Double-arc fuse collaborative additive manufacturing method of high-entropy alloy

A high-entropy alloy and additive manufacturing technology, applied in the field of high-entropy alloys, can solve problems such as uneven chemical composition and structure, inconvenient adjustment of alloy composition, voids and shrinkage cavities, etc., to achieve uniform chemical composition and structure, heat input Large adjustment range and small splash effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

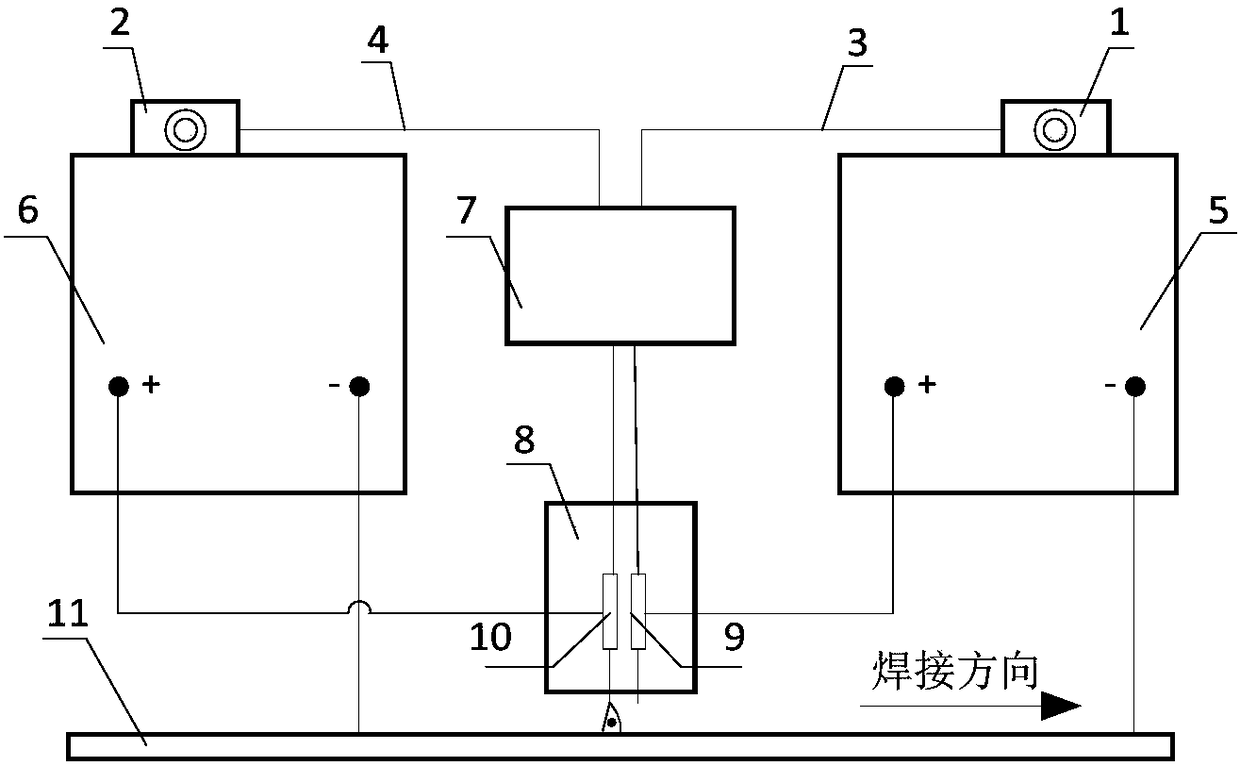

Method used

Image

Examples

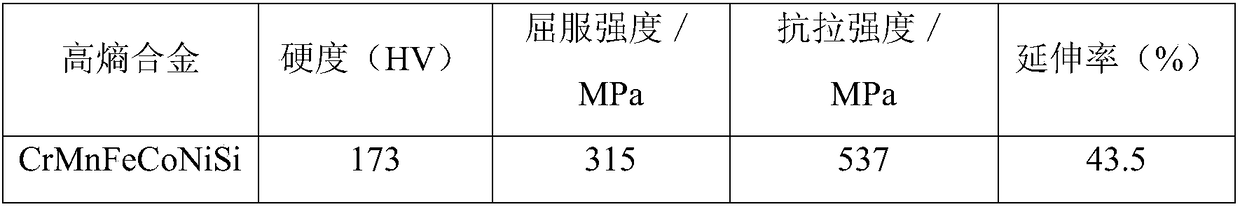

Embodiment 1

[0049] A kind of high entropy alloy CrMnFeCoNi, preparation method comprises the steps:

[0050] (1) Select the alloy strip and the drug core powder according to the raw material ratio, and the composition and content are as described in Table 1 and Table 2, wherein the width of the alloy strip 1 and the alloy strip 2 is 12mm, and the thickness is 0.3mm ;

[0051] Table 1

[0052] Numbering

Fe

Cr

mn

Ni

alloy belt 1

69.5wt%

30wt%

0.5wt%

0

Alloy Belt 2

1wt%

30wt%

1.0wt%

68wt%

[0053] Table 2

[0054] Numbering

Chrome powder

Manganese powder

cobalt powder

Drug core powder 1

26.9g

469.9g

503.2g

Drug core powder 2

26.9g

469.9g

503.2g

[0055] (2) The drug core powder 1 and the drug core powder 2 are processed as follows:

[0056] Drying treatment: use a far-infrared drying oven for drying, the drying temperature is 110°C, and the drying time is 1....

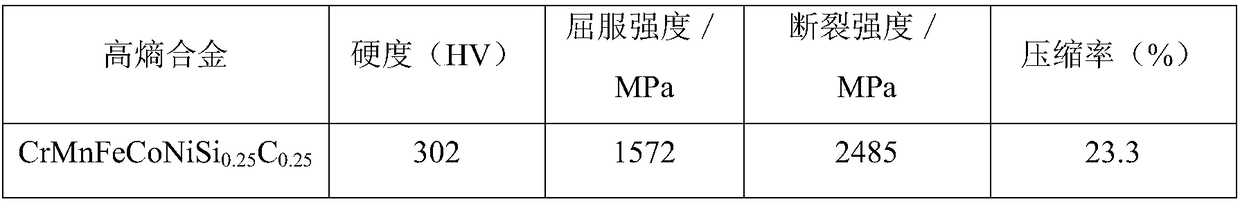

Embodiment 2

[0070] A High Entropy Alloy CrMnFeCoNiSi 0.25 C 0.25 , the preparation method comprises the following steps:

[0071] (1) Select the alloy strip and the drug core powder according to the raw material ratio, the composition and content are as described in Table 4 and Table 5, wherein the width of the alloy strip 1 and the alloy strip 2 is 10mm, and the thickness is 0.3mm;

[0072] Table 4

[0073] Numbering

Fe

Cr

mn

Ni

alloy belt 1

69.5wt%

30wt%

0

0.5wt%

Alloy Belt 2

1wt%

30wt%

1.0wt%

68wt%

[0074] table 5

[0075] Numbering

cobalt powder

Manganese powder

Drug core powder 1

475.4g

443.7g

80.9g

Drug core powder 2

475.4g

443.7g

80.9g

[0076] (2) The drug core powder 1 and the drug core powder 2 are processed as follows:

[0077] Drying treatment: use a far-infrared drying oven for drying, the drying temperature is 120°C,...

Embodiment 3

[0091] A high entropy alloy Al 0.5 CrFeCoNiCu 0.7 Ti 0.2 C 0.2 W 0.08 , the preparation method comprises the following steps:

[0092] (1) Select the alloy strip and the drug core powder according to the raw material ratio, the composition and content are as described in Table 7 and Table 8, wherein the width of the alloy strip 1 and the alloy strip 2 is 8mm, and the thickness is 0.3mm;

[0093] Table 7

[0094] Numbering

Fe

Cr

Ni

co

Cu

W

alloy belt 1

39wt%

28wt%

32wt%

0

1wt%

0

Alloy Belt 2

1wt%

19wt%

11wt%

55wt%

0

14wt%

[0095] Table 8

[0096] Numbering

Aluminum powder

copper powder

Drug core powder 1

289.3g

67.8g

642.9g

Drug core powder 2

0

1000g

0

[0097] (2) The drug core powder 1 and the drug core powder 2 are processed as follows:

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com