Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1424results about "Heat inorganic powder coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

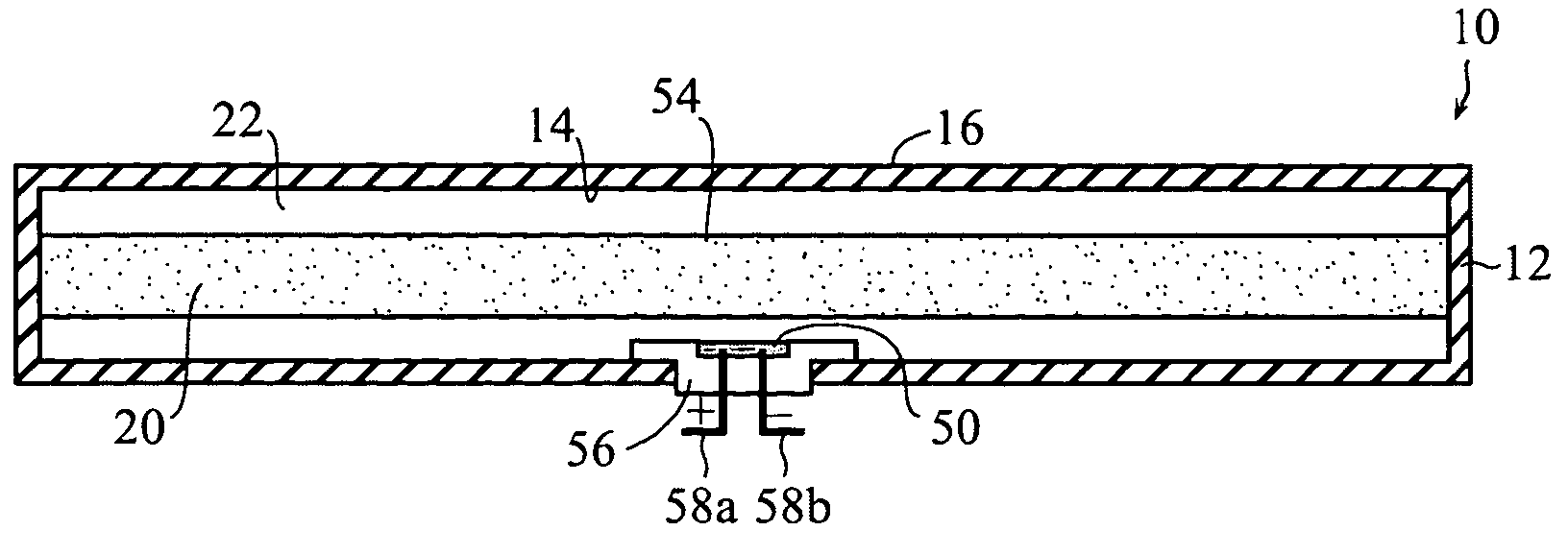

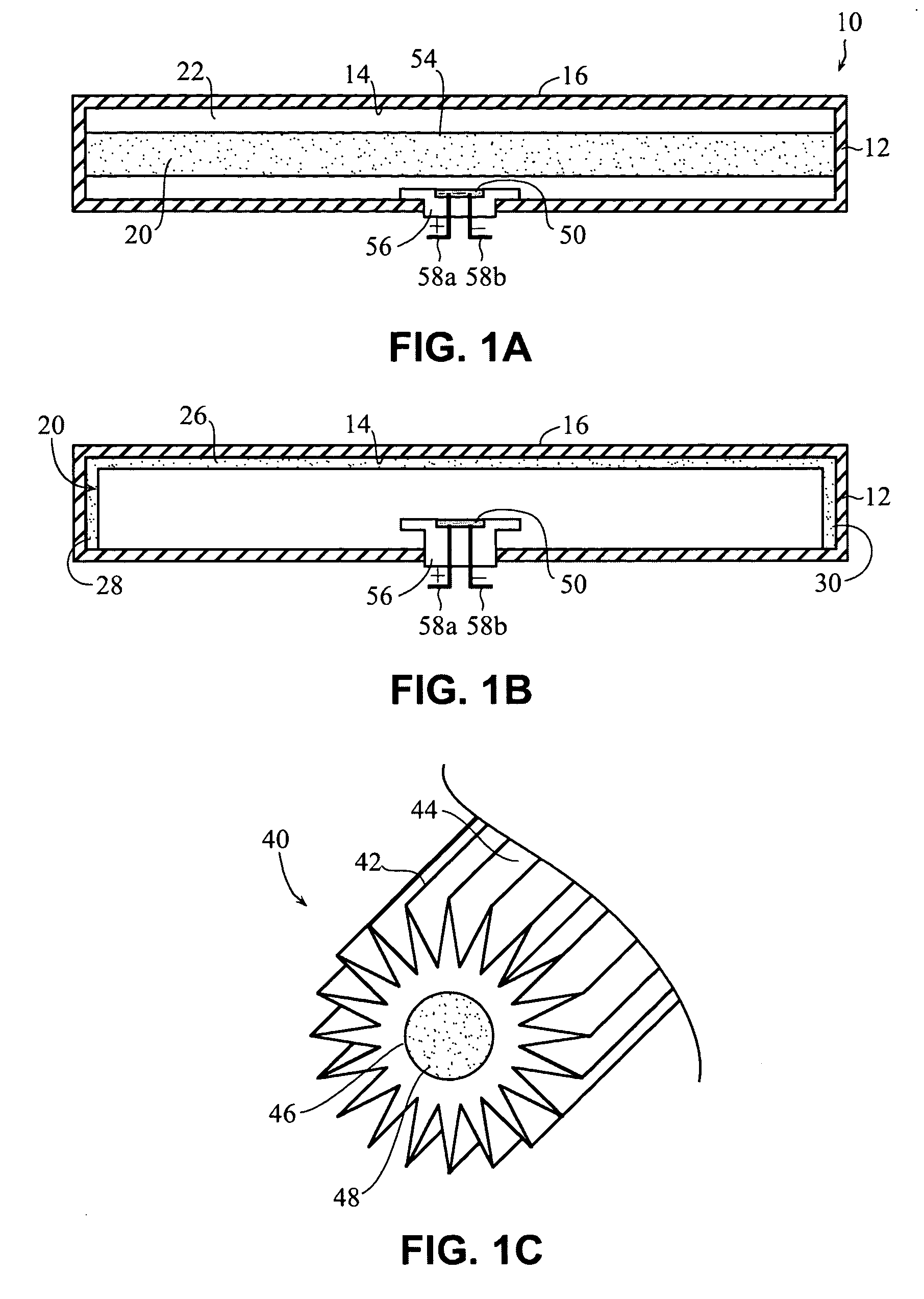

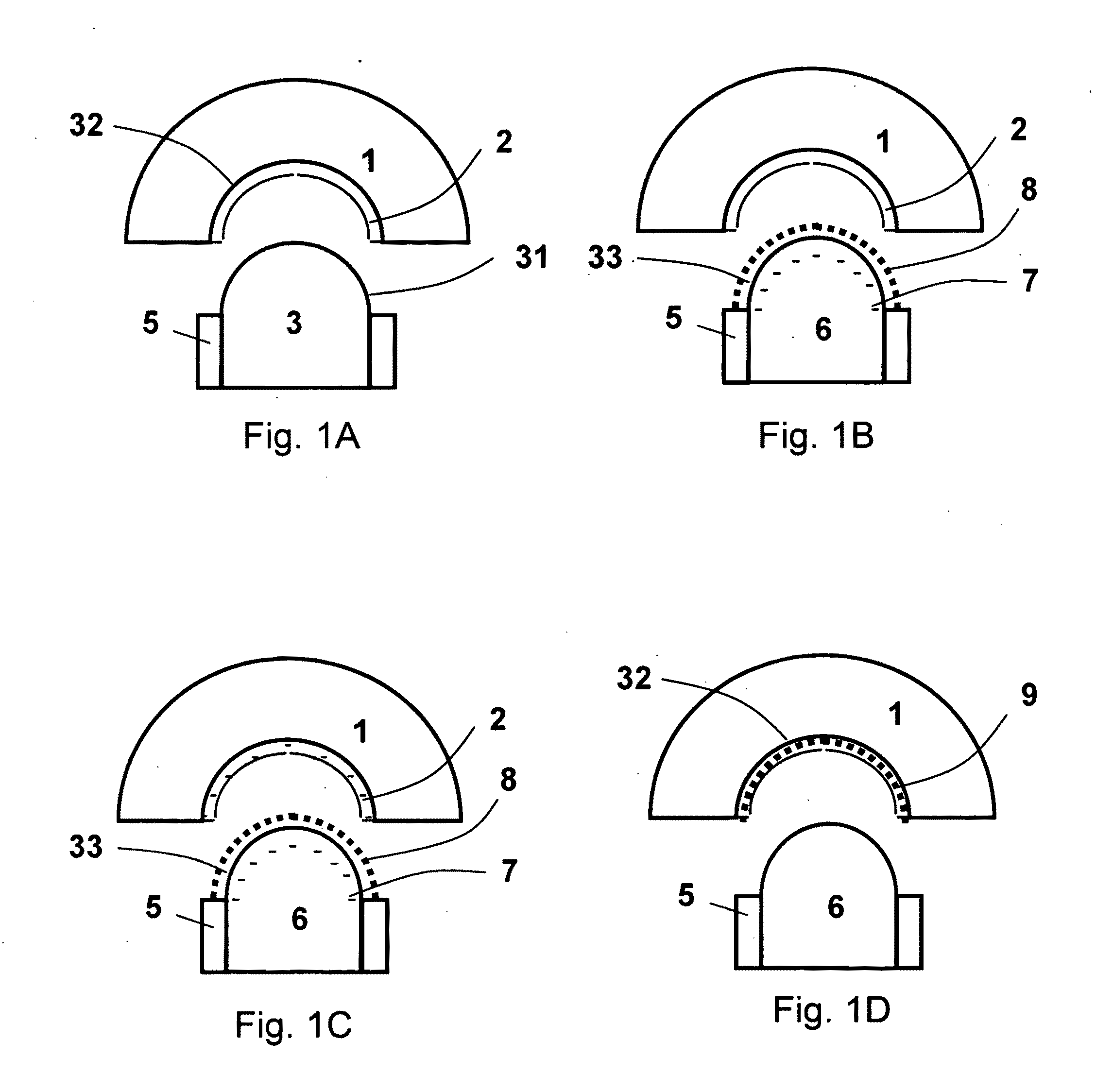

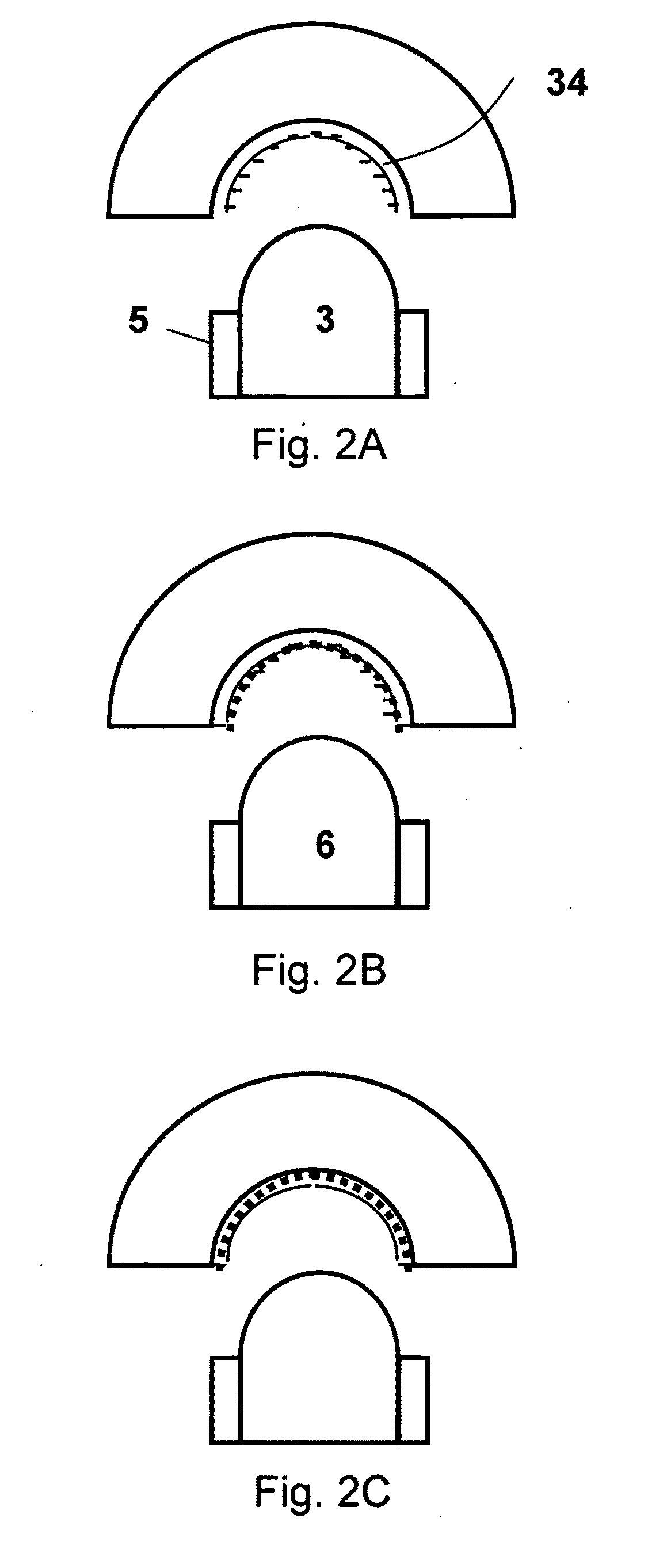

Self-contained heating unit and drug-supply unit employing same

InactiveUS20050079166A1Exothermal chemical reaction heat productionSemiconductor/solid-state device manufacturingSolid fuelEngineering

Heating units, drug supply units and drug delivery articles capable of rapid heating are disclosed. Heating units comprising a substrate and a solid fuel capable of undergoing an exothermic metal oxidation reaction disposed within the substrate are disclosed. Drug supply units and drug delivery articles wherein a solid fuel is configured to heat a substrate to a temperature sufficient to rapidly thermally vaporize a drug disposed thereon are also disclosed.

Owner:ALEXZA PHARMA INC

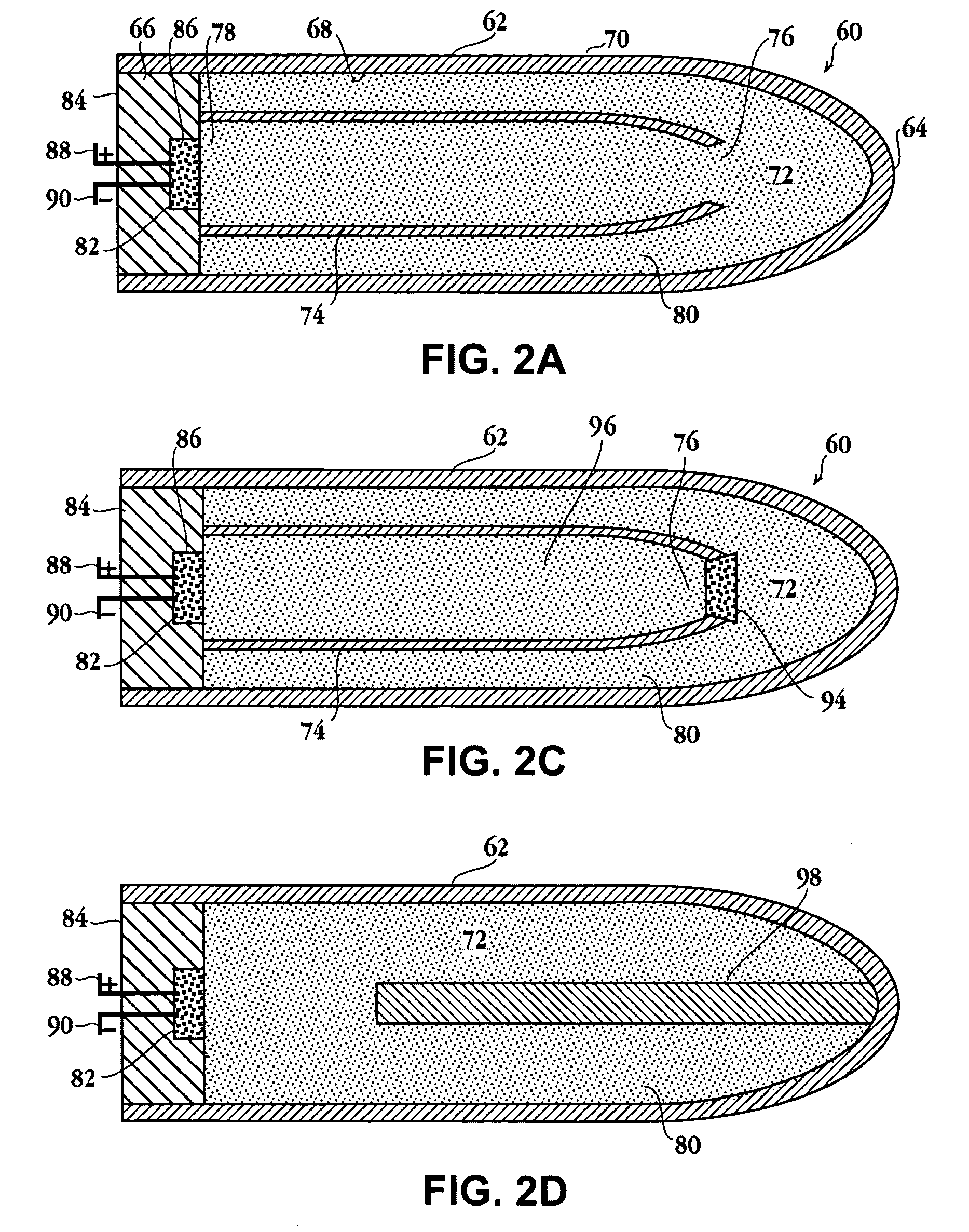

Methods and apparatus for forming uniform particle layers of phosphor material on a surface

InactiveUS20100291313A1Easy to controlHigh bulk densityLiquid surface applicatorsElectric shock equipmentsPhosphorStatic electricity

A method for forming a layer of an LED phosphor material includes disposing a first surface in a proximity of a powder that includes an LED phosphor material, forming electrostatic charges on the first surface, and forming a layer of the LED phosphor material on the first surface at least partially by using the electrostatic charges. In an embodiment, the method includes disposing the first surface in an interior of a chamber and forming an airborne distribution of the powder in the interior of the chamber in a vicinity of the first surface. In another embodiment, the method includes providing a reservoir of the powder and applying to said phosphor powder an electrostatic charge opposite to that of said electrostatic charge on the first surface.

Owner:ACHROLUX

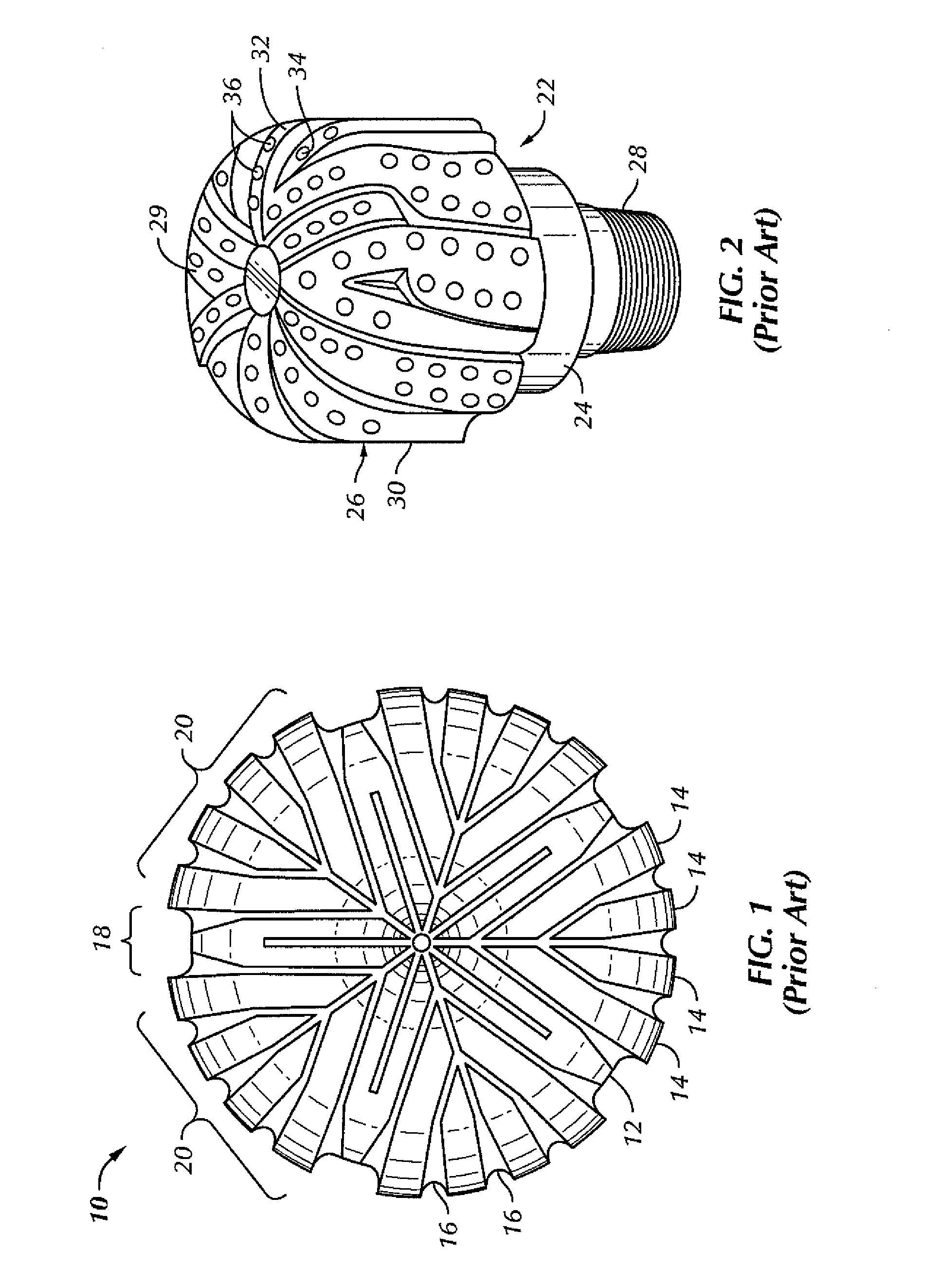

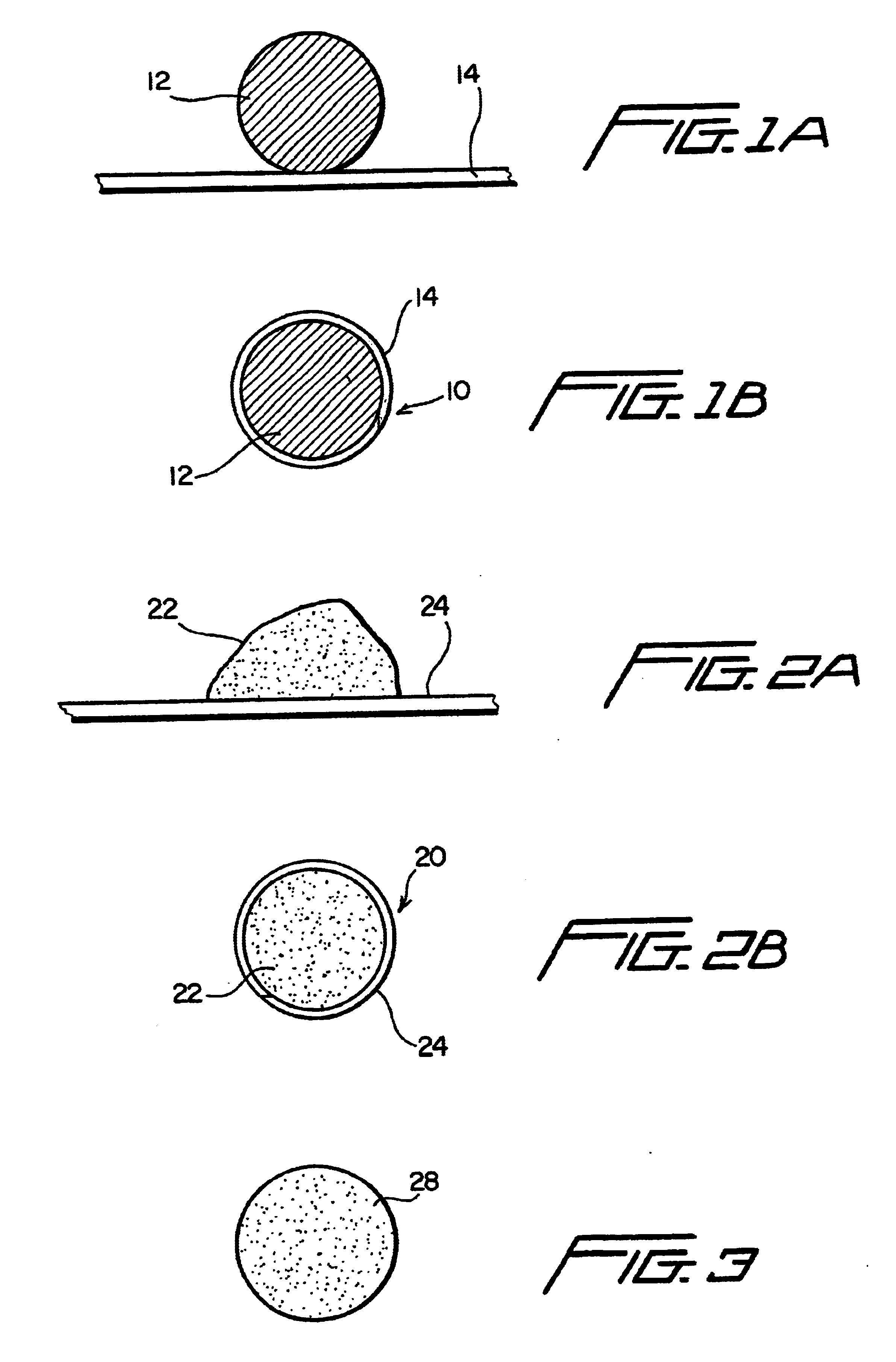

Method and apparatus for fabrication and sintering composite inserts

InactiveUS6011248AInhibit migrationNot adversely propertyMechanical apparatusLinings repairWear resistantWear resistance

The present disclosure is directed to the fabrication of a highly wear layer either directly upon an article or tool support structure or body, or as a wear resistant insert or element which is subsequently attached to the tool body. The wear material is formed by sintering particulate material using the absorption of microwave energy as a means of heating. The disclosure also encompasses post manufacture annealing, using heating by microwave radiation, of both highly wear resistant inserts and composite articles which consist of a wear resistant layer and a body. The wear resistant material, whether fabricated directly upon an article or fabricated separately and subsequently affixed to an article, provides an abrasive wear surface and greatly increases the life of the article. Microwave sintered wear resistant surfaces for mills, drills, grinders, brakes, bearings, saw blades and other articles and assemblies are disclosed.

Owner:PENN STATE RES FOUND +1

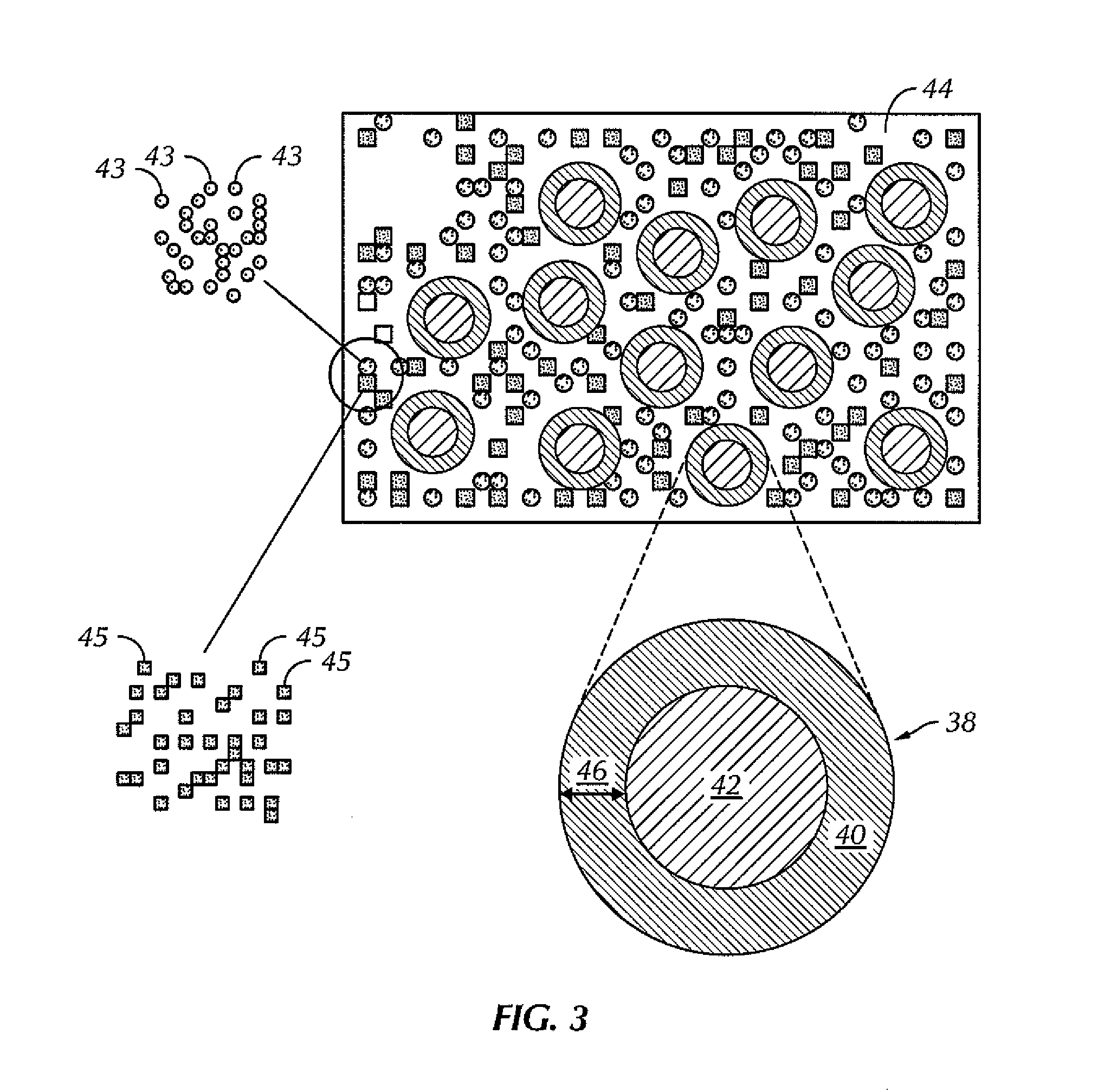

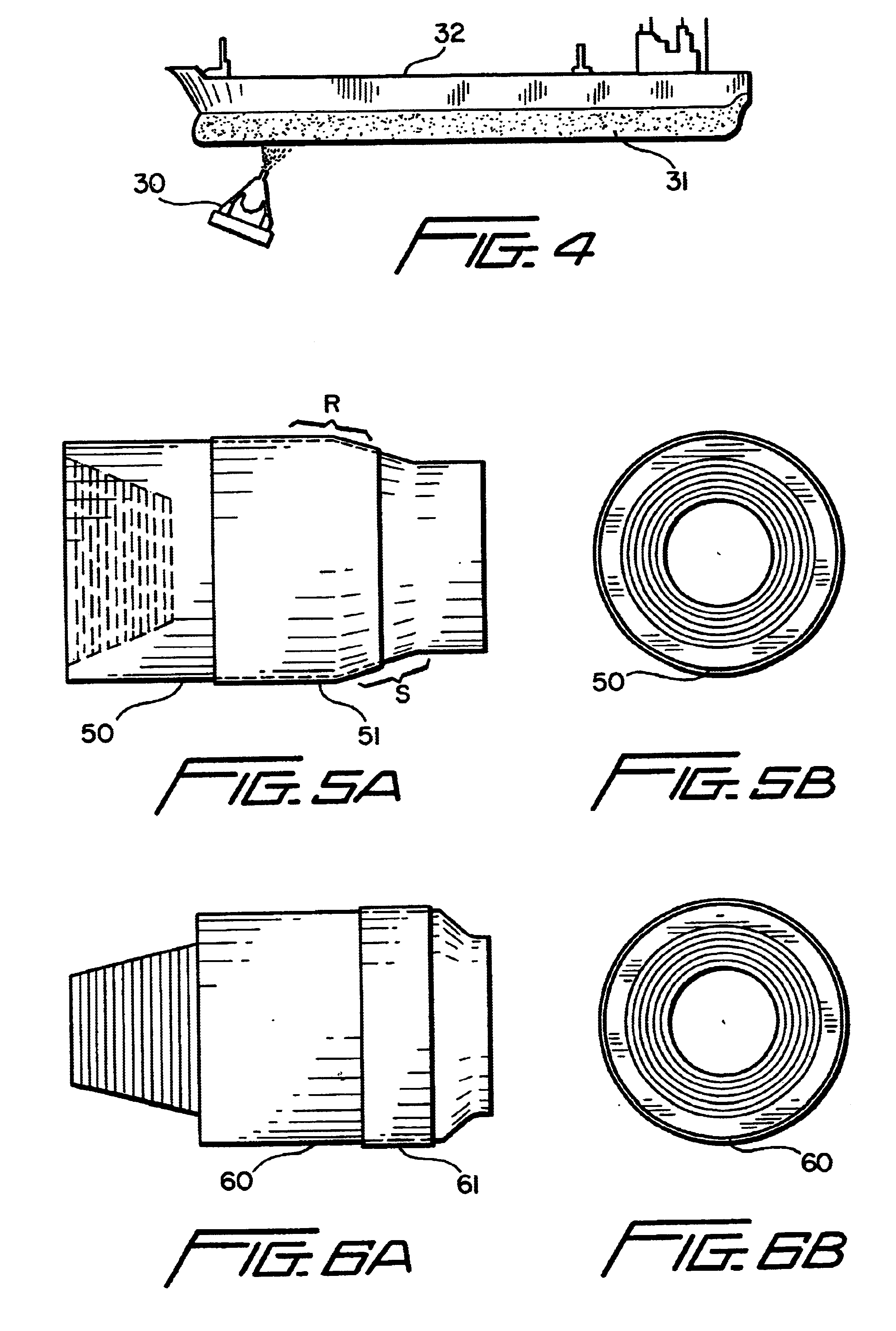

Impregnated material with variable erosion properties for rock drilling and the method to manufacture

A cutting structure that includes a plurality of encapsulated particles dispersed in a first matrix material, the encapsulated particles comprising: an abrasive grit encapsulated within a shell, wherein the shell comprises a second matrix material different from the first matrix material is disclosed.

Owner:SMITH INT INC

Glass ceramic and metal substrates with a self-cleaning surface, method for the production and use thereof

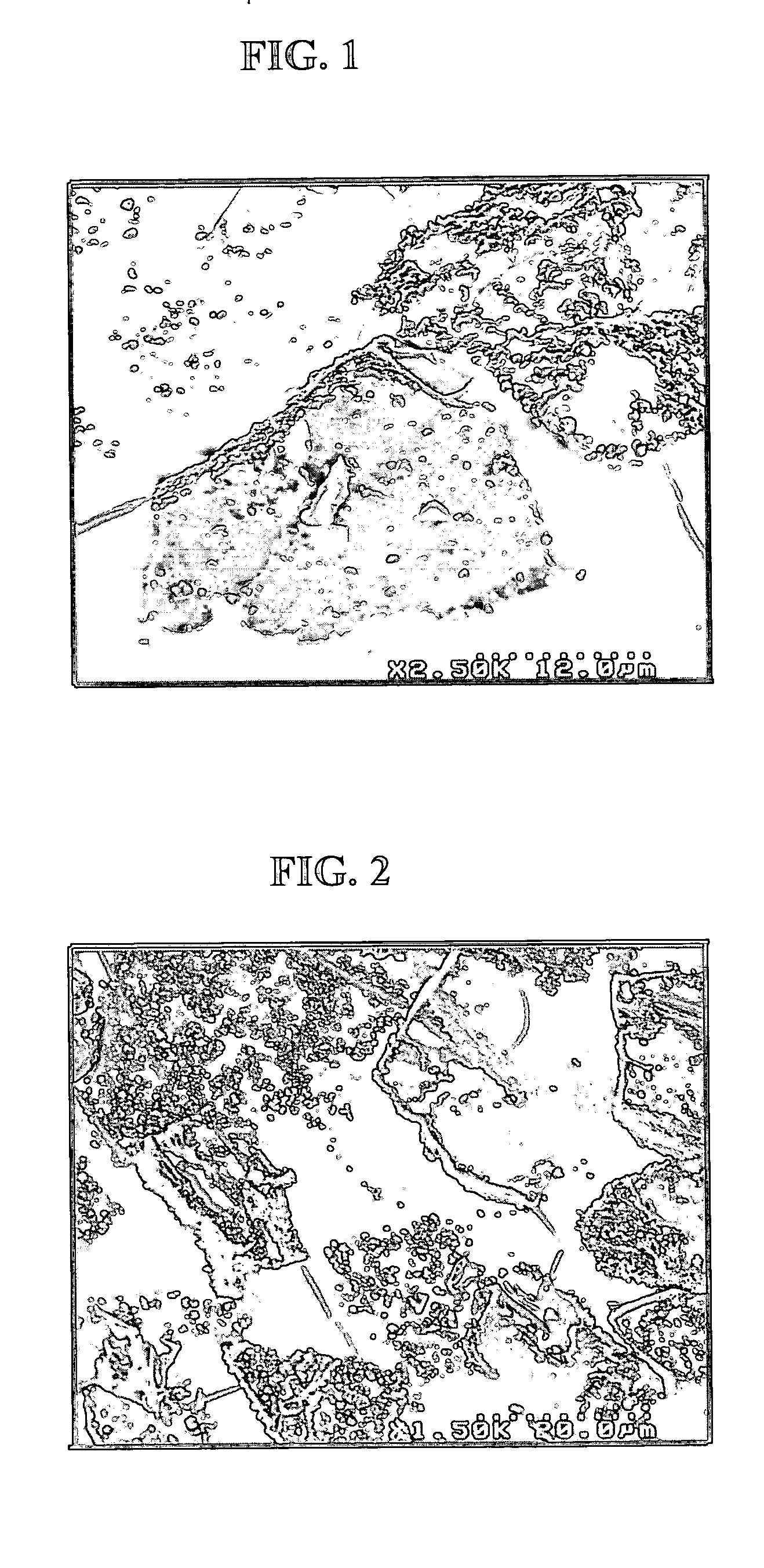

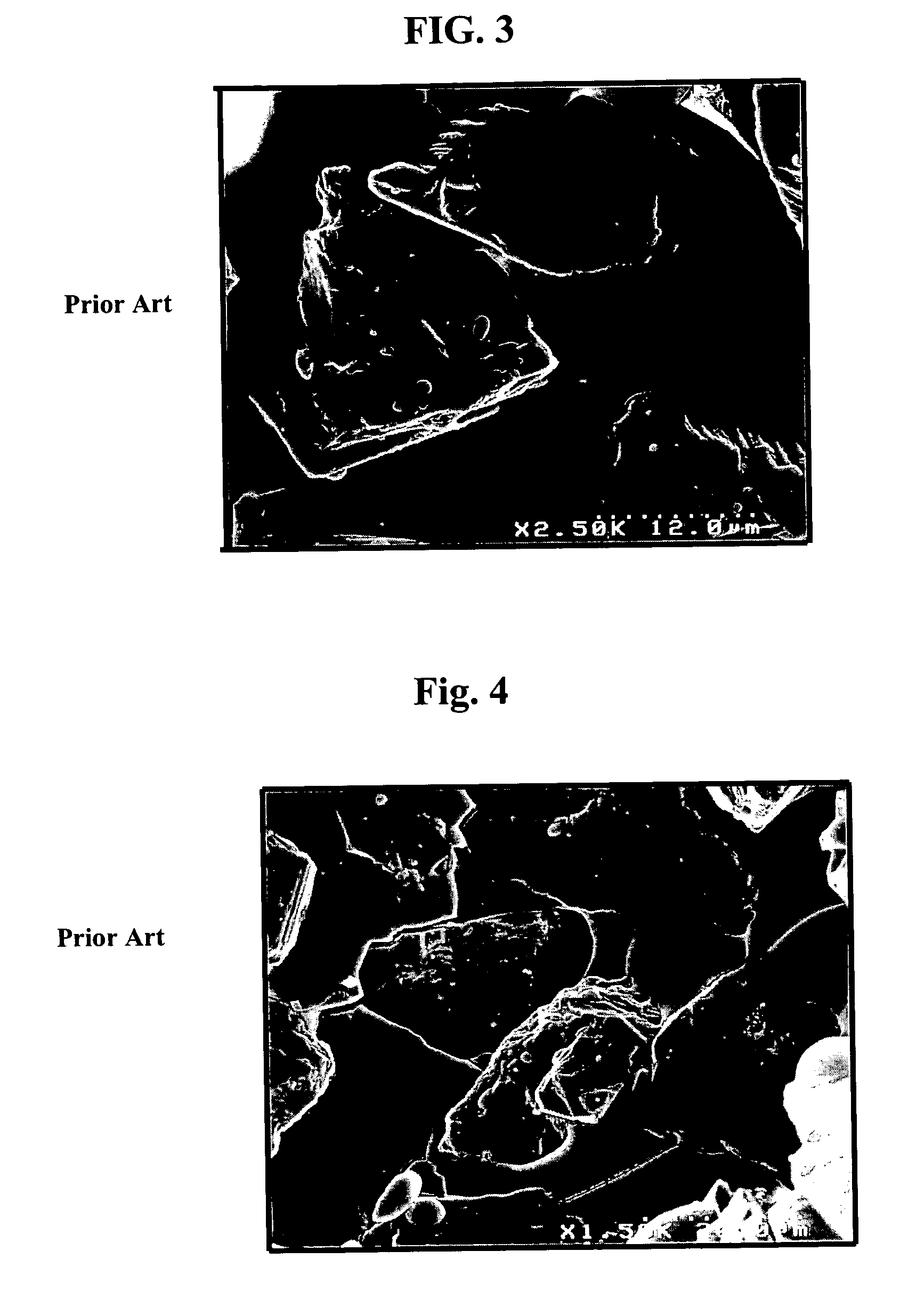

InactiveUS6872441B2Improve self-cleaningExcellent abrasion resistanceFouling preventionPretreated surfacesRough surfaceGlass-ceramic

The invention relates to glass, ceramic and metal substrates with at least one self-cleaning surface, comprising a layer with a micro-rough surface structure which is arranged on the substrate and made at least partly hydrophobic. The layer contains a glass flux and structure-forming particles with a mean particle diameter within the 0.1 to 50 μm range; the glass flux and structure-forming particles are present in a volume ratio within the 0.1 to 5 range, and the micro-rough surface structure has a ratio of mean profile height to mean distance between adjacent profile tips within the 0.3 to 10 range.To produce the subject of the invention the substrate is coated with a composition containing a glass flux and structure-forming particles, and the layer is burnt in and made hydrophobic.

Owner:FERRO GMBH

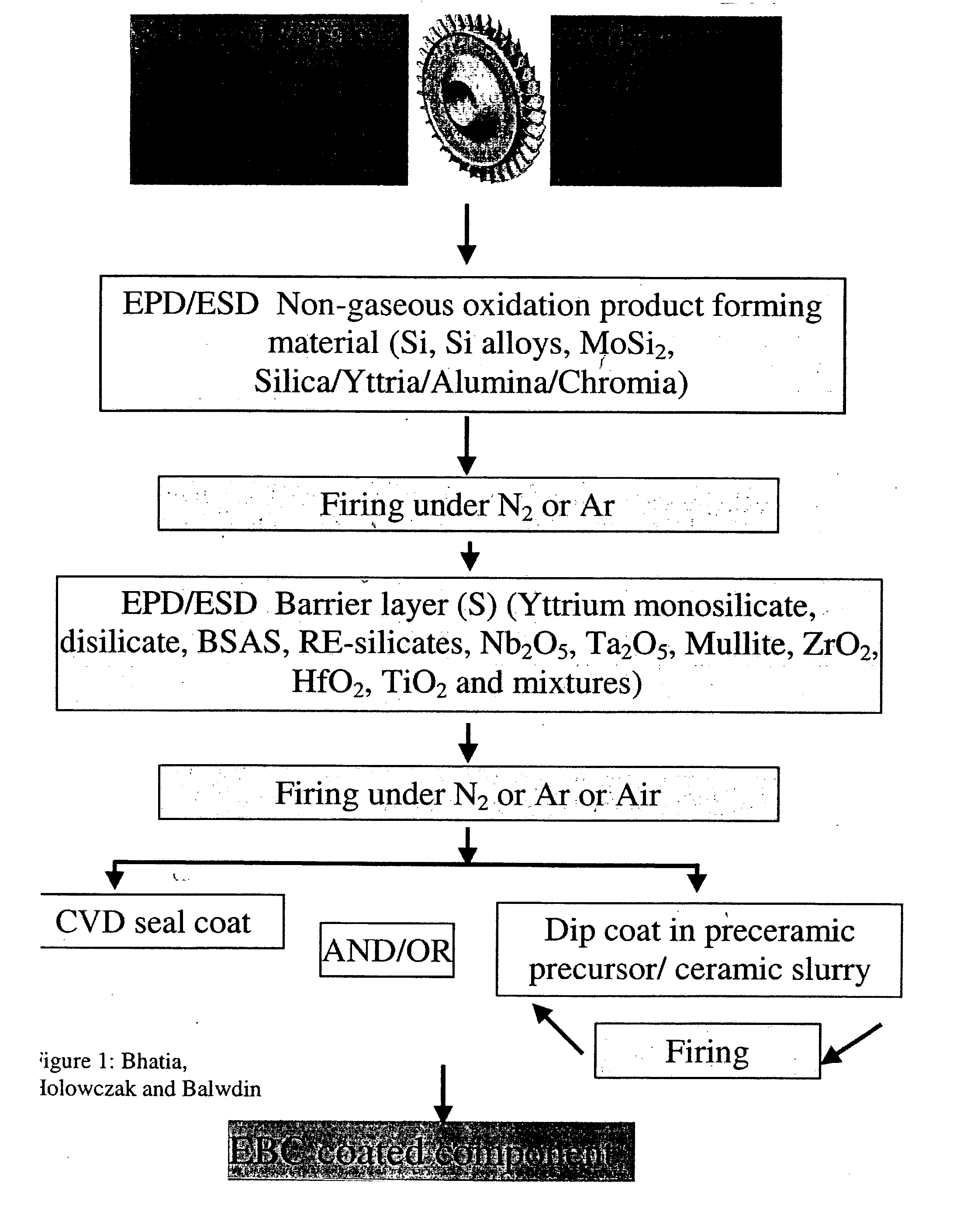

Methods of fabricating environmental barrier coatings for silicon based substrates

A method of protecting an article from a high temperature environment, the method includes providing a substrate comprising silicon, forming a slurry coating composition, wherein the composition comprises a metallic silicon powder, a rare-earth oxide, an alkaline earth metal oxide, an aluminum oxide, or a combination comprising at least one of the foregoing, and a binder effective to chemically stabilize the slurry coating, applying a layer of the slurry coating over the substrate, and heat-treating the slurry coating under conditions sufficient to oxidize the metallic silicon powder and form an alkaline earth metal aluminosilicate, a rare-earth silicate, an aluminum silicate, or a combination comprising at least one of the foregoing bonded to the substrate.

Owner:GENERAL ELECTRIC CO

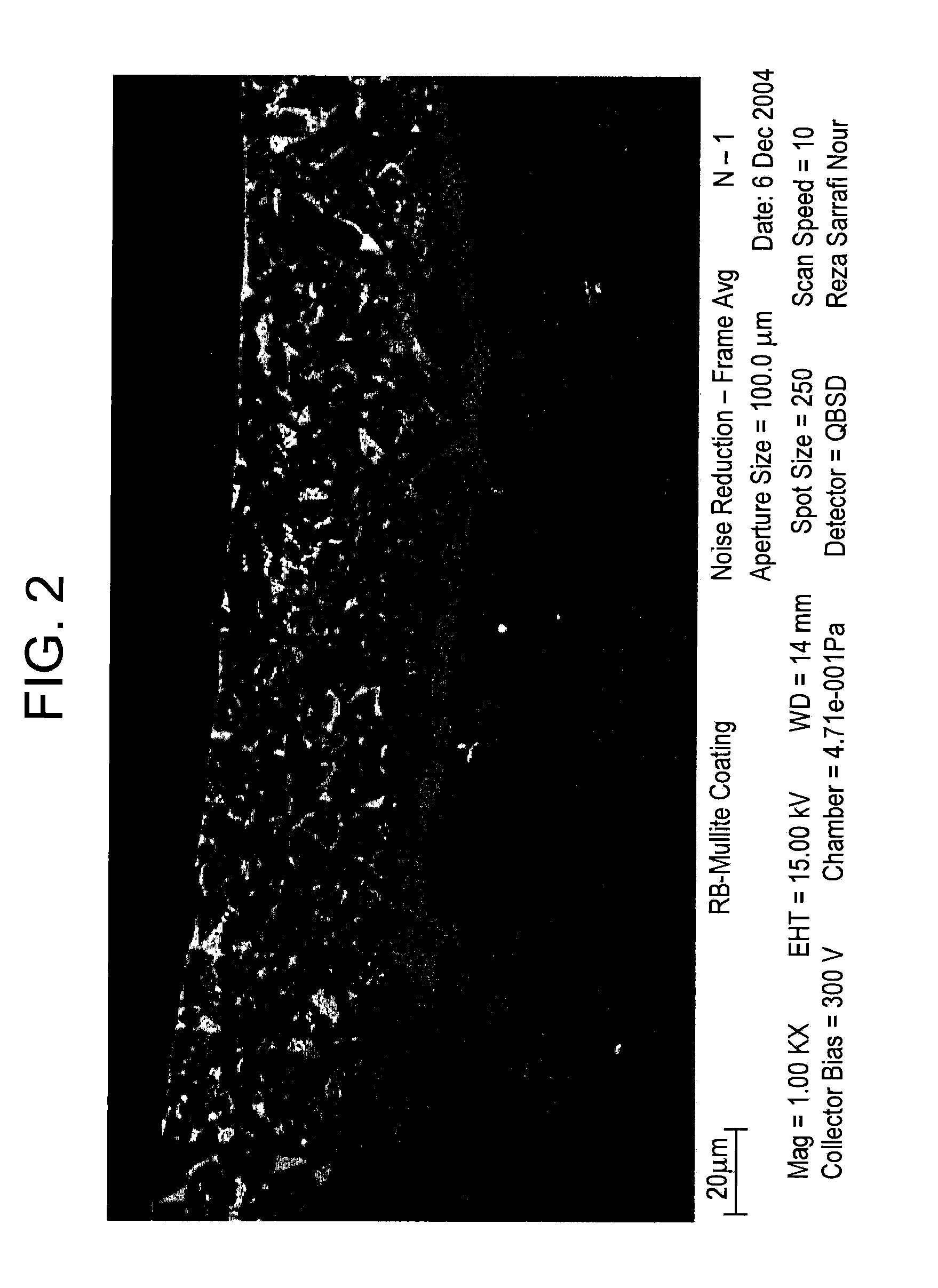

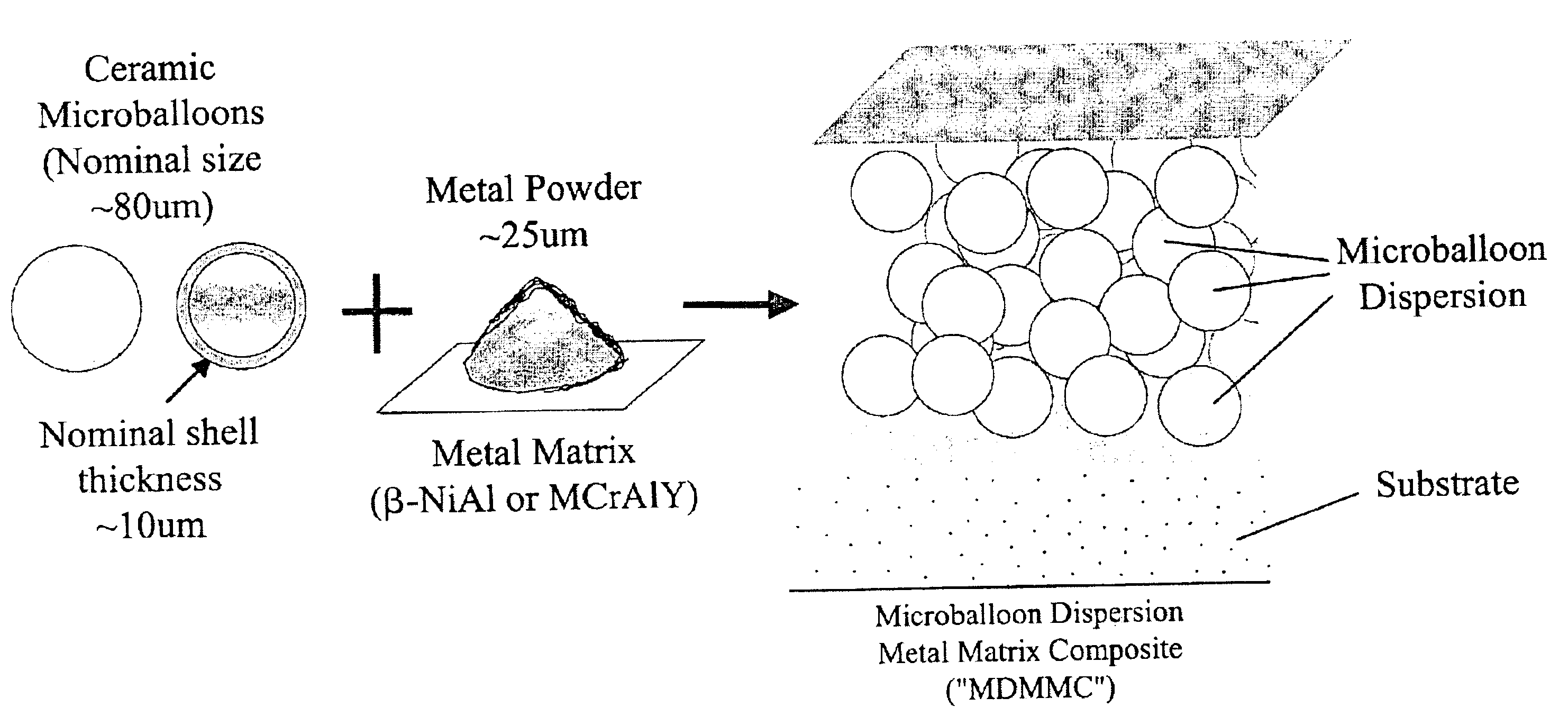

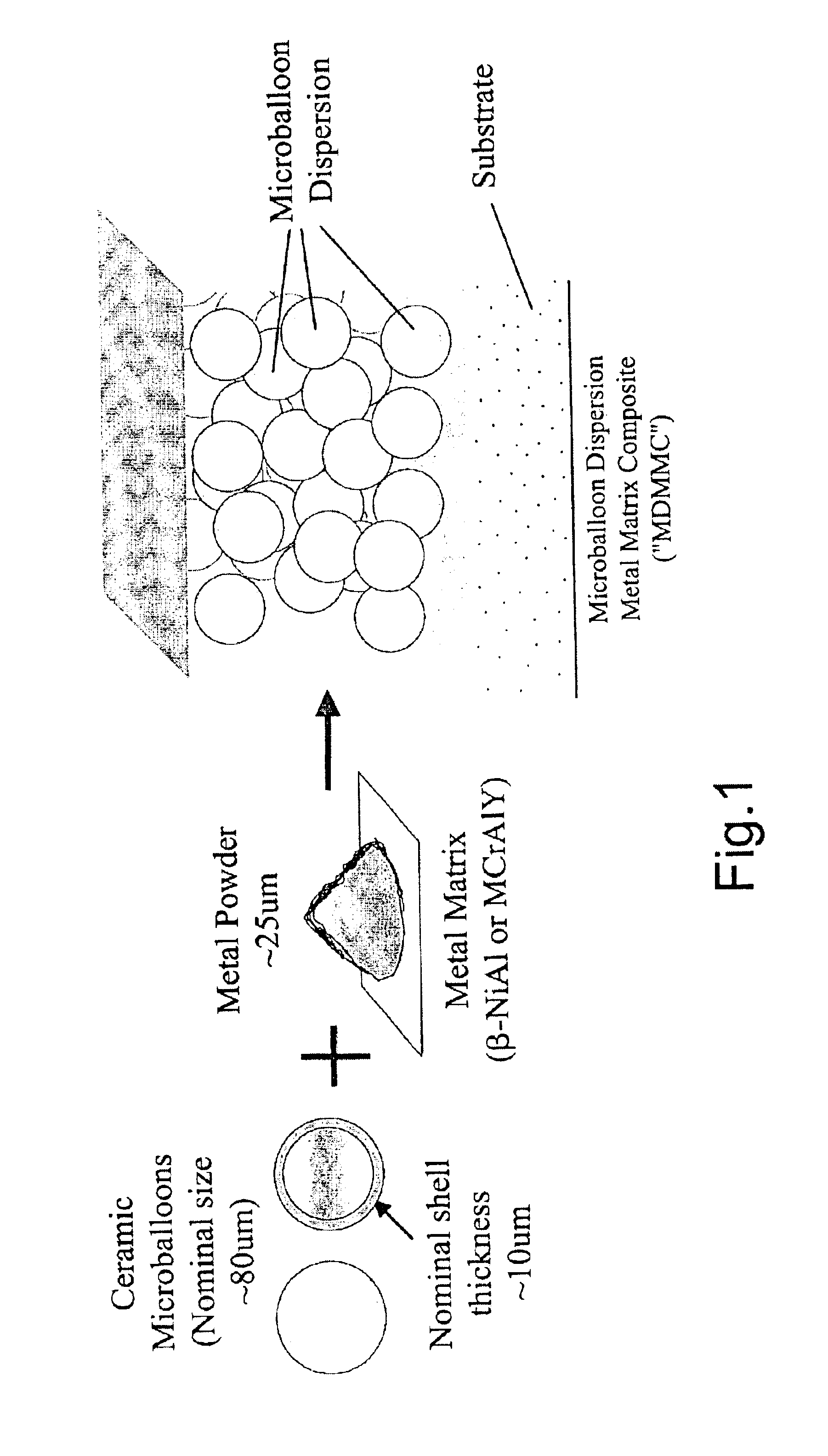

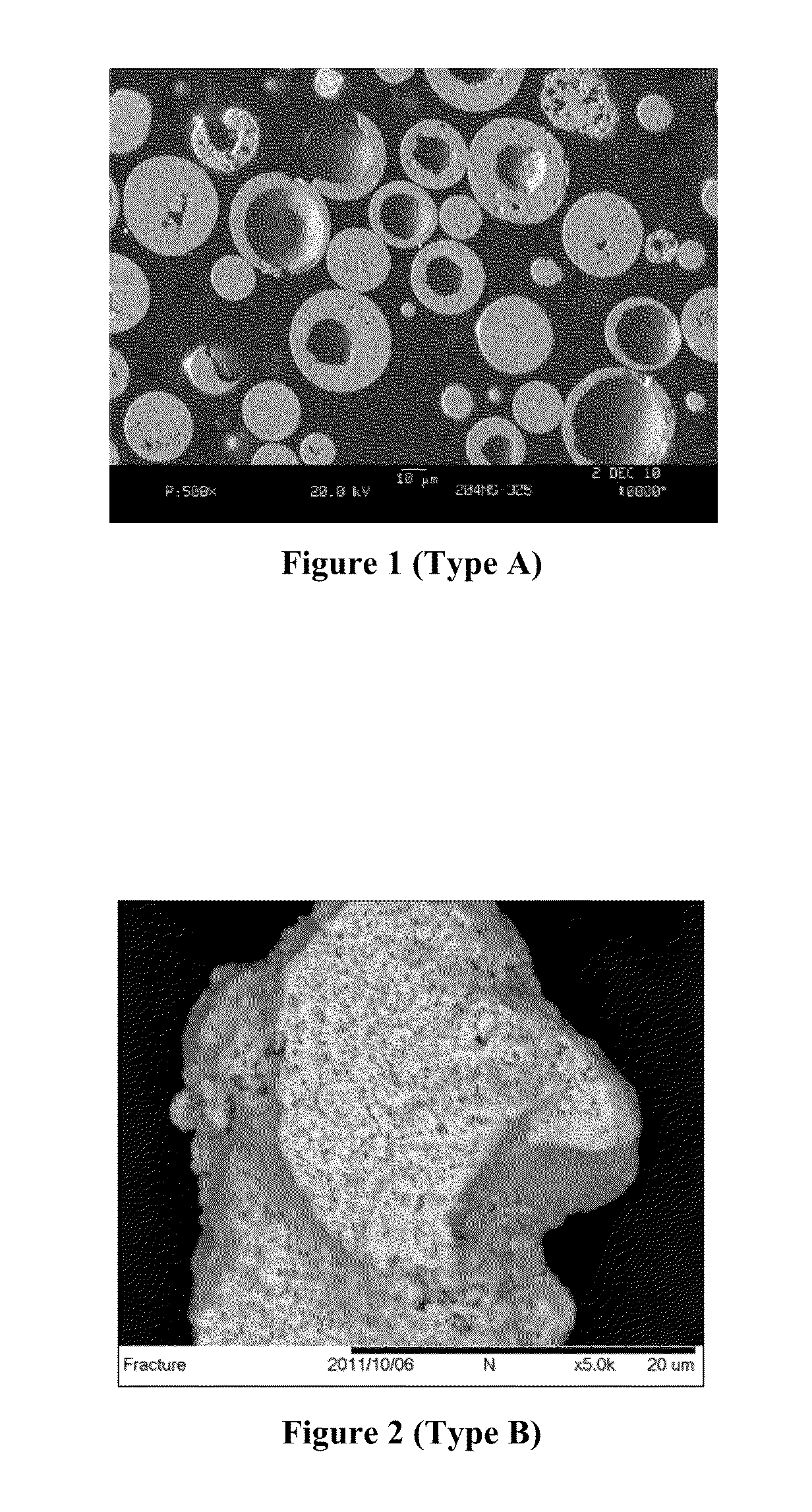

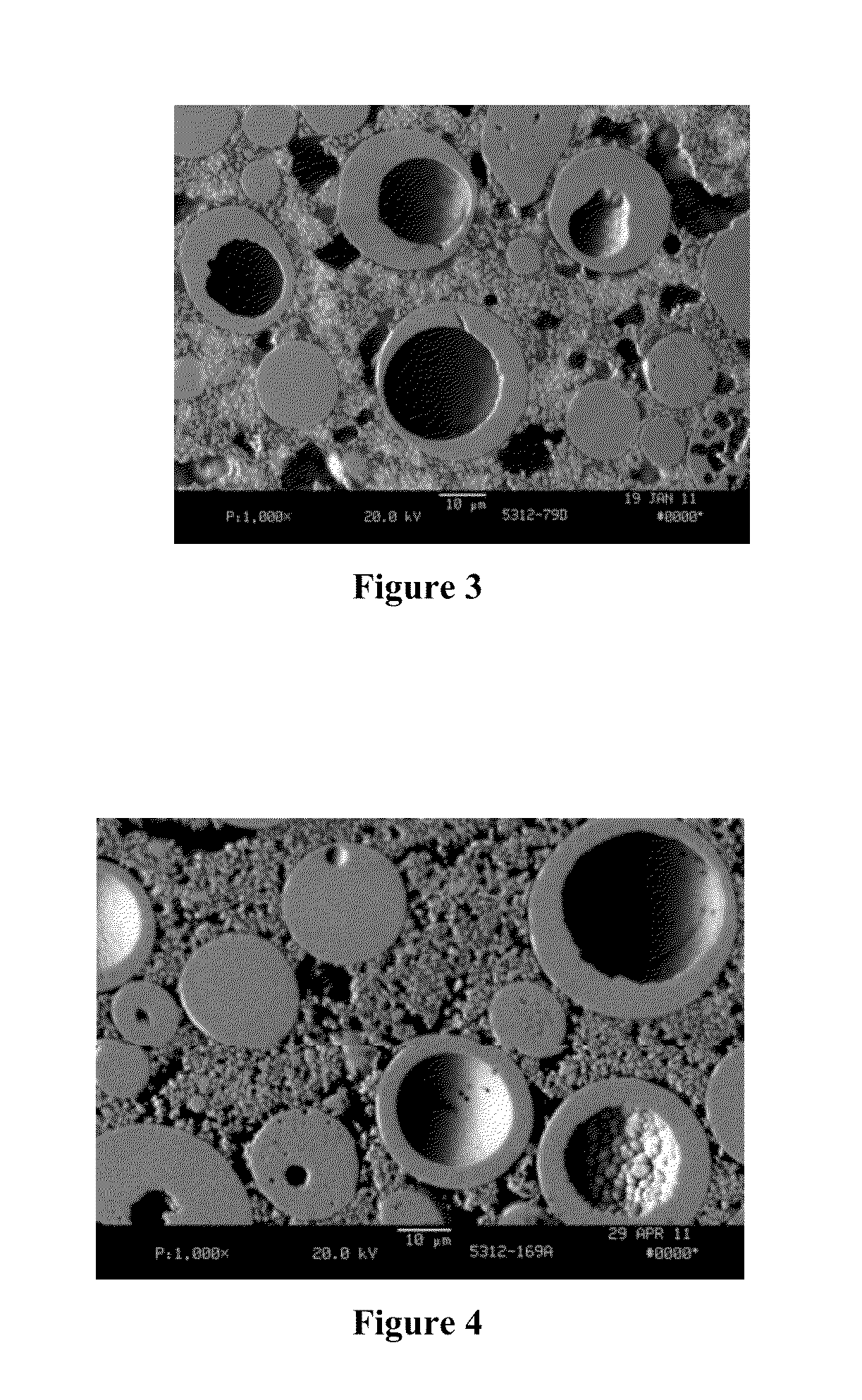

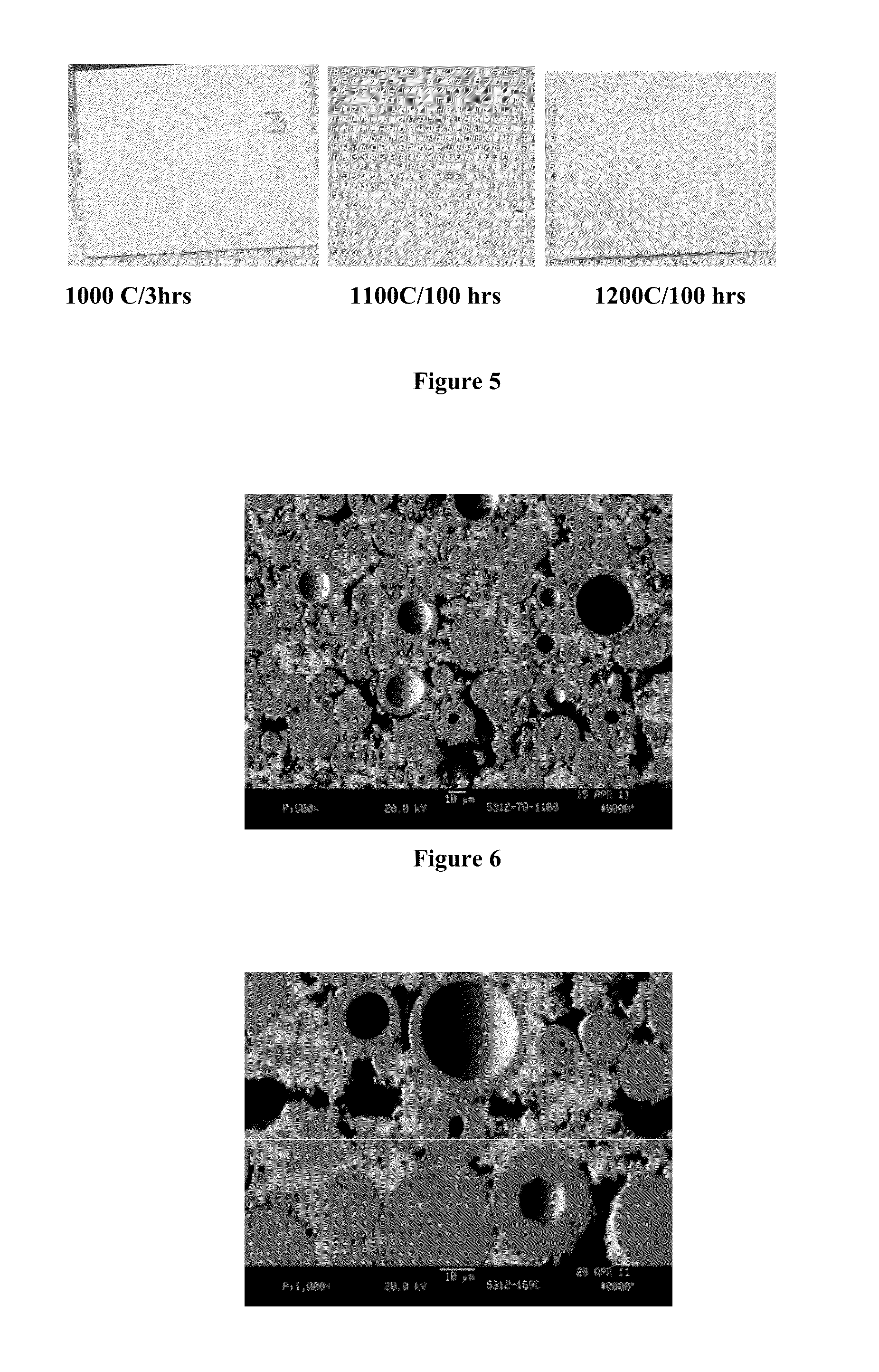

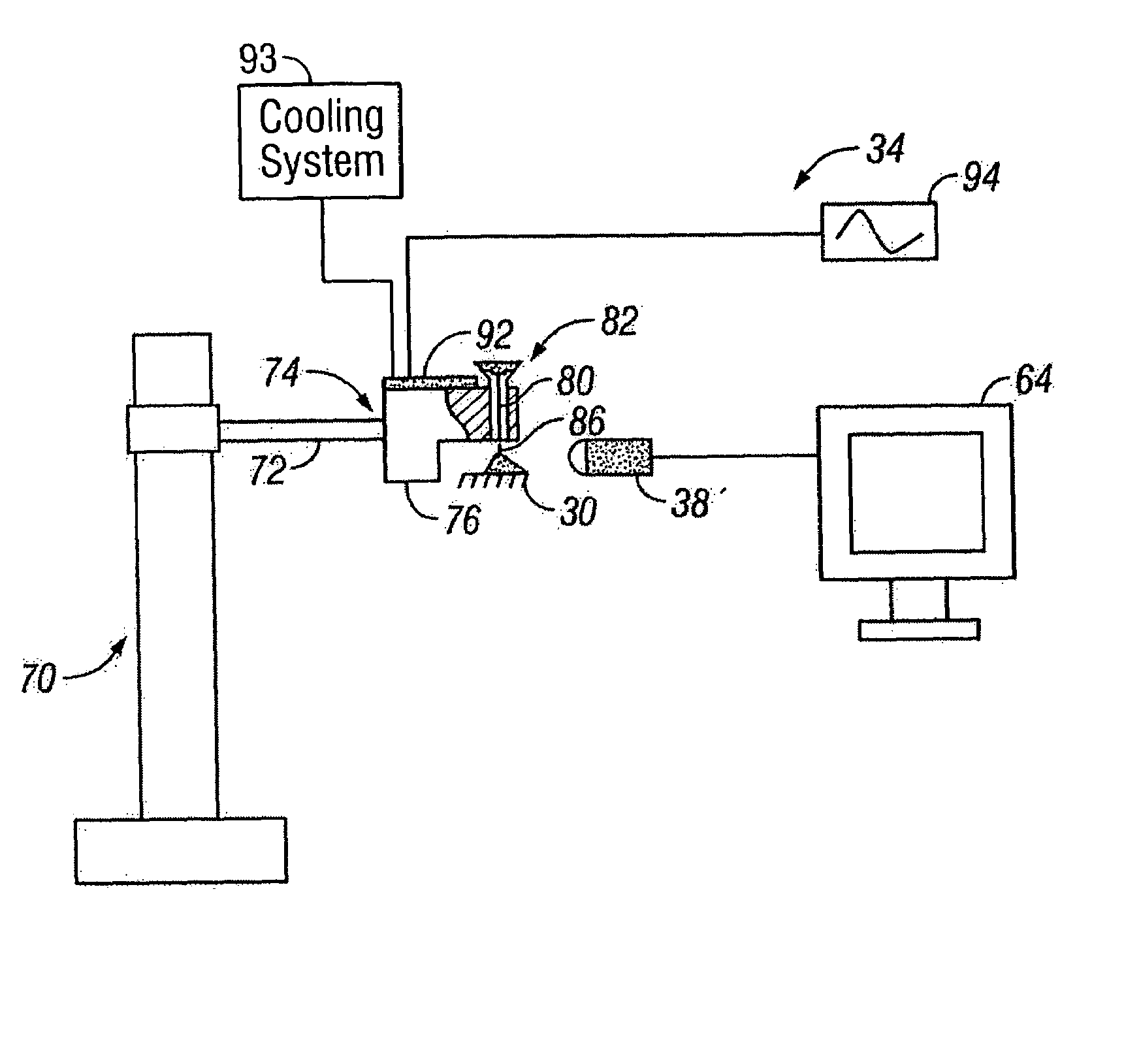

High temperature, oxidation-resistant abradable coatings containing microballoons and method for applying same

InactiveUS6916529B2Effective timeReducing hot gas leakageMolten spray coatingPropellersThermal sprayingMicrosphere

An abradable coating composition for use on shrouds in gas turbine engines or other hot gas path metal components exposed to high temperatures containing an initial porous coating phase created by adding an amount of inorganic microspheres, preferably alumina-ceramic microballoons, to a base metal alloy containing high Al, Cr or Ti such as β-NiAl or, alternatively, MCrAlY that serves to increase the brittle nature of the metal matrix, thereby increasing the abradability and oxidation resistance of the coating at elevated temperatures. Coatings having a total open and closed porosity of between 20% and 55% by volume due to the presence of ceramic microballoons ranging in size from about 10 microns to about 200 microns have been found to exhibit excellent abradability for applications involving turbine shroud coatings. An abradable coating thickness in the range of between 40 and 60 ml provides improved performance for turbine shrouds exposed to gas temperatures between 1380° F. and 1800° F. Abradable coatings in accordance with the invention can be used for new metal components or to repair existing equipment. The coatings can be applied to the metal shroud using thermal spray, processes that integrate sintering and brazing, or direct write techniques.

Owner:GENERAL ELECTRIC CO

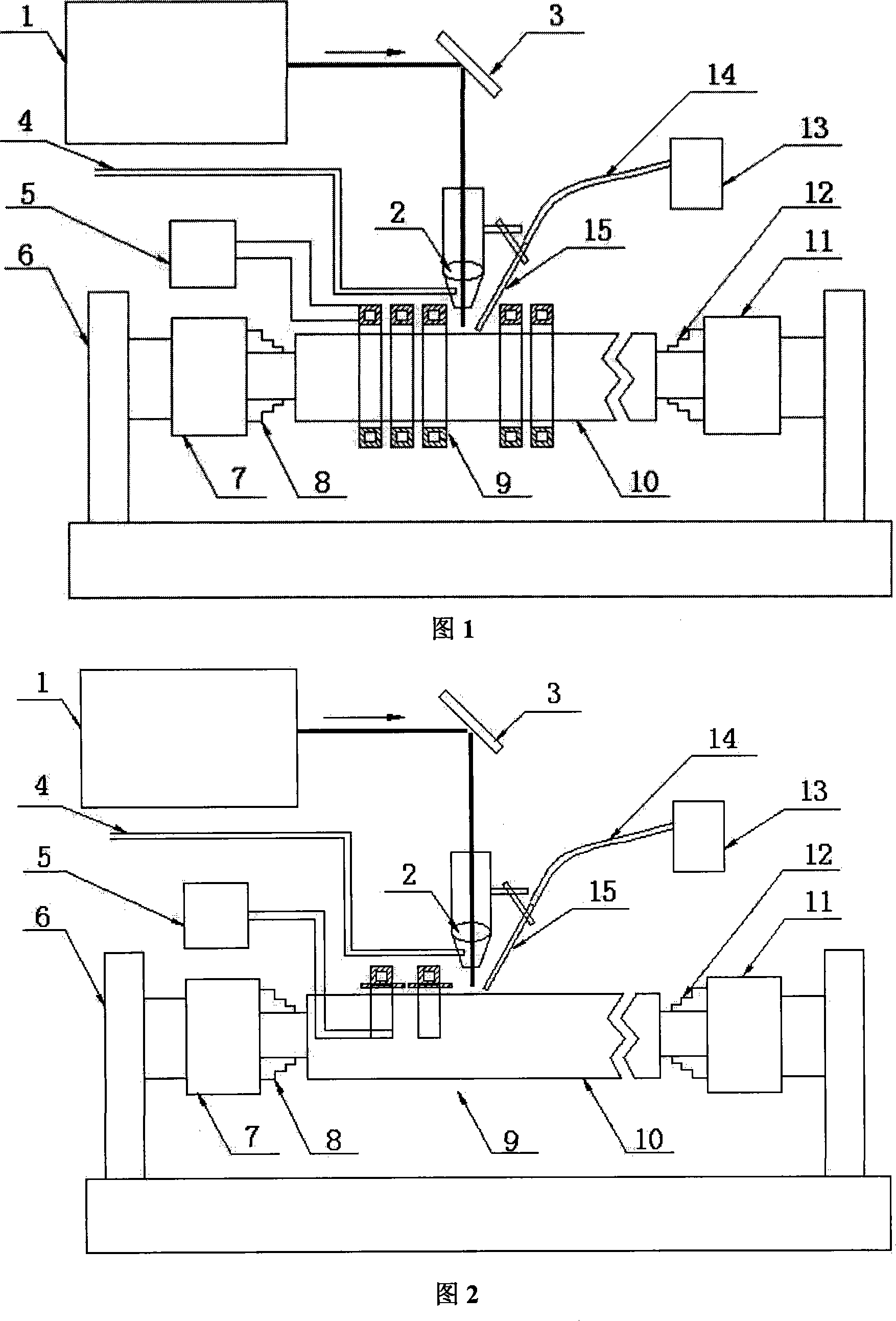

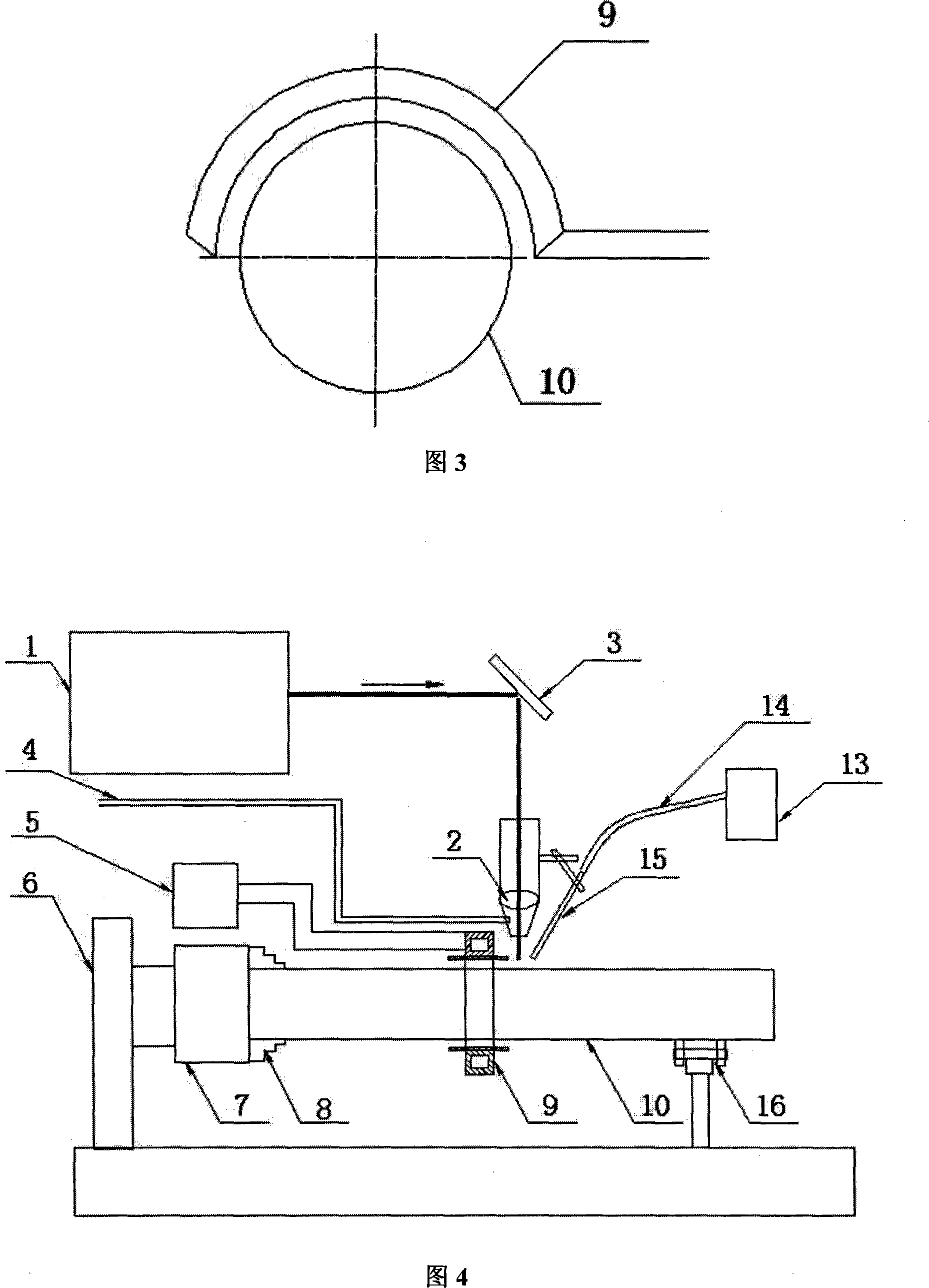

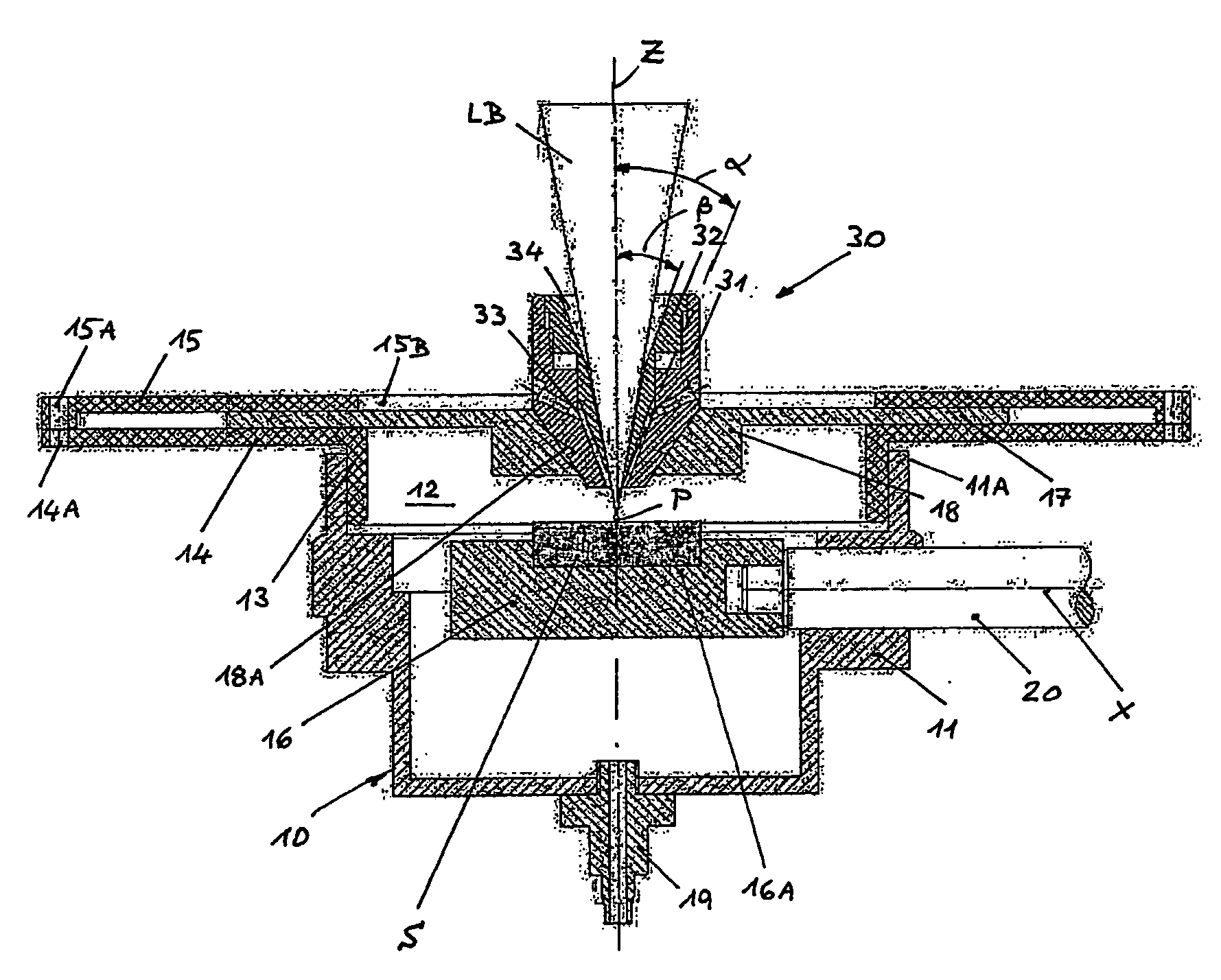

Automatic powder feeding laser induction composite coating method and device

ActiveCN101125394AImprove deposition efficiencyEasy to locate and installLaser beam welding apparatusHeat inorganic powder coatingSolid componentNumerical control

The present invention discloses a laser induced composite cladding measure and device for the automatic powder feeder. The present invention couples the laser beam and the high frequency electromagnetic induction heating so as to realize the composite cladding between the laser and the induction heating. The device comprises a laser, a laser light guide device, a laser gathering system, a high frequency induction heater, a digital control machine tool and a workpiece holding device. In work, the distance between the surface of workpiece under treatment and the induction heating coil is 1 to 10 mm. The present invention has a strong commonality and can conduct surface treatment of laser induced composite cladding high performance material coat toward the surface of the solid components in various materials and the inner and outer surfaces of the tubular spare parts. The cladding measure is characterized in that: the high frequency induction heater heats up the workpieces simultaneously and the automatic power feeder is applied to deliver the cladding powder to the laser irradiation area on the surface of the workpiece, so the alloy powder is instantaneously melted under the action of laser beam to form an alloy layer; and the maximum cladding speed reaches 10 m / min and the cladding efficiency is improved by one to ten times than the regular laser cladding and the powder utilization rate exceeds 90 percent; the applicable cladding materials have a wide range, comprising various wear resistant, corrosion resistant materials or high temperature resistant oxidizing materials as well as the composite materials; moreover, the cladding layer has no pores and crackles.

Owner:WUHAN HIVALUE INTELASER LTD

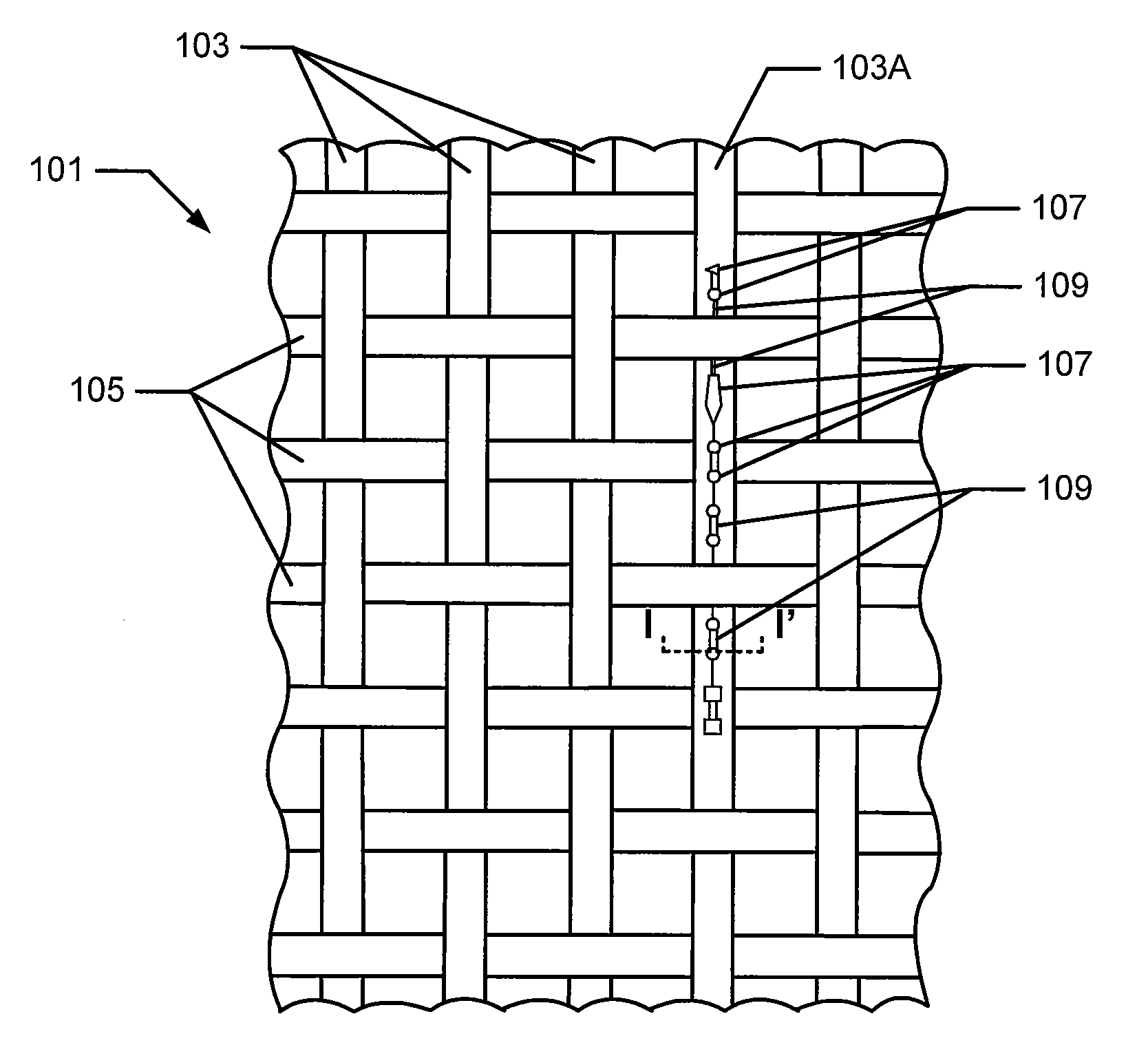

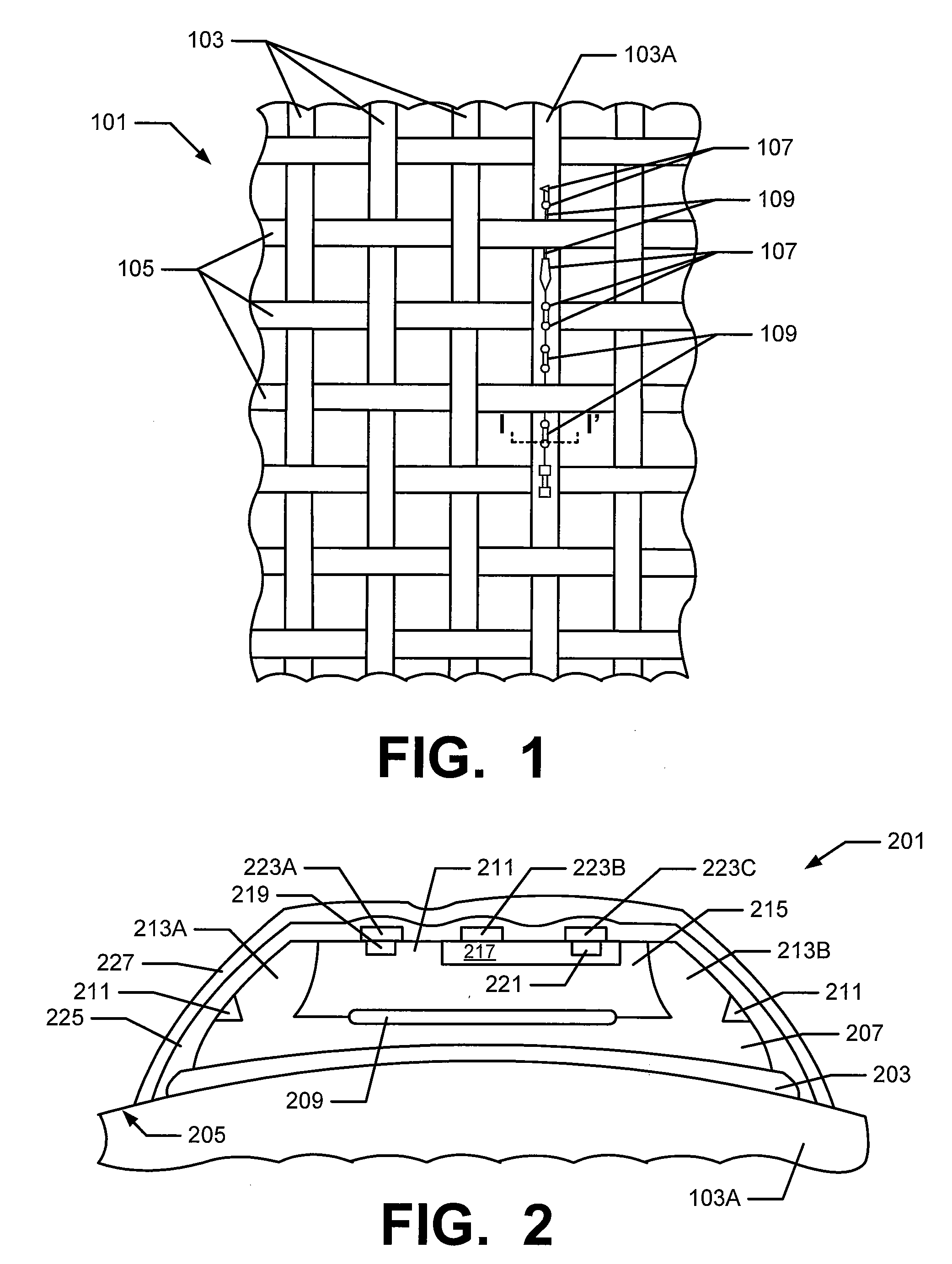

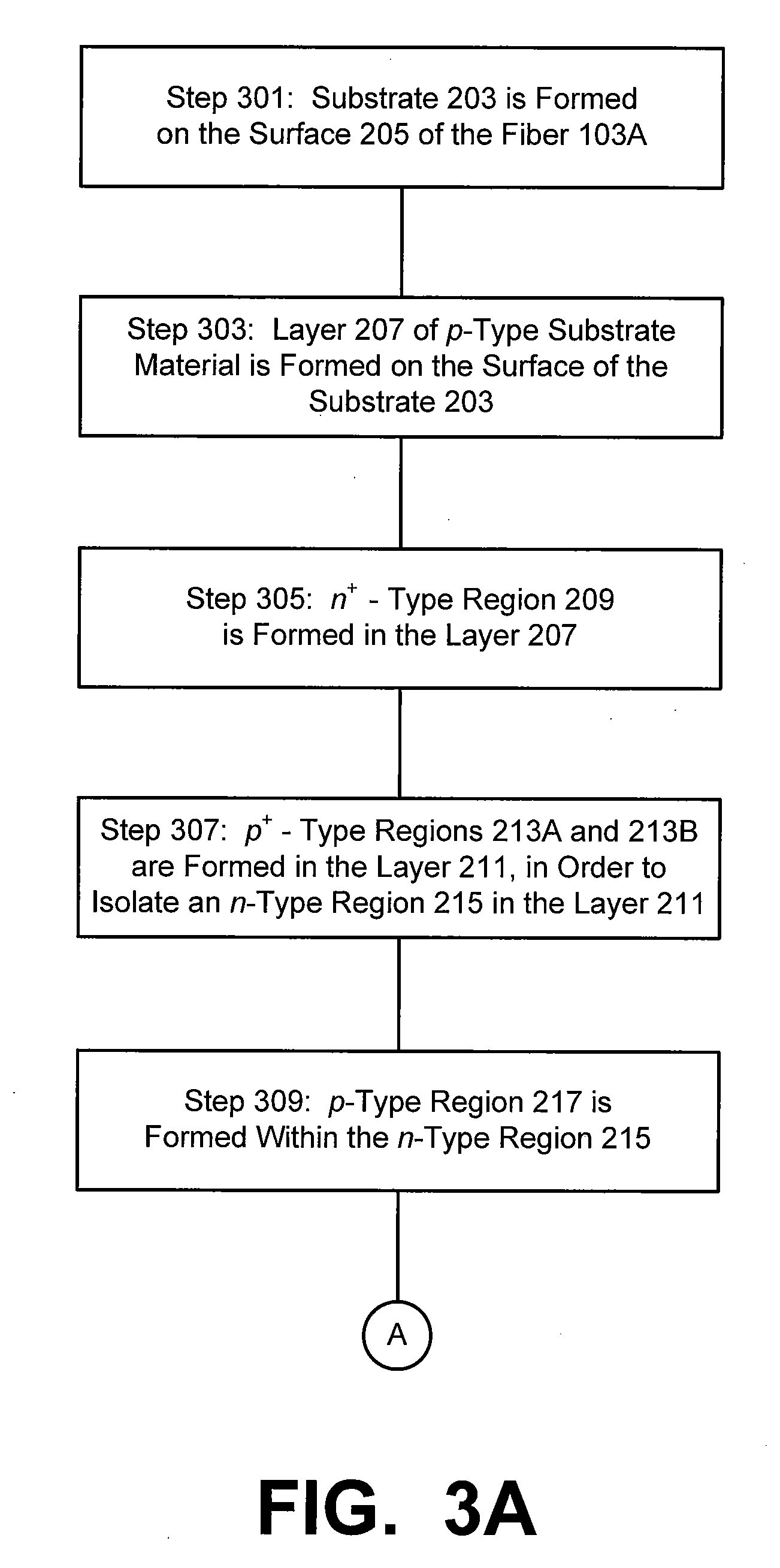

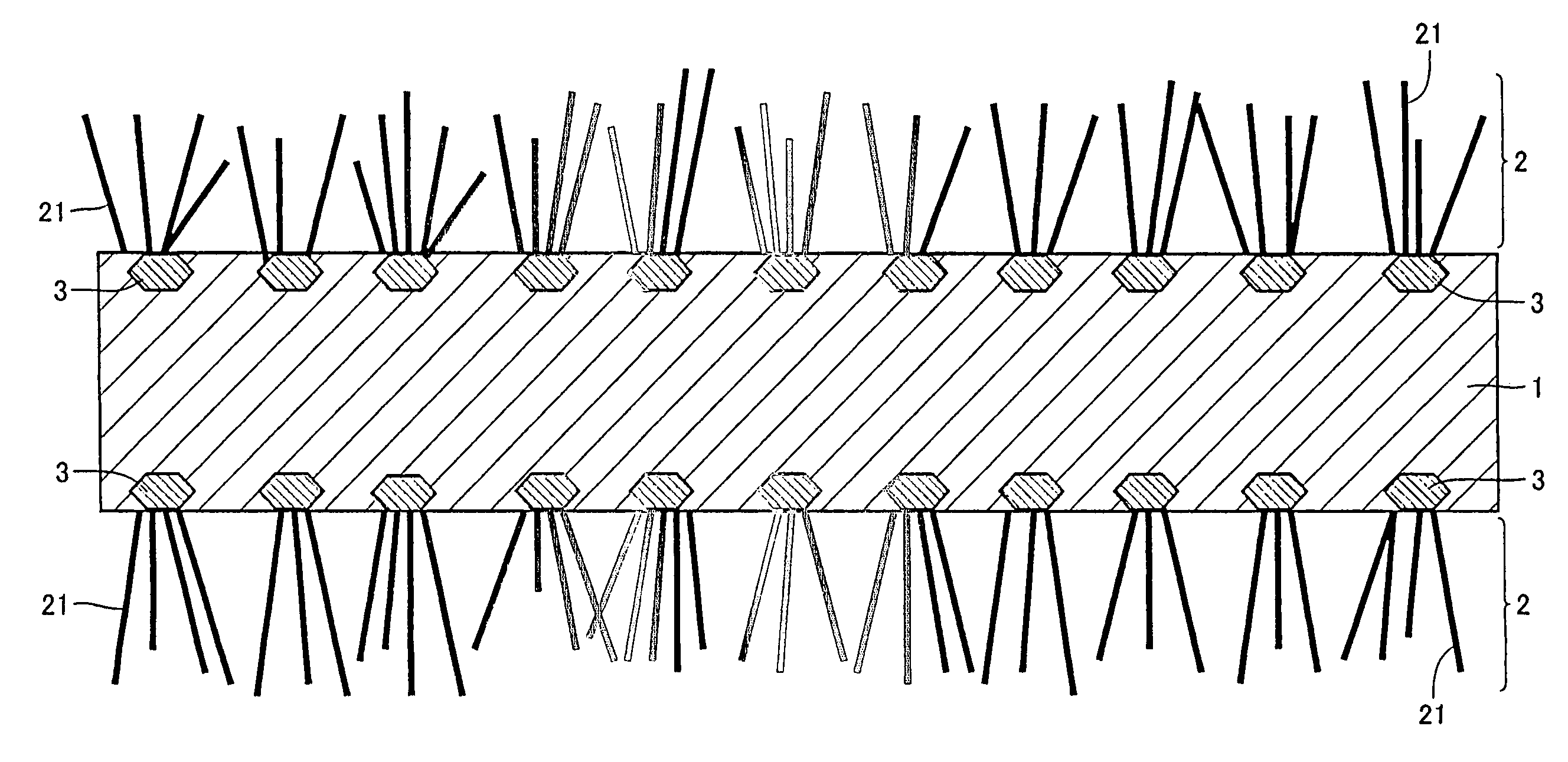

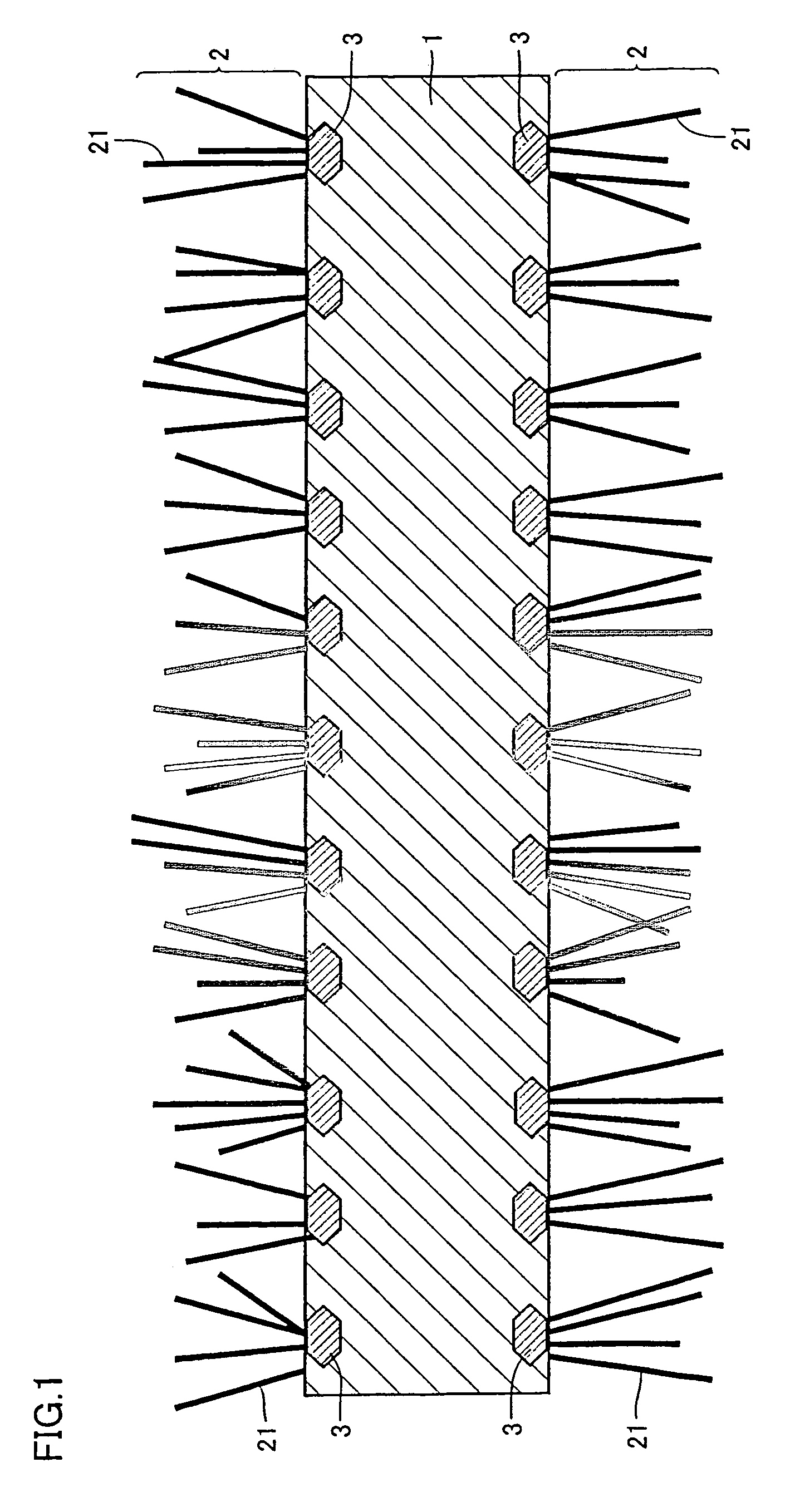

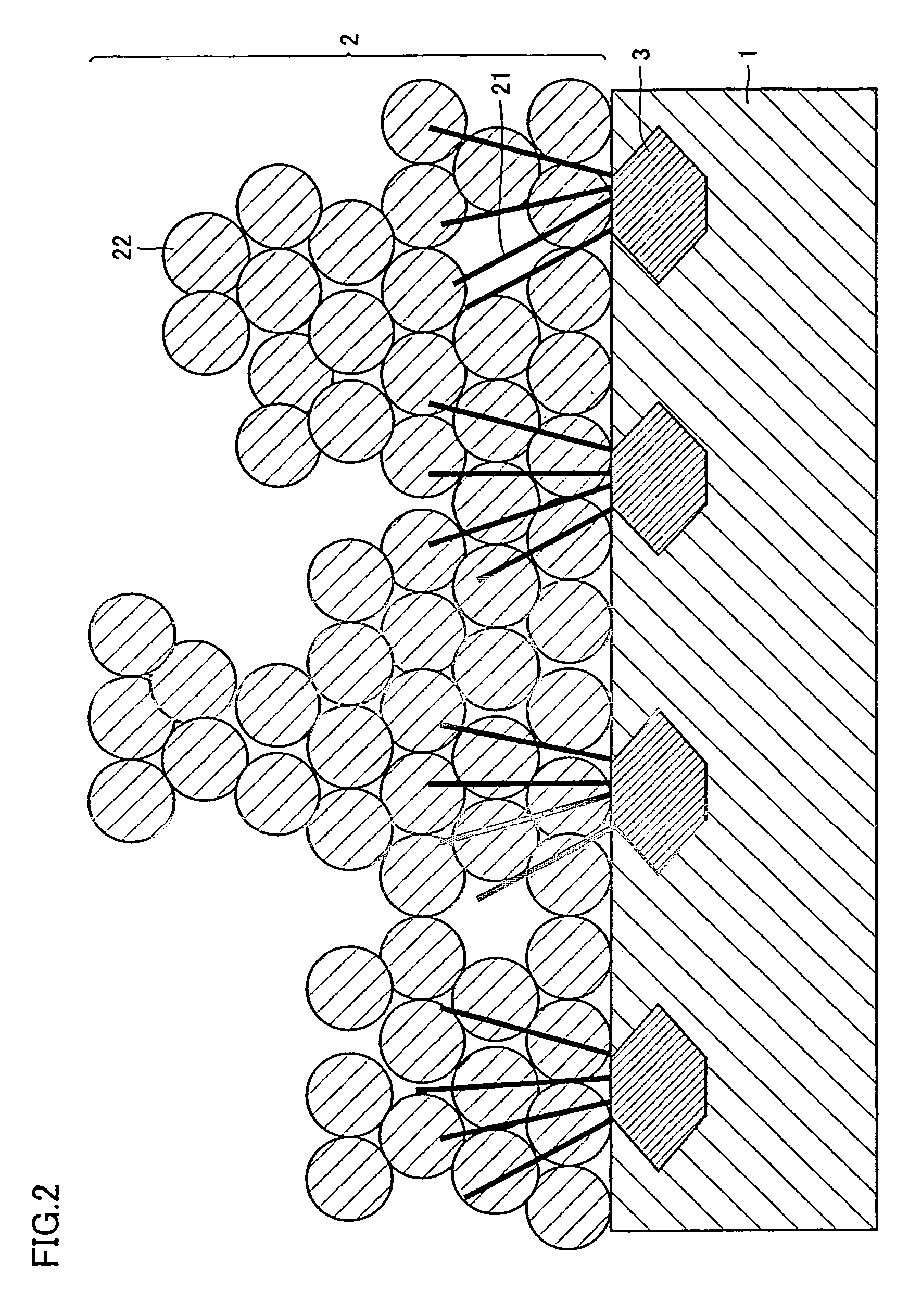

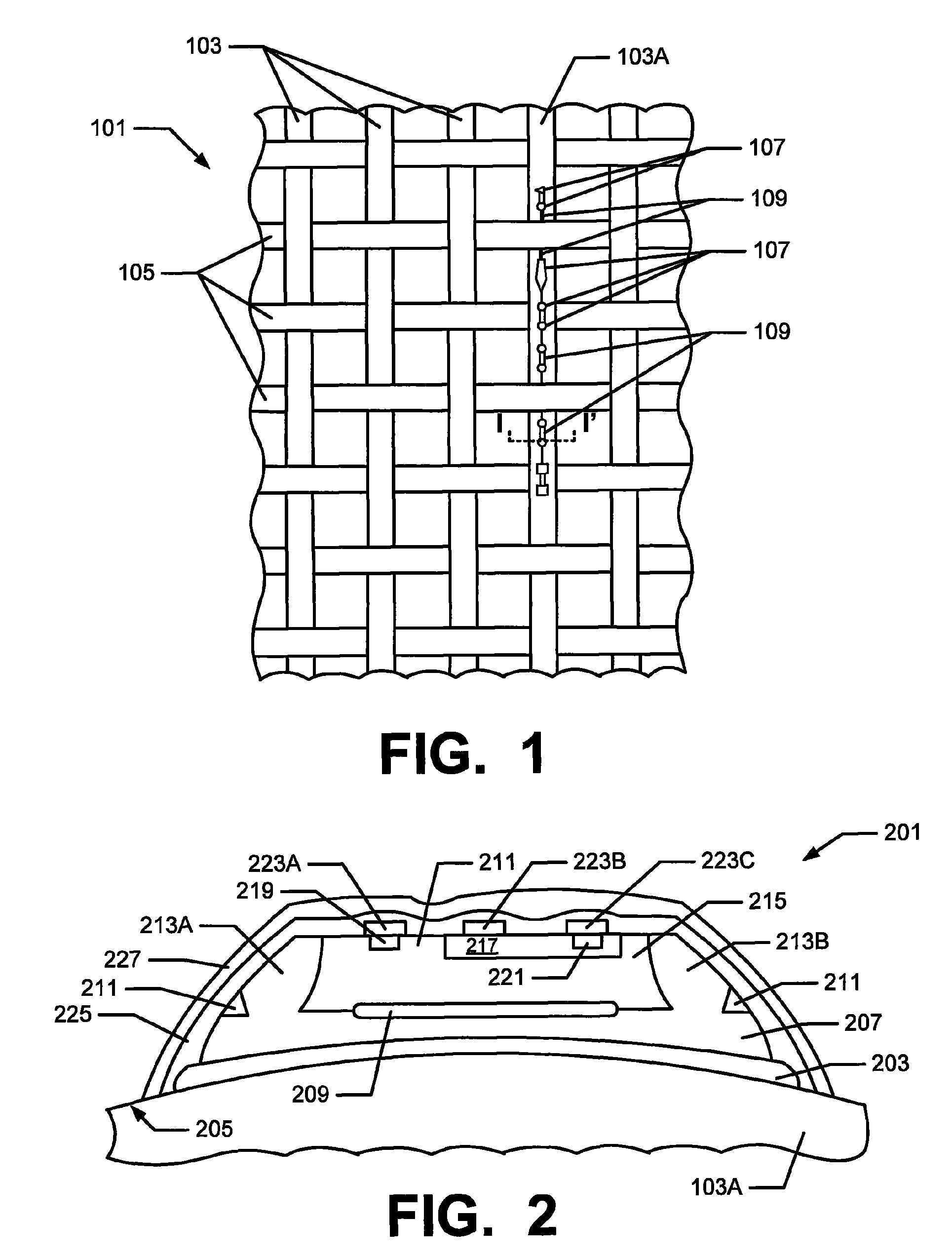

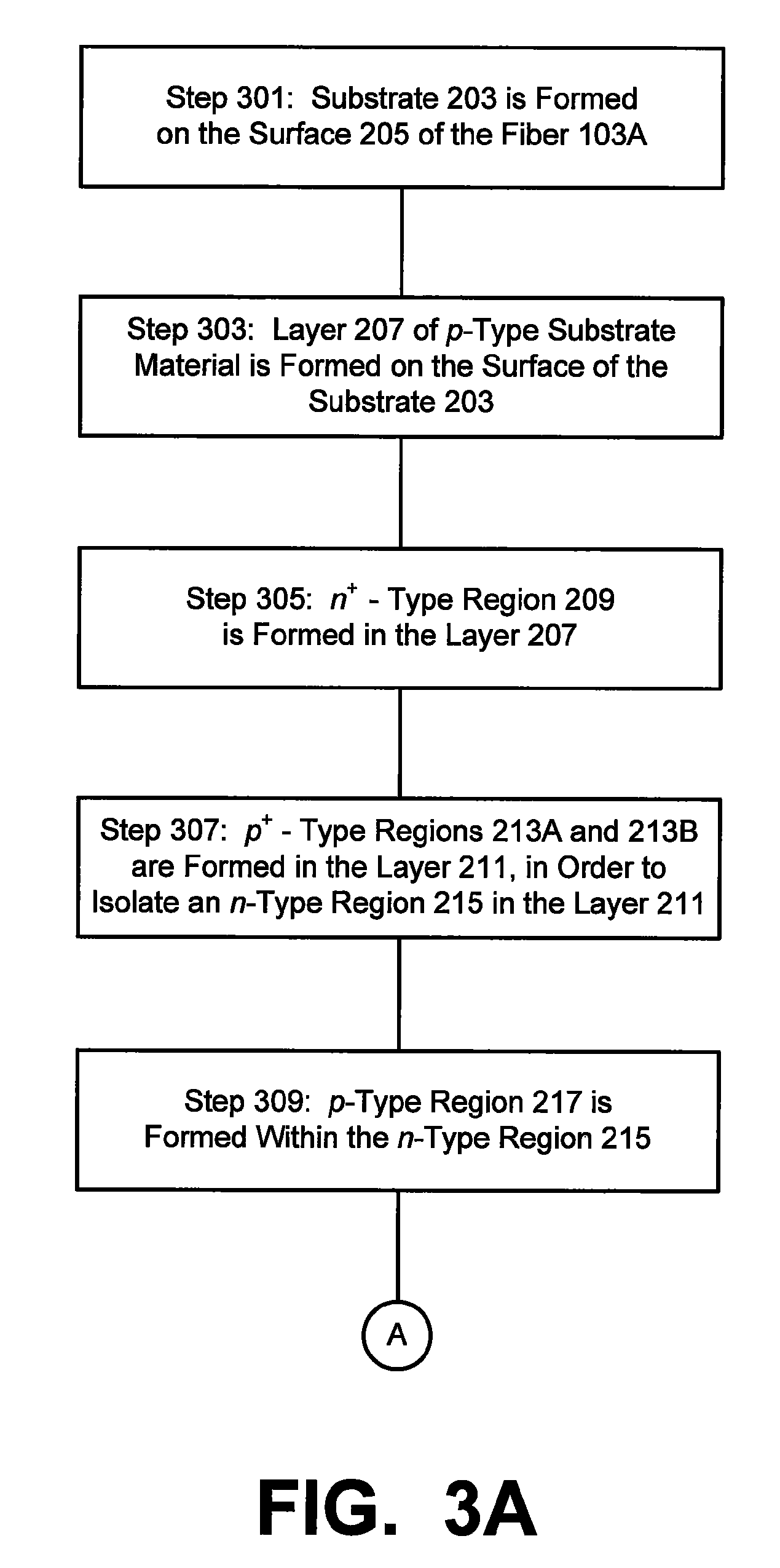

Deposition of Electronic Circuits on Fibers and Other Materials

Fibers, such as textile fibers, having electrical components deposited thereon. More particularly, one or more electrical components are formed directly onto the surface of at least one fiber. The fiber having the electrical component formed thereon may then be interlaced with other fibers to form a larger piece of fabric, which can be employed to produce an article of clothing. A group of transistors and piezoelectric components forming an accelerometer may be woven onto one or more natural or synthetic fibers. The fibers may then be employed as the warp, weft, or both, of a woven piece of fabric, or used to form a knitted piece of fabric. The fabric piece can then be cut and sewn to form a wearable item, such as a shirt, a pair of pants, a hat, or the upper piece of a shoe that includes the accelerometer.

Owner:NIKE INC

Metal oxide dispersion

ActiveUS20050069648A1Low costLess resourcesMolten spray coatingPhotosensitive materialsDispersed mediaMaterials science

The present invention relates to a metal oxide dispersion, which can form a metal thin film onto a substrate by heat treatment at a low temperature, wherein a metal oxide having a particle diameter of less than 200 nm is dispersed in the dispersion medium. By heat treating the dispersion after applying it onto a substrate, a metal thin film is formed.

Owner:ASAHI KASEI KK

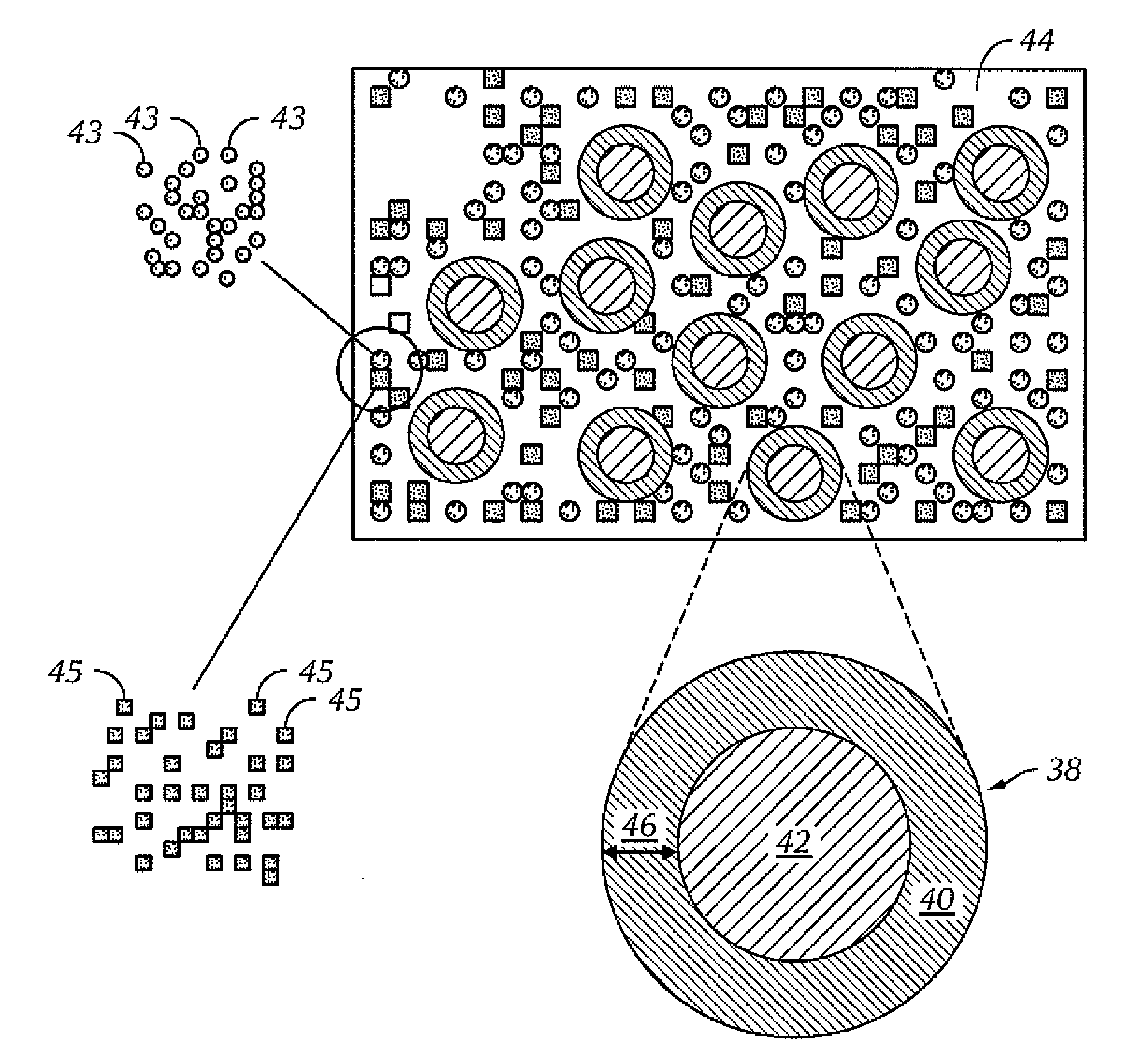

Aqueous slurry for the production of thermal and environmental barrier coatings and processes for making and applying the same

ActiveUS20130156958A1Low thermal conductivityConvenient coatingBlade accessoriesPretreated surfacesPorosityMetallurgy

An improved slurry formulation for the production of a thermal and environmental barrier coatings are provided which can withstand high temperature applications. The slurry includes a combination of a coarse ceramic powder fraction having close porosity particles and a fine ceramic powder fraction. The combination of the two powders produces a bimodal particle size distribution having a controlled amount of closed porosity that imparts desirable properties to the coating produced. The finer solid particles are interdispersed within an aqueous binder to produce a ceramic matrix with sufficient mechanical strength. The closed porosity containing coarse particles are embedded within the resultant ceramic matrix and do not disintegrate under high temperature conditions to impart a temperature resistant, non-collapsing closed porosity to the coating which can also act as an environmental barrier.

Owner:PRAXAIR ST TECH INC

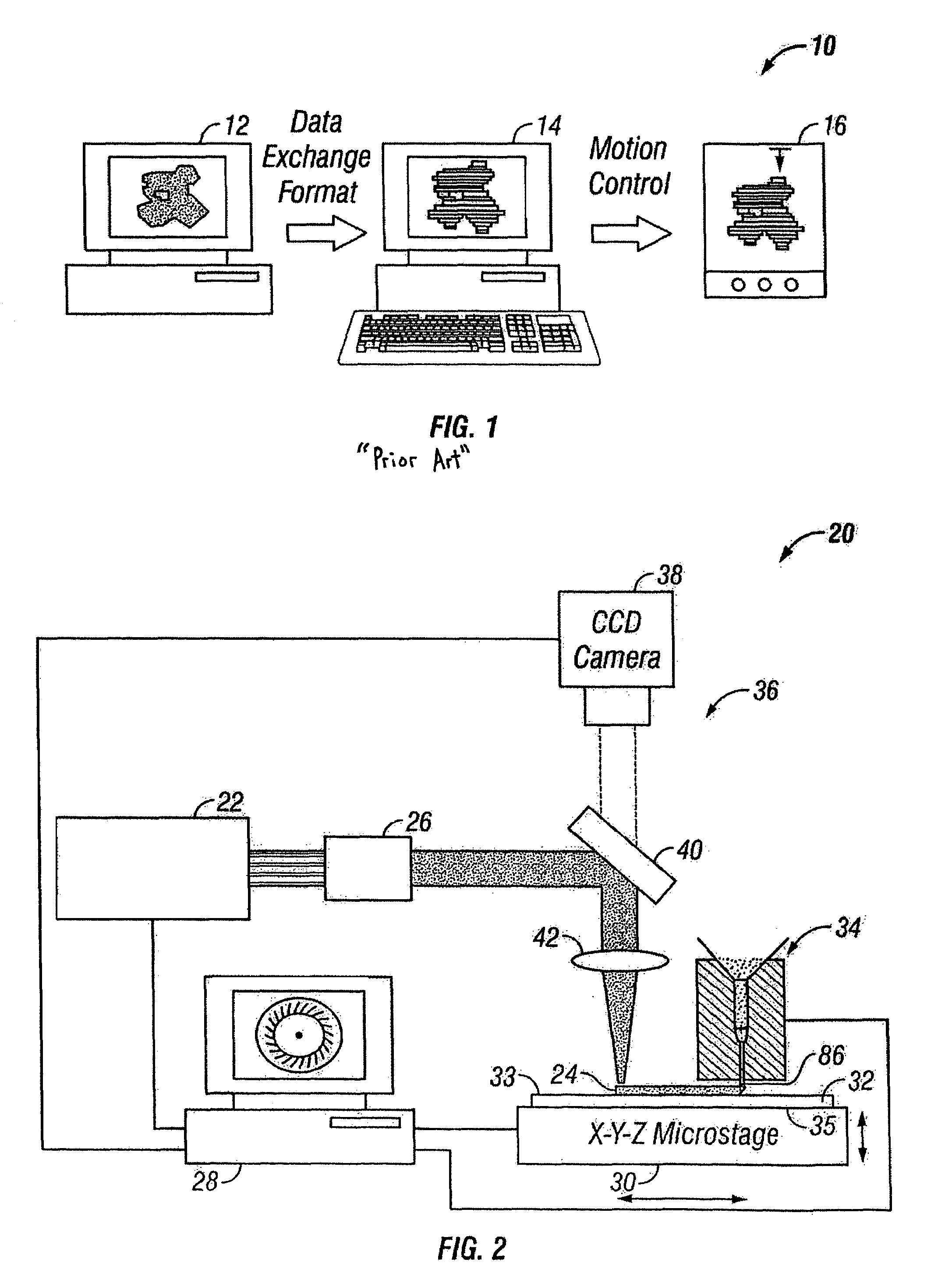

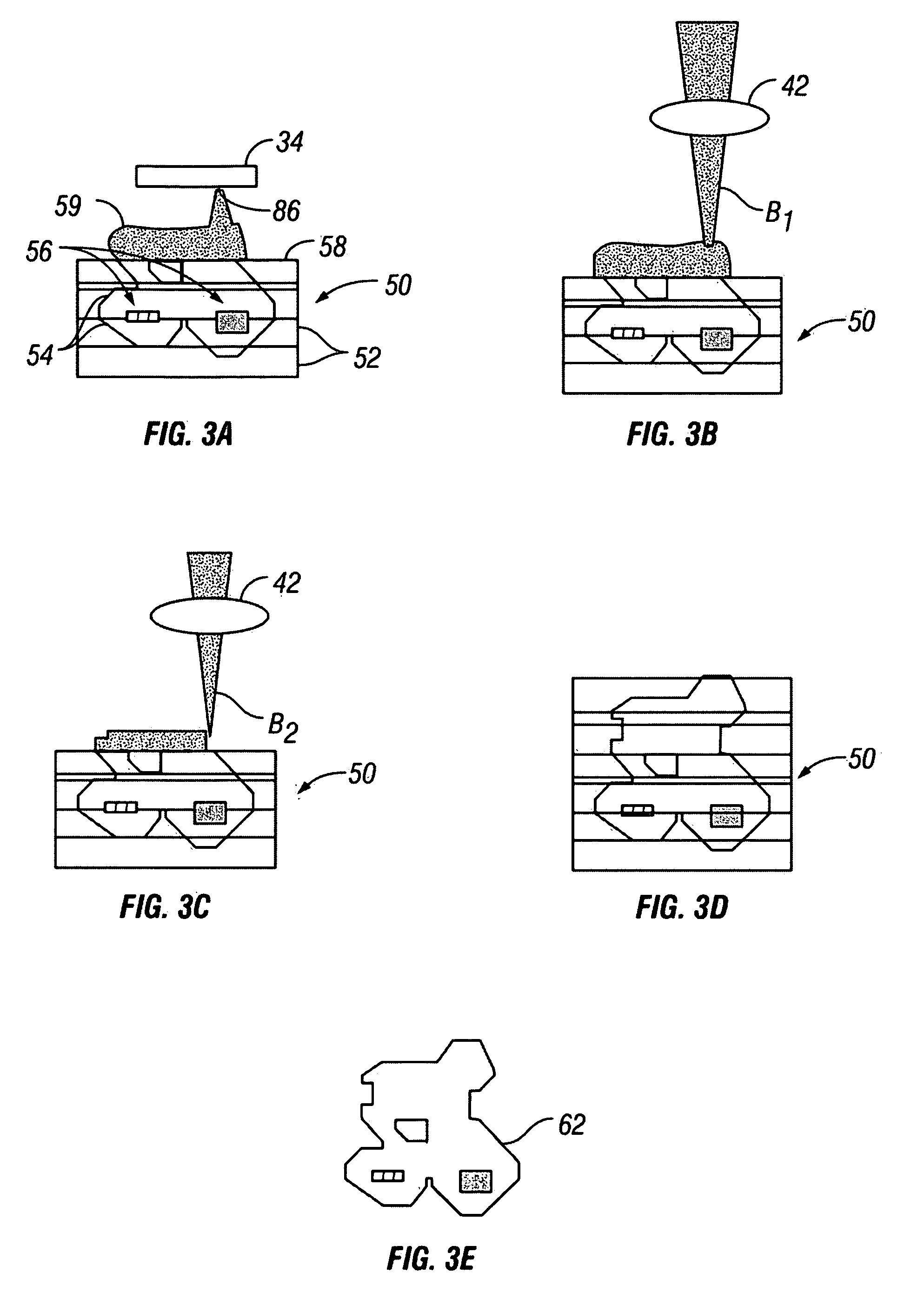

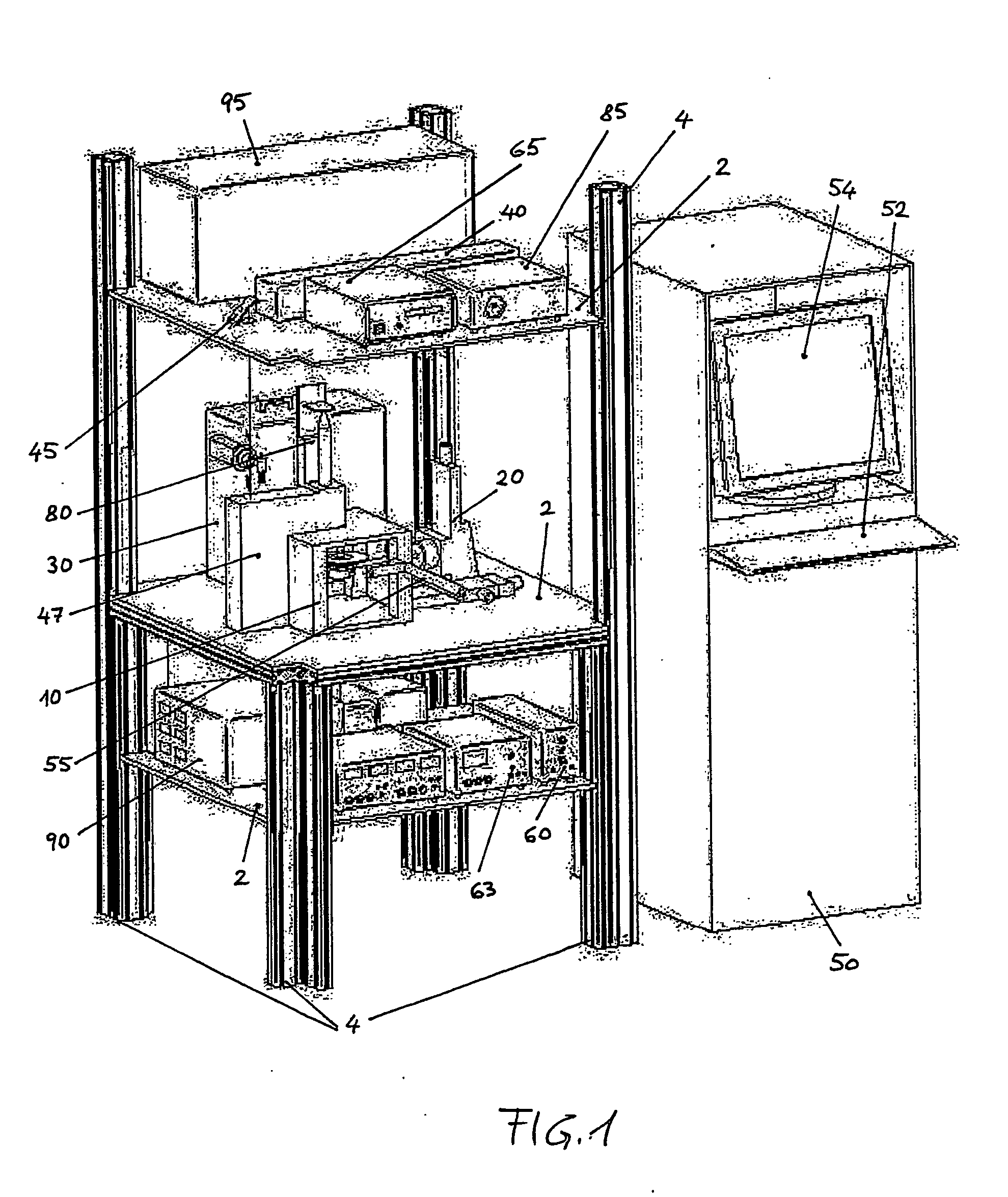

Apparatus and method of dispensing small-scale powders

InactiveUS7316748B2Facilitate depositionIncrease flow rateDispensing apparatusPretreated surfacesUltrasonic vibrationEngineering

An apparatus and method of dispensing small-scale powders for a variety of applications, including, for example, fabricating a three-dimensional heterogeneous small-scale device, includes using a feed mechanism that causes motion of the powder particles and the steps of depositing fine heterogeneous materials (such as dry powders and biological materials) towards a substrate. The depositing step preferably includes providing a feed mechanism having an input to receive the material, an output, and a source of ultrasonic vibration to impart a torsional force on the material so as to precisely discharge the material from the output. To improve particle flowability, a cooling system is provided to cool the source, generally above a threshold input voltage.

Owner:WISCONSIN ALUMNI RES FOUND

Carbon-coated aluminum and method for producing same

ActiveUS7327556B2Improve adhesionHybrid capacitor electrodesElectrode carriers/collectorsCarbon coatedHydrocarbon

Owner:TOYO ALUMINIUM KK

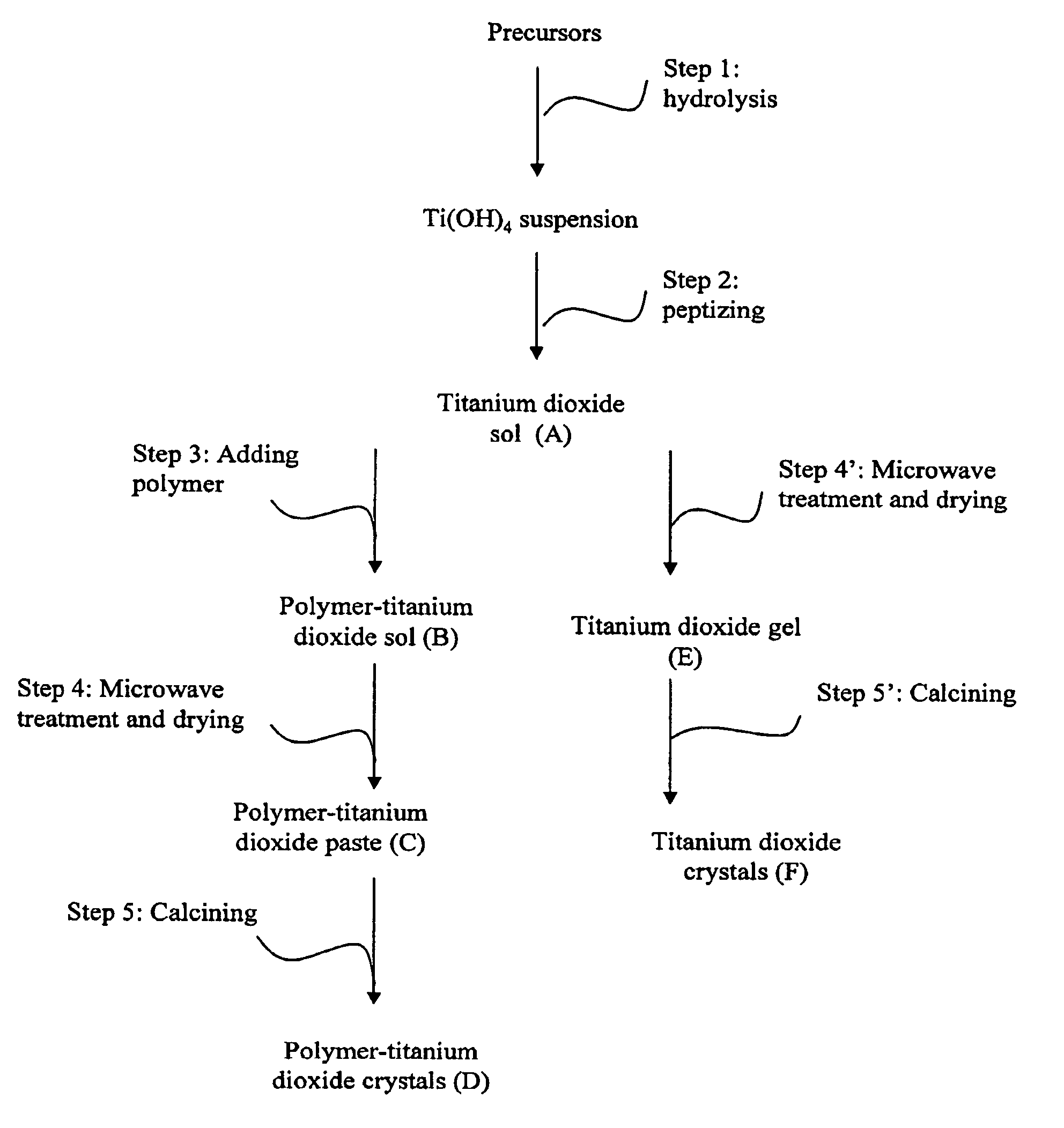

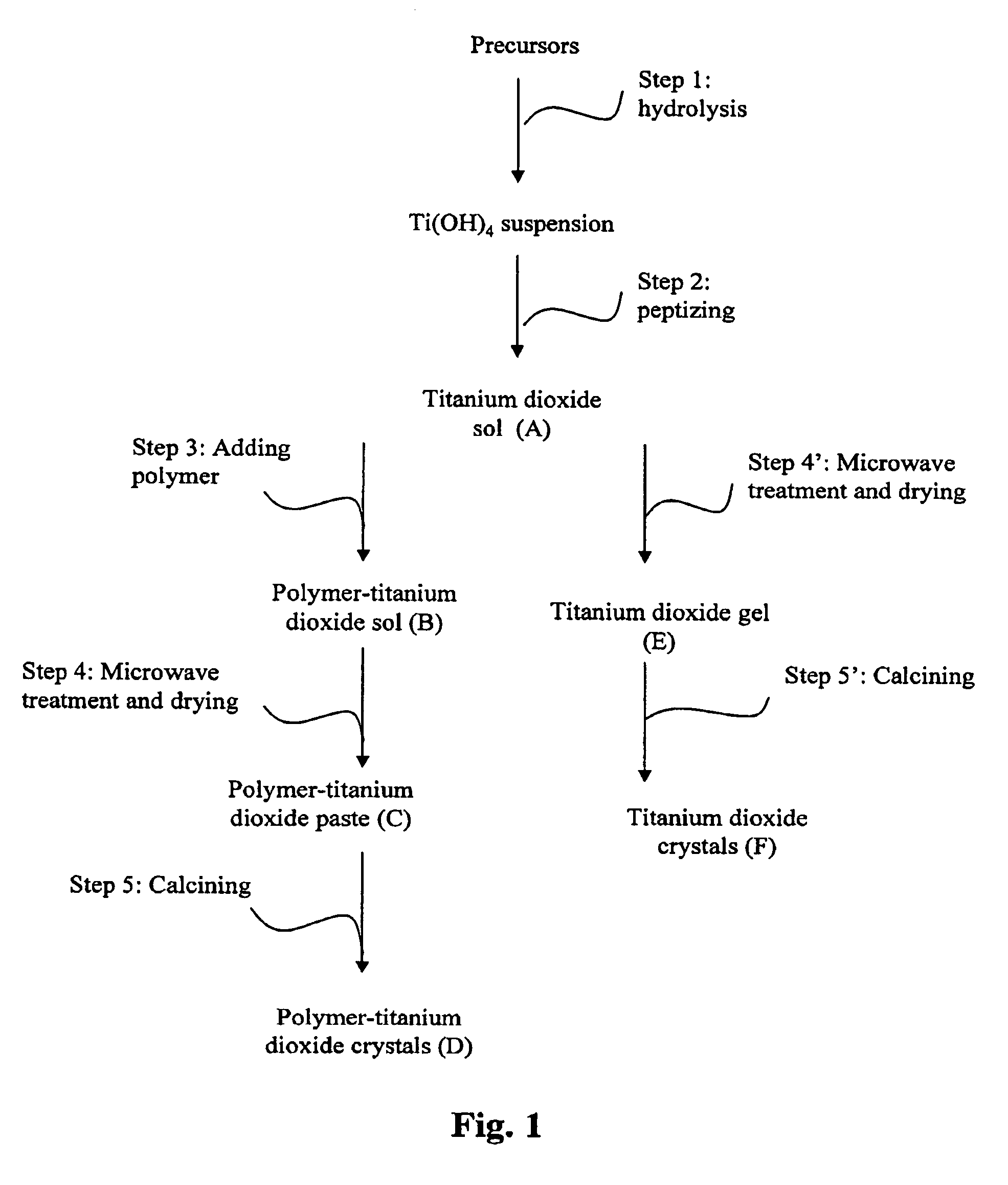

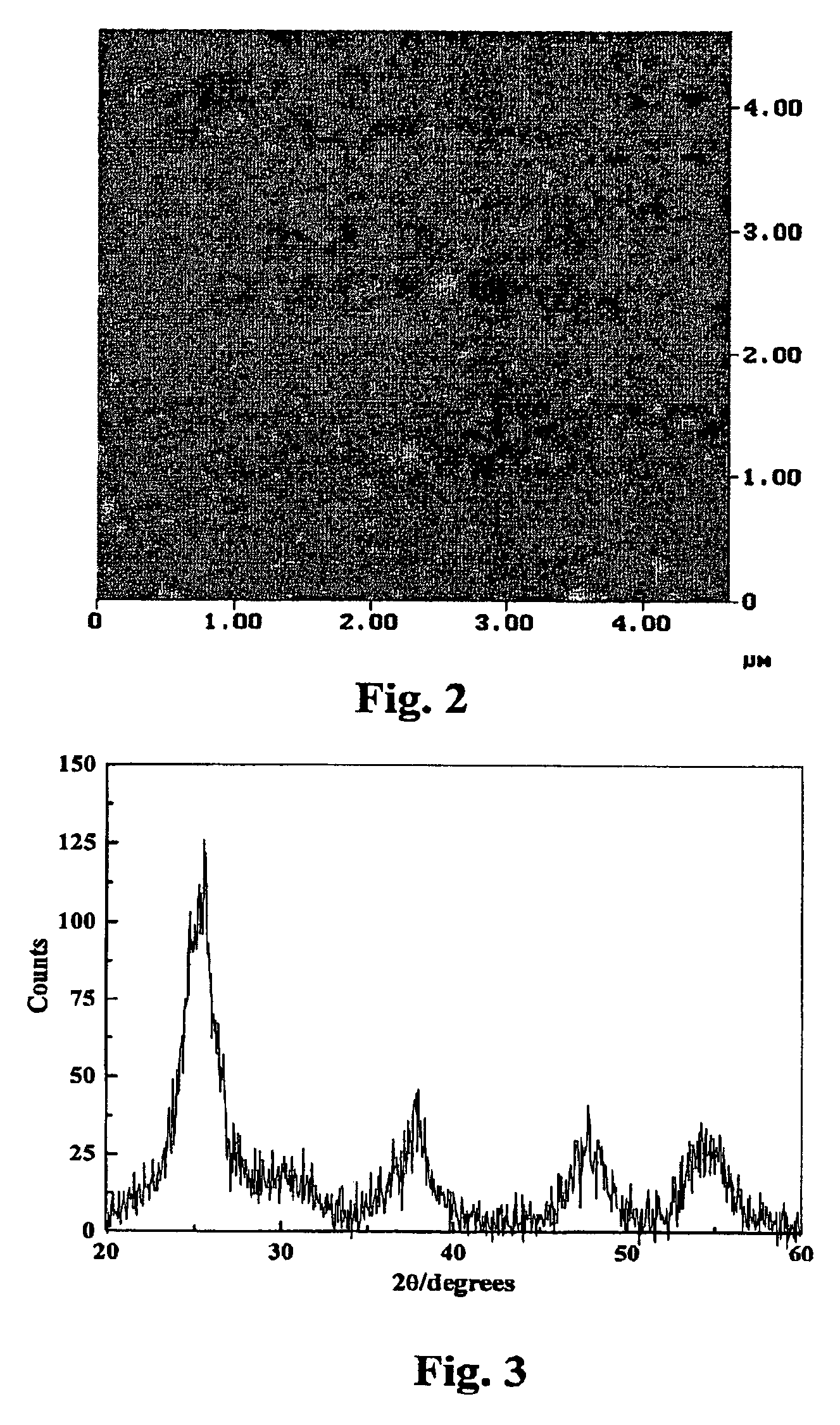

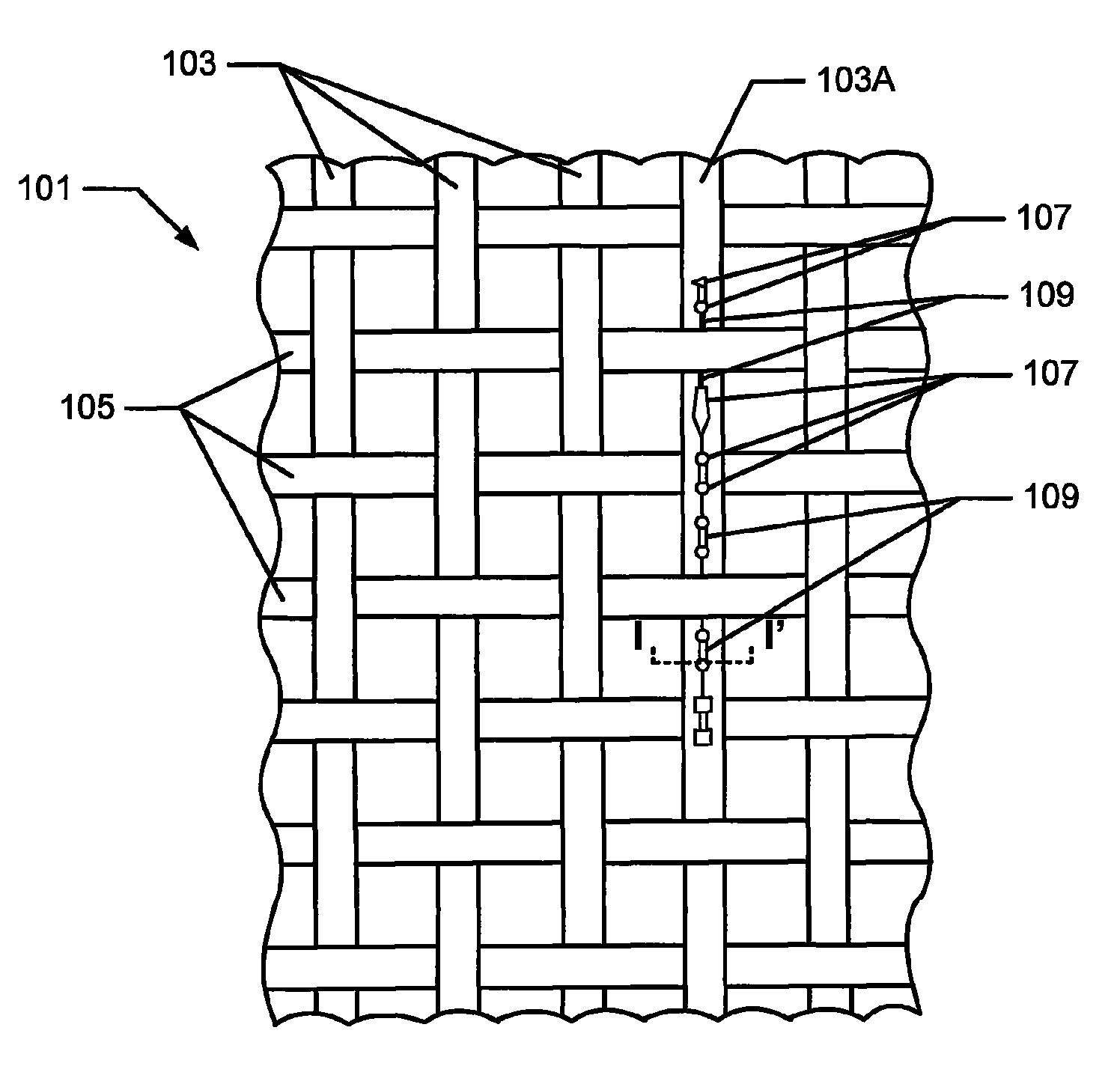

TiO2 material and the coating methods thereof

ActiveUS7144840B2Reduce moistureInhibit aggregationMaterial nanotechnologyLiquid surface applicatorsAir purificationTitanium dioxide

The present invention relates to a titanium dioxide material for coating on a substrate and method of making the same. The coated material is resistant to delamination and can be used for air-purification purposes.

Owner:THE HONG KONG UNIV OF SCI & TECH

Copper-base sintered sliding material excellent in slipperiness and machaniability

InactiveUS6165246AImprove machinabilityImproved sliding characteristic and machinabilityPlungersShaftsHardnessAlloy

PCT No. PCT / JP98 / 04685 Sec. 371 Date Jun. 16, 1999 Sec. 102(e) Date Jun. 16, 1999 PCT Filed Oct. 16, 1998 PCT Pub. No. WO99 / 20806 PCT Pub. Date Apr. 29, 1999In order to make the wear-resistance and machinability of the copper-based sliding material, in which such particles as AlN, Al2O3, NiB, Fe2B, SiC, TiC, WC, Si3N4, Fe3P, Fe2P and / or Fe3B are dispersed in the matrix consisting of sintered Cu or Cu alloy, the dispersion is performed such that the weight proportion and the average particle diameter of the medium-hardness particles of Hv 500 or more and 1000 or less are greater than those of the high-hardness particles having Hv 1100 or more.

Owner:TAIHO INDUSTRIES CO LTD

Deposition of electronic circuits on fibers and other materials

Fibers, such as textile fibers, having electrical components deposited thereon. More particularly, one or more electrical components are formed directly onto the surface of at least one fiber. The fiber having the electrical component formed thereon may then be interlaced with other fibers to form a larger piece of fabric, which can be employed to produce an article of clothing. A group of transistors and piezoelectric components forming an accelerometer may be woven onto one or more natural or synthetic fibers. The fibers may then be employed as the warp, weft, or both, of a woven piece of fabric, or used to form a knitted piece of fabric. The fabric piece can then be cut and sewn to form a wearable item, such as a shirt, a pair of pants, a hat, or the upper piece of a shoe that includes the accelerometer.

Owner:NIKE INC

Thermal protective coating

ActiveUS7105047B2Extended shelf lifeReduce weightAlkali metal silicate coatingsPretreated surfacesCalcium silicateSodium Bentonite

A coating, method of coating and substrates coated thereby, wherein the coating contains an inorganic adhesive such as an alkali / alkaline earth metal silicate such as sodium silicate, potassium silicate, calcium silicate, and magnesium silicate; a filler such as a metal oxide for example silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides and copper chromium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide may be added.

Owner:WESSEX

Nanoparticle coated material and production method of same

The invention provides a method of producing a nanoparticle coated material, comprising a support and a nanoparticle layer formed on the support, wherein the nanoparticle layer contains nanoparticles comprising a CuAu type or Cu3Au type hard magnetic ordered alloy, and wherein the method satisfies at least one of the following conditions (i) and (ii): (i) the method comprises the steps of forming a shielding layer on the support before forming the nanoparticle layer; and (ii) a step of forming the nanoparticle layer comprises: the steps of applying a coating liquid containing nanoparticles capable of forming a CuAu type or Cu3Au type hard magnetic ordered alloy phase on the support to form a coating film; and irradiating laser light on the coating film.

Owner:FUJIFILM CORP +1

Wear resistant low friction coating composition, coated components, and method for coating thereof

A composition for coating sliding or rolling or fretting or impacting members is formed by preparing a composite powder of TiB2 and BN, with a TiB2 to BN ratio ranging from 1:7 to 20:1, and a metallic matrix selected from the group consisting of nickel, chromium, iron, cobalt, aluminum, tungsten, carbon and alloys thereof.

Owner:MOMENTIVE PERFORMANCE MATERIALS QUARTZ INC

Glass, ceramic and metal substrates with a self-cleaning surface, method of making them and their use

Owner:FERRO GMBH

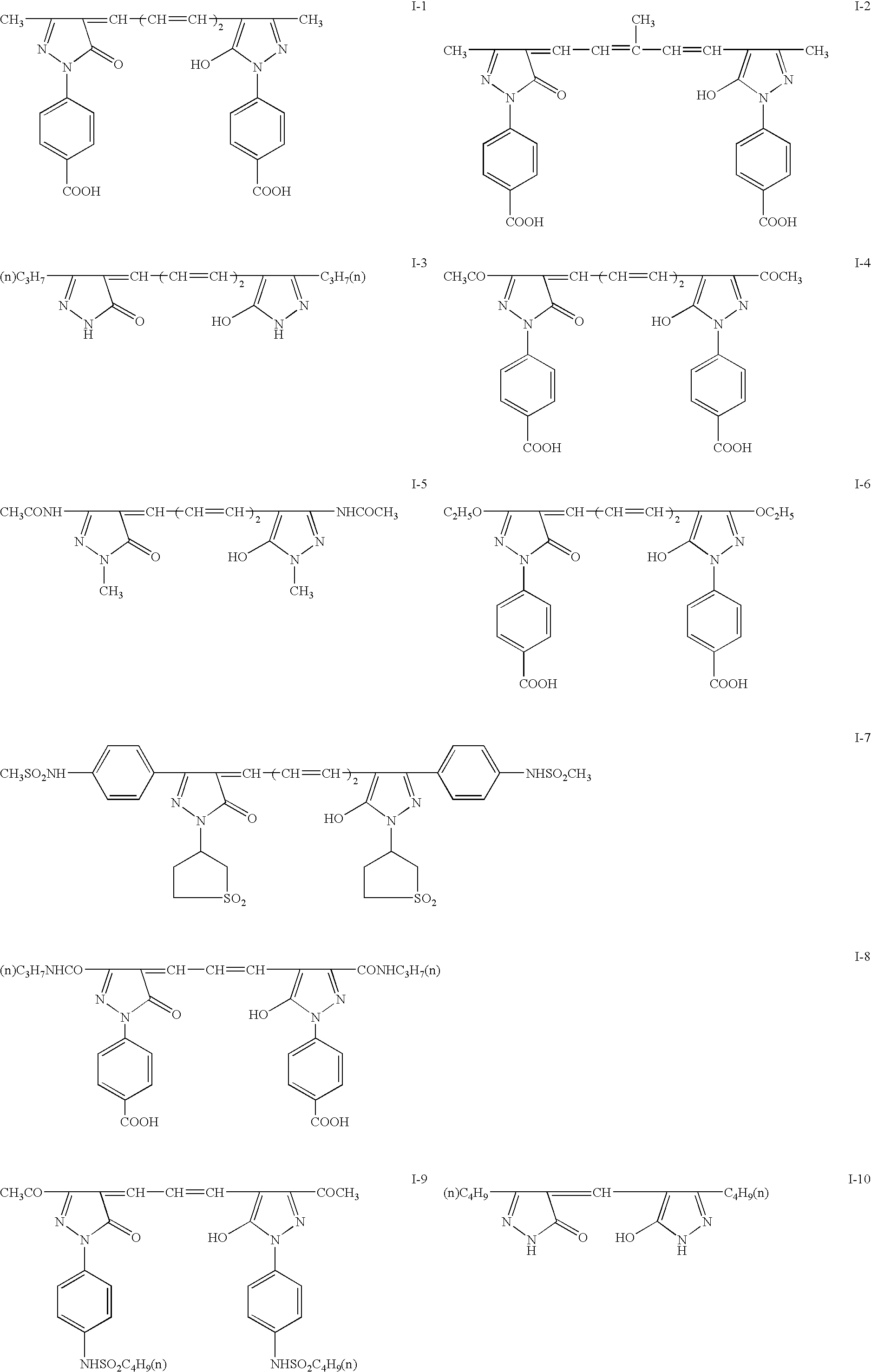

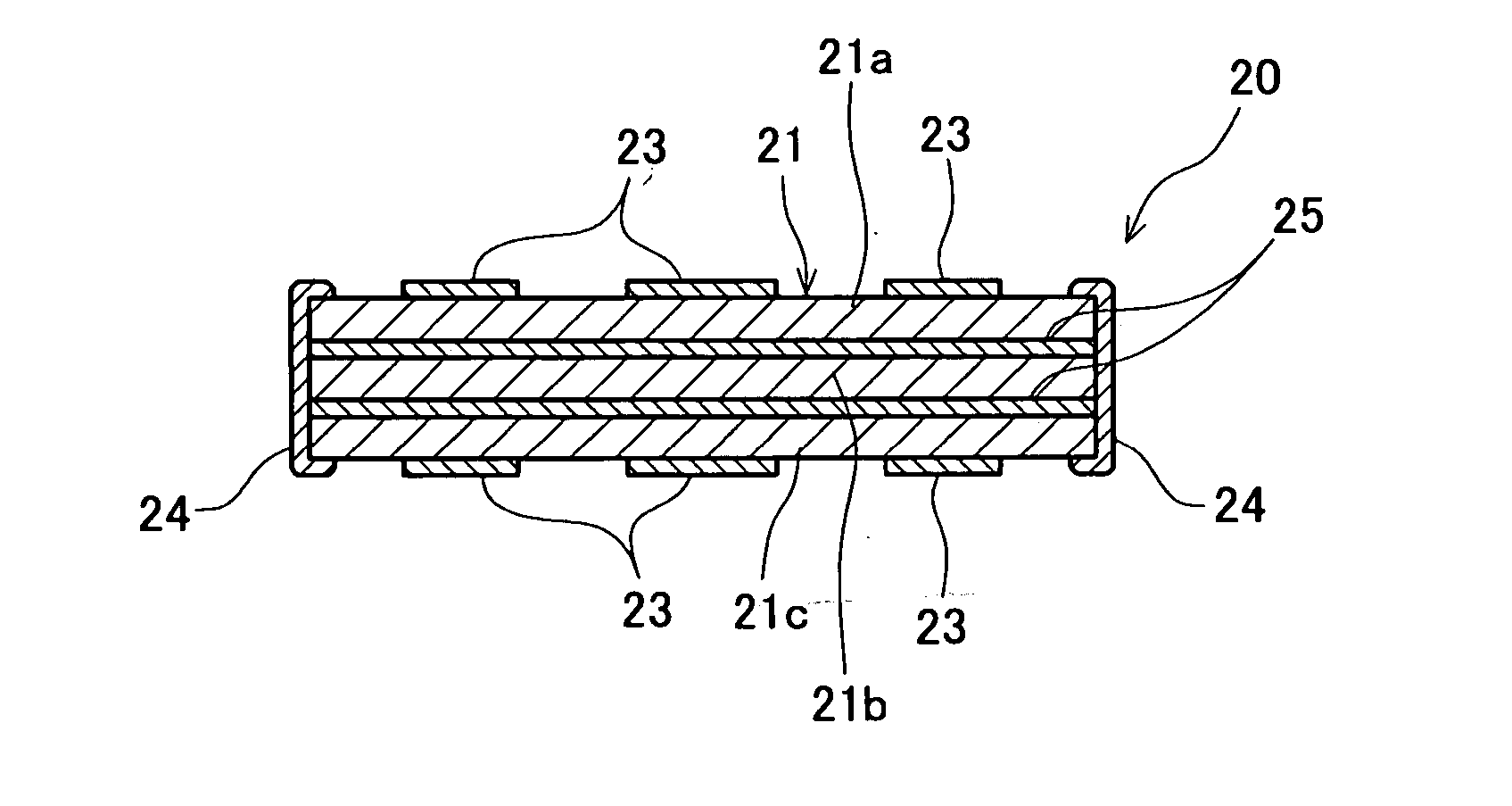

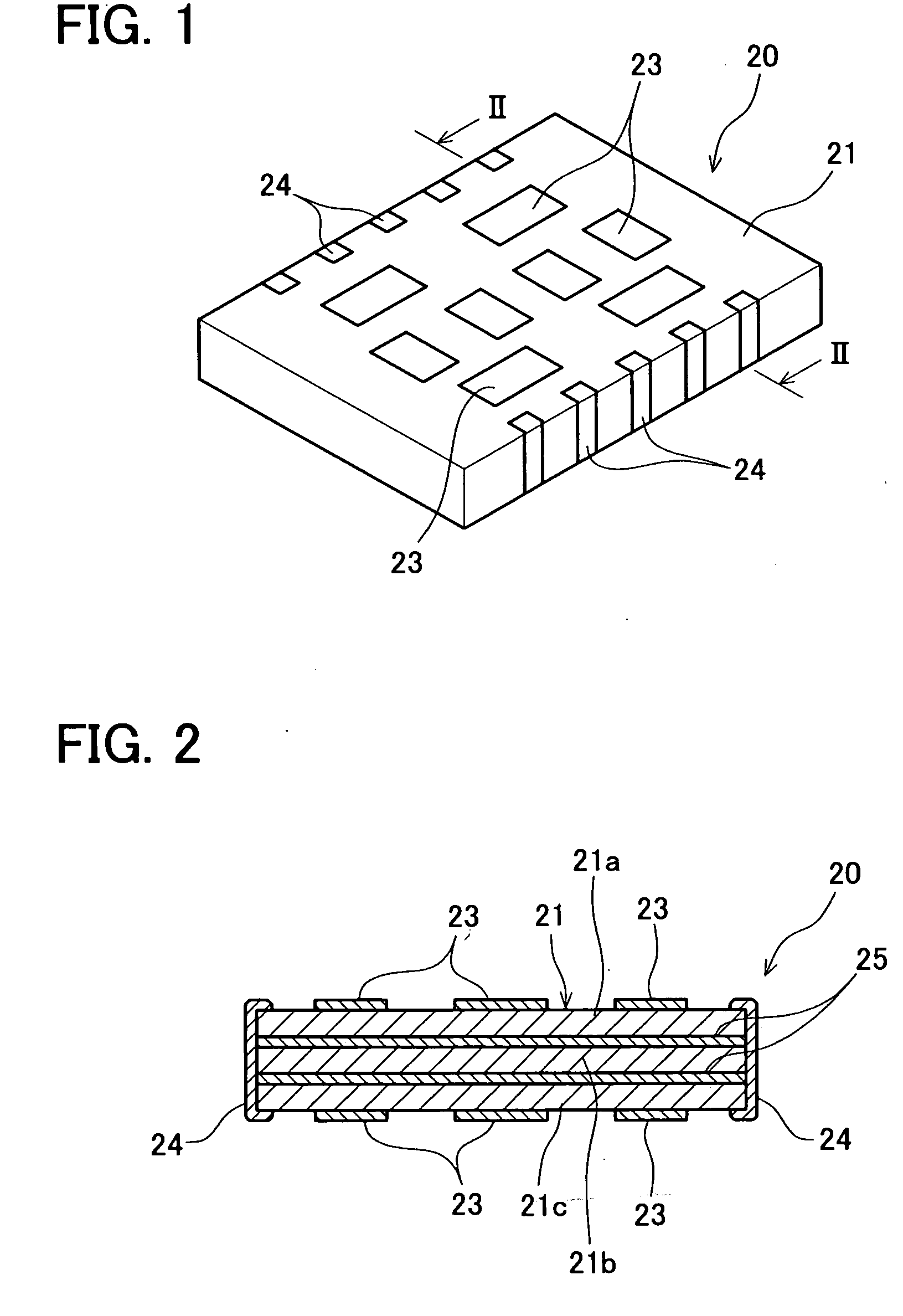

Ceramic electronic component and production method therefor

InactiveUS20040070915A1Quality improvementImprove electrical characteristicsLayered productsSemiconductor/solid-state device detailsOrganic compoundElectron

A ceramic electronic component (20) having surface conductor films (23) and side-surface conductor films (24) excellent in burning shrinkage, bonding strength, solder heat resistance, solder wettability and the like. A method of producing a ceramic electronic component which uses a conductive paste containing as a main component Ag-based metal powder, the surface of the metal powder being coated with an organic metal compound or a metal oxide having as a constituting element any one selected from a group consisting of Al, Zr, Ti, Y, Ca, Mg and Zn, to form conductor films (23, 24 25) on a ceramic base material (21). A side-surface conductor film-forming paste differs form a surface conductor film-forming paste in that (1) the former paste has a relatively small coating amount of the organic metal compound or metal oxide and / or (2) contains either at least one kind of inorganic oxide powder as an accessory composition or a comparatively high percentage of the inorganic oxide powder.

Owner:TDK CORPARATION +1

Non-line-of-sight process for coating complexed shaped structures

ActiveUS20060029733A1Difficult to coatLiquid surface applicatorsElectrolysis componentsOrganic chemistryProtective barrier

Non-line-of-sight process for coating complexed shaped structures of Si-based substrates with protective barrier layers.

Owner:RAYTHEON TECH CORP

Thermal spray coatings for semiconductor applications

InactiveUS20100272982A1Erosion is goodImproved corrosion resistant coatingLiquid surface applicatorsMolten spray coatingThermal sprayingIntegrated circuit manufacturing

This invention relates to thermal spray coatings on a metal or non-metal substrate. The thermal spray coating comprises a partially or fully stabilized ceramic coating, e.g., yttria stabilized zirconia coating, and has sufficiently high thermodynamic phase stability to provide corrosion and / or erosion resistance to the substrate. This invention also relates to methods of protecting metal and non-metal substrates by applying the thermal spray coatings. The coatings are useful, for example, in the protection of integrated circuit manufacturing equipment, internal chamber components, and electrostatic chuck manufacture.

Owner:PRAXAIR ST TECH INC

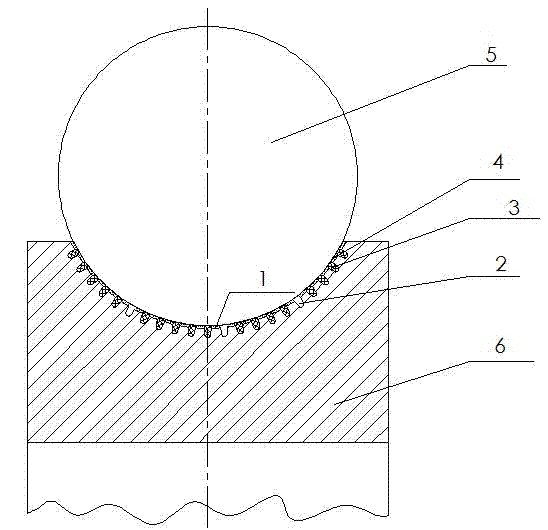

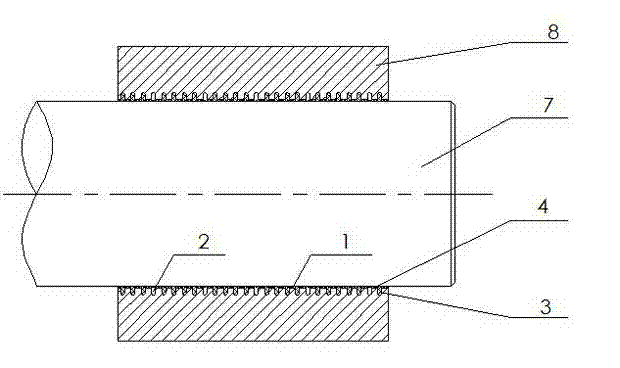

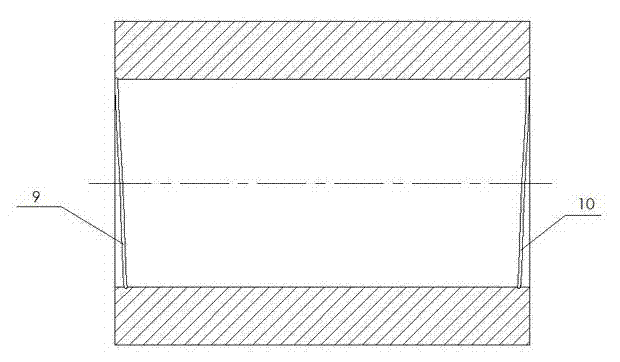

Method for self-lubricating treatment of laser micro-texture of bearing

InactiveCN102226459AImprove complex working conditionsGuaranteed carrying capacityBearing componentsLaser beam welding apparatusGraphiteOptoelectronics

The invention discloses a method for self-lubricating treatment of laser micro-texture of bearings. The invention comprises the following steps: firstly performing laser micro-processing technology of micro recessed cavities or micro grooves on a bearing surface, and then performing molding and bonding technology by a self-lubricating composite material on the bearing surface; the self-lubricating composite material comprises the following components by mass: 10-15% of polyimide (PI); 8-13% of graphite powder; 40-50% of polytetrafluoroethylene; 25-29% of MoS2; 0-5% of additives. By the self-lubricating treatment of laser micro-texture of a bearing, the invention guarantees the bearing capacity and the fitting accuracy of the bearing, realizes an optimized distribution of the lubricant on the bearing working surface, and improves comprehensive performance of antifriction and wear resistance of the bearing under complicated working conditions.

Owner:JIANGSU UNIV

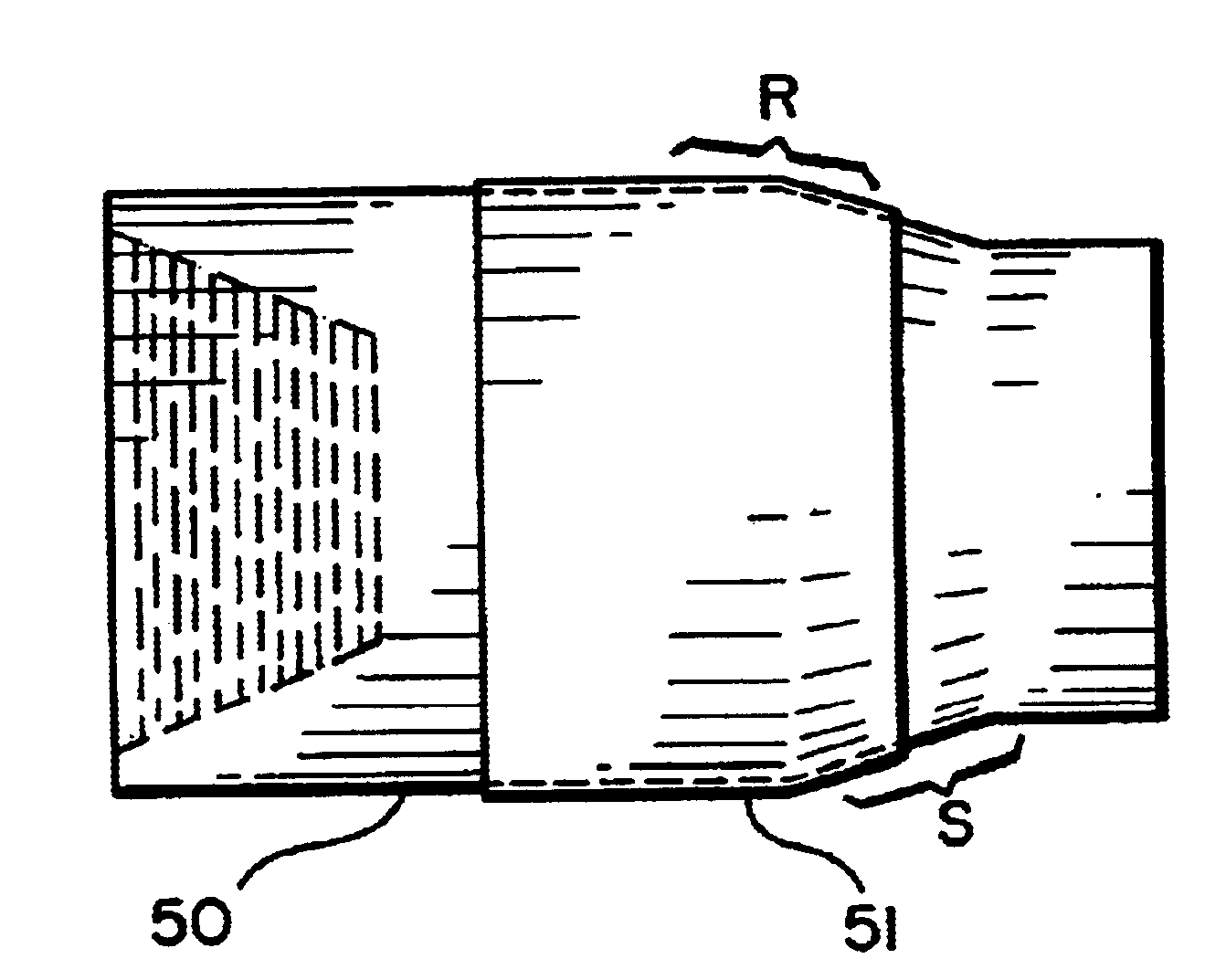

Methods for using a laser beam to apply wear-reducing material to tool joints

InactiveUS6861612B2Low heating temperatureExtremely wear resistant claddingElectric discharge heatingVacuum evaporation coatingMetallurgyLaser beams

A method for applying wear reducing material to a tool joint useful in a wellbore in drilling operations, the method, in at least certain aspects, including positioning the tool joint adjacent laser beam apparatus, delivering wear-reducing material to a location on the tool joint to which the wear-reducing material is to be applied, heating the wear-reducing material with the laser beam apparatus to a temperature not exceeding its melting temperature so that the wear-reducing material is welded to the tool joint; in one particular aspect, using a defocused laser beam to achieve desired heating temperatures; and, in one aspect, defocusing the laser so no plasma is formed.

Owner:MCCLUNG GUY L III

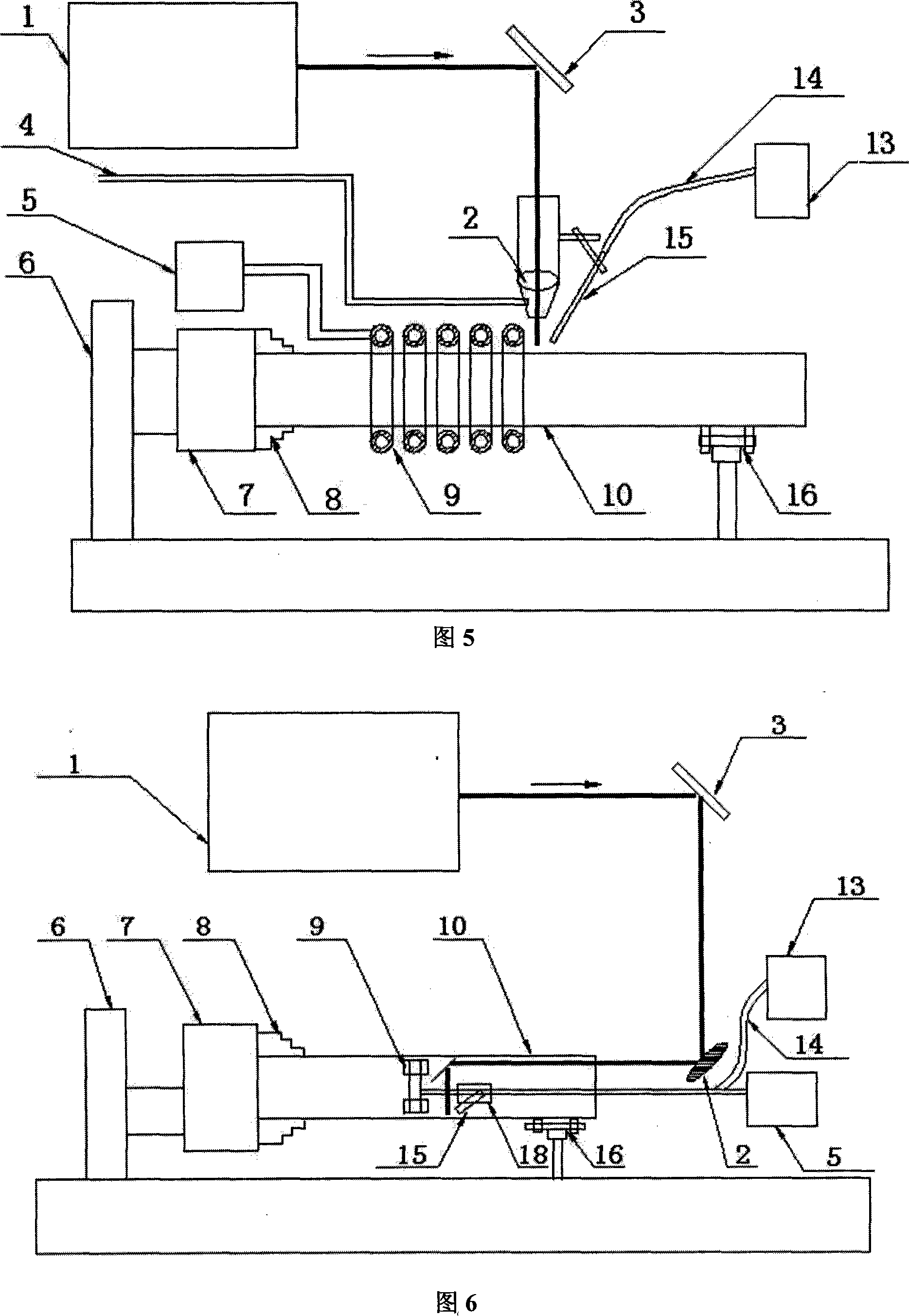

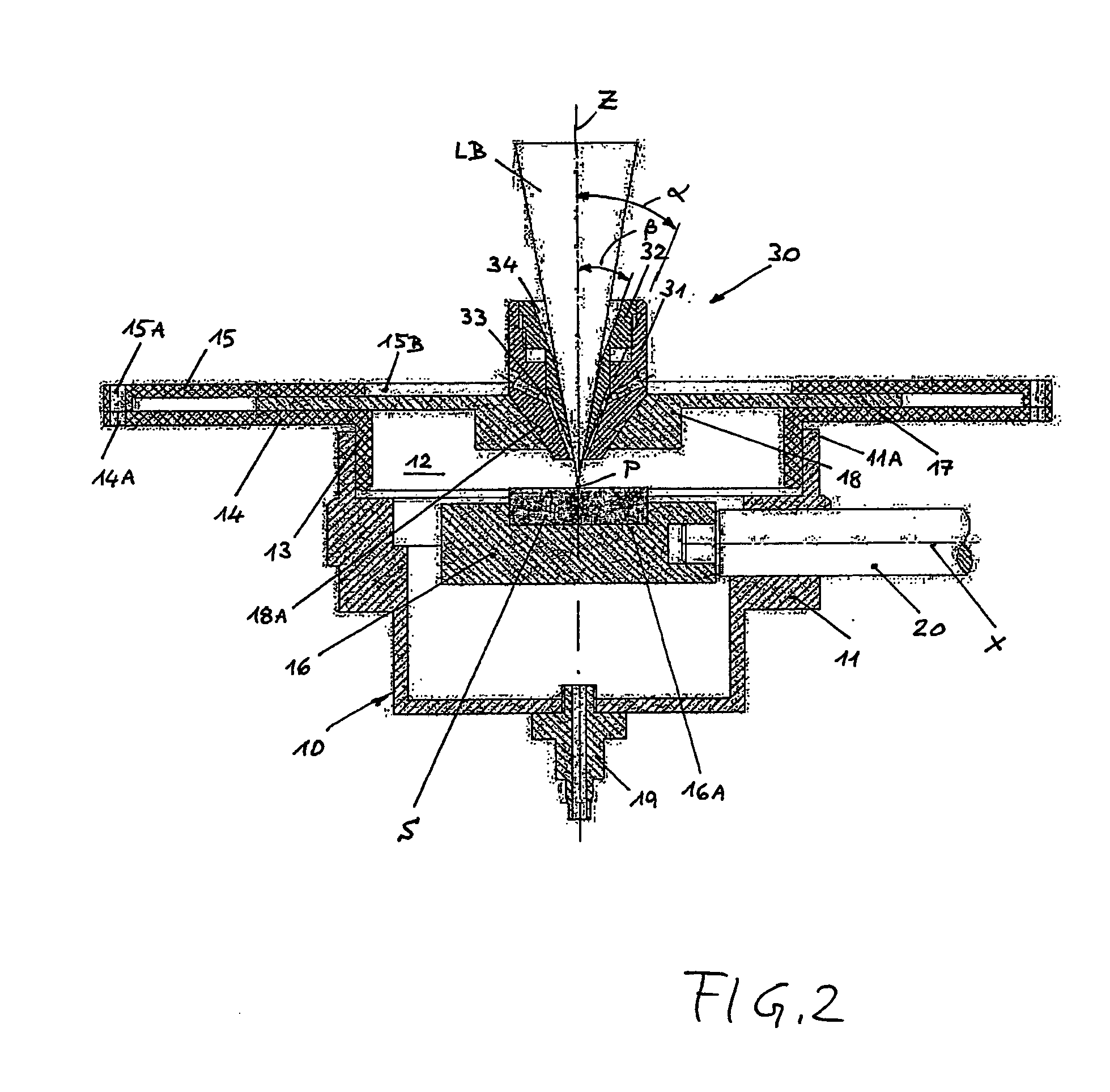

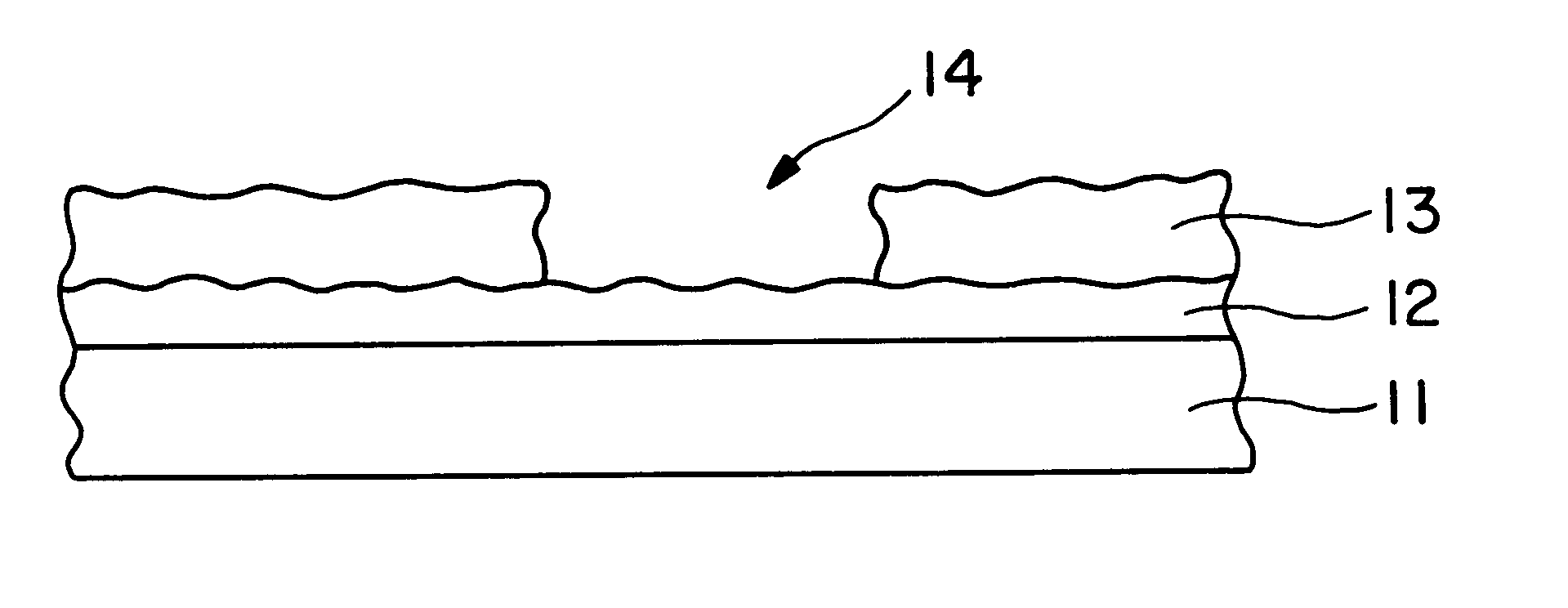

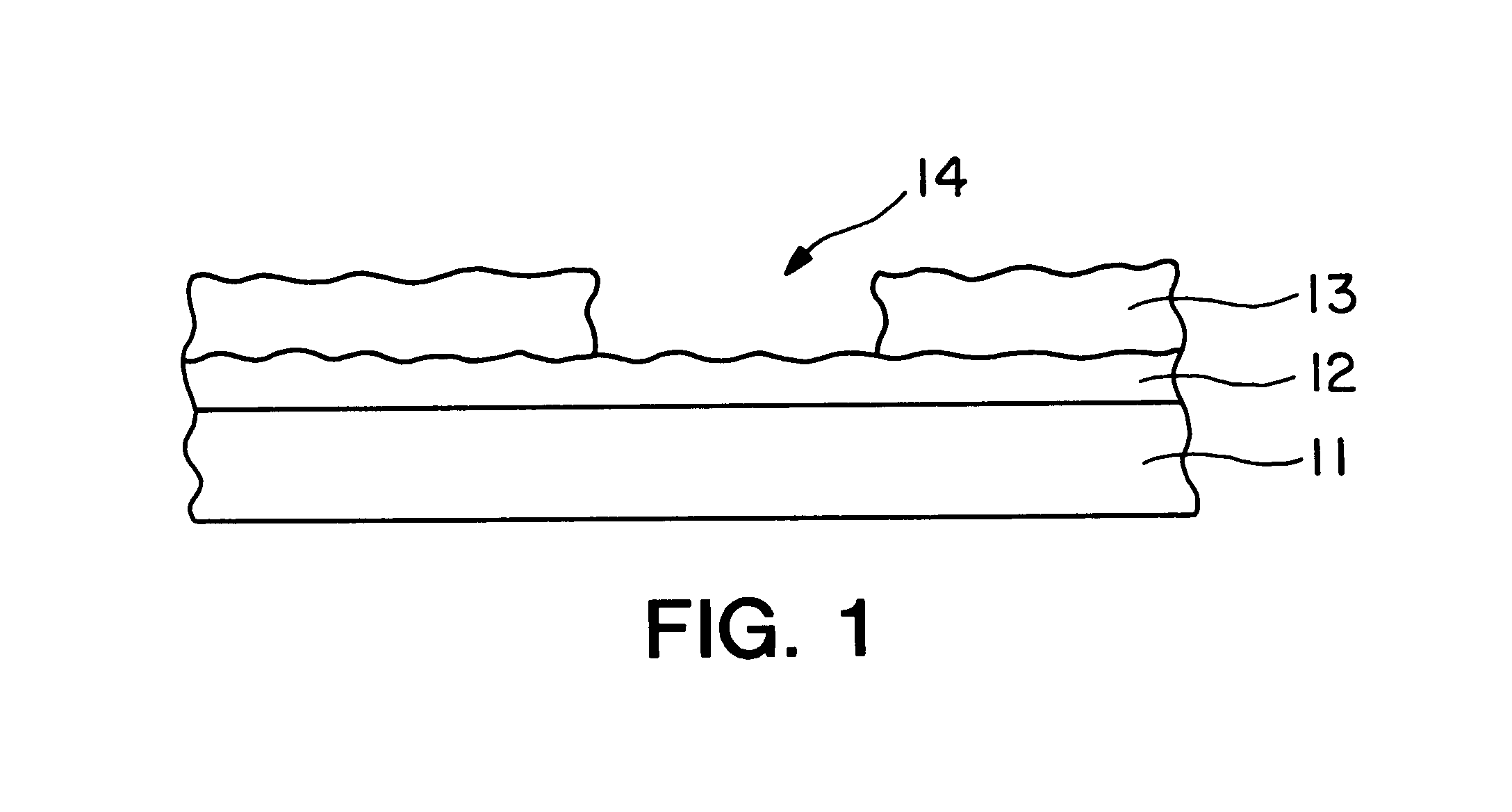

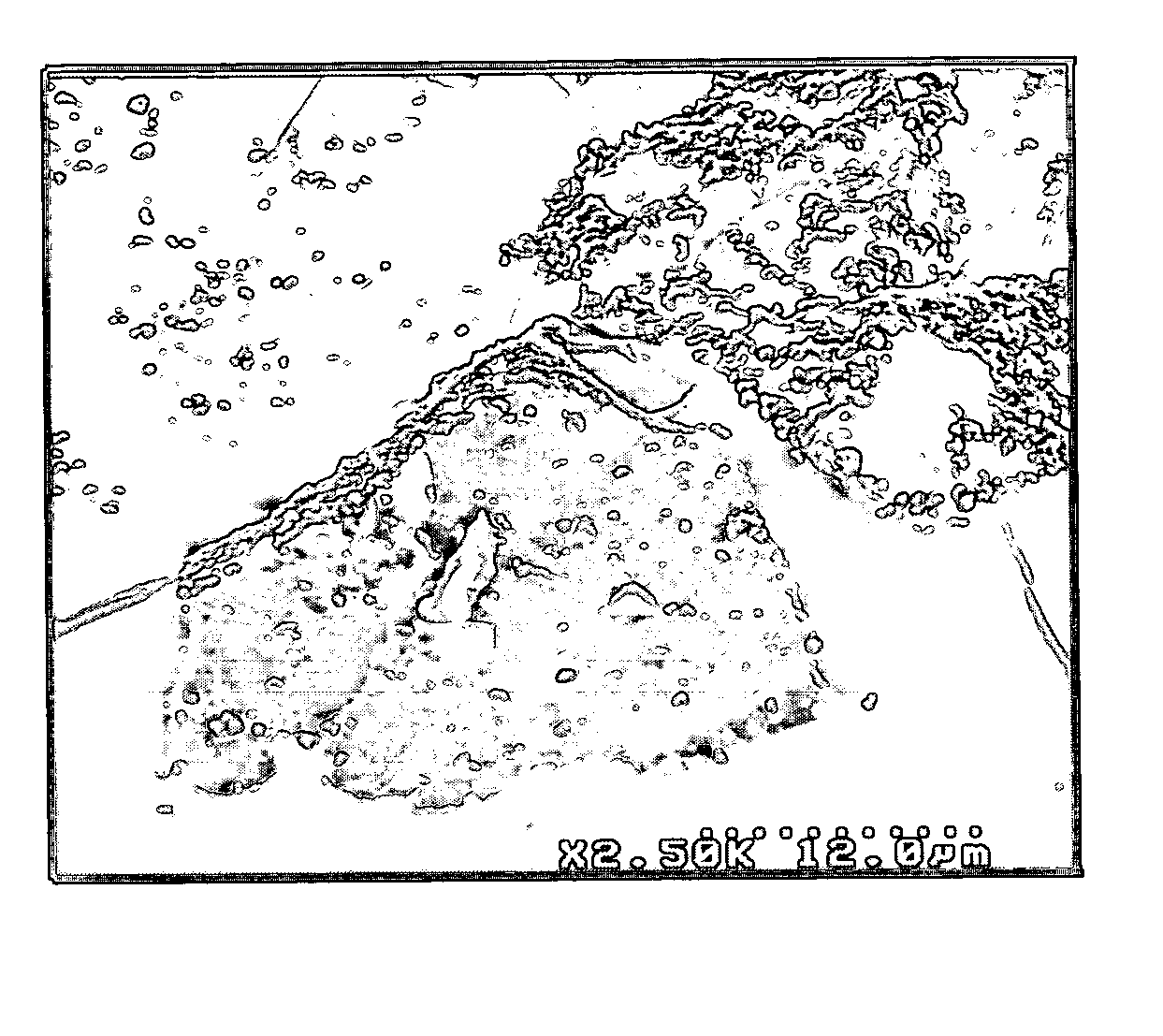

Method and Apparatus for Sintering of Inorganic Materials as Well as Resulting Objects

InactiveUS20090042050A1Improve objectivityAdditive manufacturing apparatusMolten spray coatingInorganic particleInorganic particles

The invention refers to a method and an apparatus for fabricating a tridimensional solid object by sintering inorganic particles of controlled size distribution. The particles are directed onto a target area in a powdery stream in the shape of a conical surface which is coaxial to a simultaneous heating flux while an at least bidimensional relative movement is maintained between the target area, the powdery stream and the heating flux. As a result the particles sinterization occurs in a single operation directly onto the target area. The resulting tridimensional solid objects are also claimed.

Owner:MBN NANOMATERIALIA +1

Method of repairing a thermal barrier coating

A method of repairing a damaged area of a thermal barrier coating on a component which is subjected to a hostile thermal environment, which comprises cleaning the damaged area, applying a partially stabilized zirconium sol-gel to the area, and pyrolizing the sol-gel to form a TBC repair layer.

Owner:SOUTHWEST RES INST

Preparation method of laser fusion covered nickel base nanometer WC/Co precoating layer

InactiveCN1786272AFlat surfaceEliminate cracksPretreated surfacesHeat inorganic powder coatingAlcoholNanotechnology

The invention relates to laser melting-covering nickel base nanometer WC / Co precoating manufacturing method. It includes the following steps: weighting lac absolute ethyl alcohol in proportion of 1:10-20; adding the lac into the absolute ethyl alcohol; weighting and mixing nickel base nanometer WC / Co powder and bonding agent in proportion of 1g: 0.1mL-0.25mL; fully stirring to form precoat agent; coating the precoat agent at the workpiece surface to form precoating; drying. The prepared nickel base nanometer WC / Co precoating is adopted laser melting-covering technique to form nickel base nanometer WC / Co composite coating.

Owner:SHANGHAI UNIV OF ENG SCI

Ceramic substrate for nonstick coating

InactiveUS20030059600A1Improve coating adhesionMore durableSynthetic resin layered productsPretreated surfacesFritAluminized steel

The present invention provides a new and useful nonstick coating for use on pure aluminum, alloys of aluminum, or aluminized steel surfaces. A nonstick coating according to the present invention includes a ceramic substrate disposed on an aluminum surface and a fluorocarbon polymer coating disposed on the ceramic substrate. The ceramic substrate, prior to firing, includes at least two layers: a first or bottom layer applied to the aluminum surface including an enamel ground coat; and a second or top layer applied over the enamel ground coat layer including a blend of one or more glass frits, non-ceramic refractory particles, and non-vitreous inorganic oxide particles. Upon firing, the ceramic substrate includes a continuous layer of vitreous enamel that is bonded to the aluminum surface. The exposed surface of the ceramic substrate has a micro-rough texture that is enriched with bonding sides for binder resins used in a fluorocarbon polymer primer layer. The ceramic substrate protects the aluminum surface from corrosion and mechanical damage and also protects the fluorocarbon polymer coating from abrasive wear.

Owner:FERRO CORP

Method to provide wear-resistant coating and related coated articles

InactiveUS20050014010A1Increasing its useful lifespanLiquid surface applicatorsMolten spray coatingThermal sprayingWear resistant

This invention is directed to a coated article having an increased useful lifespan, having a wear-resistant coating comprising a vitreous matrix material and metal coated superabrasive particles distributed therein. The superabrasive particles are coated with a protective metal coating selected from zinc, aluminum, aluminum-silicon alloy, titanium, chromium, nickel, silicon, tin, antimony, copper, iron, stainless steel, silver, alloys thereof, and mixtures thereof. The wear-resistant coating comprising coated superabrasive particles may be applied to the surface of an article by at least one process selected from electroless or electrolytic electroplating process, thermal spraying, and brazing.

Owner:DIAMOND INNOVATIONS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com