Method for utilizing iron containing metallurgical dust

A dust sludge and metallurgical technology, applied in the utilization field of metallurgical iron-containing dust sludge, can solve the problems of underutilization of resources, reduction of sinter output and quality, low utilization rate and metal yield, etc. The effect of high added value of mud resources, low production energy consumption and fast slag removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

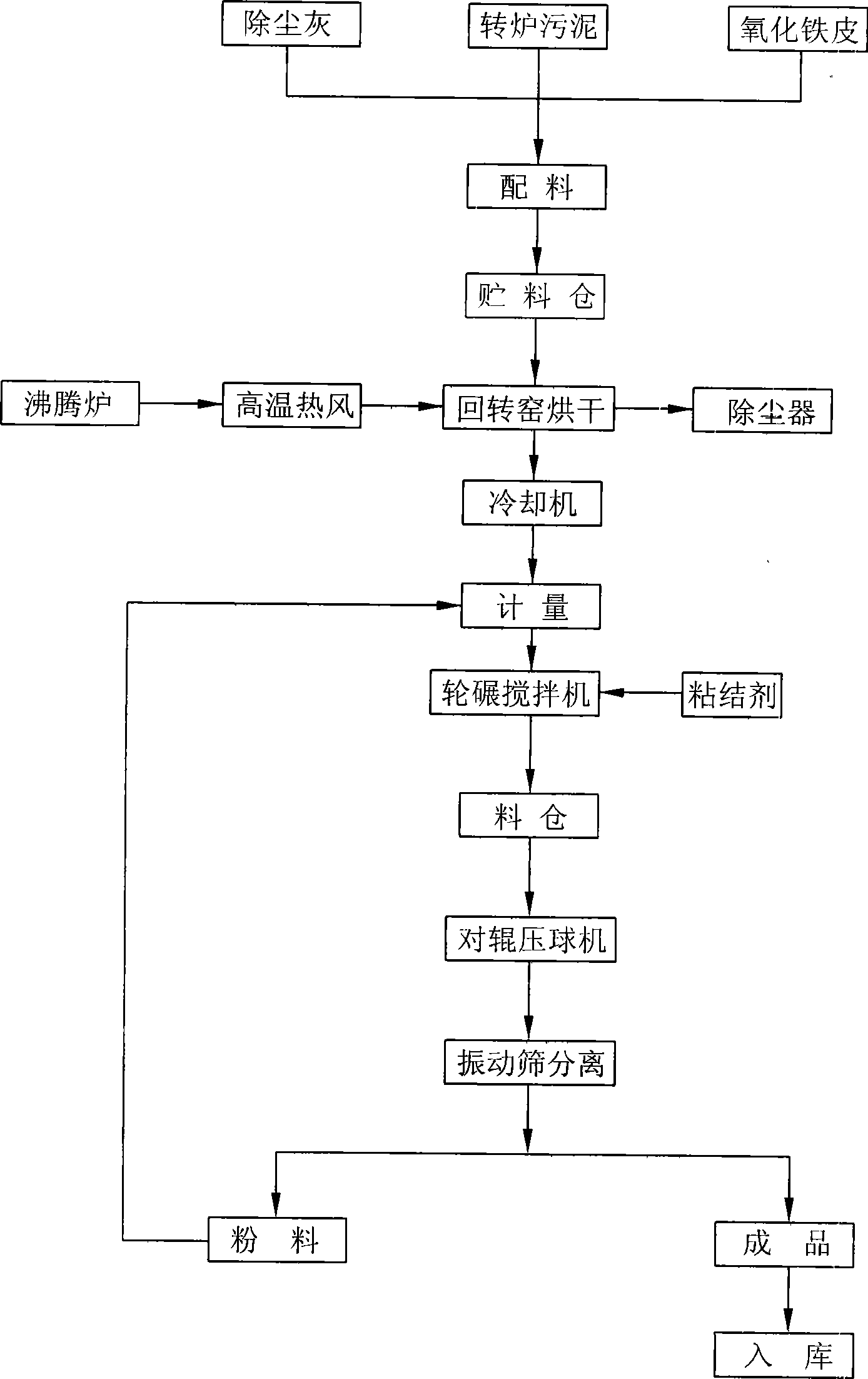

[0021] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

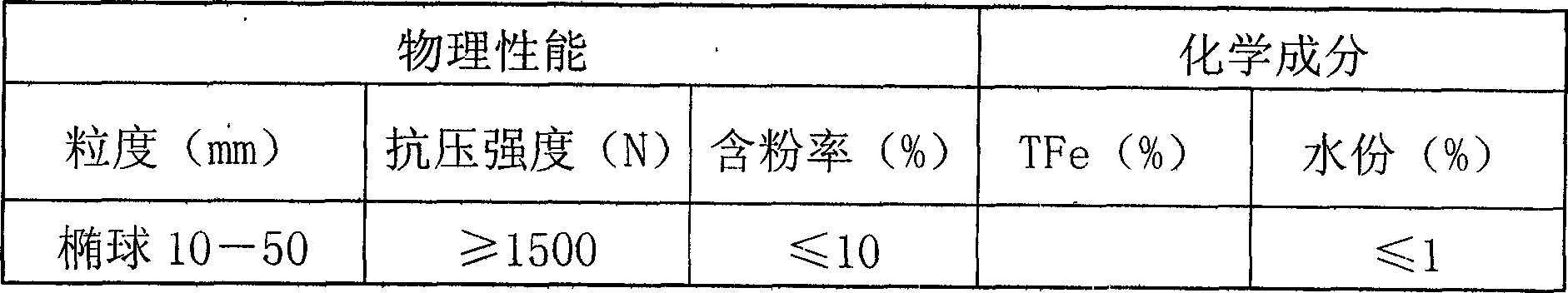

[0022] see figure 1 , a method of utilizing metallurgical iron-containing dust and sludge. The steelmaking sludge, smelting dust and iron oxide scale are used for batching treatment, and the raw materials after batching treatment are sent to the rotary kiln for drying, and the drying is determined according to the moisture content of the raw materials. Drying temperature, using high-temperature hot air from the fluidized fluidized furnace to dry the material, the drying temperature is controlled between 300-500 ° C, and the dust generated during the drying process of the rotary kiln is dedusted through the dust collector; the dried The processed material is cooled by a cooling machine, and 5-10% of binder is added to the cooled material by weight, and the binder is water glass (sodium silicate), bentonite or lime powder, so that the material and After the binder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com