Driving voltage compensation system for GOA circuit

A driving voltage and compensation system technology, applied in instruments, static indicators, etc., can solve problems such as low current of thin film transistors, reduced electron mobility, and decreased charging capacity of thin film transistors, so as to achieve improved resolution and accurate driving voltage compensation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical content disclosed in this application more detailed and complete, reference may be made to the drawings and the following various specific embodiments of the present invention, and the same symbols in the drawings represent the same or similar components. However, those skilled in the art should understand that the examples provided below are not intended to limit the scope of the present invention. In addition, the drawings are only for schematic illustration and are not drawn according to their original scale.

[0021] The specific implementation manners of various aspects of the present invention will be further described in detail below with reference to the accompanying drawings.

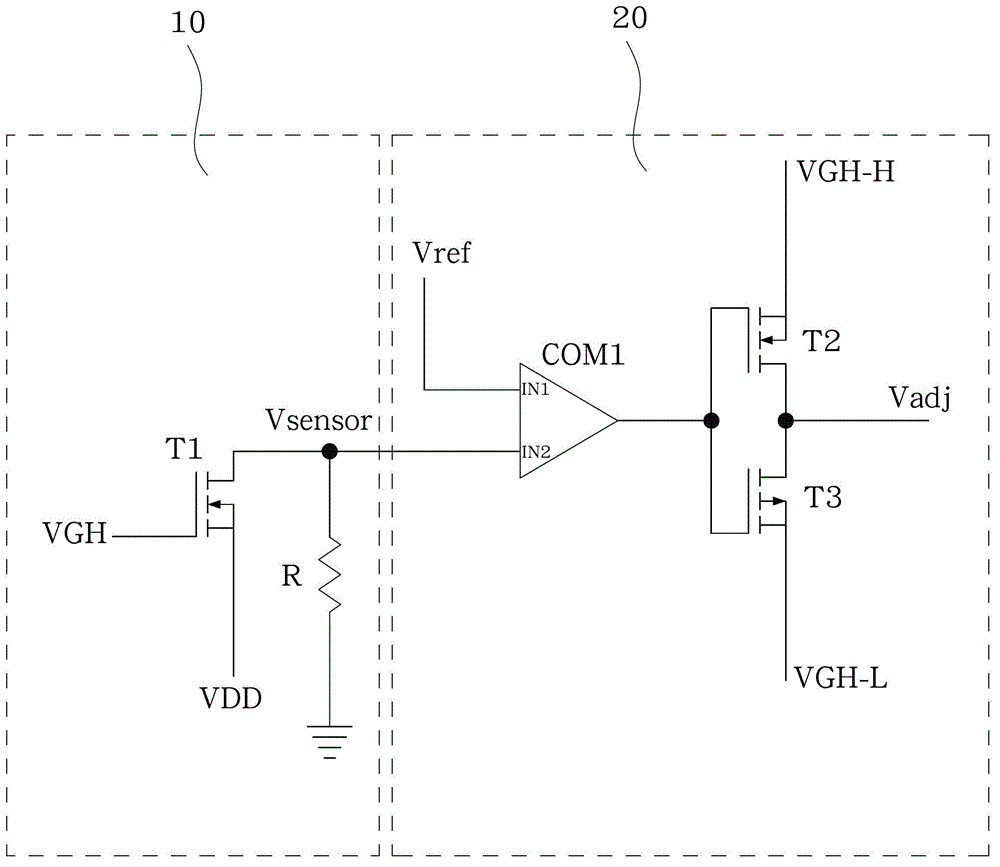

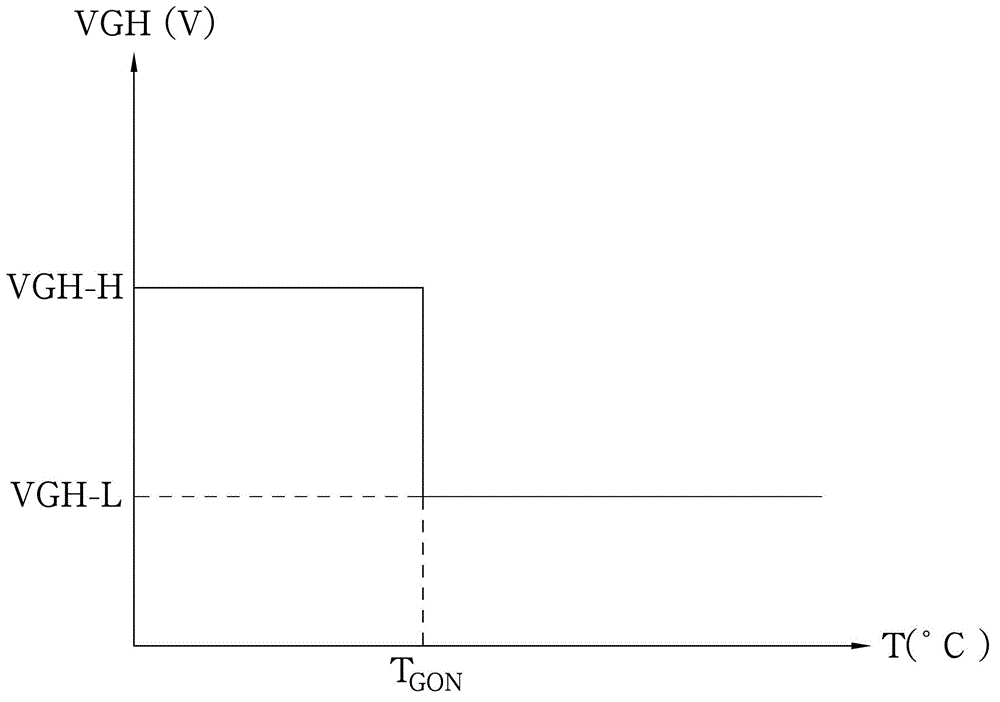

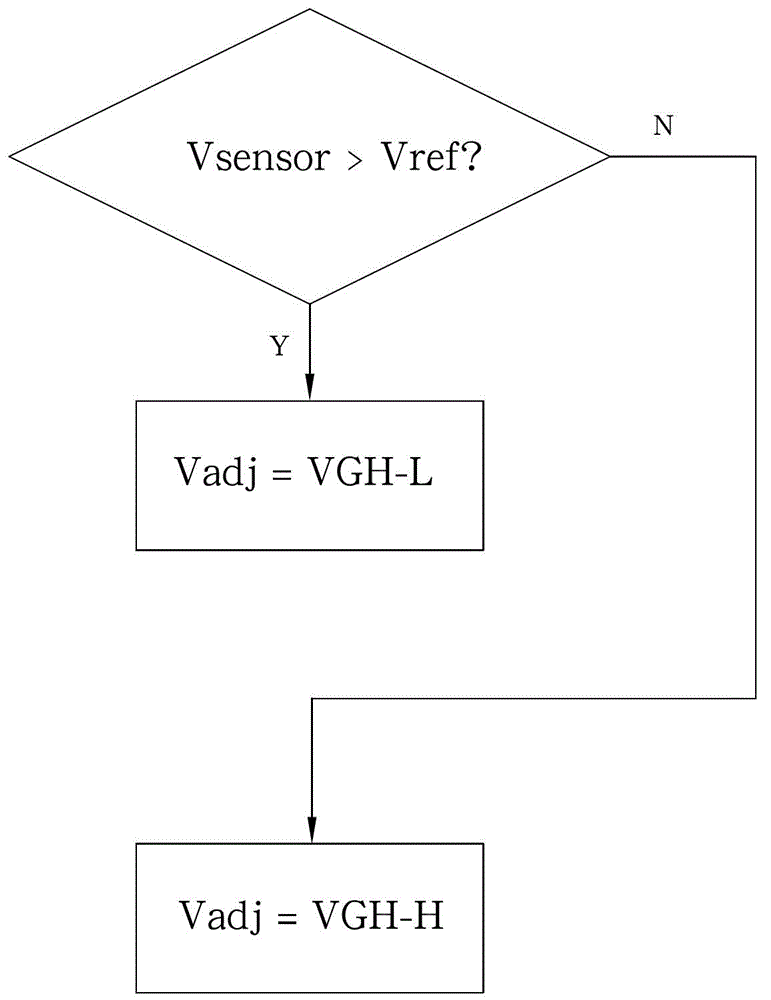

[0022] figure 1 A schematic structural diagram of a driving voltage compensation system for a GOA circuit is shown according to an embodiment of the present invention. figure 2 show figure 1 A graph showing the relationship between the first threshold v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com