Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85results about How to "Small droplet size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

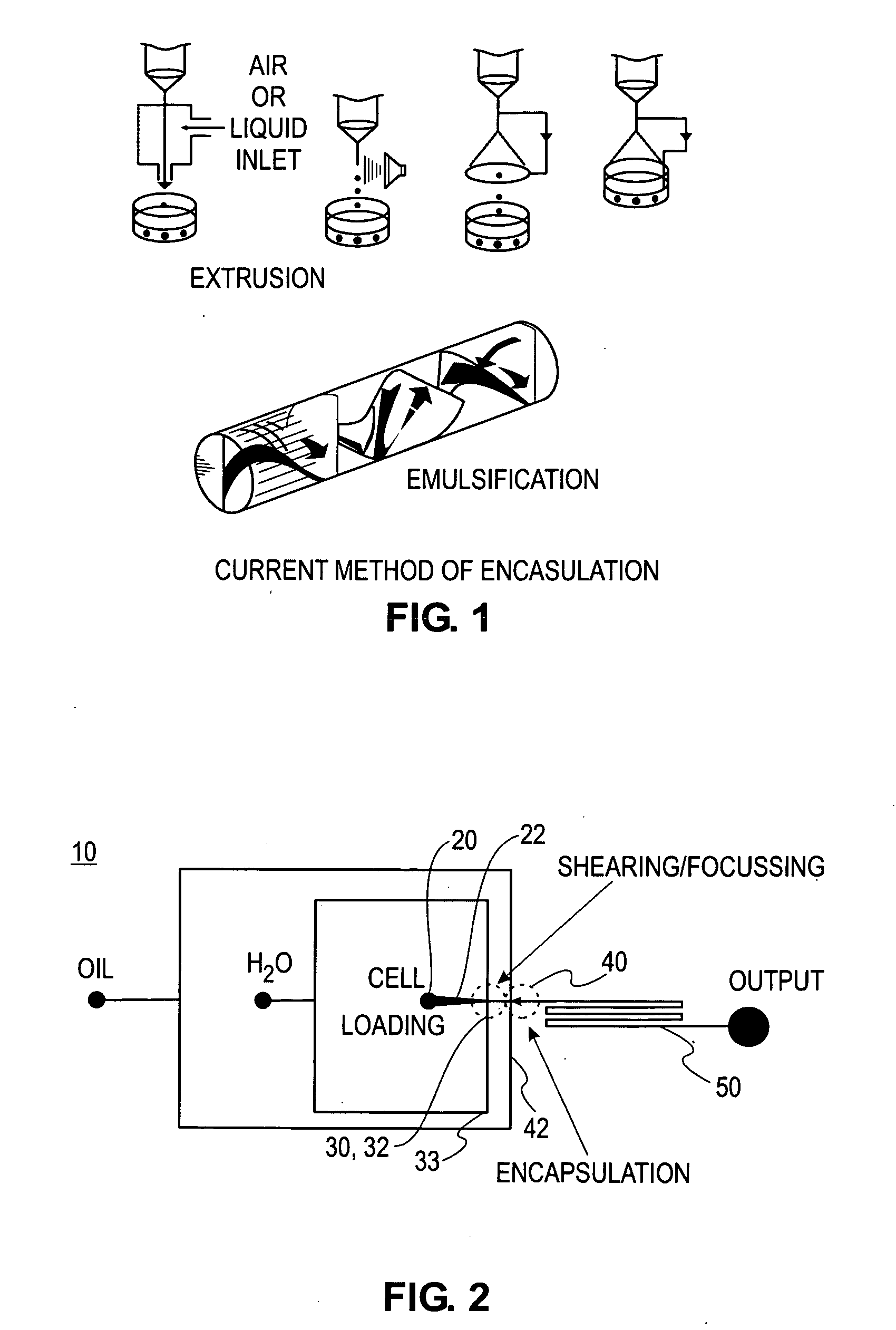

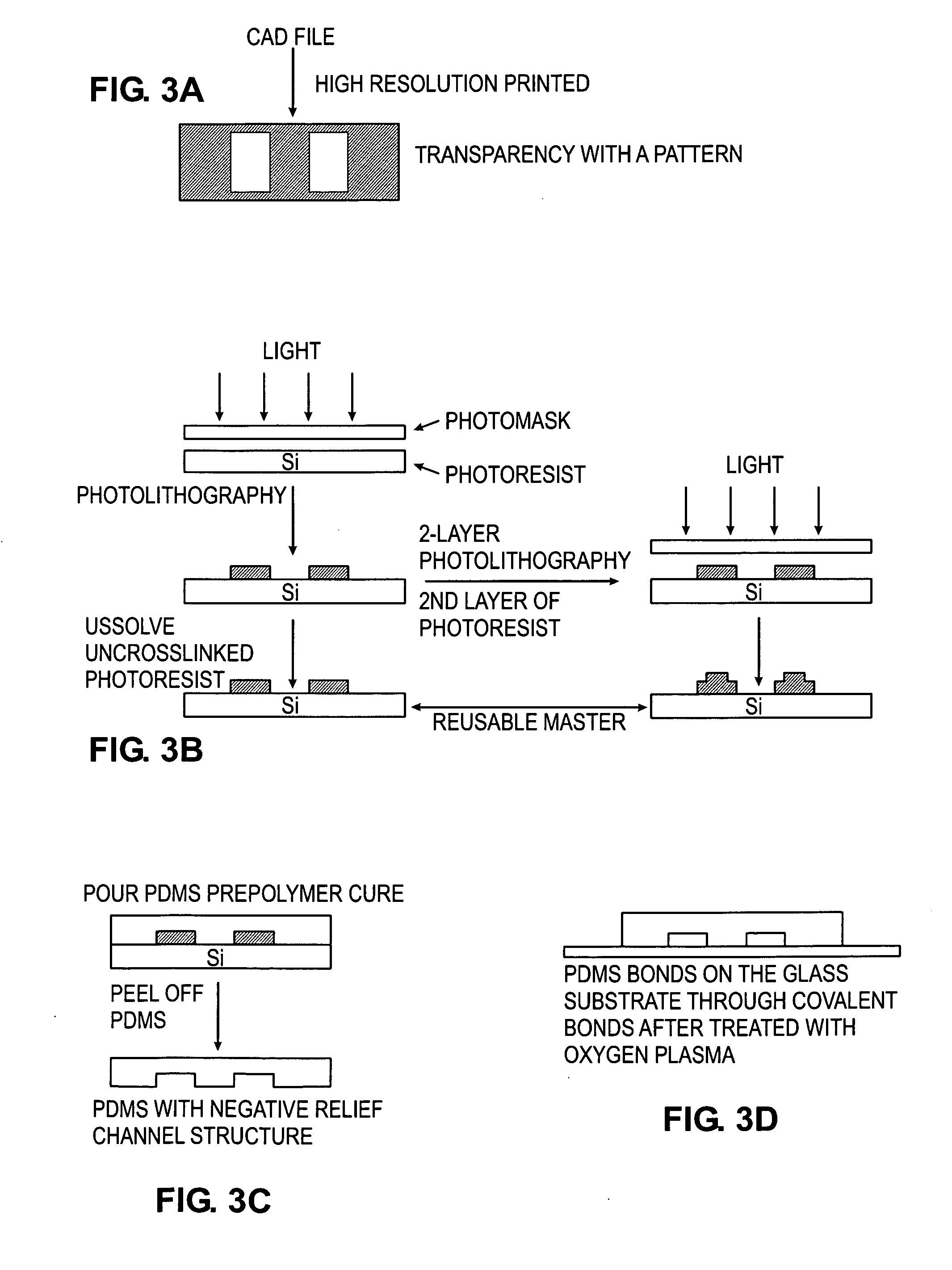

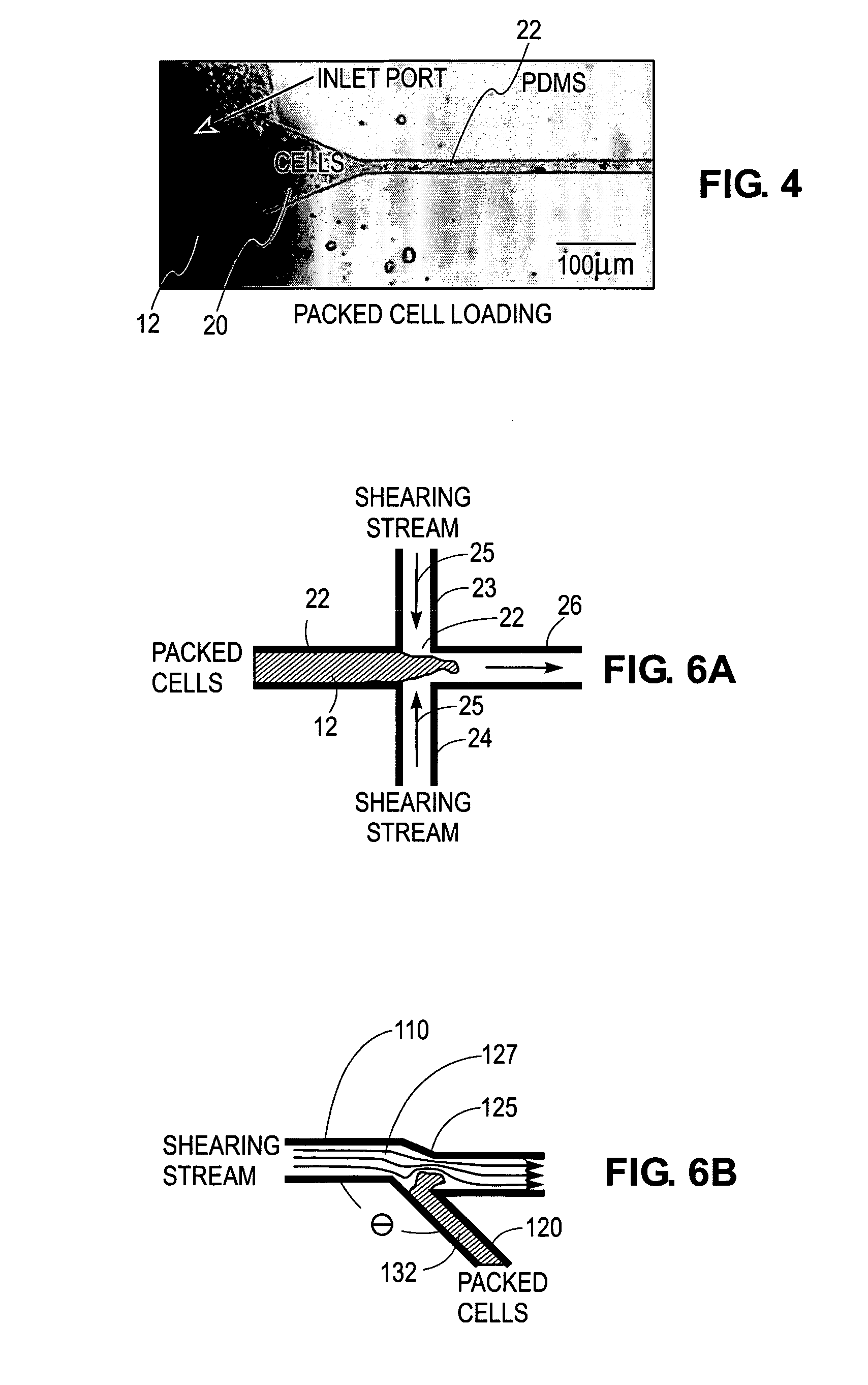

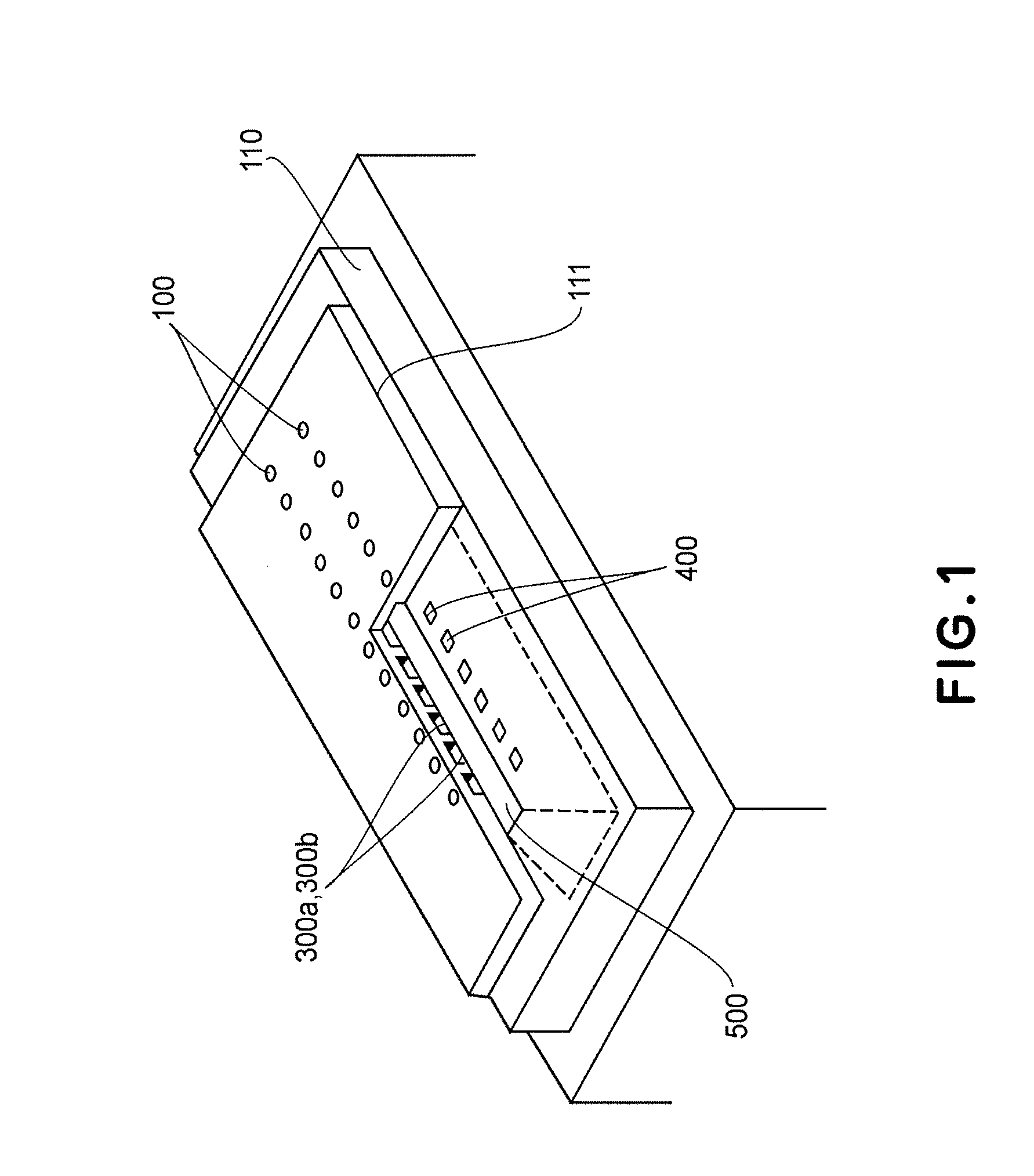

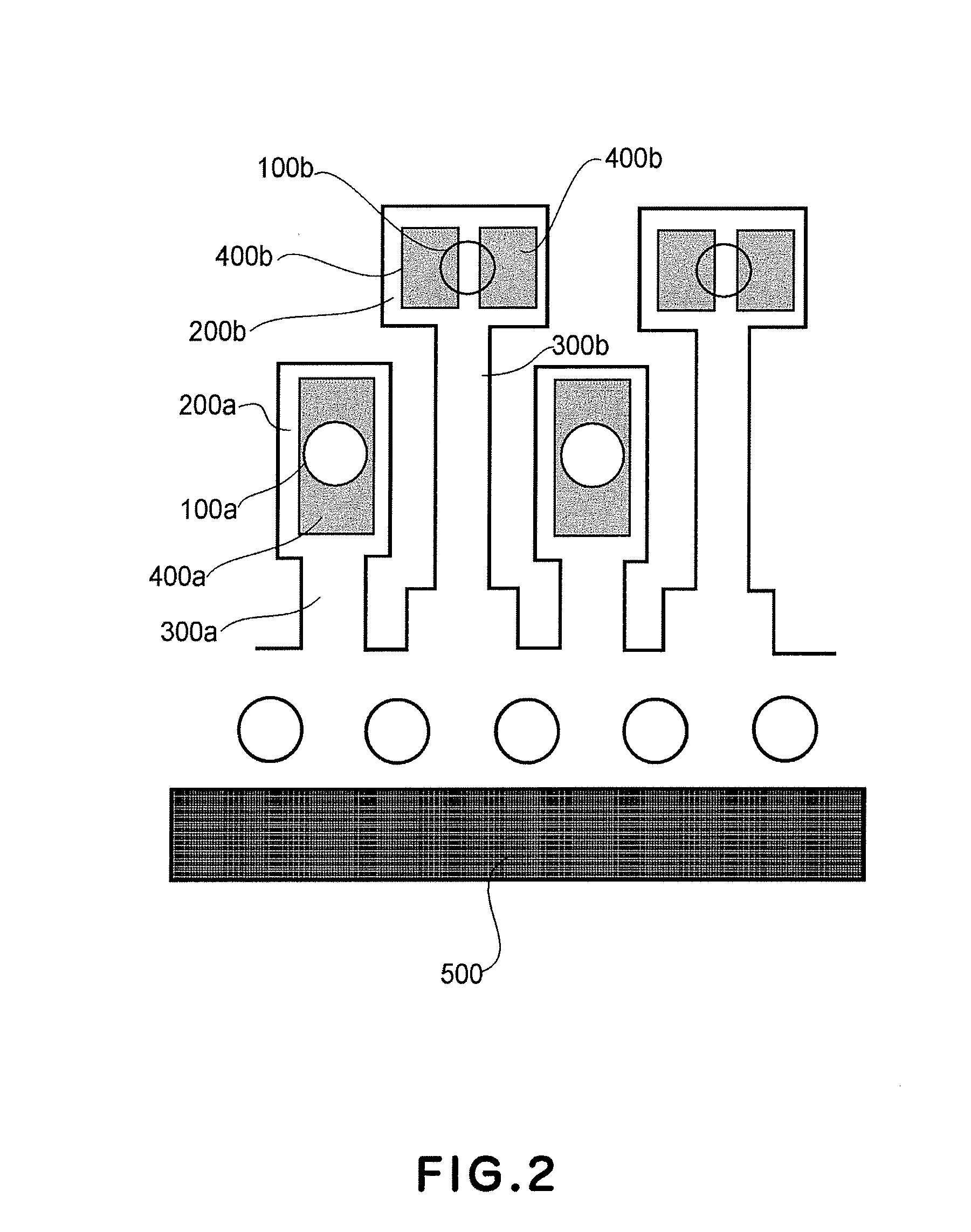

Microfluidic device for the encapsulation of cells with low and high cell densities

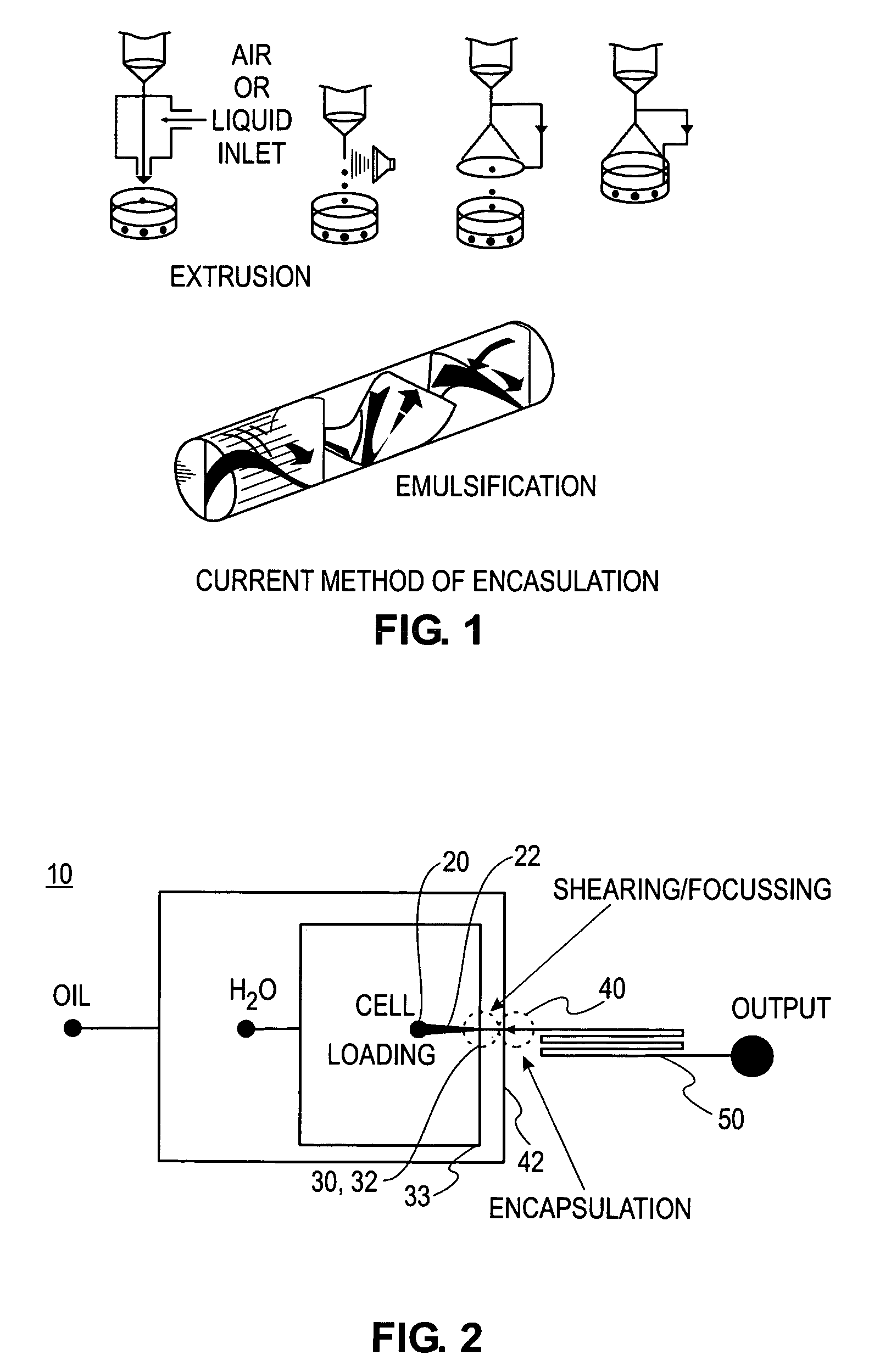

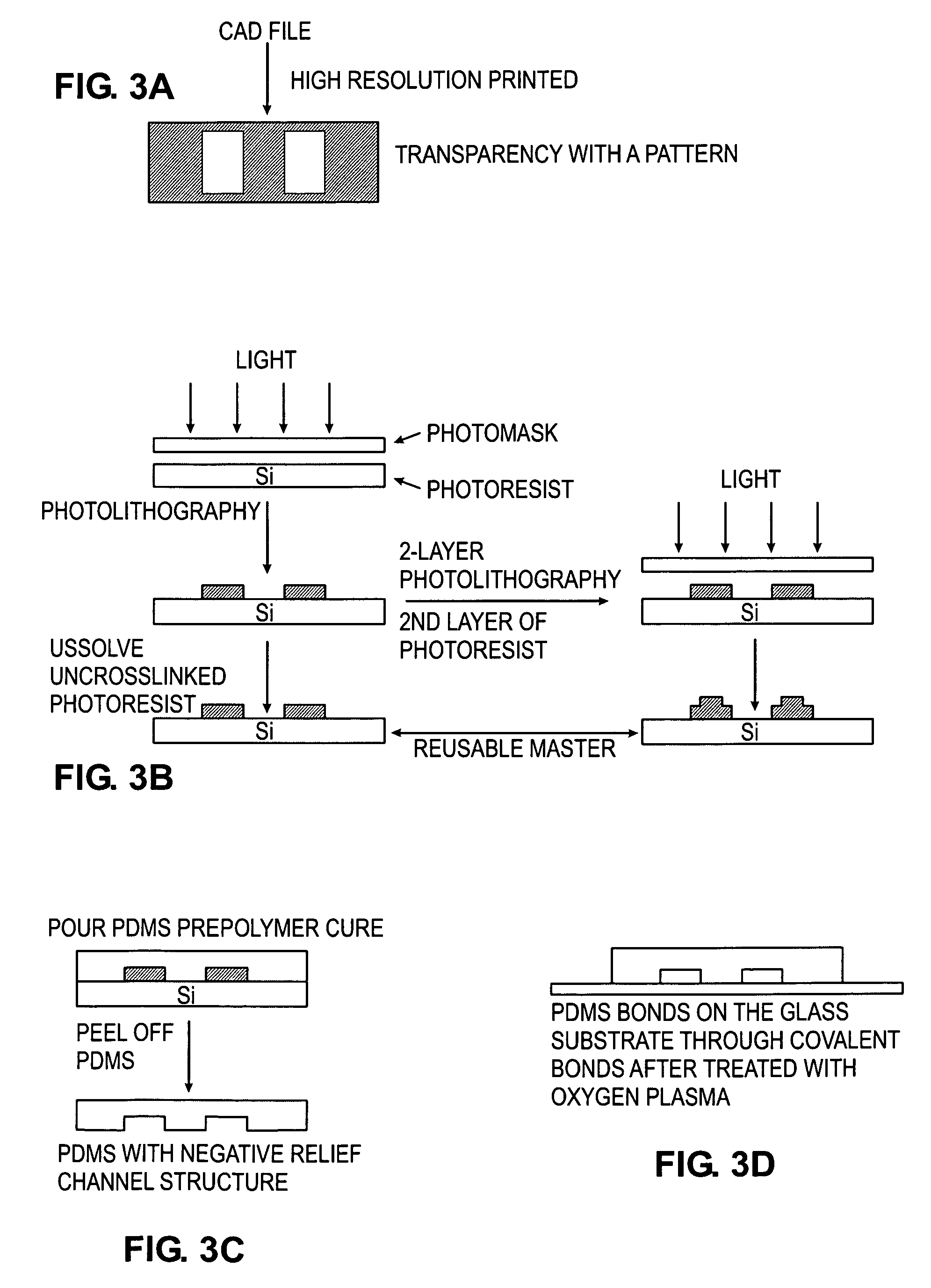

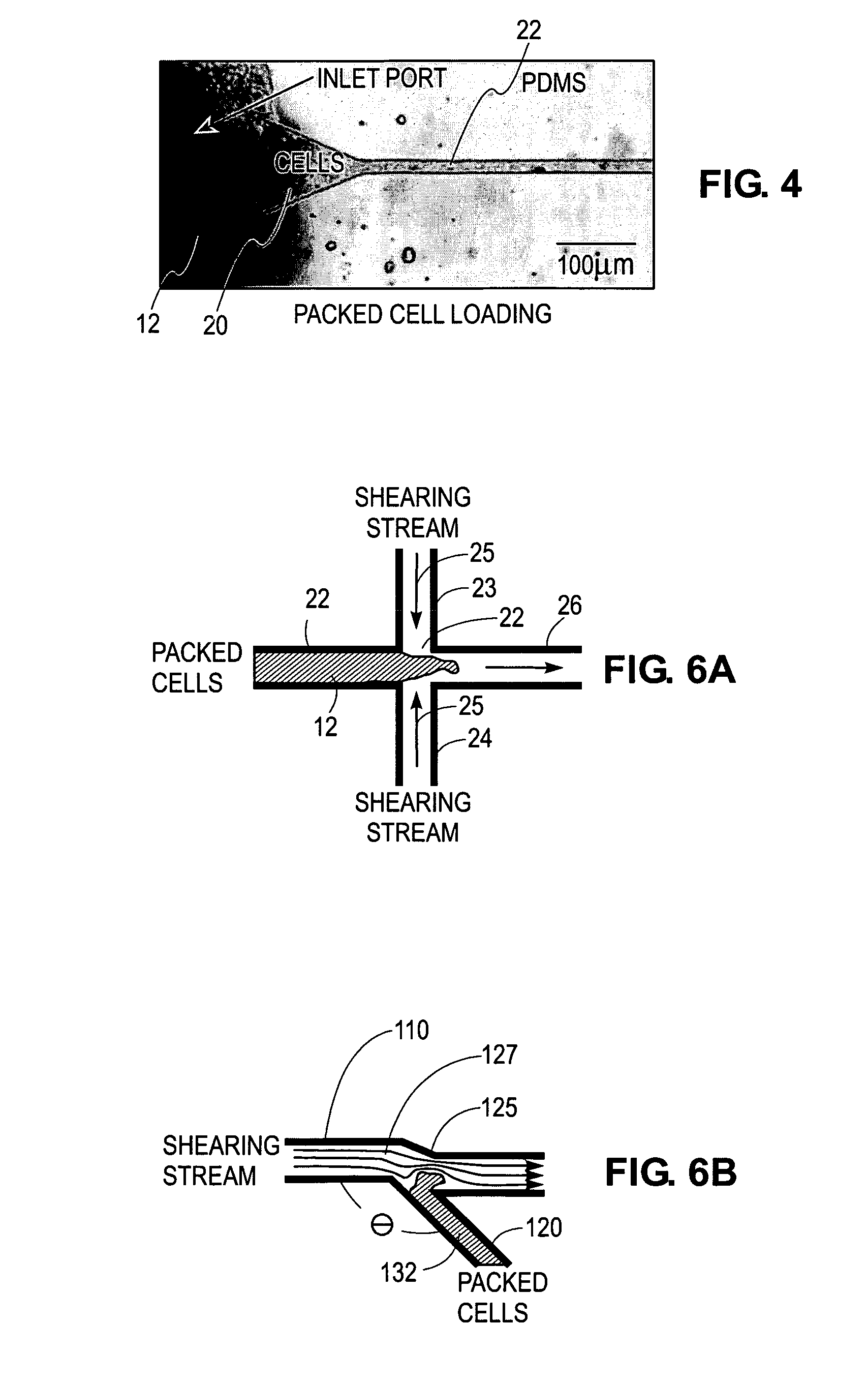

ActiveUS20060051329A1Small minimum droplet sizeUniform polymerization timeBioreactor/fermenter combinationsBiocideHigh cellEngineering

Devices and methods for the encapsulation of cells on microfluidic platforms are disclosed. The microfluidic device generally includes a plurality of functional regions to shear, focus, and encapsulate a desired cell or group of cells into a droplet. The microfluidic device can further comprise a polymerization zone to form a polymer bead around the droplet.

Owner:RGT UNIV OF CALIFORNIA

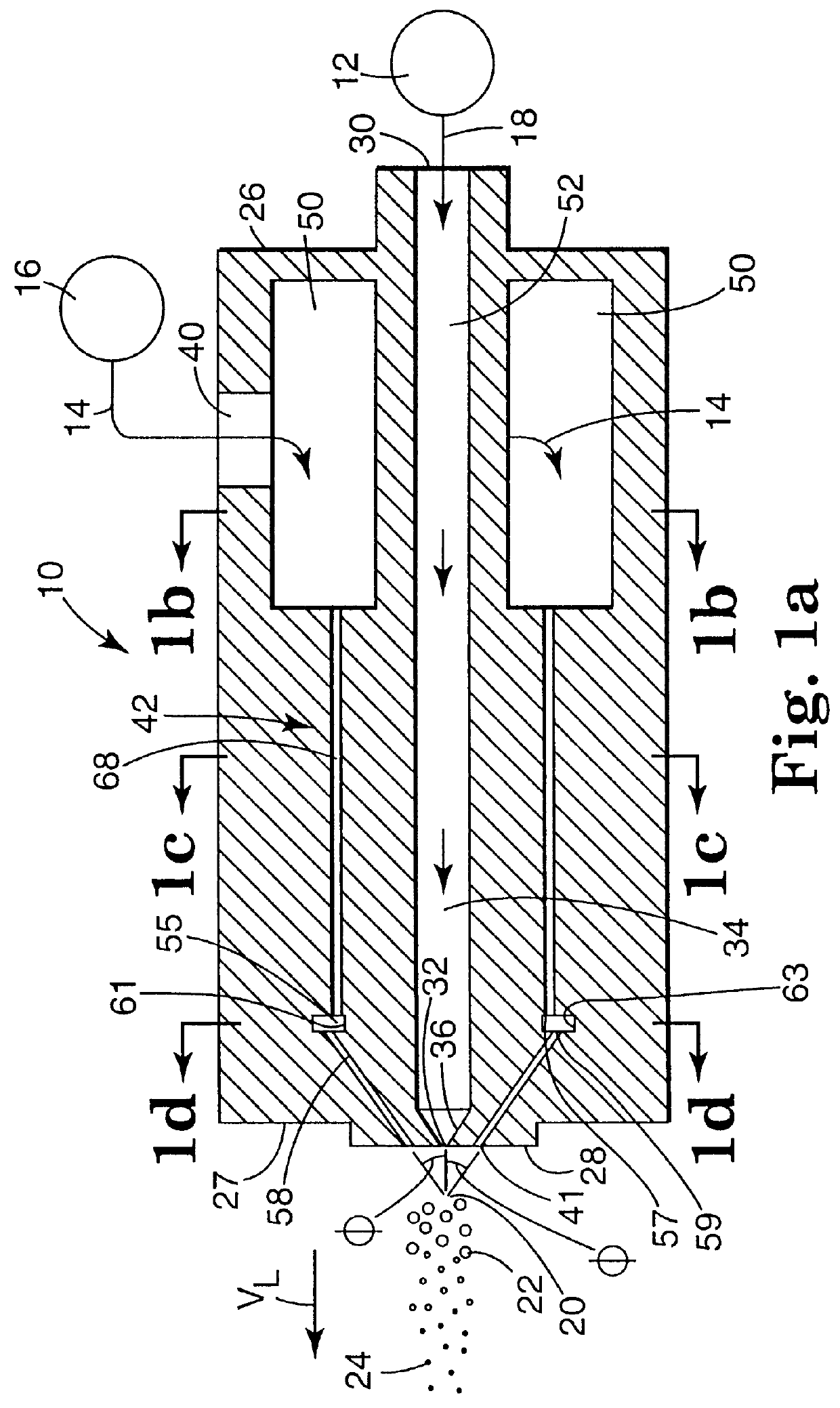

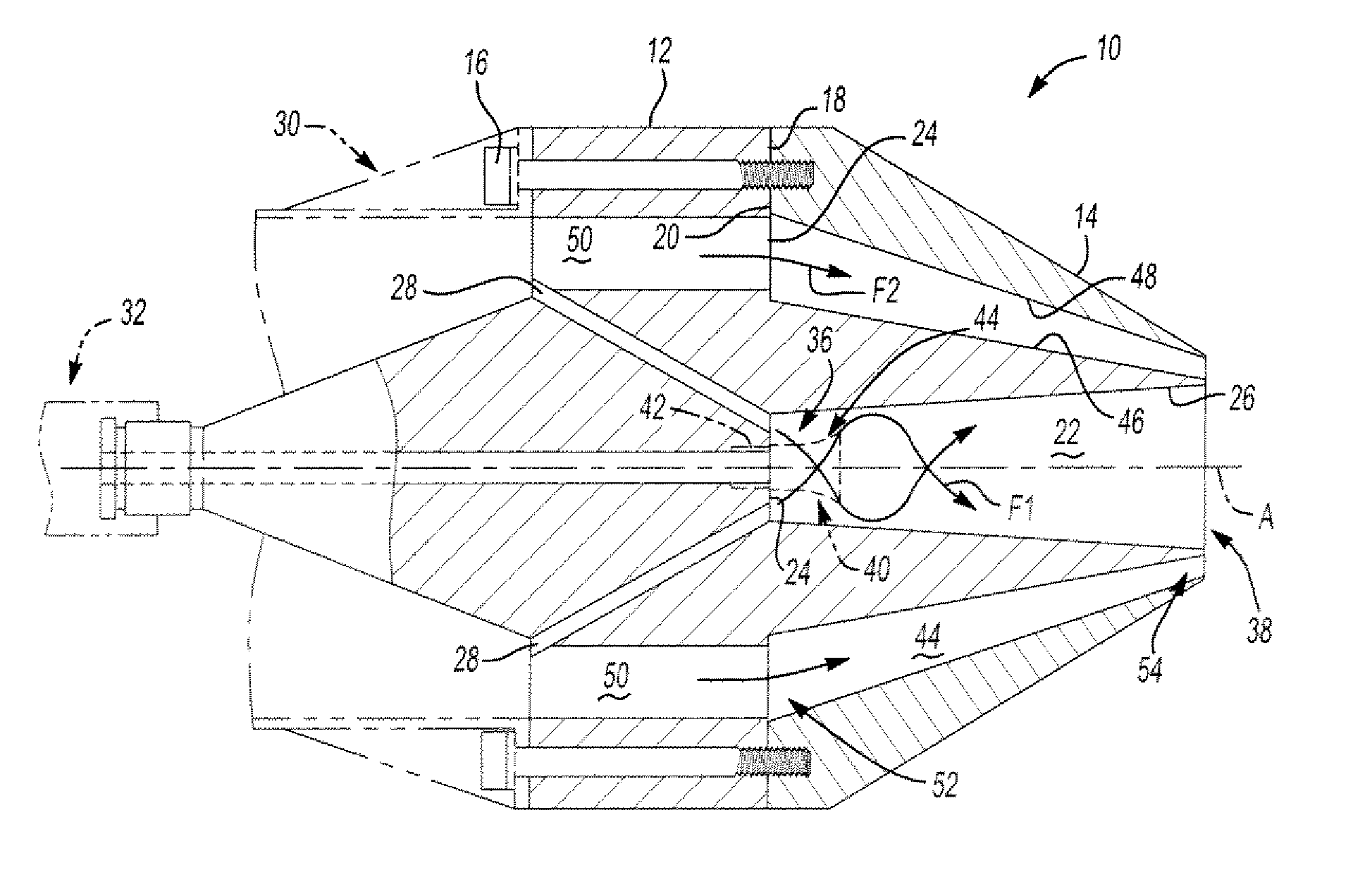

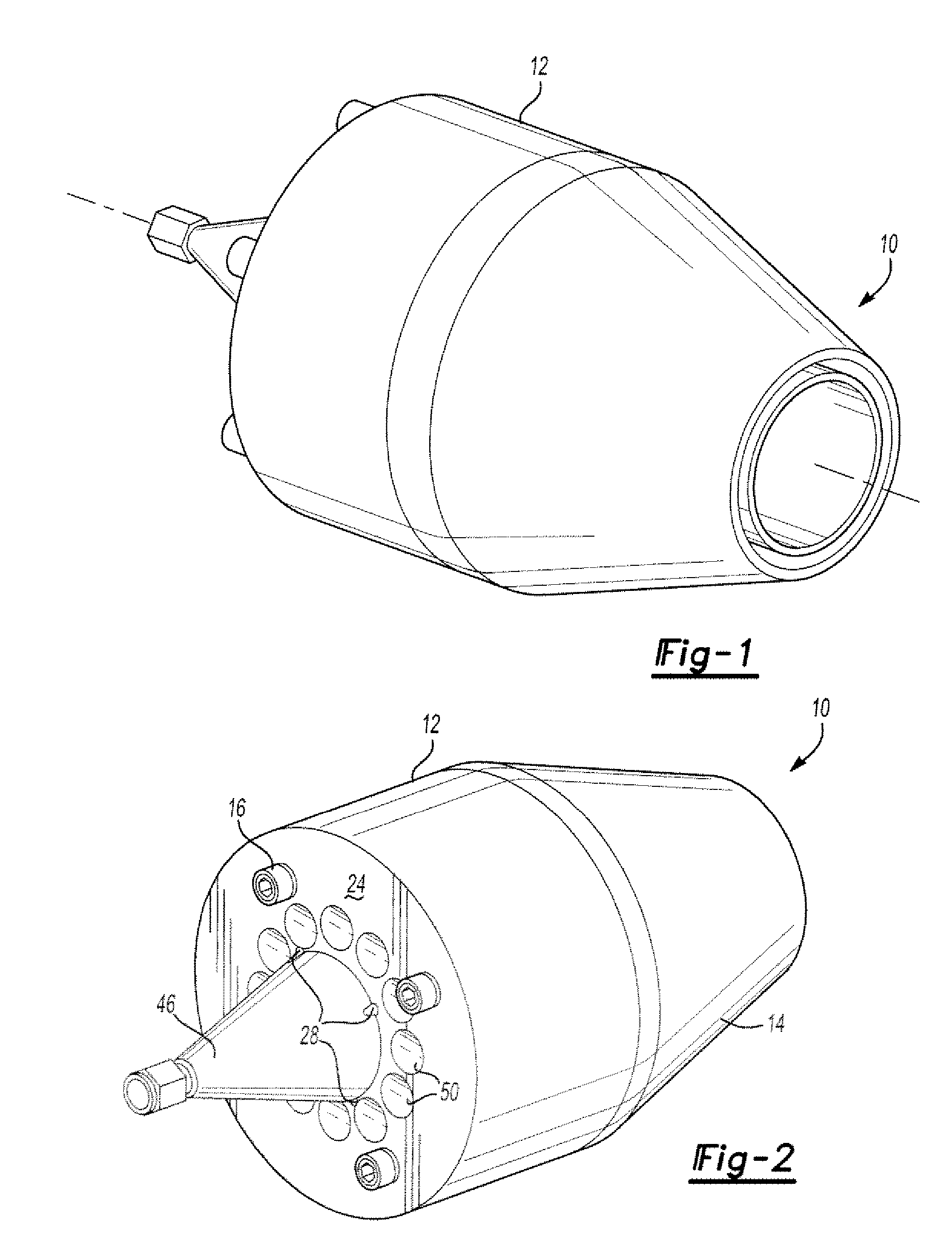

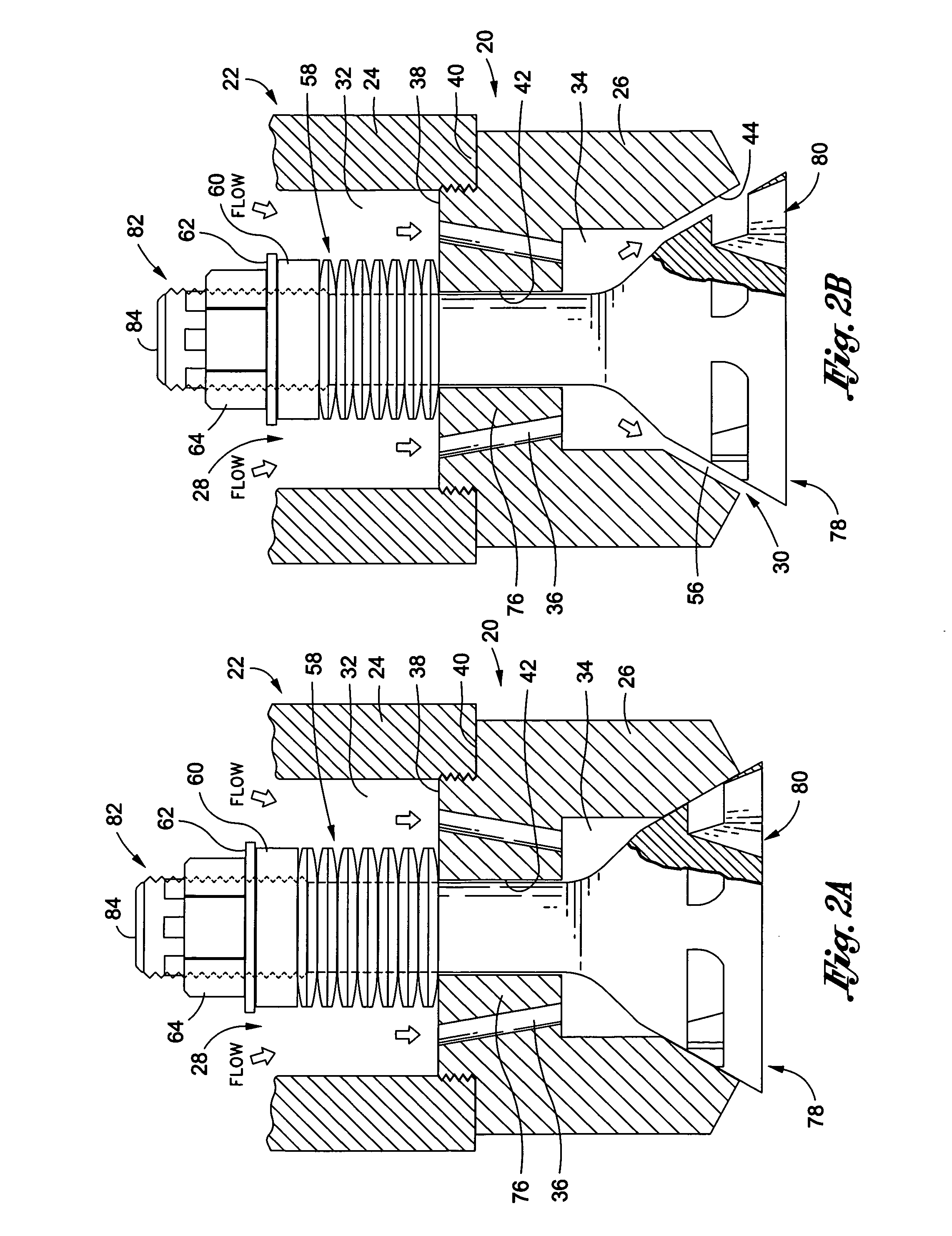

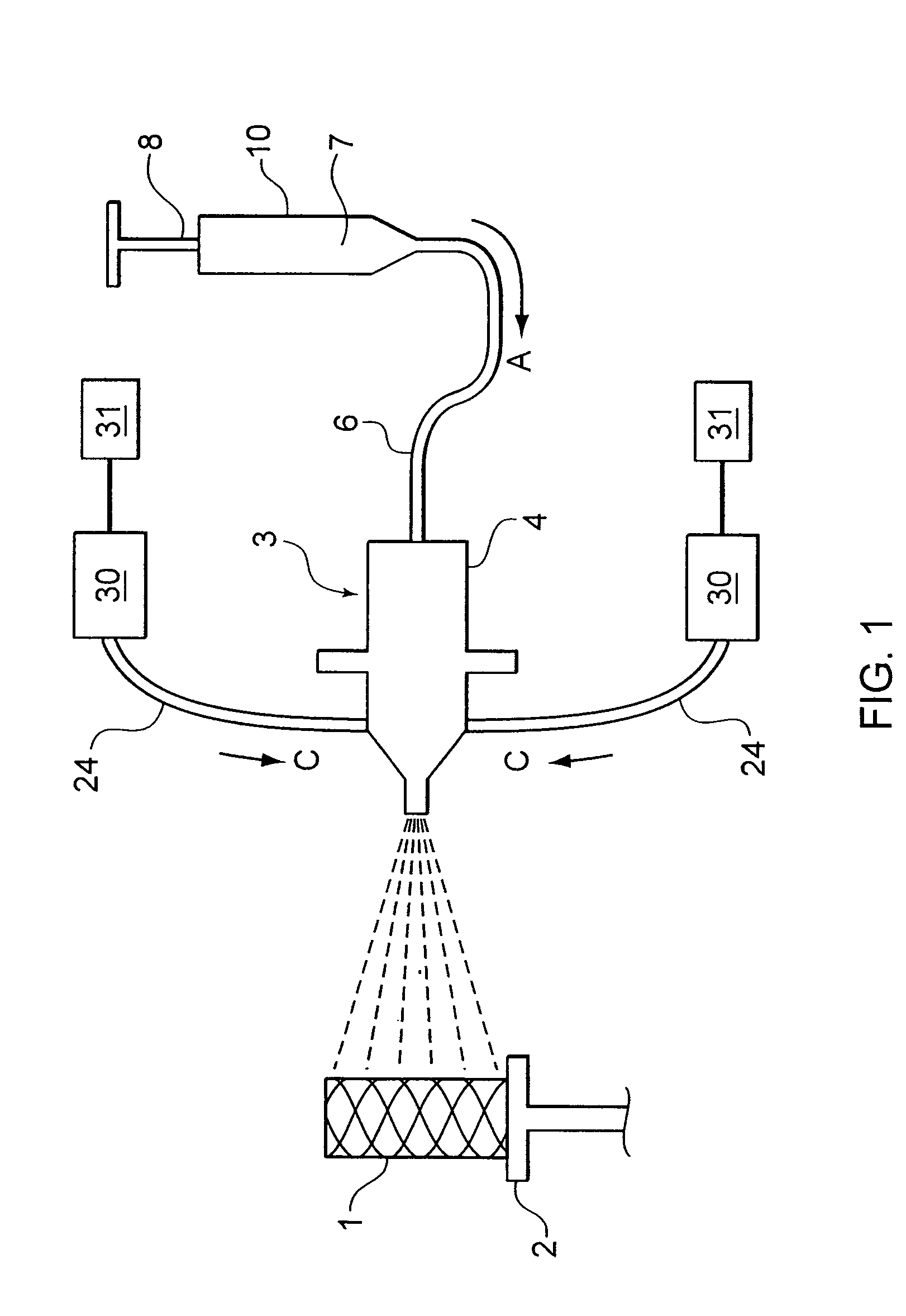

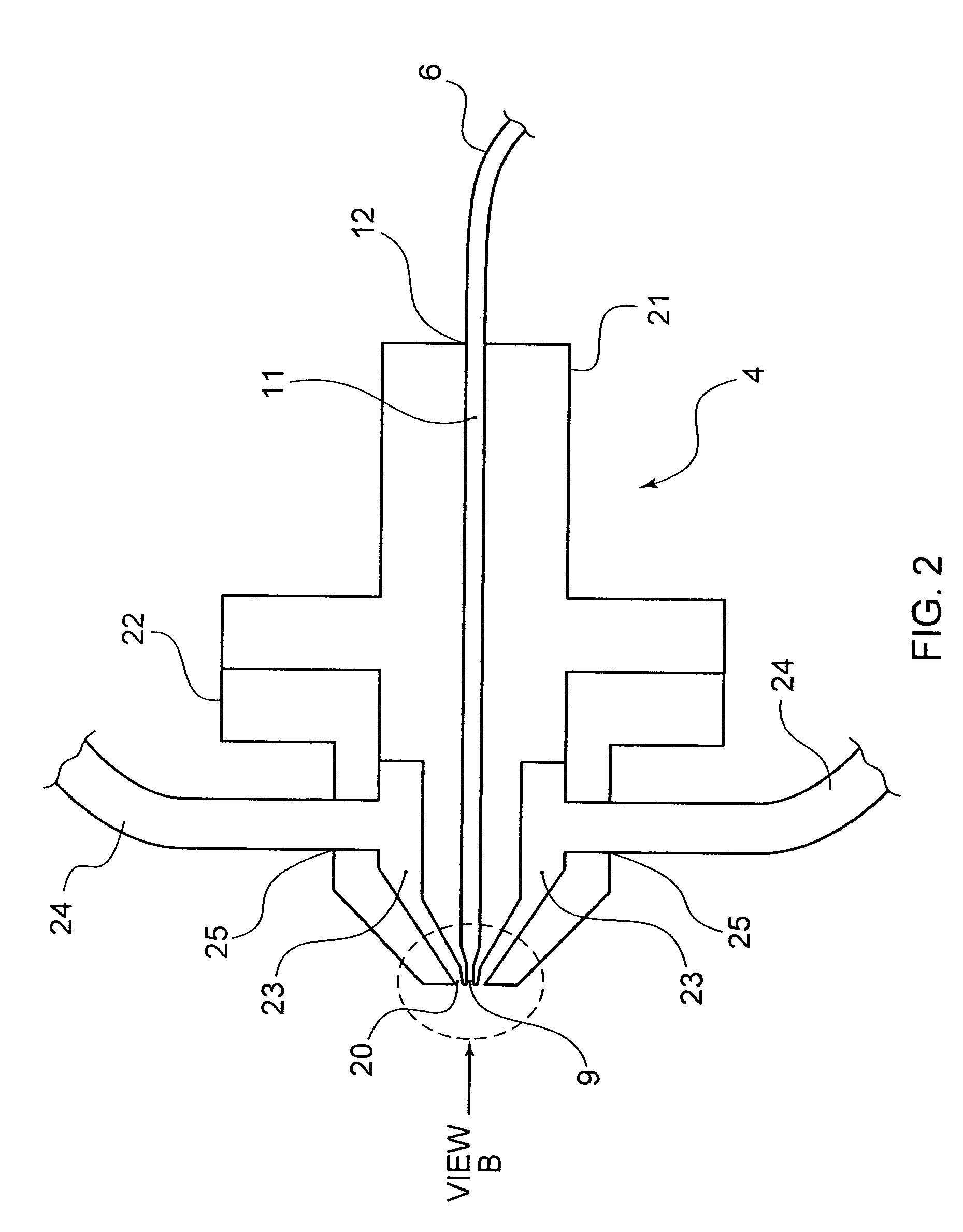

Apparatus and method of atomizing and vaporizing

InactiveUS6012647AMinimal slippageVaporization fastBurnersSpray nozzlesGas passingProcess engineering

Apparatus suitable for atomizing and vaporizing at least a first liquid by colliding at least one gas with the first liquid. The apparatus includes a gas inlet through which the gas enters the apparatus and a first liquid inlet through which the first liquid enters the apparatus. A discharge end of the apparatus includes at least one first liquid discharge outlet through which at least one stream of the first liquid is discharged from the apparatus. The discharge end also includes at least one gas discharge outlet through which at least one stream of gas is discharged from the apparatus to collide with and thereby atomize the discharged stream of the first liquid. A first liquid passageway interconnects the first liquid inlet with the first liquid discharge outlet. A gas passageway interconnects the gas inlet with the at least one gas discharge outlet. In one embodiment, the gas passageway comprises at least one gas chamber in thermal contact with an initial portion of the first liquid passageway such that a heated quantity of the gas in the chamber preheats the first liquid in the initial portion of the first liquid passageway. In alternative embodiments, the gas passageway includes a pressure dampening chamber allowing gas to be continuously discharged without pulsating.

Owner:3M INNOVATIVE PROPERTIES CO

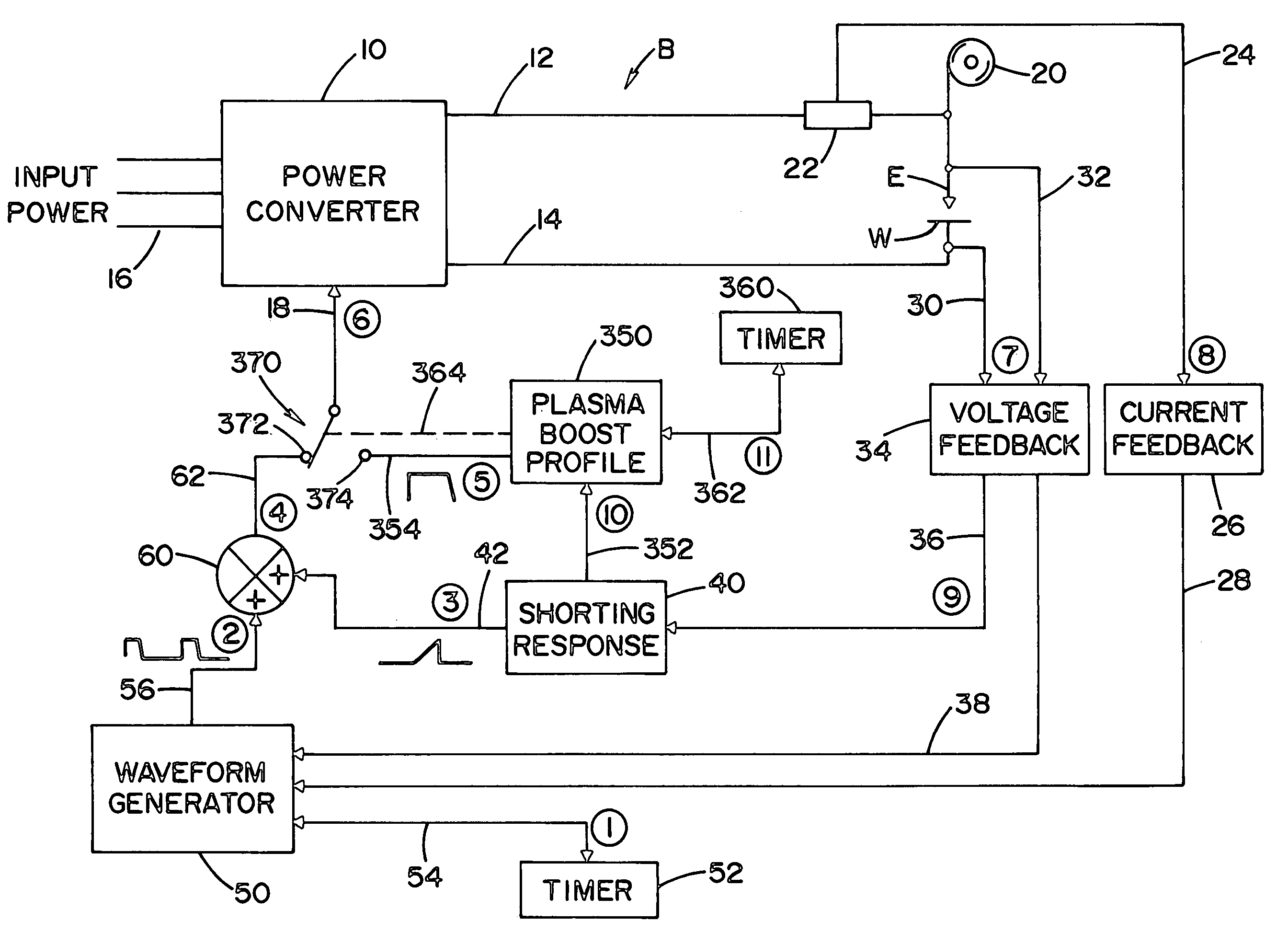

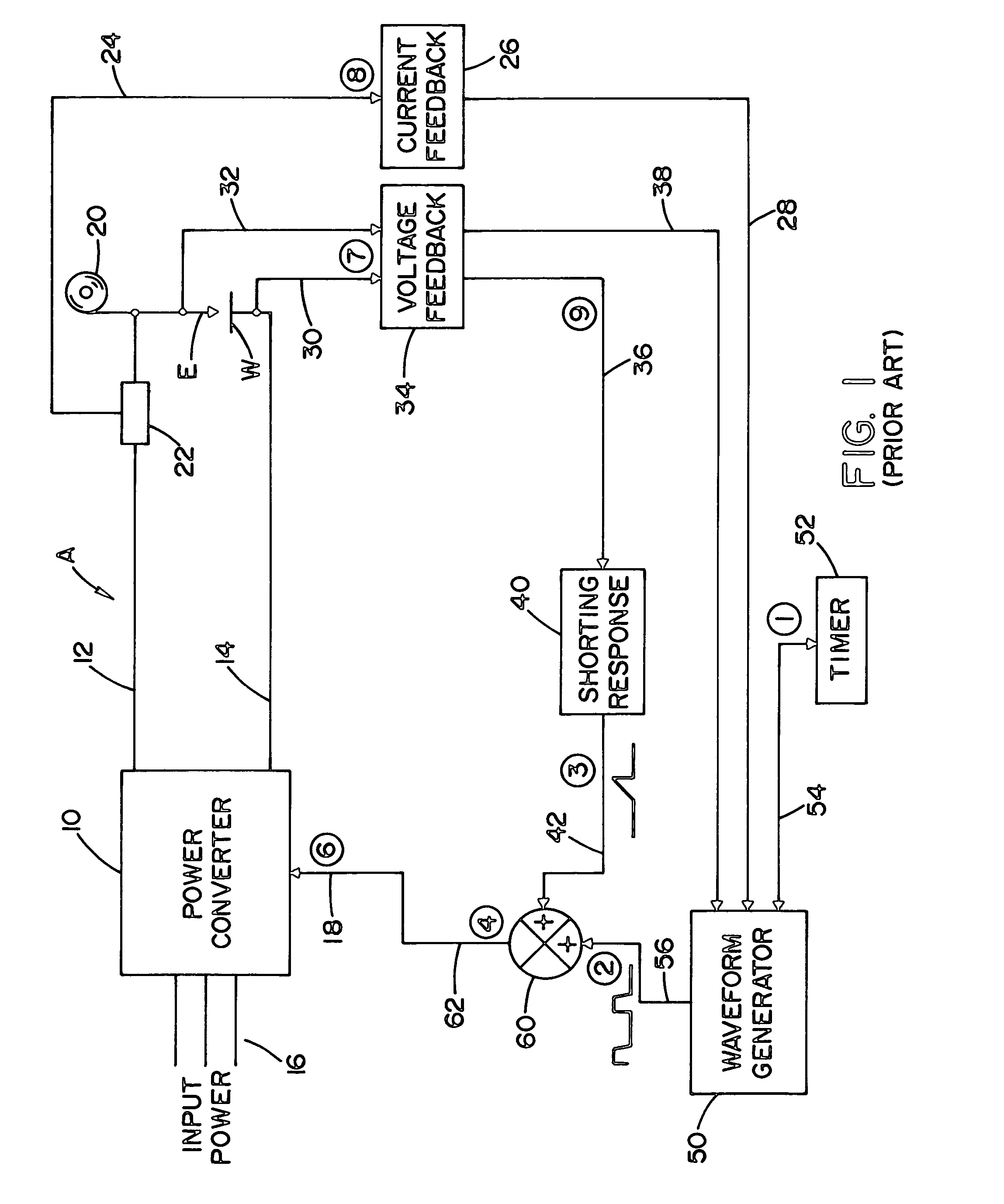

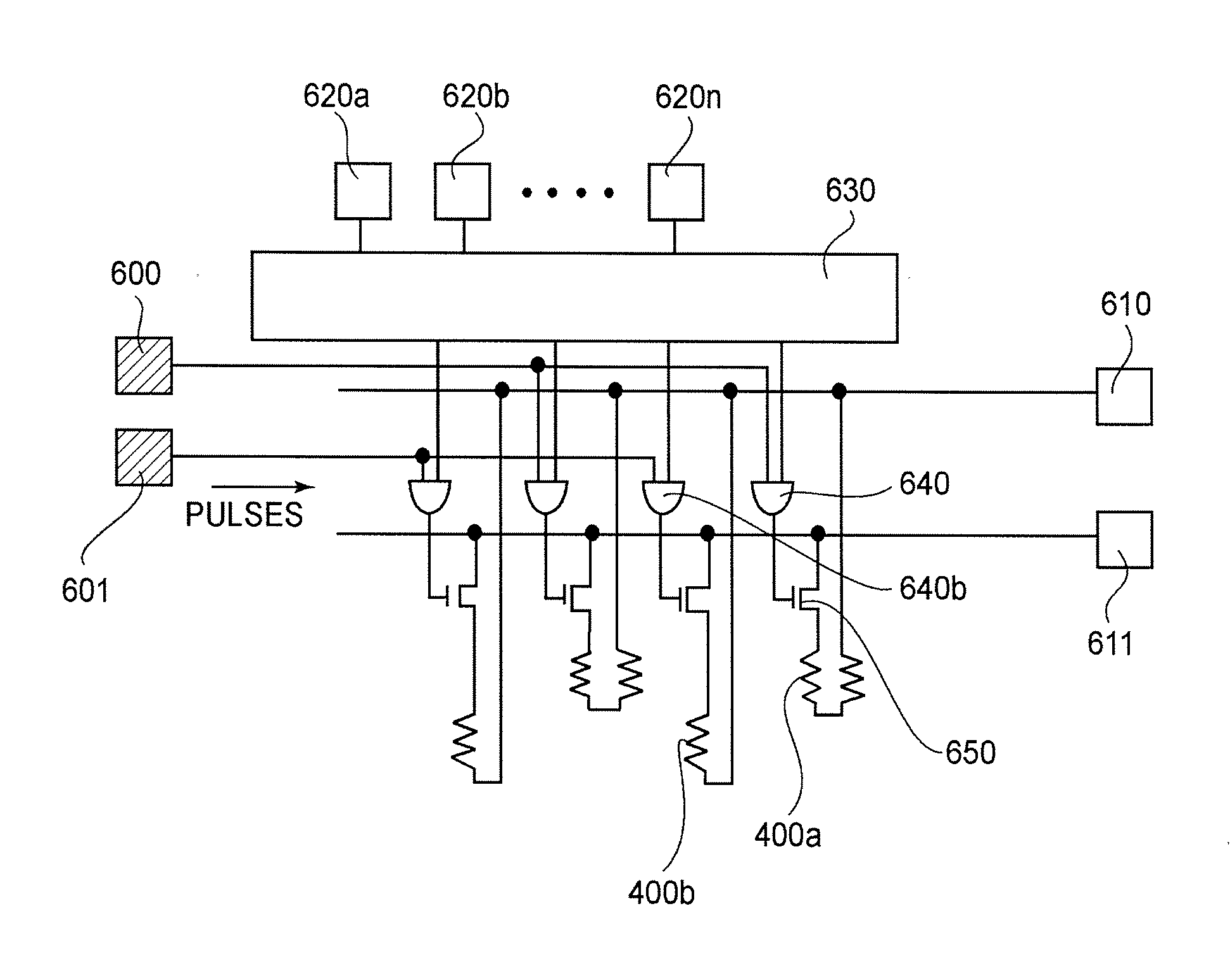

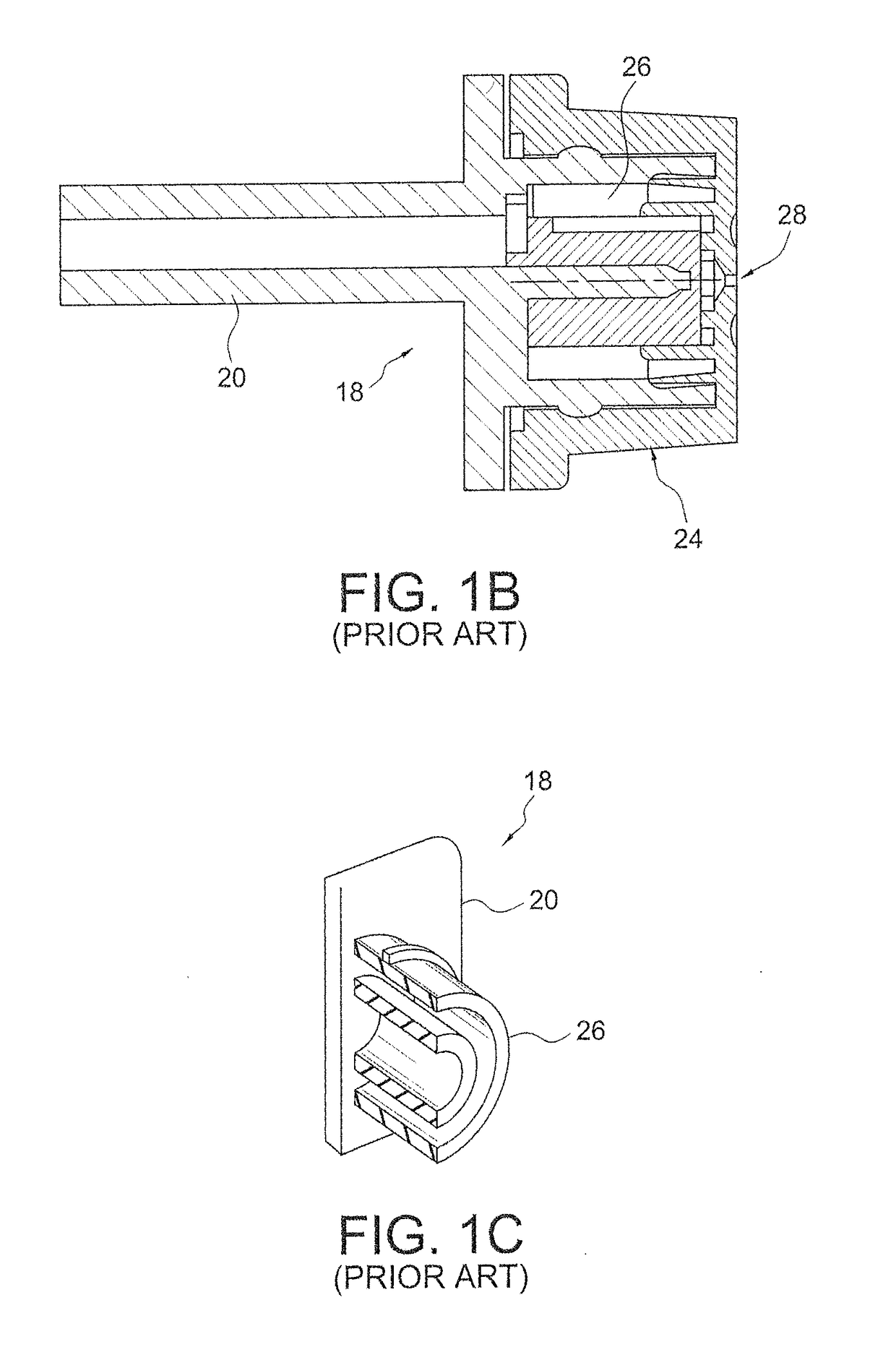

Pulse welder and method of using same

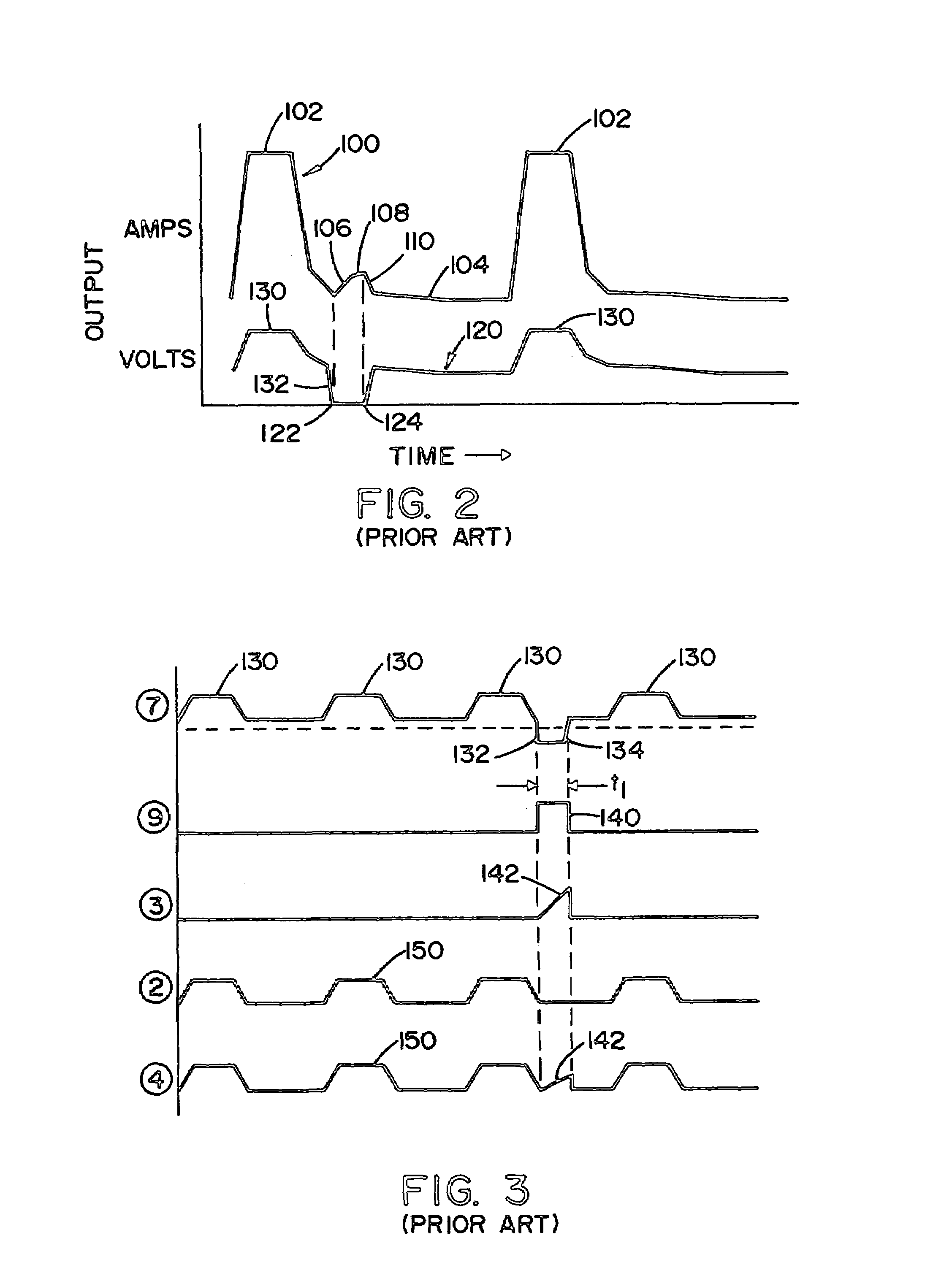

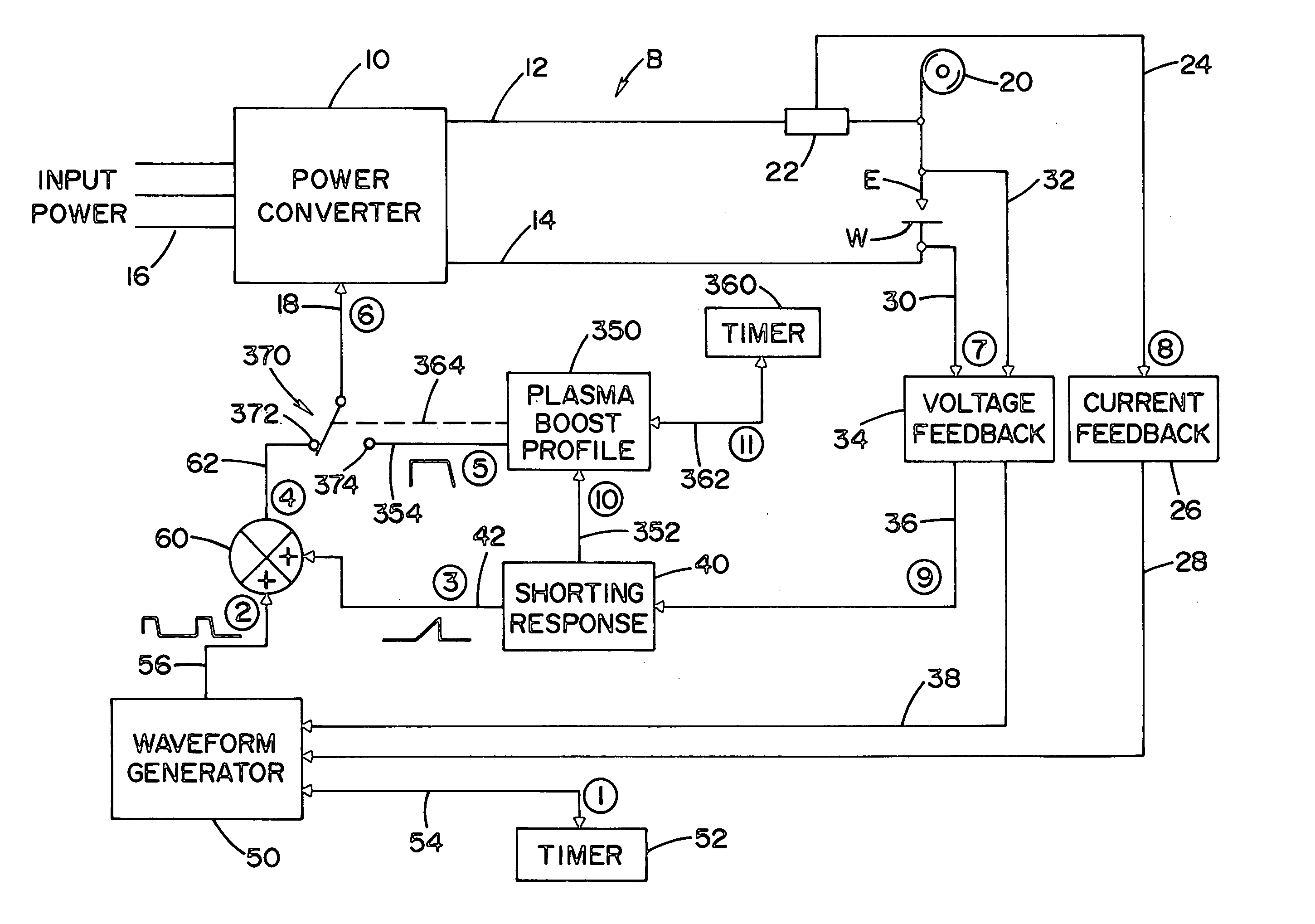

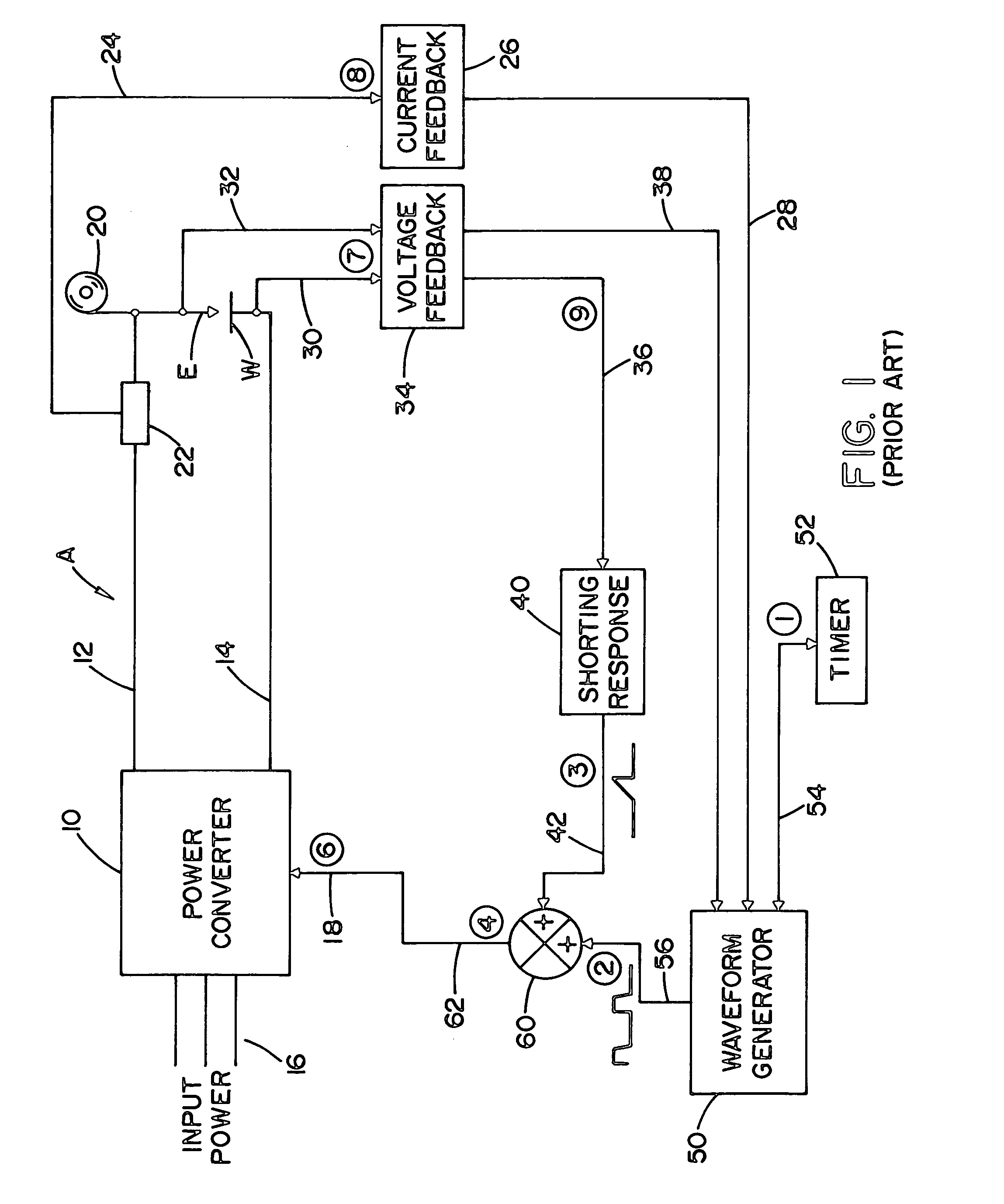

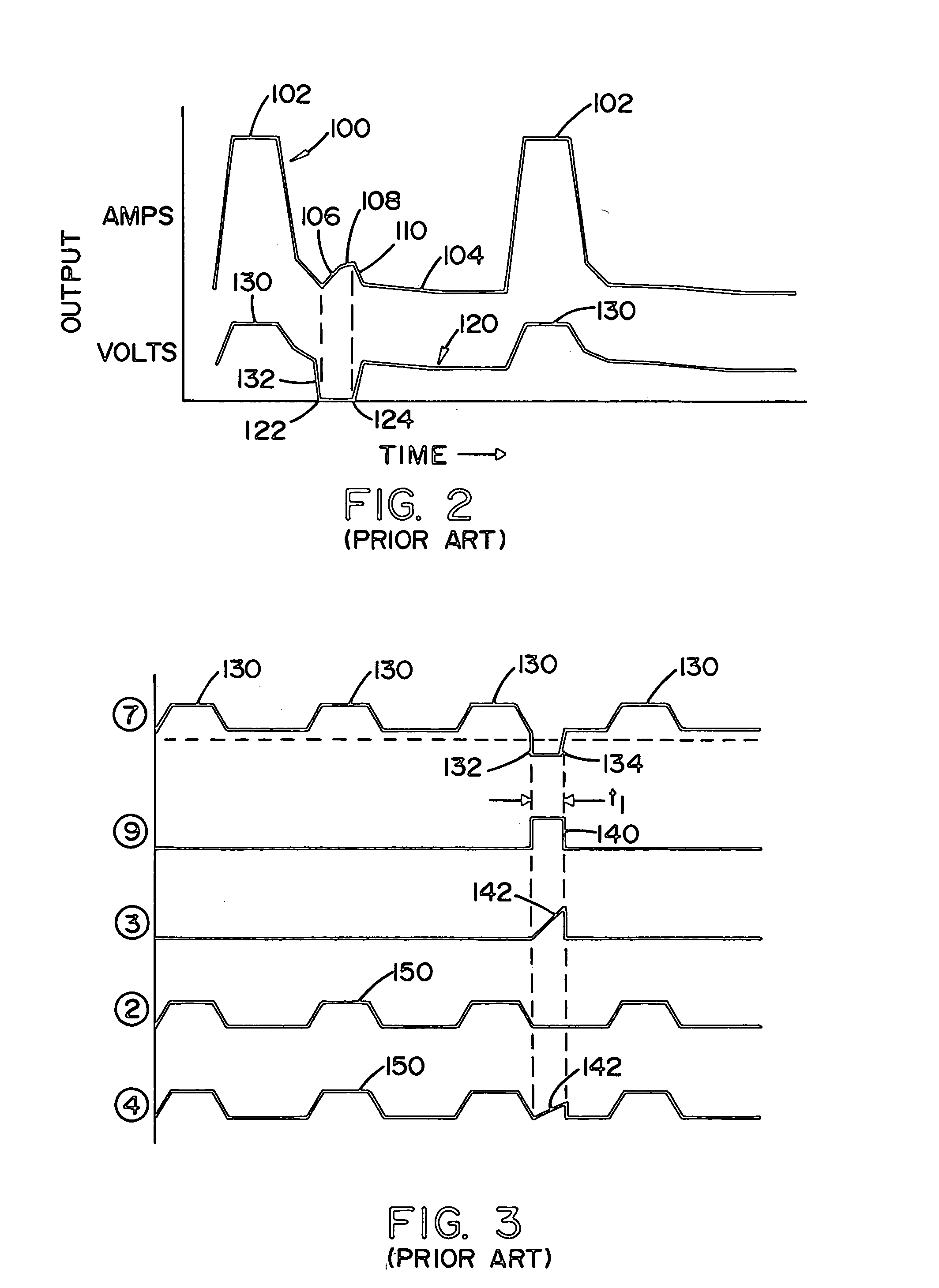

ActiveUS7304269B2Reduce arc forcePromote shorting eventsCoin-freed apparatus detailsArc welding apparatusPower flowEngineering

An electric arc welder for performing a pulse welding process by a current between an advancing electrode and workpiece where the welder comprises a short detecting circuit for creating a short signal upon occurrence of a short circuit between the advancing electrode and the workpiece and a boost circuit to create a plasma boost pulse after the short circuit is cleared during the time period when the welder is not outputting the peak pulse current.

Owner:LINCOLN GLOBAL INC

Pulse welder and method of using same

ActiveUS20050269306A1Reduce forceSmall droplet sizeCoin-freed apparatus detailsArc welding apparatusElectric arcEngineering

An electric arc welder for performing a pulse welding process by a current between an advancing electrode and workpiece where the welder comprises a short detecting circuit for creating a short signal upon occurrence of a short circuit between the advancing electrode and the workpiece and a boost circuit to create a plasma boost pulse after the short circuit is cleared during the time period when the welder is not outputting the peak pulse current.

Owner:LINCOLN GLOBAL INC

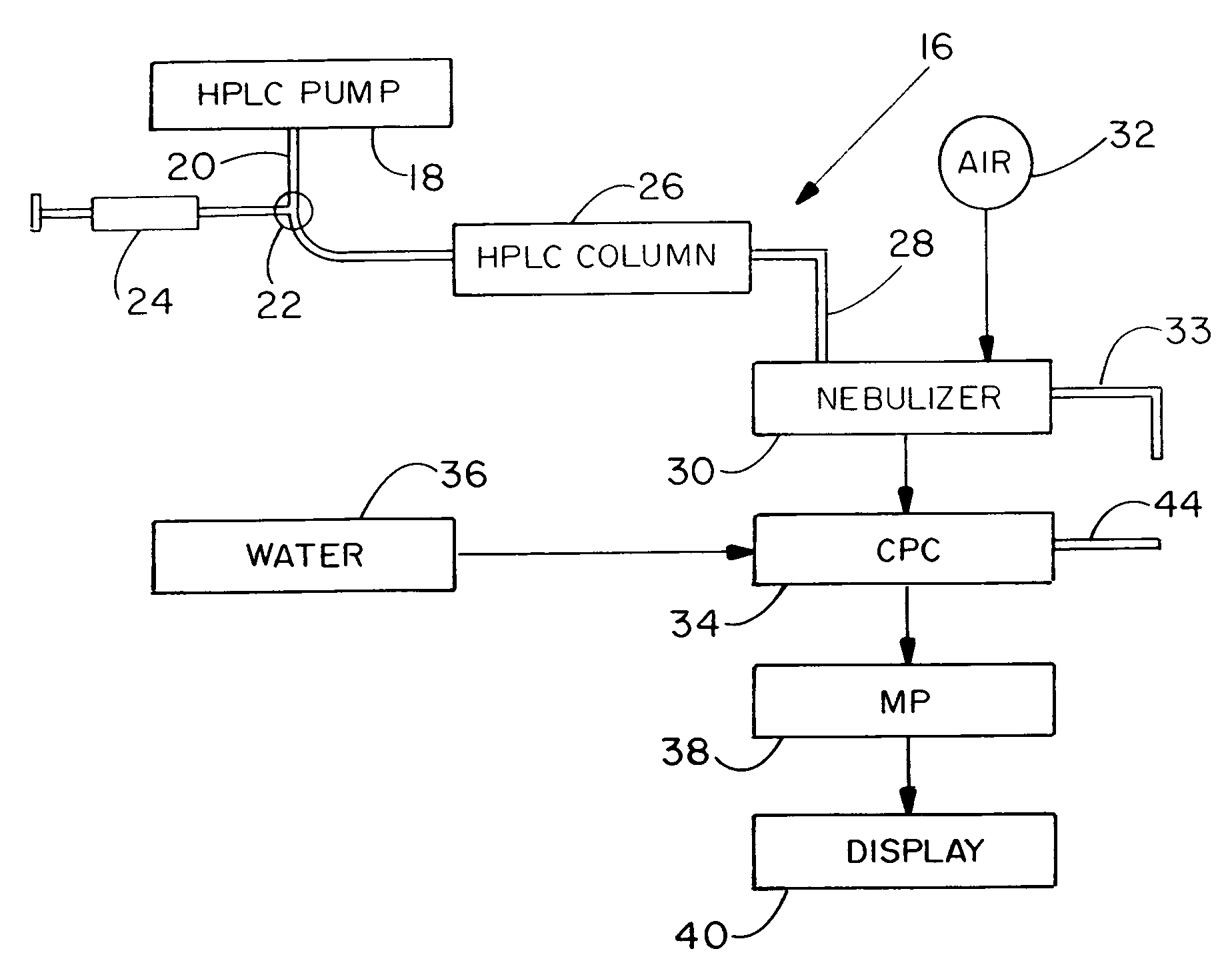

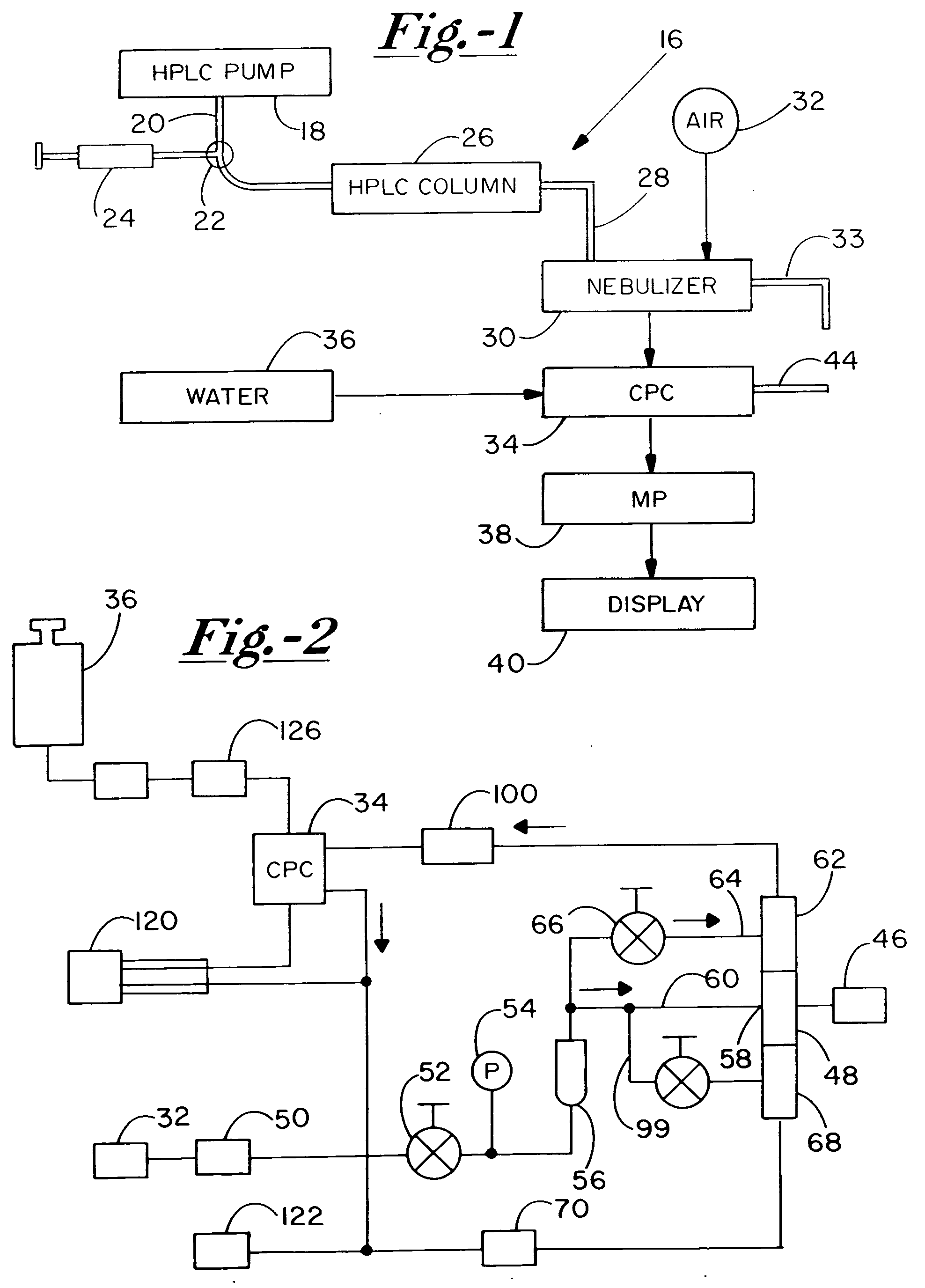

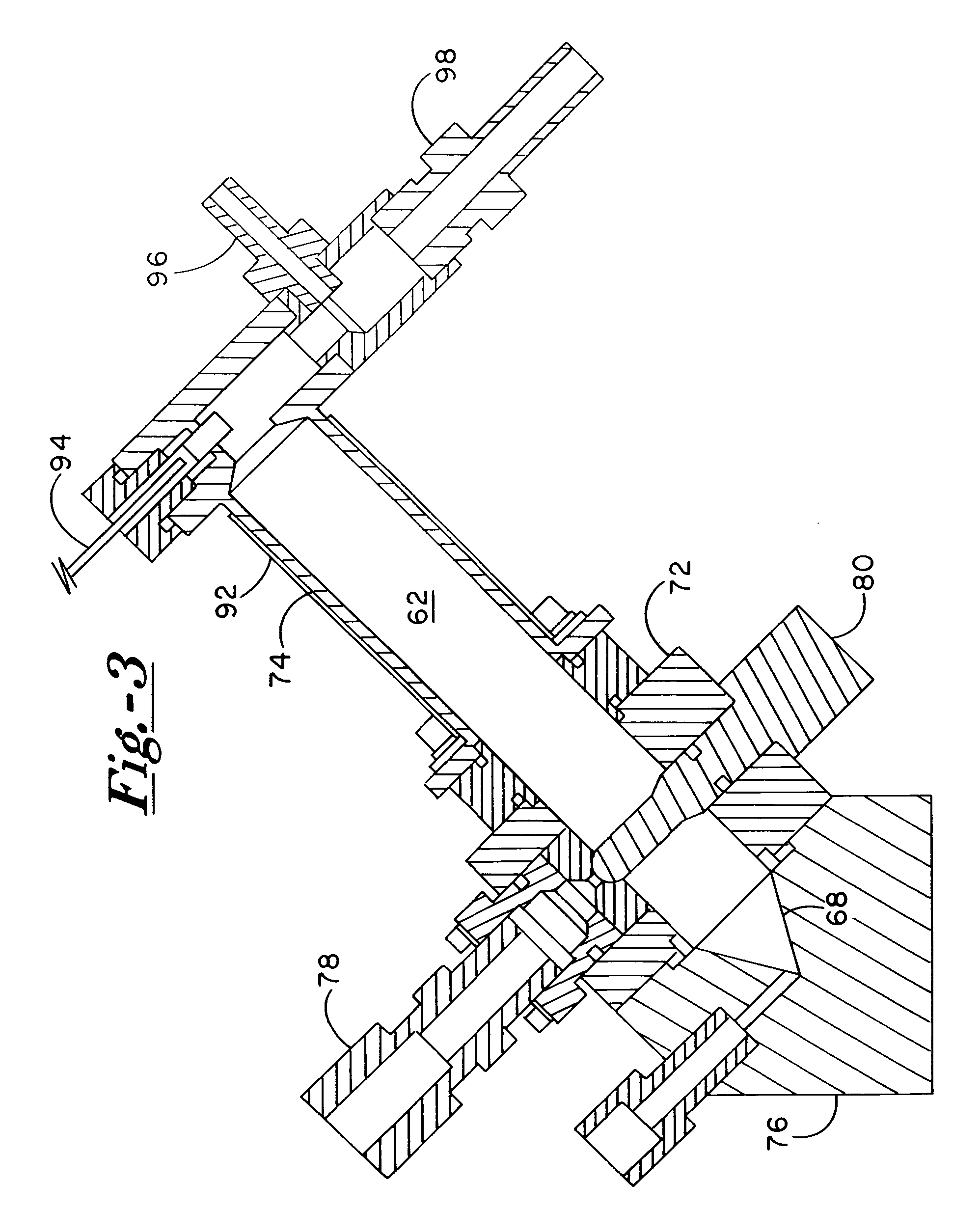

Measuring Analyte Concentrations in Liquids

InactiveUS20080137065A1Higher kinetic energy mixingSmall dropletSamplingComponent separationElectrical mobilityDroplet size

A high performance liquid chromatography system employs a nebulizer with a flow restriction at the exit of its mixing chamber to produce finer droplets, and an adjustable impactor for increased control over droplet sizes. Downstream of the mixing chamber, the nebulizer can incorporate tubing that is permeable to the sample liquid, to promote aerosol drying through perevaporation. A condensation particle counter downstream of the nebulizer uses water as the working medium, and is adjustable to control threshold nucleation sizes and droplet growth rates. A particle size selector employing diffusion, electrostatic attraction or selection based on electrical mobility, is advantageously positioned between the nebulizer and the CPC.

Owner:TSI INC

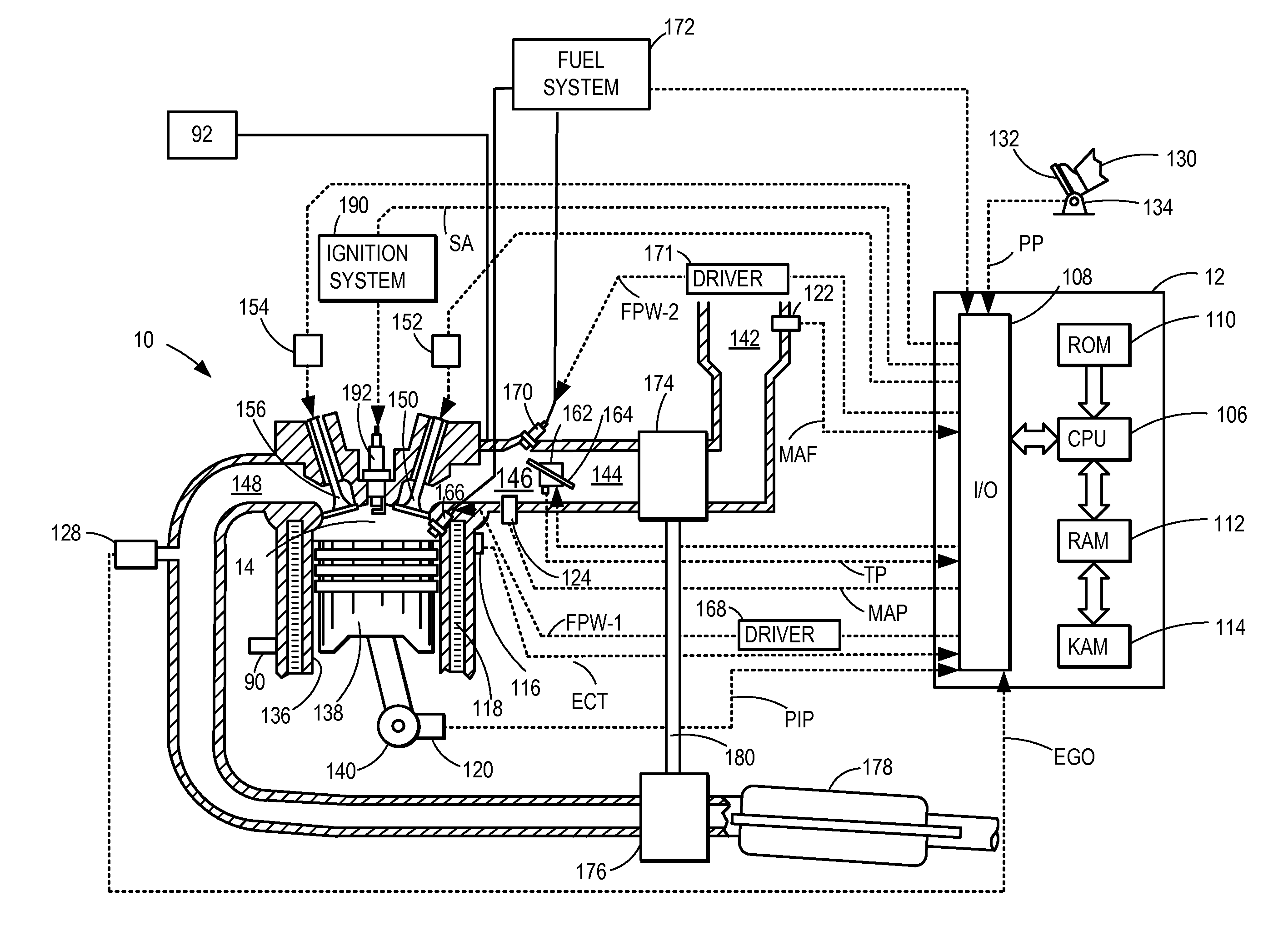

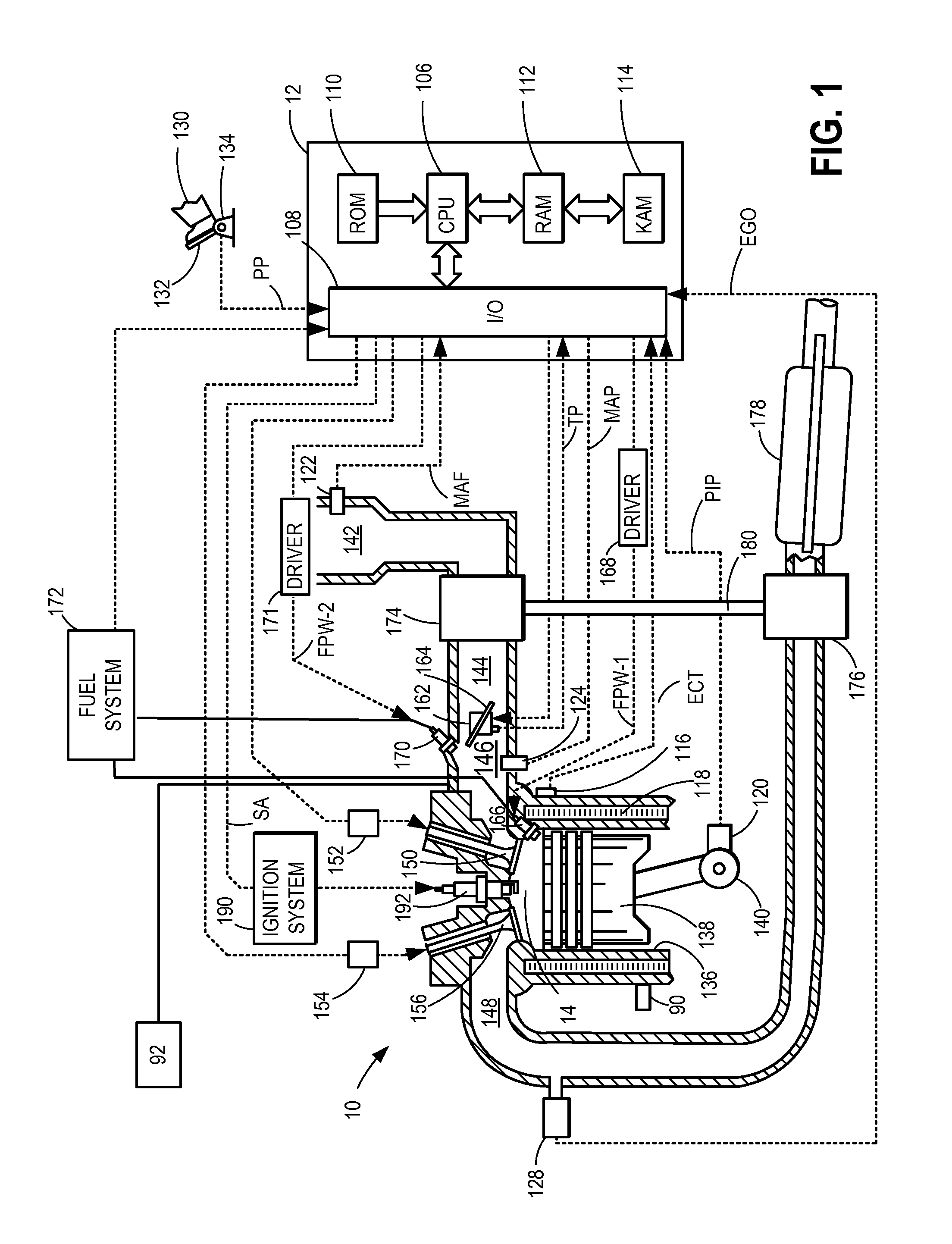

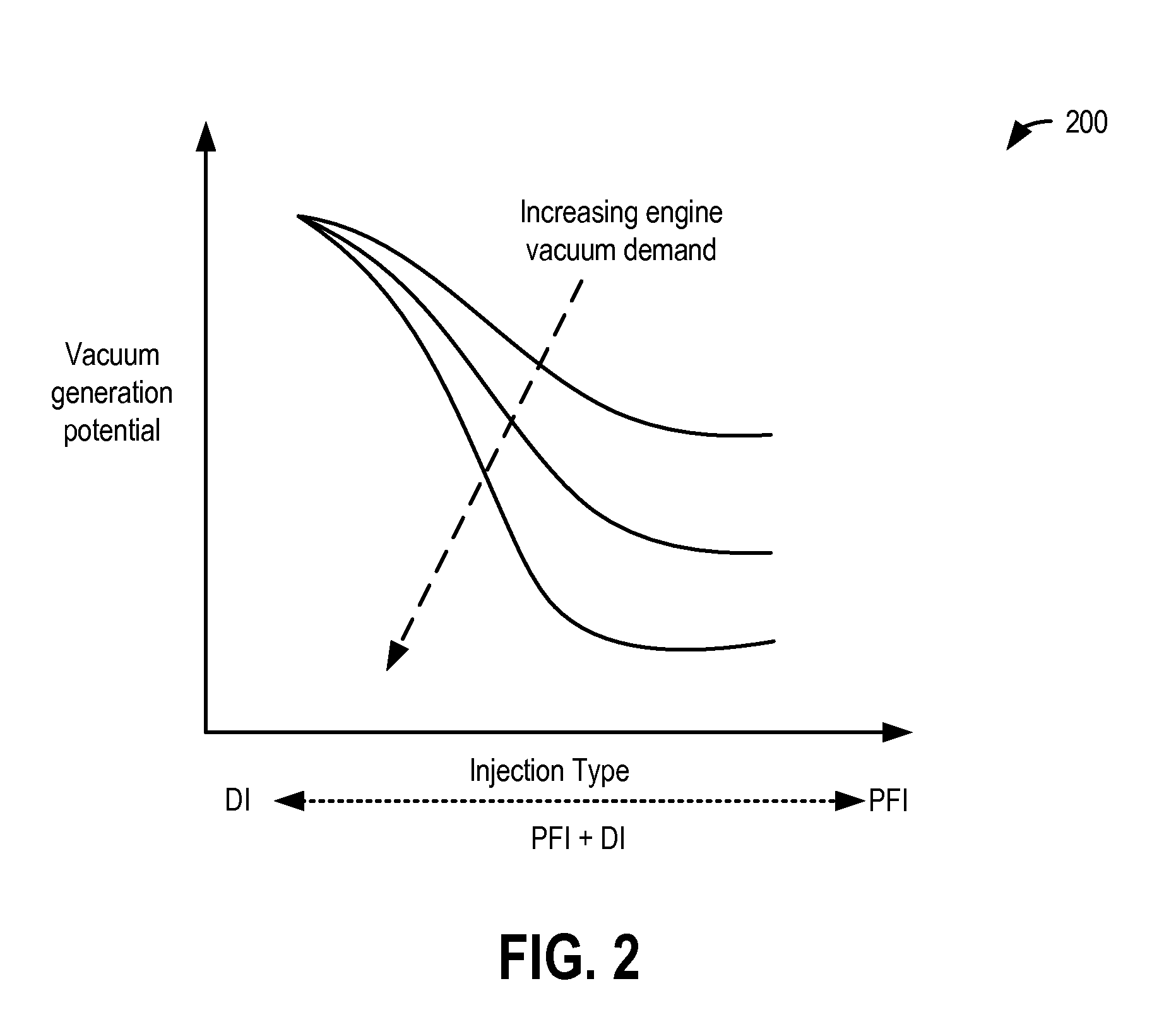

Method and system for vacuum control

ActiveUS20140261301A1Small droplet sizeImprove volumetric efficiencyElectrical controlInternal combustion piston enginesEngineeringCrankcase

Methods and systems are provided for adjusting a fuel injection split between a direct injection and a port injection based on engine vacuum demand. When more intake manifold vacuum is required, relatively more direct injection is used to take advantage of the associated throttling for generating vacuum. The vacuum may then be used for canister purging, crankcase ventilation, or actuating an engine vacuum consumption device.

Owner:FORD GLOBAL TECH LLC

High efficiency solar cell fabrication

InactiveUS20090008787A1Small droplet sizeIncrease etch rateLiquid surface applicatorsSemiconductor/solid-state device detailsSemiconductor materialsEngineering

A method of forming a contact structure and a contact structure so formed is described. The structure contacts an underlying layer of a semiconductor junction, wherein the junction comprises the underlying layer of a semiconductor material and is separated from an overlying layer of semiconductor material by creating an undercut region to shade subsequent metal formation. Various steps are performed using inkjet printing techniques.

Owner:NEWSOUTH INNOVATIONS PTY LTD

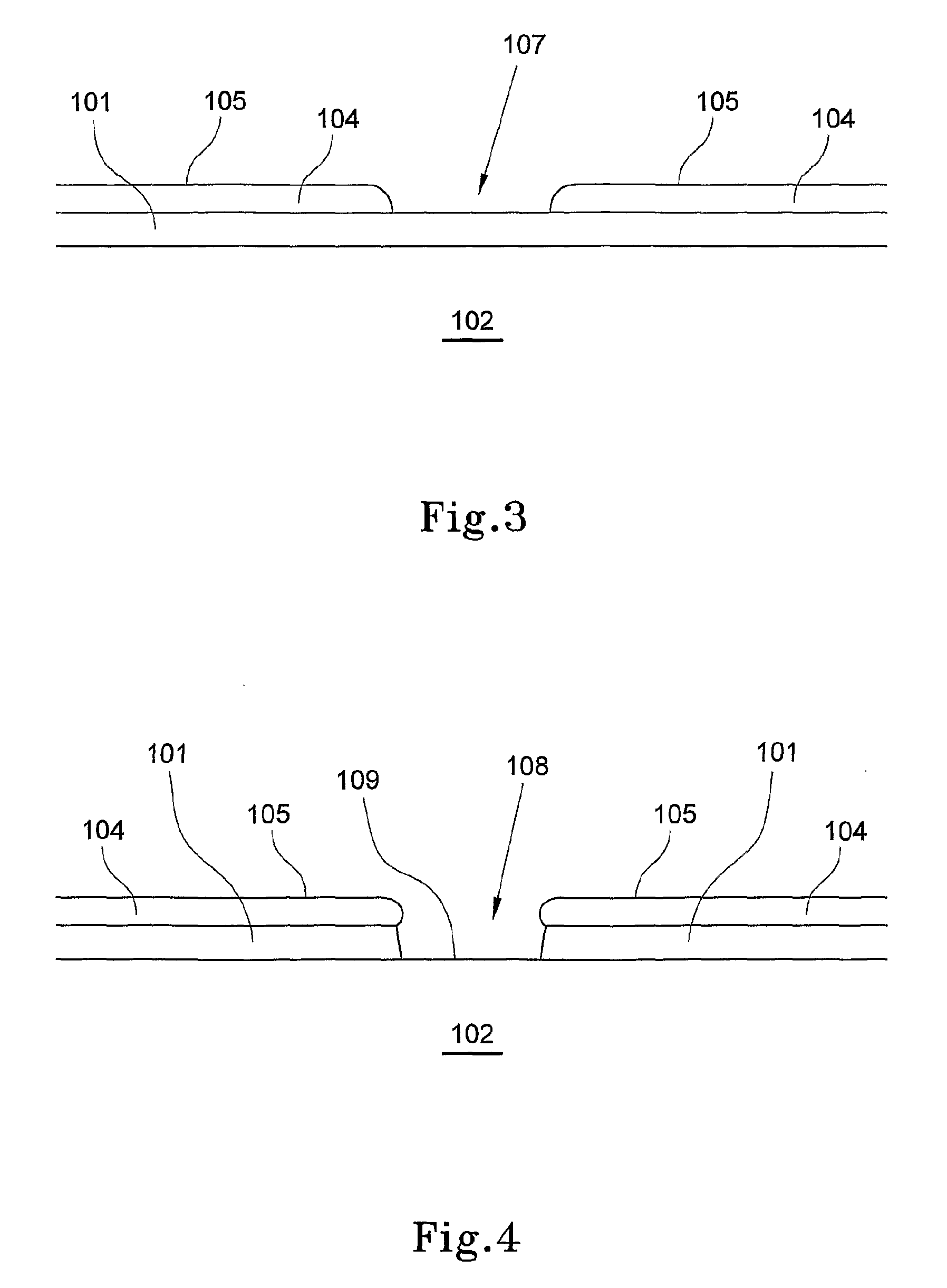

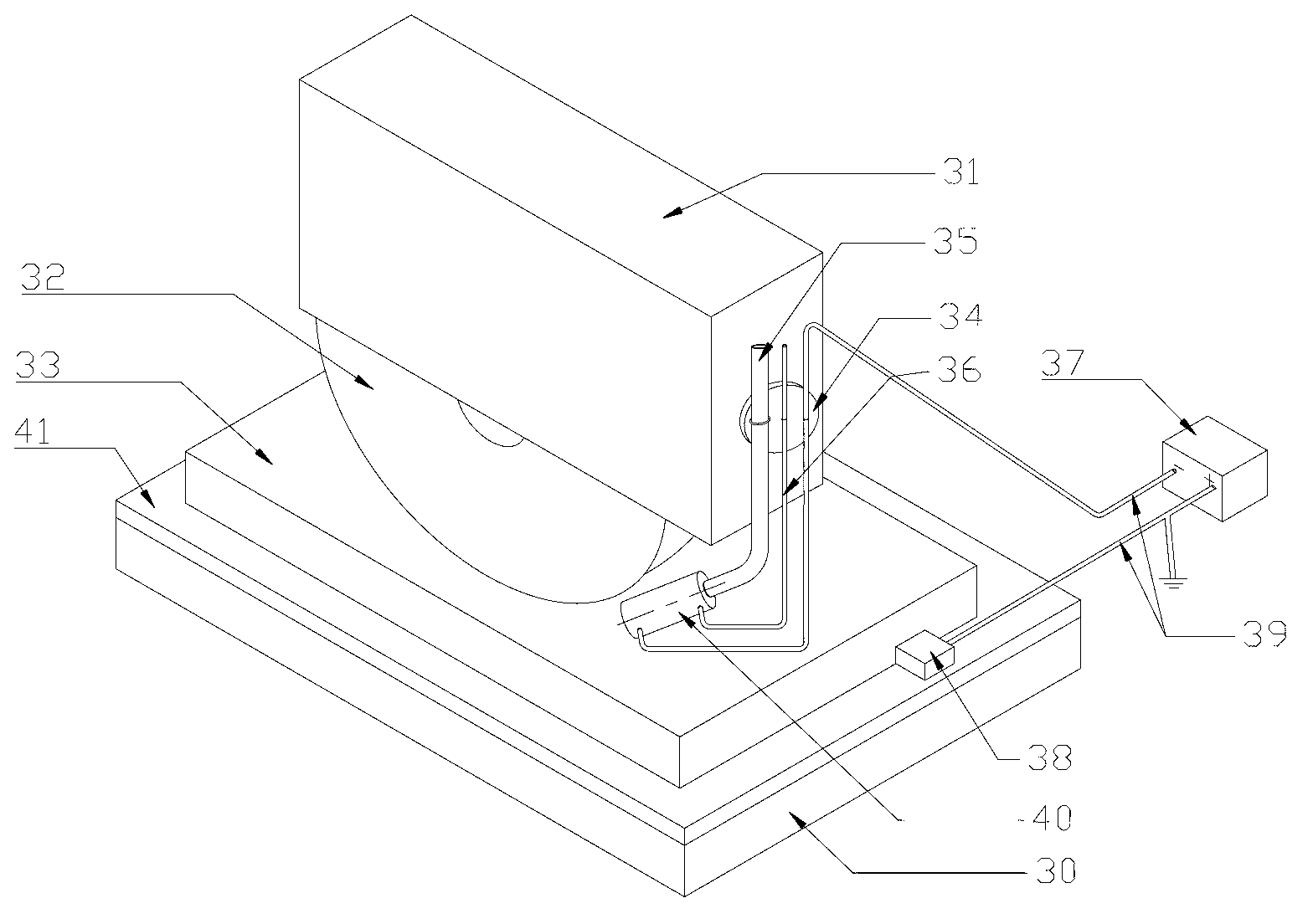

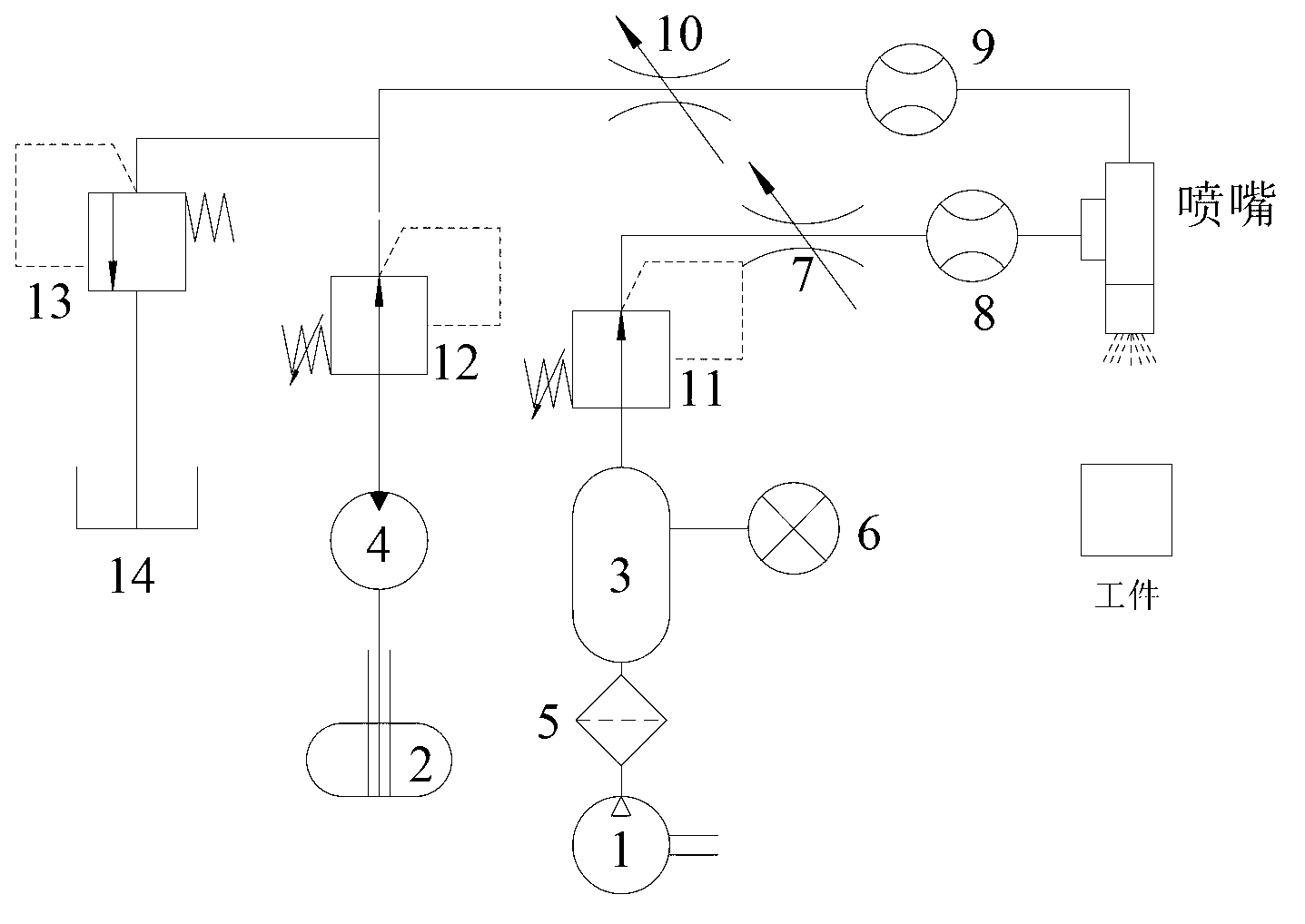

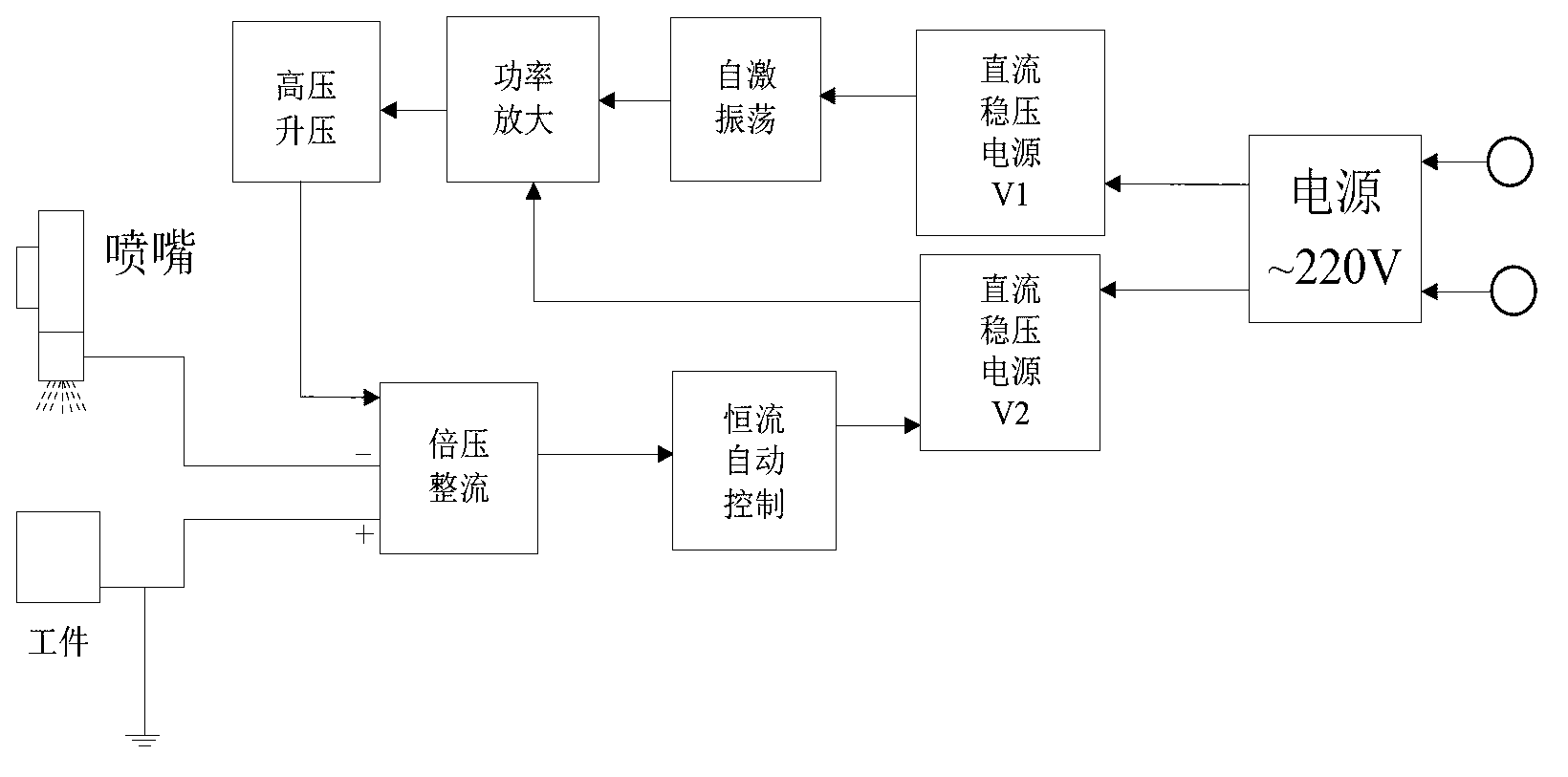

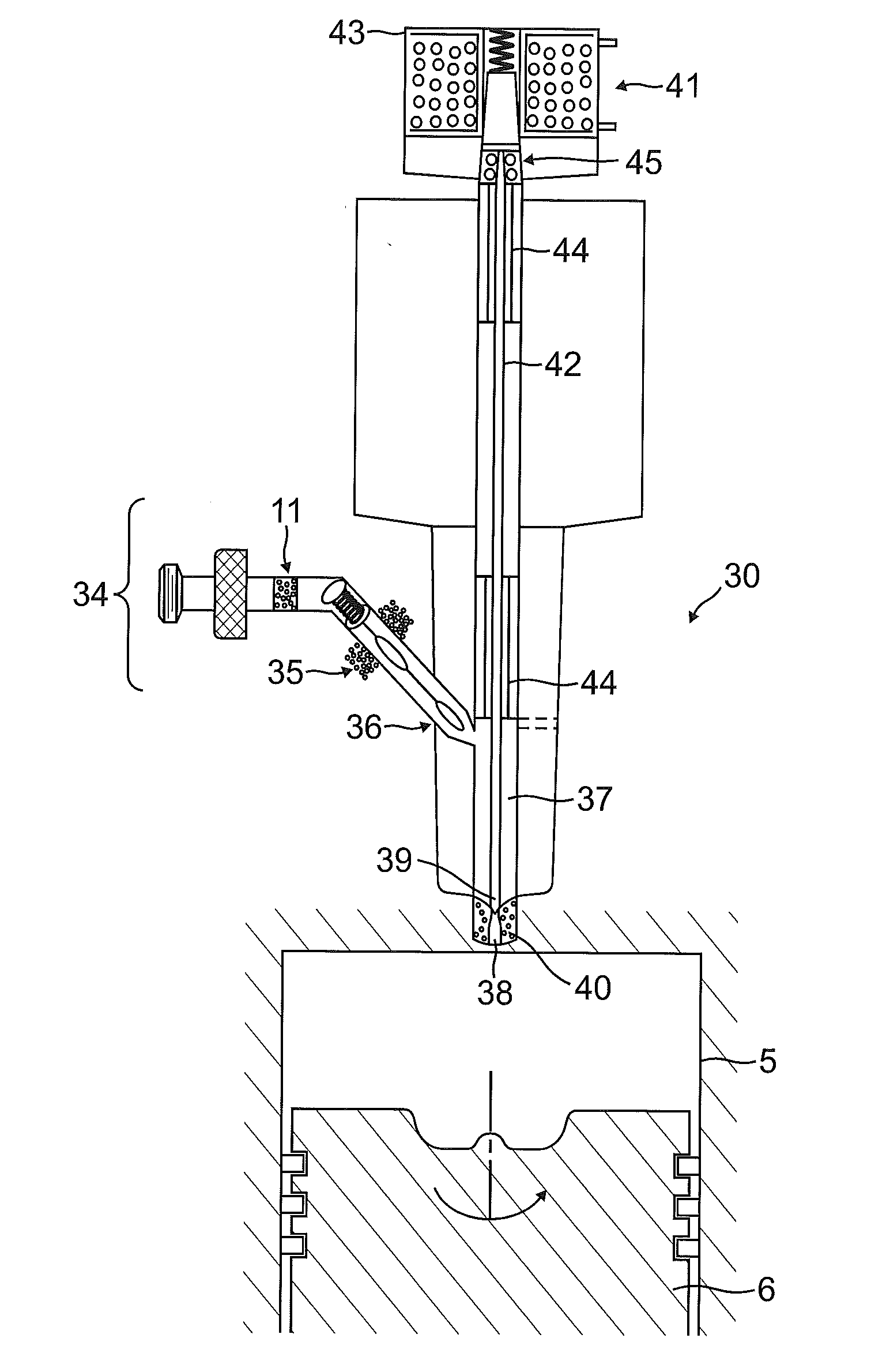

Nano fluid electrostatic atomizing controllable jet stream minimal lubricating and grinding system

ActiveCN103072084AReduce drift lossIncrease profitGrinding/polishing safety devicesMachined surfaceHigh-voltage direct current

The invention relates to a nano fluid electrostatic atomizing controllable jet stream minimal lubricating and grinding system. Sprayed fog drops can be controllably distributed through the electrostatic principle, so that the pollution to environment is reduced, and better health security is provided to workers. A grinding system is provided with a corona charging nozzle, wherein a nozzle body of the corona charging nozzle is connected with a liquid supply system and an air supply system; a high-voltage direct-current electrostatic generator on the lower part of the nozzle body is connected with the cathode of an adjustable high-voltage direct-current power supply; the anode of the adjustable high-voltage direct-current power supply is connected with a workpiece charging device; and the workpiece charging device is attached to the non-machined surface of a workpiece. Nano fluid grinding liquid is fed into the corona charging nozzle through the liquid supply system, meanwhile the air supply system feeds compressed air into the corona charging nozzle, the nano fluid grinding liquid is charged into controllable jet stream by the high-voltage direct-current electrostatic generator while being driven by the compressed air to be sprayed out and atomized from the nozzle body, and the controllable jet stream is controllably distributed to a grinding area of the machined workpiece under the actions of electric field force and aerodynamic force.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

Inhaler and store for a dry medicament formulation and related methods and use thereof

InactiveUS20070154407A1Good storage stabilityEasy to measurePowder deliveryDispersion deliverySolventPharmaceutical formulation

An inhaler, a store and a method for atomizing a dry medicament formulation are disclosed. The medicament formulation is first dissolved by a liquid solvent and then atomized together with the solvent. This allows easy metering and satisfactory storage of the medicament formulation in the dry state. Particularly preferably, the dry medicament formulation is prepared by drying an initially liquid medicament formulation. Alternatively, the dried medicament formulation may also be expelled in dry form by means of a gas current and atomized.

Owner:BOEHRINGER INGELHEIM INT GMBH

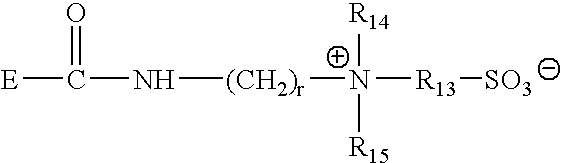

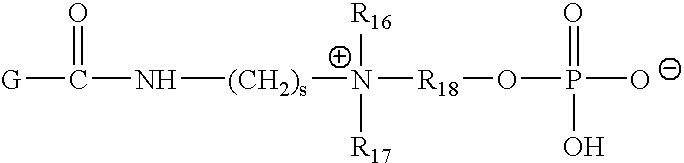

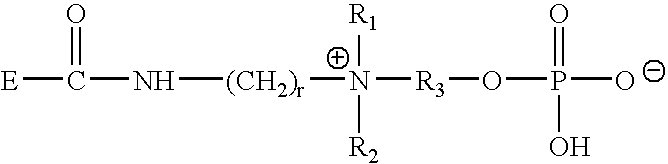

Conditioning detergent compositions

InactiveUS20050019299A1Easy to adjustLow degreeCosmetic preparationsHair cosmeticsSuspending AgentsOpacifier

A conditioning detergent composition comprised of a surfactant portion comprising at least one of anionic, amphoteric, and nonionic surfactants and a conditioner portion comprising at least one branched cationic polymers and a silicone which is different from said branched cationic polymer and which is matrix soluble. The conditioning detergent composition imparts cleansing, wet detangling, dry detangling and manageability to hair and which is relatively non-irritating and thus suitable for use by young children and adults having sensitive skin and eyes. The conditioning detergent composition is able to provide such benefits in an aesthetically pleasing formulation without the need for suspending agents, opacifiers, or pearlizing agents.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

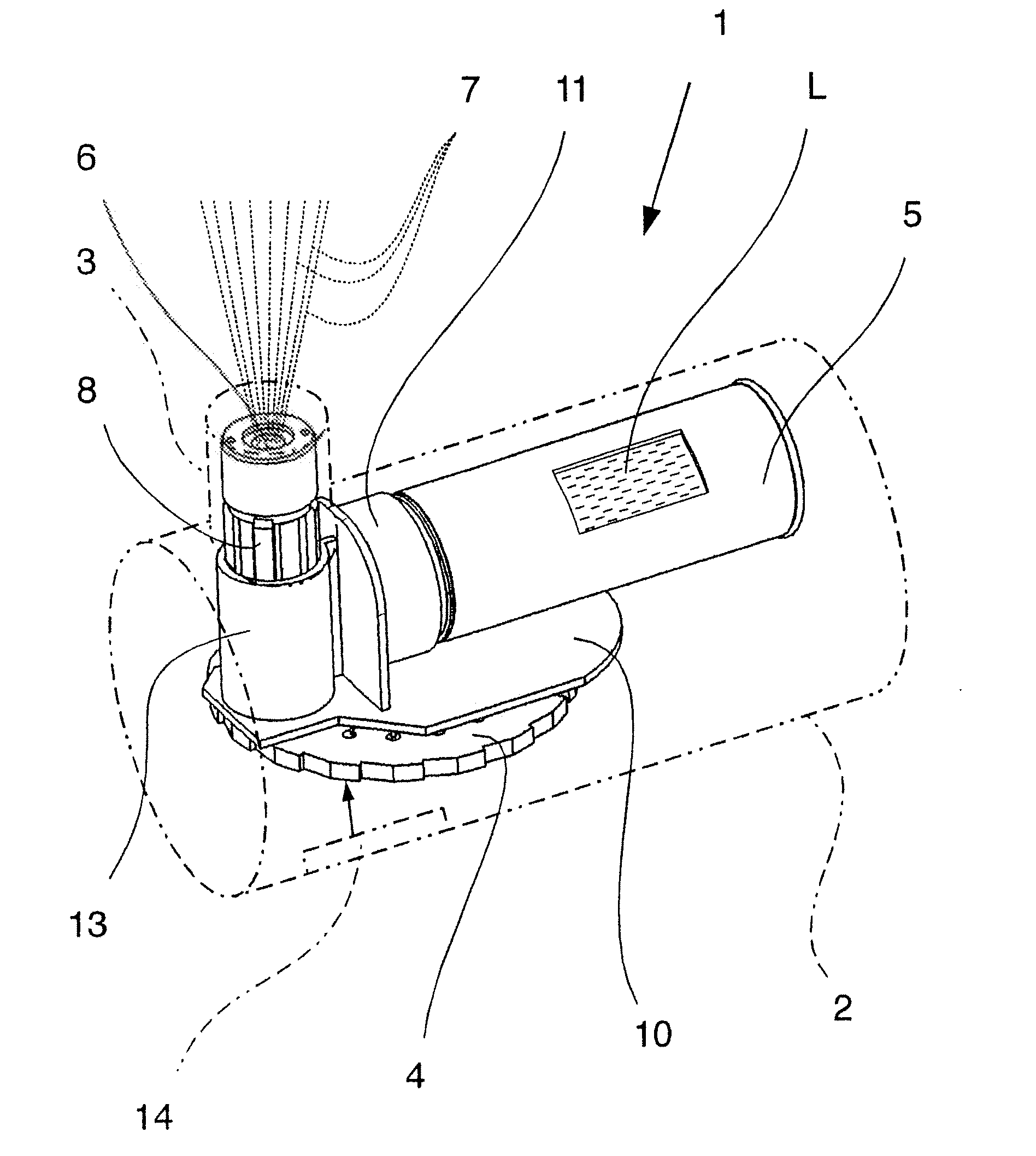

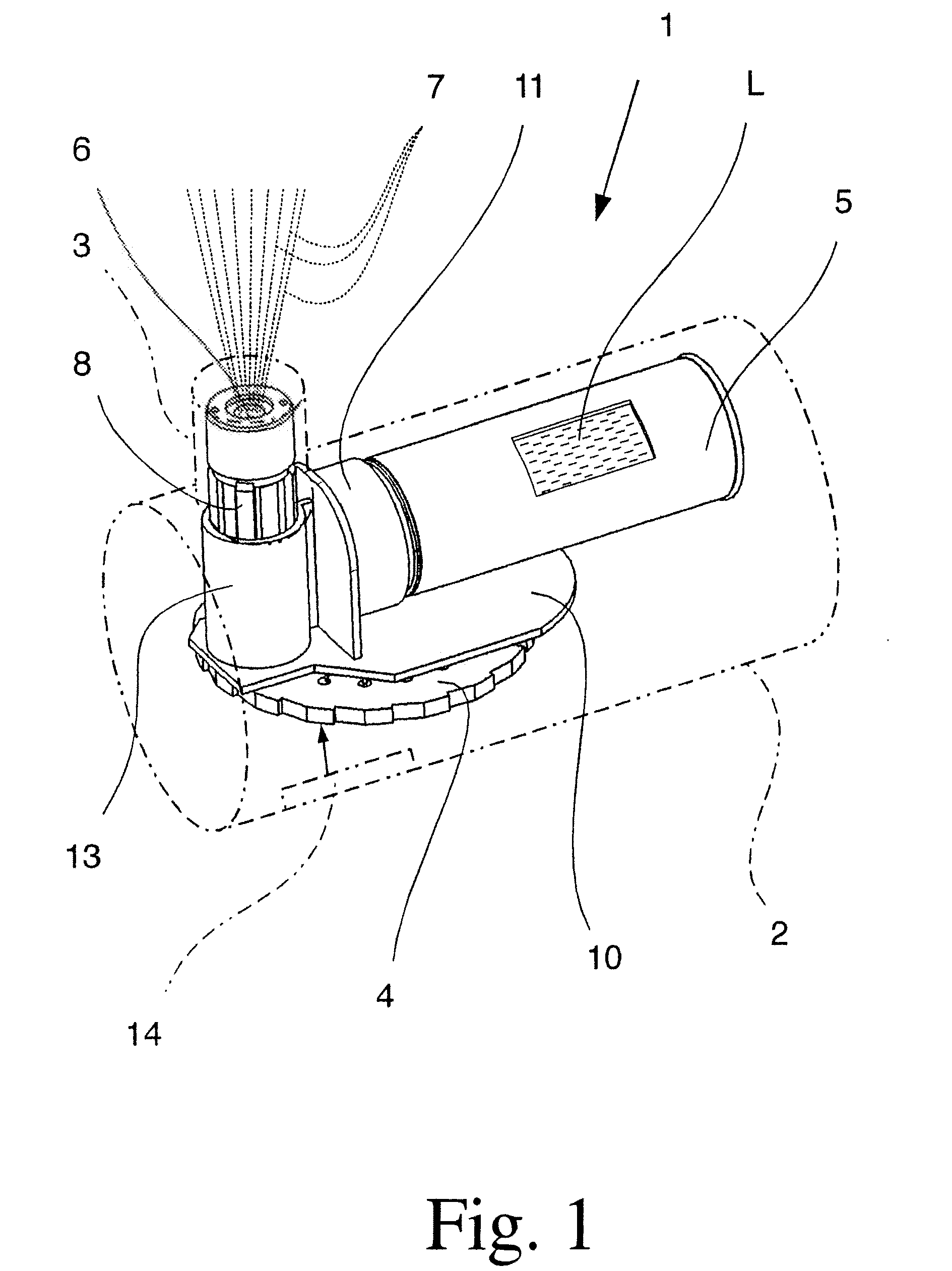

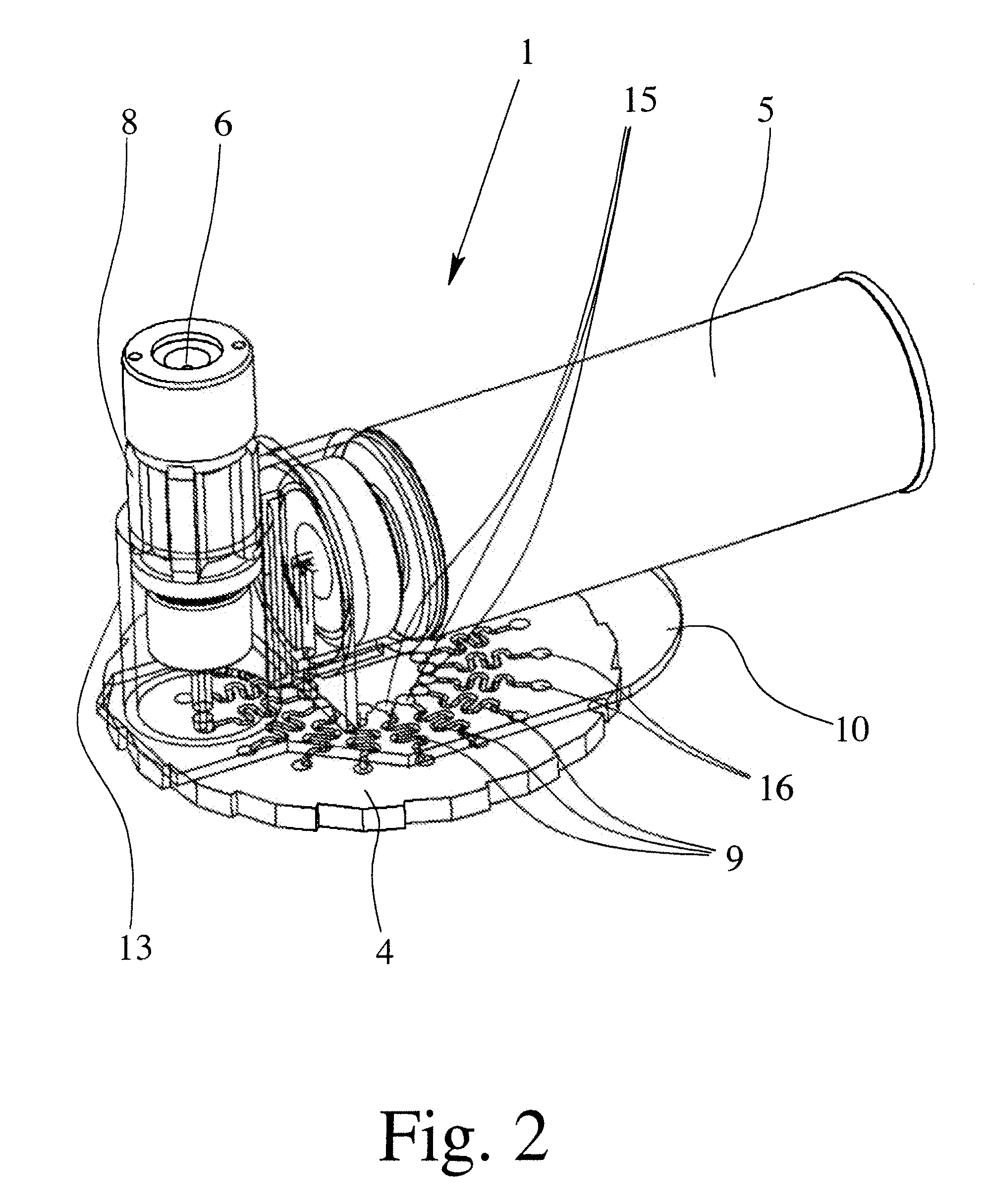

A liquid atomizing nozzle

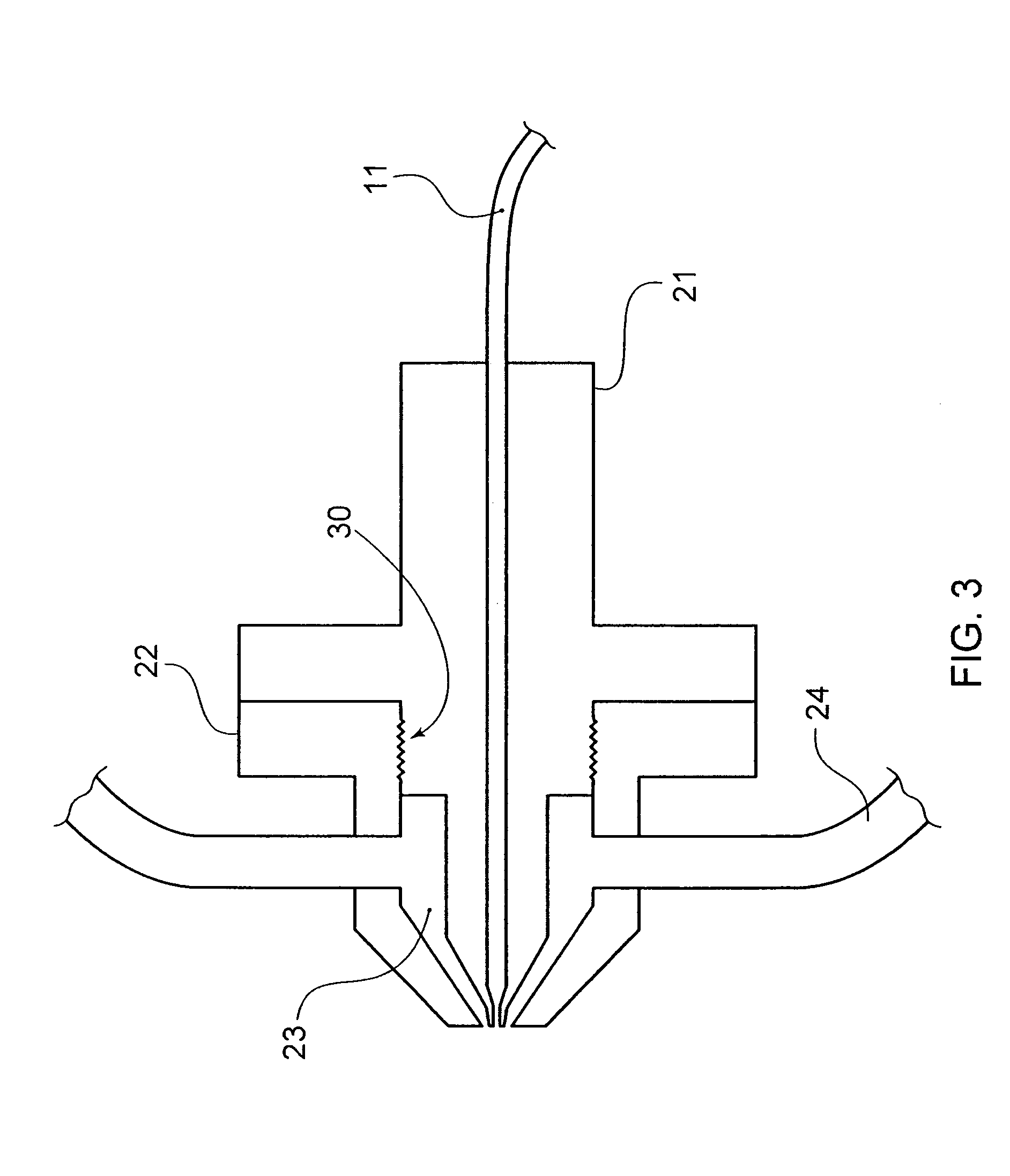

InactiveUS20070194146A1Improved and simplifiedLow costSpray nozzlesLiquid spraying apparatusSpray nozzleCost savings

The present invention provides a nozzle capable of multiple atomizing steps of a liquid. In one configuration the nozzle provides atomization of a liquid fluid in a first direction and subsequent post atomization of the same liquid in a second direction to form a counter-flow nozzle. Accordingly, the liquid fluid to be dispensed is atomized in at least two separate stages causing improved atomization and the creation of particulate matter size of the liquid within a specified droplet spectrum. Furthermore, the present invention provides these features through an improved and simplified design providing potential cost savings to the end user due to the more effective operation of the nozzle and more efficient dispensing of fluid agents.

Owner:ADVANCED SPECIALIZED TECH

Fuel injection method and combustion engine with early pre-injection

InactiveUS20140251278A1Rapid evaporation and mixingSmall droplet sizeElectrical controlInternal combustion piston enginesCombustionInternal combustion engine

A fuel injection method in an internal combustion engine and an internal combustion engine for performing the fuel injection method. The method includes heating fuel to a temperature between 300° F. and 840° F. (150 and 450° C.); pressurizing the fuel to a pressure exceeding 40 bar; pre-injecting at least 10% of the fuel charge as a pre-injected fuel during the intake stroke; injecting a fuel charge over at least part of the compression stroke into the cylinder; and injecting an ignition-injection of at least 10% of the fuel in a supercritical condition during the compression stroke at a rotational angle between 90° BTDCF and TDCF into the cylinder. The method and related combustion engine create a good mix of premix combustion and diffusion combustion increasing efficiency and consequently reducing emissions to the environment while also keeping noise and vibrations low.

Owner:ECOMOTORS

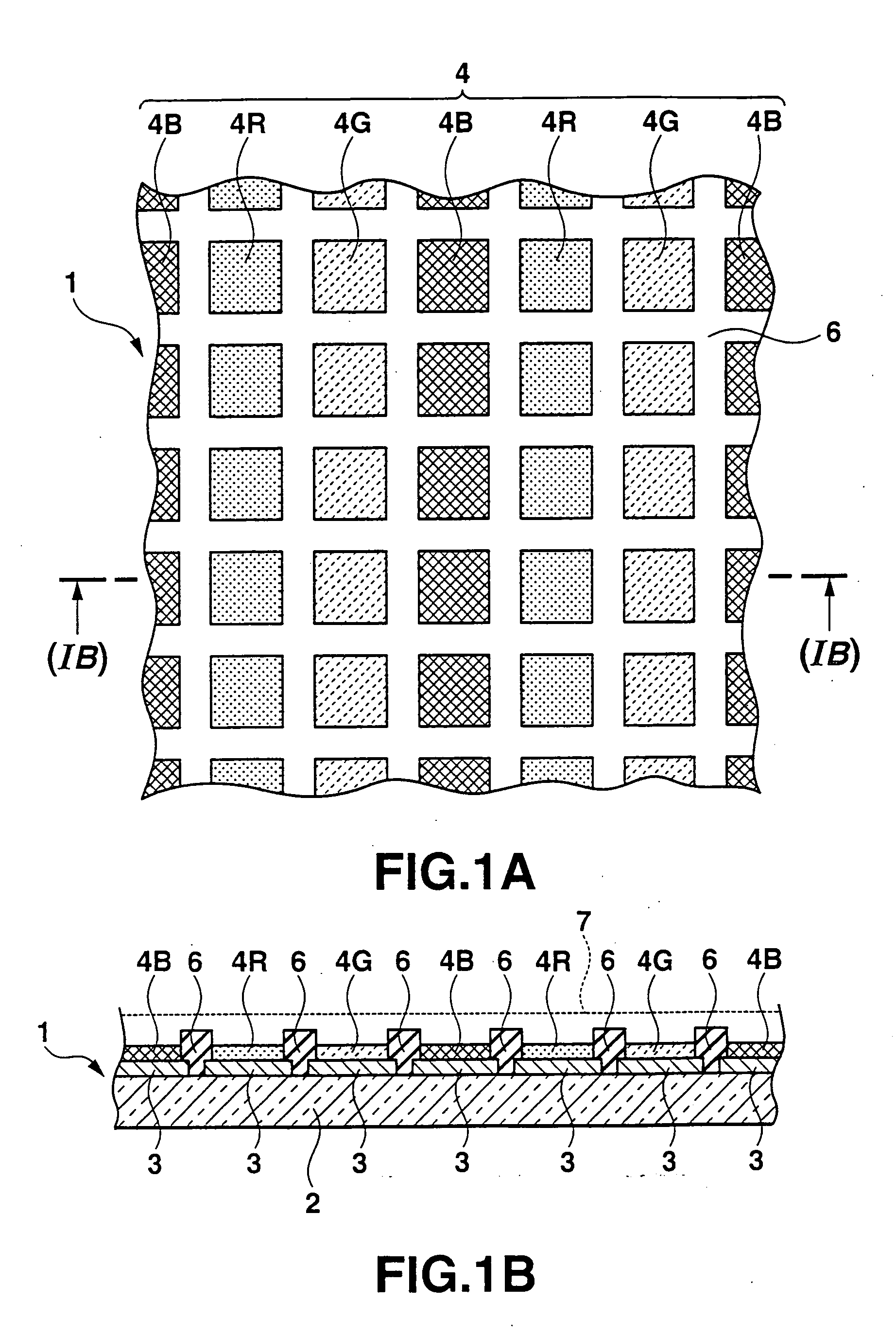

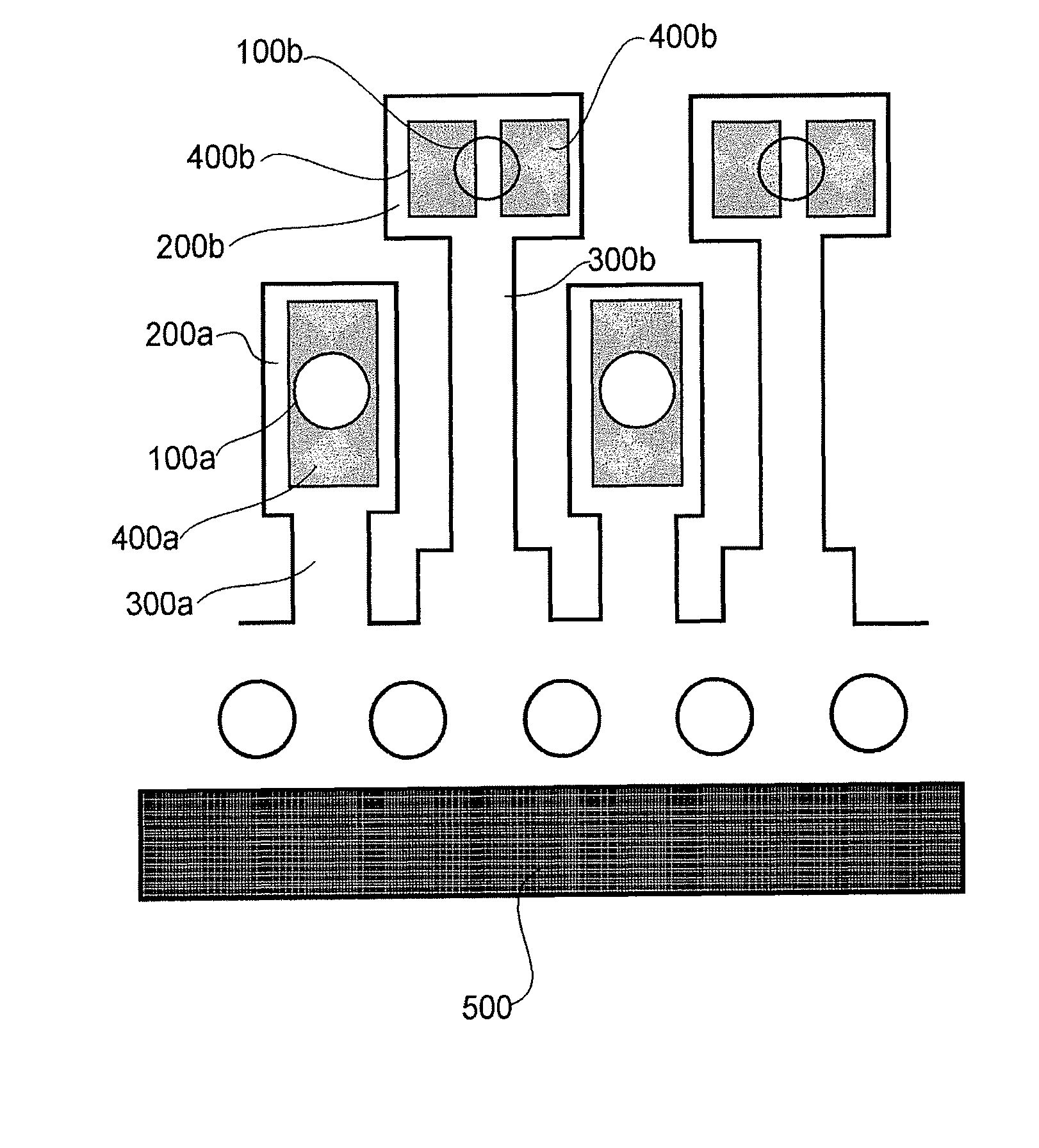

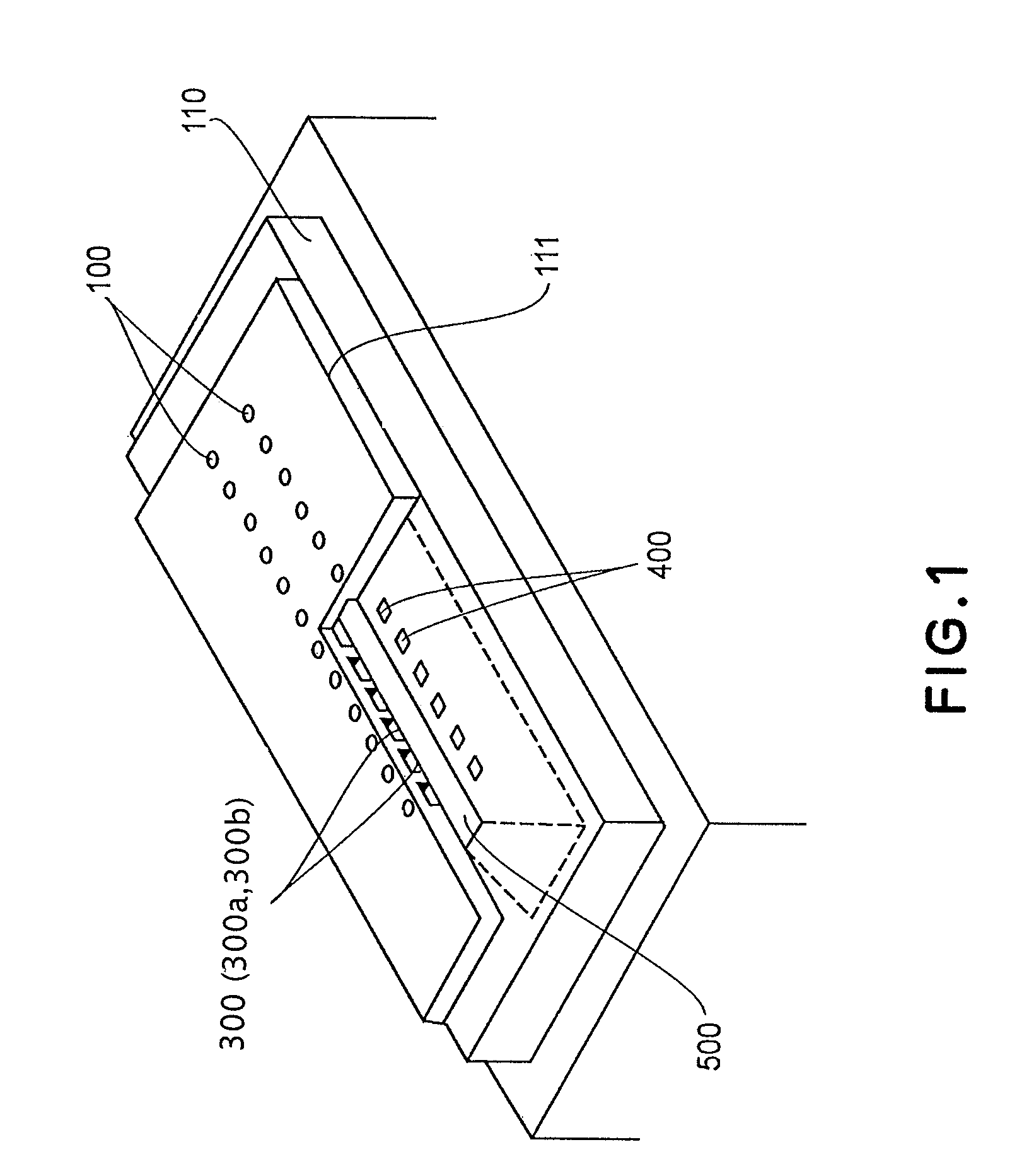

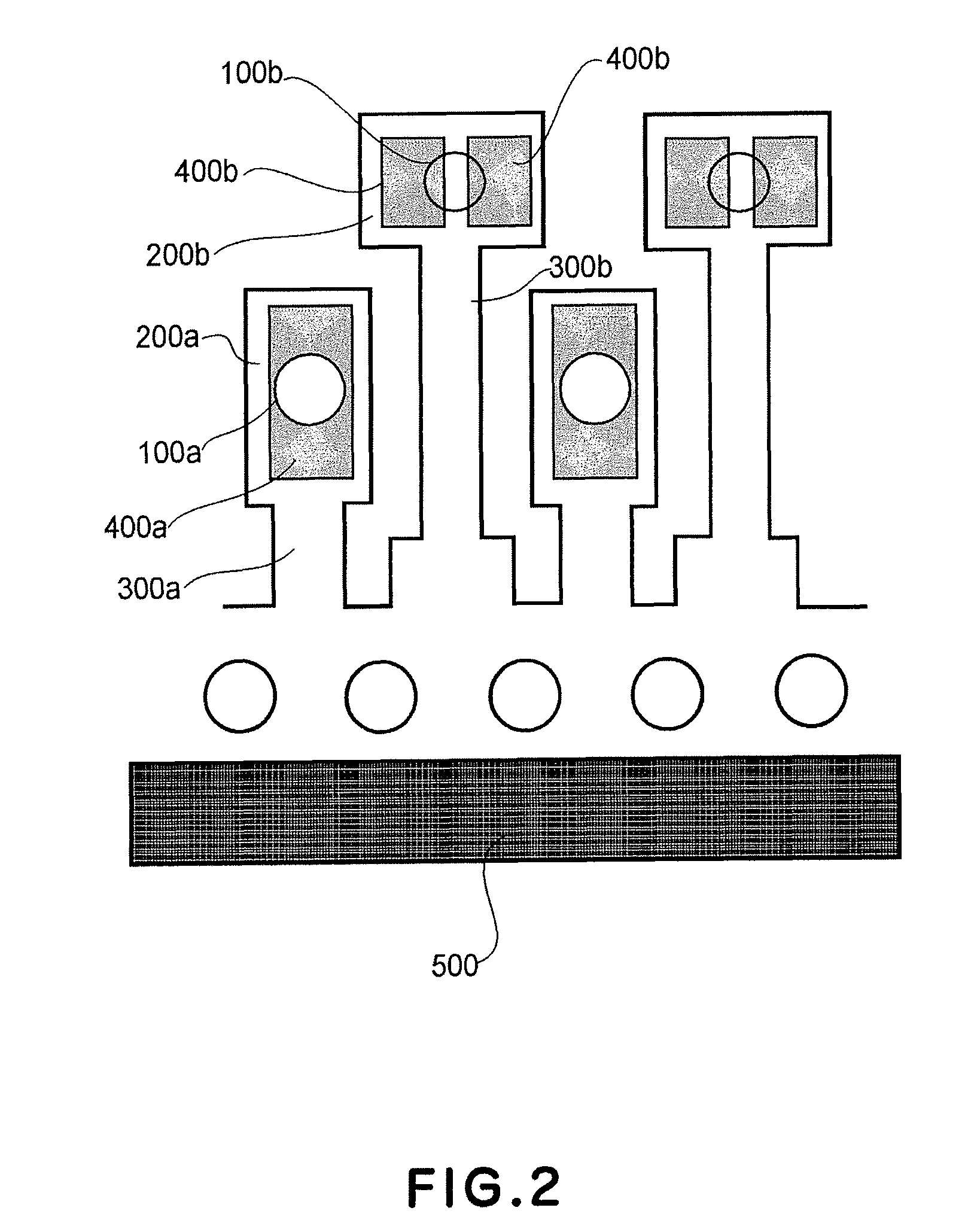

Liquid jet head

InactiveUS20080055368A1Without manufacturing costJetting performance becomes unstablePrintingLiquid jetEngineering

A liquid ejecting head includes a plurality of ejection outlets for ejecting droplets; liquid flow paths in fluid communication with said ejection outlets; and a liquid supply opening for supplying the liquid to said liquid flow path; wherein said ejection outlets include first ejection outlets and second ejection outlets which are disposed at least at one side of said liquid supply opening, wherein said first ejection outlets are nearer from said liquid supply opening than said second ejection outlets, and said first ejection outlets and said second ejection outlets are arranged in a staggered fashion; first recording elements for said first ejection outlets; second recording elements for said second ejection outlets, wherein each of said first recording elements includes one heat generating resistor in the form of a rectangular shape having a long side extending along a direction crossing with an arranging direction of said ejection outlets; and wherein said second recording element includes a plurality of heat generating resistors each of which is in the form of a rectangular shape and which are adjacent to each other at the long sides thereof, said plurality of heat generating resistors being electrically connected in series.

Owner:CANON KK

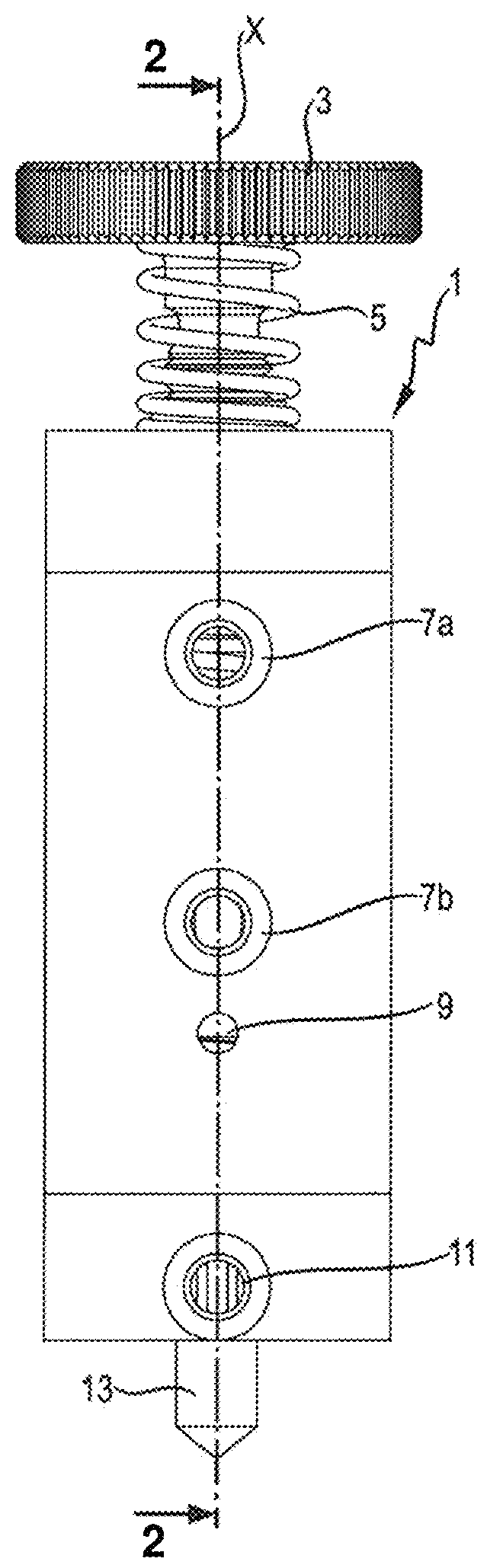

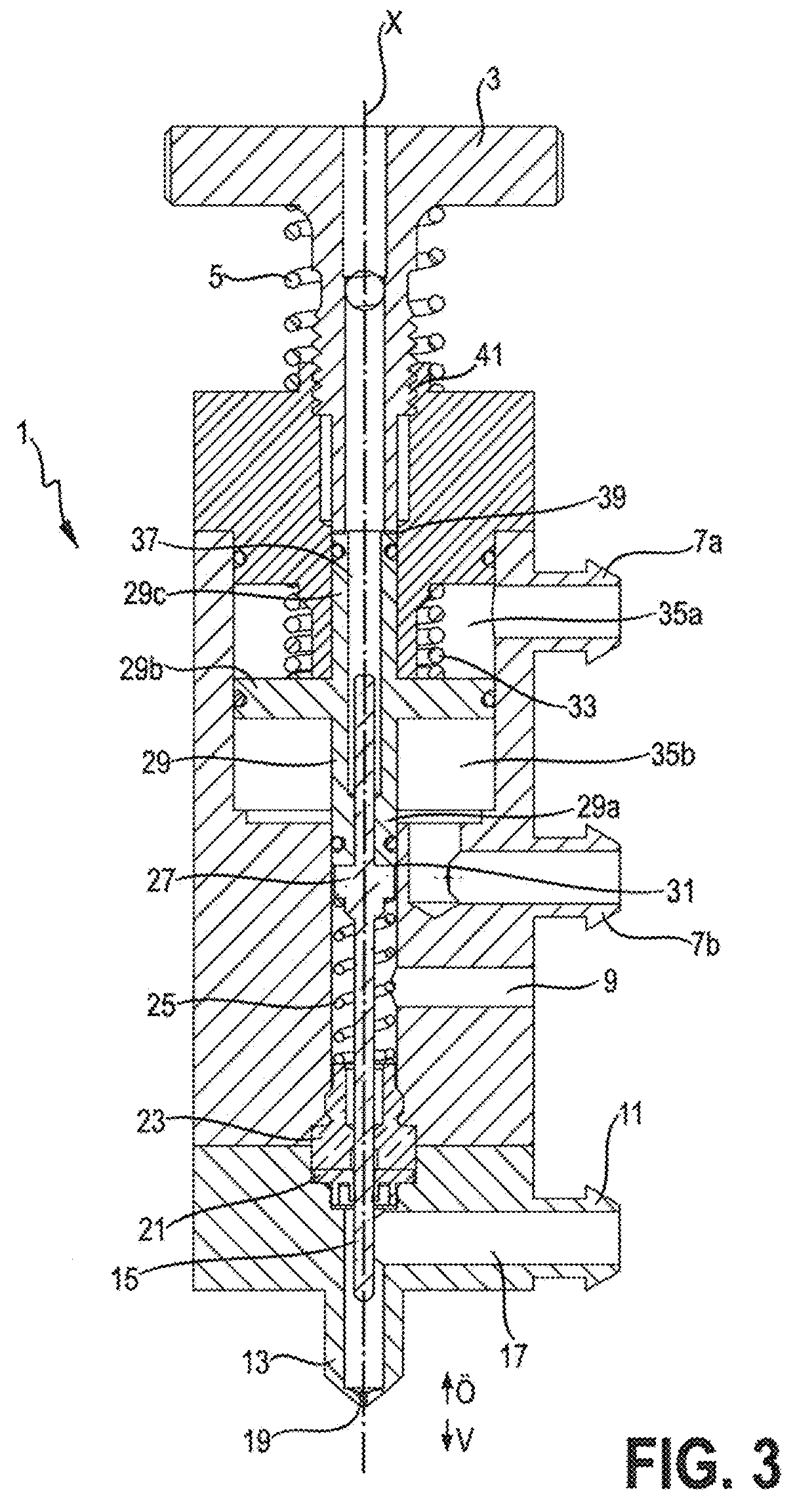

Dosing system and dosing method

ActiveUS9339839B2Optimising dosing of dosingSmall droplet sizeLiquid surface applicatorsContracting/expanding measuring chambersEngineeringActuator

Owner:VERMES MICRODISPENSING GMBH

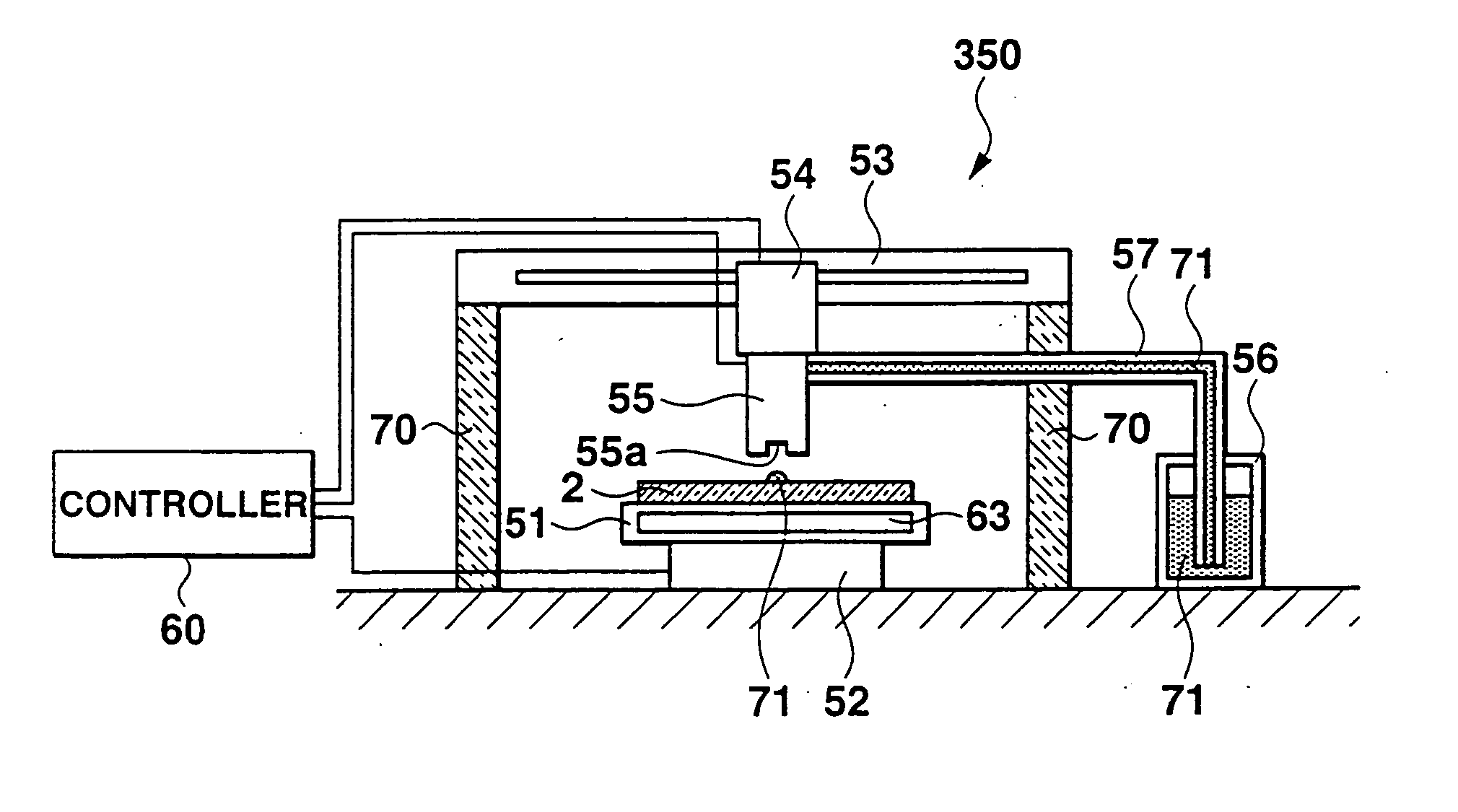

Solution spray apparatus and solution spray method

ActiveUS20050133616A1Small droplet sizeHigh concentrationLiquid surface applicatorsElectroluminescent light sourcesBoiling pointEngineering

A solution spray apparatus includes a nozzle which sprays a droplet of a solution such as EL solution, a heater is provided on the nozzle to heat the solution in the nozzle to a temperature lower than a boiling point of the solution in the nozzle, so that the droplet of the heated solution is ejected from the spray to an object.

Owner:ARIS TECH LTD

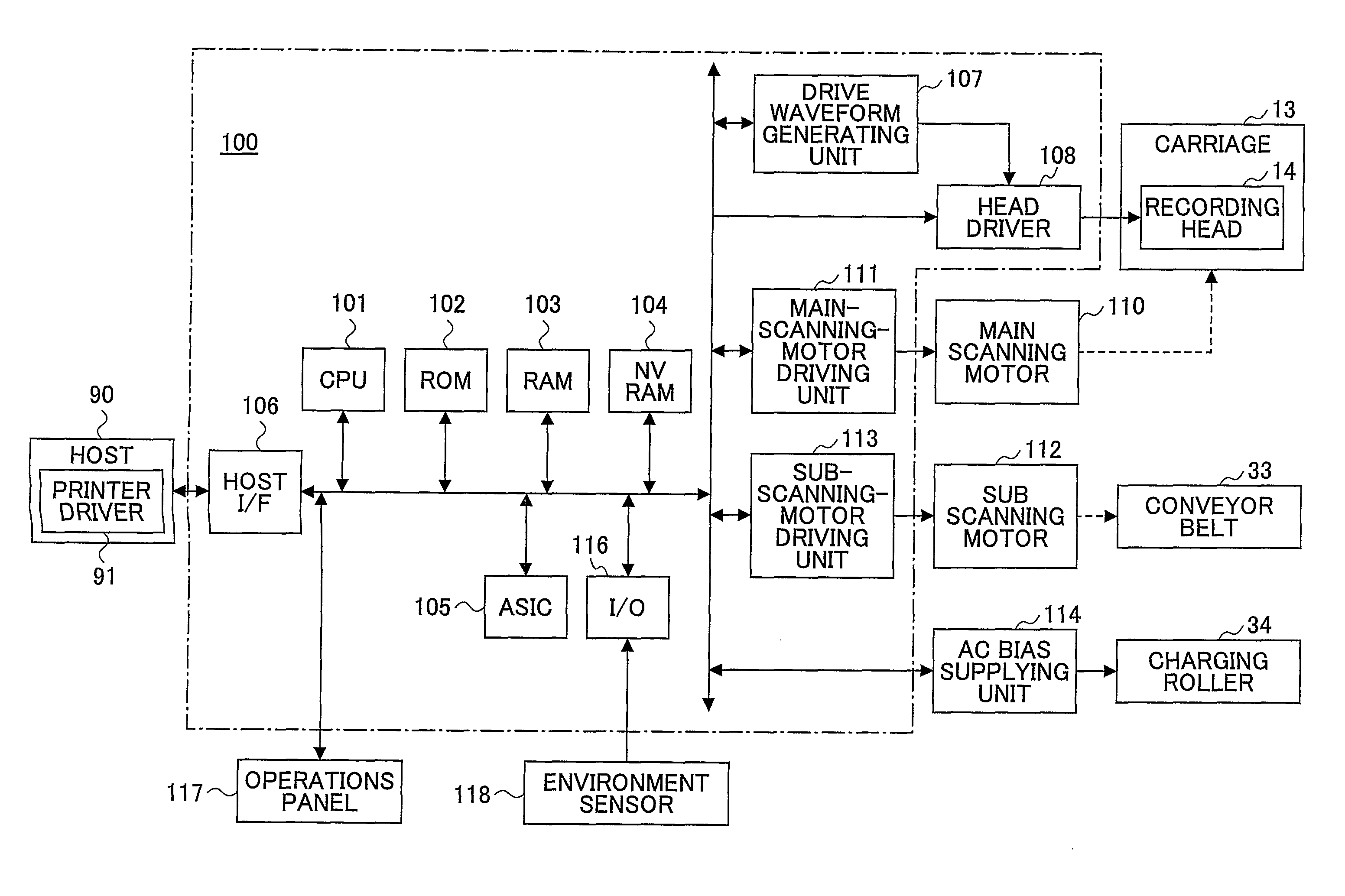

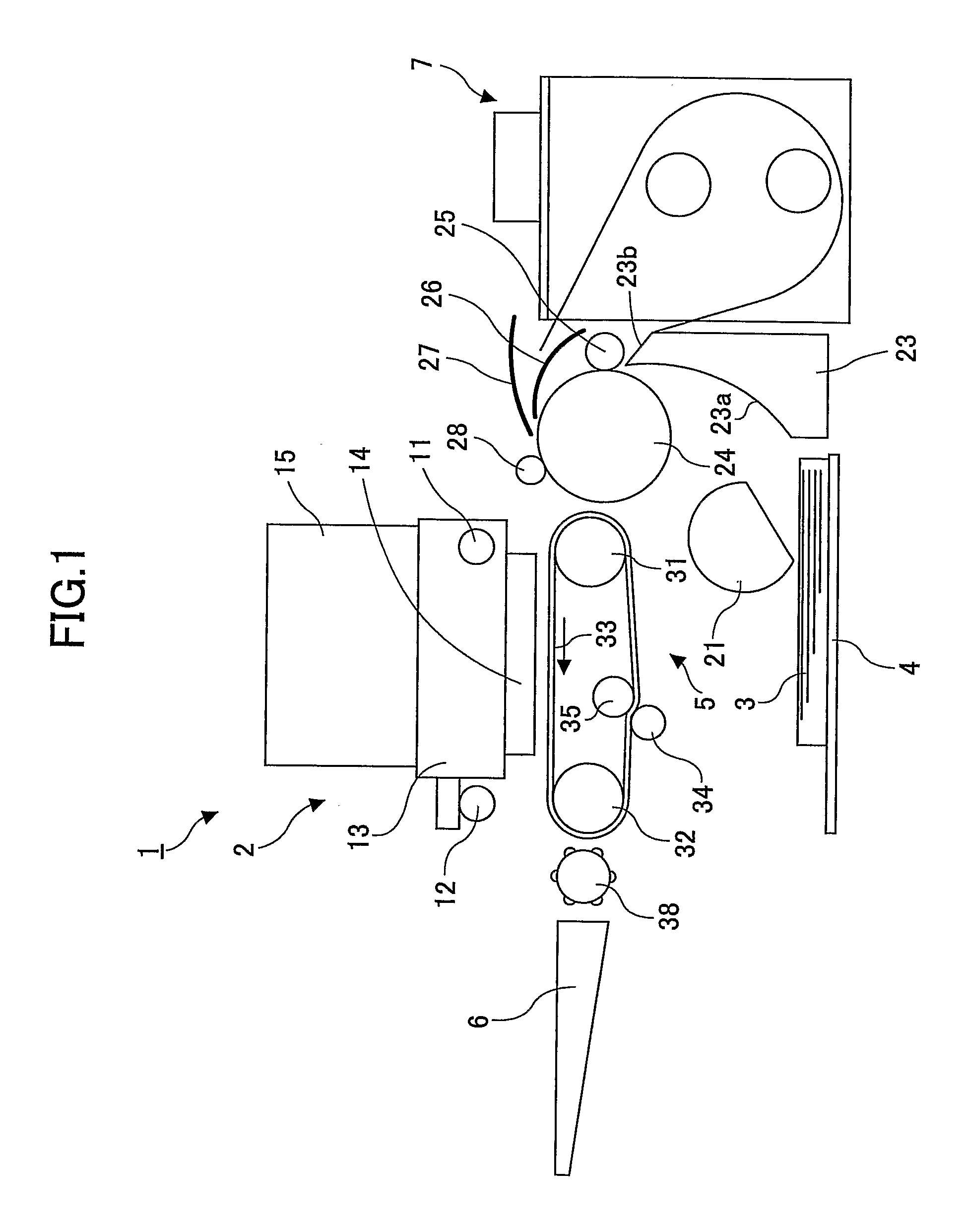

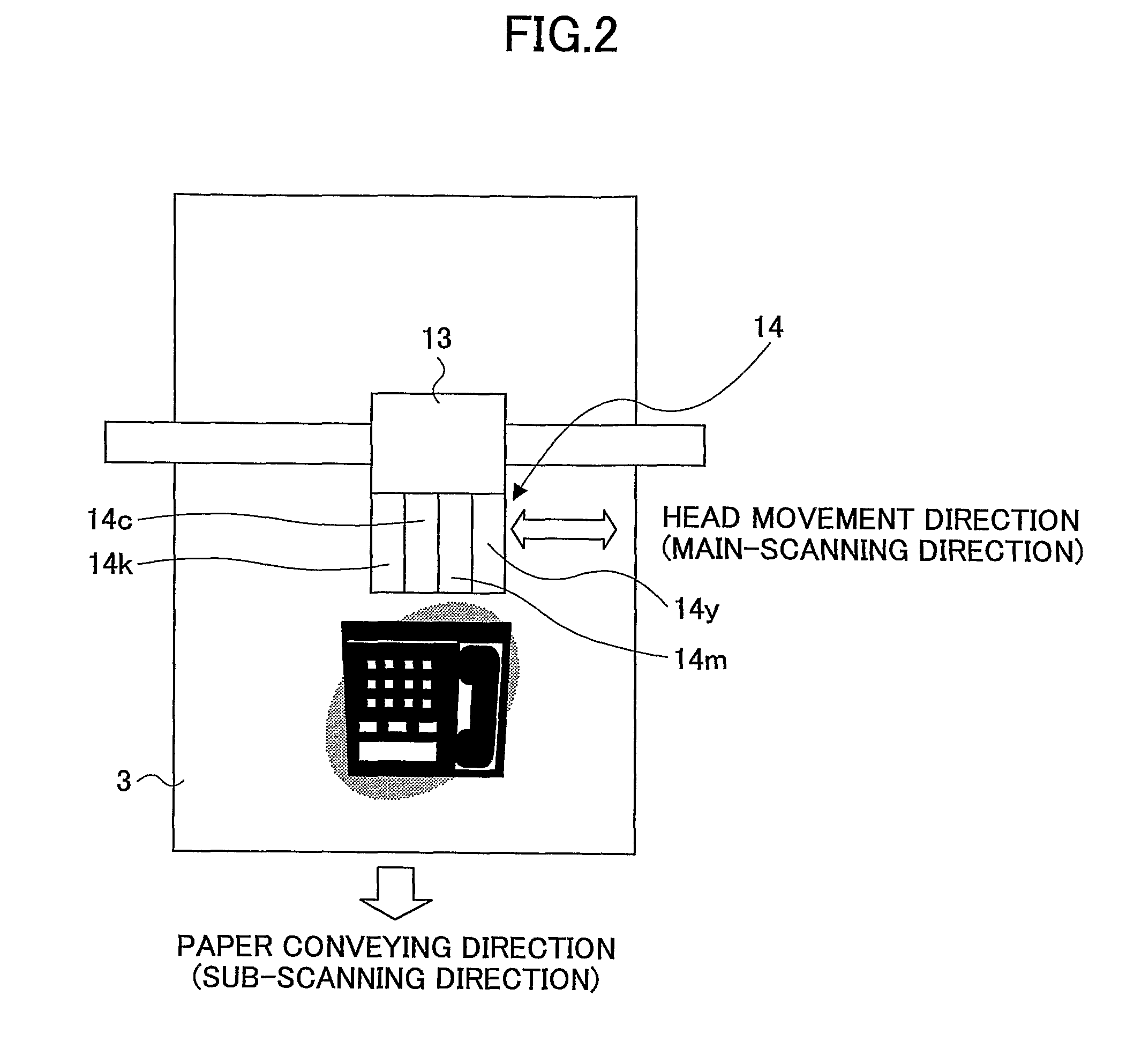

Image processing method, image processing apparatus, image forming apparatus, image forming system, and storage medium

InactiveUS20110090276A1Small droplet sizeSolve or reduce one or more problemsOther printing apparatusPictoral communicationImaging processingComputer graphics (images)

An image processing method includes converting multilevel data of an image into a dot pattern using a multilevel error diffusion process. The conversion includes determining a pixel corresponding to an abnormal nozzle based on abnormal nozzle information provided for each of droplet sizes supported by nozzles of an image forming apparatus; preventing jetting of a droplet onto the determined pixel; distributing a quantization error of the determined pixel calculated in the multilevel error diffusion process to neighboring pixels; and if extra-large droplets with a droplet size greater than the droplet size of a full-size droplet capable of filling a pixel are to be formed in the neighboring pixels as a result of distributing the quantization error, removing one or more of the extra-large droplets or reducing the droplet size of one or more of the extra-large droplets.

Owner:RICOH KK

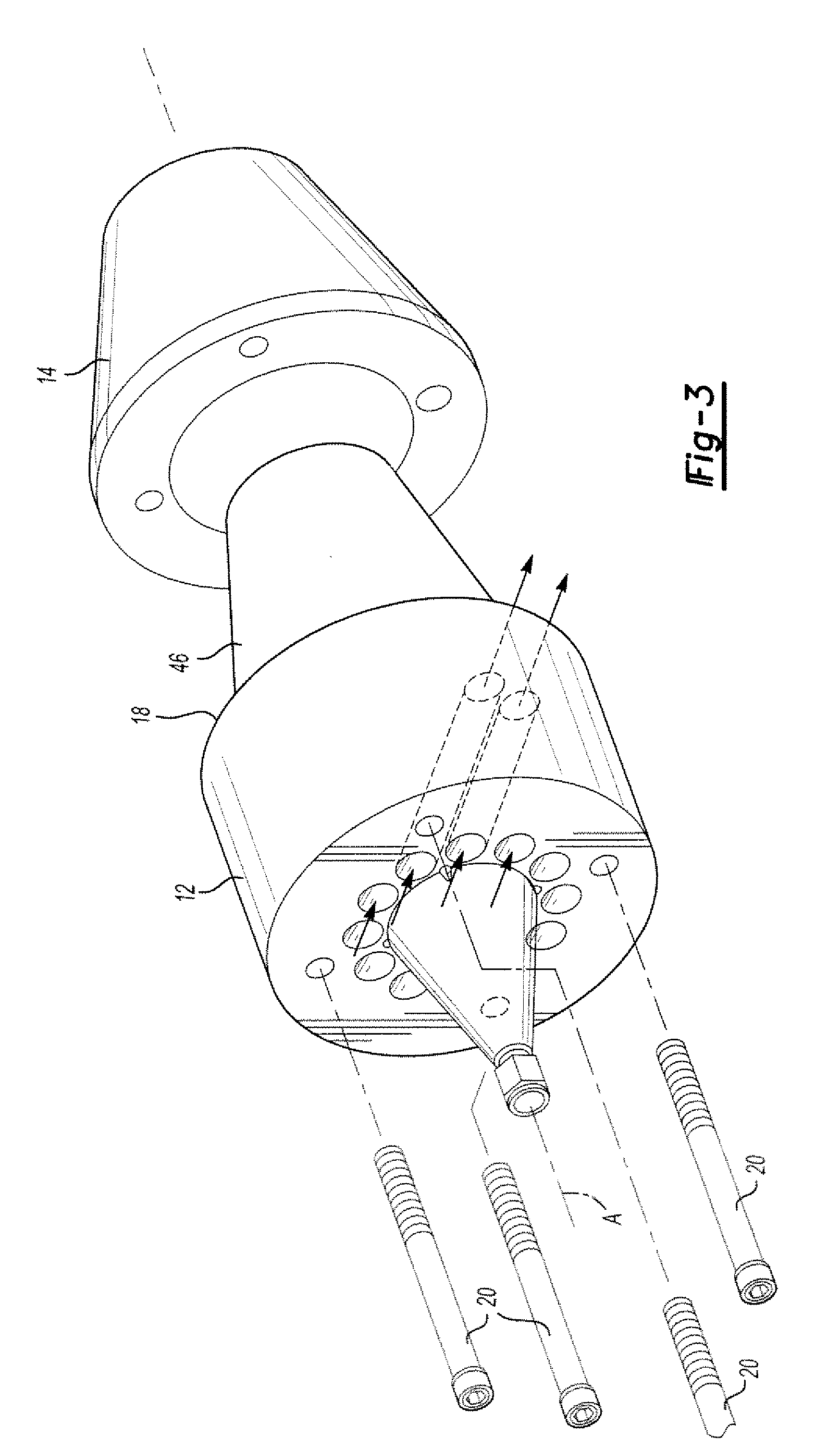

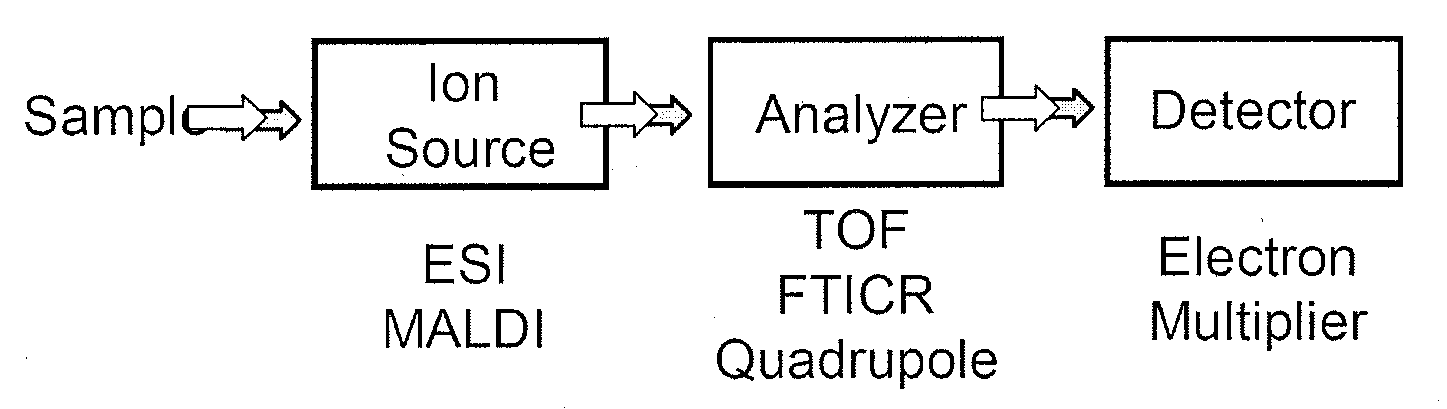

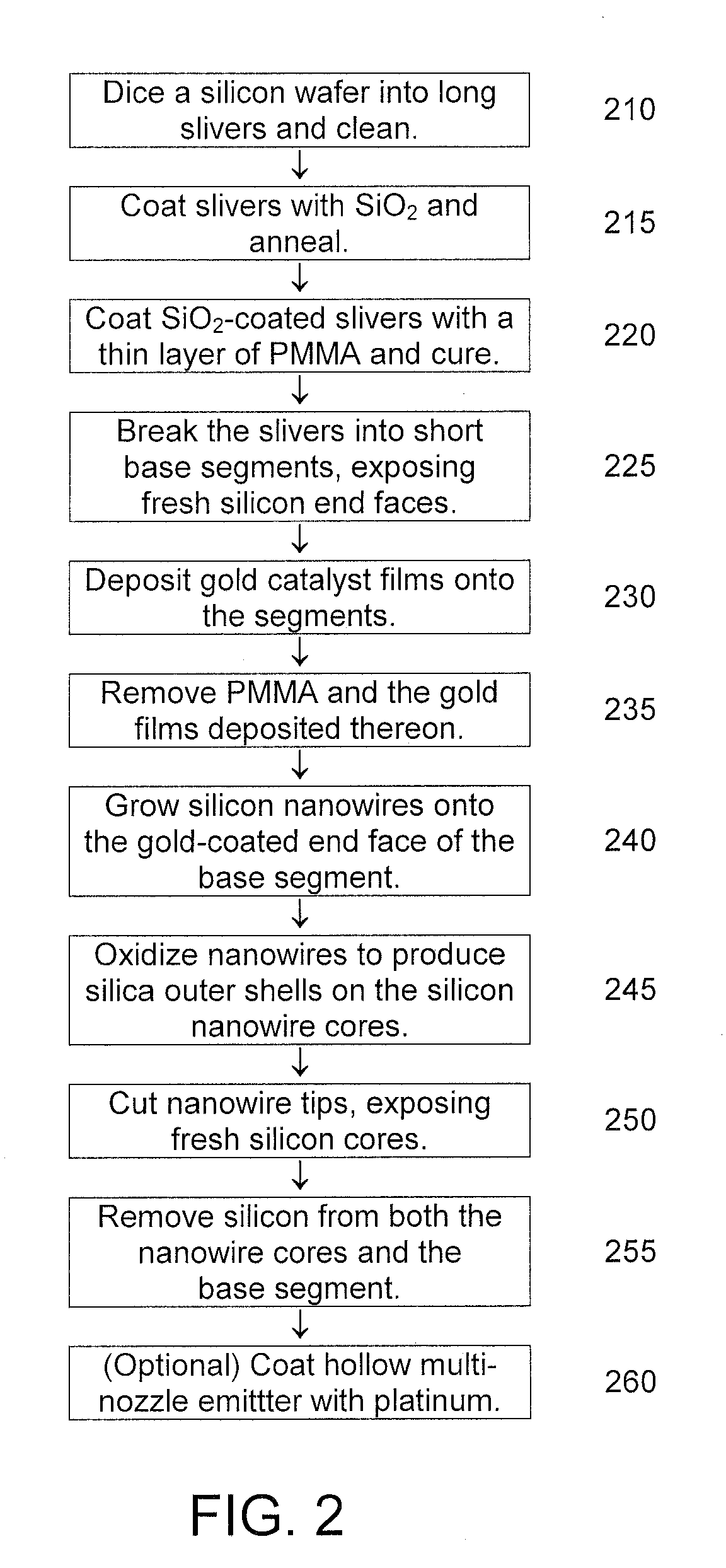

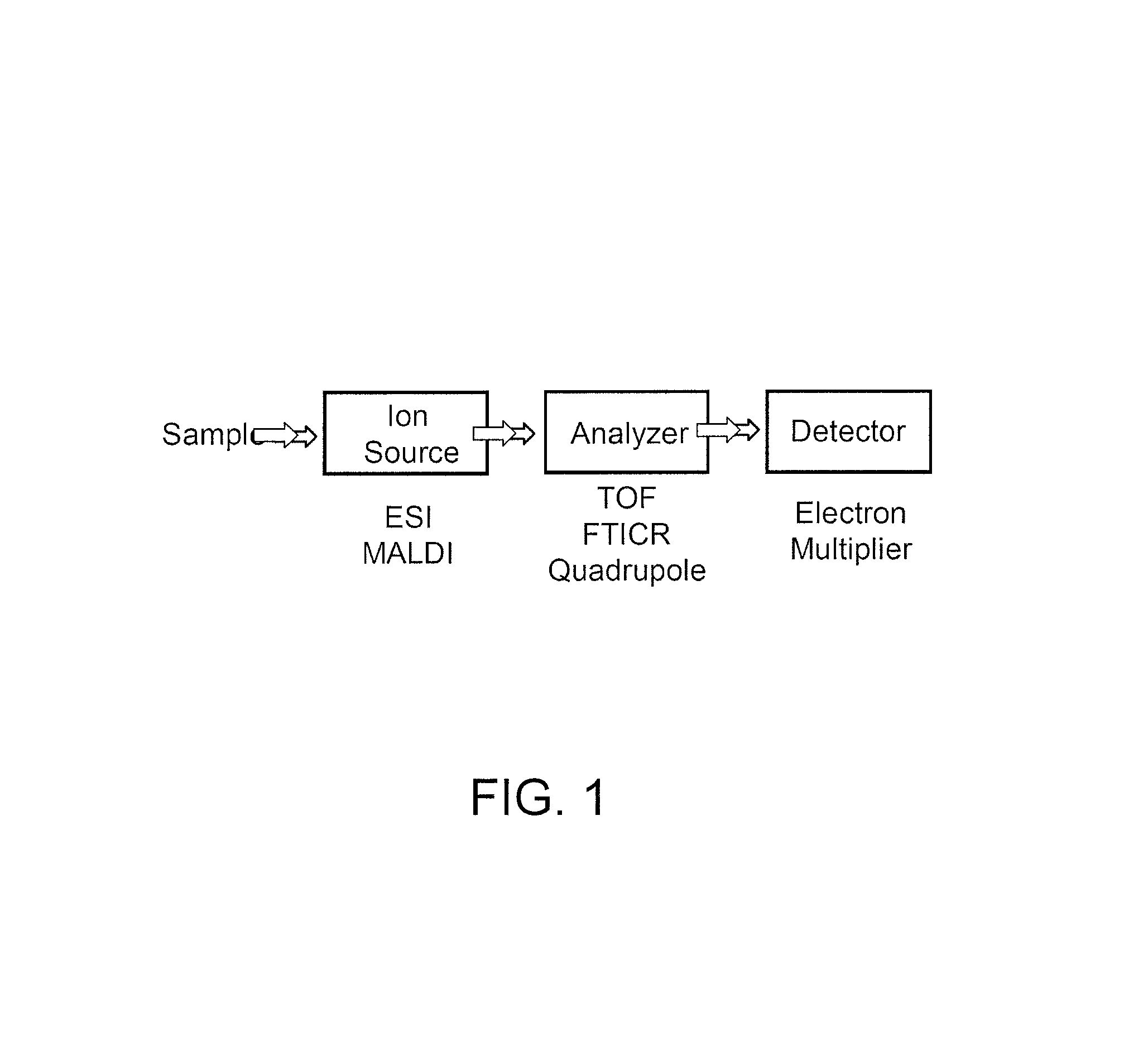

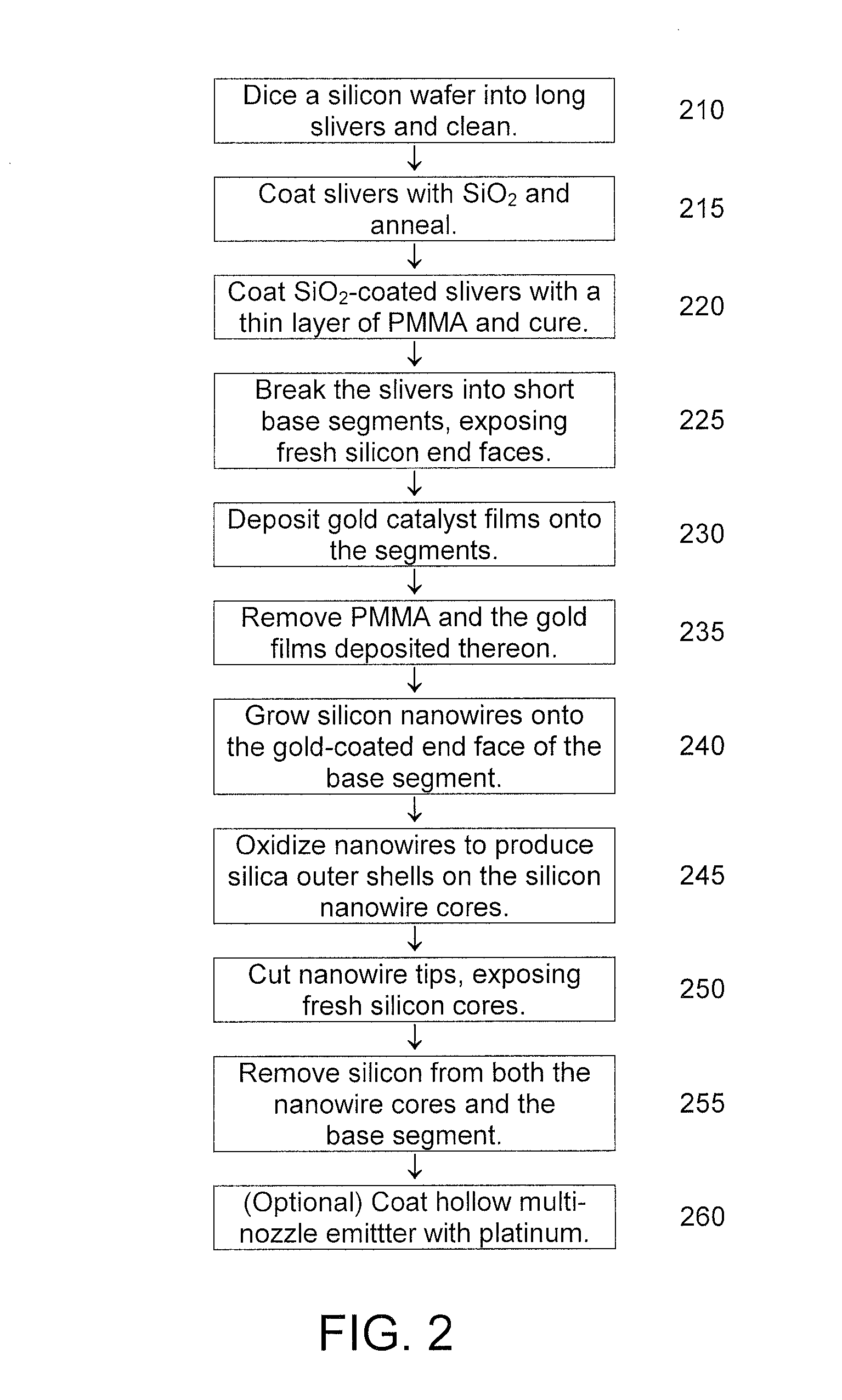

Monolithic Multinozzle Emitters for Nanoelectrospray Mass Spectrometry

ActiveUS20100075428A1Promote formationPossibility for surface functionalizationBurnersParticle separator tubesNano manufacturingMass Spectrometry-Mass Spectrometry

Novel and significantly simplified procedures for fabrication of fully integrated nanoelectrospray emitters have been described. For nanofabricated monolithic multinozzle emitters (NM2 emitters), a bottom up approach using silicon nanowires on a silicon sliver is used. For microfabricated monolithic multinozzle emitters (M3 emitters), a top down approach using MEMS techniques on silicon wafers is used. The emitters have performance comparable to that of commercially-available silica capillary emitters for nanoelectrospray mass spectrometry.

Owner:RGT UNIV OF CALIFORNIA

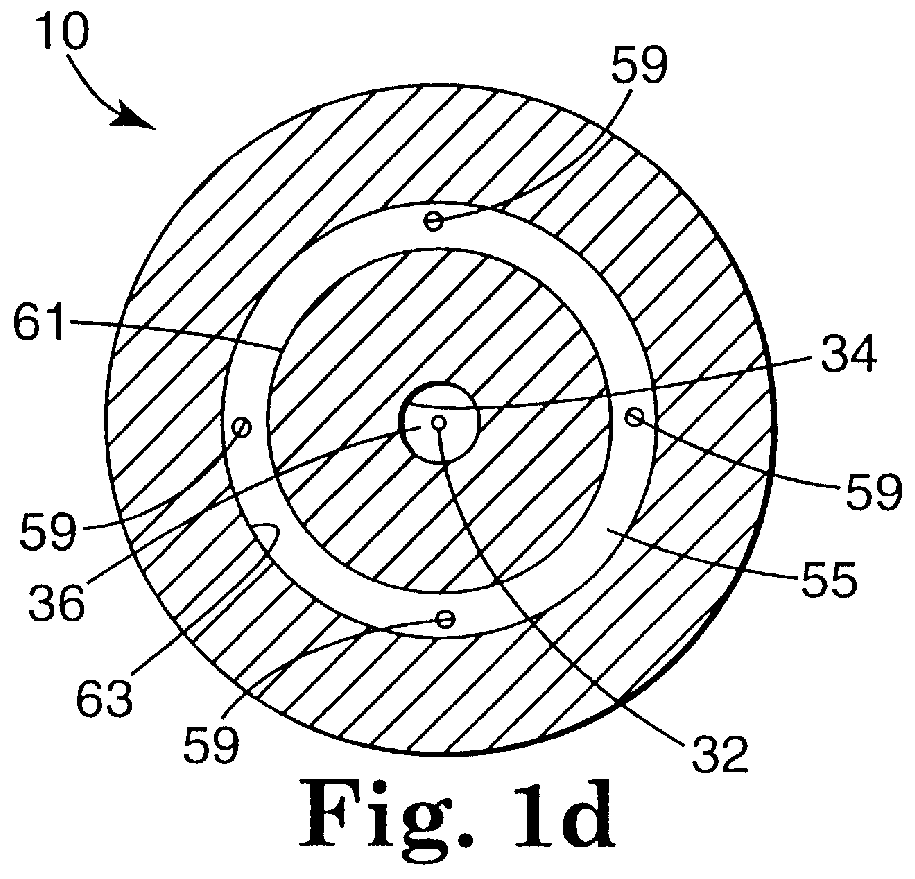

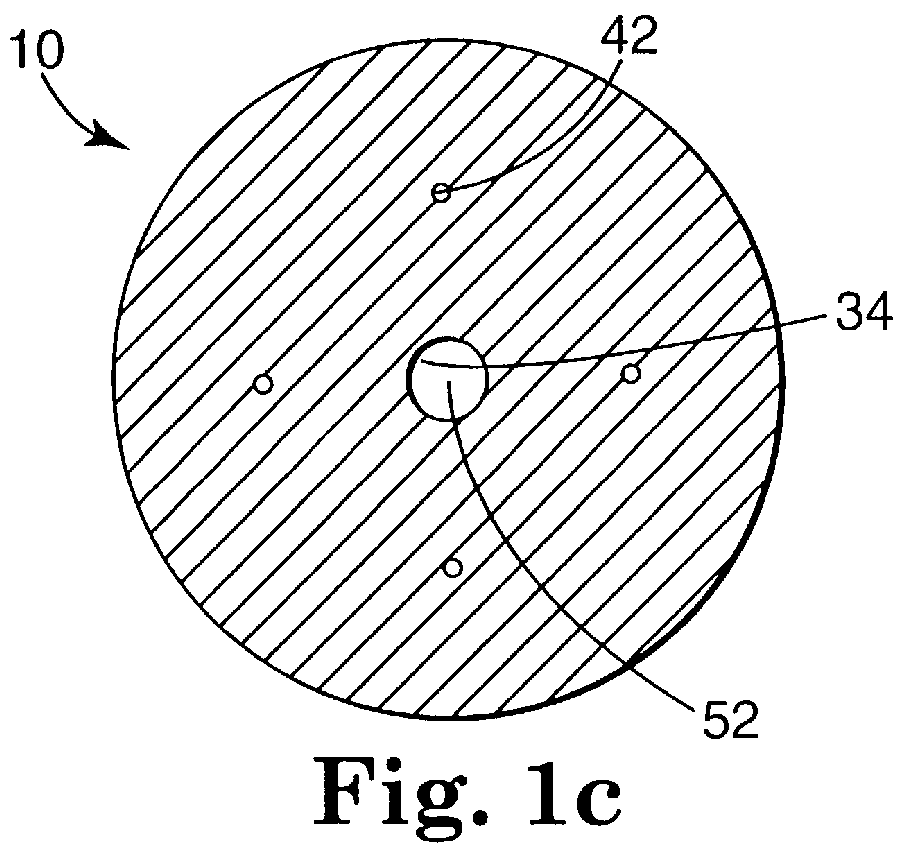

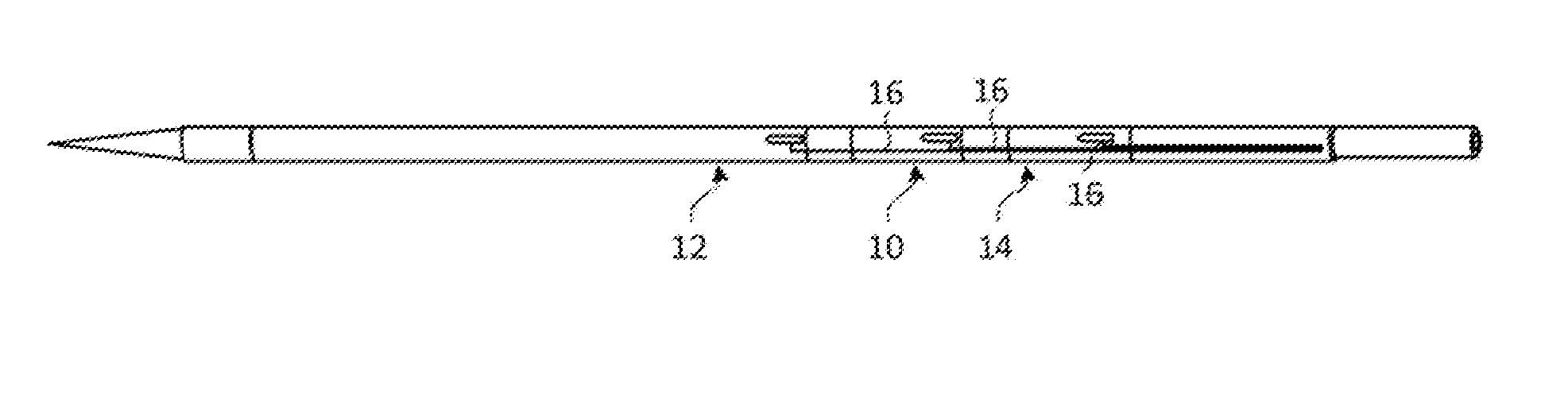

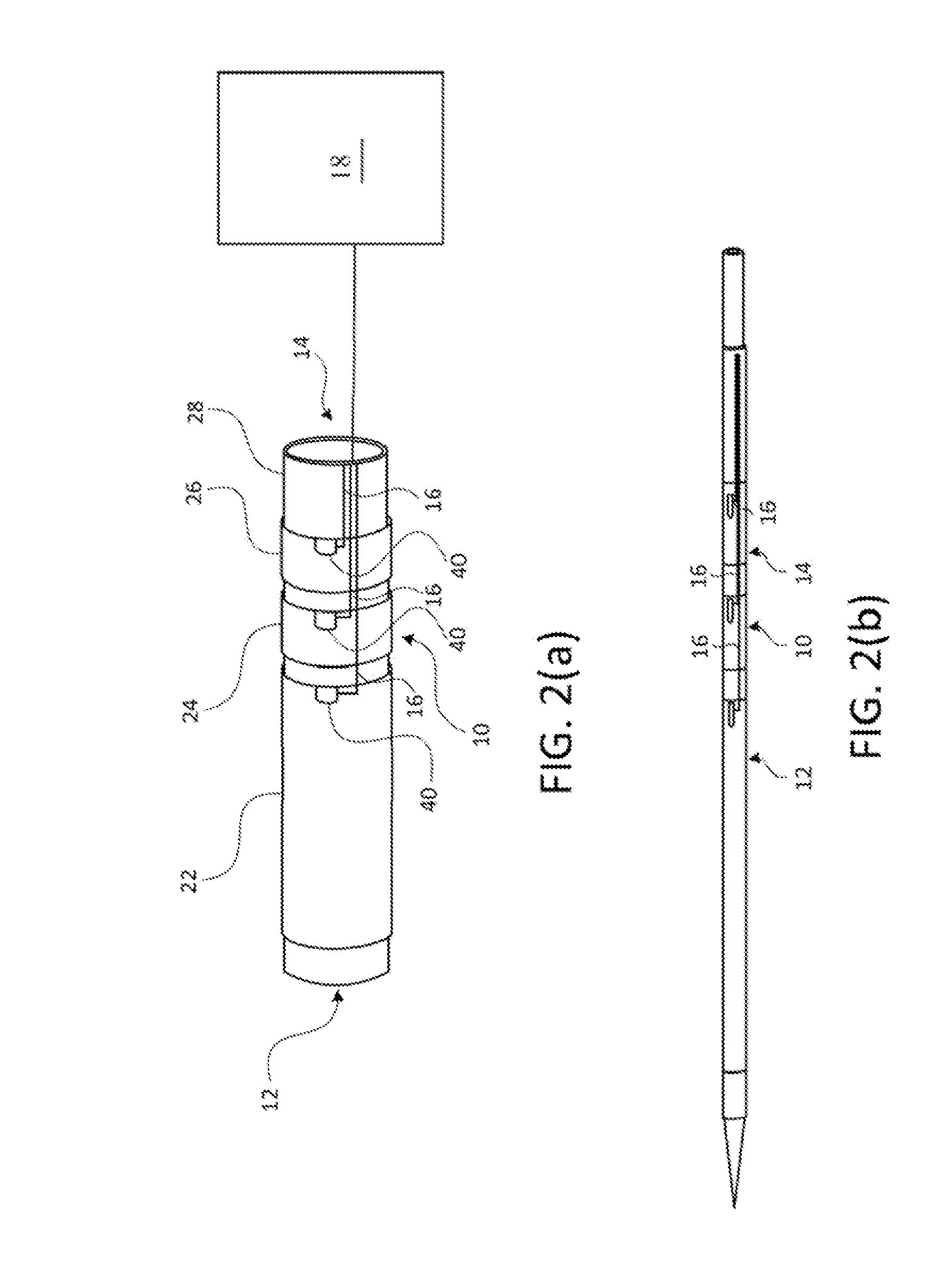

Dual-use Catheter for Continuous Analyte Measurement and Drug Delivery

A sensing assembly (10), including a body (12) and one or more first indicating electrodes disposed on the body (26). The first indicating electrodes include an electrochemically active layer (32) and a layer (38) of an active functioning enzyme of a first enzyme type on top of the electrochemically active layer. Also, one or more second indicating electrodes (24) are disposed on the body and include an electrochemically active layer (32) and a layer (36) of an inactivated enzyme of the first enzyme type on top of the electrochemically active layer. A reference electrode (22) is also disposed on the body. Finally, an electrical and data processing system (18) is adapted to bias the electrodes and measure electrical signals from the electrodes, and uses said signals to determine an analyte concentration and communicates the analyte concentration to a location apart from the first and second indicating electrodes.

Owner:PACIFIC DIABETES TECH INC +1

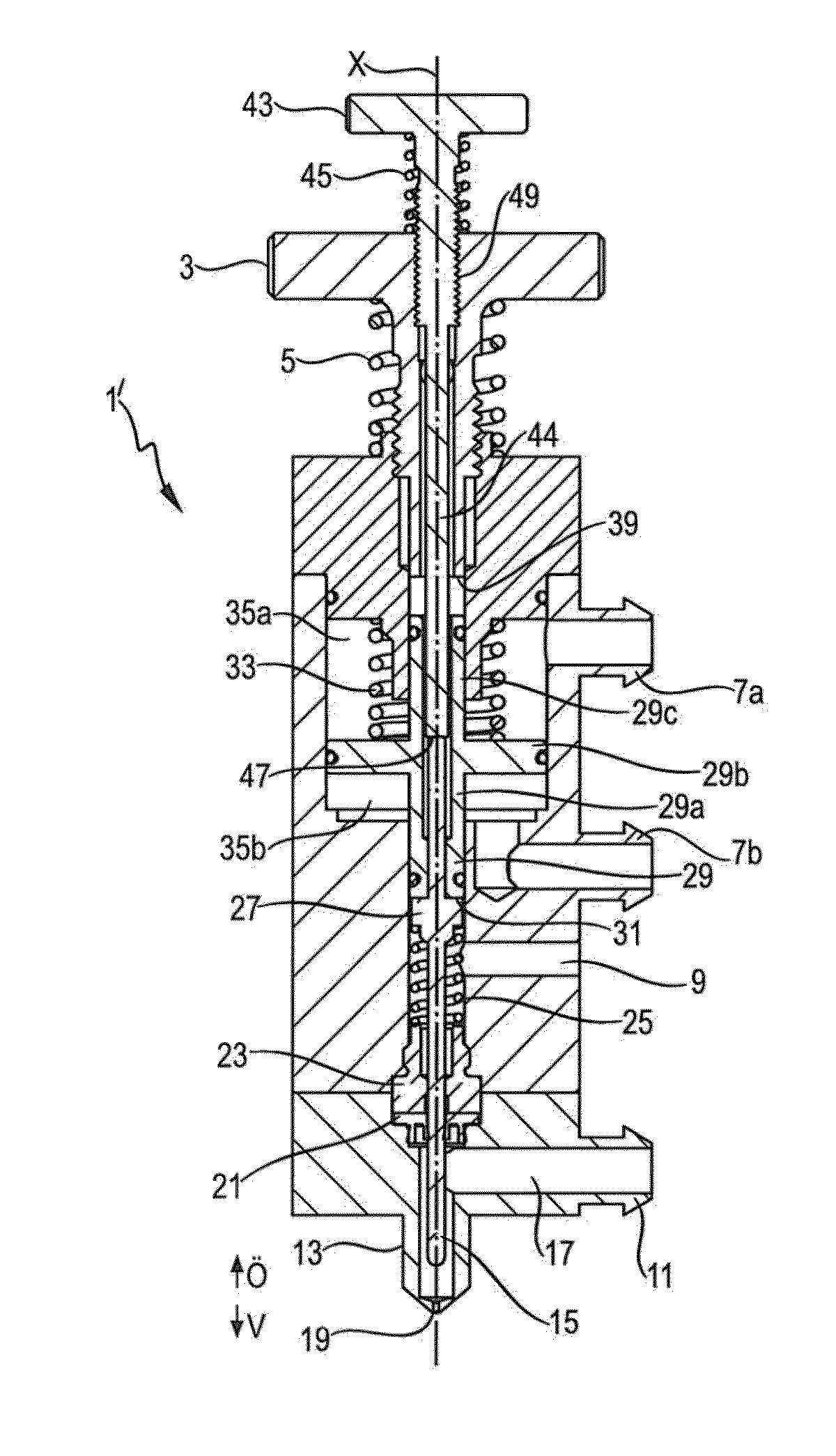

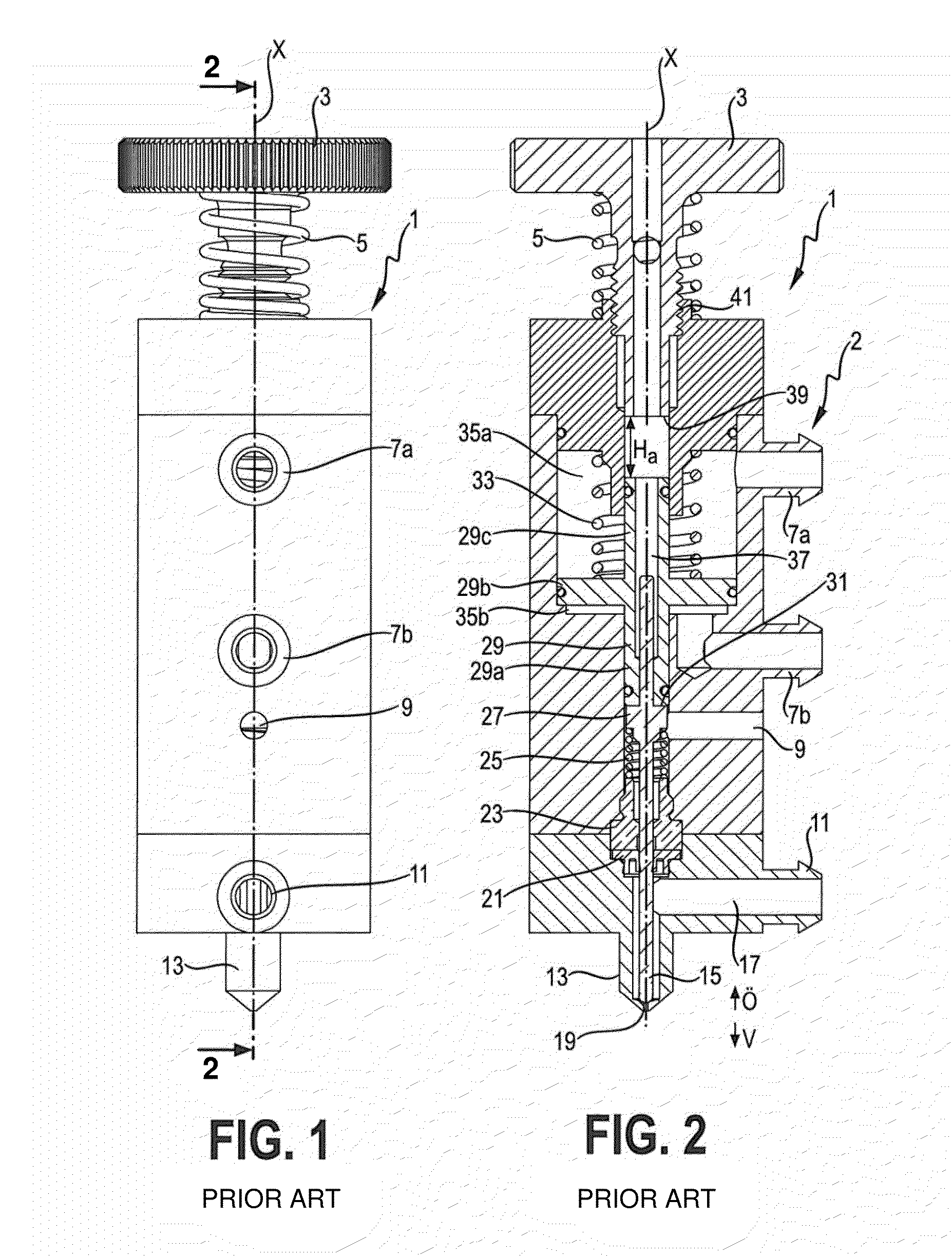

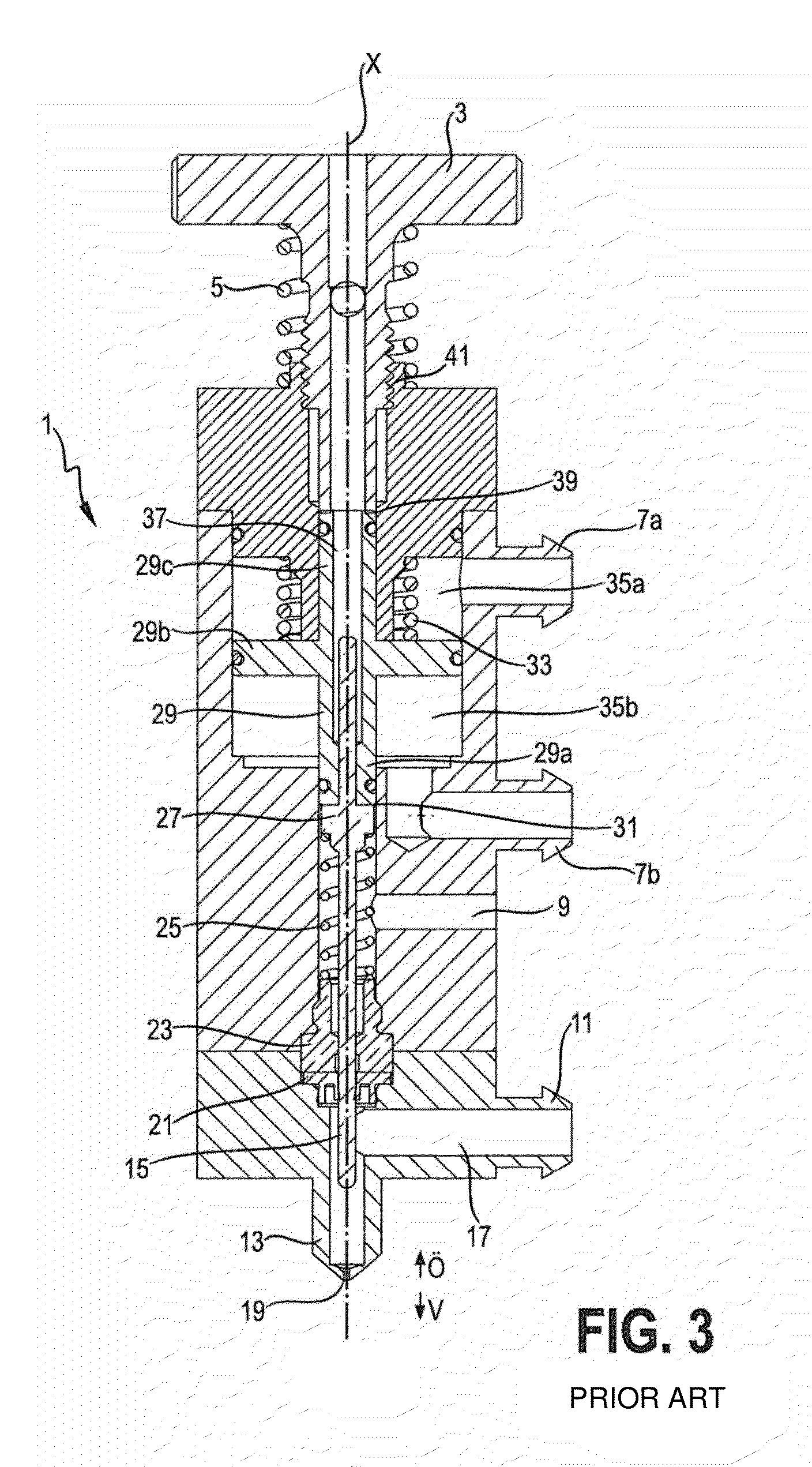

Dosing system and dosing method

ActiveUS20140291358A1Take advantage ofEffect be exertLiquid surface applicatorsLiquid flow controllersEngineeringActuator

A dosing system for a liquid or viscous dosing material, including an actuator system, that has at least one actuating element and a nozzle with an outlet opening. The dosing system is designed so that during a movement in a closure direction the actuating element is initially moved in a first partial movement in such a way that the actuating element is separated from the closure element at a stop location, intended for that purpose, and then comes into contact with the closure element at the stop location and exerts an impulse on the closure element. This also relates to a corresponding dosing method.

Owner:VERMES MICRODISPENSING GMBH

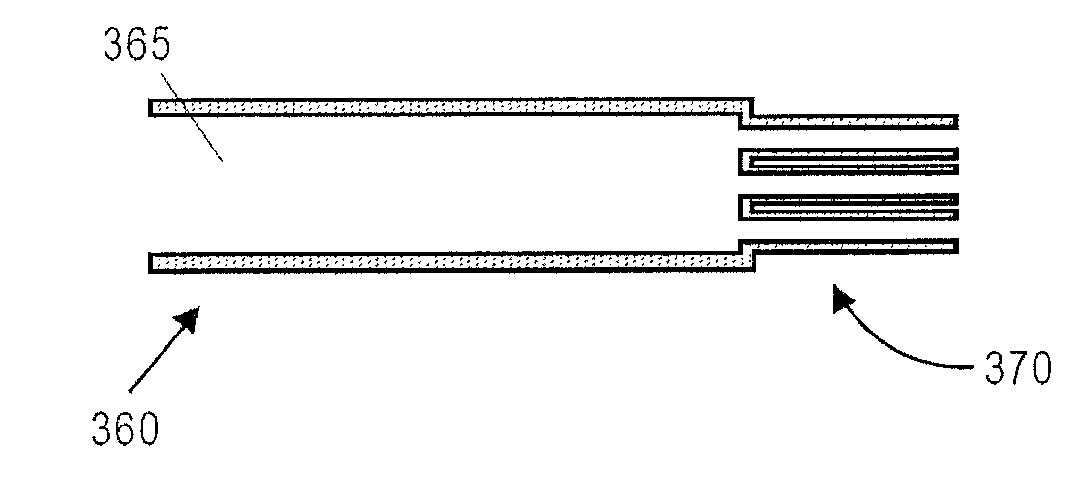

Cell encapsulation microfluidic device

ActiveUS7759111B2Small droplet sizeUniform polymerization timeBiocideBioreactor/fermenter combinationsEngineeringCell encapsulation

Devices and methods for the encapsulation of cells on microfluidic platforms are disclosed. The microfluidic device generally includes a plurality of functional regions to shear, focus, and encapsulate a desired cell or group of cells into a droplet. The microfluidic device can further comprise a polymerization zone to form a polymer bead around the droplet.

Owner:RGT UNIV OF CALIFORNIA

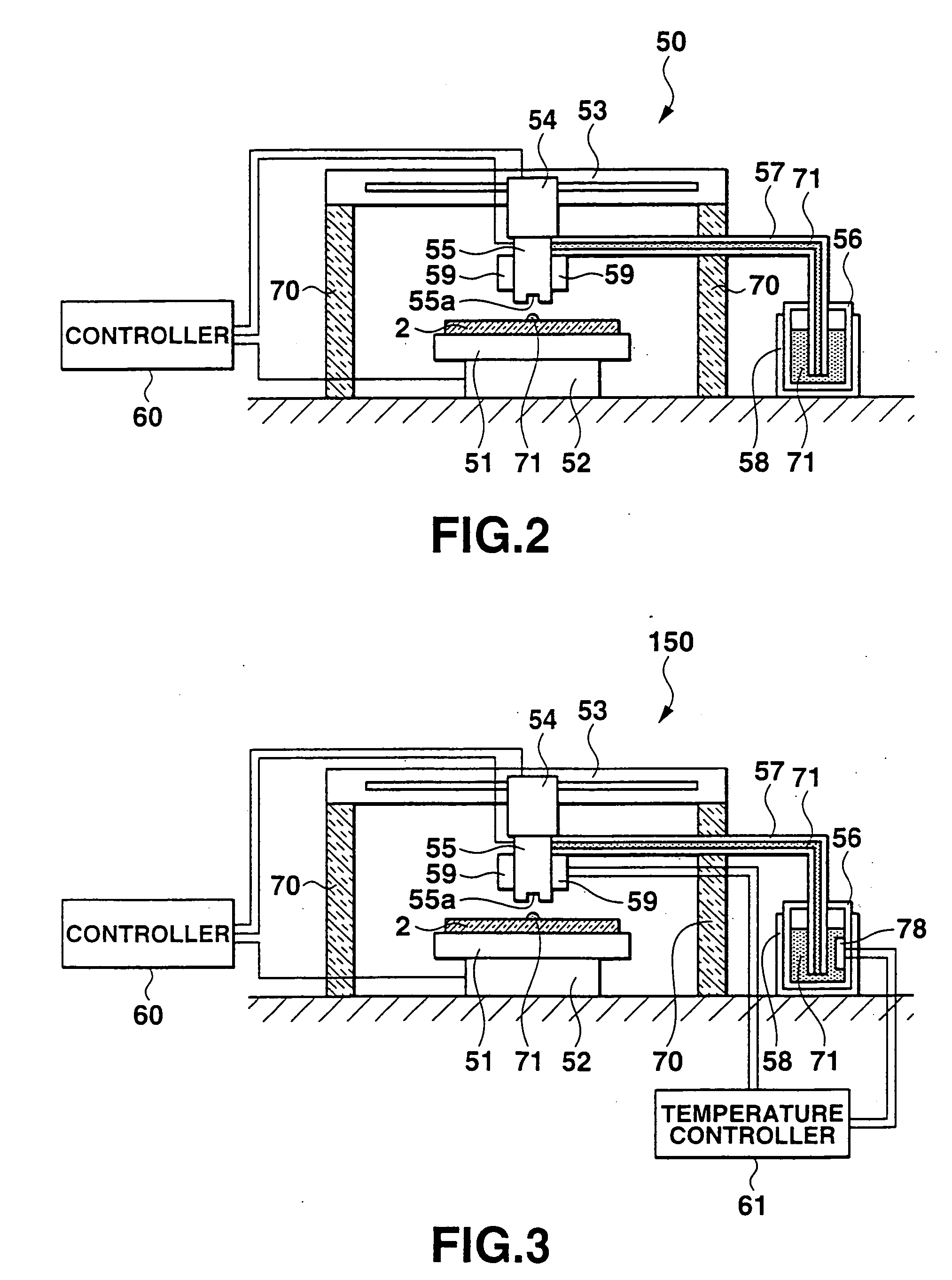

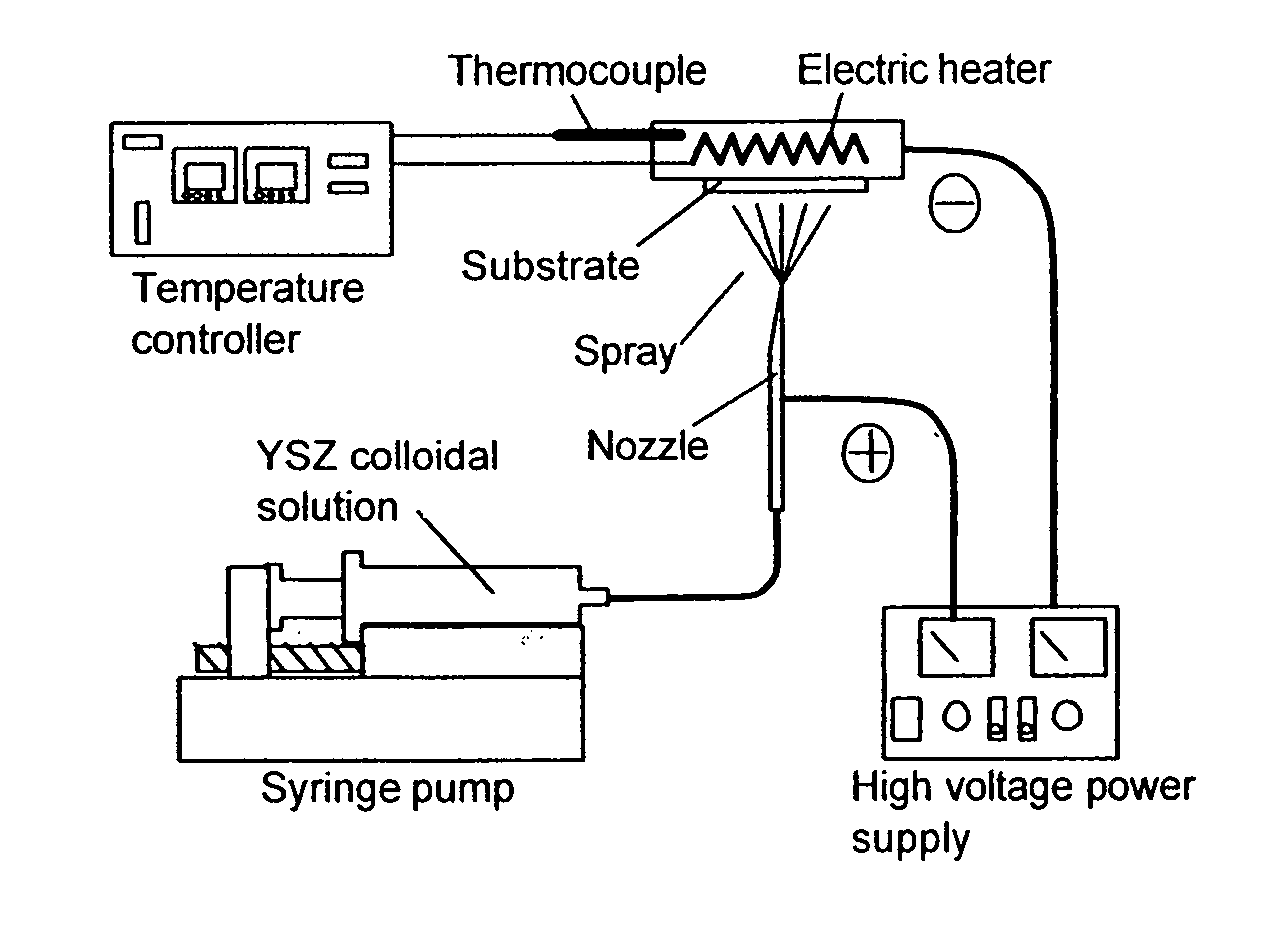

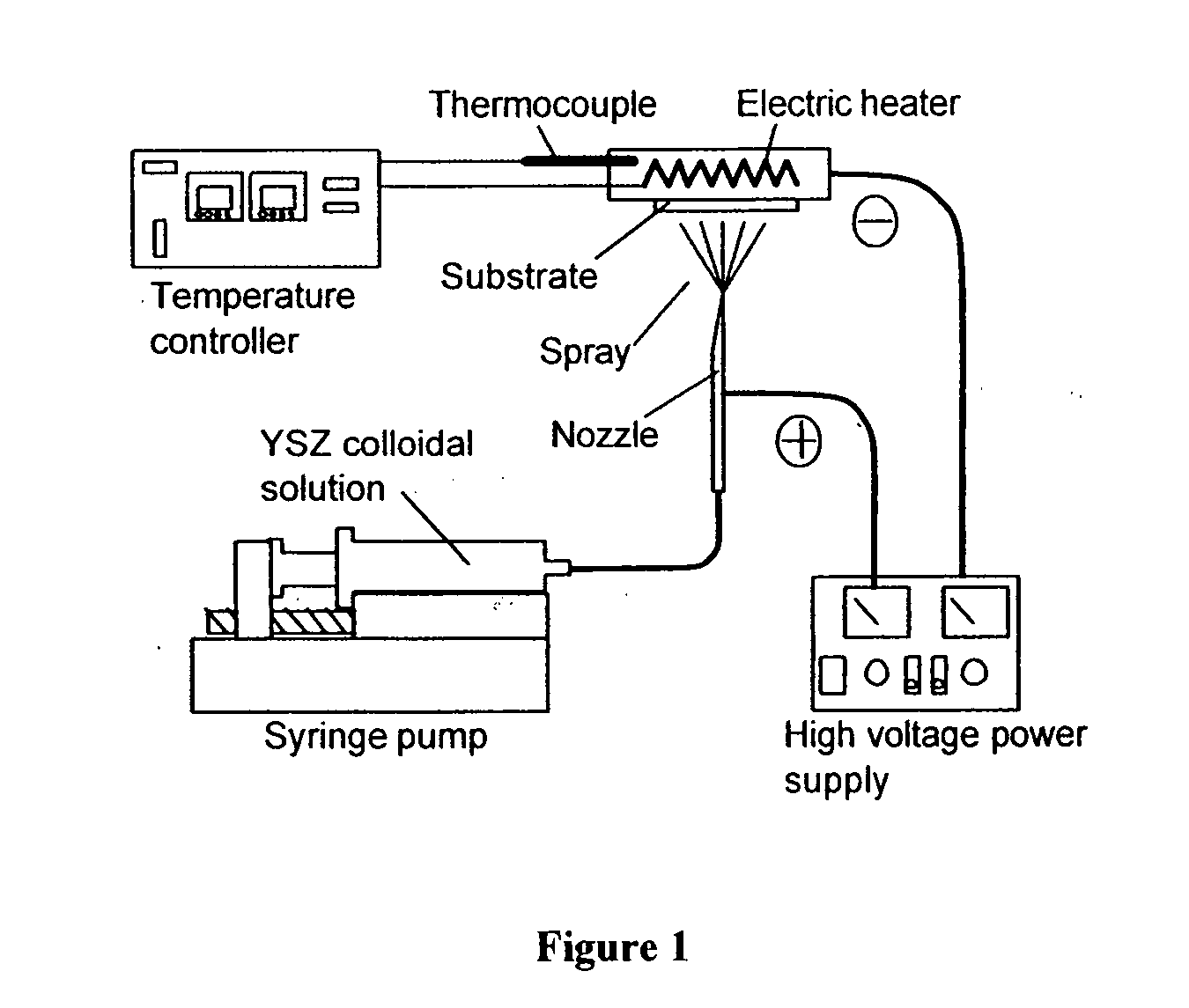

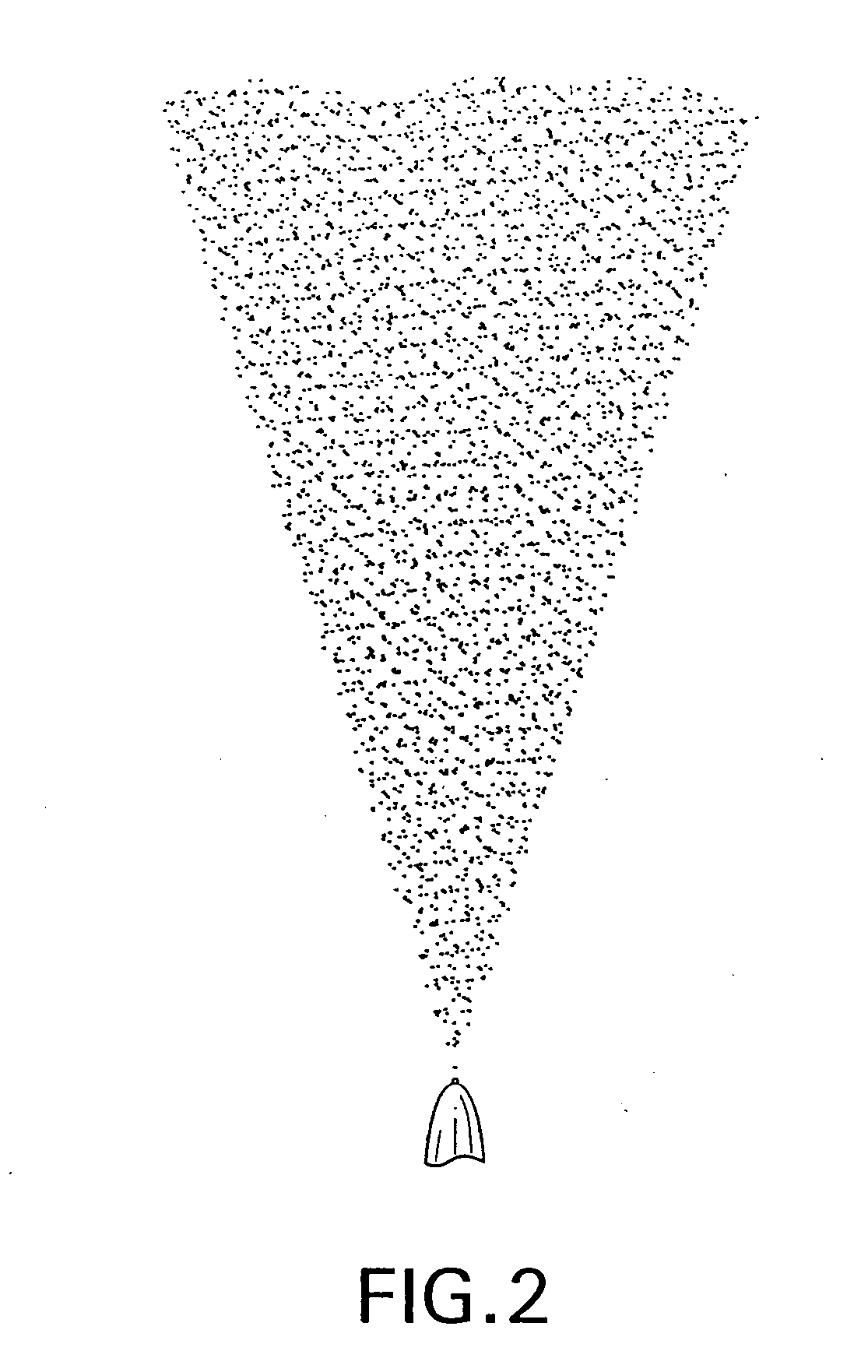

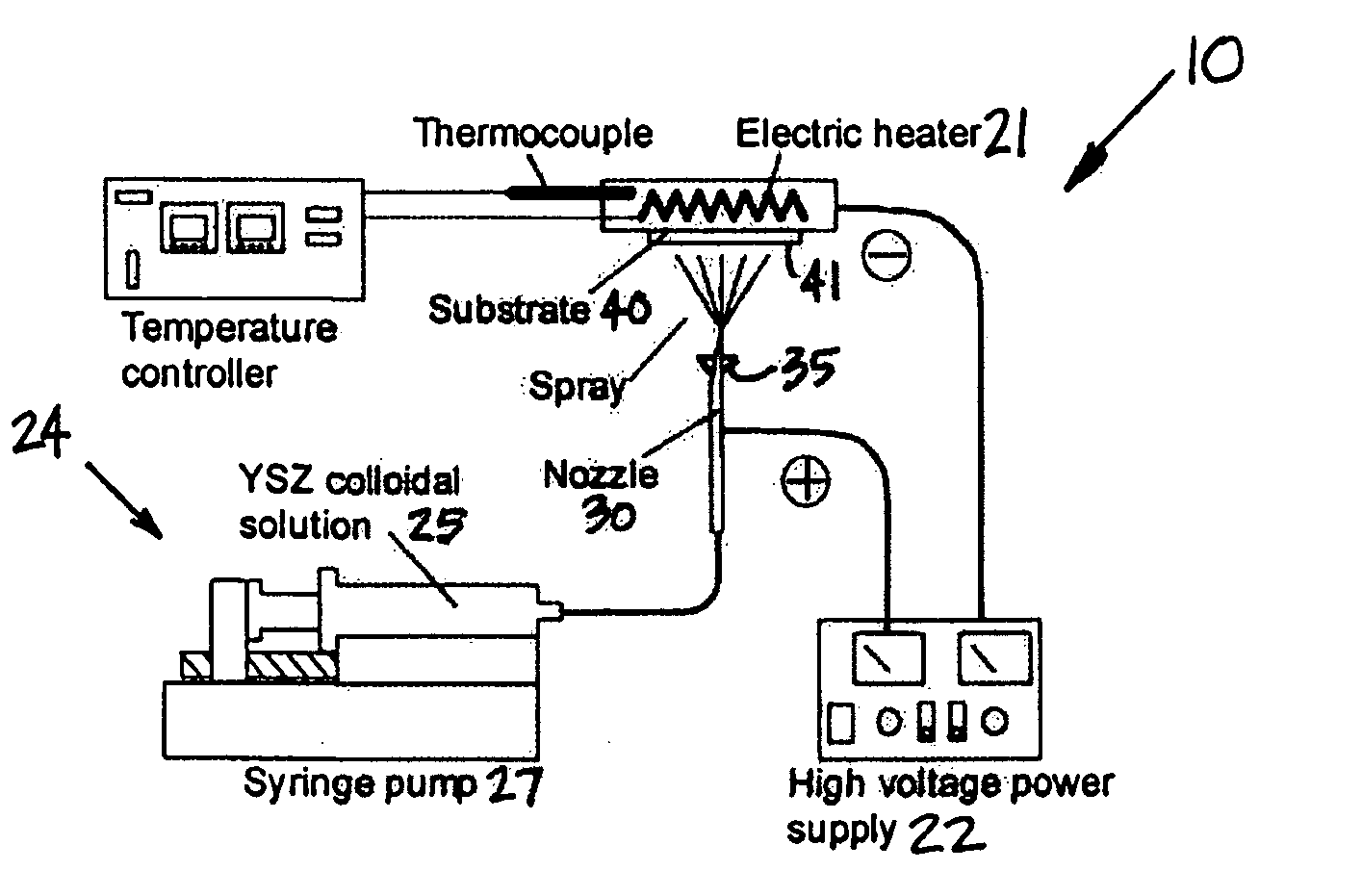

Method and apparatus for electrostatic spray deposition for a solid oxide fuel cell

InactiveUS20080029026A1Easy to set upLarge film growth rateBurnersLiquid surface applicatorsThin layerSpray nozzle

A method and apparatus for electrostatic spray deposition (ESD) for fabricating a thin-layer yttria-stabilized zirconia (YSZ) electrolyte on a solid oxide fuel cell (SOFC) anode substrate constructed of nickel-YSZ cermet. By reducing the thickness of the electrolyte, and thereby reducing the cell internal IR drop, an intermediate temperature SOFC (ITSOFC) can operate at 600-800° C. A collar positioned at a distance from a discharge end of a spray nozzle enhances a spray pattern of a precursor including the electrolyte material and thus provides a very thin electrolyte layer.

Owner:ILLINOIS INSTITUTE OF TECHNOLOGY

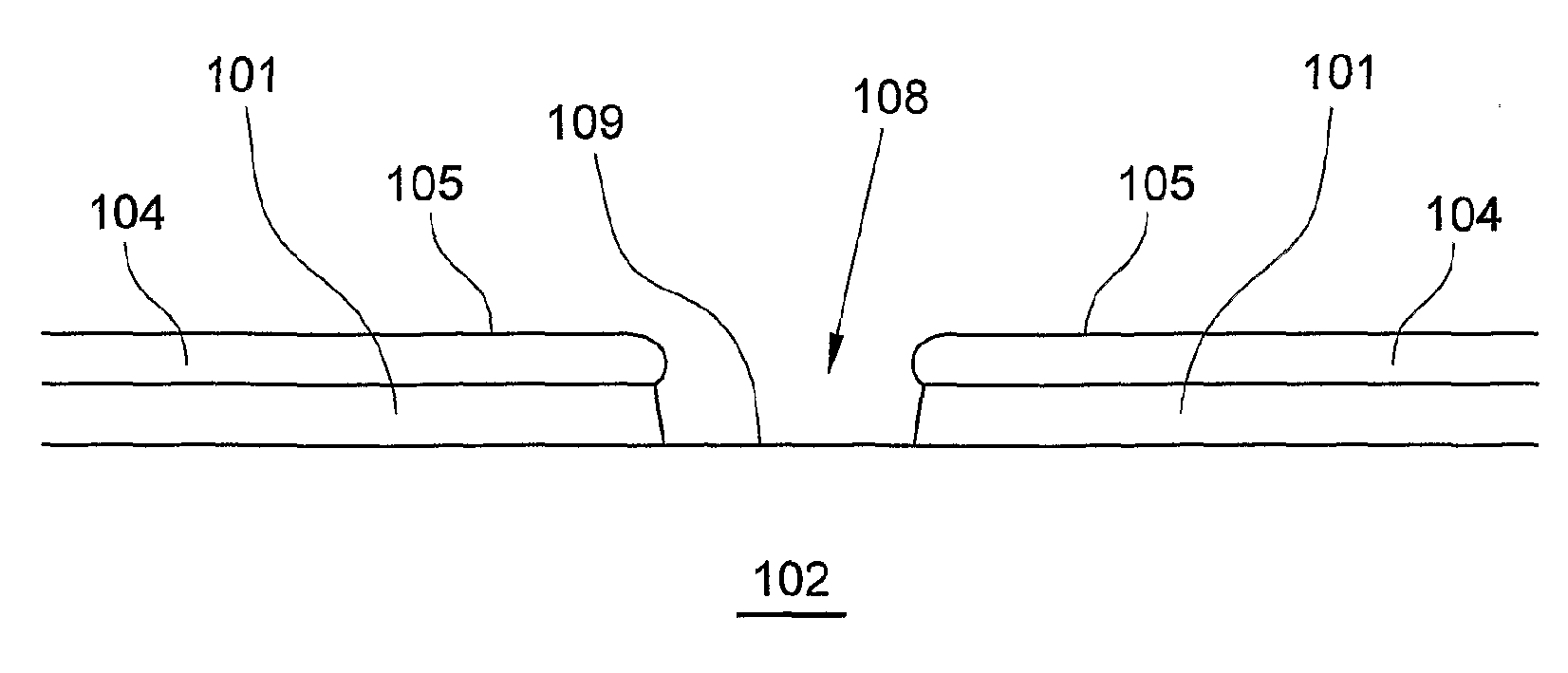

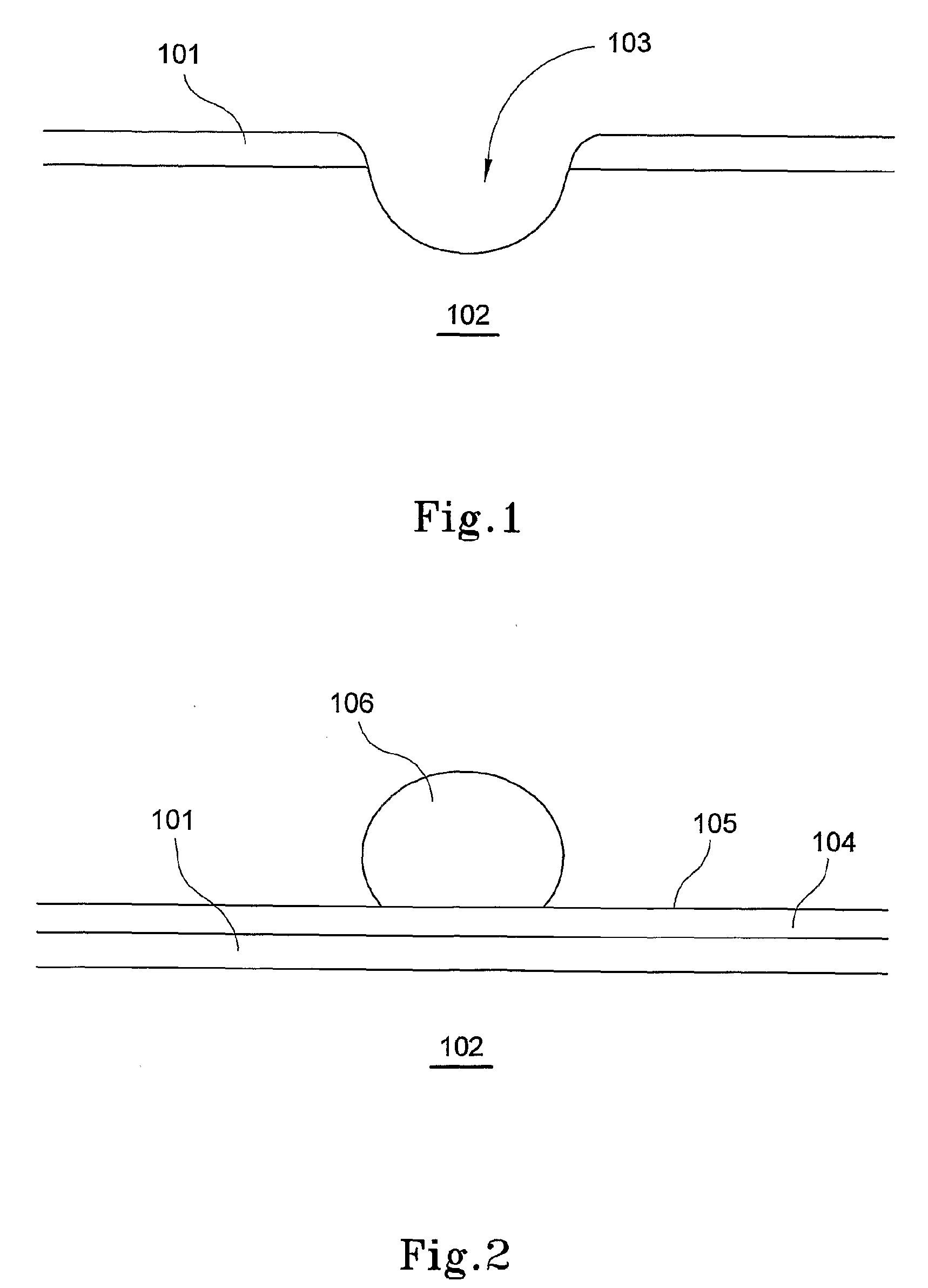

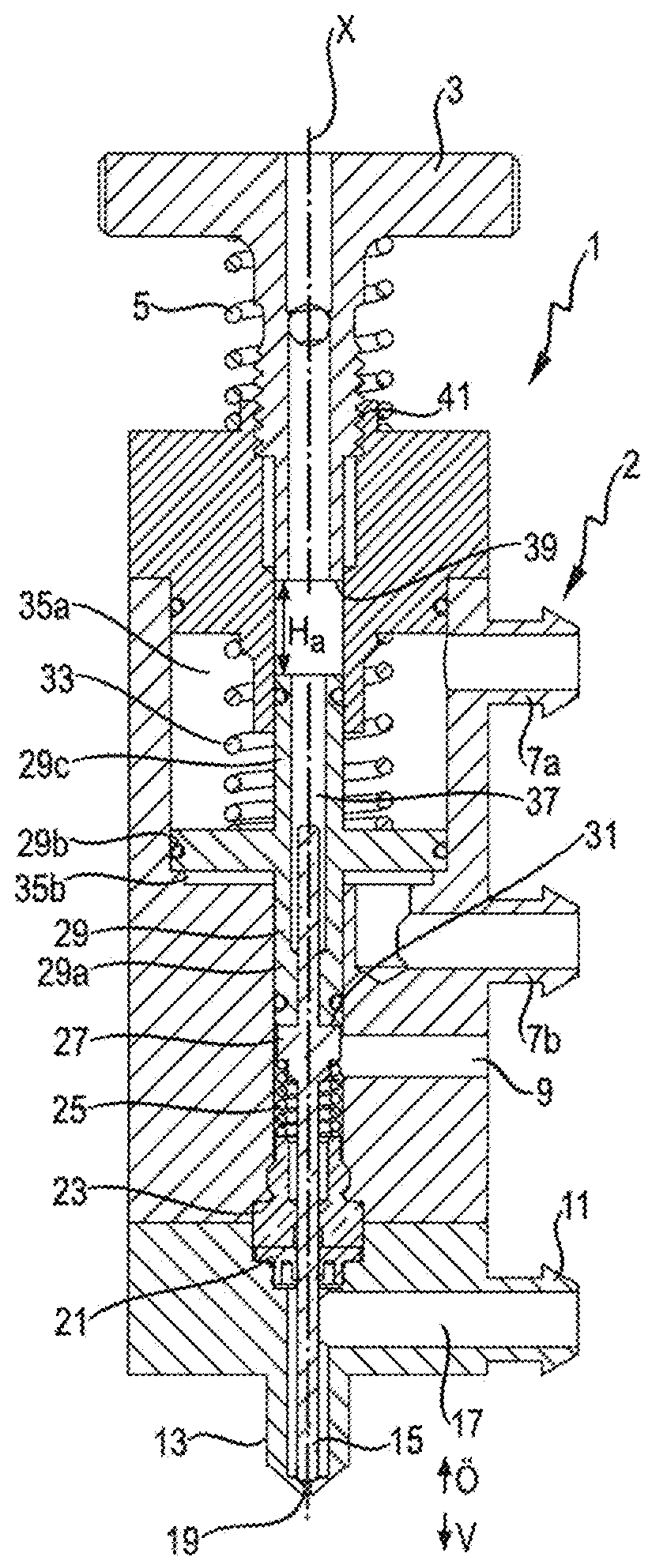

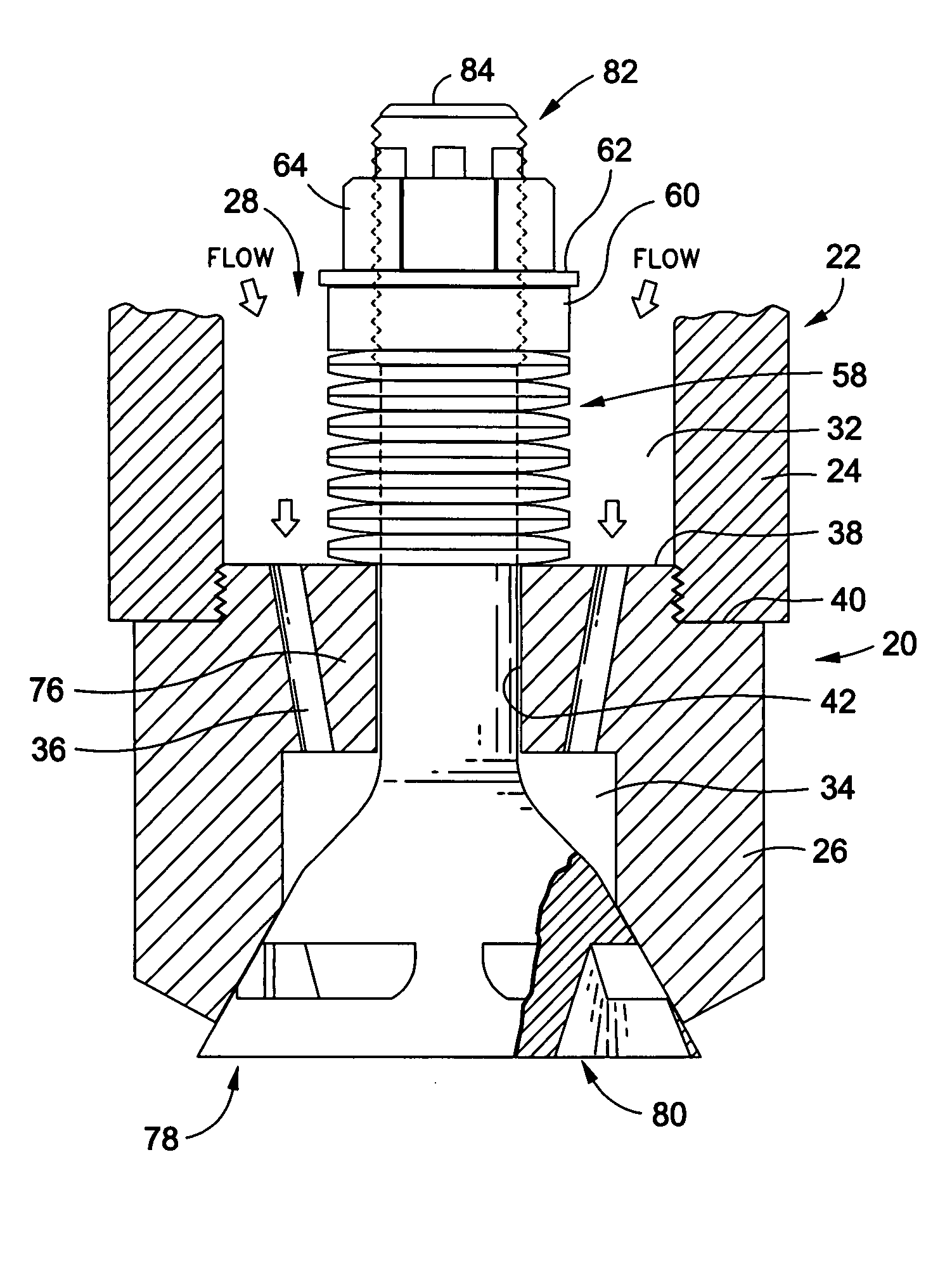

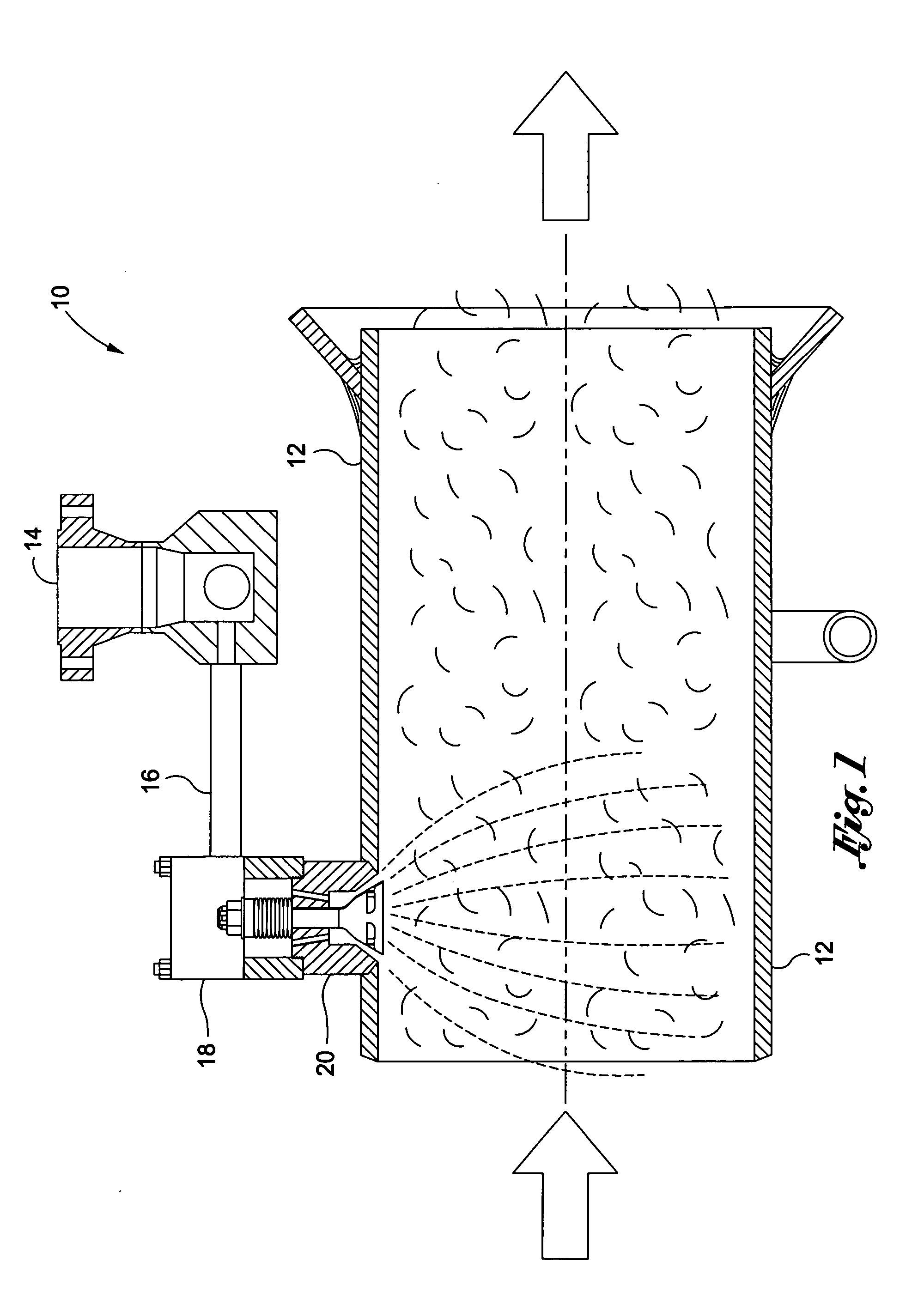

Desuperheater spray nozzle

ActiveUS20090278266A1Easy to makeDifficult to manufactureMixing methodsUsing liquid separation agentEngineeringSuperheated steam

An improved valve element for a spray nozzle assembly of a steam desuperheating device that is configured to spray cooling water into a flow of superheated steam in a generally uniformly distributed spray pattern. The valve element comprises a valve body and an elongate valve stem that is integrally attached to the valve body and extends axially therefrom. The valve body itself comprises a nozzle cone which is integrally connected to the valve stem, and defines an outer surface. Integrally formed on a bottom surface of the nozzle cone is a hub having multiple ribs protruding therefrom. Integrally connected to each of the ribs is a generally circular fracture ring. The fracture ring is disposed in spaced relation to the lower edge of the nozzle cone which circumvents the bottom surface thereof. In this regard, a series of windows are formed in the valve body, with each window being framed by a segment of the lower edge of the nozzle cone, an adjacent pair of the ribs, and a segment of the top edge of the fracture ring.

Owner:CONTROL COMPONENTS INC

Liquid jet head

Owner:CANON KK

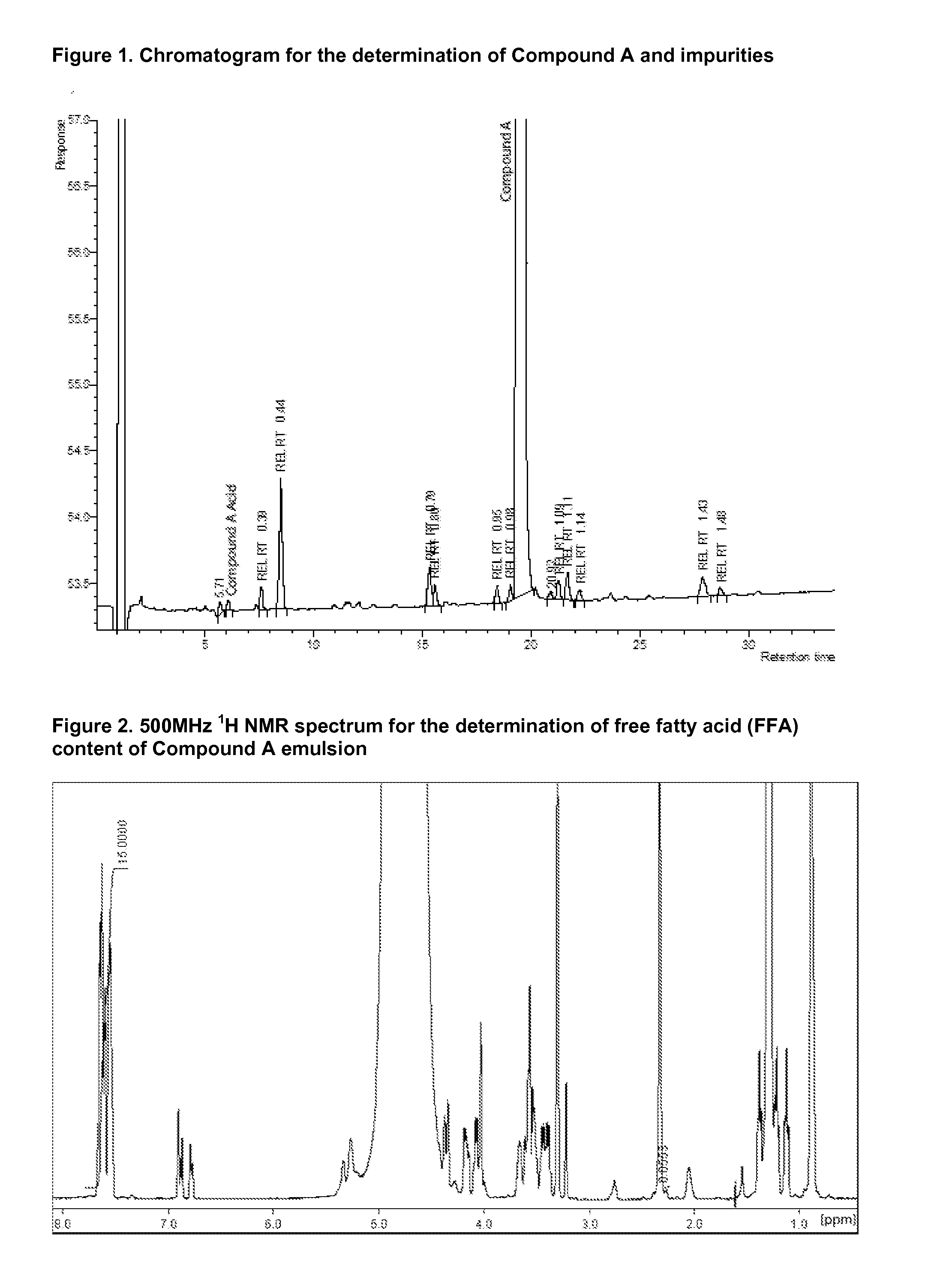

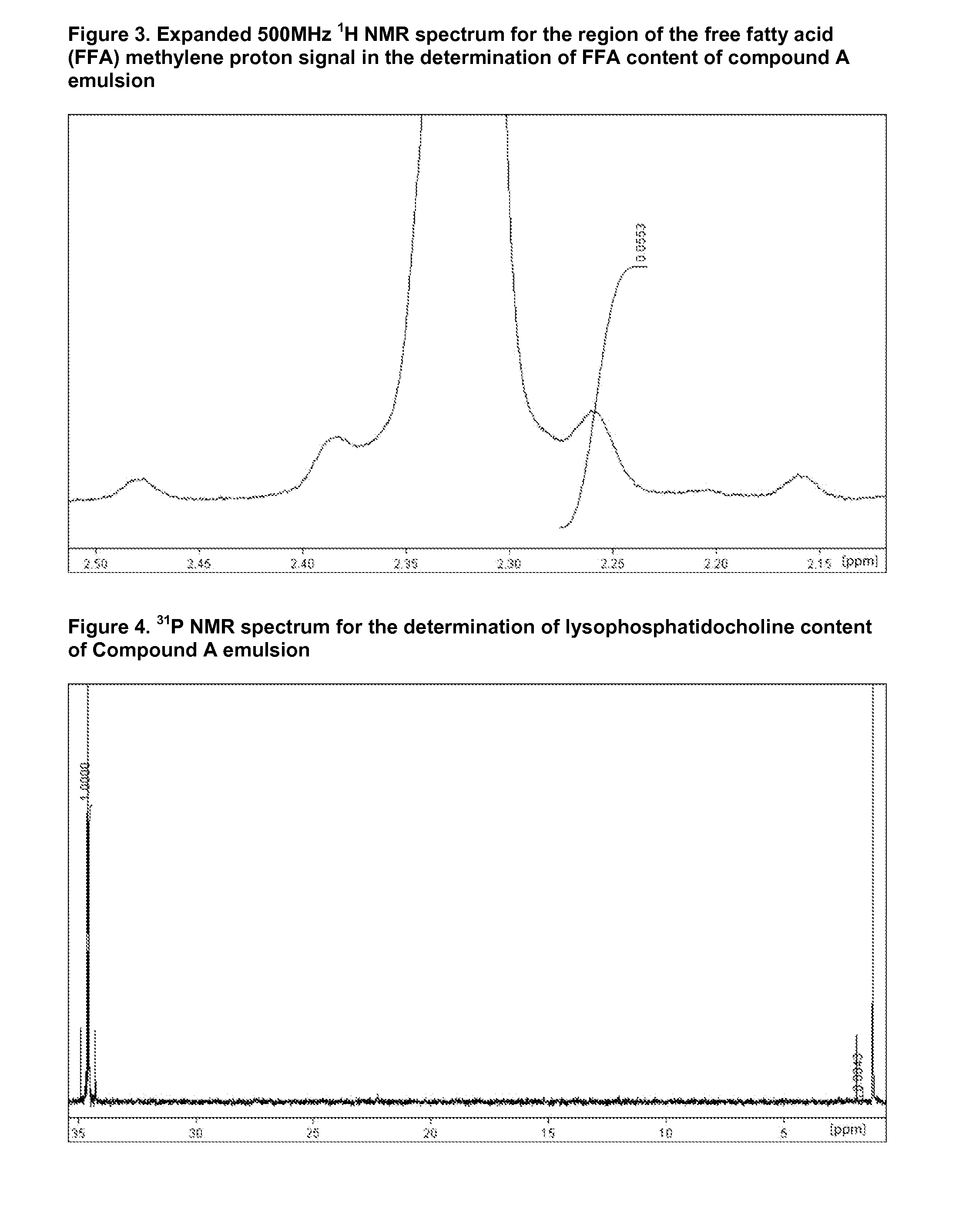

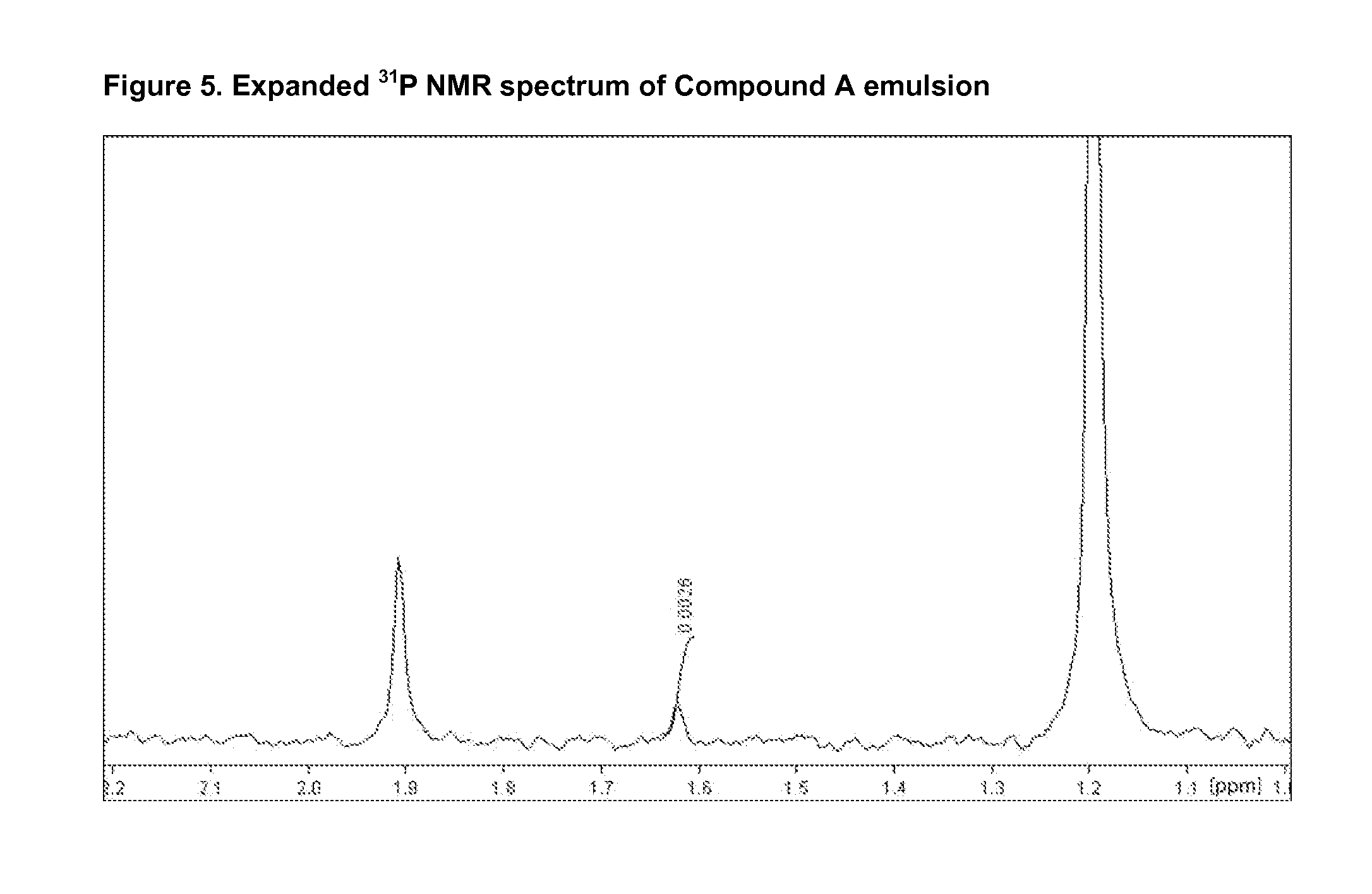

Injectable Emulsion of Sedative Hypnotic Agent

InactiveUS20130236501A1Improve physical stabilityGood storage stabilityBiocideNervous disorderHypnotic agentPhenylacetic acid

The present invention provides novel pharmaceutical formulations of a substituted phenylacetic acid ester compound, which is useful as a short-acting sedative hypnotic agent for anesthesia and sedation. The pharmaceutical formulations are oil-in-water emulsions suitable for administration by injection. The invention further provides processes for the preparation of the formulation and the use of the formulation in medical treatment of a mammal.

Owner:ASTRAZENECA AB

Monolithic multinozzle emitters for nanoelectrospray mass spectrometry

ActiveUS8022361B2Promote formationPossibility for surface functionalizationBurnersParticle separator tubesMass Spectrometry-Mass SpectrometrySilicon nanowires

Novel and significantly simplified procedures for fabrication of fully integrated nanoelectrospray emitters have been described. For nanofabricated monolithic multinozzle emitters (NM2 emitters), a bottom up approach using silicon nanowires on a silicon sliver is used. For microfabricated monolithic multinozzle emitters (M3 emitters), a top down approach using MEMS techniques on silicon wafers is used. The emitters have performance comparable to that of commercially-available silica capillary emitters for nanoelectrospray mass spectrometry.

Owner:RGT UNIV OF CALIFORNIA

Method for fine bore orifice spray coating of medical devices and pre-filming atomization

ActiveUS6979473B2Stable spray plumeIncrease back pressurePharmaceutical containersPretreated surfacesSpray coatingDroplet size

A method for spray deposition of small targets, such as medical devices like stents. The method includes the steps of positioning a spray nozzle body, which has a fine bore diameter to pressurize the coating material within the nozzle body, near a medical device, and dampening vibration of the nozzle body during operation by maintaining a steady back pressure in the coating material line sufficient to eliminate or minimize vibration modes from external and internal sources; and stabilizing the spray coating plume. In another embodiment, a coating method is disclosed in which a finer atomized spray droplet size is achieved by pre-filming the coating material onto a flat face before entraining the coating material within the atomizing fluid, which improves manufacturing repeatability, reduces coating variances, and increases therapeutic dosage predictability. In certain embodiments of the invention, the coating materials include therapeutic agents and biologically active materials.

Owner:BOSTON SCI SCIMED INC

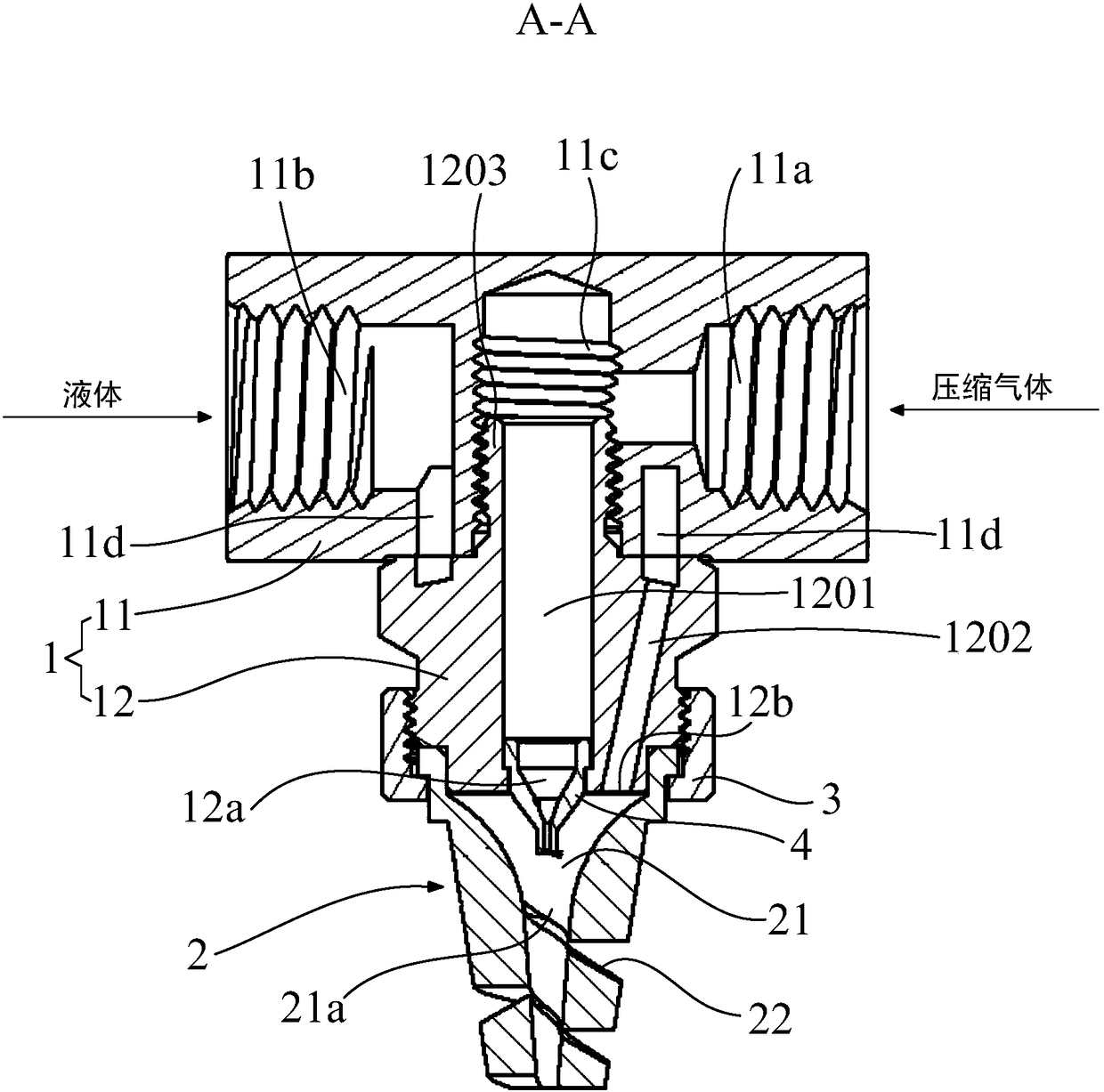

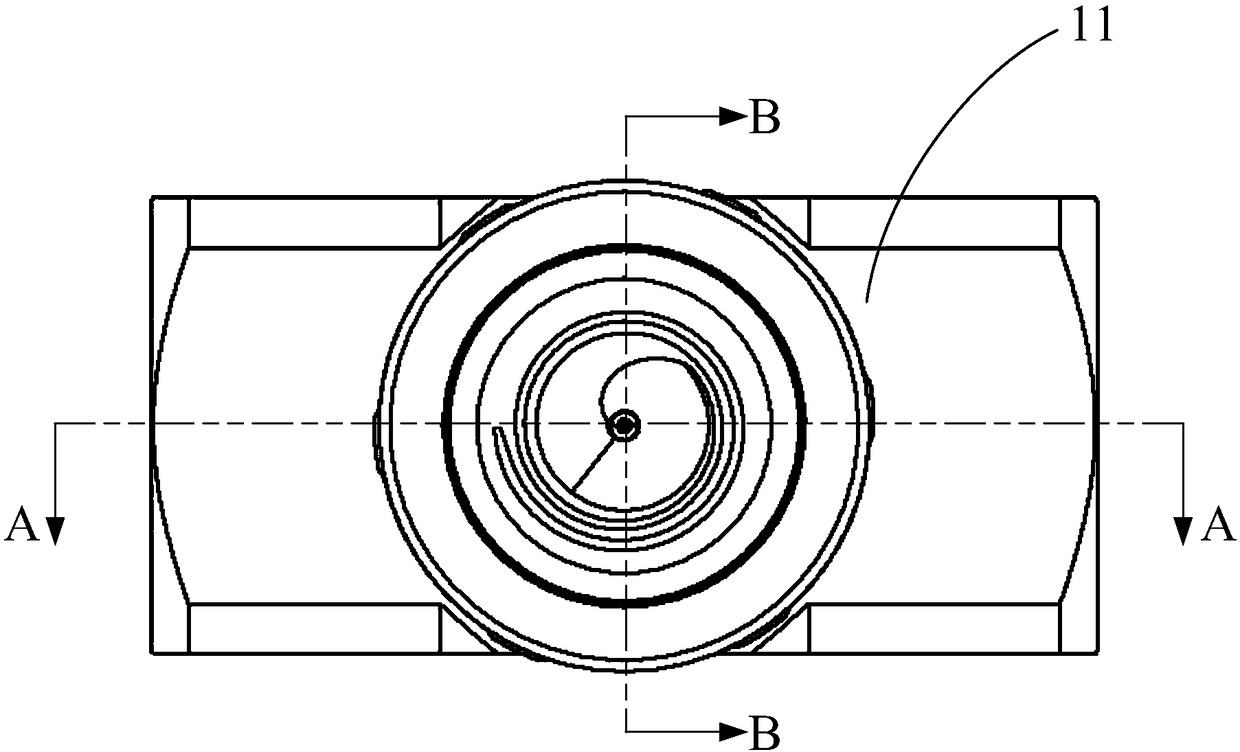

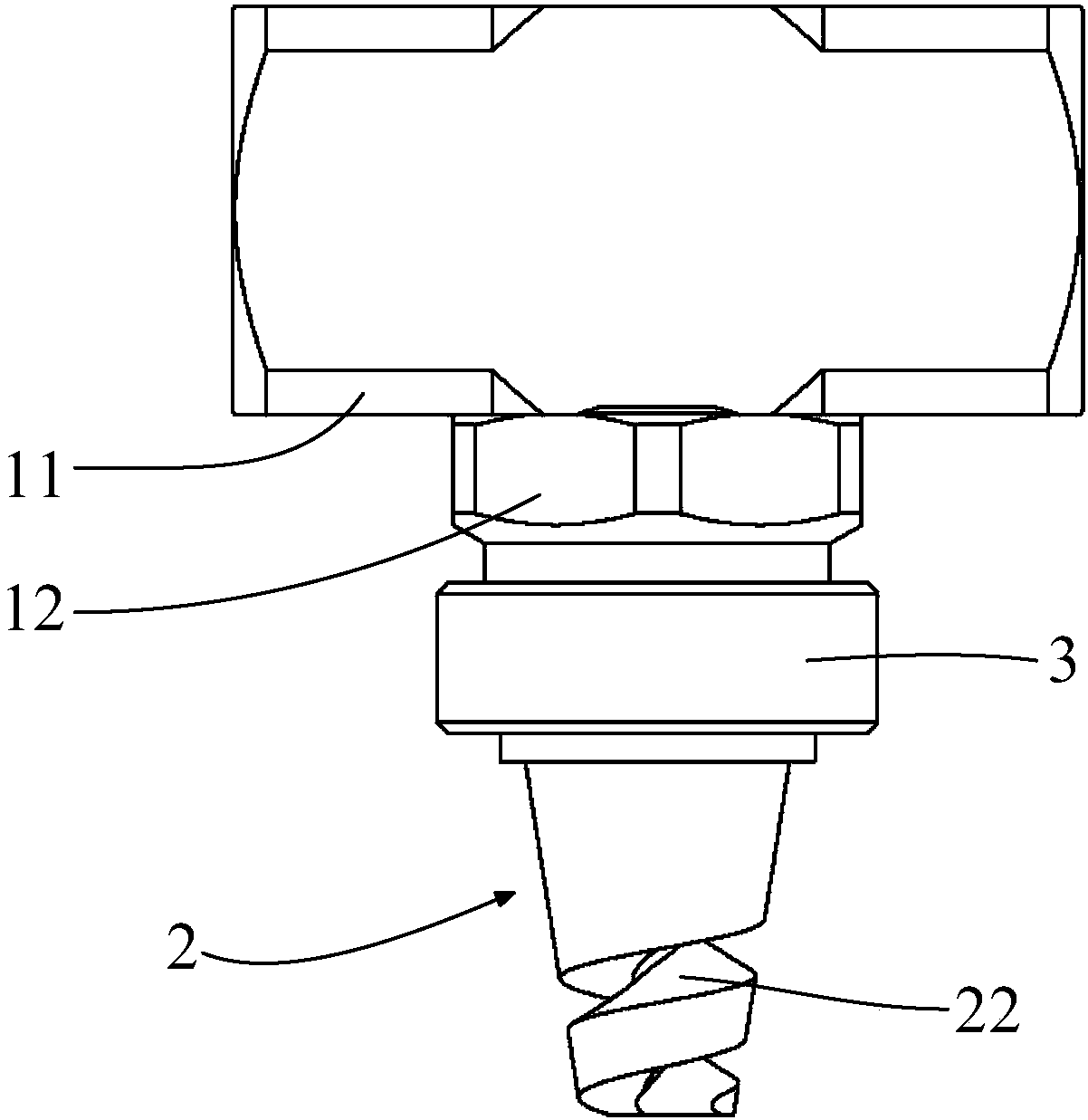

Atomizing nozzle

PendingCN108421655AWidely distributedSmall droplet sizeSpray nozzlesLiquid spraying apparatusEngineeringLiquid drop

The invention aims at providing an atomizing nozzle. The atomizing nozzle comprises a gas-liquid conveying assembly and an air cap. The air cap comprises a reduced mixing cavity and a collision wall.Compressed air can flow into the mixing cavity from a gas outlet and impact on liquid flowing out of a liquid outlet to form first atomized liquid drops. The first atomized liquid drops can be accelerated to flow out of the mixing cavity and collides with a colliding wall, and second atomized liquid drops are formed. The second atomizing liquid drops have the beneficial effects of being wide in distribution range and small in liquid drop particle.

Owner:SPRAYING SYST (CHINA) CO LTD

Method and apparatus for electrostatic spray deposition for a solid oxide fuel cell

InactiveUS20050095369A1Easy to set upLarge film growth rateElectric shock equipmentsFinal product manufactureThin layerSpray nozzle

A method and apparatus for electrostatic spray deposition (ESD) for fabricating a thin-layer yttria-stabilized zirconia (YSZ) electrolyte on a solid oxide fuel cell (SOFC) anode substrate constructed of nickel-YSZ cermet. By reducing the thickness of the electrolyte, and thereby reducing the cell internal IR drop, an intermediate temperature SOFC (ITSOFC) can operate at 600-800° C. A collar positioned at a distance from a discharge end of a spray nozzle enhances a spray pattern of a precursor including the electrolyte material and thus provides a very thin electrolyte layer.

Owner:ILLINOIS INSTITUTE OF TECHNOLOGY

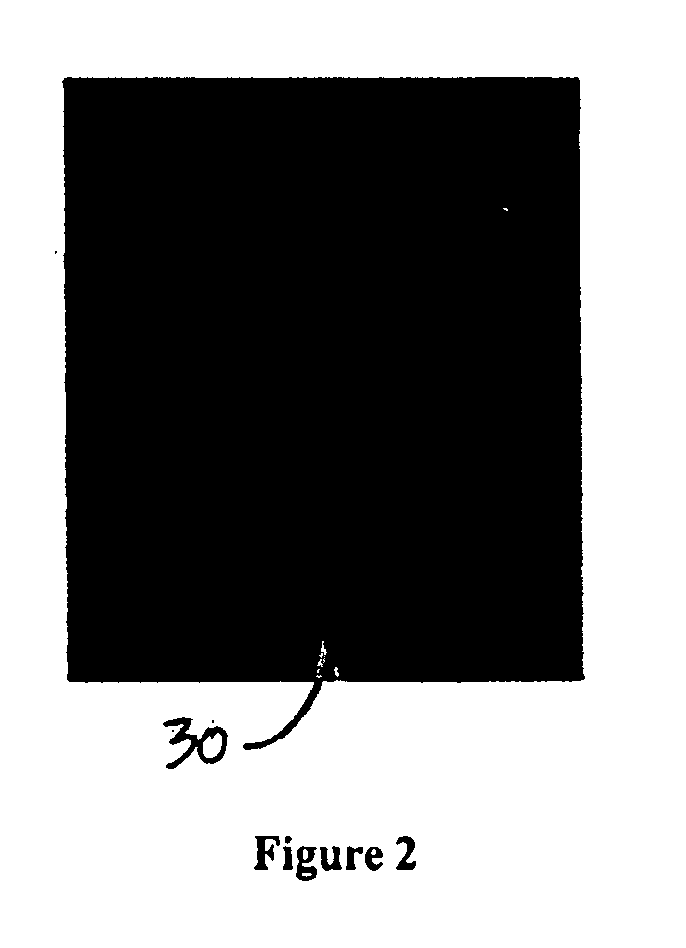

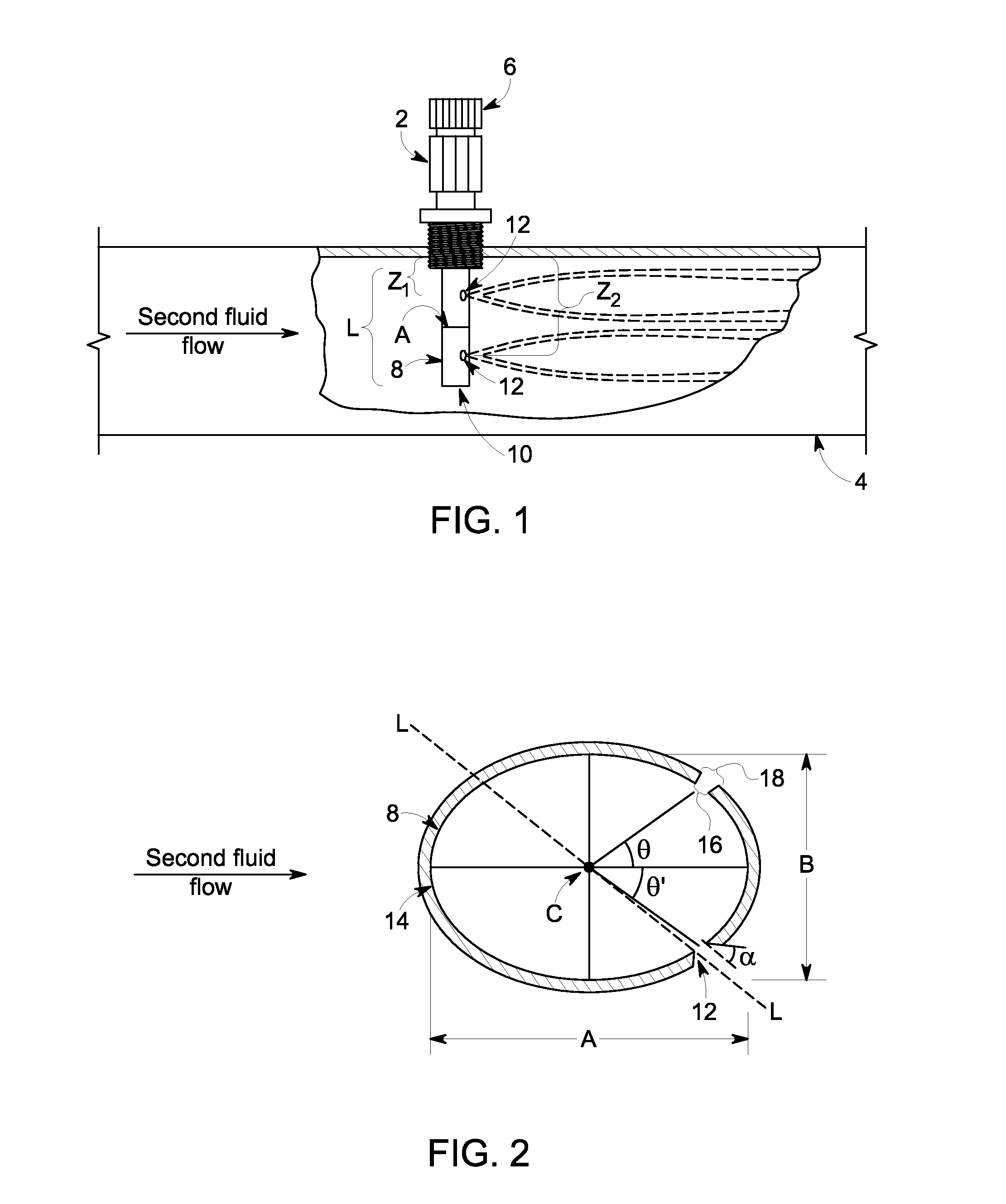

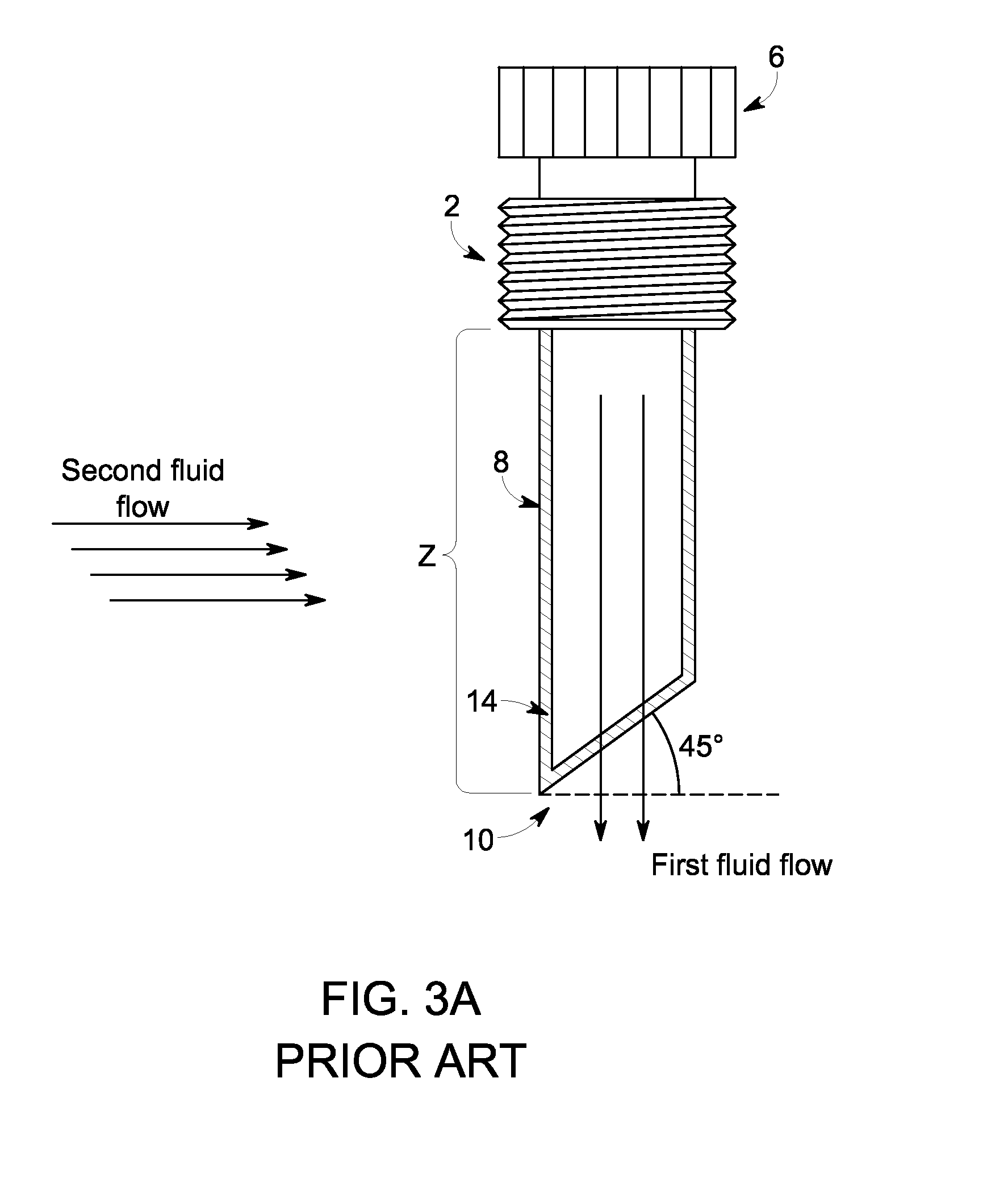

Injection quill designs and methods of use

InactiveUS20160263537A1Increase volume fractionMinimized pressure dropFlow mixersTransportation and packagingMinor axisBiomedical engineering

An injection quill design and methods of use for injecting a first fluid into a second fluid. The injection quill may comprise a hollow stem having a closed end and a sidewall, the stem having a curved cross-section defined by a major axis, and a minor axis, and at least one orifice for injecting the first fluid into the second fluid, wherein the major axis is greater than the minor axis and / or the orifice extends through the sidewall and / or the orifice has an internal chamfer with a chamfer angle ranging from less than 0° but greater than 90°.

Owner:BL TECH INC

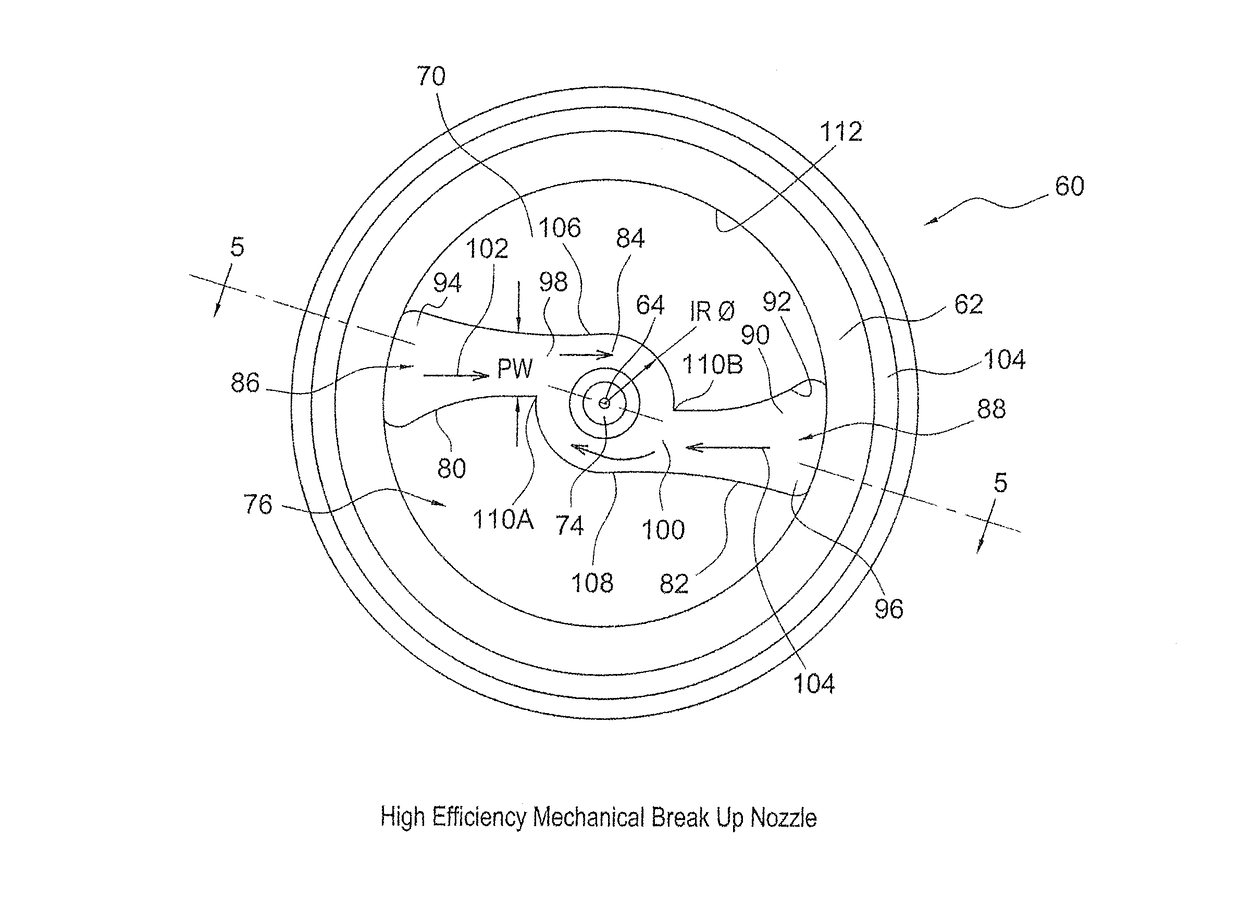

Swirl nozzle assemblies with high efficiency mechanical break up for generating mist sprays of uniform small droplets

ActiveUS20170065990A1Reduce splashMaximizing creation and preservationSpray nozzlesSingle-unit apparatusSmall dropletAngular velocity

A spray dispenser is configured to generate a swirled output spray pattern 152 with improved rotating or angular velocity ω and smaller sprayed droplet size. Cup-shaped nozzle member 60 has a cylindrical side wall 62 surrounding a central longitudinal axis 64 and has a circular closed end wall 68 with at least one exit aperture 74 passing through the end wall. At least one enhanced swirl inducing mist generating structure is formed in an inner surface 70 of the end wall, and including a pair of opposed inwardly tapered offset power nozzle channels 80, 82 terminating in an interaction chamber 84 surrounding the exit aperture 74. The power nozzle channels generate opposing offset flows which are aimed to very efficiently generate a vortex of fluid which projects distally from the exit aperture as a swirled spray of small droplets 152 having a rapid angular velocity.

Owner:DLHBOWLES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com