A liquid atomizing nozzle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

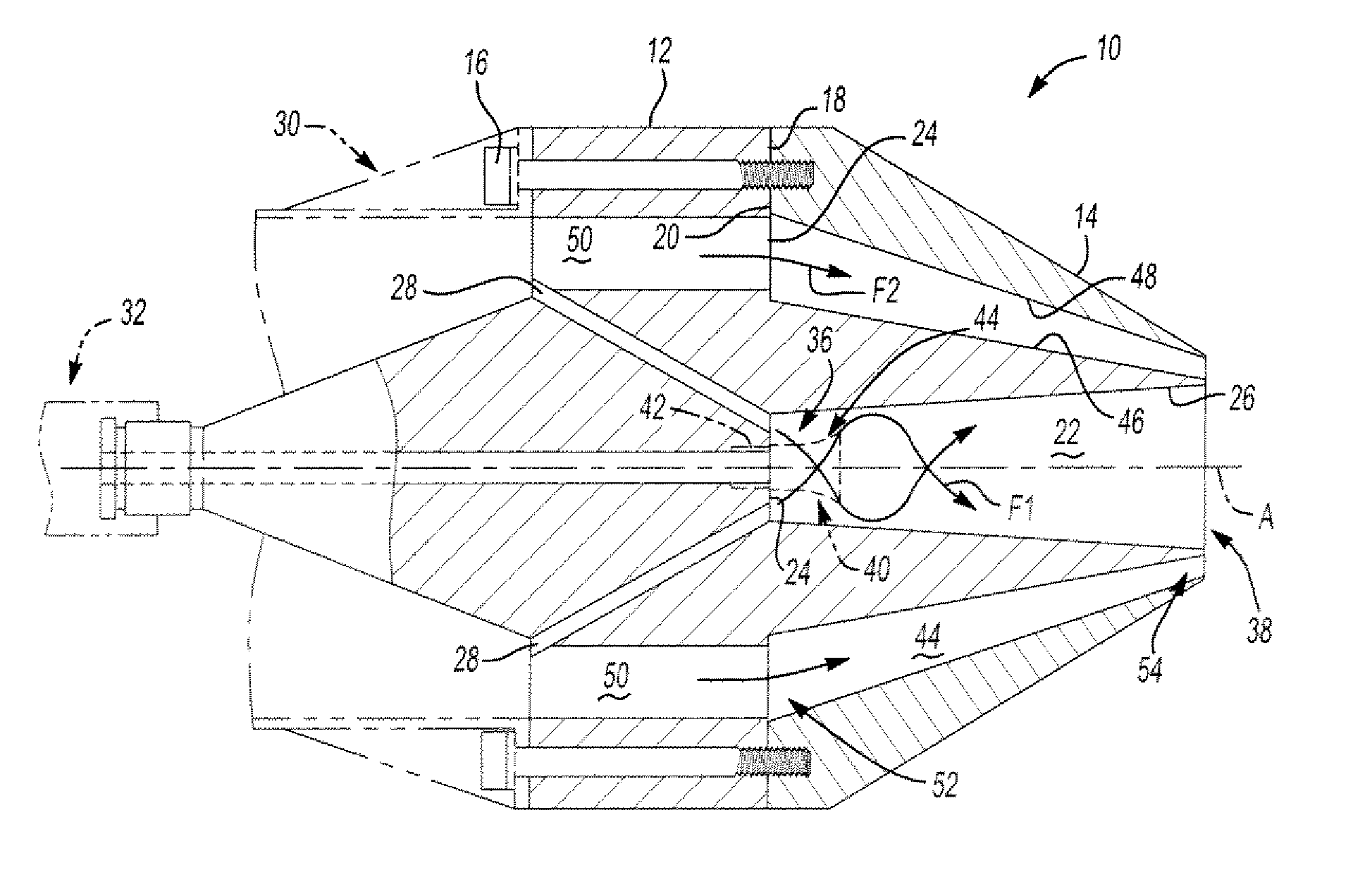

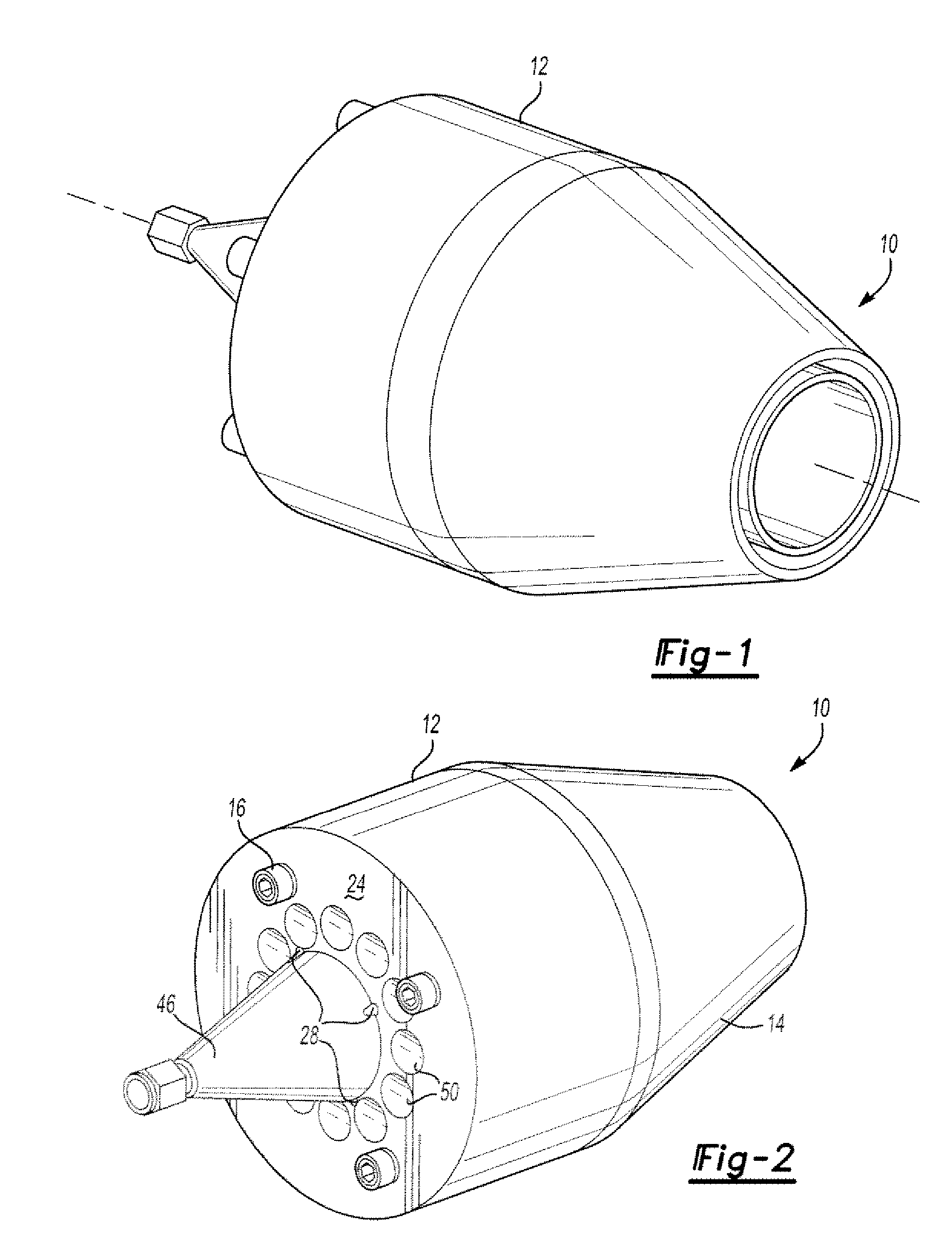

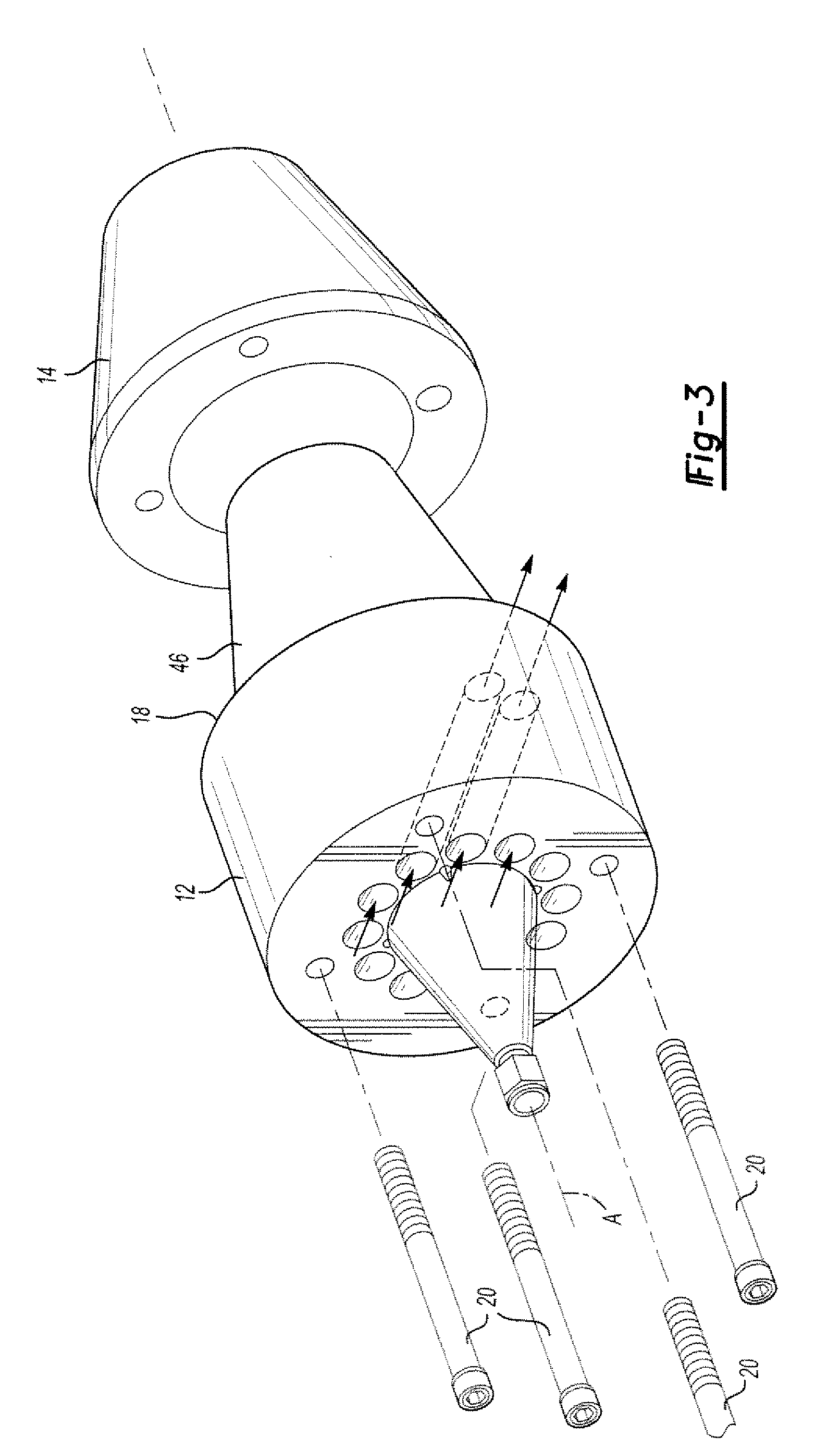

[0023] The present invention provides a method and apparatus for improved dispensing and atomization of fluid. In one aspect, the invention provides a nozzle for dispensing liquid wherein the liquid to be dispensed undergoes more than one atomization stage. In another aspect, the nozzle of the present invention may comprise two or more components, which during assembly do not require the use of gasket material to prevent leakage of fluid through the nozzle. Other features should be appreciated as described herein.

[0024] The nozzle of the present invention is particularly useful with the dispensing of liquid fluids in conjunction with gaseous fluids. For example a first fluid may comprise a gaseous fluid (such as air, nitrogen, carbon dioxide, argon, or any other gas capable of use with an atomization process), and the second fluid may comprise a liquid fluid (such as water, oil, chemical composition or otherwise). While it should be appreciated that the numerous gases and liquids m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com