Method of repairing a thermal barrier coating

a thermal barrier and coating technology, applied in the direction of coatings, foil printing, liquid/solution decomposition chemical coatings, etc., can solve the problems of thermal barrier localization, inability to adapt to field repair of components, and possible thermal barrier palllation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

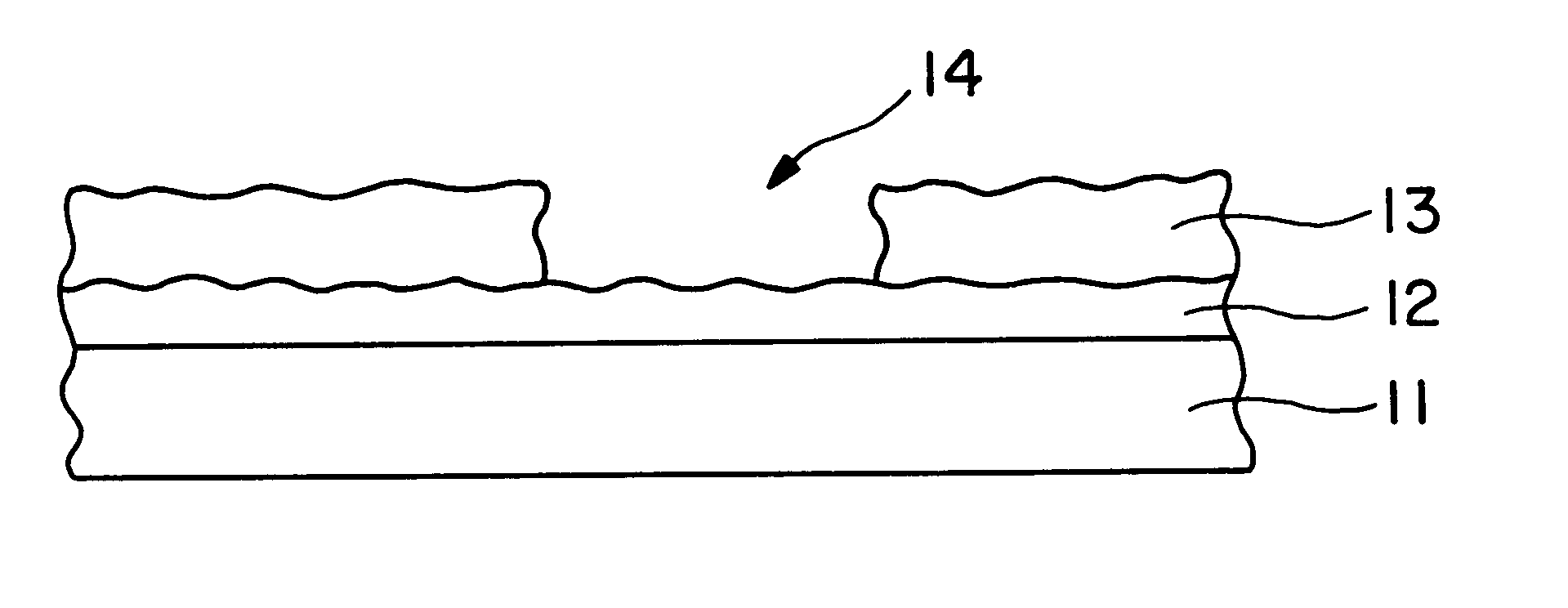

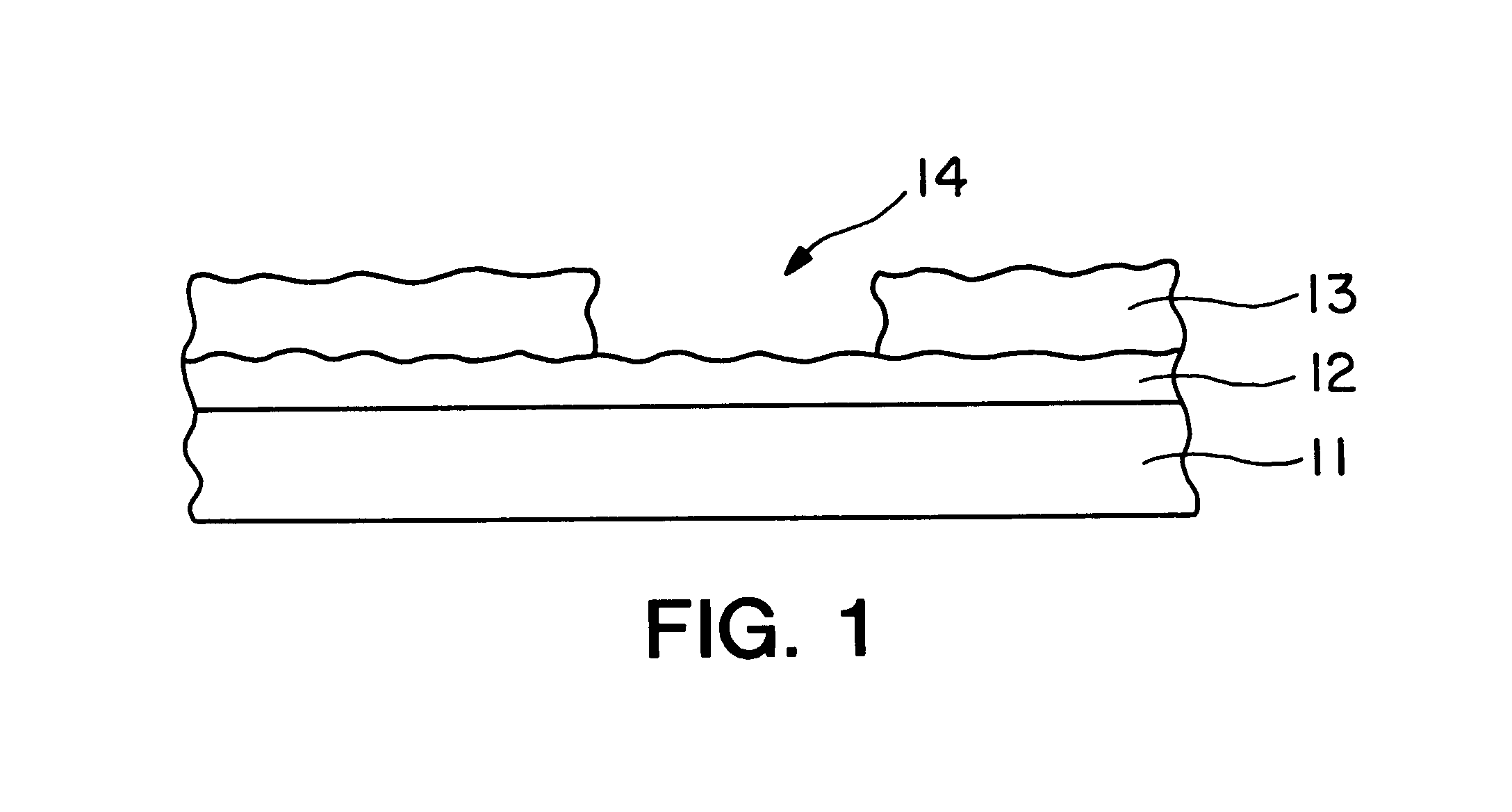

Referring to FIG. 1, a cross section of a portion of a component 11 is shown with a suitable metallic bond layer 12 and a thermal barrier coating 13. The area 14 indicates damage or spallation of the thermal barrier coating, which typically is from 75 to about 300 micrometers in thickness. Typically, the damage only extends partially through the thermal barrier coating; however, the present method of repair also could be used to repair damage which extended completely through the thermal barrier coating to the bondcoat.

In accordance with the present invention, the damaged area is cleaned to remove any oxides or fragments of the ceramic thermal barrier coating to expose the metallic bond layer 12. The damaged area 14 is repaired by applying a sol-gel of partially stabilized zirconia (PSZ). After the sol-gel is applied to the damaged area and the solvent allowed to evaporate leaving the PSZ precursor. This process can be repeated until a precursor of suitable thickness is achieved. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com