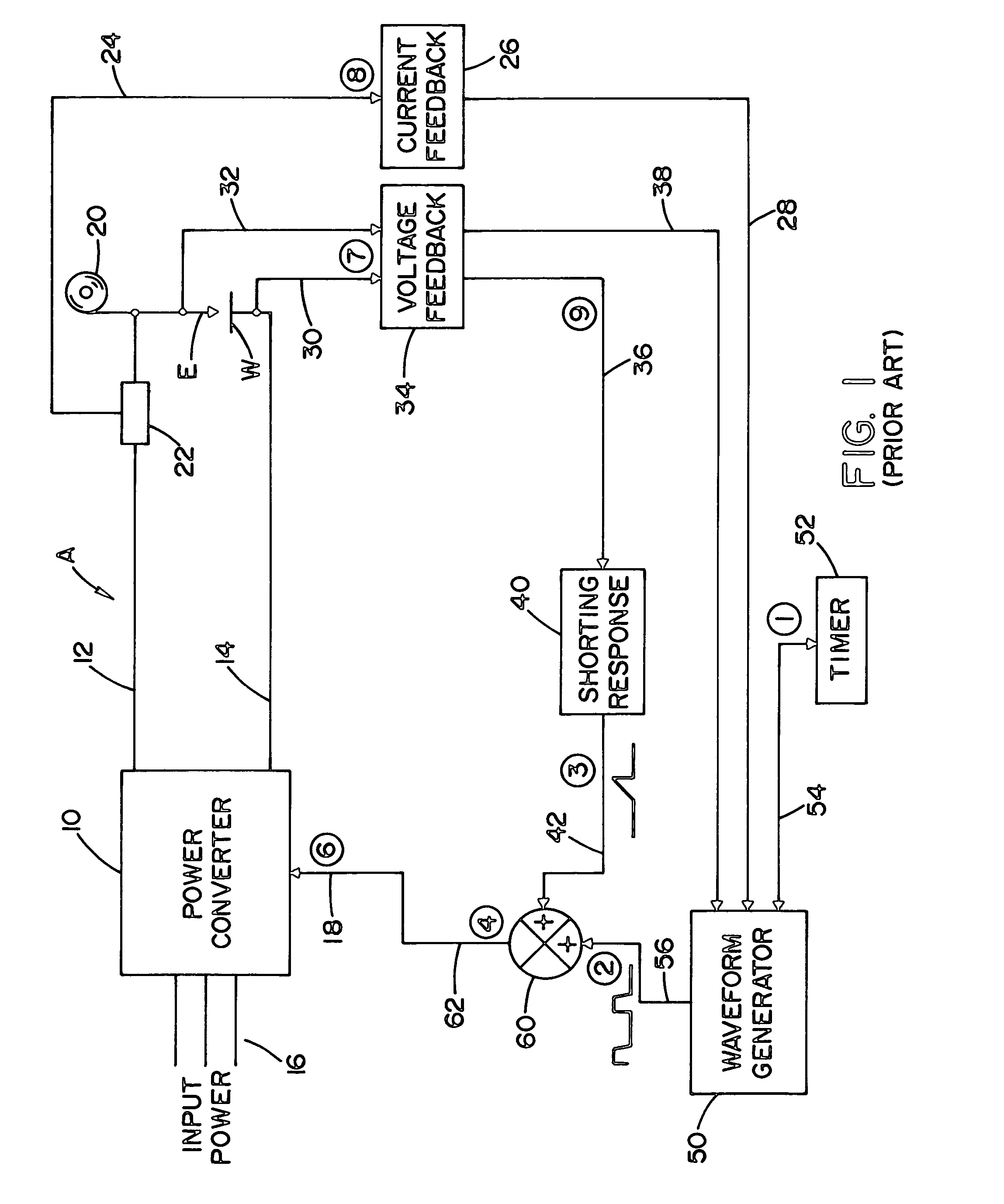

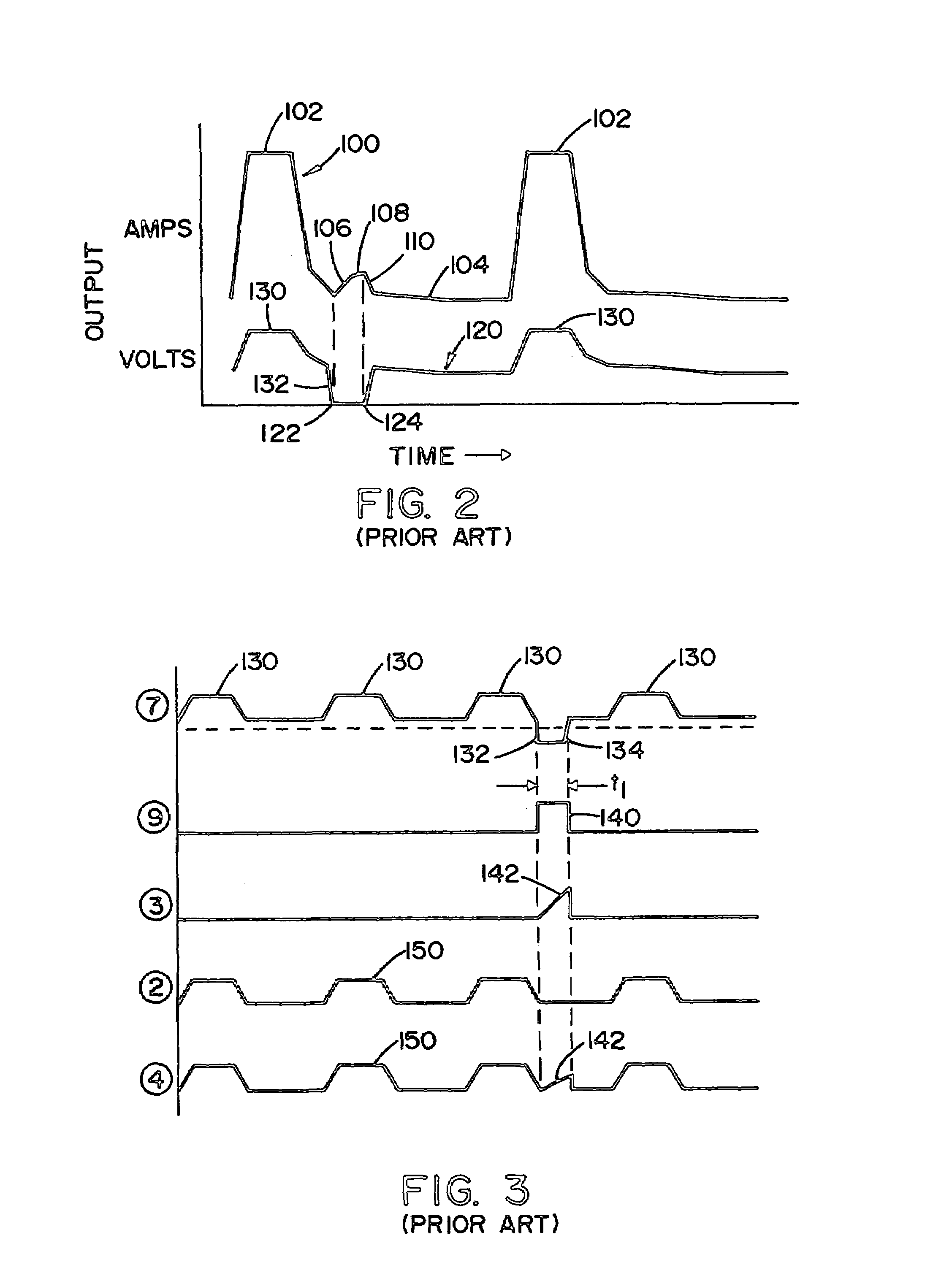

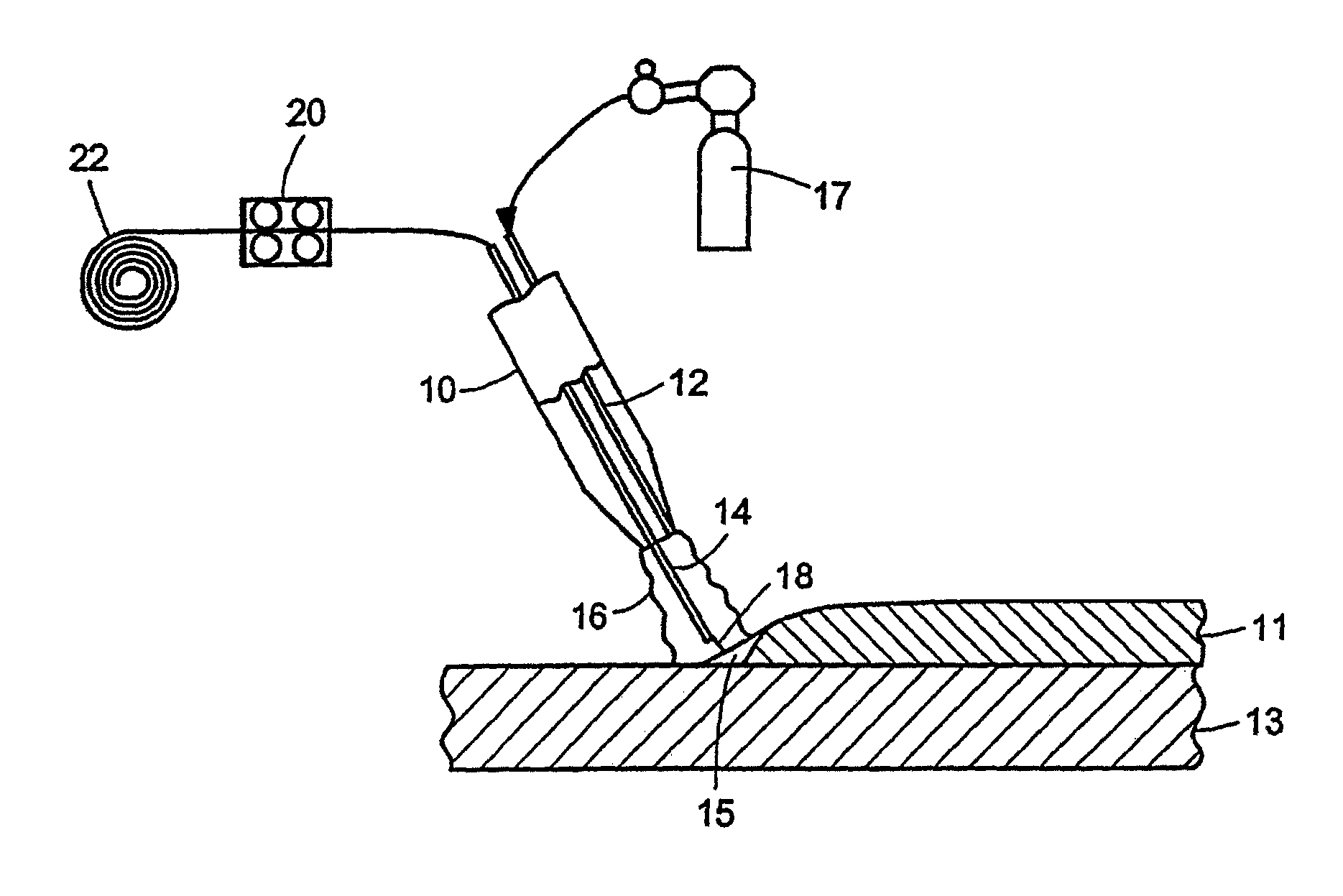

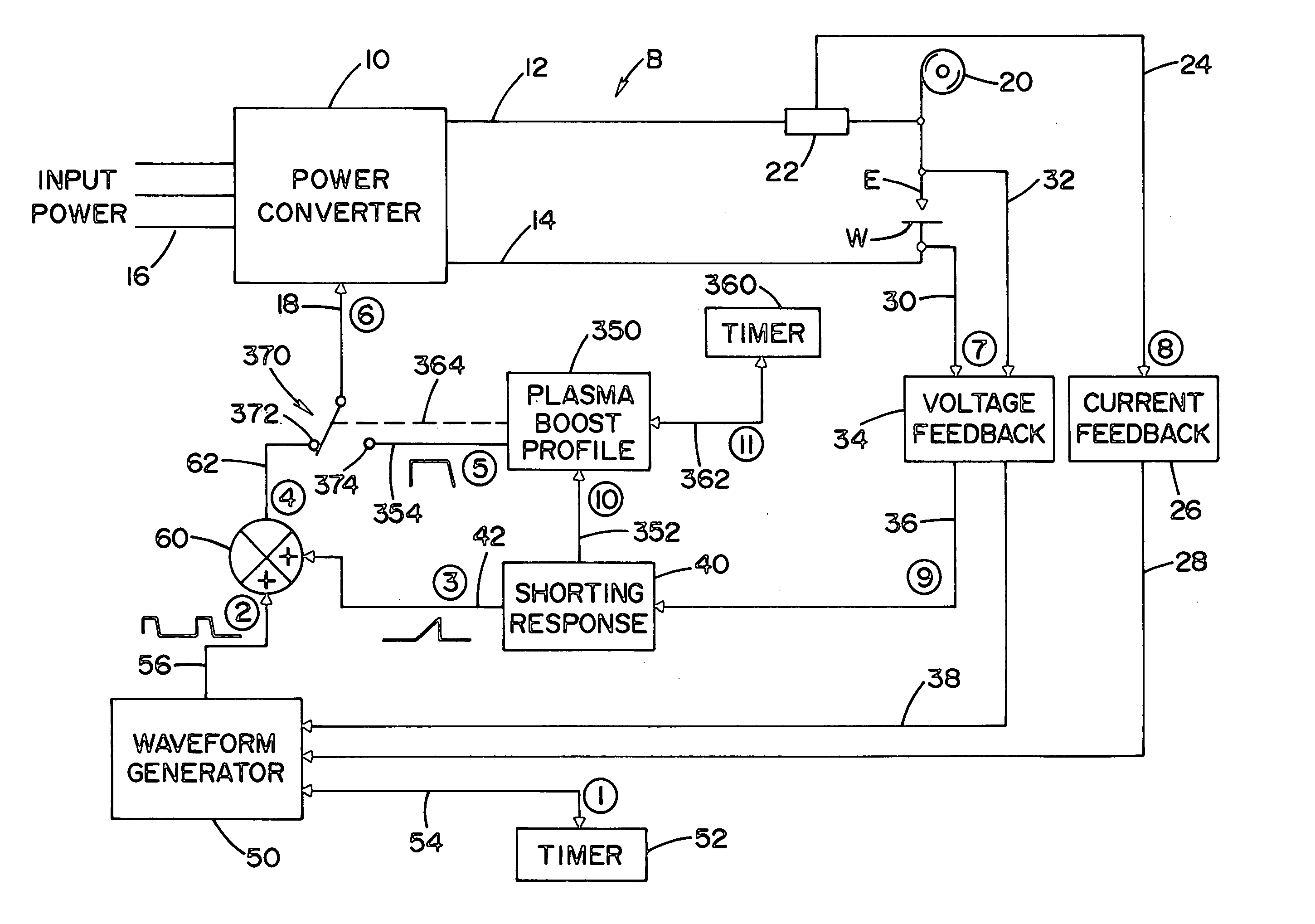

An electric arc welder for performing a pulse welding process by a current between an advancing electrode and workpiece where the welder comprises a short detecting circuit for creating a short signal upon occurrence of a short circuit between the advancing electrode and the workpiece and a boost circuit to create a plasma boost pulse after the short circuit is cleared during the time period when the welder is not outputting the peak pulse current.

Owner:LINCOLN GLOBAL INC

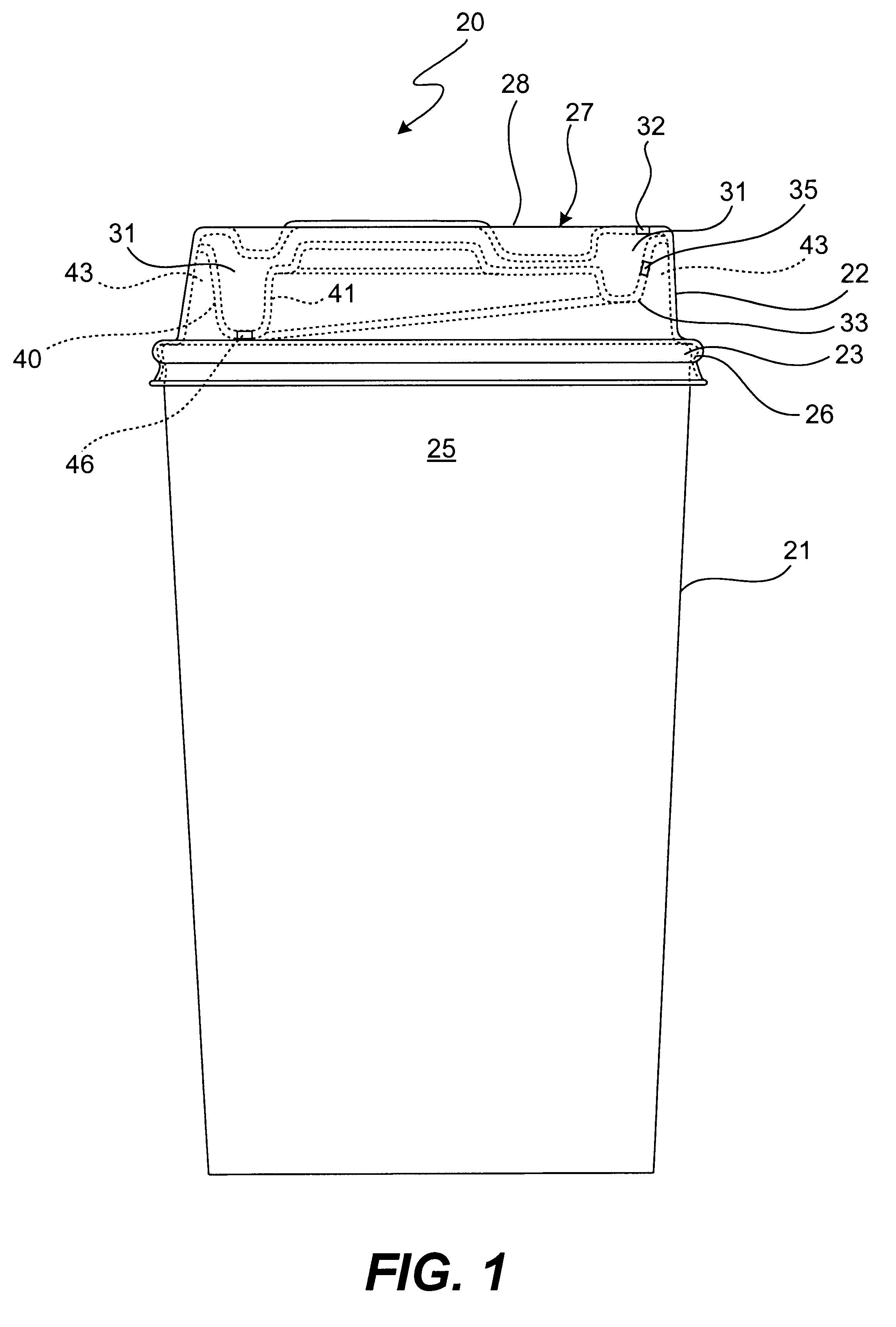

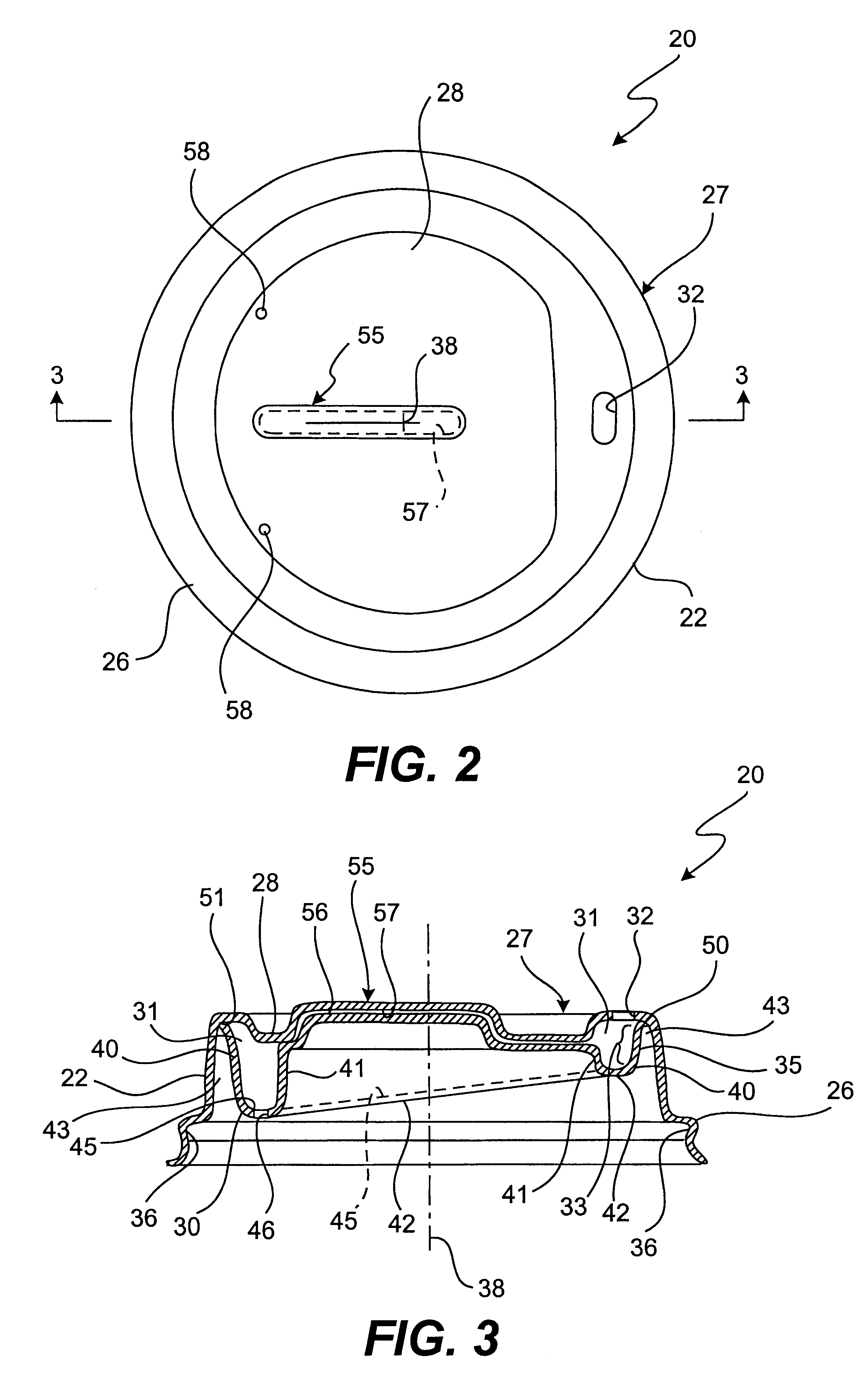

Lid device with splashless baffle

Owner:CHU DONNY

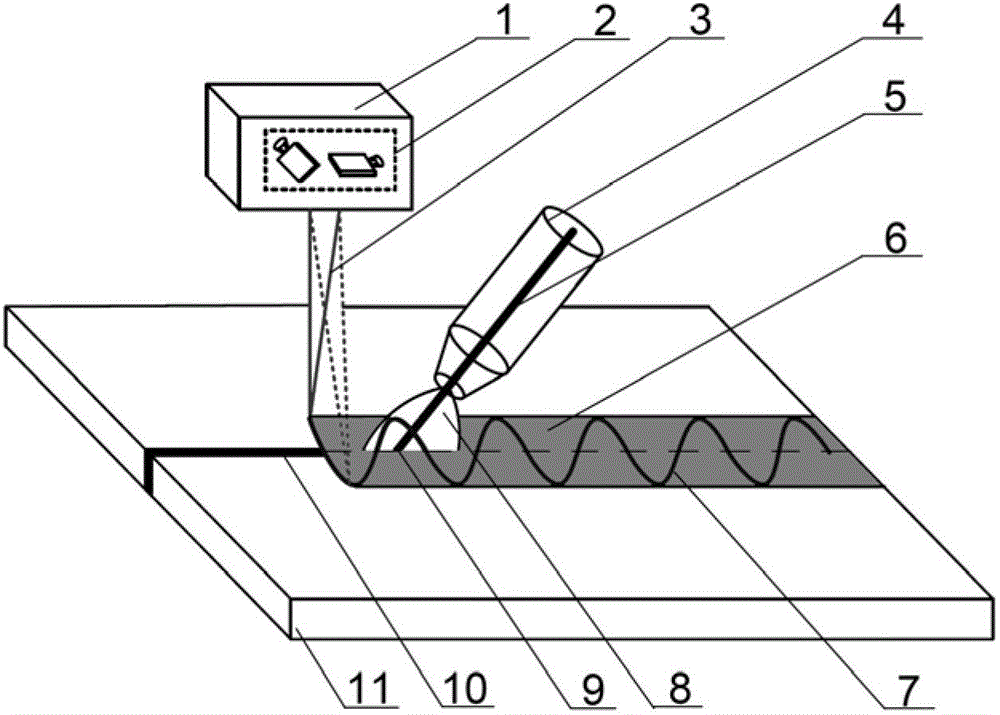

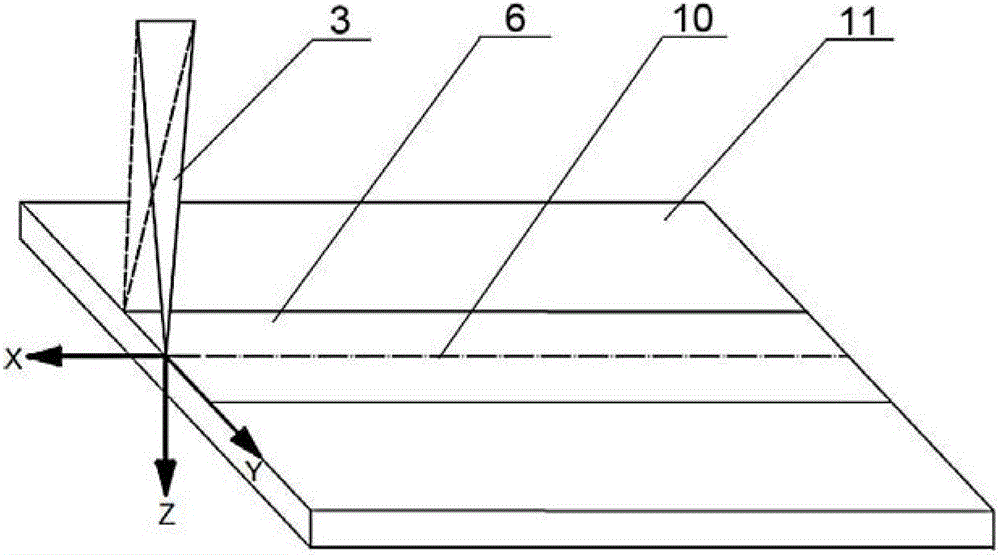

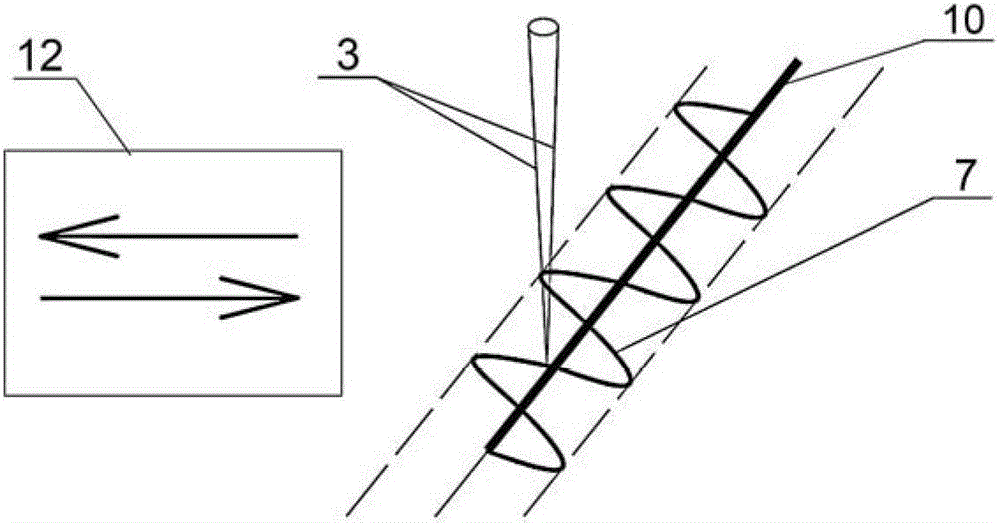

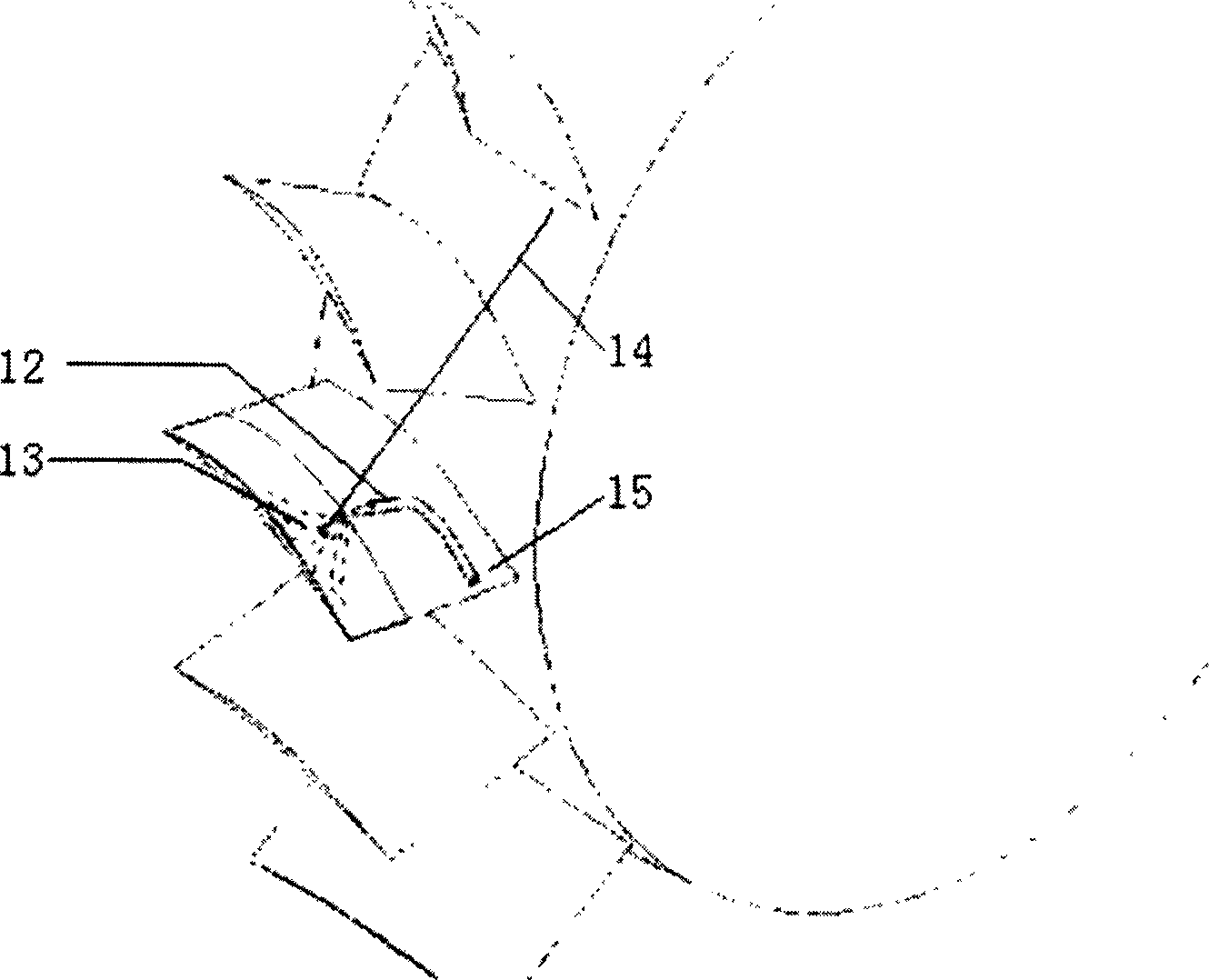

Oscillatory scanning laser beam-electric arc hybrid welding method and system

ActiveCN103056533AImprove featuresImprove welding qualityLaser beam welding apparatusPorosityLaser scanning

The invention discloses an oscillatory scanning laser beam-electric arc hybrid welding method and system. Laser beams and electric arc move together along an abutted seam in large range space, simultaneously the laser beams surround acting points of the electric arc to perform oscillatory scanning movement in a local small area, and an actual welding track is a curve formed by overlying two types of movements. As for an optimal range of laser beam oscillatory scanning displacement, the range in the direction of an X axis is minus 2mm to 3mm, the range in the direction of an Y axis is minus 5mm to 5mm, the range in the direction of a Z axis is minus 2mm to 2mm, and the oscillation frequency is in a range from 20Hz to 500Hz. According to the method and the system, an enhanced technical effect is achieved by the aid of interaction of a laser beam oscillatory scanning effect and a laser-electric arc synergistic effect, and the welding quality is improved. Compared with existing laser-electric arc hybrid welding and laser scanning welding methods and systems, the method and the system have the advantages that higher weld porosity inhibiting capability is achieved, and the weld strength is improved by 10% to 50%.

Owner:武汉飞能达激光技术有限公司

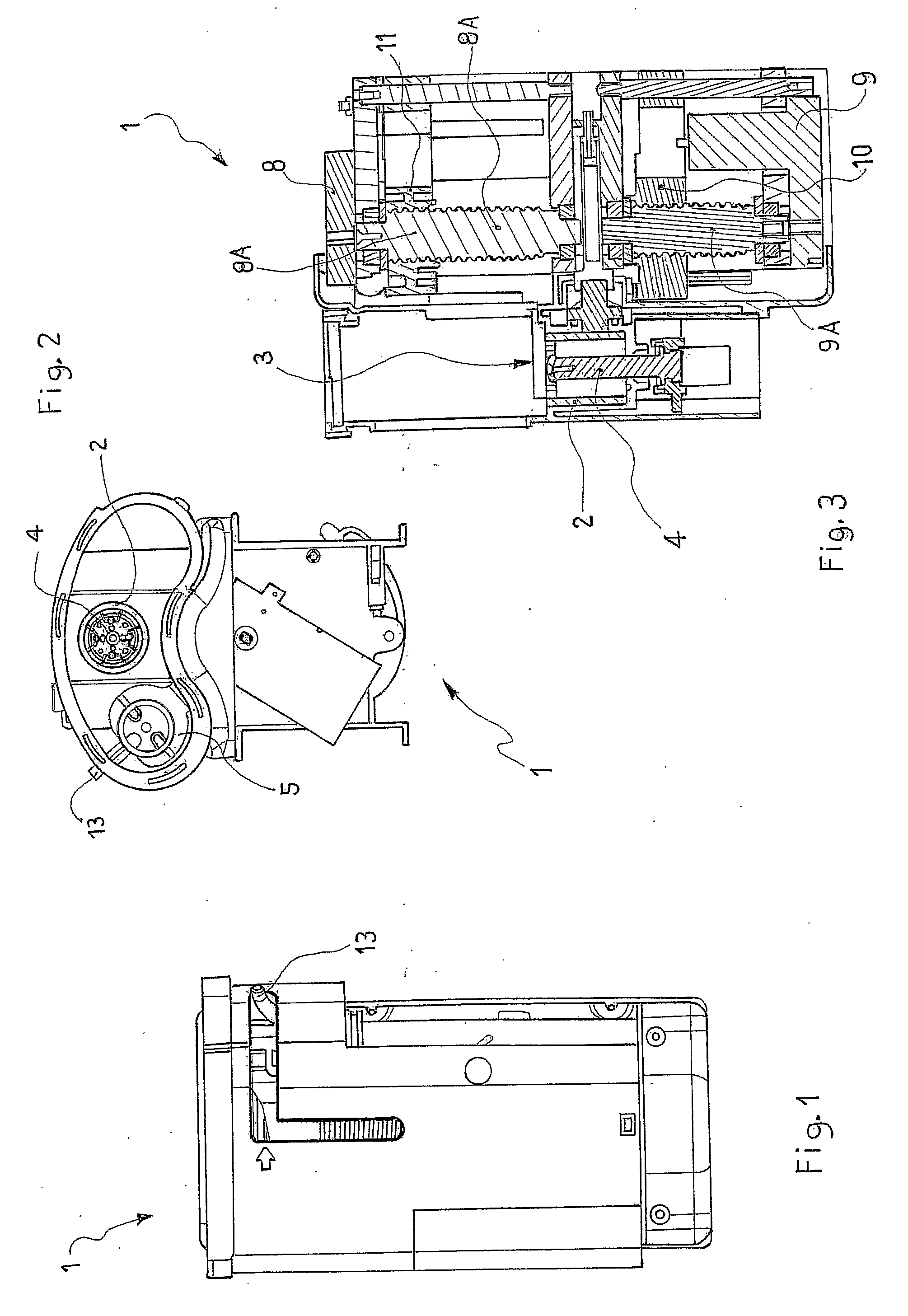

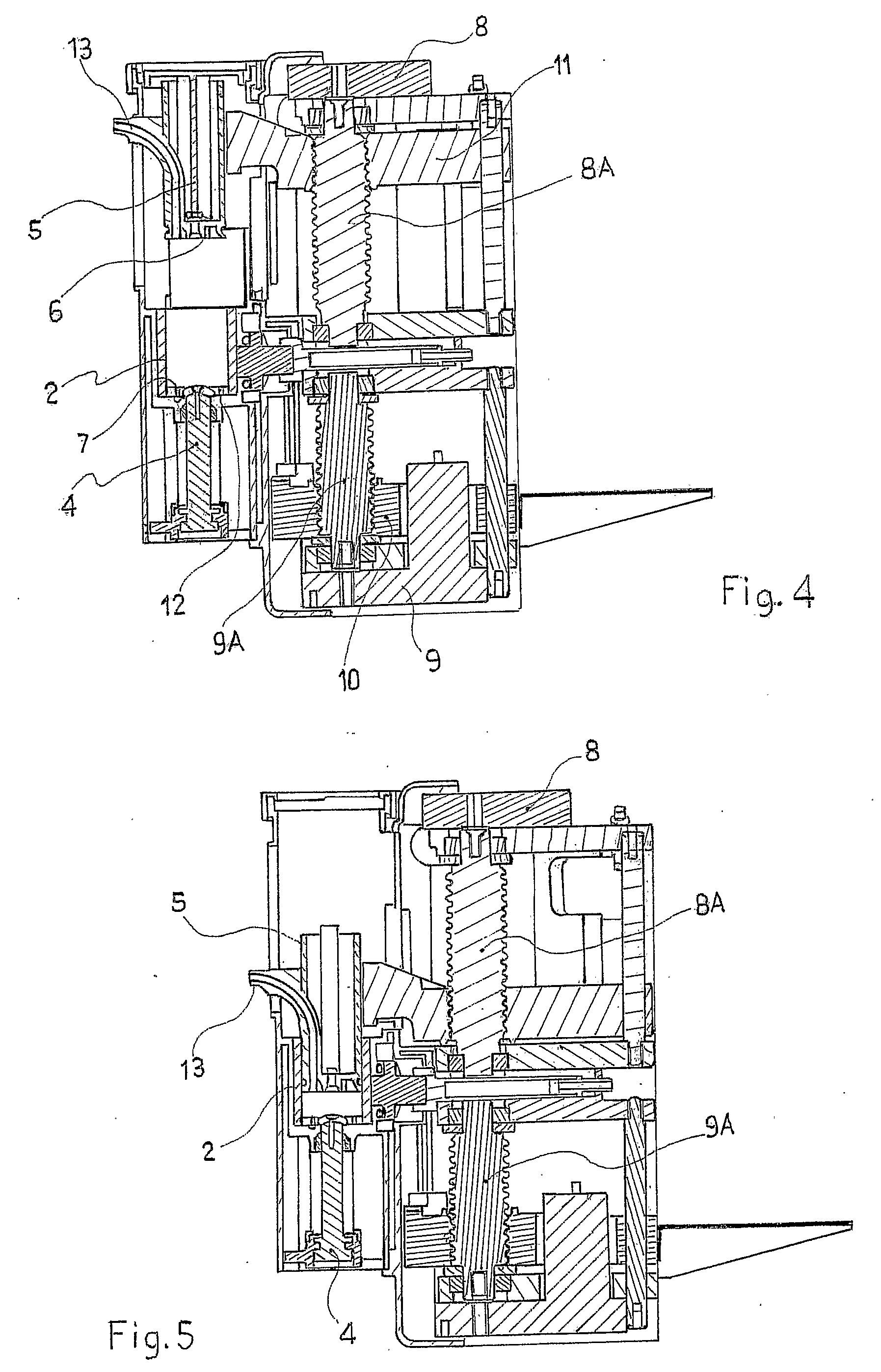

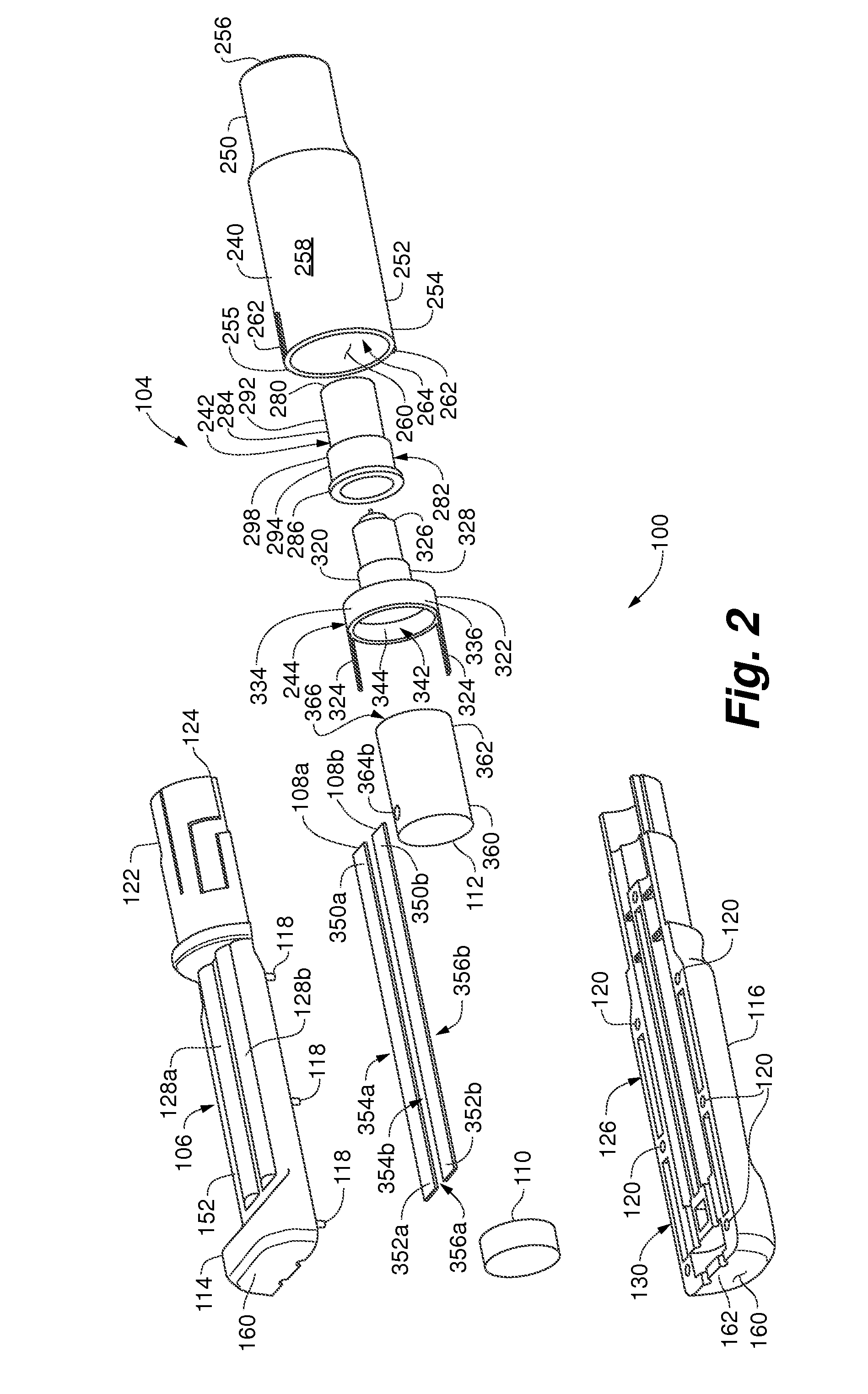

Process and Apparatus for Controlling the Preparation of Beverages

ActiveUS20080050480A1Improve coffee qualityMaximize quality and extraction yieldBeverage vesselsAvicultureReal-time dataAdditive ingredient

A dispensing apparatus for hot beverages is provided with means (4,5) to filter hot pressurised water through ground edible ingredients such as coffee, tea or herbal remedies in a chamber, means (17,18,20) of monitoring real-time data concerning brewing parameters; a controlling unit (16) comprising means of storing data, means of comparing the real-time data to a set of stored data and / or threshold parameters, stored in the controller's memory associated with the brewing system, to determine whether a correction to the parameters should be made, and means (8,9,24) of altering at least one of the relevant brewing parameters, when required to bring said real time parameter in line with said recorded parameter to obtain consistent high quality of the dispensed beverage.

Owner:RHEAVENDORS SERVI CES SPA

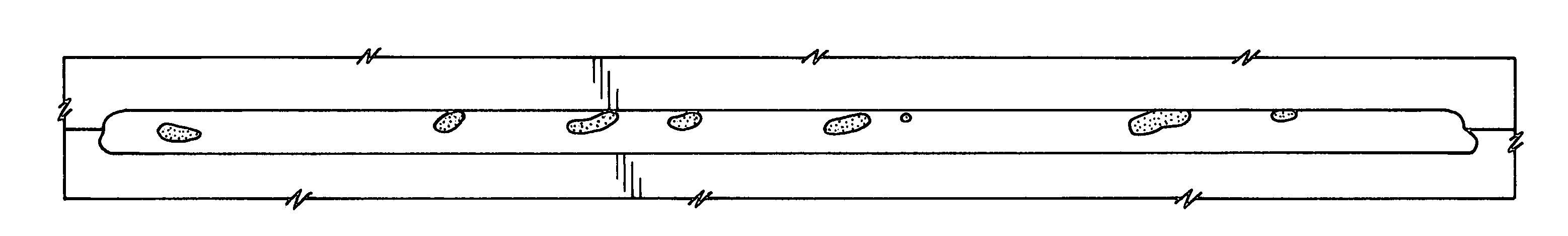

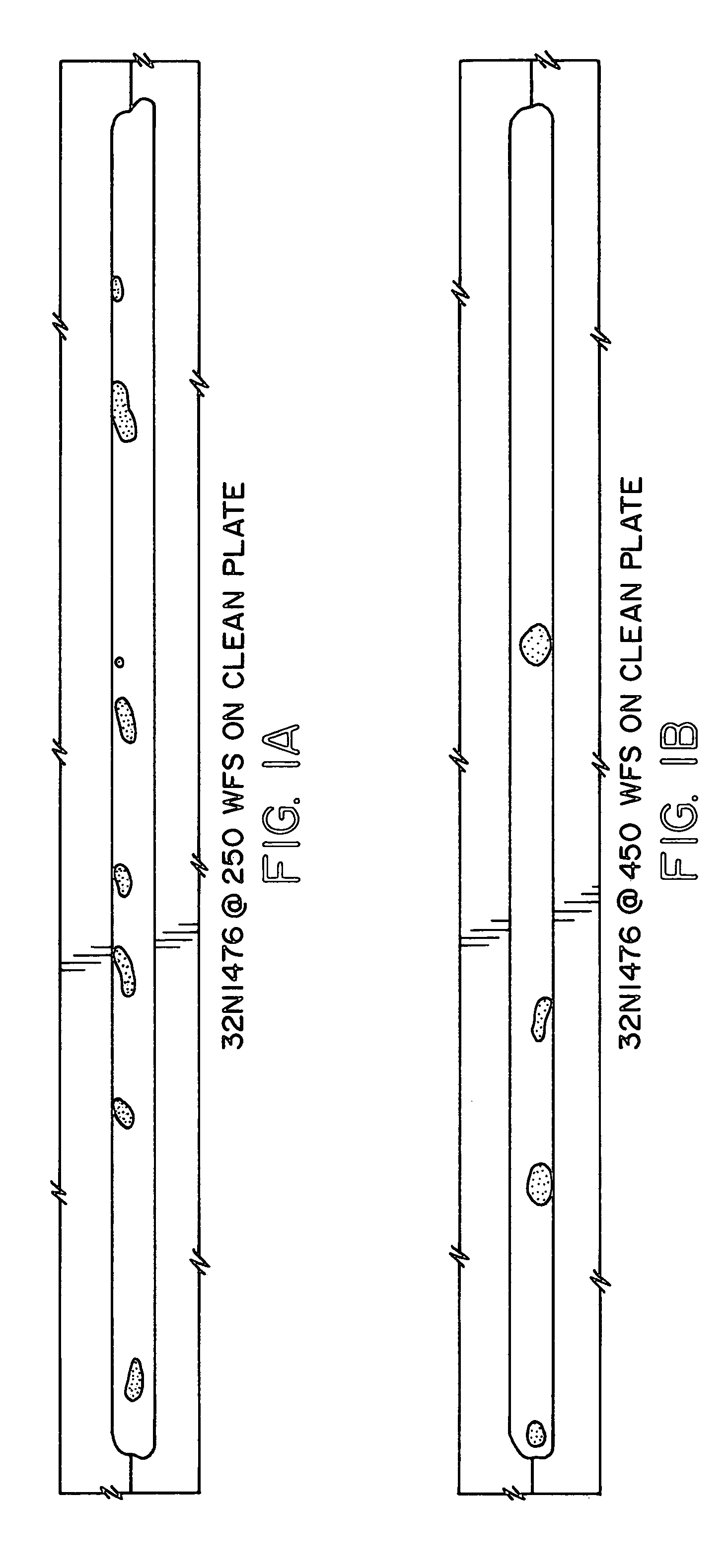

Straight polarity metal cored wires

InactiveUS7087860B2Increase deposition rateImprove welding qualityArc welding apparatusWelding/cutting media/materialsManganeseGraphite

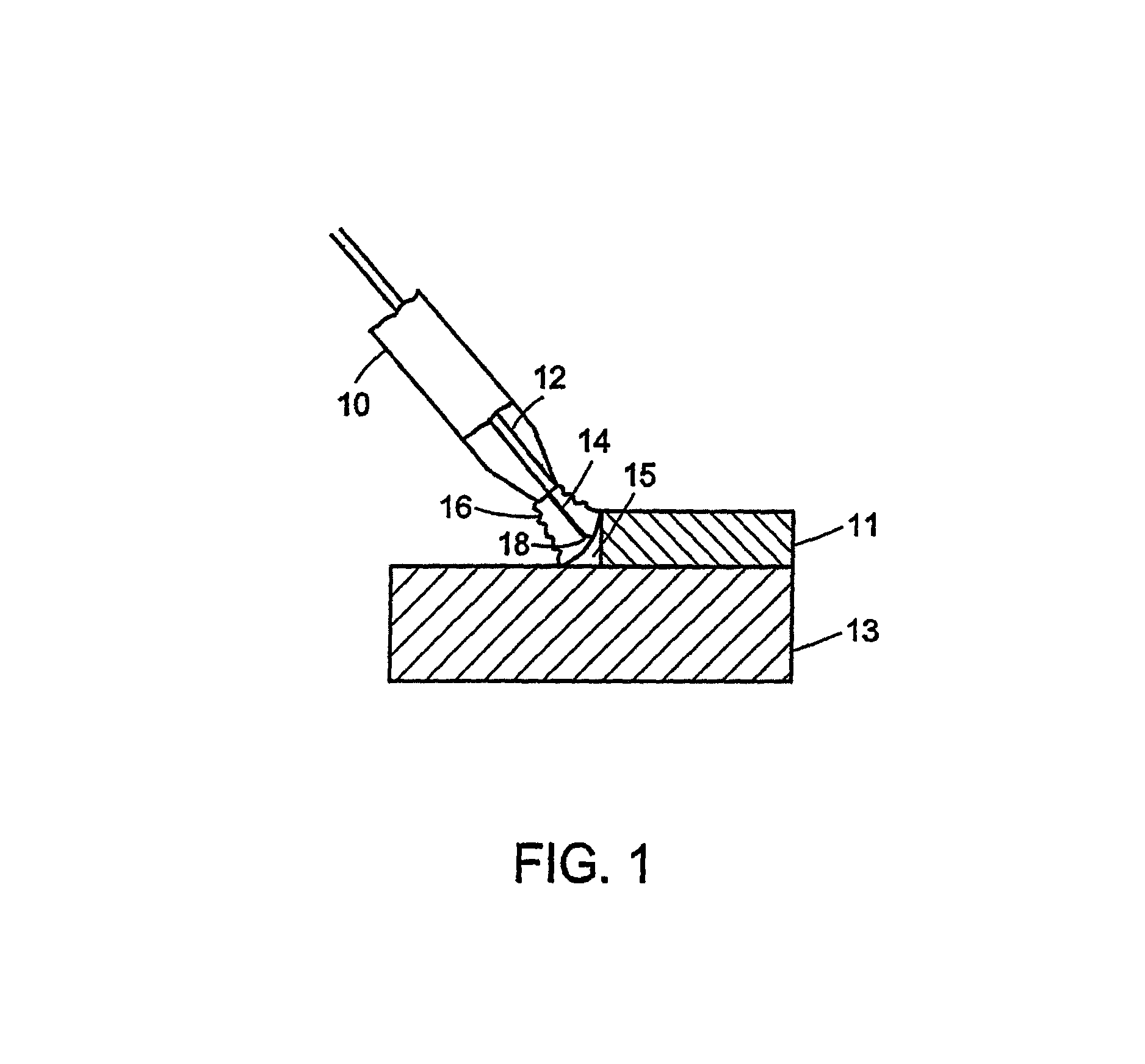

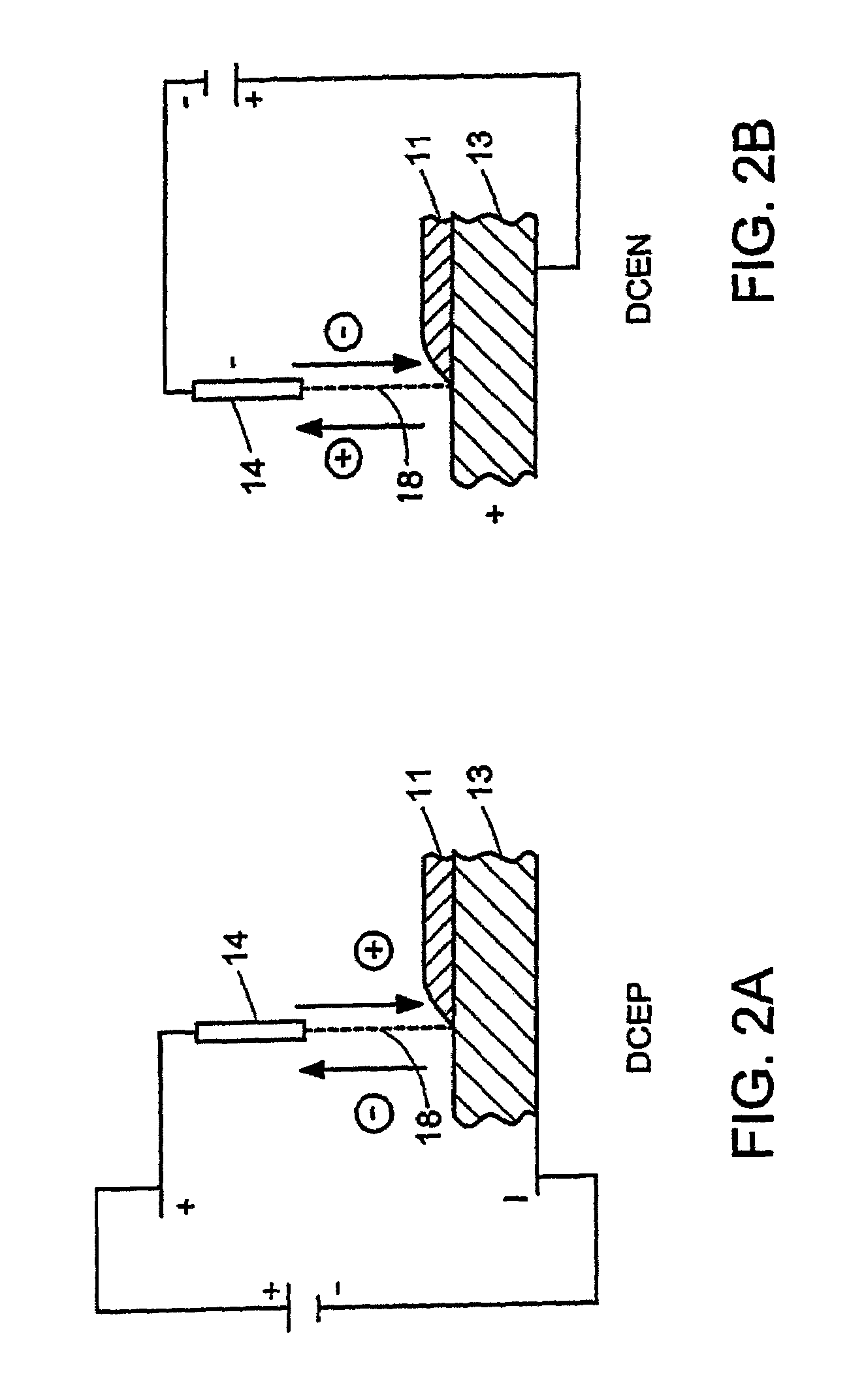

A core composition of a metal-cored wire comprising a combination of graphite and potassium compounds has been proven to stabilize the arc in a straight polarity welding configuration. In particular, adding a combination of graphite and potassium manganese titanate (K2MnTiO4) and potassium sulfate (K2SO4) in the preferred combination of graphite and potassium compounds from the range of about 0.3% to about 5.0% wt resulted in a greatly stabilized arc, reduced spatter and reduced warpage while maintaining high deposition rates of the DCEN welding process

Owner:HOBART BROS

Pulse welder and method of using same

ActiveUS20050269306A1Reduce forceSmall droplet sizeCoin-freed apparatus detailsArc welding apparatusElectric arcEngineering

An electric arc welder for performing a pulse welding process by a current between an advancing electrode and workpiece where the welder comprises a short detecting circuit for creating a short signal upon occurrence of a short circuit between the advancing electrode and the workpiece and a boost circuit to create a plasma boost pulse after the short circuit is cleared during the time period when the welder is not outputting the peak pulse current.

Owner:LINCOLN GLOBAL INC

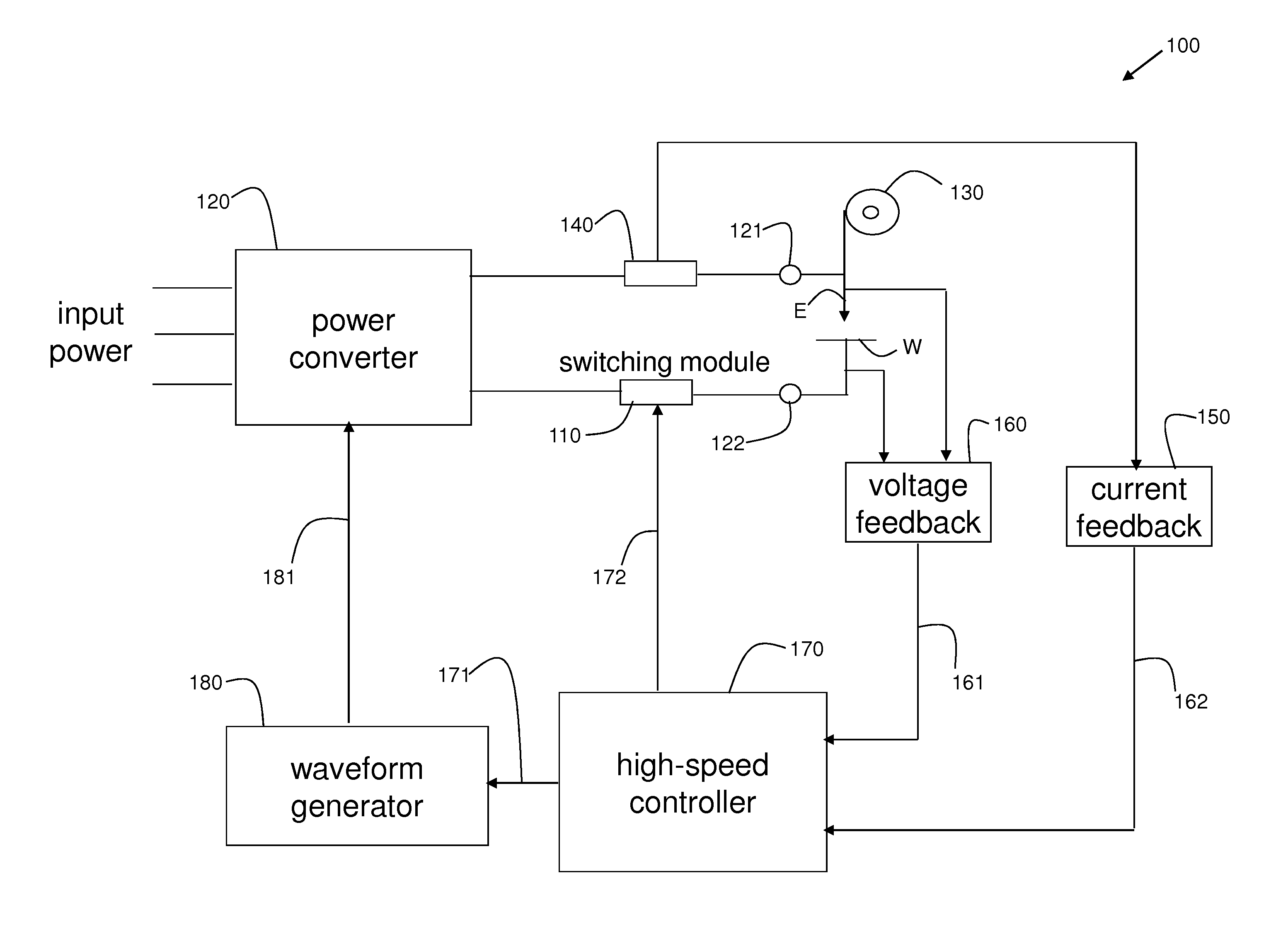

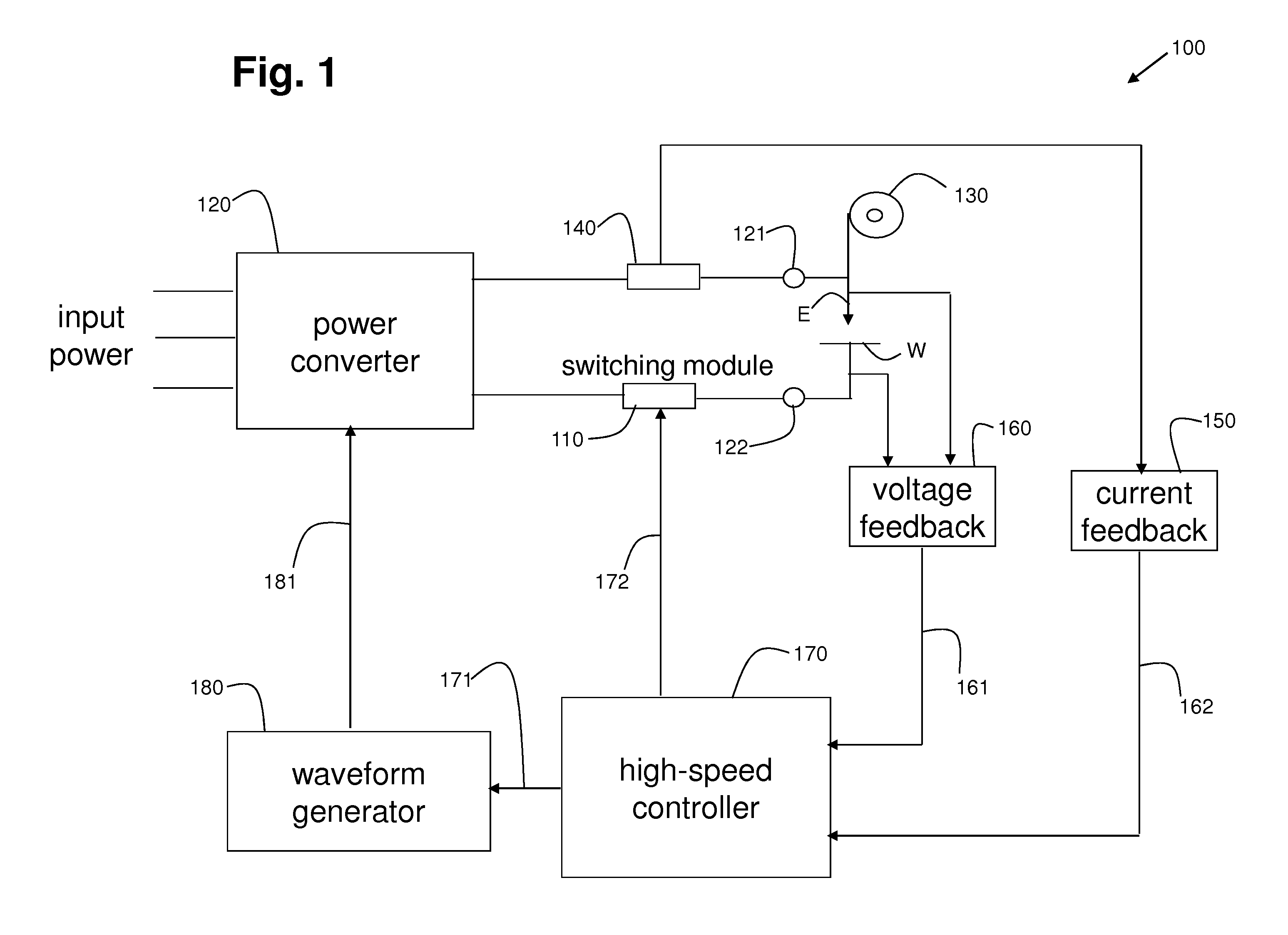

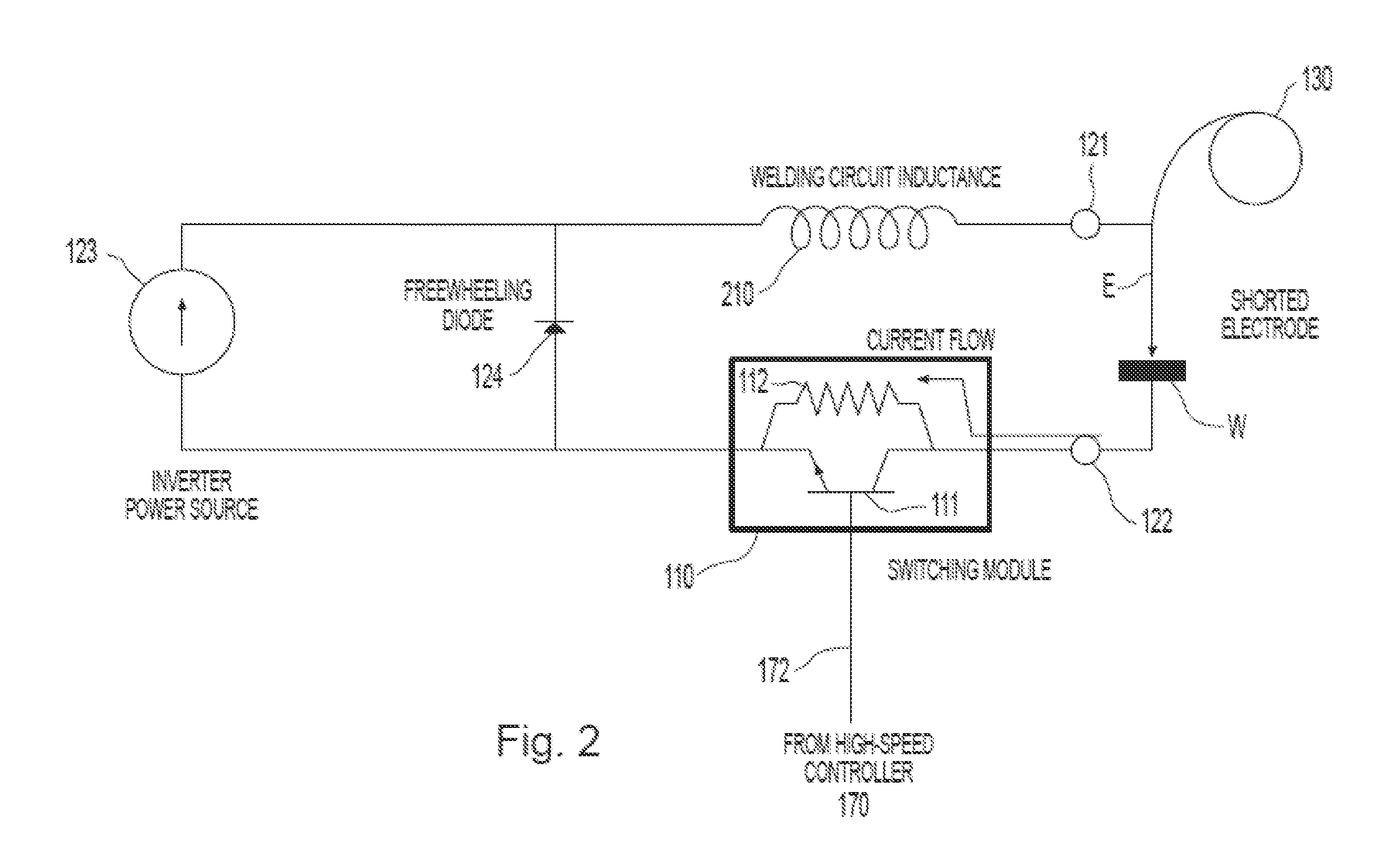

Method to control an arc welding system to reduce spatter

ActiveUS20120097655A1Reduce splashLess spatterArc welding apparatusElectricityElectrical resistance and conductance

An electric arc welder and a method for performing a pulse welding process producing reduced spatter. The welder produces a current between an advancing electrode and a workpiece. The welder includes a short-detecting capability for detecting a short condition upon occurrence of a short circuit between the advancing electrode and the workpiece. The welder may also include a switching module in the welding circuit path of the welder having an electrical switch and a resistive path. Times of occurrence of short intervals can be tracked and a blanking signal can be generated based on the tracked short intervals to anticipate a next short interval in a next pulse period of the pulsed welding process. The blanking signal can be used to reduce a welding current in the welding circuit path by introducing additional resistance into the welding circuit path via the switching module, for example.

Owner:LINCOLN GLOBAL INC

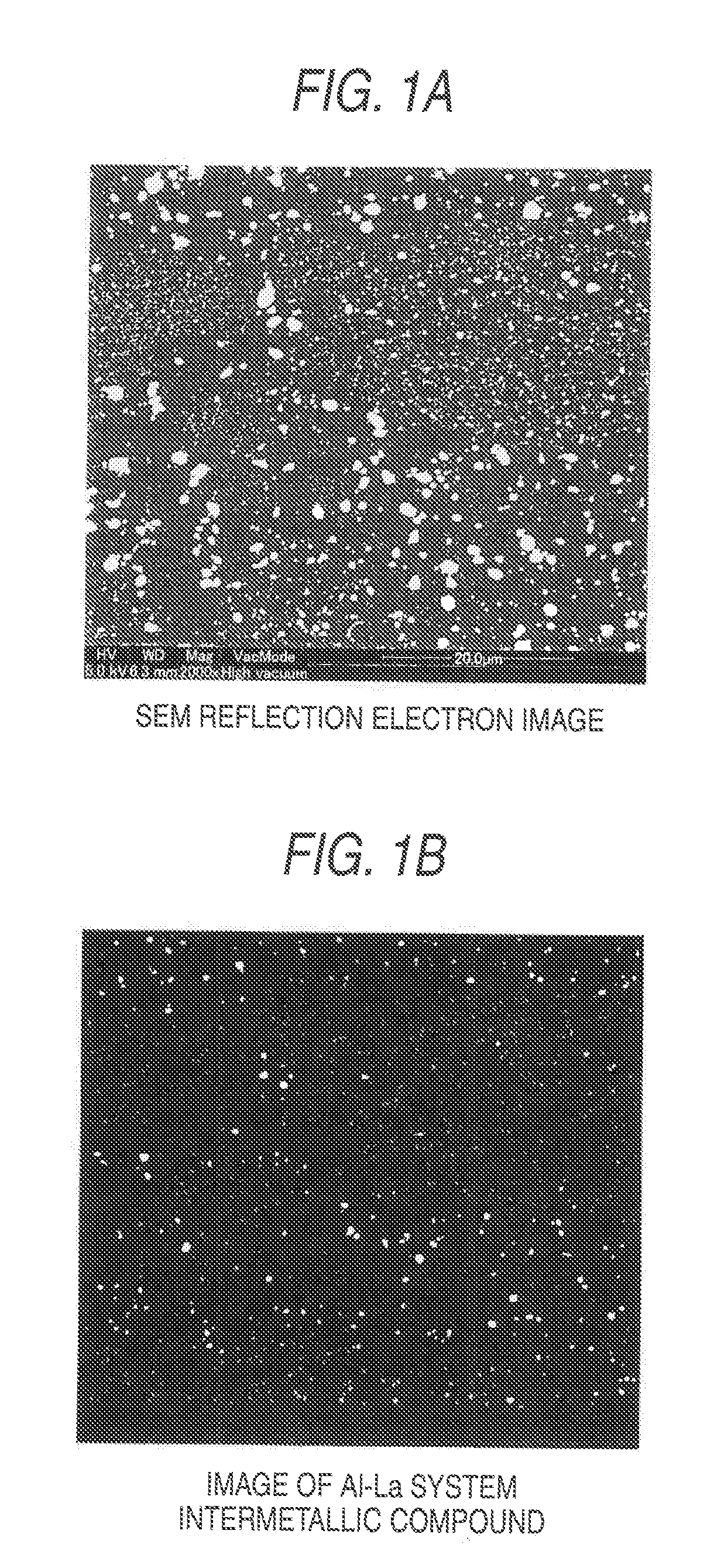

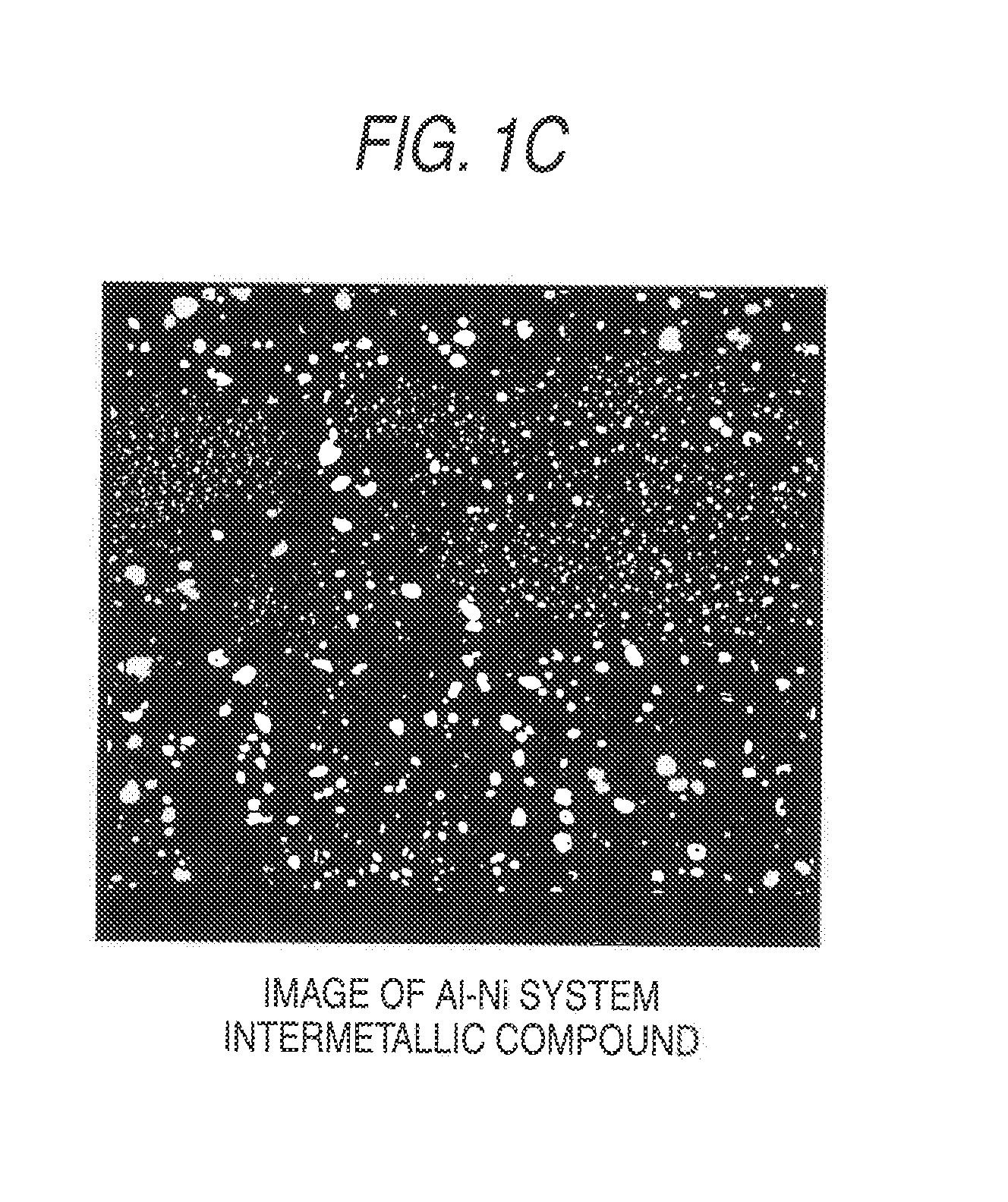

Ai-ni-la system ai-based alloy sputtering target and process for producing the same

ActiveUS20080121522A1Reduce splashCellsMolten spray coatingScanning electron microscopeMagnification

The invention relates to an Al—Ni—La system Al-based alloy sputtering target comprising Ni and La, wherein, when a section from (¼)t to (¾)t (t: thickness) in a cross section vertical to a plane of the sputtering target is observed with a scanning electron microscope at a magnification of 2000 times, (1) a total area of an Al—Ni system intermetallic compound having an average particle diameter of 0.3 μm to 3 μm with respect to a total area of the entire Al—Ni system intermetallic compound is 70% or more in terms of an area fraction, the Al—Ni system intermetallic compound being mainly composed of Al and Ni; and (2) a total area of an Al—La system intermetallic compound having an average particle diameter of 0.2 μm to 2 μm with respect to a total area of the entire Al—La system intermetallic compound is 70% or more in terms of an area fraction, the Al—La system intermetallic compound being mainly composed of Al and La.

Owner:KOBE STEEL LTD +1

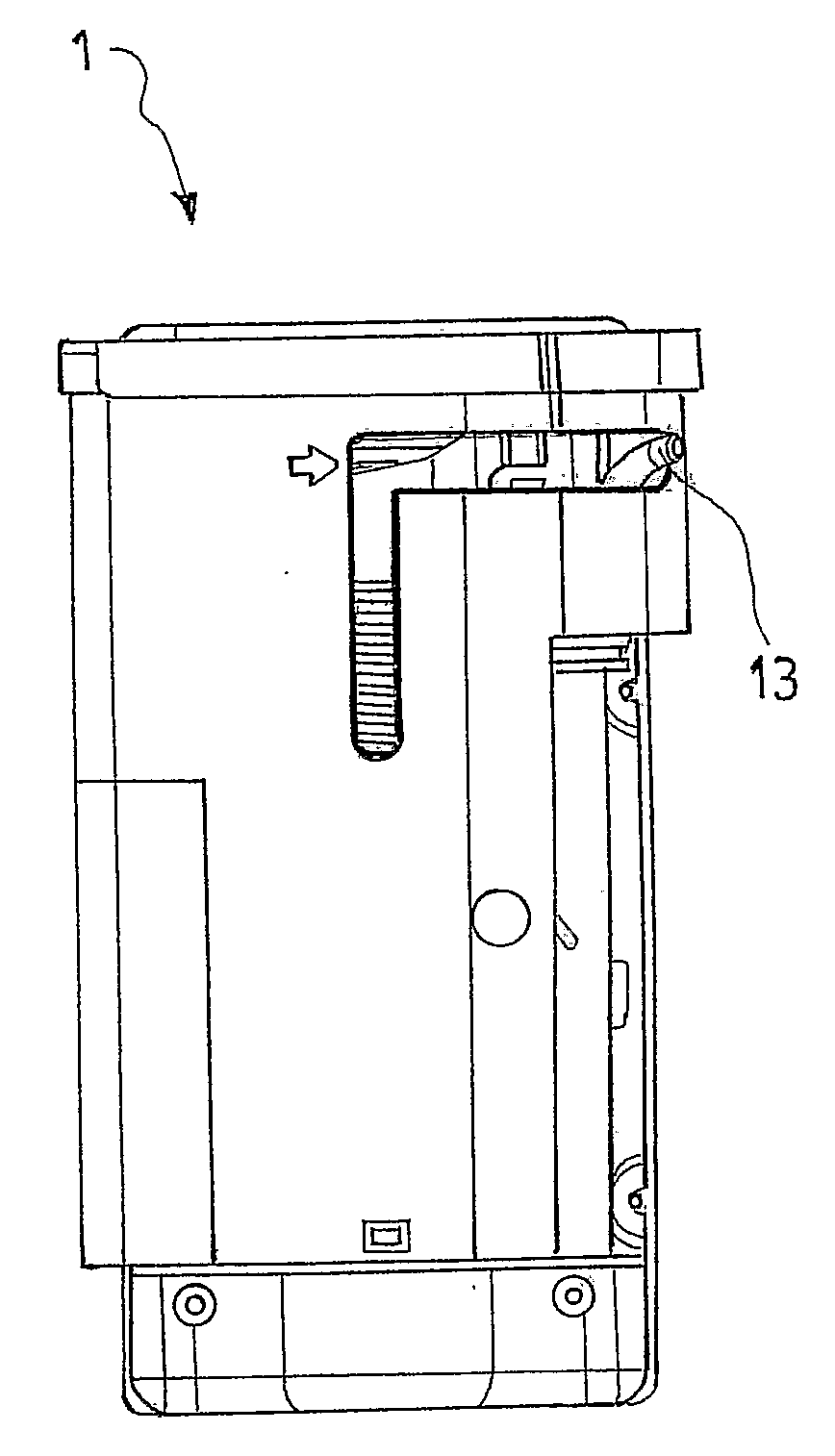

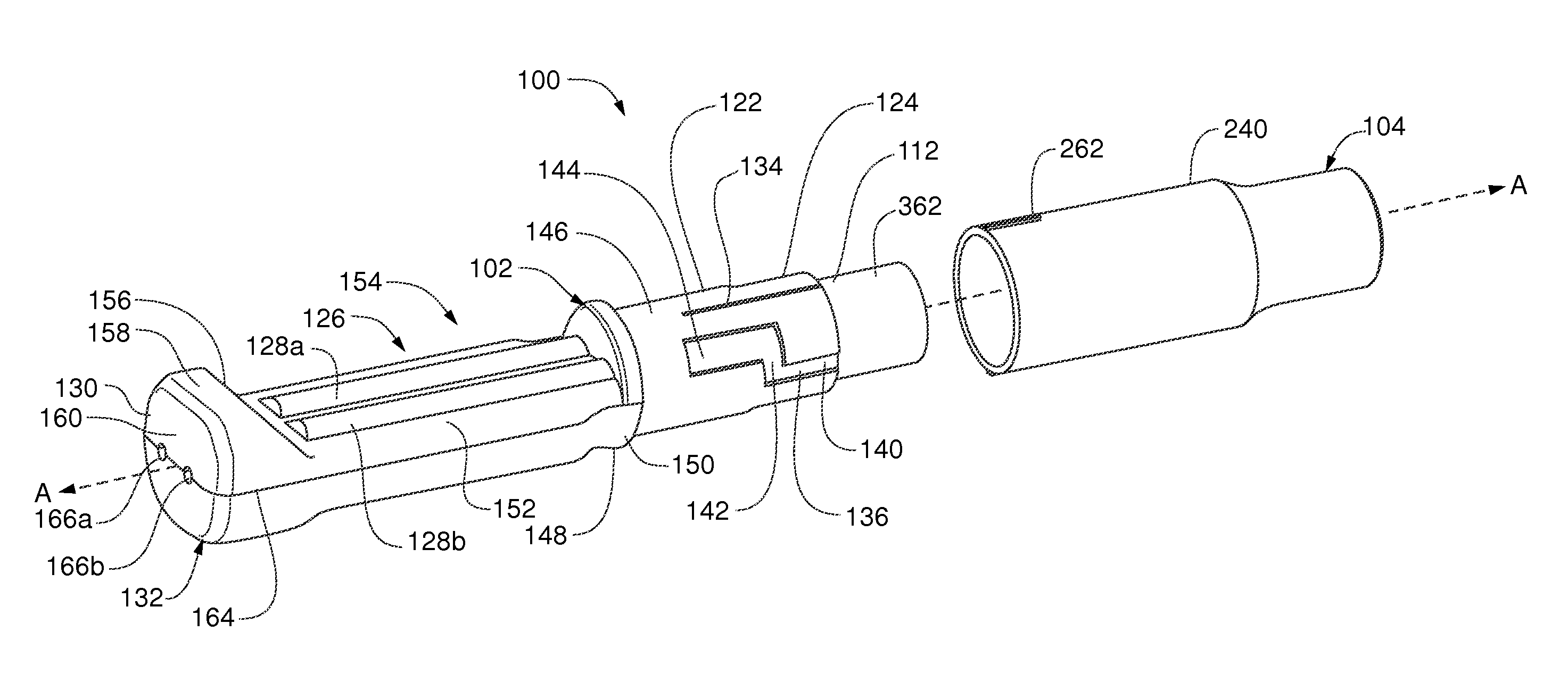

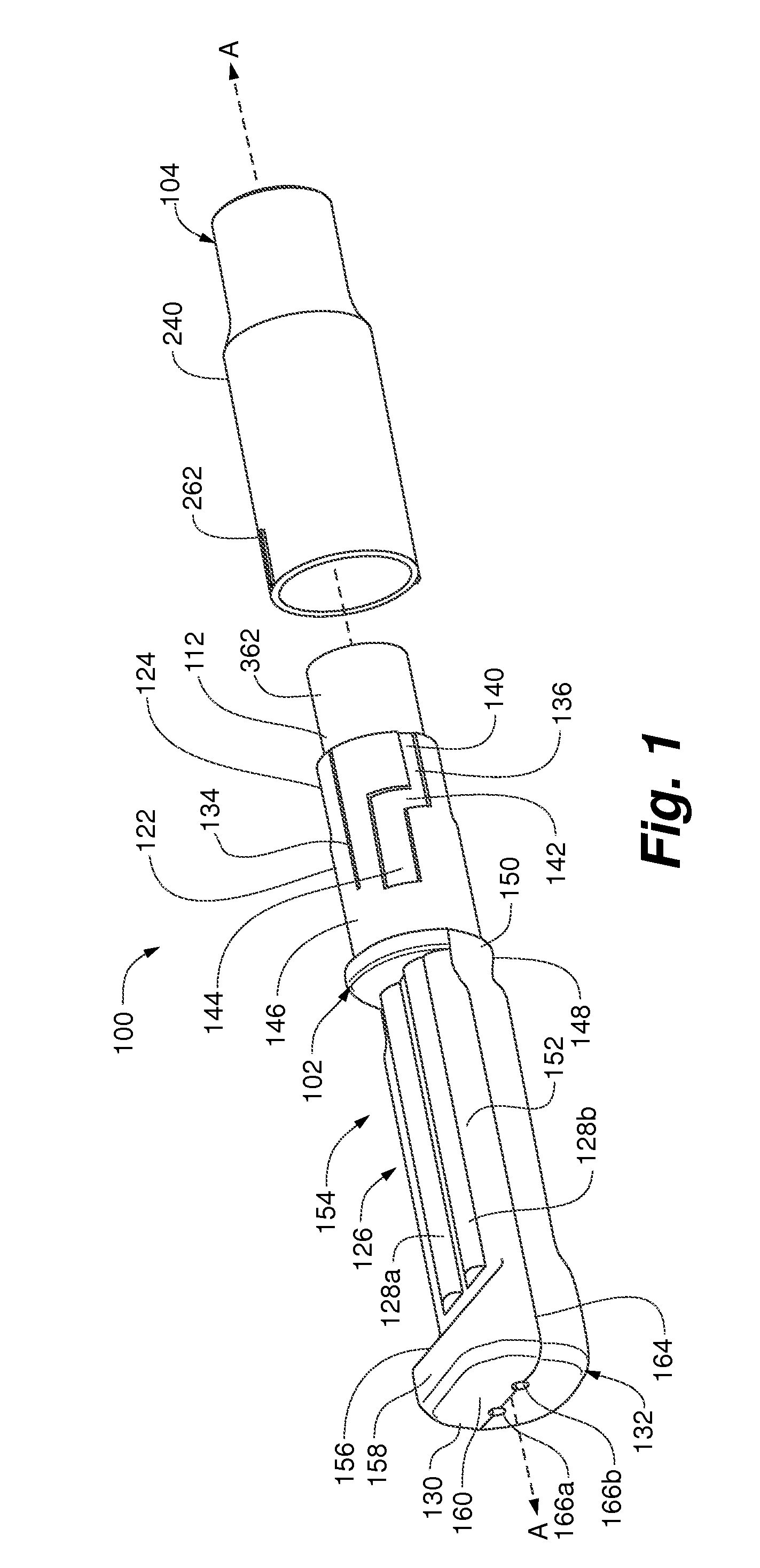

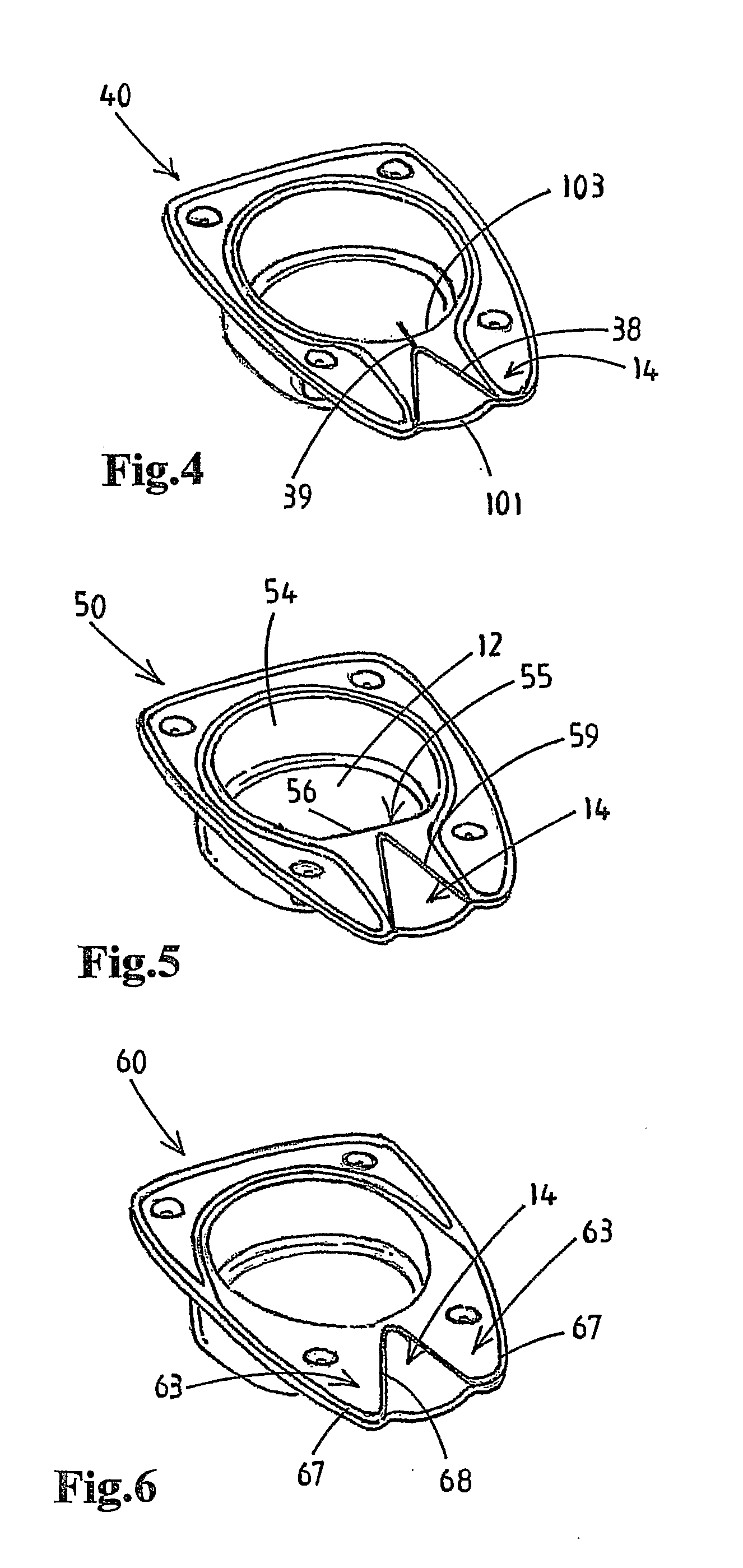

Multi-stage oral-fluid testing device

ActiveUS20160121322A1Easy to useTest accurateAnalysis using chemical indicatorsVaccination/ovulation diagnosticsEngineeringOral fluid

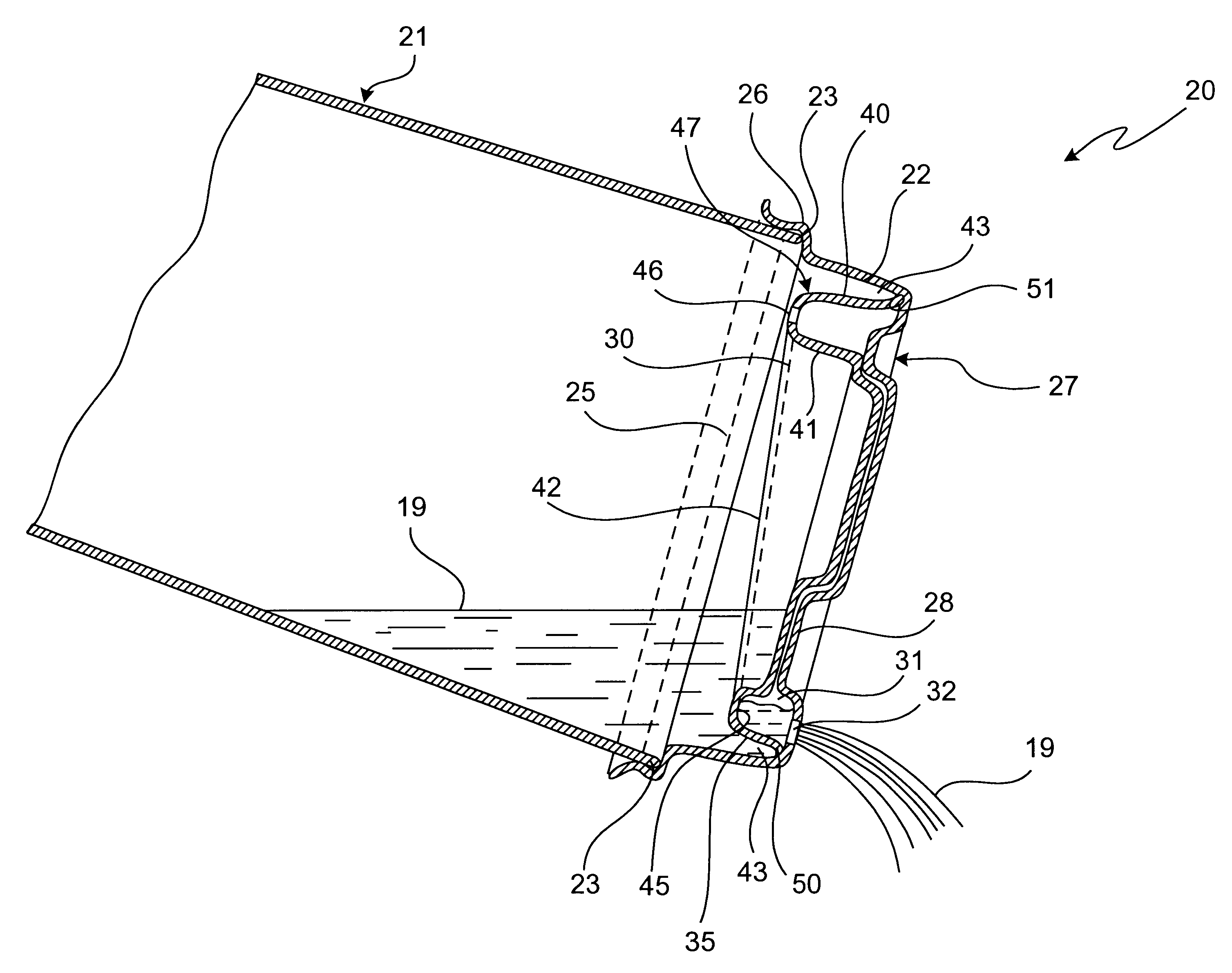

In an embodiment, the claimed invention includes an oral-fluid collection and testing device that. is simple to operate. The device includes a body assembly and a cap assembly that are easy to handle by a user. A collection sponge projects from an end of the body assembly for absorbing the oral fluid of a donor, A cap assembly is easily aligned with the body assembly by way of visual alignment indicators on both the body and the cap. Once the cap is aligned with the body, a user simply pushes the cap onto the 'body, which causes a first stage fluid, flow. More specifically, a buffer fluid is released from the cap and mixes with the oral fluid collected on the sponge—After waiting a short time* the cap is rotated, then pushed again, causing a second-stage fluid flow in which the sponge is compressed such that the buffer fluid / oral fluid exits the sponge and flows toward a. pair of test strips. A user can then easily view the test results by observing a visual indication, such as a color change of the test strips through a viewing window.

Owner:PREMIER BIOTECH LLC

Consumable electrode arc welding method and consumable electrode arc welding device

ActiveUS20120074114A1Uniform beadImproved arc stabilityWelding/cutting media/materialsWelding electrode featuresMechanical engineeringElectric arc

If a short circuit does not occur during deceleration of a wire feed speed in forward feed of a welding wire before the wire feed speed reaches a predetermined wire feed speed, a cyclic change is stopped and the wire feed speed is constantly controlled at the first feed speed. If a short circuit occurs during forward feed at the first feed speed, deceleration from the first feed speed starts, and the cyclic change is resumed for welding. This achieves uniform weld bead without increasing spatters even if any external disturbance such as change of distance between a tip and base material occurs.

Owner:PANASONIC CORP

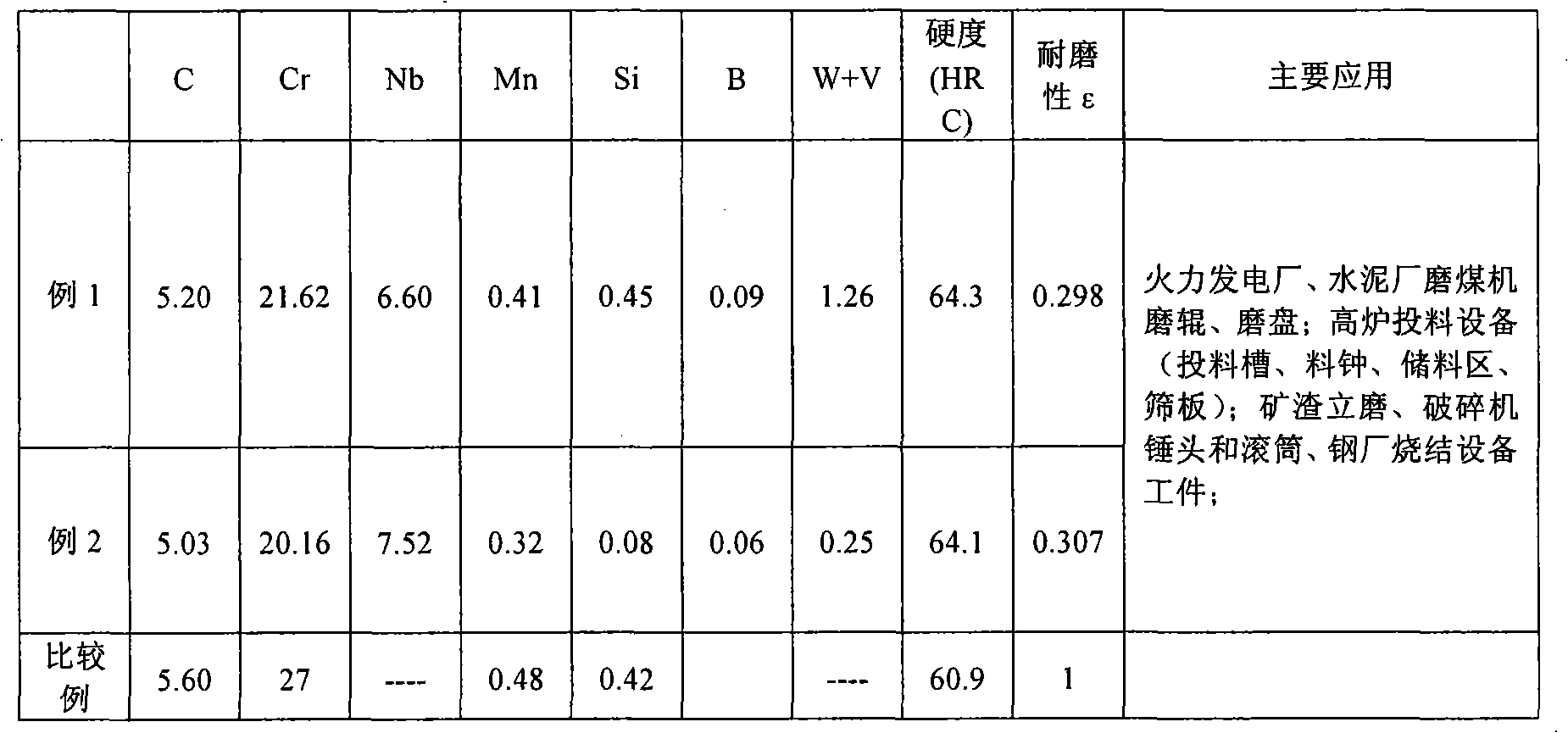

High-carbon high-chromium high-niobium cast iron self-protecting flux-cored wire

InactiveCN101406994AHigh hardnessLow viscosityWelding/cutting media/materialsSoldering mediaHigh carbonNiobium

The invention provides a high-carbon high-chromium high-niobium cast iron self-protection flux-cored wire. The flux-cored wire has a steel belt as an outer skin. The flux core comprises the following components in weight percentage: 10 to 30 percent of ferroniobium, 20 to 30 percent of high carbon ferrochrome, 0.1 to 3 percent of V, 0.2 to 3 percent of W, 0.6 to 0.8 percent of ferromanganese, 0.2 to 0.8 percent of 75 ferrosilicon, 20 to 30 percent of chromium carbide, 5 to 12 percent of graphite, 1 to 10 percent of aluminum-magnesium alloy, 1 to 5 percent of silicon carbide and 1 to 3 percent of ferroboron; and the percentage of a counter weight is between 46 and 54 percent. The high-carbon high-chromium high-niobium cast iron self-protection flux-cored wire has the advantages of high hardness, good wear resistance, good oxidation resistance and strong shock resistance, and is widely applied to grinding rolls and grinding disks of coal grinding machines in thermal power plants and cement plants, material charging equipment in blast furnaces(material charging slots, receiving cones, material storage areas and sieve plates), slag vertical mills, hammer heads and rollers of crushers and sintering equipment workpieces in steel plants.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

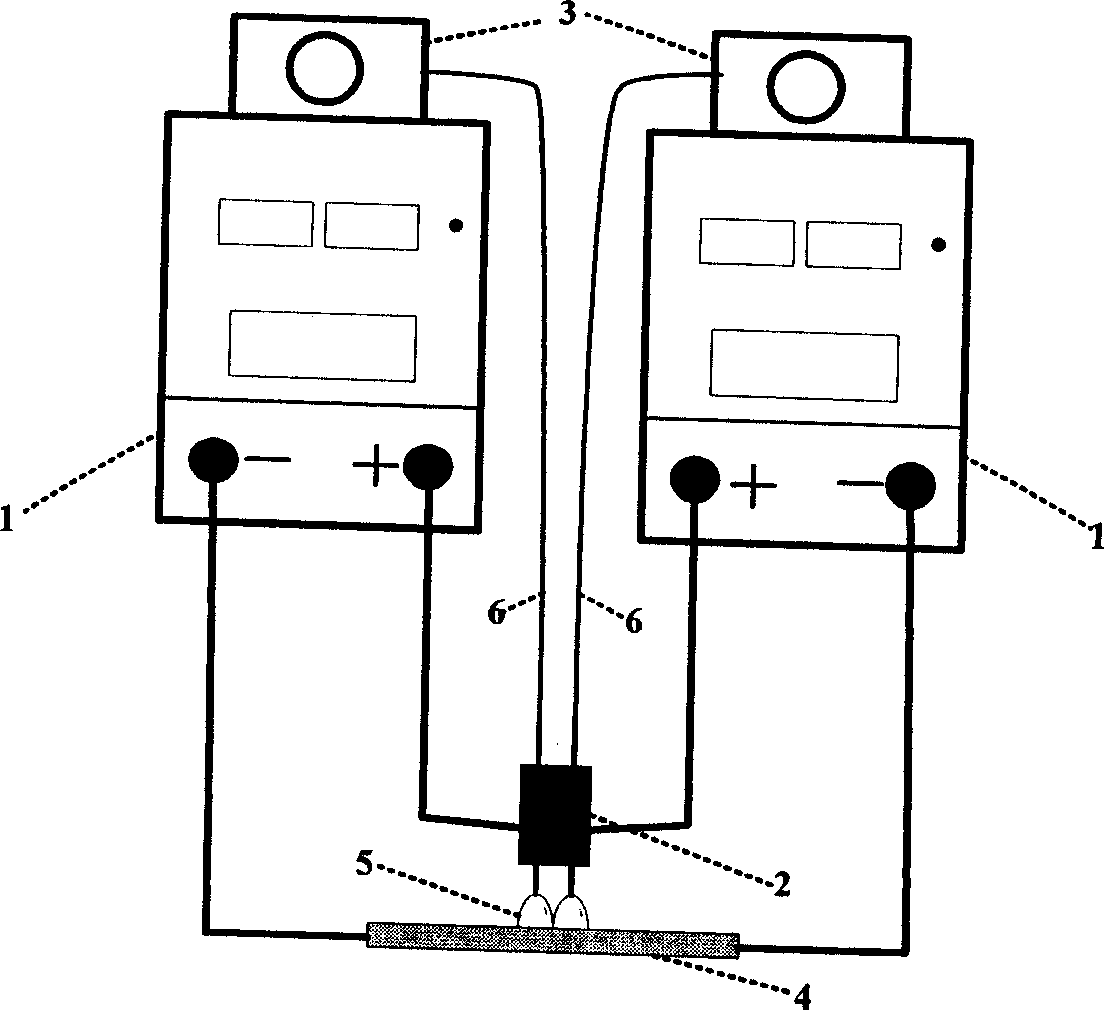

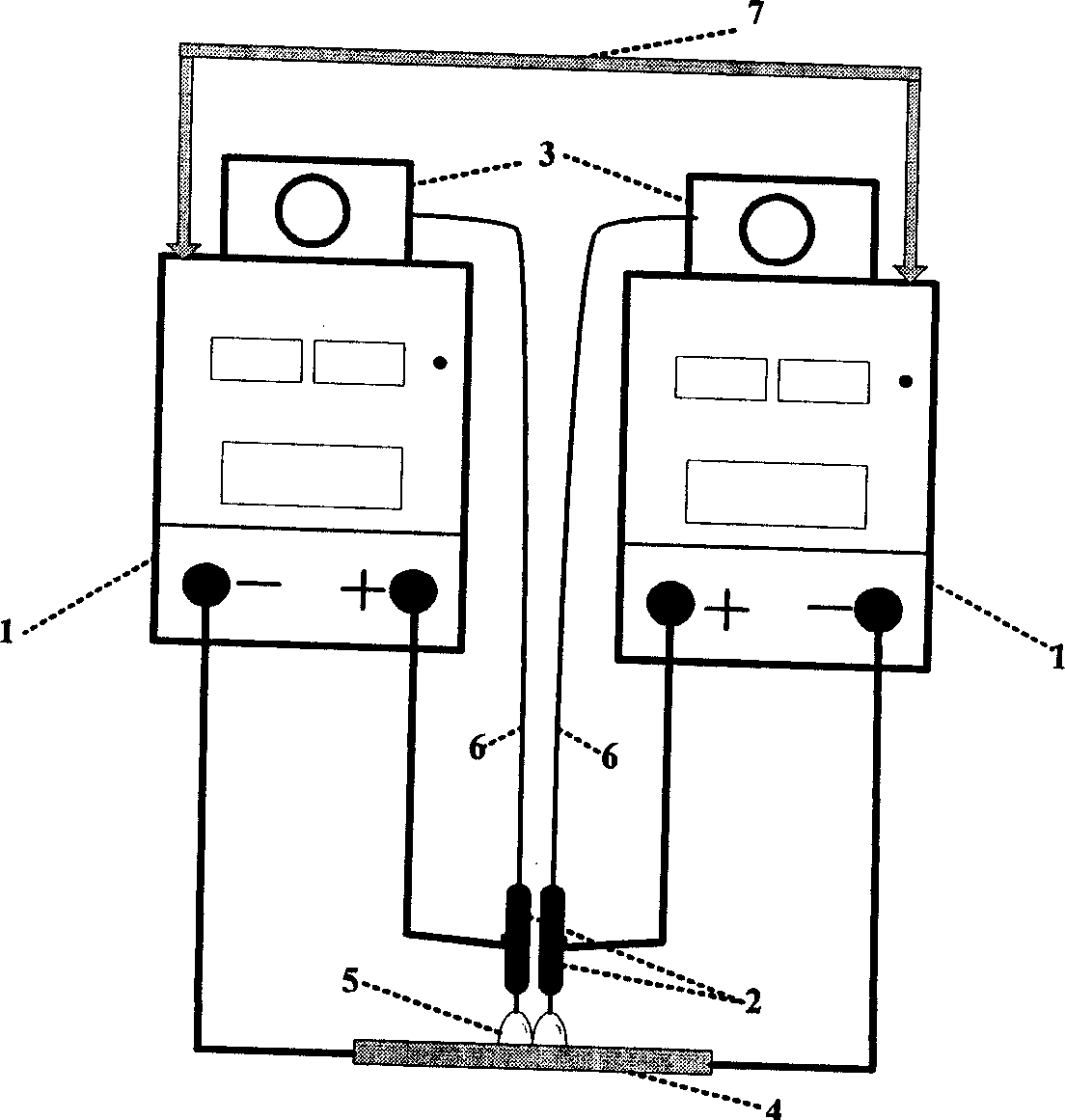

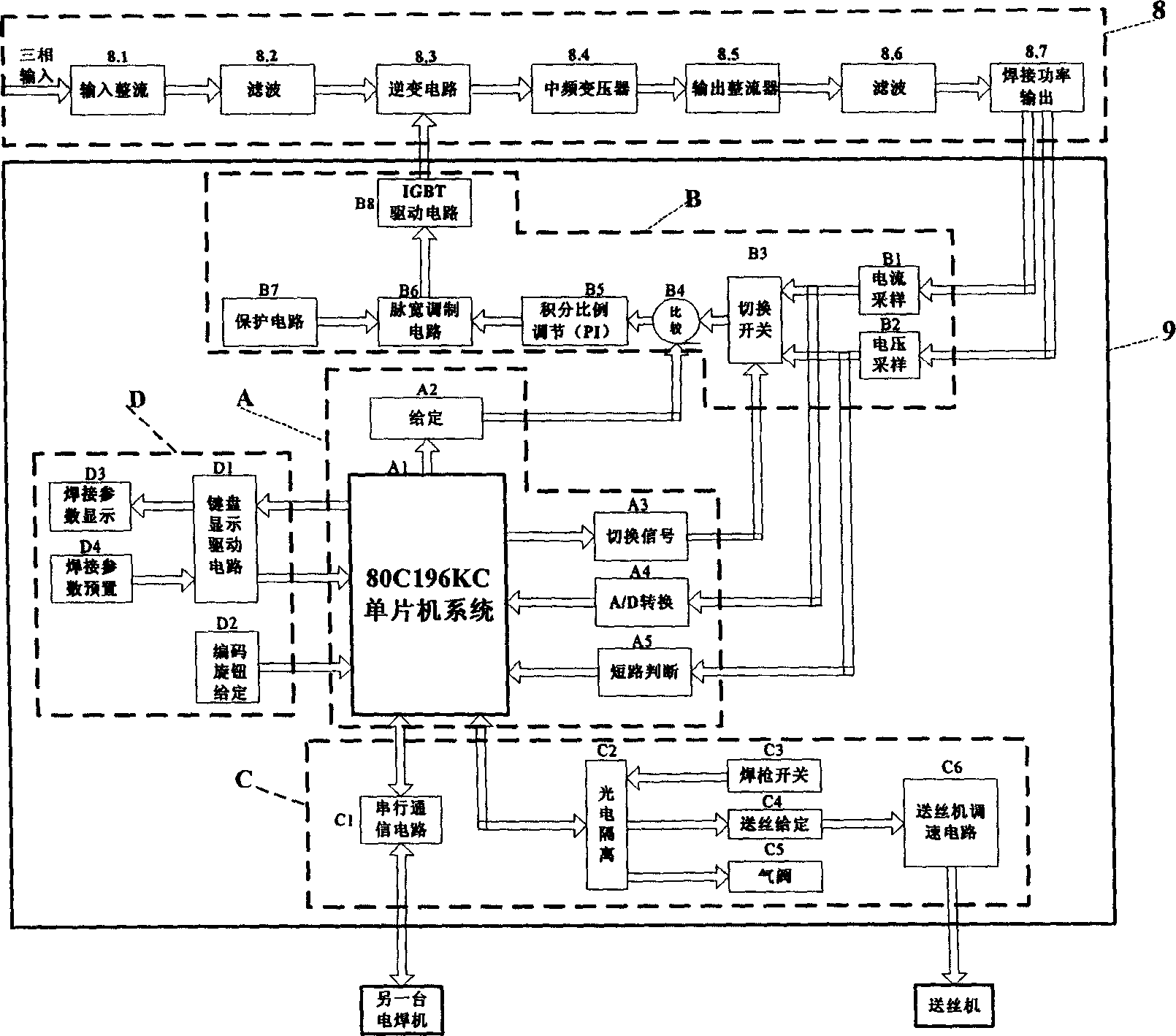

Welding control method of diplonema MAG and welding source

InactiveCN1695866AImprove stabilityControl the level of distractionArc welding apparatusConstant frequencyArc stability

A dual-wire MAG welding control method features that the welding current feedback and voltage feedback are compared with the given signals in time shared mode, a control circuit is used to control welding, and during the welding two welders with constant frequency are used by keeping certain phase relation for high stability. Its welding power supply features that its controller uses a switching circuit consisting of current sampler, voltage sampler, switching switch, comparator, integral proportioner and amplifier connected to welding power output unit.

Owner:BEIJING UNIV OF TECH

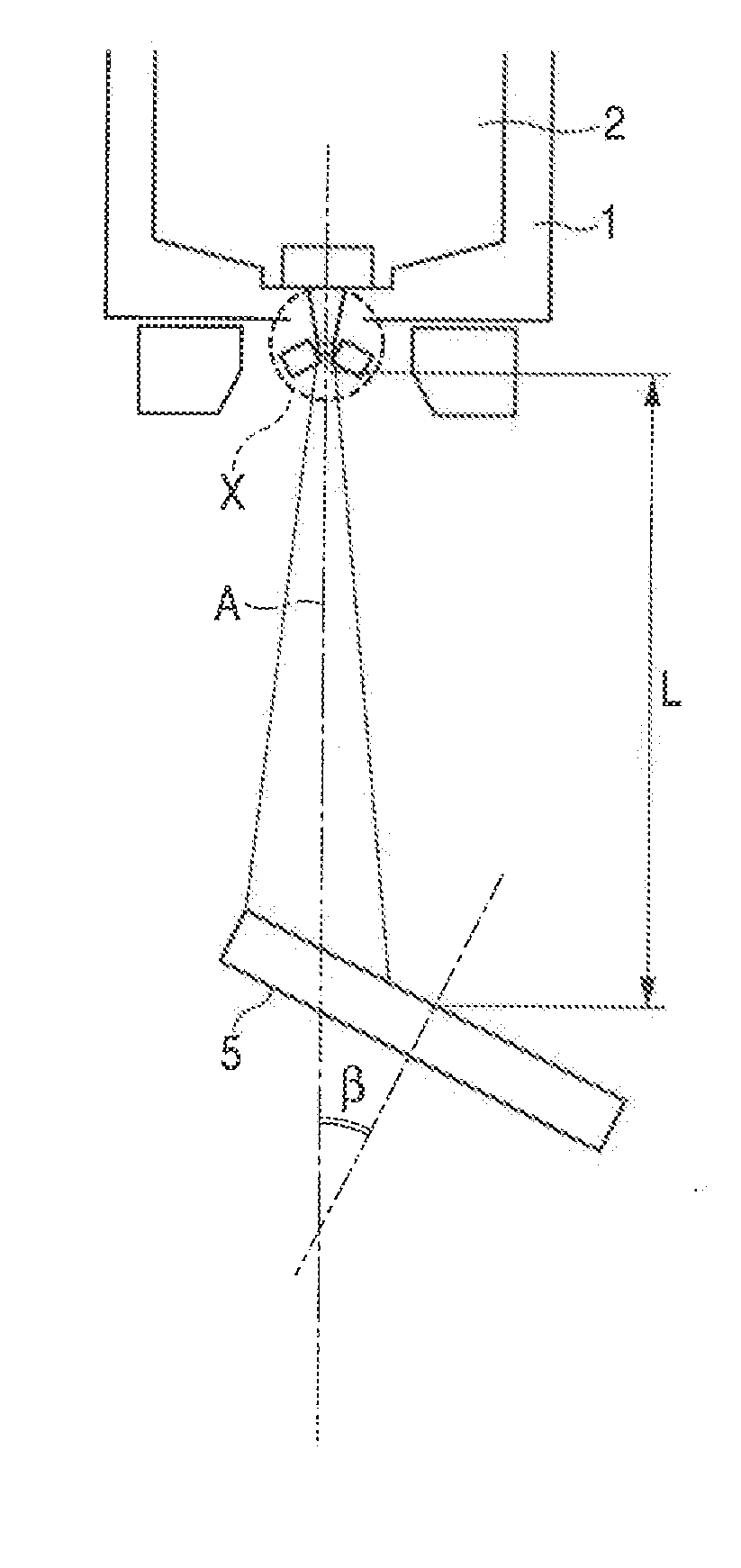

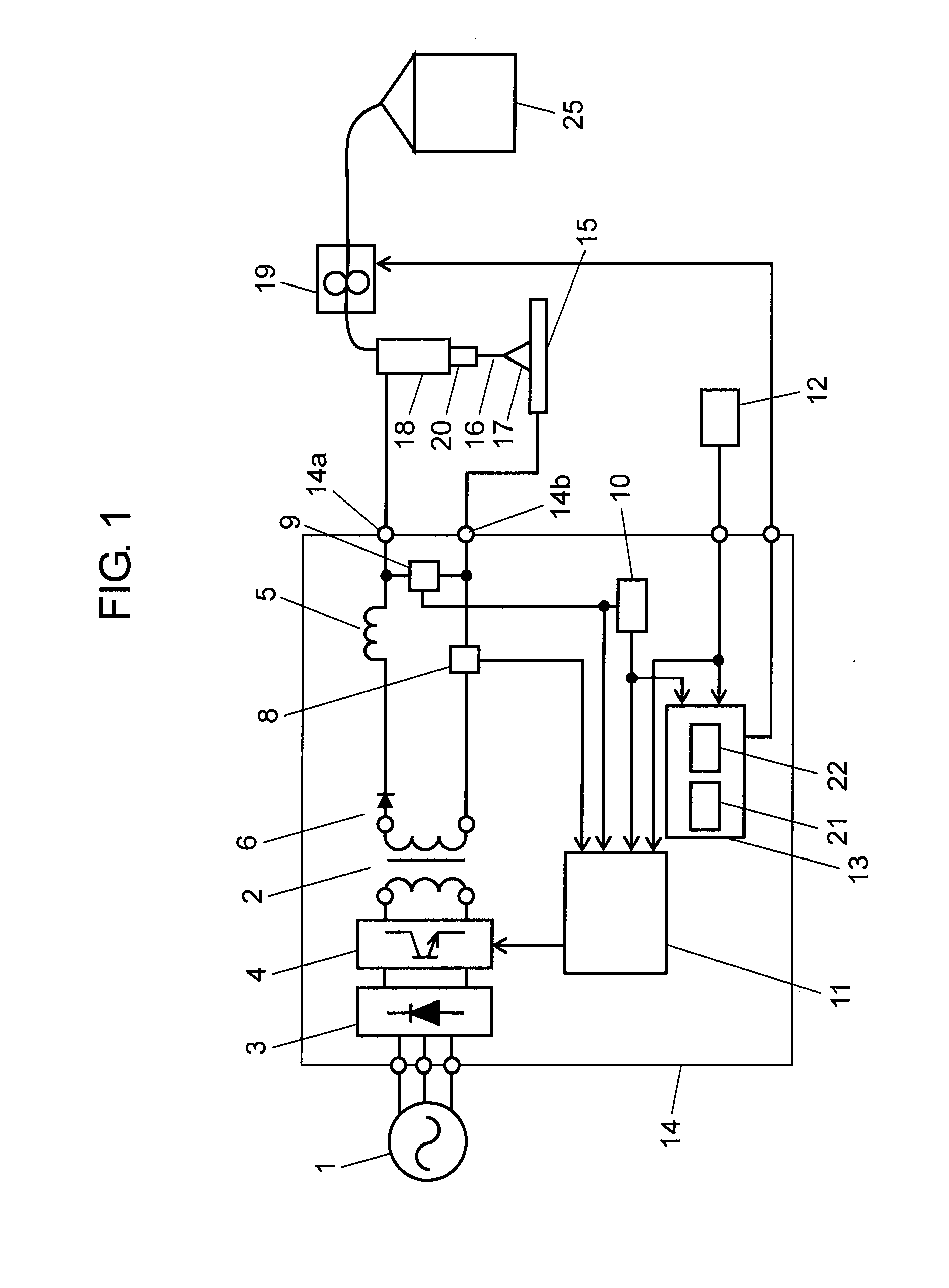

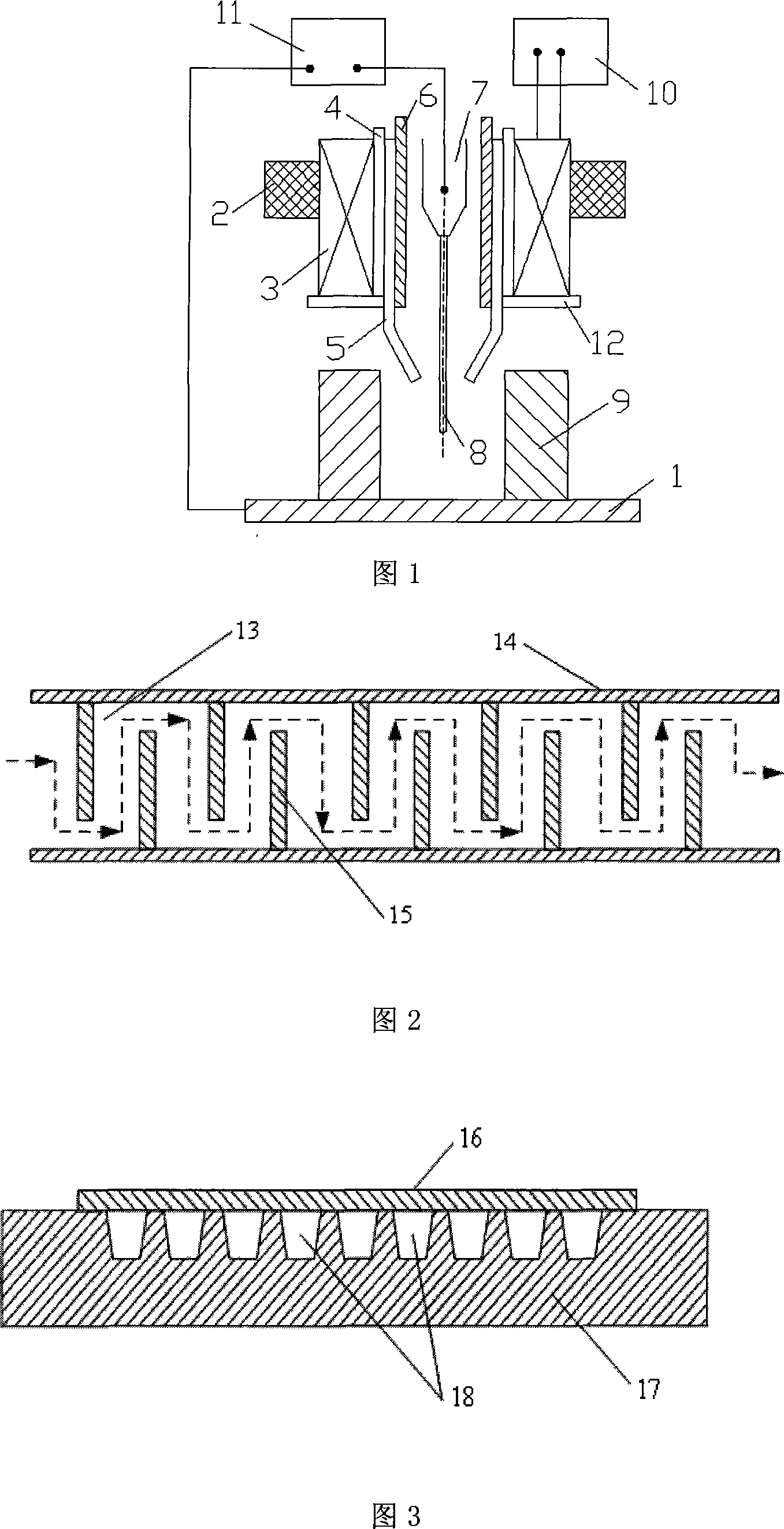

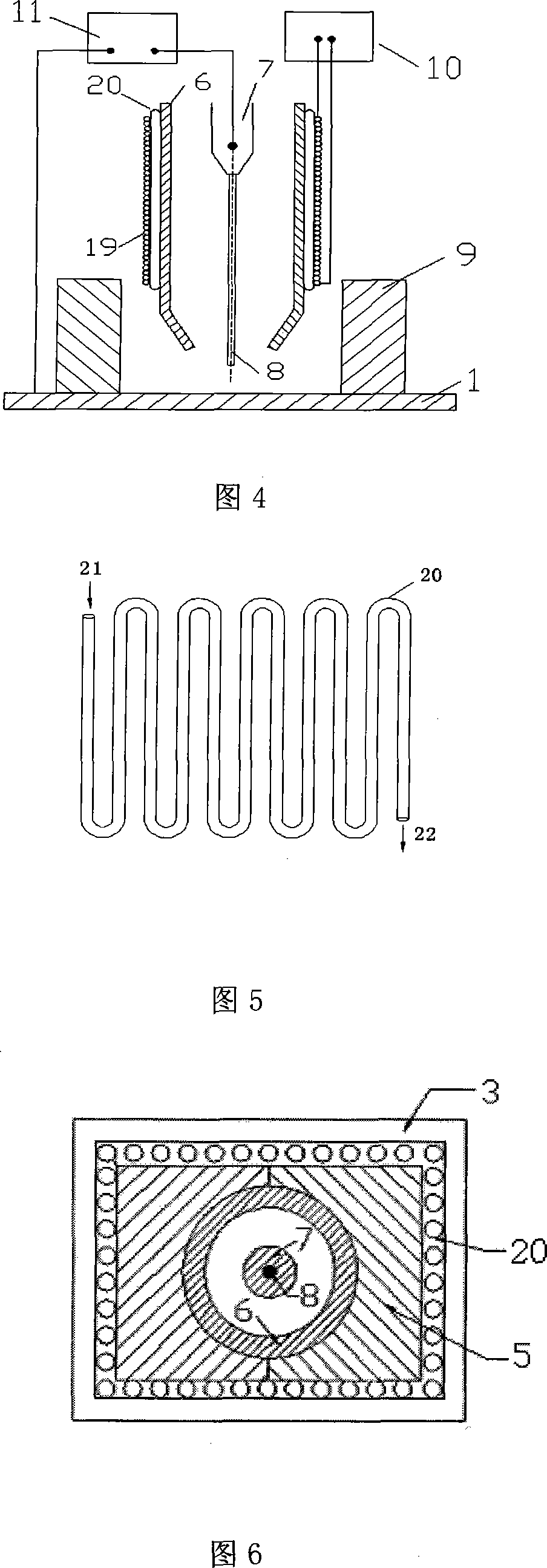

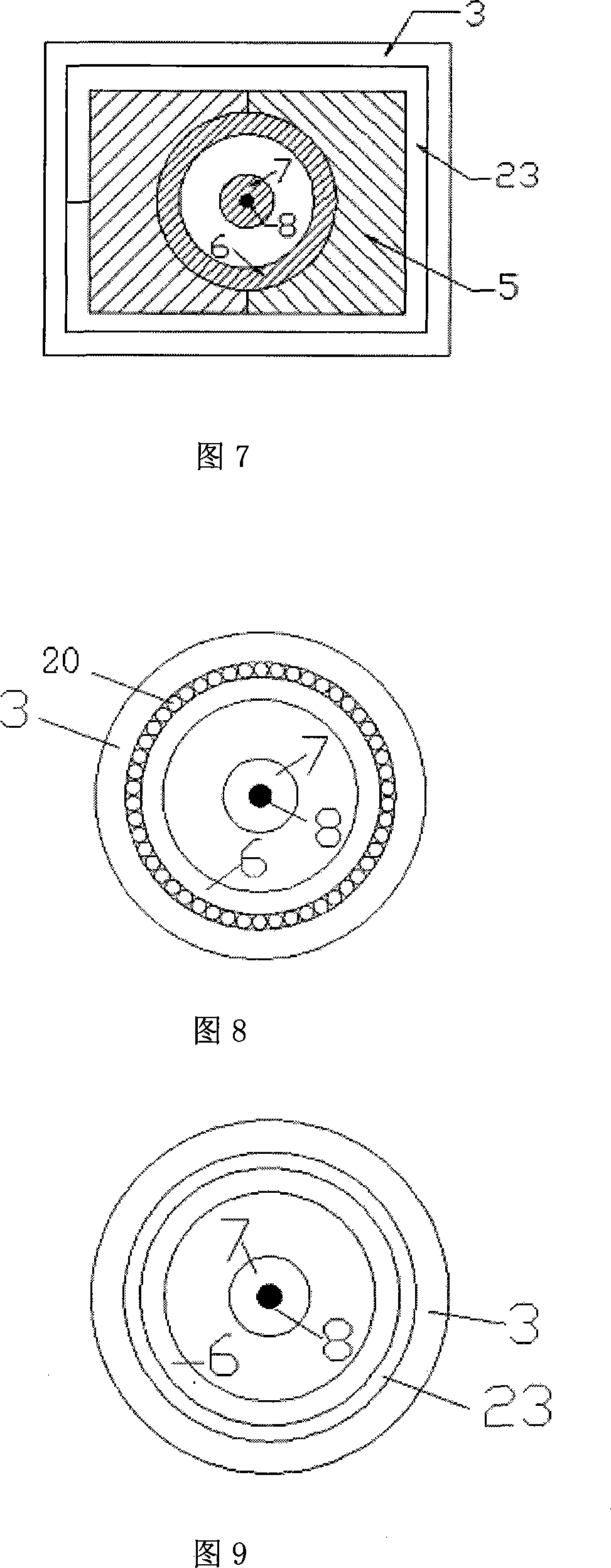

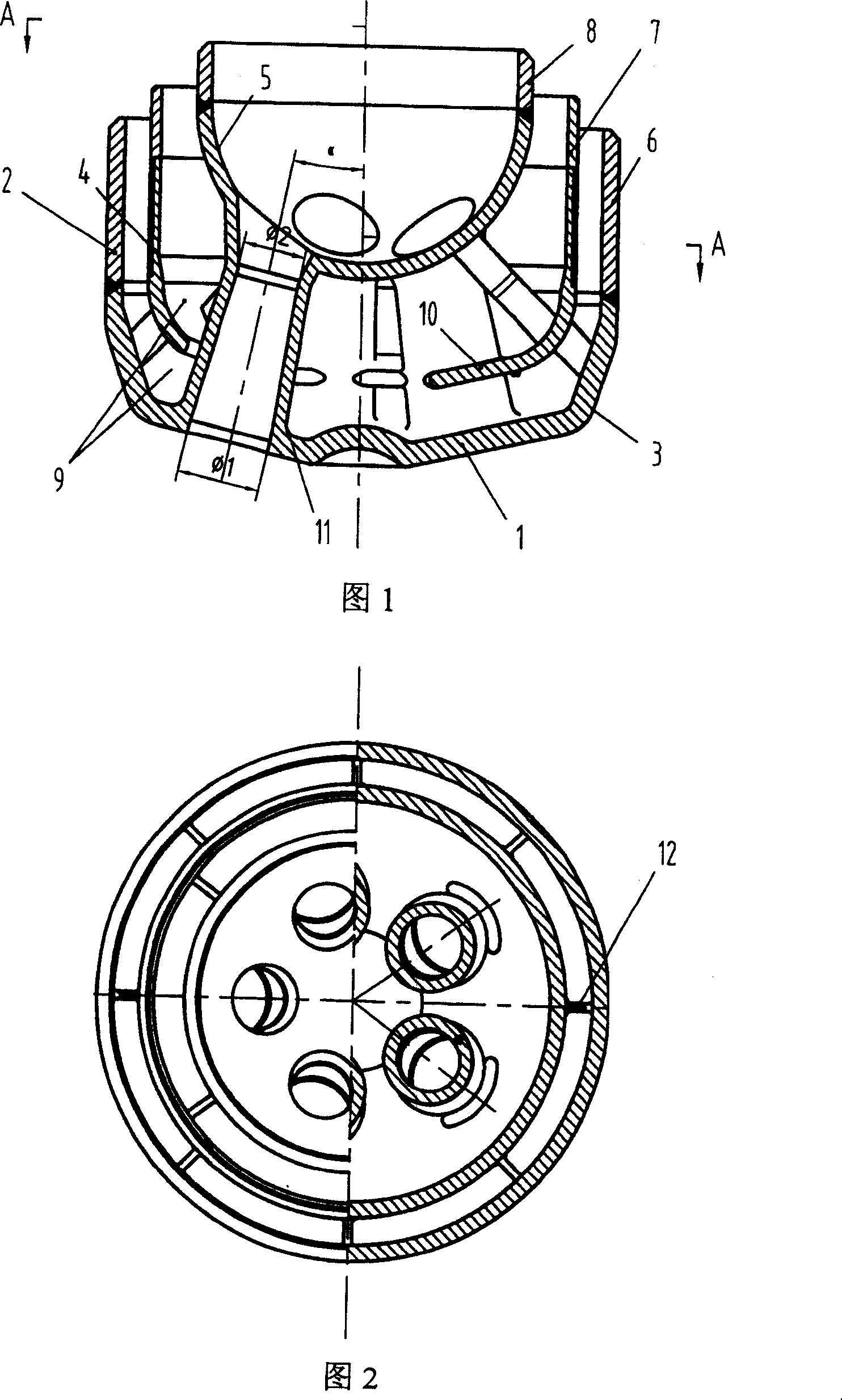

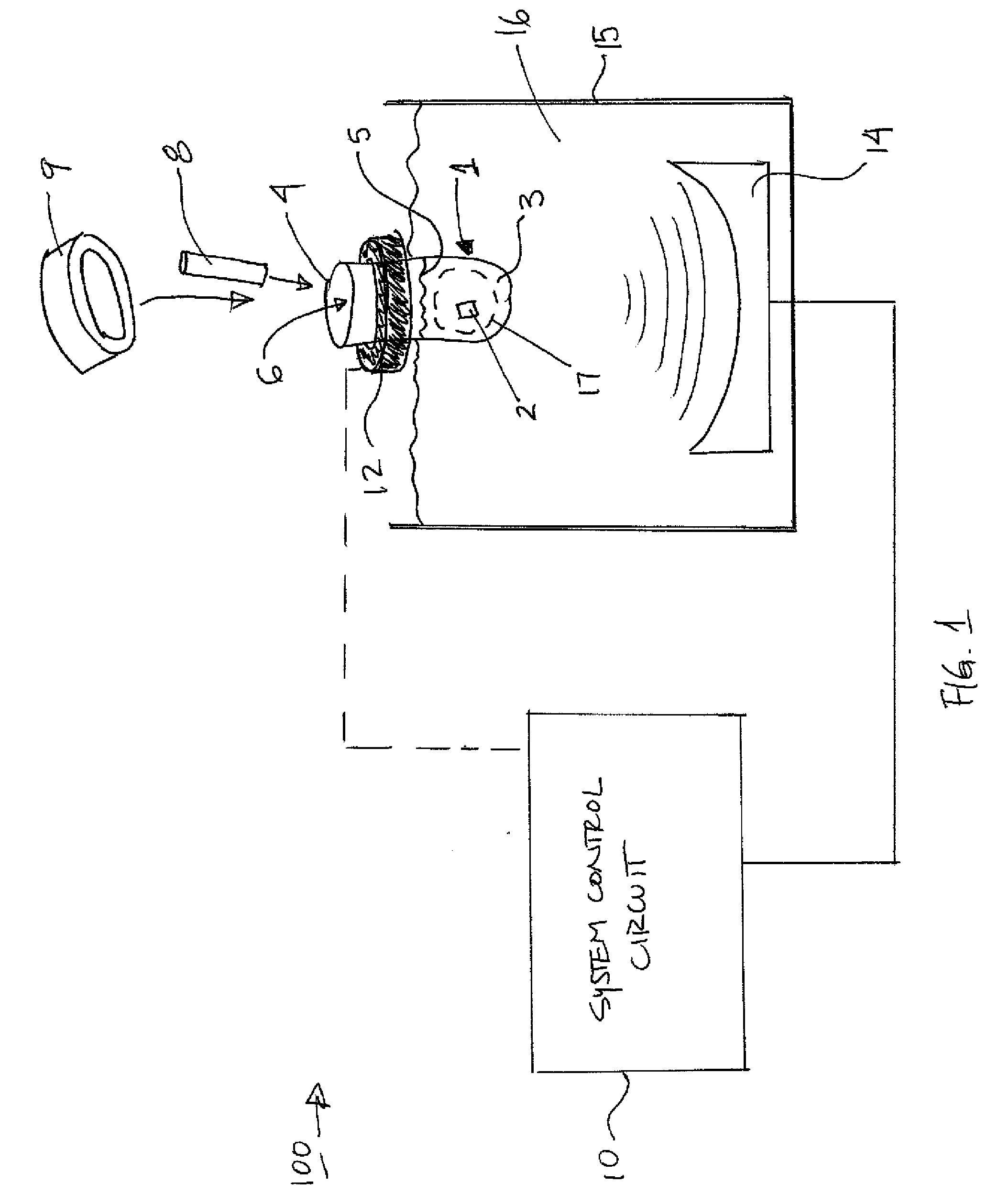

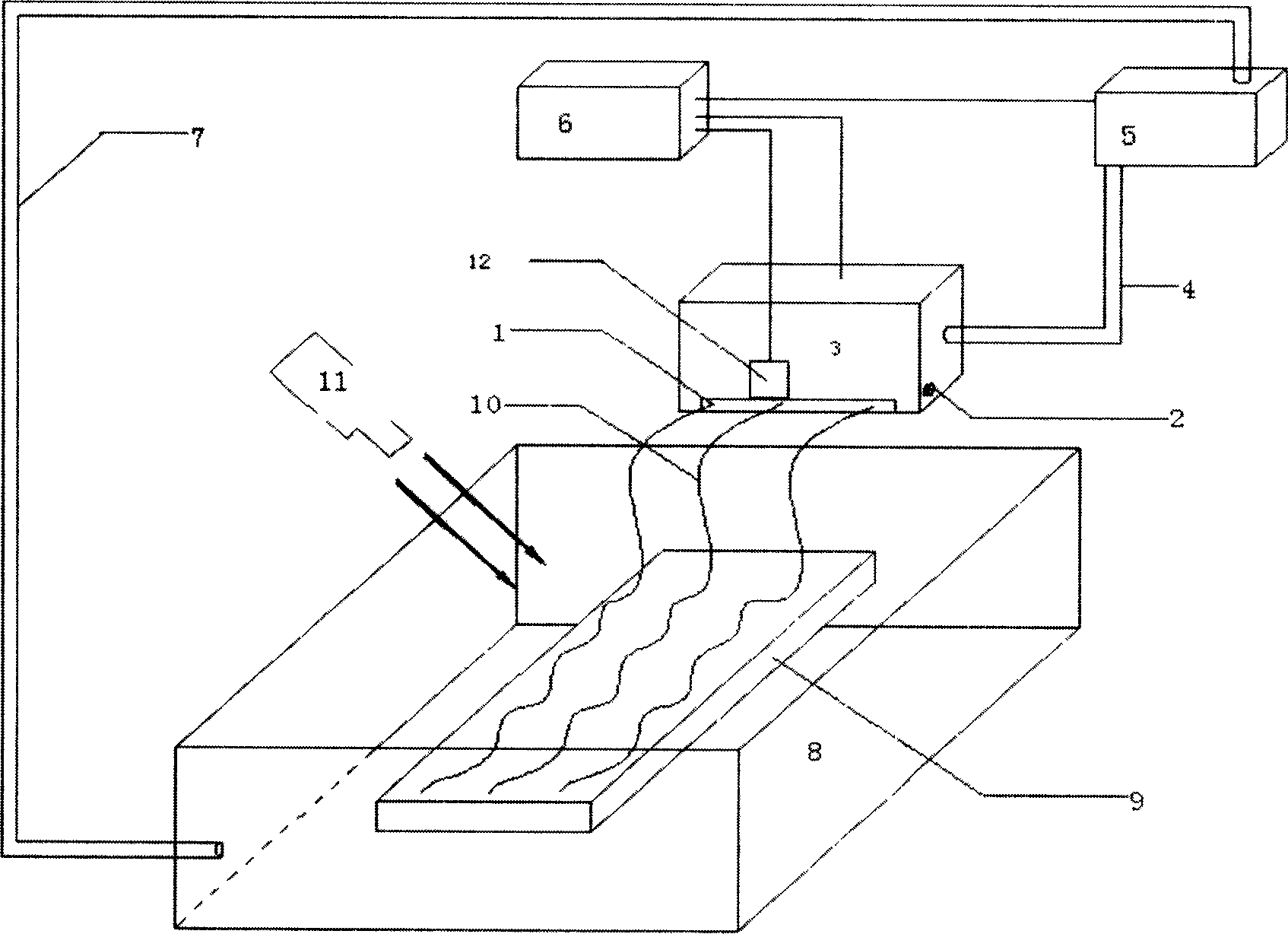

Moderate and high strength large-thickness component electromagnetic controlling narrow gap or ultra-narrow gap pulse efflux molten electrode gas-shield welding method and equipment

InactiveCN101143401AOvercoming arcingImprove crystallizationTransformers/inductances coolingWelding/cutting media/materialsElectric arcEngineering

The invention relates to a gas shielded welding method and device of a narrow gap or a super-narrow gap impulse jet current consumable electrode controlled by electromagnetic of the heavy section part with middle and high strength. The invention uses a magnetic coil (3) to provide excitation current processed by an excitation source, which can generate an extra magnetic field. Under the conditions of narrow gap or super-narrow gap, high feed rate, fused drop spray transfer and impulse welding current, the process of the gas shielded welding of the rotating jet current consumable electrode with high-melting frequency pulse that is controlled by the electromagnetic for the heavy section part with middle and high strength can be realized. The device of the invention comprises the excitation source, excitation equipment, auxiliary equipment and a water cooling system. The excitation equipment is the magnetic coil (3) with or without a conducting core (5). The excitation equipment is fixed on a welding burner (6), which is positioned above a work piece (9). The excitation current provided by the excitation source (10) produces stationary or time-varying electromagnetic mixing magnetic field that has the combination control over the processes of arc welding, wire burn-off, drop transfer, melting bath flow and welding line coagulation, which finally forms the welding line of good quality.

Owner:CHONGQING UNIV

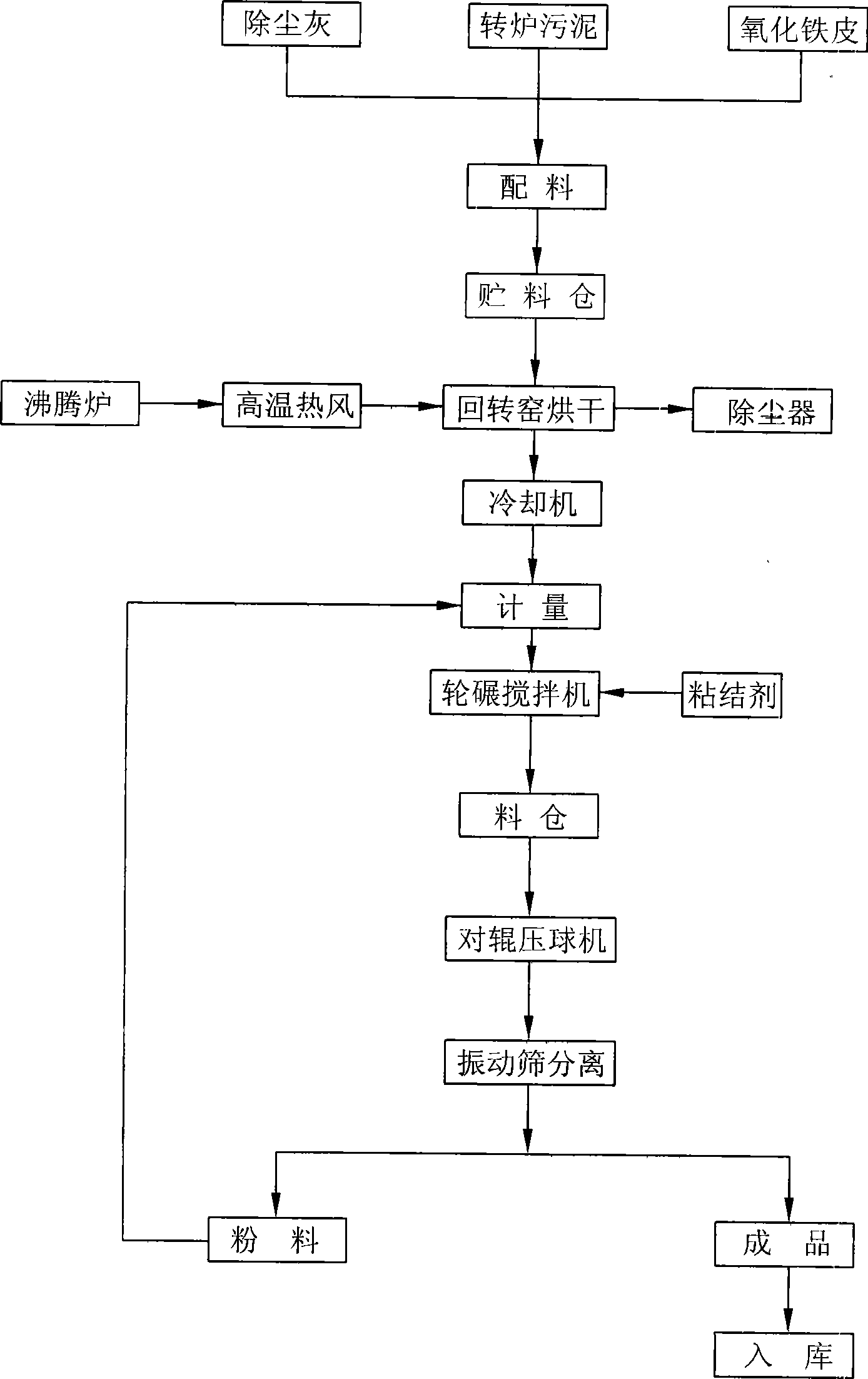

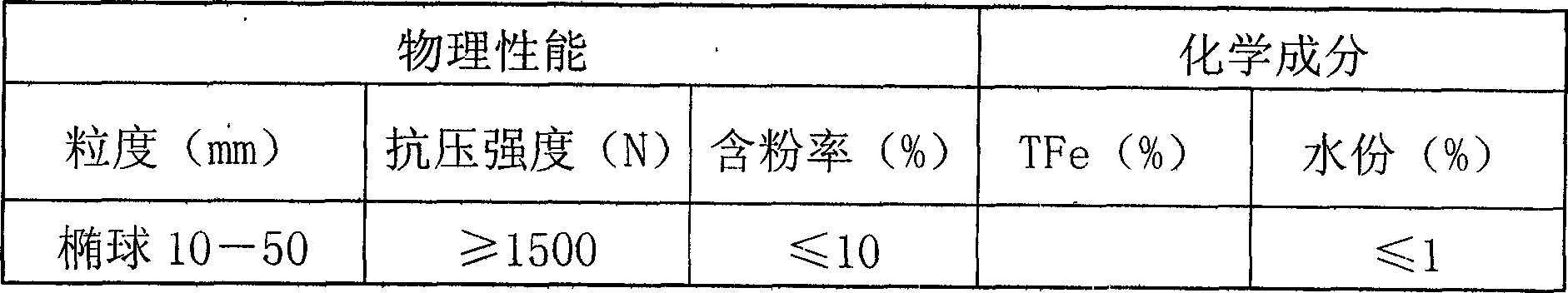

Method for utilizing iron containing metallurgical dust

The invention relates to a method for utilizing iron containing metallurgical dust, which comprises that: steel-making sludge, metallurgical dust-removing powder and iron scale are mixed; the mixed raw materials are sent into a rotary kiln and dried, and the drying temperature is determined according to moisture content of the raw materials and controlled to be between 300 and 500 DEG C; the dried materials are cooled by a cooler, the cooled materials are added with 5 to 10 percent of caking agent by weight, and the material and the caking agent are fully stirred evenly by a wheel-rolling mixer; and finally, the mixture is pressed into cooled agglomerated pellet products by a twin-roller machine, the pressure of the twin-roller machine is more than or equal to 500 Kg / cm<2>, and the cooled agglomerated pellet products are prepared into finished products after separation by a vibration sieve. The method has the advantages of low production energy consumption, high product strength, low moisture content and good quality, and can realize full effective utilization of resources; and the finished products of cooled agglomerated pellets can be directly used as a cooling agent and a slag former in steel making, can improve smelting effect and achieve functions of cooling and slag forming, and can be also used for blast furnace process.

Owner:SHAOGUAN QUJIANG SHENGDA EQUIP & MATERIALS

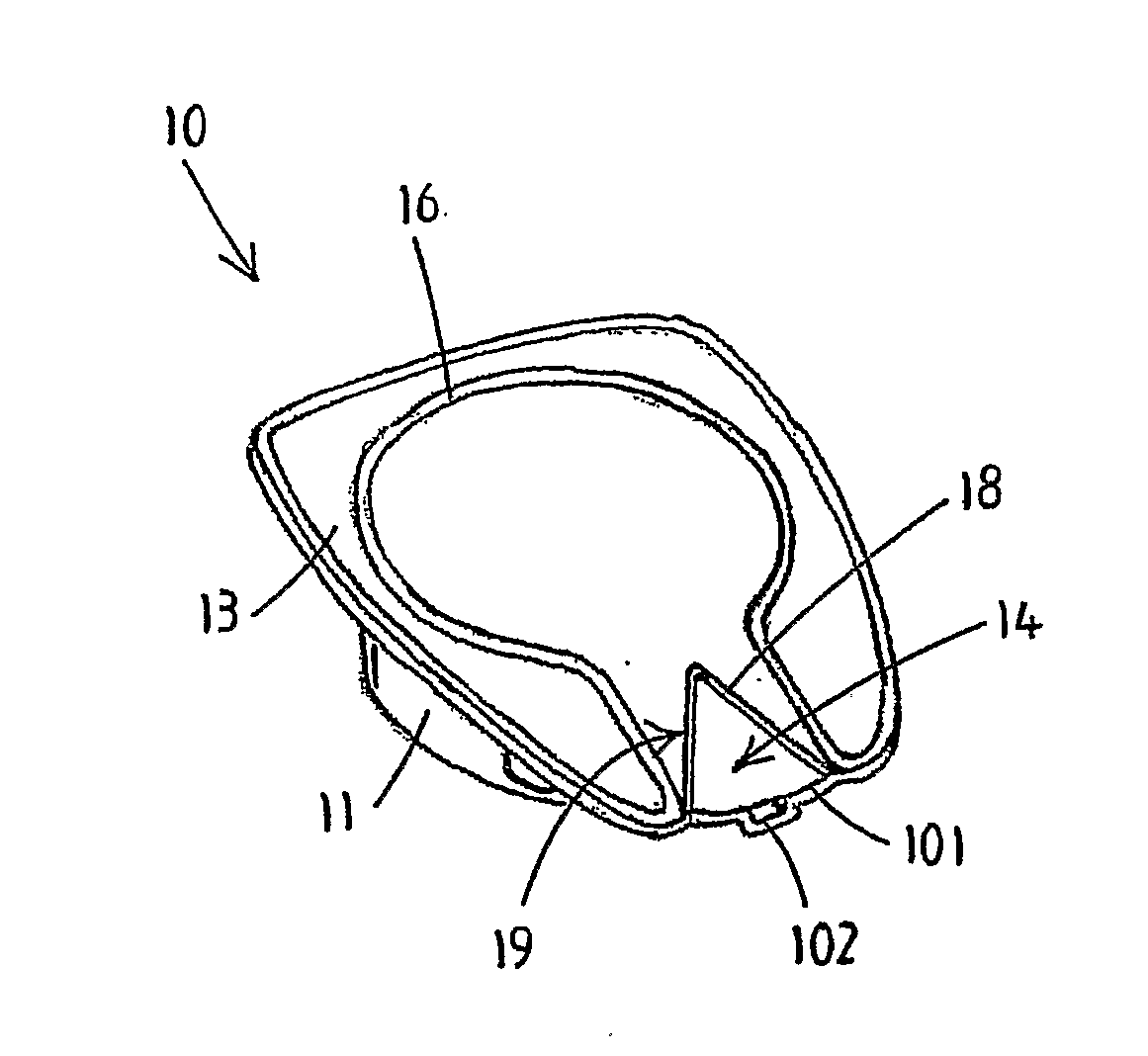

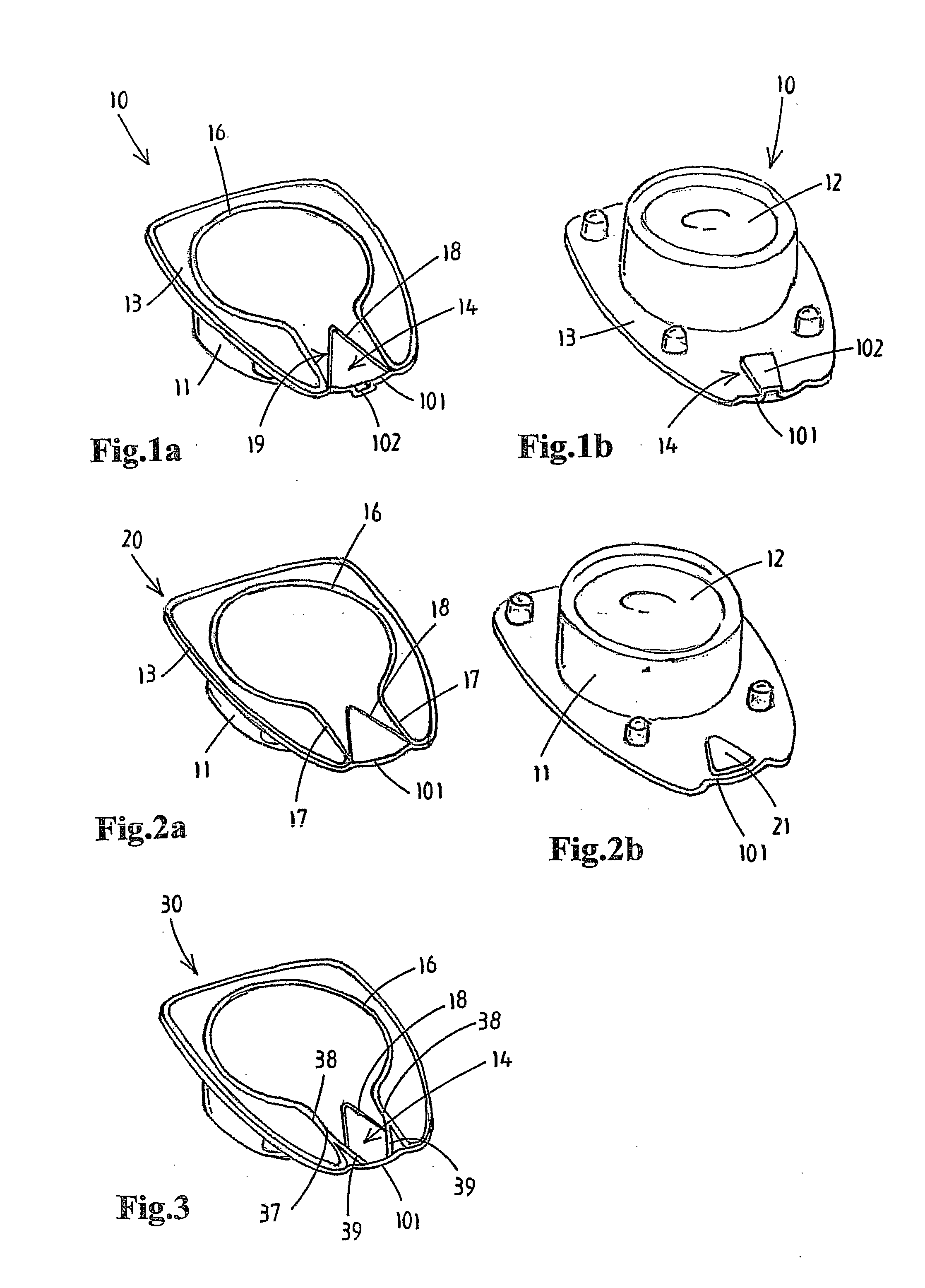

Container for dispensing a substance

InactiveUS20120241455A1Solve the lack of spaceSpoiling of the dispensing apparatus is preventedOpening closed containersBottle/container closureEngineeringMechanical engineering

Owner:MDS GLOBAL HLDG

Wire electrode with improved slag properties

ActiveUS20060186103A1Easy to shapeIncrease and decrease viscosityWelding/cutting media/materialsSoldering mediaIndiumMolten slag

A metal core electrode used to form weld deposits having improved slag forming properties with respect to reduced accumulation of slag in toes of the weld bead. The metal cored electrode includes a metal rod and a fill composition. The electrode includes a slag-modifying additive that contains metallic indium and / or one or more indium compounds.

Owner:LINCOLN GLOBAL INC

High-strength and high-tenacity gas shielded welding wire

ActiveCN101992365AThe smelting process is stableEasy to implementWelding/cutting media/materialsSoldering mediaManganeseMixed gas

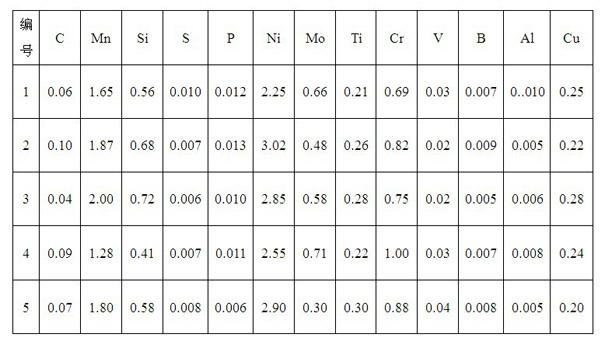

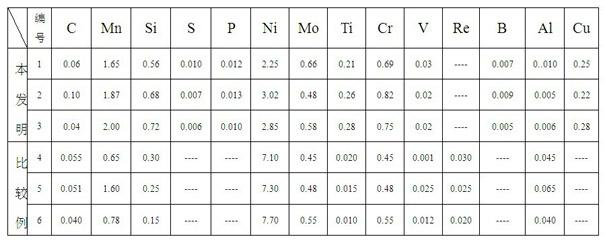

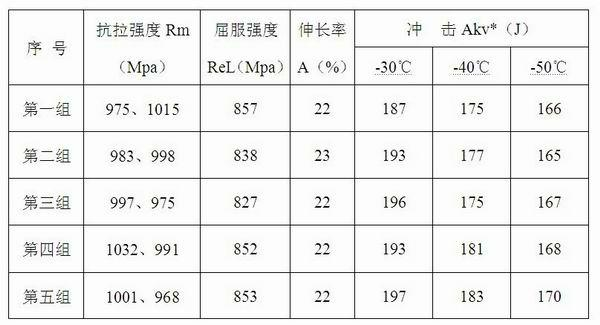

The invention discloses a high-strength and high-tenacity gas shielded welding wire. The welding wire comprises the following chemical composition in percentage by mass: 0.02 to 0.12 percent of carbon (C), 1.20 to 2.10 percent of manganese (Mn), 0.20 to 1.00 percent of silicon (Si), less than or equal to 0.010 percent of sulfur (S), less than or equal to 0.015 percent of phosphorus (P), 2.00 to 3.50 percent of nickel (Ni), 0.20 to 0.80 percent of molybdenum (Mo), 0.20 to 0.30 percent of titanium (Ti), 0.60 to 1.20 percent of chromium (Cr), less than or equal to 0.05 percent of vanadium (V), 0.005 to 0.010 percent of boron (B), less than or equal to 0.015 percent of aluminum (Al), less than or equal to 0.35 percent of copper (Cu) and the balance of iron (Fe). The welding wire is used for welding steels of a strength grade of between 850 and 950MPa; and under the protection of a mixed gas (80 percent of argon (Ar) and 20 percent of carbon dioxide (CO2)), the weld metal tensile strength of the welding wire is more than or equal to 850MPa, the yield strength is more than or equal to 720MPa, the elongation is more than or equal to 22 percent, and the low-temperature impact toughness Akv is more than or equal to 181J at the temperature of -30 DEG C, or more than or equal to 175J at the temperature of -40 DEG C, or more than or equal to 162J at the temperature of -50 DEG C.

Owner:CHENGDU XINDAYANG WELDING MATERIAL

Flux cored electrode with fluorine

InactiveUS20060219685A1Quality improvementReduce the amount requiredPropellersToothed gearingsSlagCompounds of fluorine

Owner:LINCOLN GLOBAL INC

Method for producing cold-rolled steel strips

ActiveCN102416404AImprove pull performanceGood welding performanceMetal rolling arrangementsSlagLight treatment

The invention discloses a method for producing cold-rolled steel strips. The method comprises the following steps of: performing krypton (KR) desulfurization treatment, converter dephosphorization-less slag decarburization and relative humidity (RH) light treatment on molten iron, and performing continuous casting to obtain a high-purity plate blank; heating the plate blank, performing rough rolling and precision rolling to obtain a hot-rolled plate, cooling the hot-rolled plate and coiling the hot-rolled plate into a hot-rolled coil; and performing cold rolling, annealing and flattening on the hot-rolled coil, and coiling the hot-rolled coil into a finished product. By the method for producing the cold-rolled steel strips, the cold-rolled steel strips which have high drawing property and good welding performance and can be used for flux-cored wires can be produced, the production requirement of the flux-cored wires is met, splash in the welding process is reduced, seams with good welding quality are obtained, and the automation level of welding is improved.

Owner:SHOUGANG CORPORATION

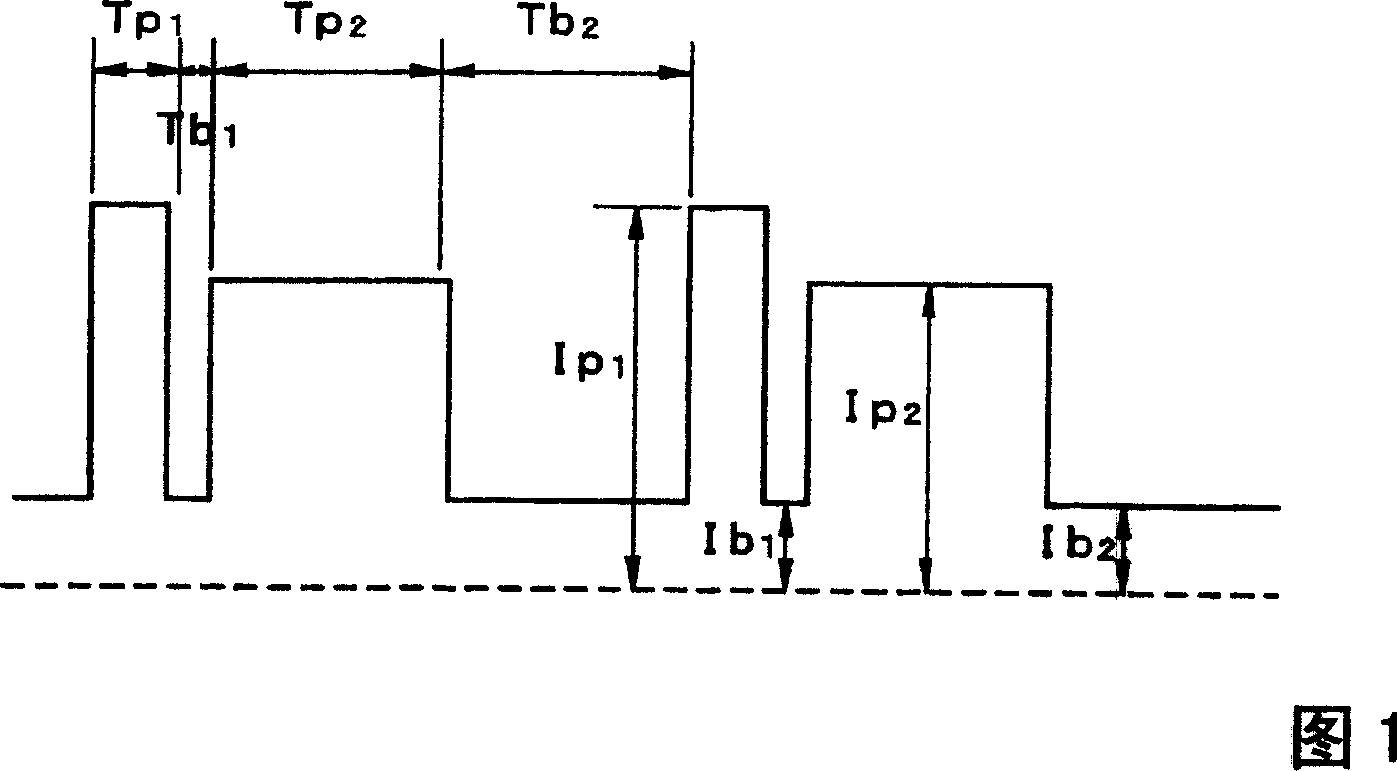

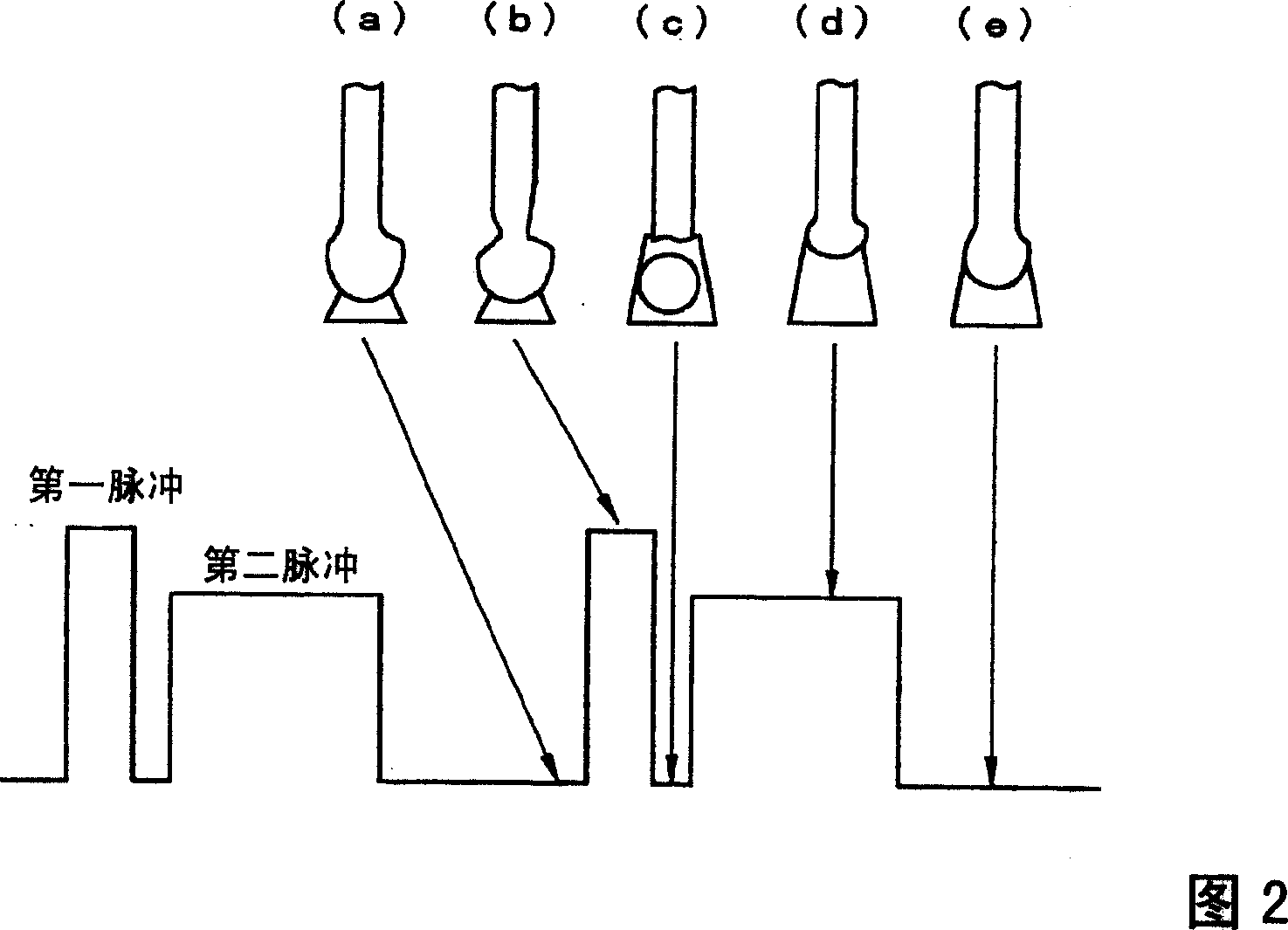

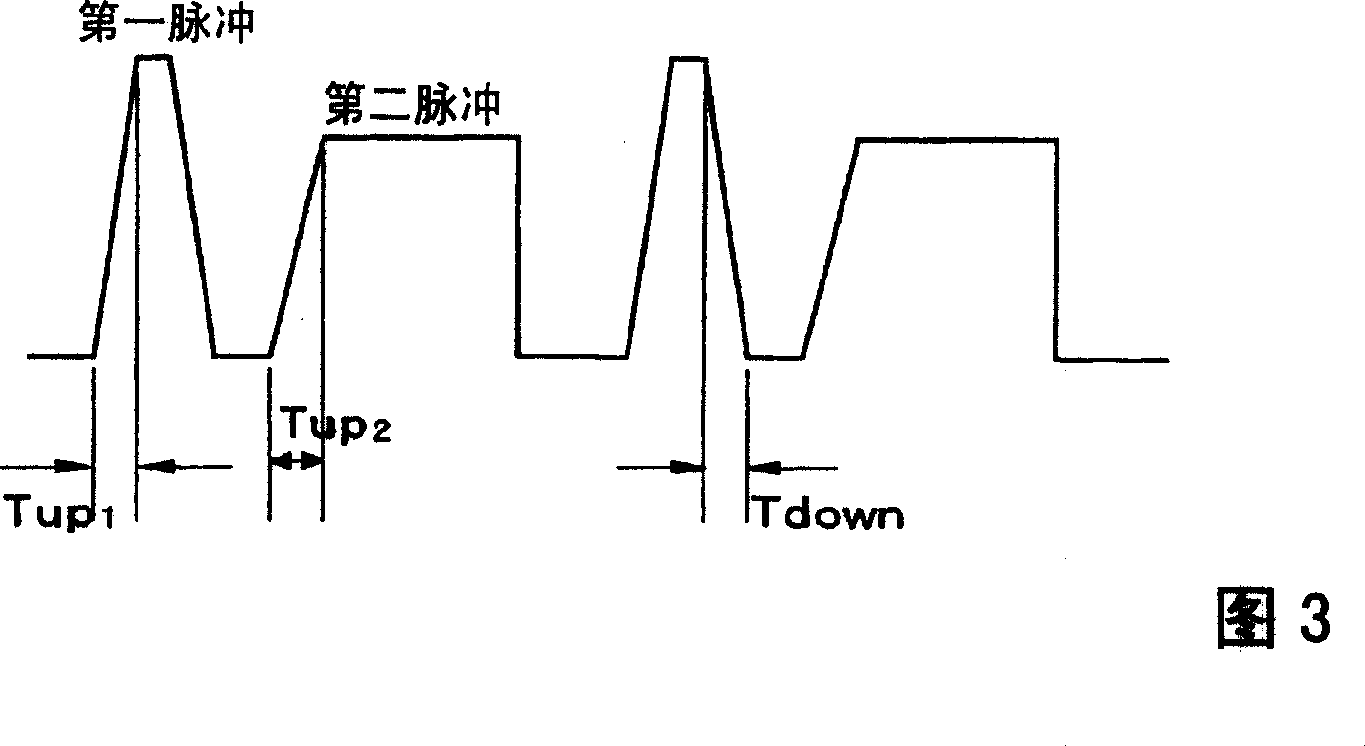

Pulsed arc welding method

ActiveCN101032778AInevitable formationReduce splashArc welding apparatusWelding/cutting media/materialsGeneration rateShielding gas

Disclosed is a pulsed arc welding method using a pulse current of alternately repeating first and second pulses as a weld current, wherein the first pulse and the second pulse have a pulse waveform of a different pulse peak current level and a different pulse width, respectively, and the following conditions are satisfied: peak current of the first pulse (Ip1)=300 to 700A; peak period (Tp1)=0.3 to 5.0 ms; base current Ib1=30 to 200A, base period (Tb1)=0.3 to 10 ms; peak current of the second pulse (Ip2)=200 to 600A; peak period (Tp2)=1.0 to 15 ms; base current (Ib2)=30 to 200A; and base period (Tb2)=3.0 to 20 ms. In this manner, the consumable electrode arc welding using carbon dioxide gas alone or a mixed gas made mainly of carbon dioxide gas as a shield gas can benefit from stabilized welding arc, improved regularity of droplet transfer, and significantly reduced generation rates of spatters and fumes.

Owner:KOBE STEEL LTD

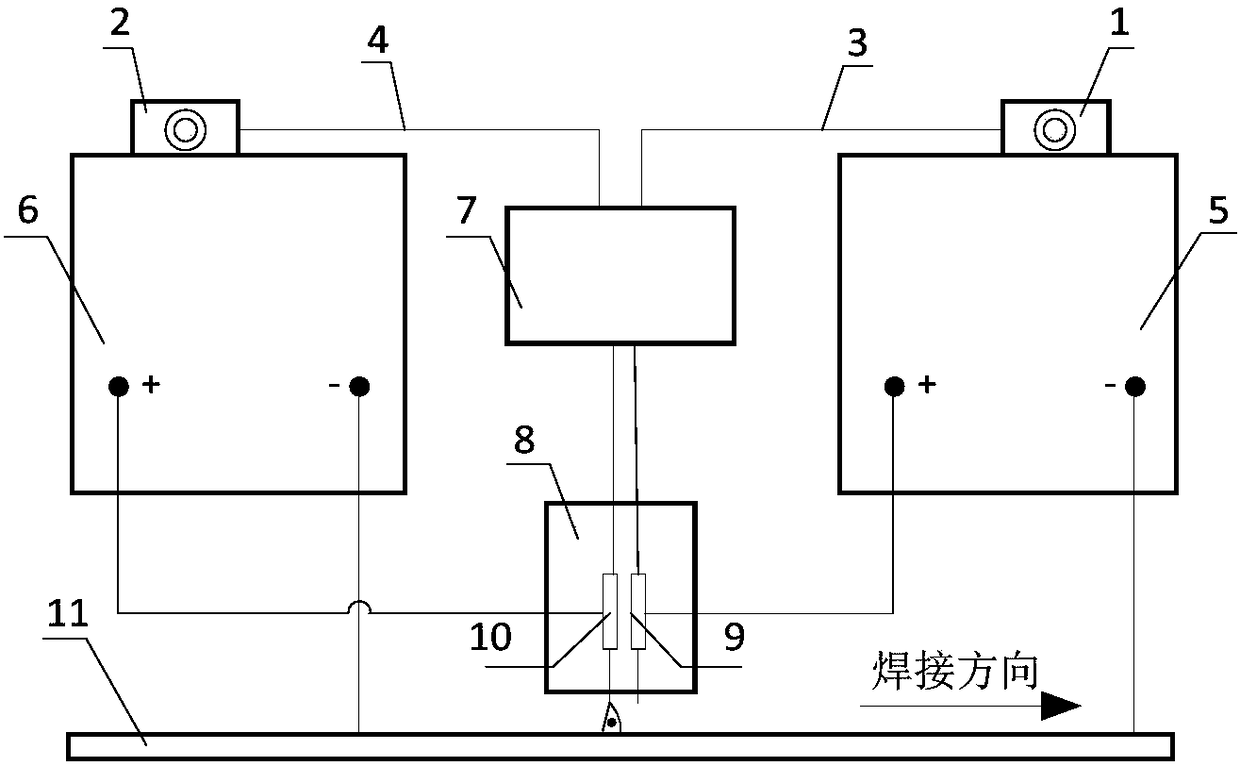

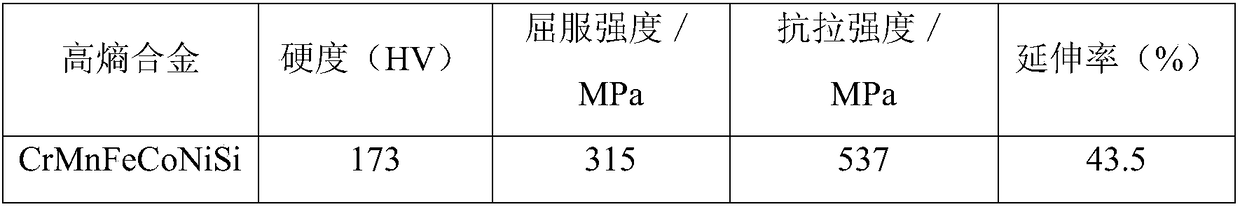

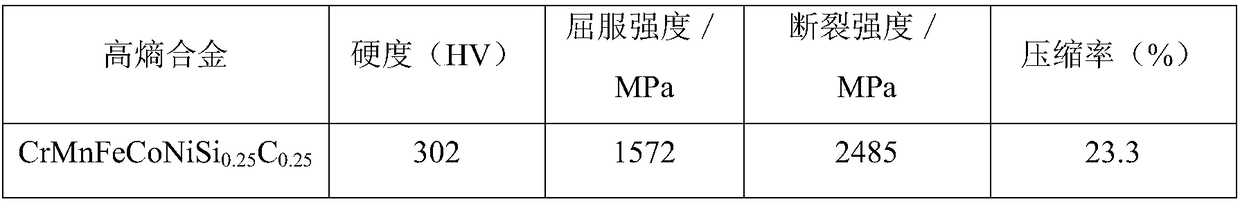

Double-arc fuse collaborative additive manufacturing method of high-entropy alloy

ActiveCN108326427AEasy to adjust ingredientsEasy to adjust grain sizeAdditive manufacturing apparatusLaser beam welding apparatusManufacturing technologyHigh entropy alloys

The invention relates to the technical field of high-entropy alloys, and specifically discloses a double-arc fuse collaborative additive manufacturing method of a high-entropy alloy. The method is characterized in that raw materials are supplied based on a formula of the high-entropy alloy, wherein the raw materials include an alloy strip and flux core powder; the alloy strip and the flux core powder are prepared into a flux cored welding wire; and then a double-arc fuse collaborative additive manufacturing method is carried out to obtain a part or a blocky alloy as requirement. The method isstable in processes, high in cladding efficiency, high in preparation efficiency, wide in heat input adjusting range, low in cost, convenient to adjust the components of the alloy and the size of crystal grains; in addition, the method is applicable to manufacturing of massive high-entropy alloys as well as precise high-entropy alloy parts.

Owner:SHIJIAZHUANG TIEDAO UNIV

Converting process for converter low-silicon molten iron

ActiveCN101117651AOxygen blowing time shortenedGood foamingManufacturing convertersProcess efficiency improvementMelting tankSlag

The present invention provides a siliconeisen iron melt blowing and refining method in a converter, and the method includes the steps as follows: (1) waste steel and iron melt are loaded into the converter, and oxygen blowing and steel making begin, the oxygen flux is 900Nm3 / min to 1050Nm3 / min, the height that the oxygen gun spraying head departs the metal liquid surface in the melt pond is 1.8-3.0m; (2) a first batch of slag charge is added after oxygen is blown in the first batch of the slag charge is 60-80 percent of the total slag charge, and the rest slag charge can be charged in 2-3 batches after the first batch of the slag charge is melted. The consumption of the slag charge: the lime 18-28kg / t steel, the light calcined dolomite 15-25kg / t steel, the ironstone 5-10kg / t steel, the carbonaceous heat generating agent 0-7kg / t steel, the compound slag 0-6kg / t steel; and the rest process are same as the prior art. The oxygen blowing duration of the present invention decreases 1.8min per furnace averagely, and the problem that the heat quantity is short and the slag forming is difficult can be solved simultaneously, and the present invention can make the converter steel-making to produce efficiently.

Owner:BAOSHAN IRON & STEEL CO LTD +1

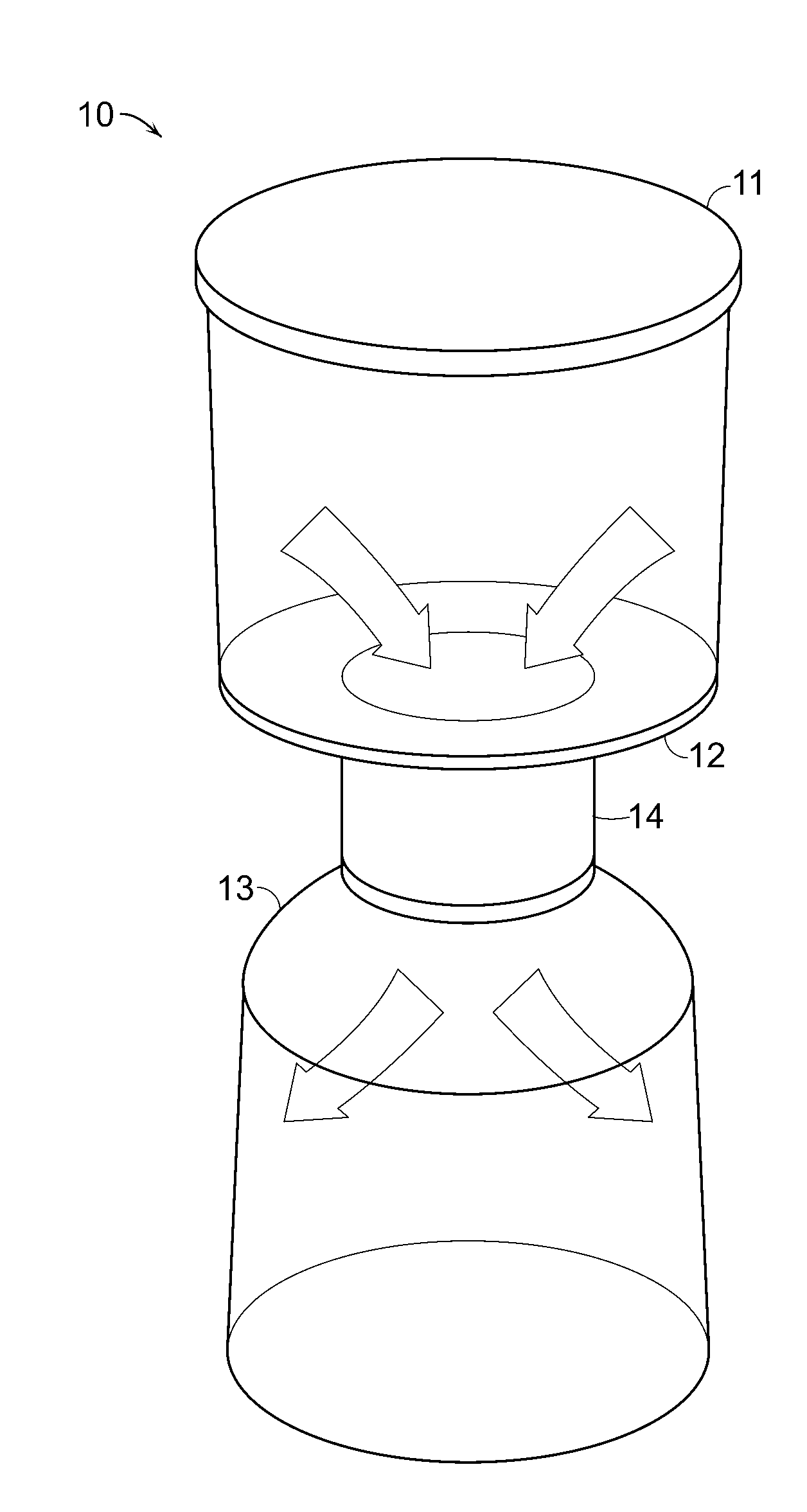

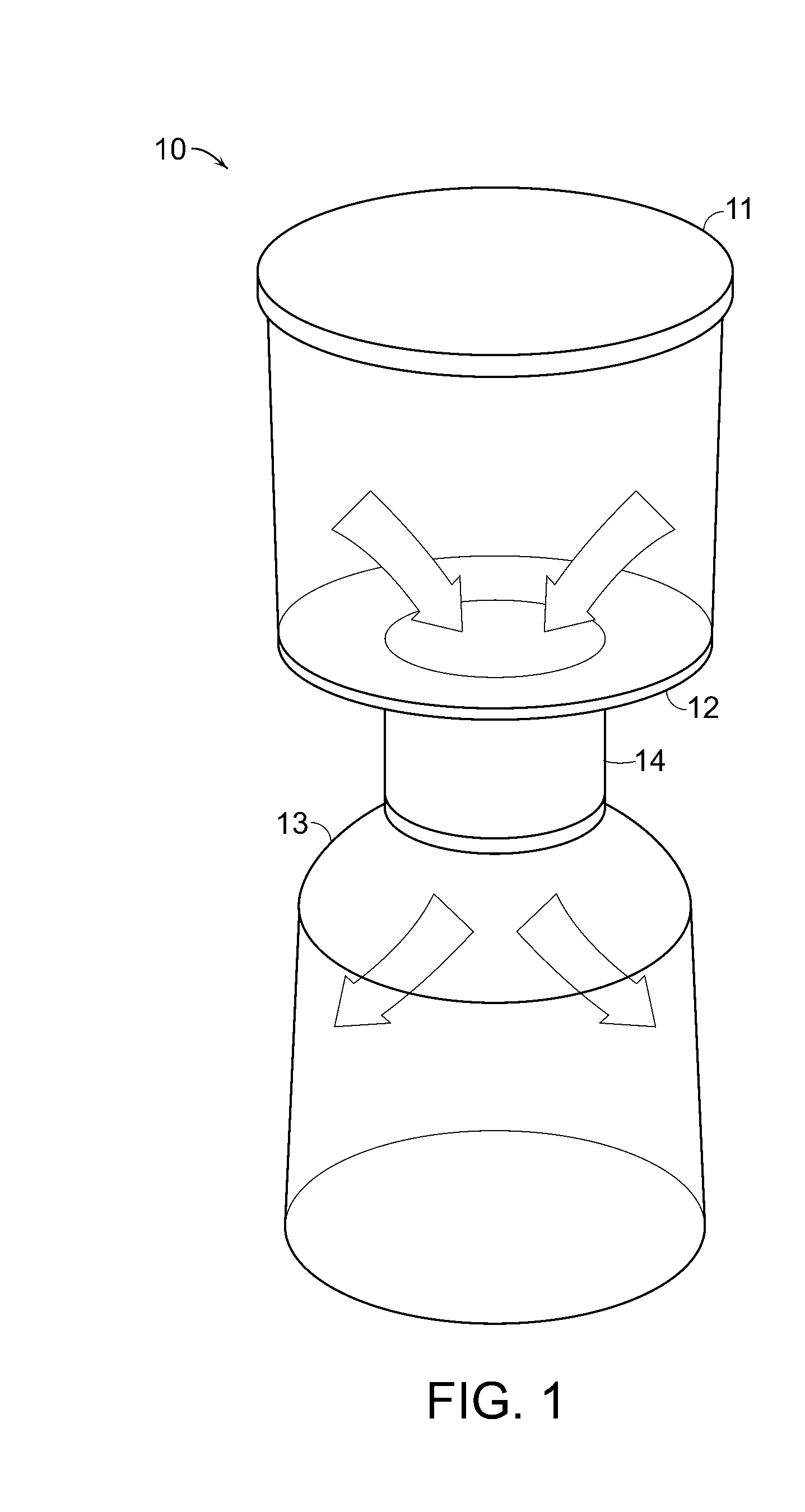

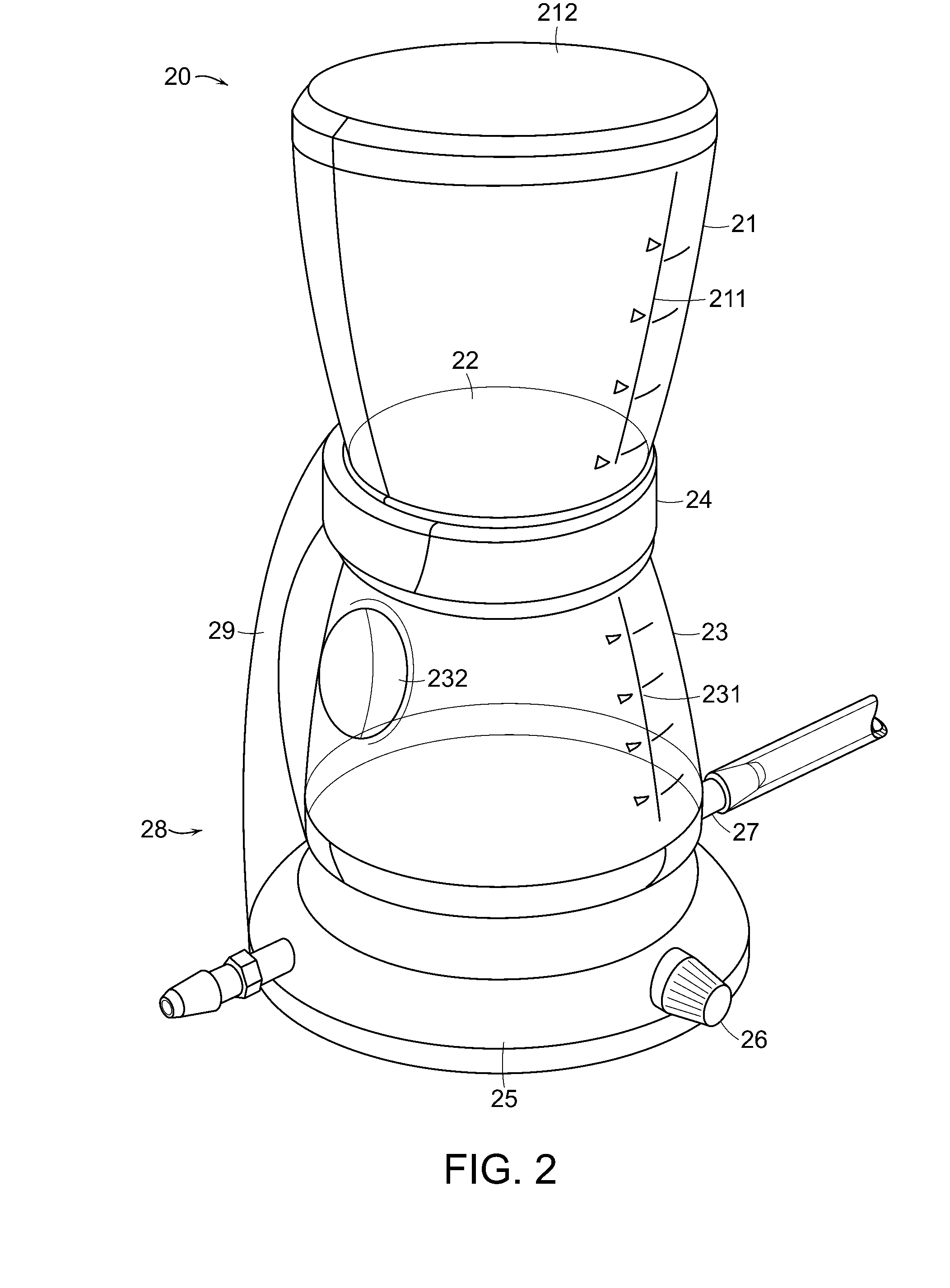

Methods and Apparatus for Foam Control in a Vacuum Filtration System

InactiveUS20080290040A1Reduces splashing and foamingReduce foamingSamplingLaboratory glasswaresFiltrationFilter system

A flow diverter, vacuum control and tilting of the liquid filtering system are used alternatively or in conjunction to reduce foam production in a filtered liquid sample. A liquid filtering system includes an upper sample reservoir, a filter and a lower storage bottle. A vacuum is applied below the sample filter to draw sample liquid through the sample filter into the storage bottle. A flow diverter may be used to direct flow of the filtered liquid sample onto a sidewall of the storage bottle or guide flow to a bottom of the storage bottle. The vacuum may be regulated to reduce foaming. The liquid filtering system may be tilted to direct fluid to the sidewall of the lower storage bottle and reduce foaming.

Owner:FOXX LIFE SCI

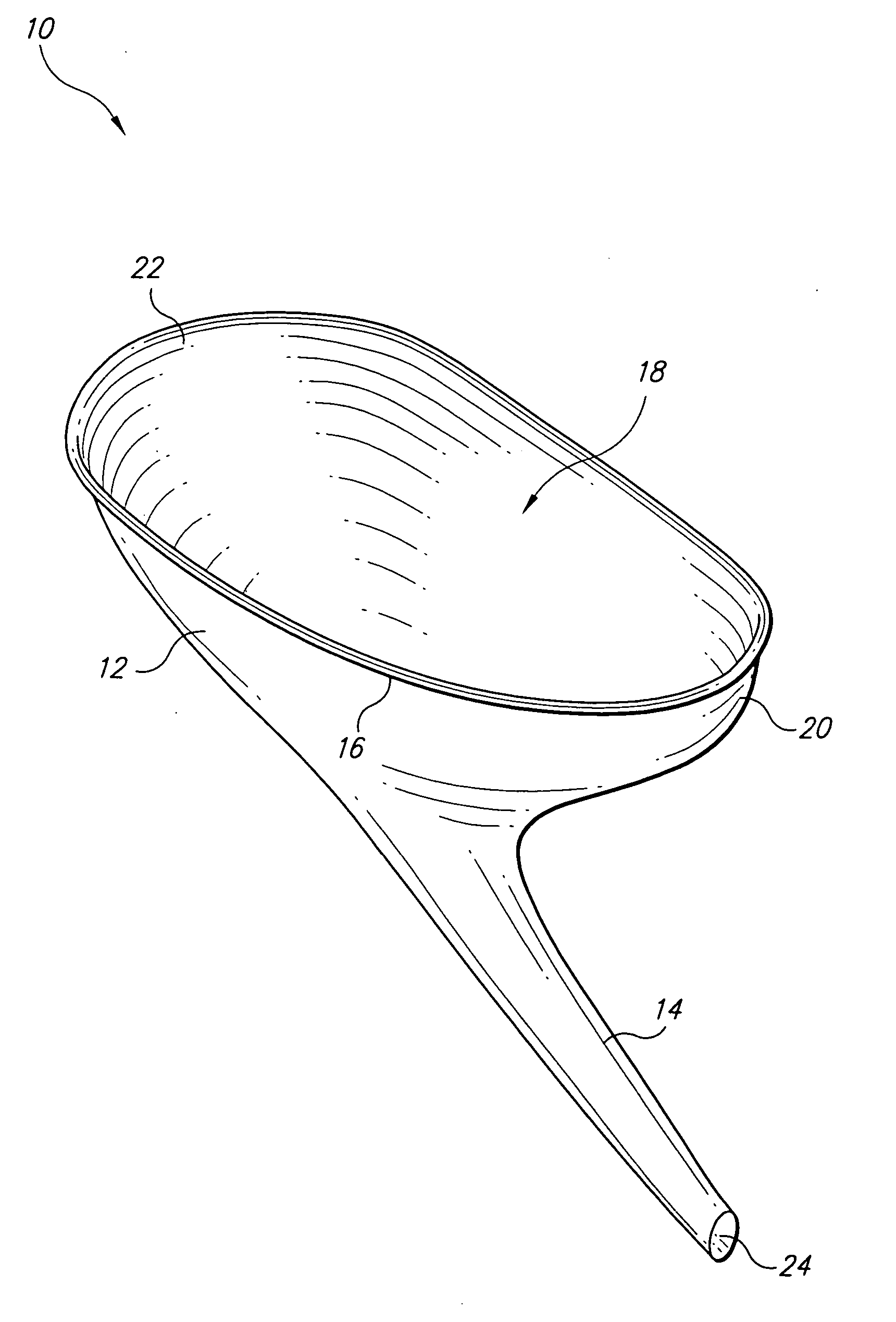

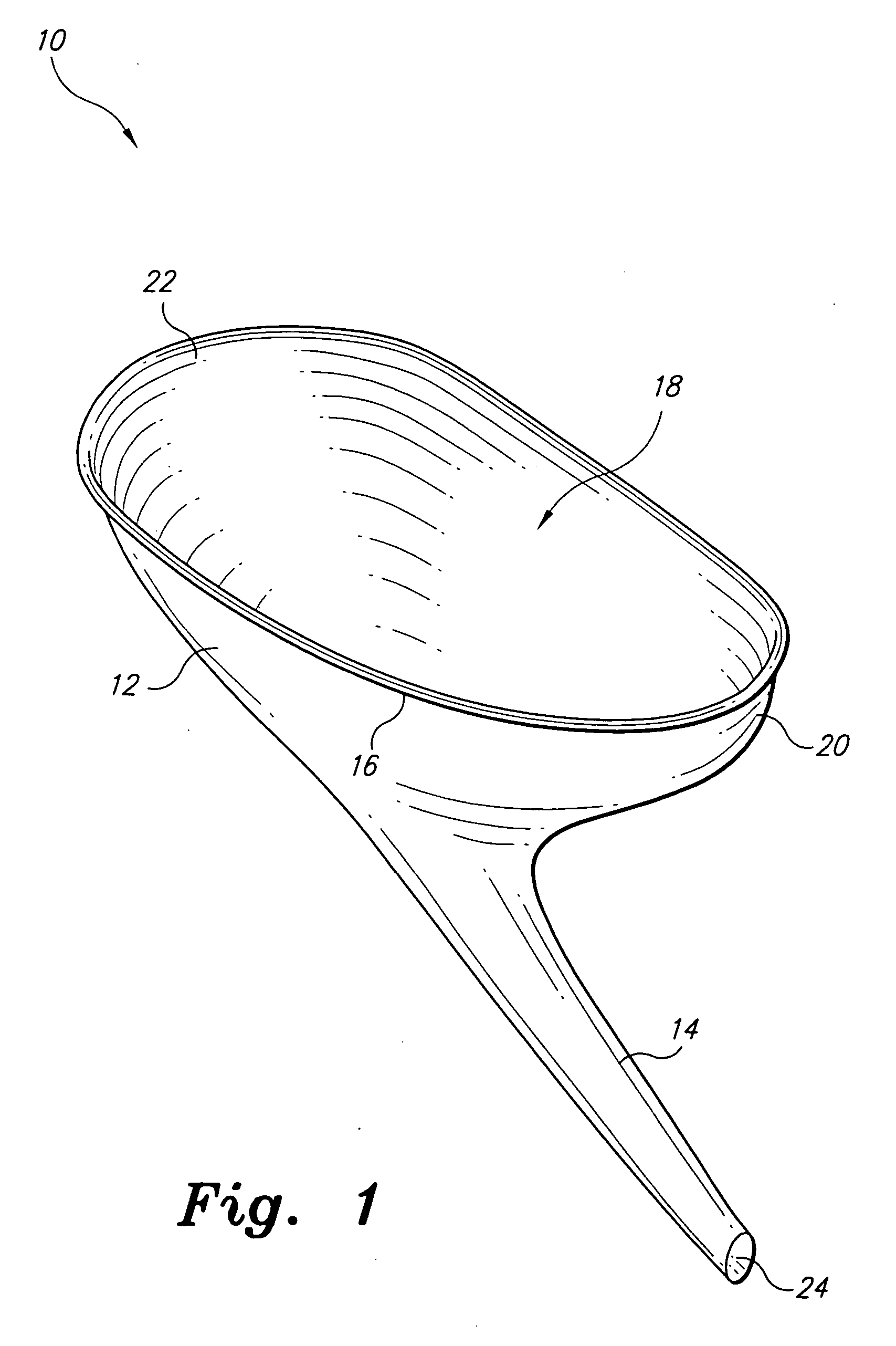

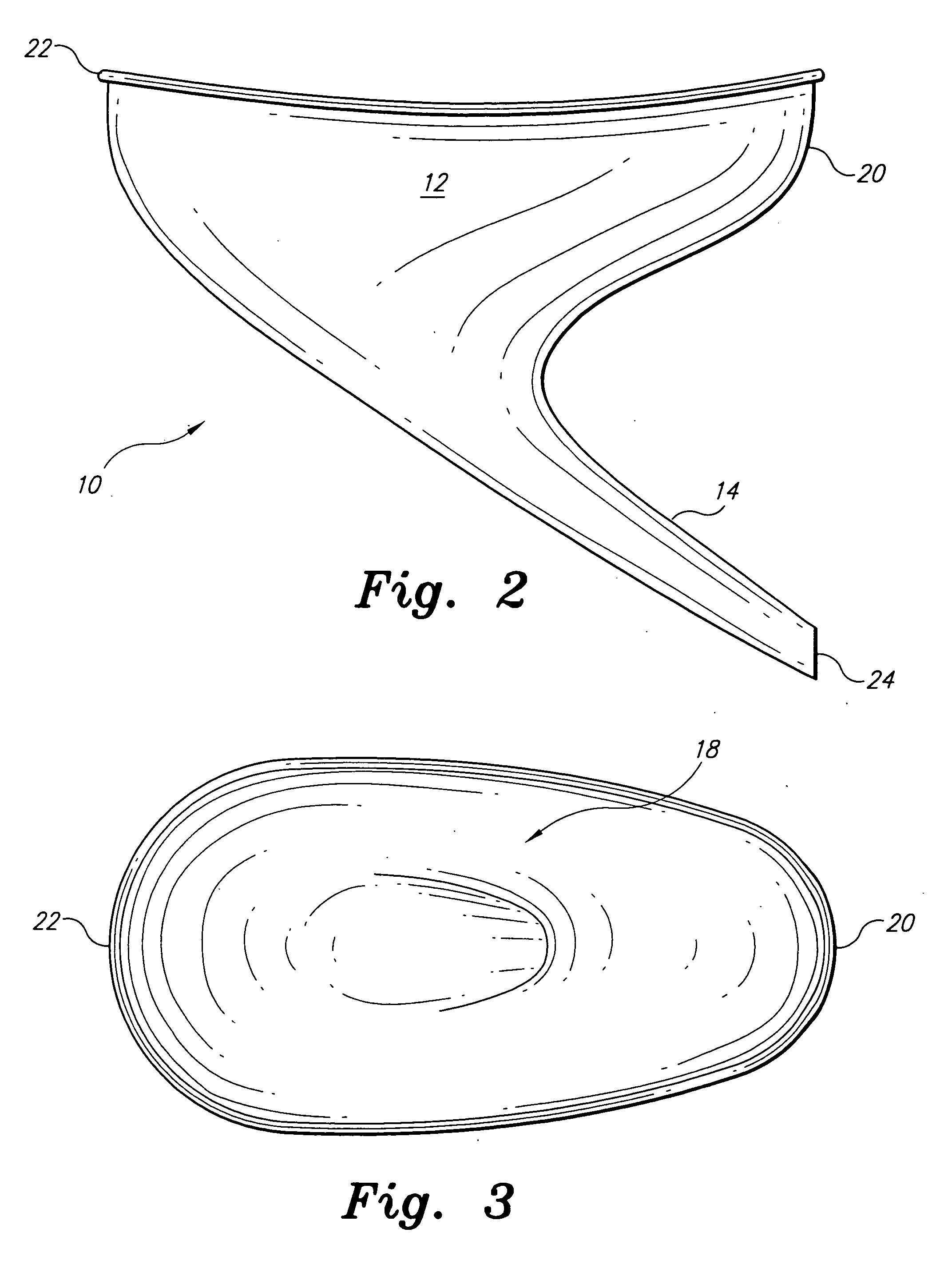

Disposable funnel for urine samples

InactiveUS20070006368A1Easy to collectExpand coverageBathroom accessoriesVaccination/ovulation diagnosticsUpper lipUrine production

The disposable urine funnel is a urinary aid device that is placed upon a vaginal opening when the user is seated in order to guide urine into a urine sample cup. The disposable urine funnel is a bowl-shaped container that may be integrally connected to a tube, or the tube may be omitted entirely. The container has an upper lip that defines a mouth of the container. The mouth of the container has a first end and a second end, the first end being narrower from one side of the mouth to the other than the second end. The tube is optionally attached to the container and extends angularly downward from the container and in the direction of the first end of the mouth of the funnel, terminating in a discharge opening from which urine passes.

Owner:KEY LORI A

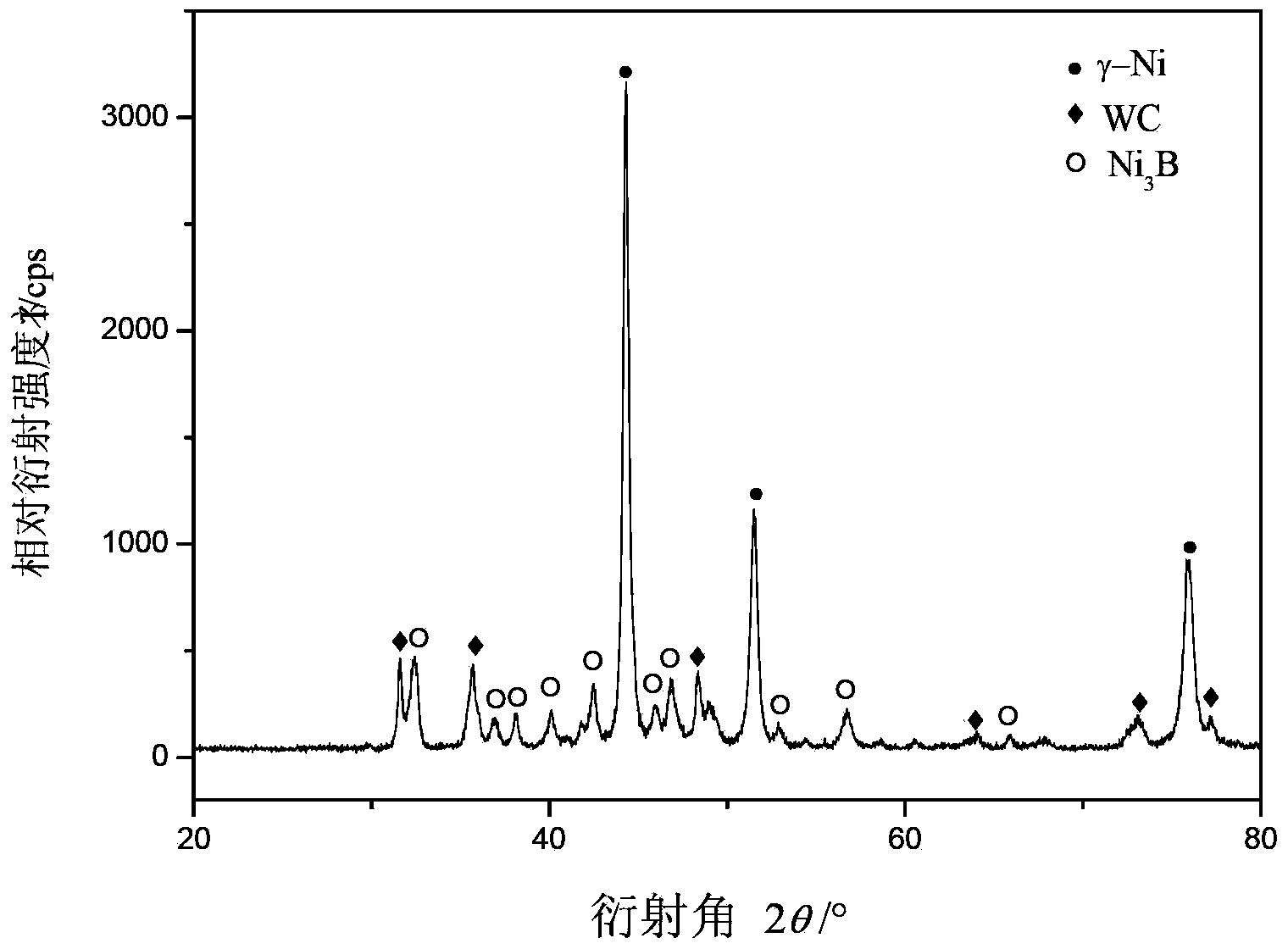

WC particle-reinforced Ni-based MIG hardfacing flux-cored wire

InactiveCN103406689AImprove toughnessGood "supportArc welding apparatusWelding/cutting media/materialsManganeseBoron carbide

The invention discloses a WC particle-reinforced Ni-based MIG hardfacing flux-cored wire and belongs to surface-modified cored wires used in the technical field of engineering application. The flux-cored wire is composed of a nickel strap wrapper and core portion powder. Core ingredients comprise, by mass, 30%-75% of tungsten carbide, 4%-17% of silicon carbide, 3%-15% of boron carbide, 1%-5% of electrolytic manganese powder, 1%-12% of sodium fluoride and the balance of nickel powder. Ingredients of obtained deposited metal comprise 11.1%-30% of tungsten carbide, 1.3%-5.6% of silicon, 1%-5% of boron, 0.3%-1.48% of manganese and the balance of nickel. A surfacing layer prepared by flux-cored wires is high in hardness (>45HRC), and the hardness of WC hard phases in the surfacing layer reaches 1800HV0.3. According to the WC particle-reinforced Ni-based MIG hardfacing flux-cored wire, the 'shadow protection' effect is achieved mainly through matching of added WC particles and a Ni-based substrate, and therefore wear resistance can be achieved; besides, welding performance of surfacing alloy is improved by adding the deoxidizing agents including silicon and manganese, alterative Na / F and the like.

Owner:BEIJING UNIV OF TECH

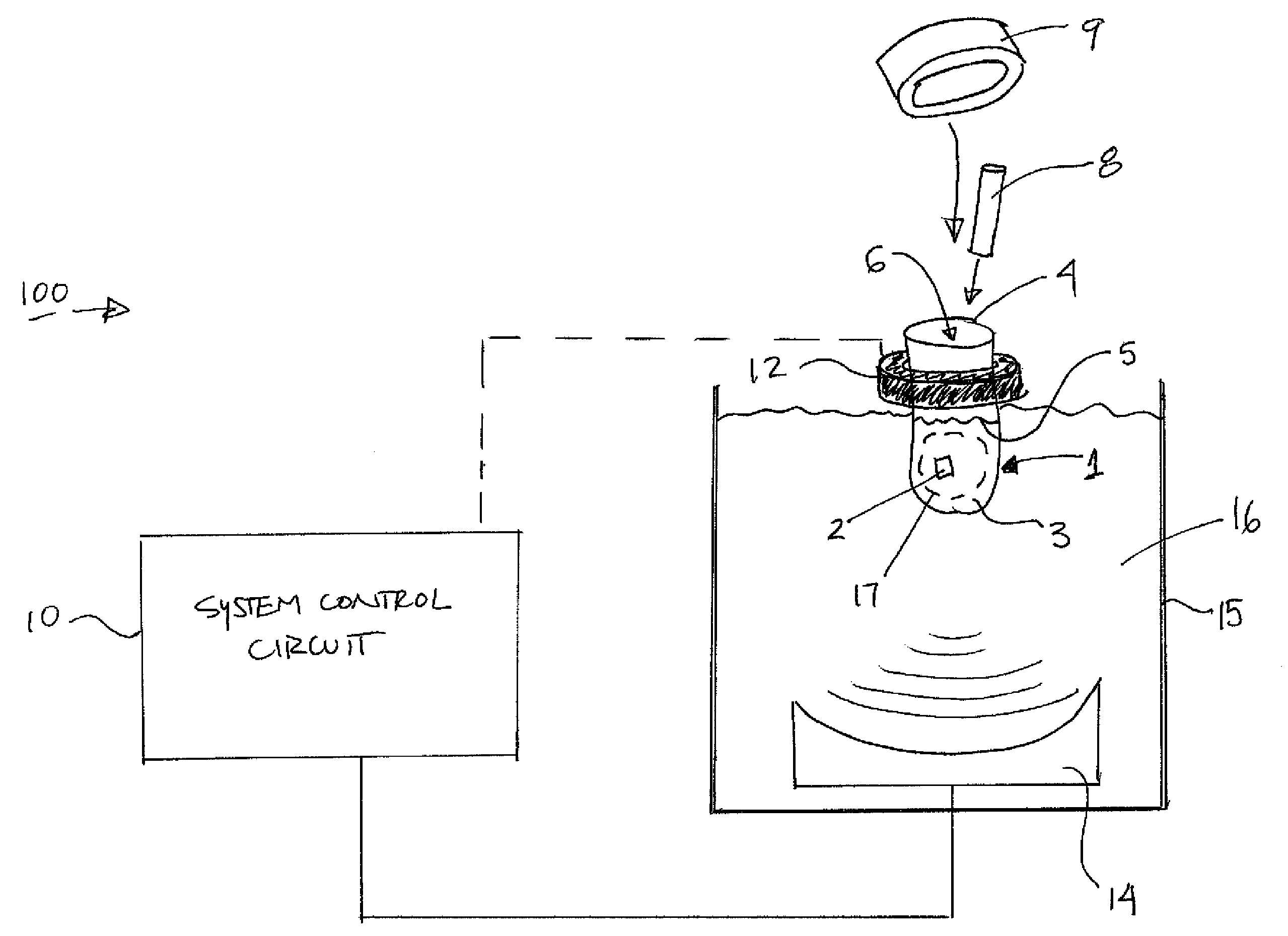

Method and apparatus for treatment enhancement in acoustic processing of samples

ActiveUS20090317884A1Reduce sound energySlow and incomplete processing of sampleBioreactor/fermenter combinationsShaking/oscillating/vibrating mixersAcoustic energyProduct gas

Method and apparatus for controlling acoustic treatment of a sample including a liquid. A processing volume in which the sample is acoustically treated may be controlled, e.g., by positioning a suitable element so as to reduce and / or eliminate a headspace at a sample / gas interface. An interaction between the acoustic energy and the sample may be controlled, e.g., by using an energy director positioned at least partially in the sample that helps to reduce splashing or other sample ejection that would otherwise occur.

Owner:COVARIS INC

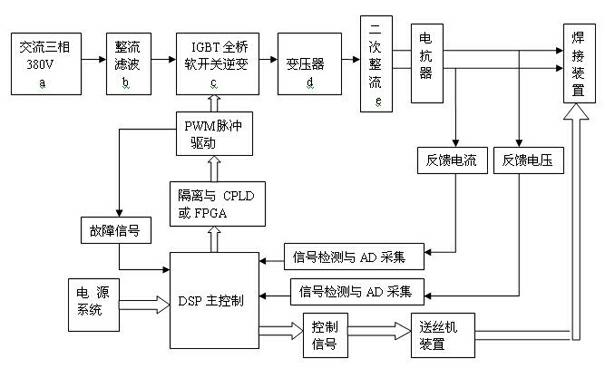

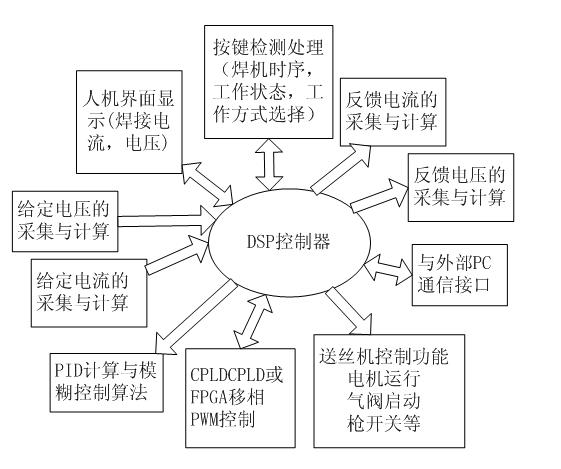

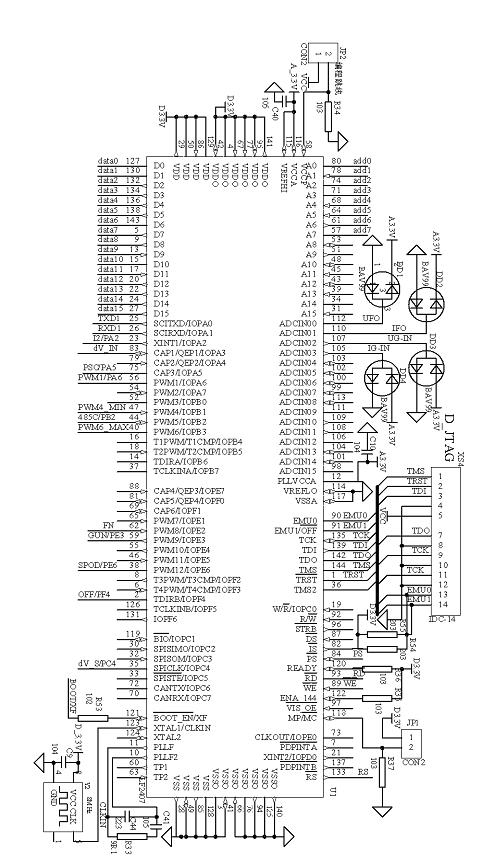

Multifunctional digitized welding machine

InactiveCN102350569ABeautiful shapeImprove dynamic response performanceArc welding apparatusFull bridgeTransformer

The invention relates to a multifunctional digitized welding machine, which comprises a full-bridge type inversion main circuit, a control circuit and a soft switch PWM (Pulse-Width Modulation) driving circuit, wherein the full-bridge type inversion main circuit is composed of an IGBT (Insulated Gate Bipolar Translator); the soft switch PWM driving circuit of a symmetric carrier is based on a CPLD (Complex Programmable Logic Device) or FPGA (Field Programmable Gate Array); the inversion main circuit comprises a rectifying filtering module, an IGBT full-bridge inversion module, a main transformer and a secondary rectifying filtering module; the control circuit comprises a DSP (Digital Signal Processor) control processor, a manual idle-dropping circuit, a regulating, detecting and sampling circuit for a feedback current and voltage signal outputted by the welding machine, a collecting and setting circuit for a feeding speed and given voltage of the welding machine, a display circuit for an interface and parameter of an external keyboard and a communication circuit connected to a PC (Personal Computer); the regulating, detecting and sampling circuit for the feedback current and voltage signal outputted by the welding machine comprises a Hall voltage sensor for detecting a feedback arc voltage outputted by the welding machine and a Hall current sensor for detecting an output current of the welding machine; and the collecting and setting circuit for the feeding speed and given voltage of the welding machine comprises a collecting circuit for a given voltage and given current, namely the feeding speed, on a panel of a feeder.

Owner:PANDA ELECTRONICS GROUP +2

Method and apparatus for supercharging water constraint layer based on laser impact technology

InactiveCN1745955AGuaranteed uniformityReduce splashLaser beam welding apparatusMicrocomputerWater flow

An apparatus based on laser impact technique for pressurizing the water restraining layer is composed of water cleaning unit, water flow controlling box, adjustable tap, following controller of tap, water recovering unit, pressure regulating knob and microcomputer controller. Its method includes such steps as cleaning water, controlling the speed and flow of water stream for preventing turbulent flow and ensuring high thickness uniformity of water layer and pressurizing effect, and recovering water for reuse.

Owner:JIANGSU UNIV

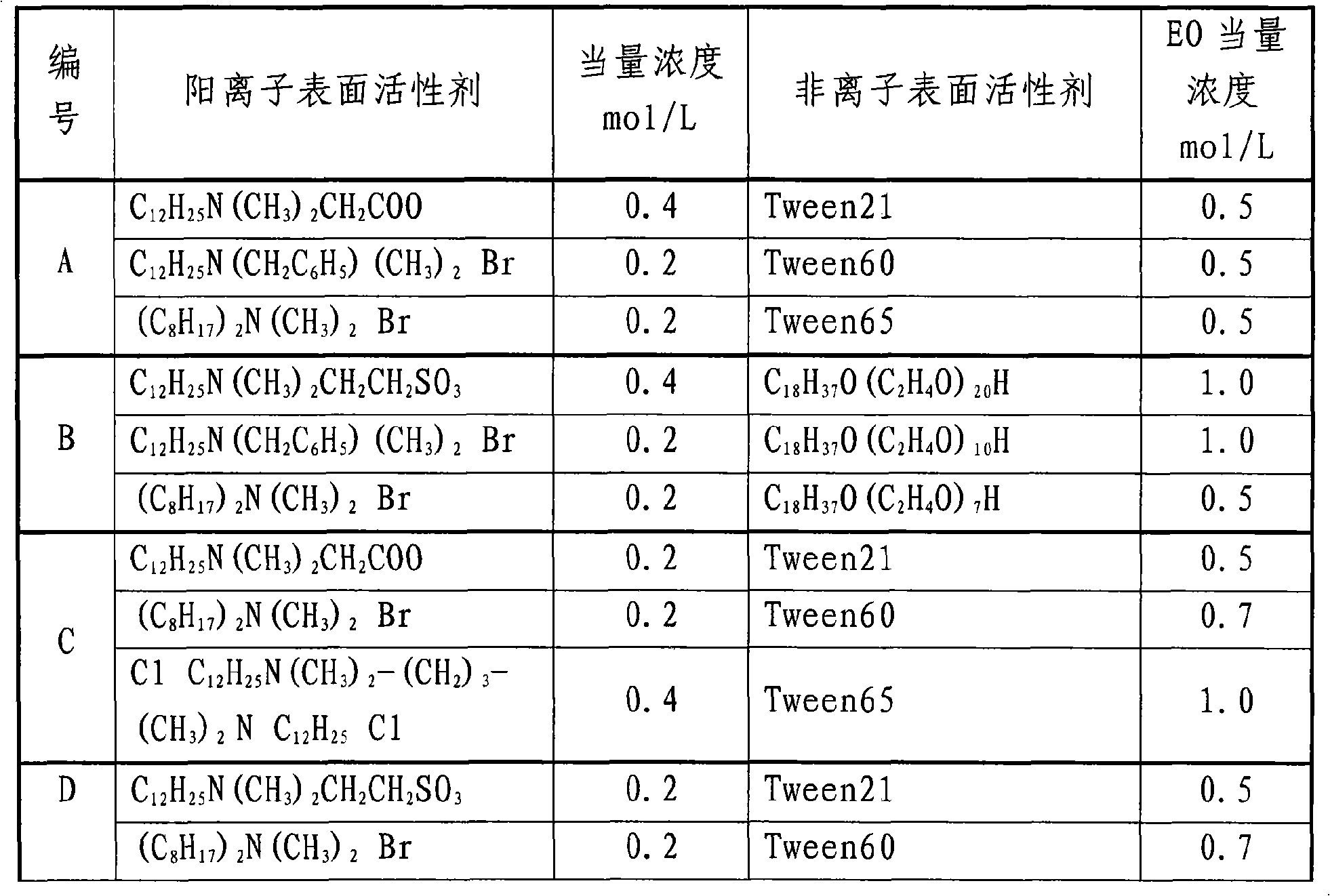

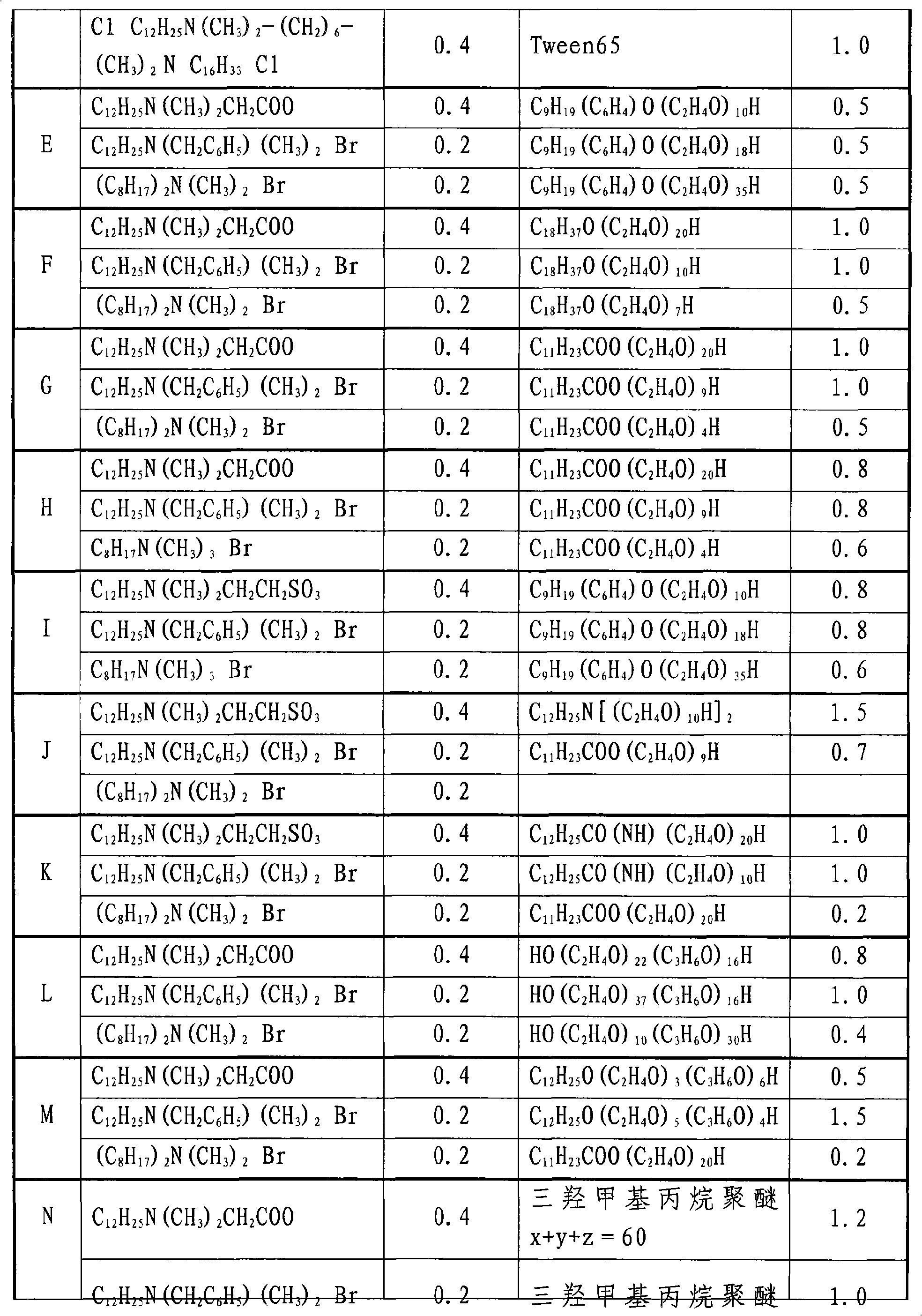

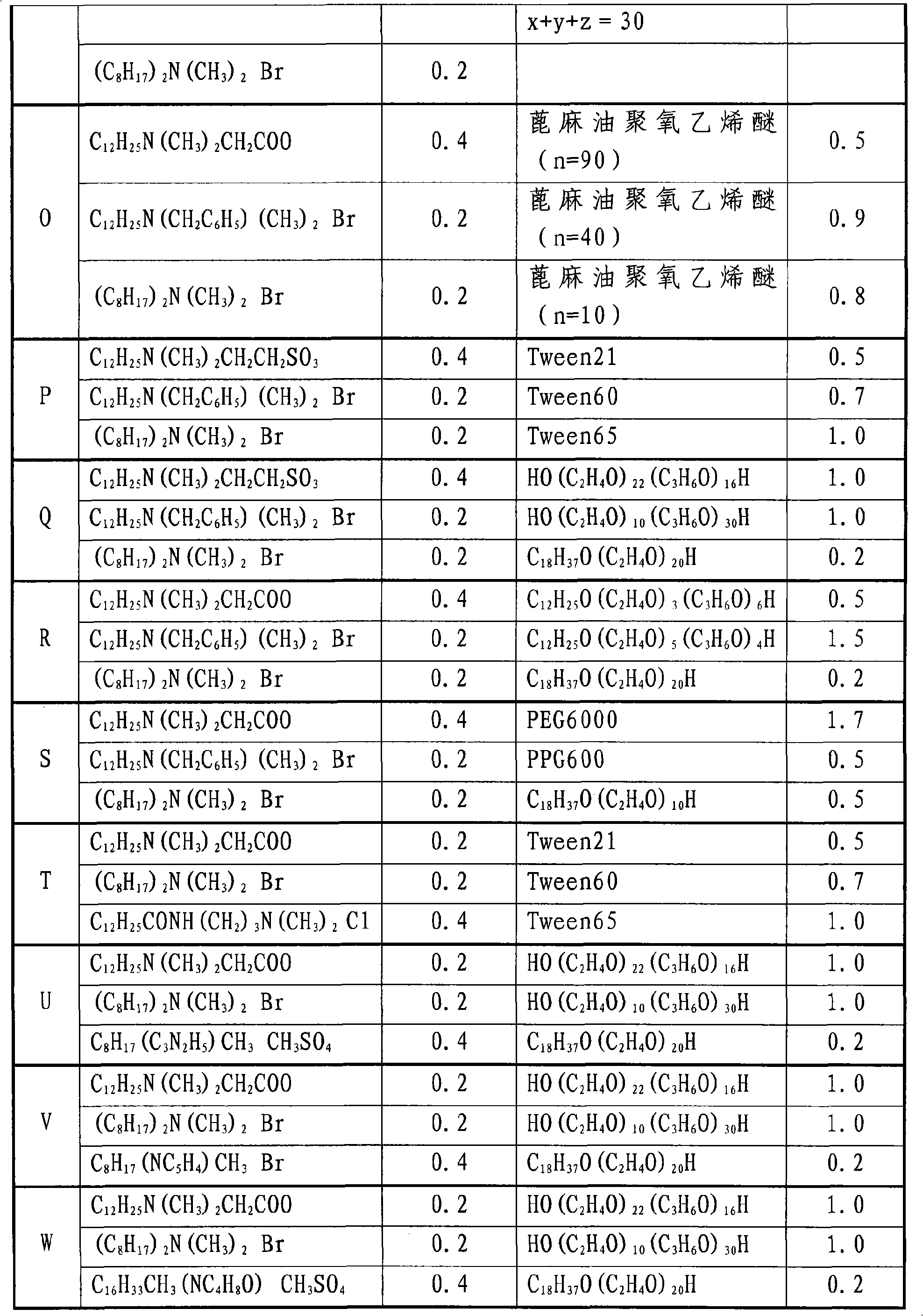

Multifunctional assistant plating additive for hot dip plating process, preparation and use method thereof

ActiveCN101328568AReduce lossImprove stabilityHot-dipping/immersion processesDissolutionLiquid metal

The invention relates to a multifunctional plating assisting additive for a hot dipping metallization process and a preparation and application method thereof, and belongs to the metal material anticorrosive technical field for providing multiple plating assisting efficacy. The technical proposal of the invention comprises that: a plurality of cations or an amphoteric surfactant ( an equivalent concentration of a quaternary ammonium group is between 0.1 and 2 mol / L) and nonionics (an equivalent concentration of a polyoxyethylene group is between 0.5 and 5 mol / L) are dissolved in deionized water. The method can improve the wetting quality between a liquid-state metal and a workpiece, and the adhesive uniformity and continuity of the plating assisting additive, reduces the drying time, prevents the liquid-state metal from falling and splashing, shortens the dipping and plating time, saves raw materials, improves a residue form, reduces an ash content, increases an ash discharge speed, isolates air, stops oxidation, disperses residual dirt and is suitable for a plurality of processes of hot galvanizing, hot plating zinc-aluminum alloy, hot plating aluminum, etc. The preparation steps comprise dissolution, cubage determination, cooling, keeping stand and filling; when the multifunctional plating assisting additive is used, the multifunctional plating assisting additive is directly added into a plating assisting additive solution and is evenly stirred.

Owner:JIANGSU FEITUO INTERFACE ENG TECH CO LTD

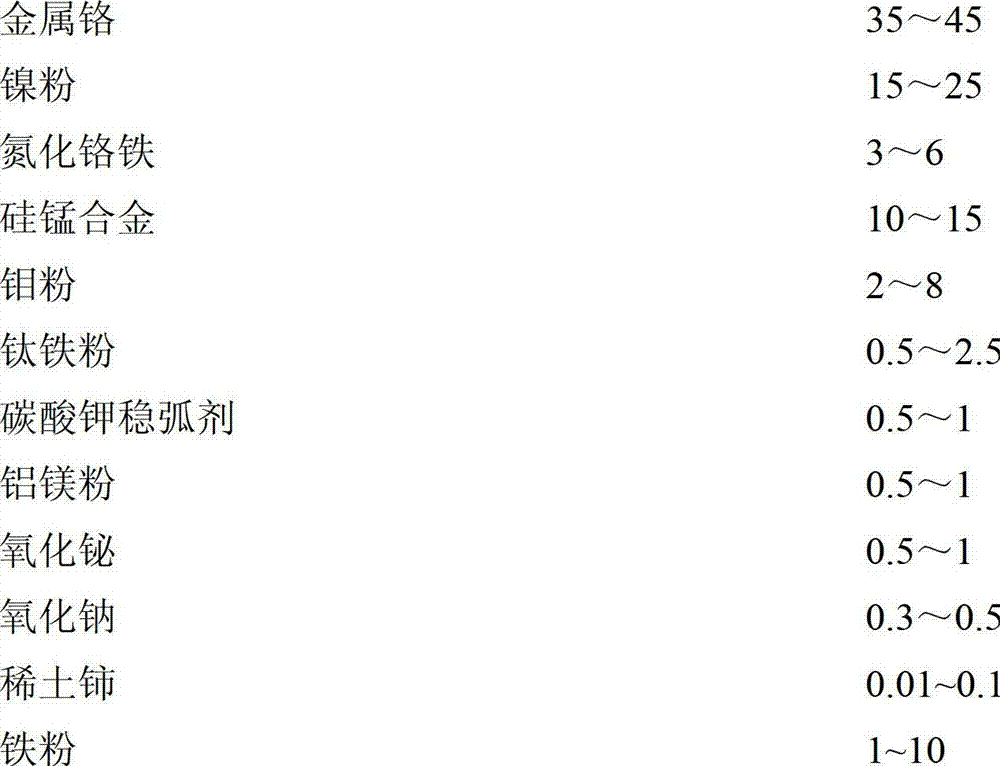

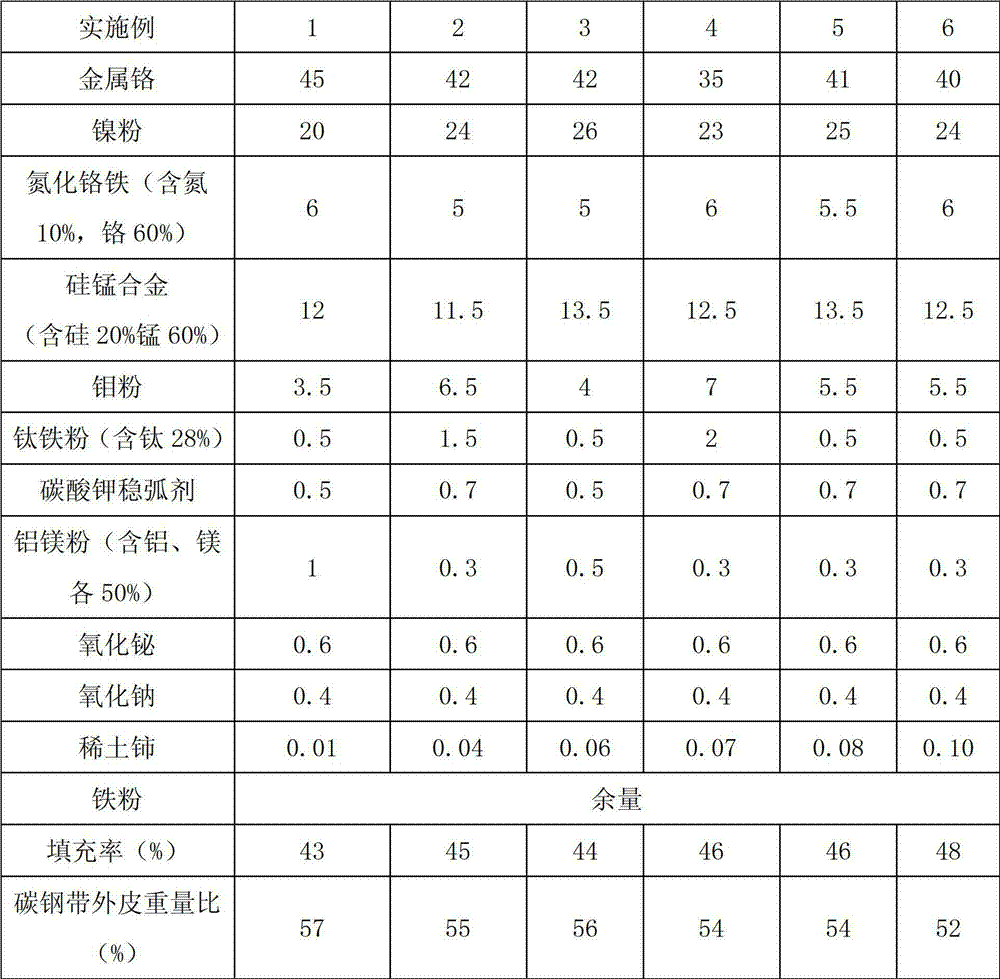

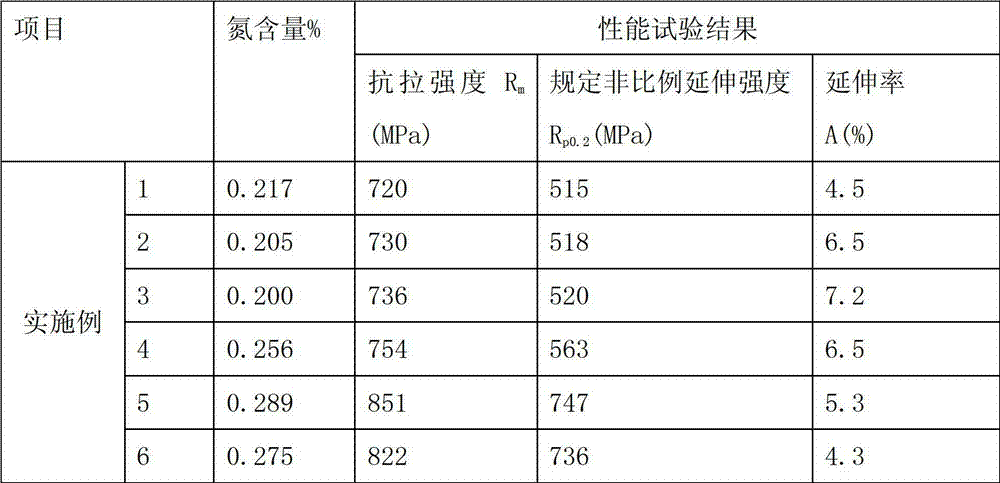

Metal powder-cored type nitrogen austenite stainless steel flux-cored wire and method for manufacturing same

ActiveCN103042321AEffective combinationGood wire qualityWelding/cutting media/materialsSoldering mediaCeriumMechanical property

The invention relates to a metal powder-cored type nitrogen austenite stainless steel flux-cored wire and a method for manufacturing the same. The metal powder-cored type nitrogen austenite stainless steel flux-cored wire comprise a carbon steel cored shell and powder filled in the shell, and is characterized in that the powder comprises, by weight, from 35% to 45% of metal chromium, from 15% to 25% of nickel powder, from 3% to 6% of ferrochromium nitride, from 10% to 15% of silicon-magnesium alloy, from 2% to 8% of molybdenum powder, from 0.5% to 2.5% of ferrotitanium powder, from 0.5% to 1% of potassium carbonate arc stabilizers, from 0.5% to 1% of aluminum-magnesium powder, from 0.5% to 1% of bismuth oxide, from 0.3% to 0.5% of sodium oxide, from 0.01% to 0.1% of rare-earth cerium and from 1% to 10% of iron powder, and the weight of the powder ranges from 40% to 50% of the total weight of the wire. Compared with the prior art, the metal powder-cored type nitrogen austenite stainless steel flux-cored wire has the advantages that weld metal has excellent mechanical properties such as good toughness and high strength after the wire is applied to welding high-nitrogen steel, and a corrosion resistant effect is good.

Owner:北方材料科学与工程研究院有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com