Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1633 results about "Textile fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

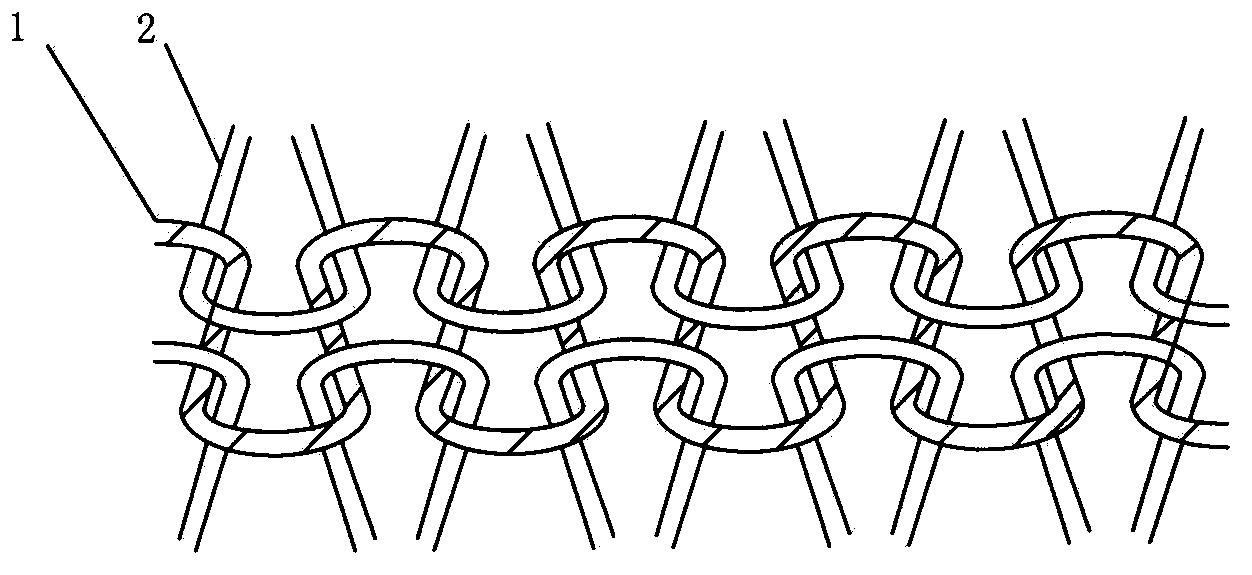

In textile arena; textile fiber is the raw materials to produce various types of textile finished products. A fiber that can be spun into yarn or processed into textile such as a woven fabric, knit fabric, lace, felt, non-woven etc by means of an appropriate interlacing method is called as textile fiber.

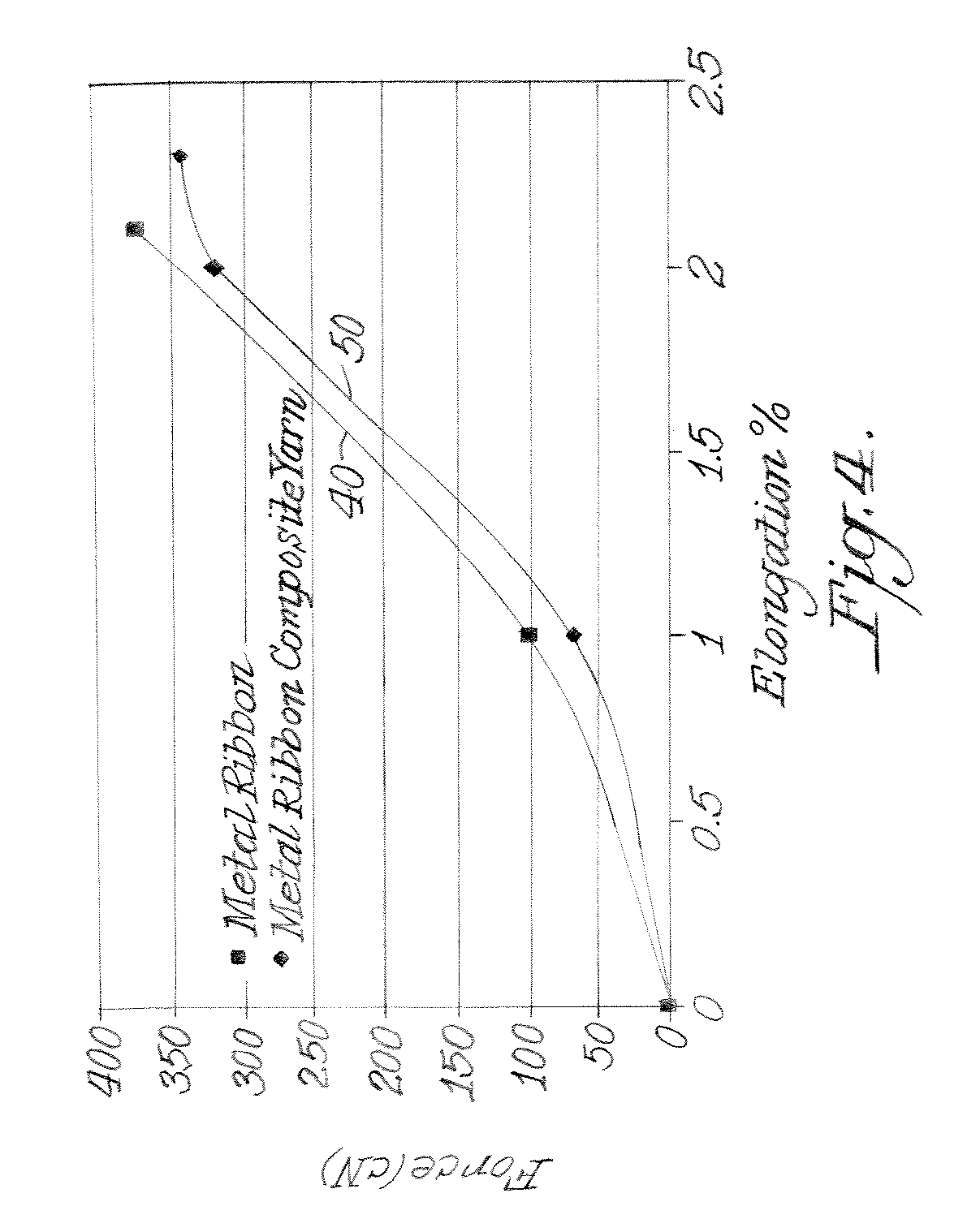

Method for producing an electrically conductive yarn, the electrically conductive yarn and use of the electrically conductive yarn

InactiveUS6032450ACounteracts brittlenessImprove adhesionInorganic material artificial filamentsContinuous wound-up machinesTextile fiberYarn

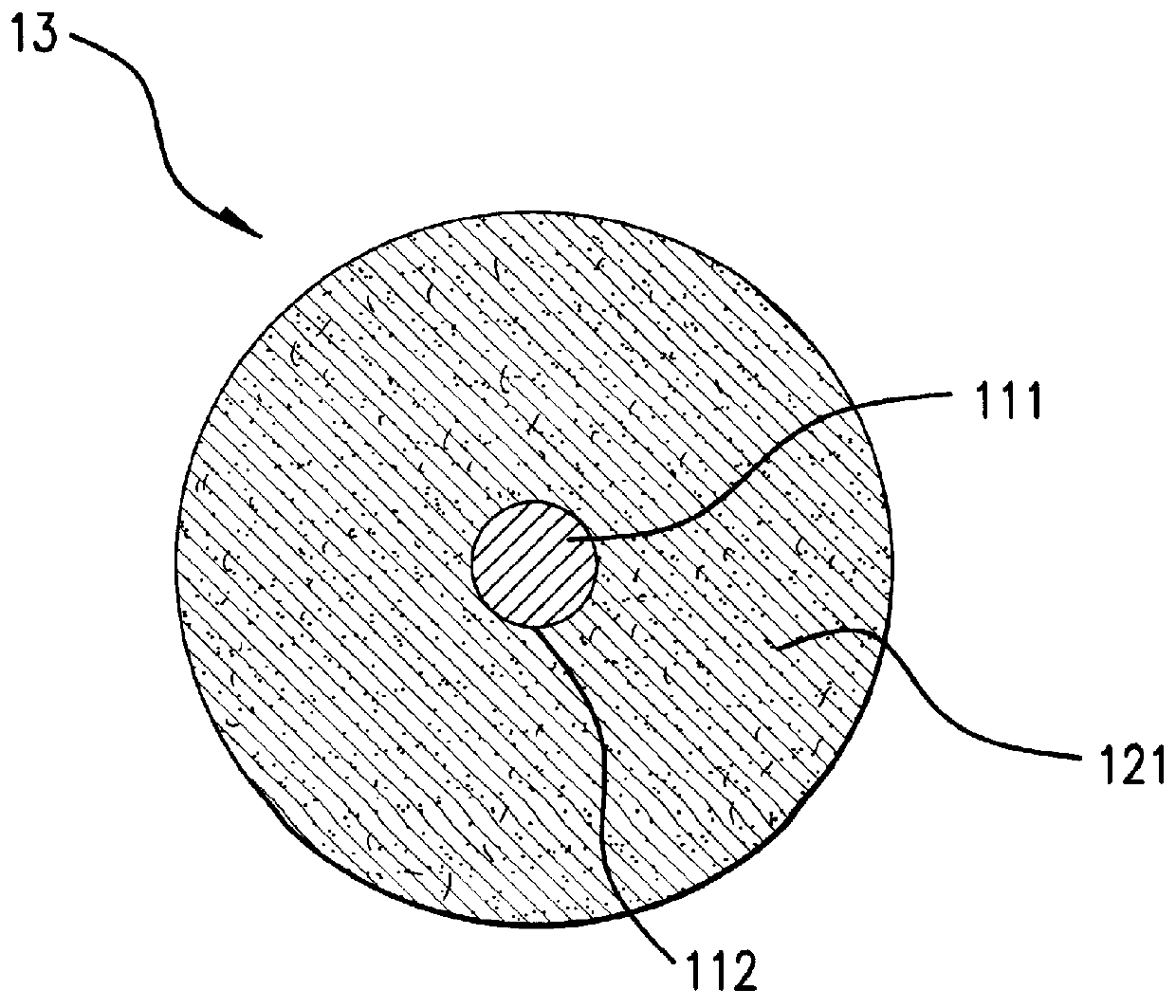

A method for producing an electrically conductive compound yarn. An electrically conductive monofilament metal thread is spun into a compound yarn together with textile fibers. A compound yarn of this type is particularly suitable for producing woven and knit materials.

Owner:SPOERRY 1866 AG

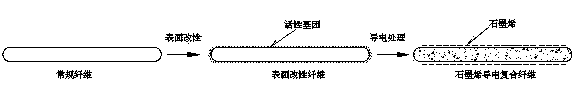

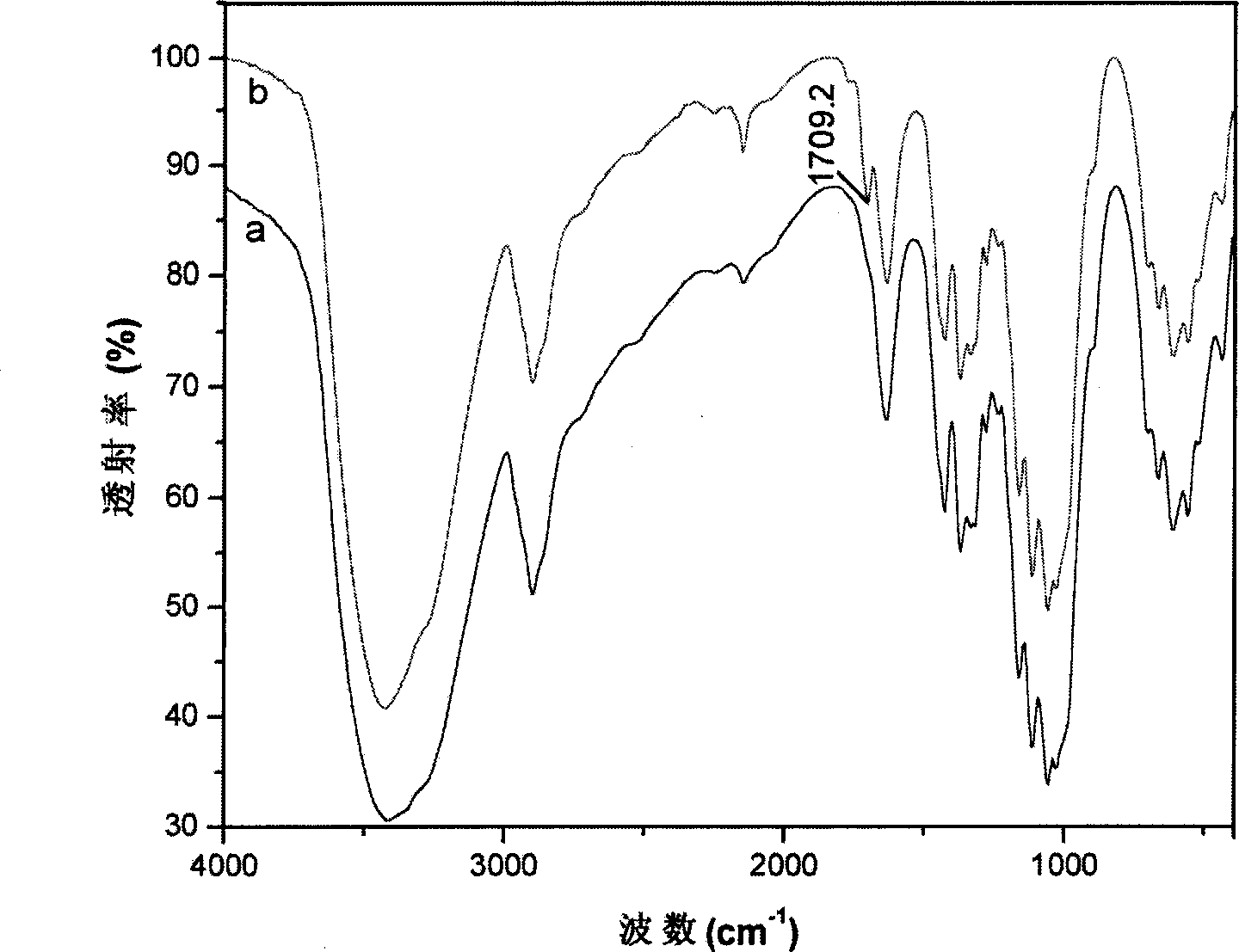

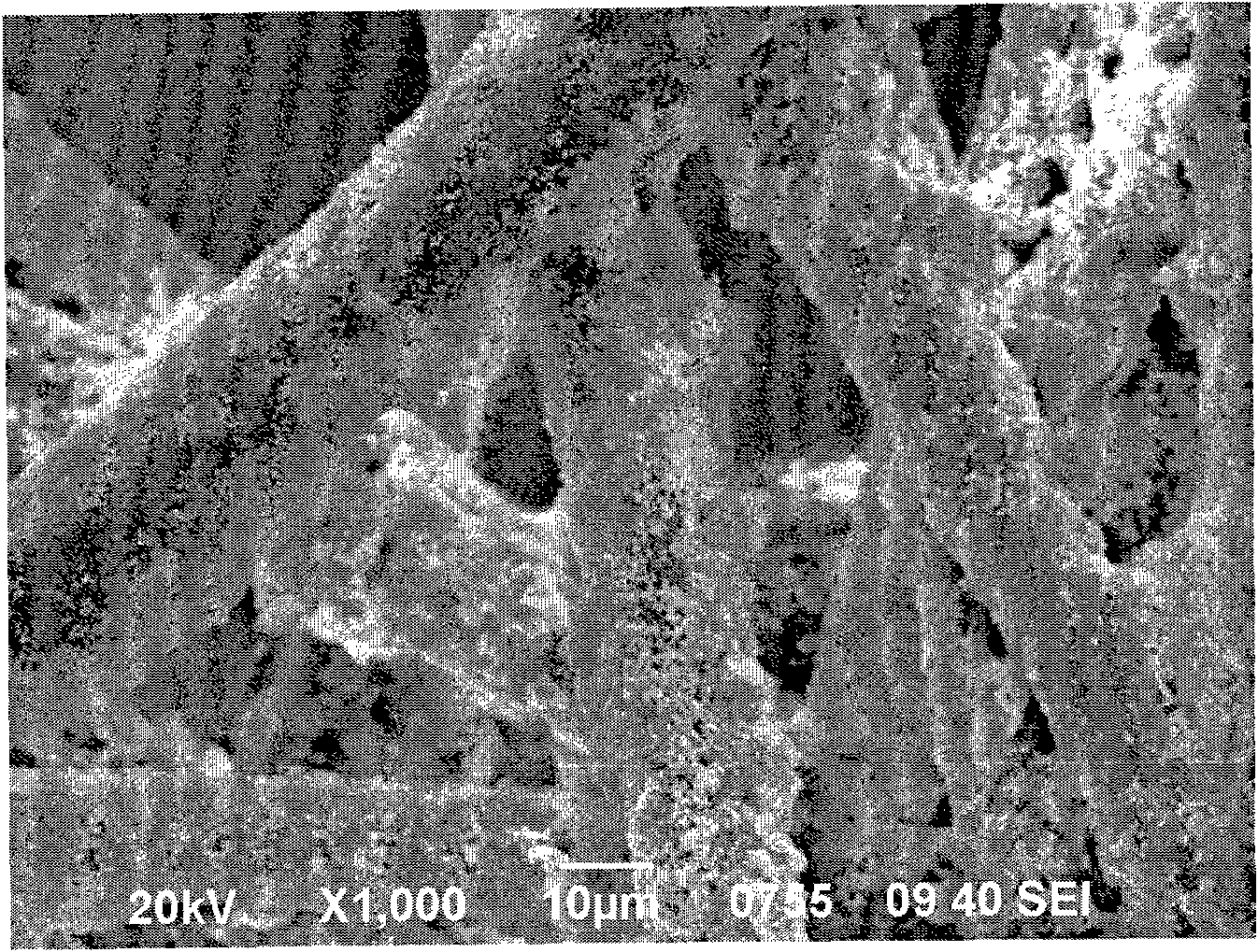

Preparation method of graphene electroconductive composite fiber

The invention provides a preparation method of a graphene electroconductive composite fiber. The method is characterized by comprising the following procedures: in a textile fiber surface modification procedure, a textile fiber is soaked into a silane coupling agent KH560 solution with the concentration of 1-30 percent for 2-3 hours and then is put into an oven of 50-65 DEG C to be dried to prepare the surfactant modified textile fiber; in a graphene dispersion system preparation procedure, graphene is prepared from an oxidized graphene aqueous solution prepared by means of a Hummer's method in a chemical reduction method, and a uniform and stable graphene dispersion system with the concentration of 0.1-5 percent is prepared under the function of a dispersing agent; in a graphene composite fiber preparation procedure, the modified textile fiber is soaked in the graphene dispersion system for 2-3 hours and then put into the oven of 50-65 DEG C to be dried to obtain the graphene electroconductive composite fiber. The preparation method is simple and reasonable in process, easy to operate, high in yield, high in reduction degree and high in conductivity and anti-radiation performance; the using amount of graphene is less and the dispersion system is uniform and stable.

Owner:QINGDAO UNIV

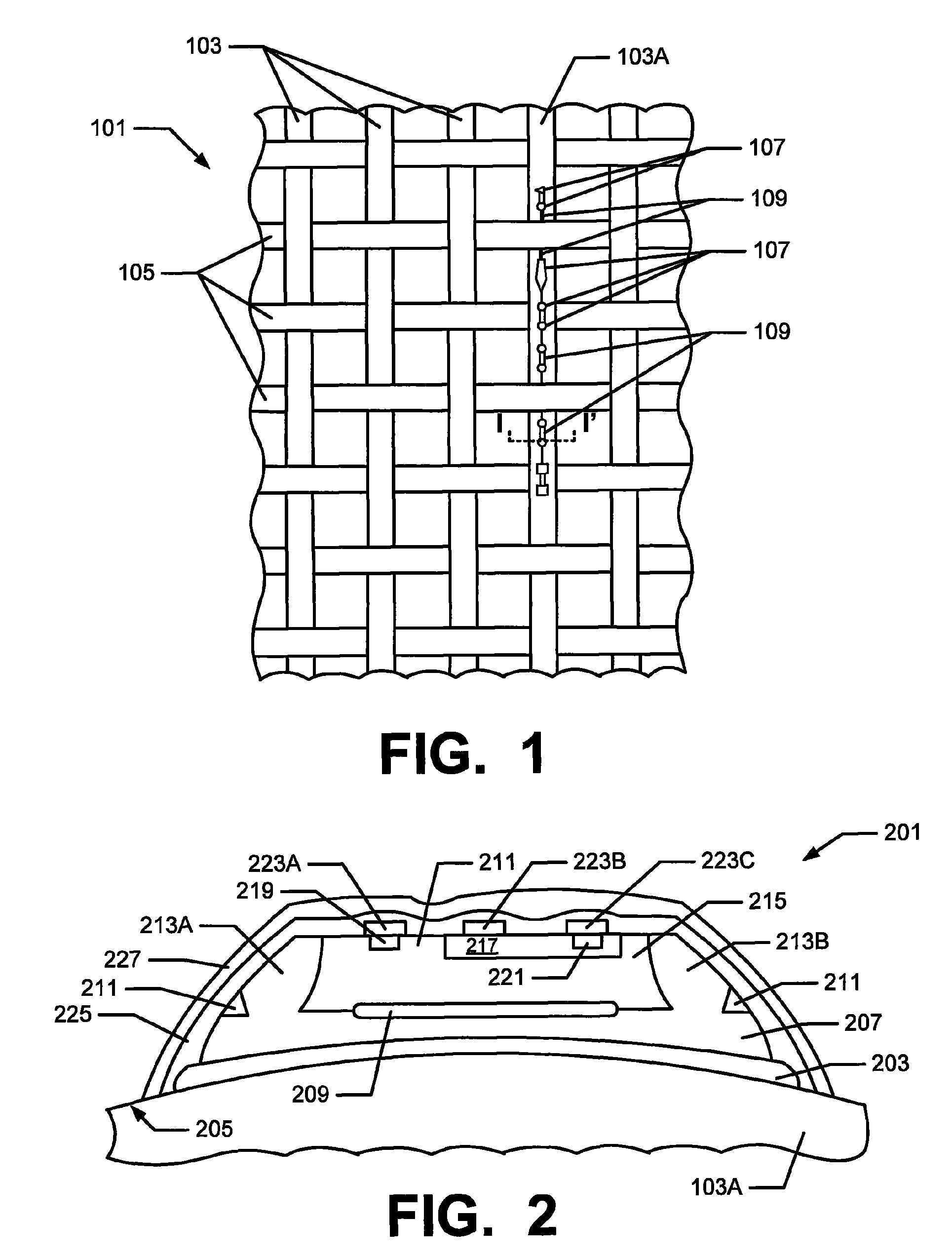

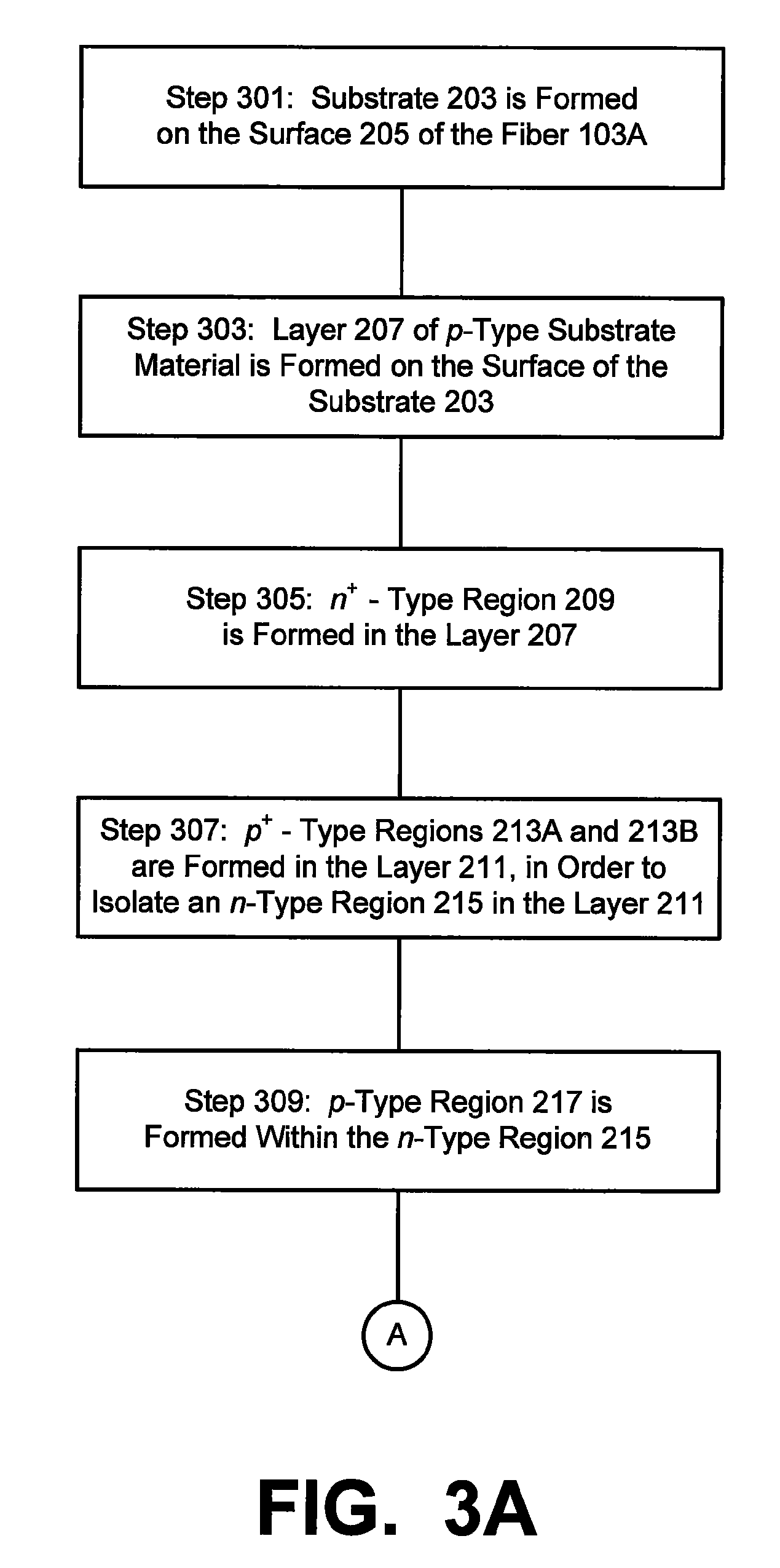

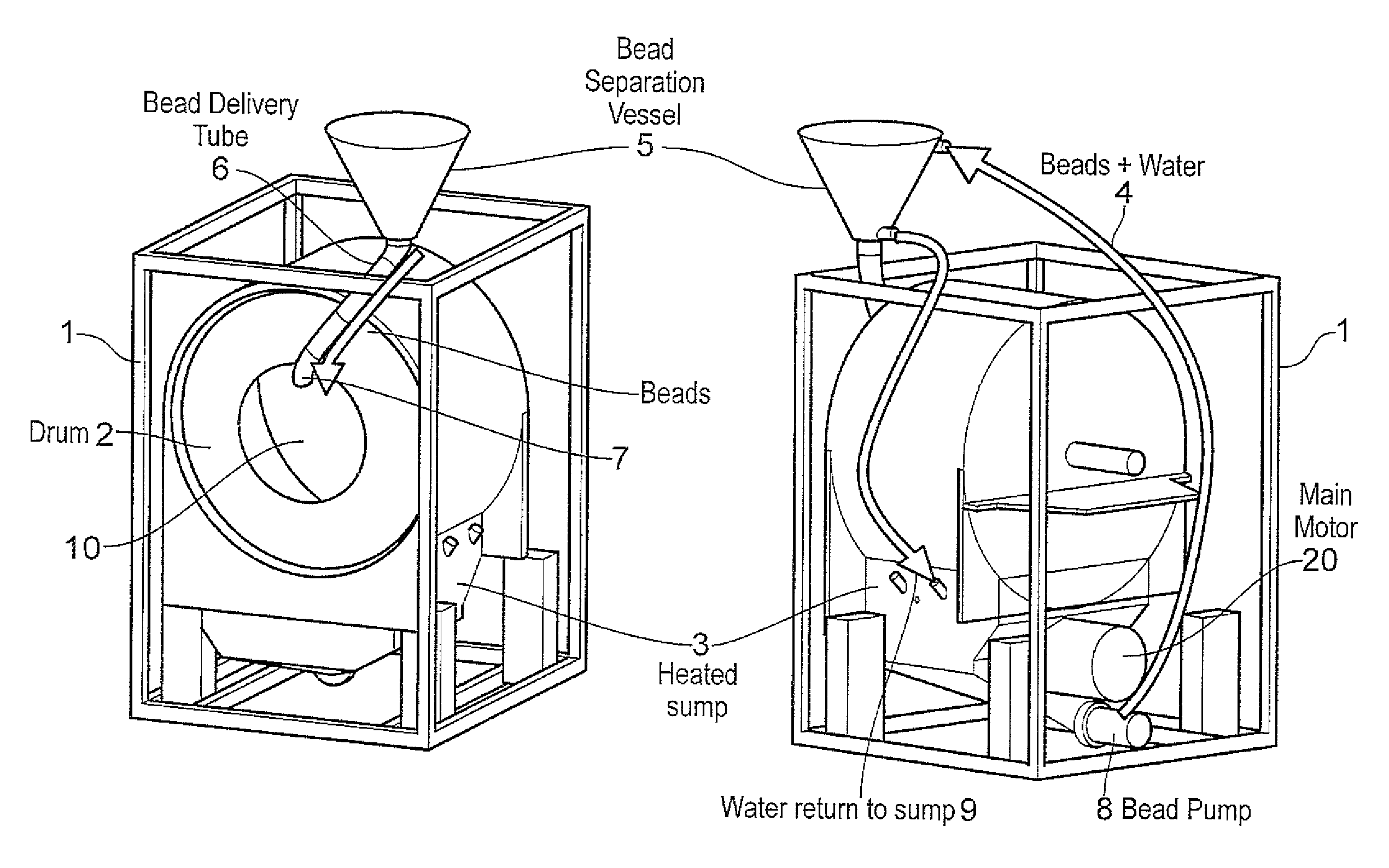

Deposition of Electronic Circuits on Fibers and Other Materials

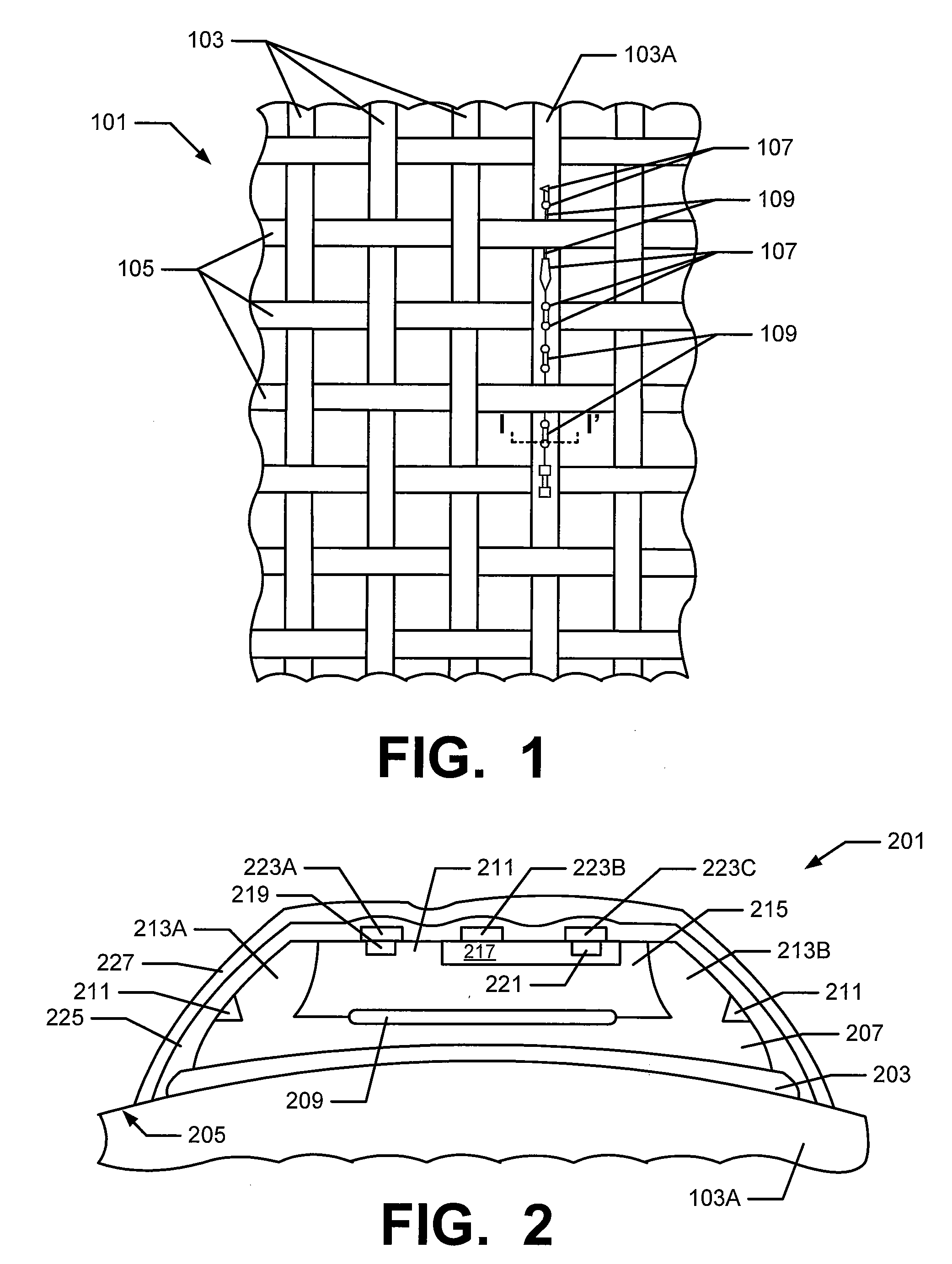

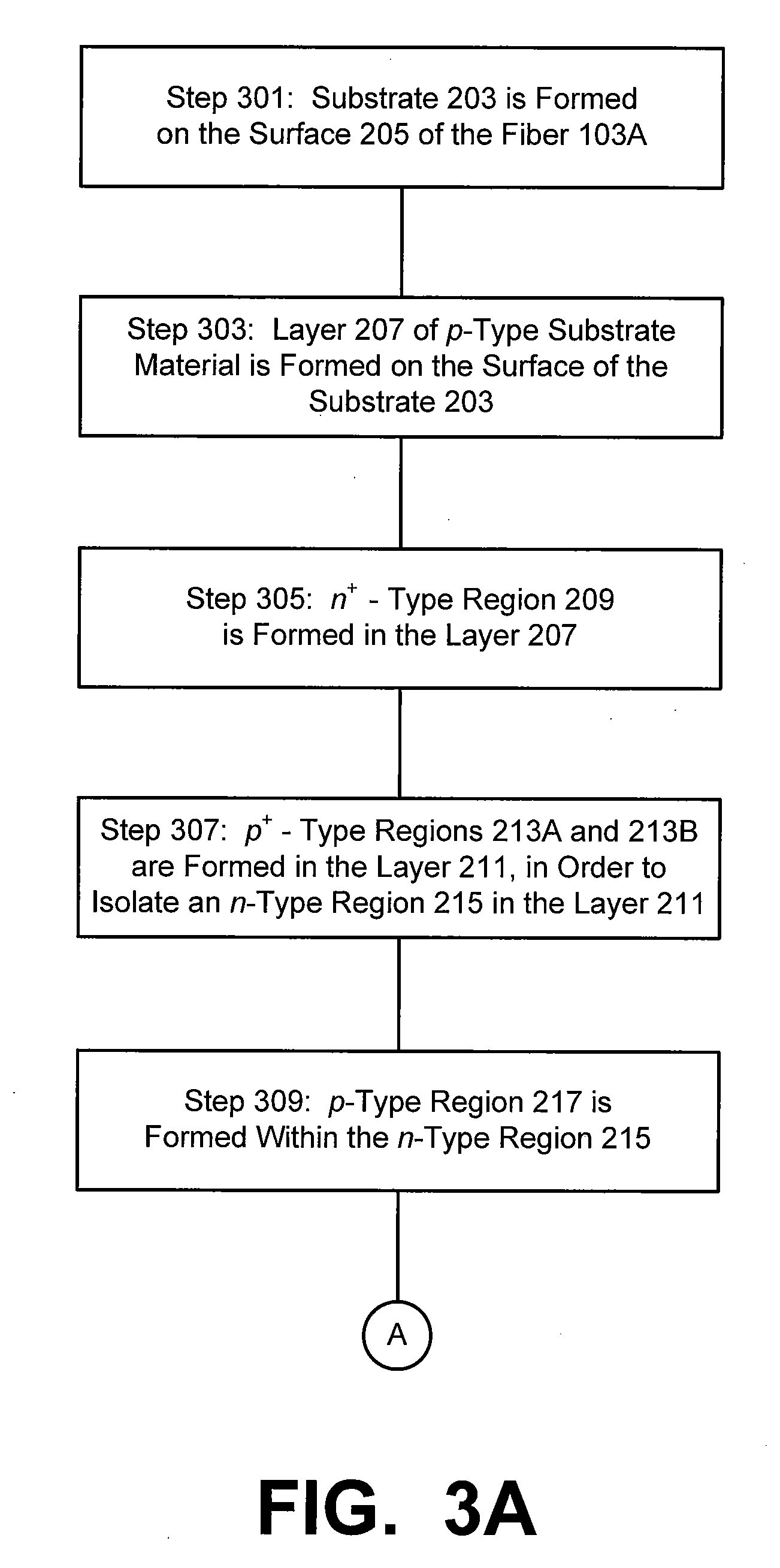

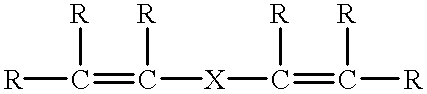

Fibers, such as textile fibers, having electrical components deposited thereon. More particularly, one or more electrical components are formed directly onto the surface of at least one fiber. The fiber having the electrical component formed thereon may then be interlaced with other fibers to form a larger piece of fabric, which can be employed to produce an article of clothing. A group of transistors and piezoelectric components forming an accelerometer may be woven onto one or more natural or synthetic fibers. The fibers may then be employed as the warp, weft, or both, of a woven piece of fabric, or used to form a knitted piece of fabric. The fabric piece can then be cut and sewn to form a wearable item, such as a shirt, a pair of pants, a hat, or the upper piece of a shoe that includes the accelerometer.

Owner:NIKE INC

Finishing of textile fibers, tissues and fabrics

InactiveUS7056845B2Improve the level ofImprove functional propertiesOther chemical processesPhysical treatmentTextile fiberEngineering

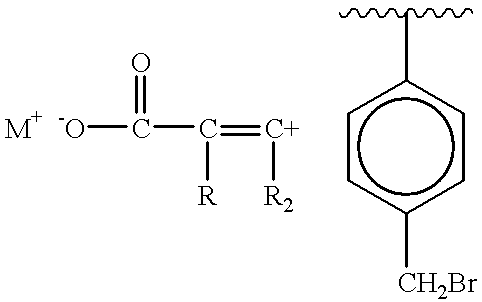

A method is provided for the application of a finishing layer to a textile support material. A water repellent or oil repellent layer, a so-called finishing layer, is applied to a textile support material selected from the group of fibers, tissues, and fabrics. The water repellent or oil repellent finishing layer comprises at least two water repellent or oil repellent components wherein a first component comprises one or more dispersants and a second component comprises one or more dispersed phases or colloids, and wherein the dispersant and the dispersed phase are present in the gel state.

Owner:SCHOELLER TEXTIL

TPE composition that exhibits excellent adhesion to textile fibers

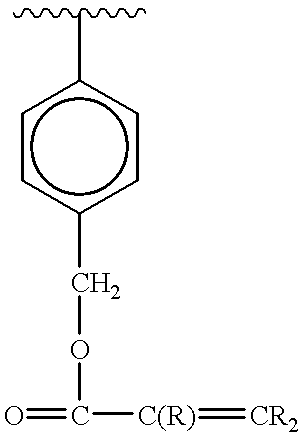

InactiveUS6503984B2Increase stiffnessHigh modulusFibre typesOther rubber adhesivesTextile fiberPolyester

A combination of a low flexural modulus and low crystallinity polyolefin and a functionalized polyolefin were found to result in an olefin composition with excellent adhesion to metals and polar polymers (e.g. polyesters, polyamides, etc) especially fibers therefrom. When these two polyolefins were added to a thermoplastic vulcanizate (e.g. used to partially or fully replace the semicrystalline polyolefin of a thermoplastic vulcanizate), the thermoplastic vulcanizate was found to have the necessary adhesion to form fiber reinforced thermoplastic vulcanizate.

Owner:EXXONMOBIL CHEM PAT INC

Textile dyeing wastewater advanced treatment recycling technology

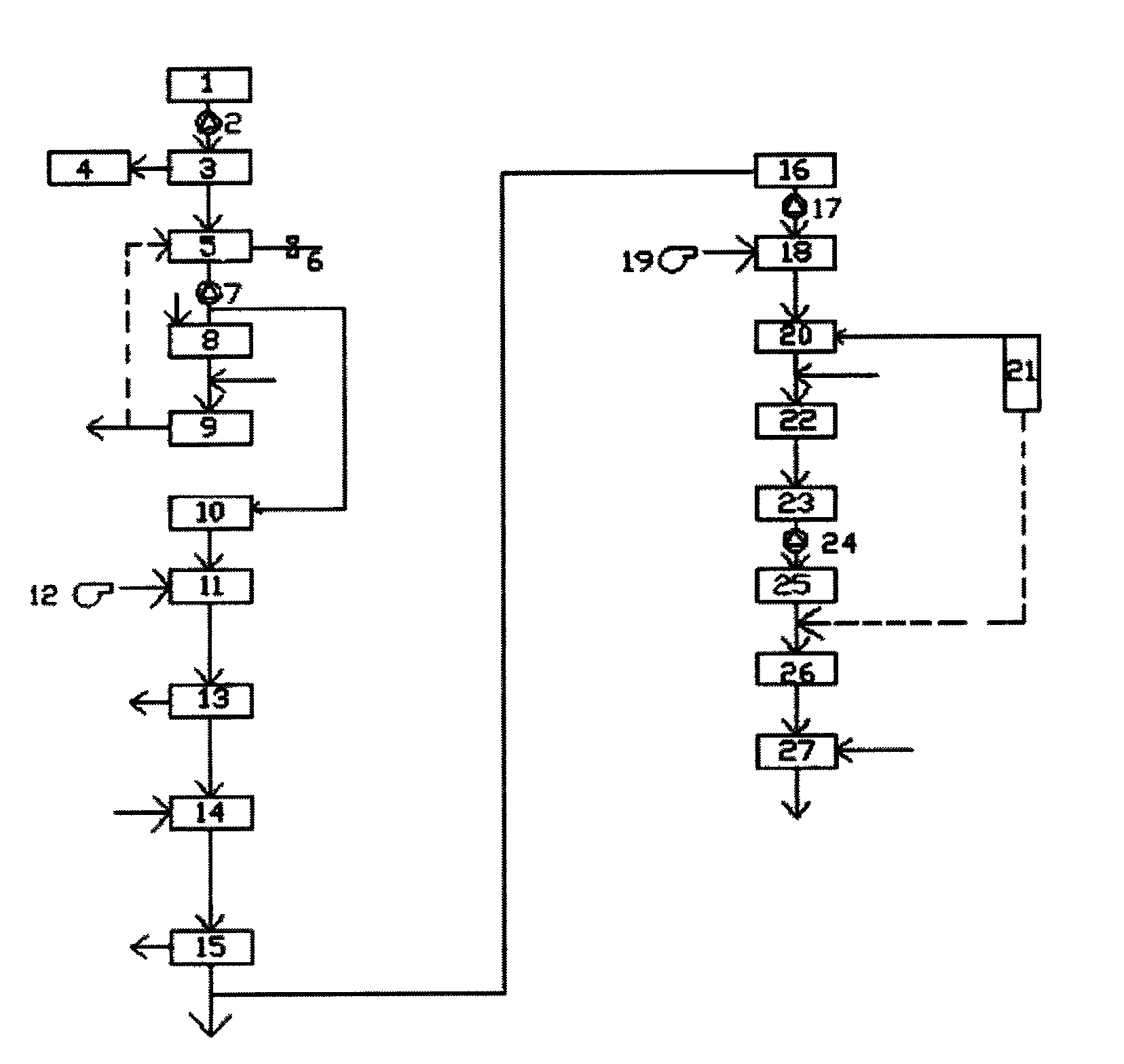

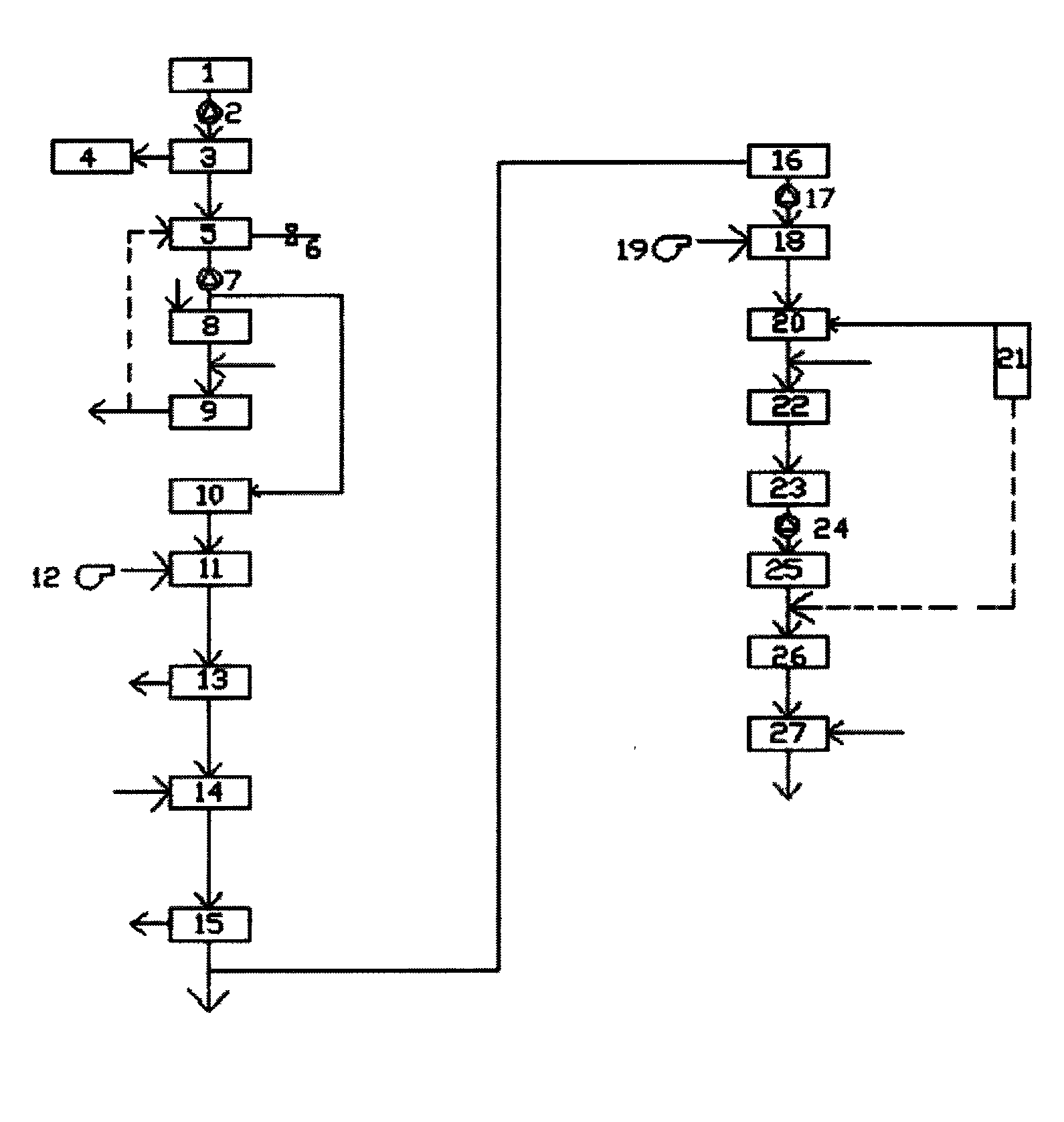

InactiveCN102145965AReduce chromaImproved BioprocessingMultistage water/sewage treatmentWater/sewage treatment by neutralisationTextile fiberChemical treatment

The invention discloses a textile dyeing wastewater advanced treatment recycling technology. The technology comprises the following steps: filtering to remove textile fibers; cooling; neutralizing, degrading organic matters and decomposing, replacing or degrading (cracking) the chormophoric groups of the organic matters to reduce the chroma of the wastewater; performing biochemical treatment with the biomembrane; precipitating to ensure that the precipitated sludge enters a sludge treatment system and the supernatant enters a flocculation pool; performing chemical treatment, namely adding a medicament in the flocculation pool to remove the suspended matter (SS), CODcr (chemical oxygen demand), BOD (biochemical oxygen demand) and chroma of the water; performing secondary precipitation to ensure that the free SS is precipitated and the wastewater is decolored further; separating to remove and degrade the chloride ions of the reuse water; performing secondary biochemical treatment to further reduce the concentrations of the SS, CODcr and BOD in wastewater; performing ozone oxidation treatment, decoloring, degrading organic matters; performing chemical treatment to remove insoluble dye materials and SS and reduce the COD and chroma; and performing secondary filtration, and forming an ozone / activated carbon system to ensure that the hydroxyl radicals of activated carbon are used and the organic reaction in wastewater is adopted to decolor and degrade organic matters. The invention overcomes the defects of the existing physical method, chemical method and chemical method treatment technologies; and the technology has been used in many enterprises, and the good treatment effects are obtained.

Owner:李斌 +2

Deposition of electronic circuits on fibers and other materials

Fibers, such as textile fibers, having electrical components deposited thereon. More particularly, one or more electrical components are formed directly onto the surface of at least one fiber. The fiber having the electrical component formed thereon may then be interlaced with other fibers to form a larger piece of fabric, which can be employed to produce an article of clothing. A group of transistors and piezoelectric components forming an accelerometer may be woven onto one or more natural or synthetic fibers. The fibers may then be employed as the warp, weft, or both, of a woven piece of fabric, or used to form a knitted piece of fabric. The fabric piece can then be cut and sewn to form a wearable item, such as a shirt, a pair of pants, a hat, or the upper piece of a shoe that includes the accelerometer.

Owner:NIKE INC

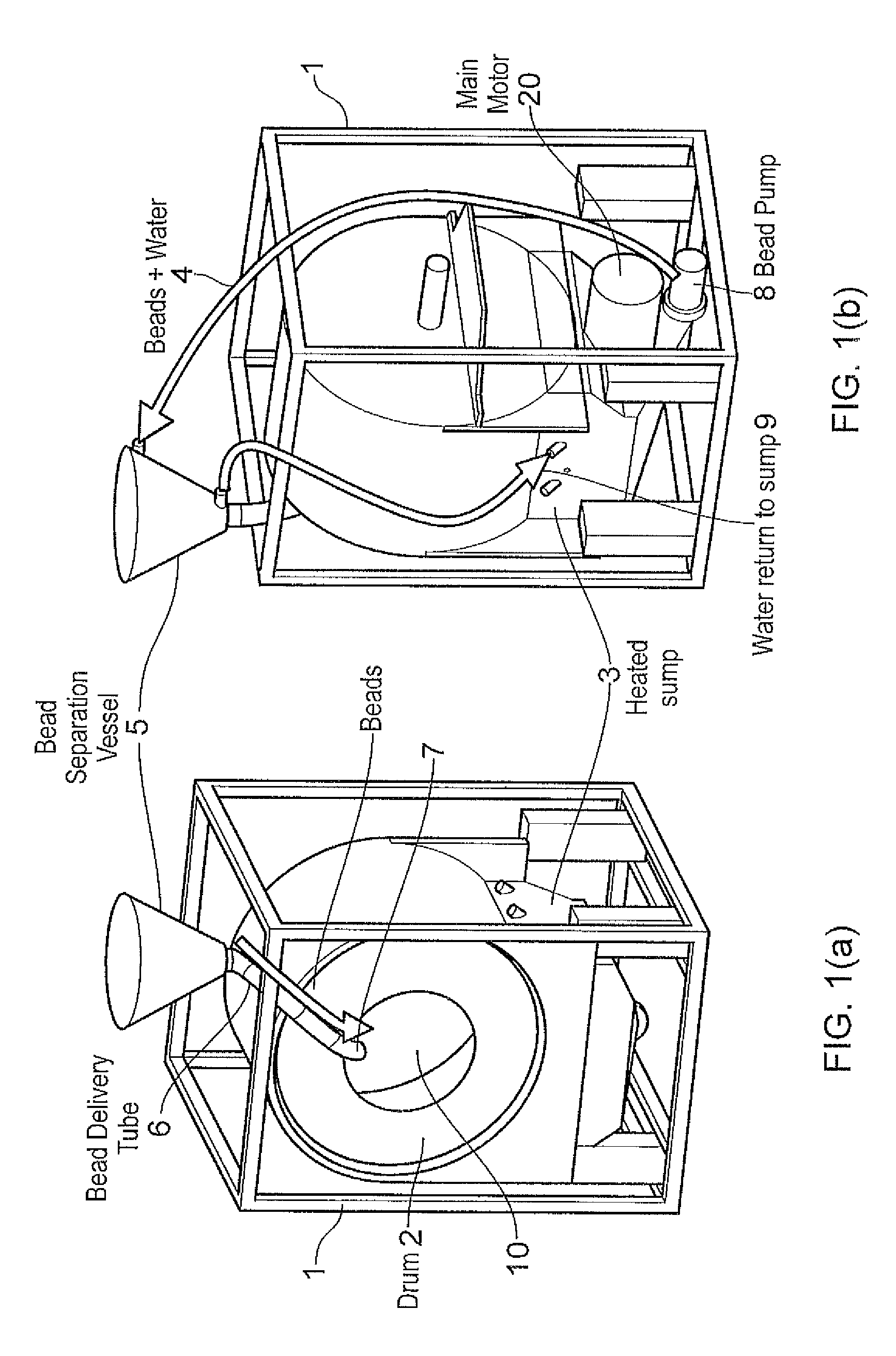

Cleaning method

InactiveUS9121000B2Enhance appearance and other propertyImprove liquidityInorganic/elemental detergent compounding agentsBiocideTextile fiberPolyester

The invention provides a method and formulation for cleaning a soiled substrate, the method comprising the treatment of the moistened substrate with a formulation comprising a multiplicity of polymeric particles, wherein the polymeric particles comprise at least one antimicrobial agent. Preferably, the substrate is wetted so as to achieve a substrate to water ratio of between 1:0.1 to 1:5 w / w. Optionally, the formulation additionally comprises at least one additional cleaning agent and, in this embodiment, it is preferred that the polymeric particles are mixed with the at least one additional cleaning agent. Preferably, the additional cleaning material comprises a surfactant, which most preferably has detergent properties. Most preferably, the substrate comprises a textile fiber. Typically, the polymeric particles comprise particles of polyester or nylon, most preferably in the form of beads. The results obtained are very much in line with those observed when carrying out conventional aqueous cleaning processes and the method provides the significant advantage that the use of antimicrobial agents in or on the polymer bead greatly improves the overall hygiene in the washing machine by preventing mold and bacterial growth on the polymer particle surfaces, particularly at low temperatures.

Owner:XEROS LTD

Sublimation Printing Processes and Fabric Pretreatment Compositions for Ink Jet Printing onto Arbitrary Fabrics

InactiveUS20110169901A1Outstanding washfastness to repeated launderingImprove washing fastnessTransfer printing processDyeing processTextile fiberEngineering

An ink jet printing process for sublimation printing of arbitrary textile fiber substrates, wherein the fiber materials are pretreated with an aqueous coating composition, enabling ink jet printing of natural and regenerated cellulosic fibers and blends thereof with synthetic fibers, by direct sublimation or sublimation transfer printing, applying to said fibers a novel textile coating or fabric pretreatment composition, wherein said textile coating or fabric pretreatment comprises: an aqueous dispersion of fluoropolymer particles and a non-fluoropolymer binder.

Owner:ADVANCED COMM SOLUTIONS

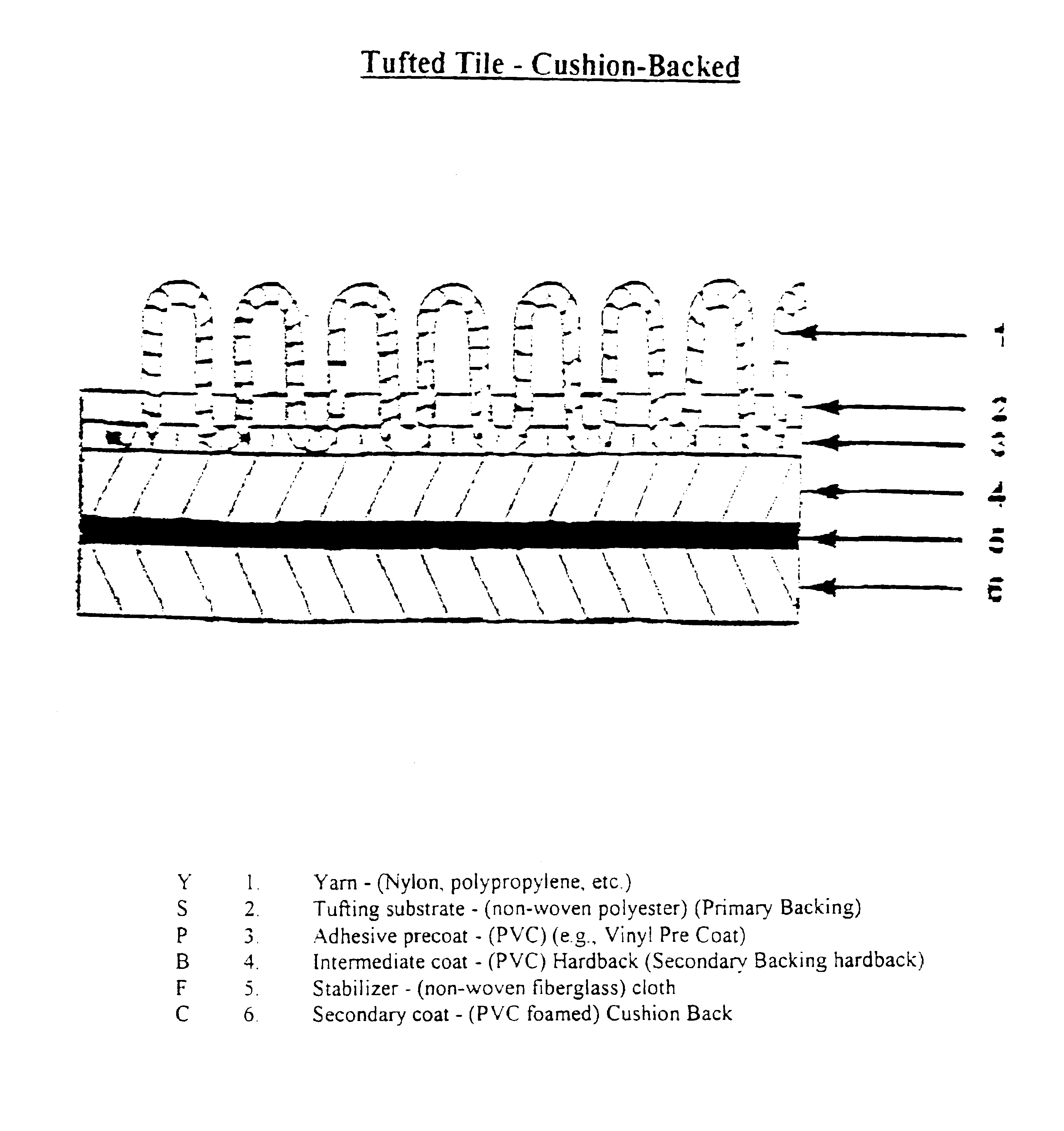

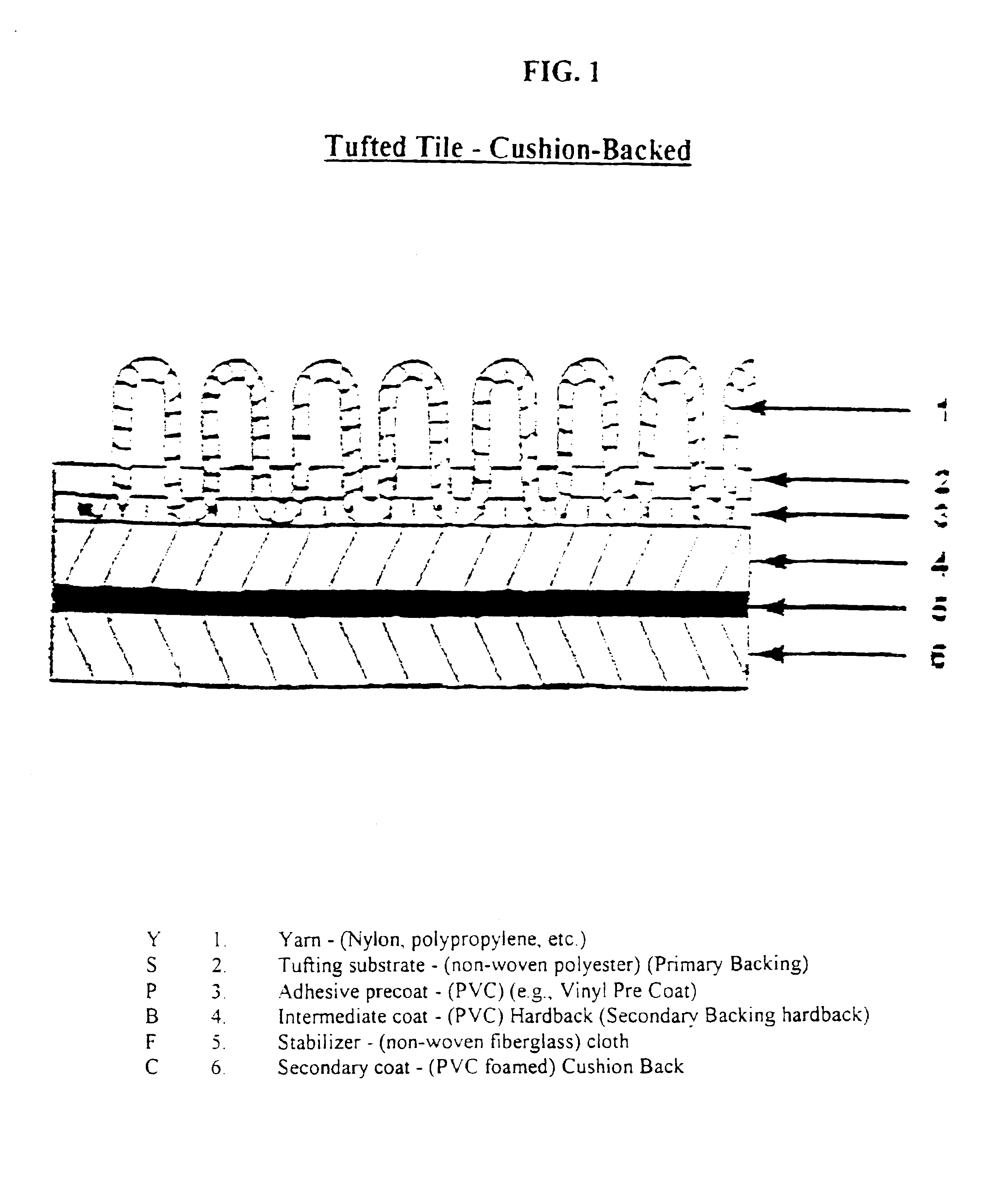

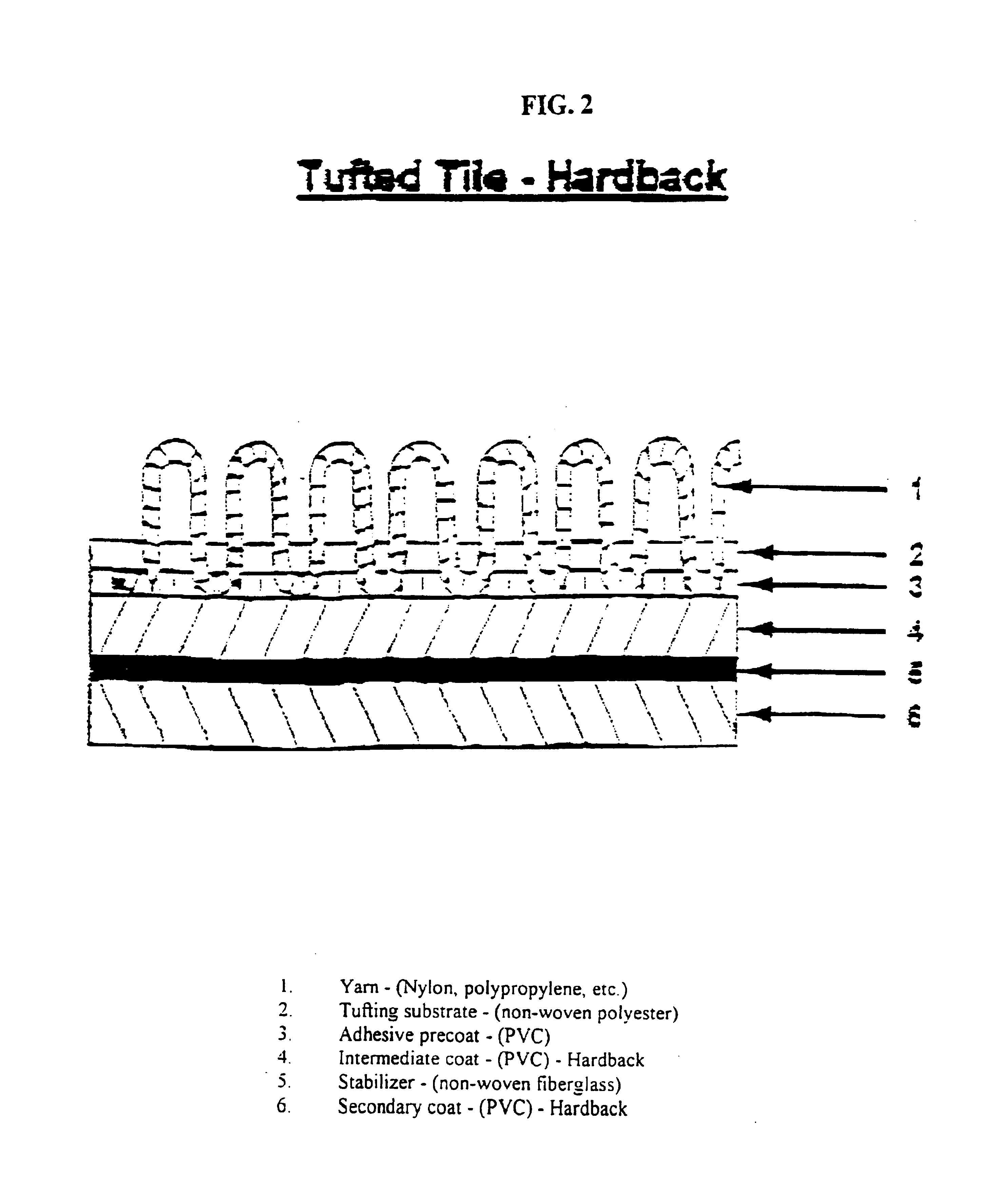

Surface covering backing containing polymeric microspheres and processes of making the same

A secondary backing for surface coverings is disclosed which comprises at least one thermoplastic material optionally having polymeric microspheres dispersed therein. A textile substrate comprising a primary backing with textile fibers extending upwardly from the backing and forming a surface and the above-described secondary backing attached thereto is also described. Methods of making the textile substrate and the secondary backing which can be foam or hardback are also described. Also described is a resilient surface covering, such as vinyl flooring, using the secondary backing of the present invention in one or more layers.

Owner:MANNINGTON MILLS

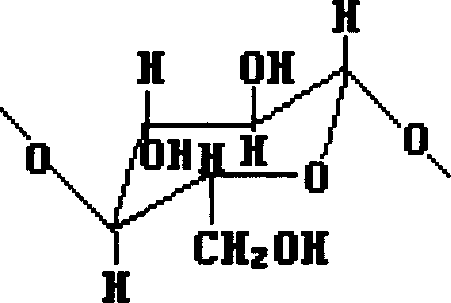

Process for preparing modified cotton fibre

The invention relates to a modified cotton fiber manufacturing method. It belongs to textile fiber material modification technique. It includes the following steps: boiling-off twisted cotton yarn and bleaching; processing selective oxidation reaction by putting the cotton yarn into periodate with 0.1-3g / L concentration at 30-60 centigrade degree for 1-2h; removing the oxidant; washing; dehydrating; drying; gaining oxidation cotton fiber with less than 25% strength stretch ratio; using the matter with -NH2, -OH active group to graft and cross link. Thus the cotton fiber is modified to gain multifunction composite cotton fiber. It can increase its wearability and addition value, expand application area, and solve the cotton fiber function in textile fiber material field.

Owner:SUZHOU UNIV

Preparation method of essence microcapsules

InactiveCN102039108AGood chemical stabilityHigh mechanical strengthEssential-oils/perfumesMicroballoon preparationTextile fiberEthylic acid

The invention discloses a preparation method of essence microcapsules. The preparation method comprises the following steps: (1) dissolving chitosan in acetum; (2) adding emulsifier and essence into the chitosan acetum for high-speed emulsification and dispersion to obtain the chitosan essence emulsion; (3) adding the mixed solution of sodium alginate and sodium tripolyphosphate dropwise into the chitosan essence emulsion; (4) adjusting the pH value of the system to 5-7 with NaOH solution to obtain the condensed essence microcapsules; and (5) adding cross-linking agent into the condensed essence microcapsule system to perform chemical cross-linking process on the condensed essence microcapsules to obtain the essence microcapsules. For the essence microcapsules prepared according to the method disclosed by the invention, as chemical cross-linking process is implemented on the walls of the capsules, the density of the capsule walls and the resistance to the solution alkalinity / acidity are improved, and the application stability of the essence microcapsules is increased; moreover, with small size, the capsules can easily permeate into textile fiber, and the water-washing resistance of the textile fiber is greatly improved.

Owner:广州市戴文高分子材料科技有限公司 +1

Element-negative-ion-releasing sterilizing mite-preventing electromagnetic-wave-preventing fire-retarding nano-grade fabric used in vehicles

InactiveCN102400238AMonocomponent protein artificial filamentMonocomponent cellulose artificial filamentTextile fiberSlurry

The invention relates to element-negative-ion-releasing sterilizing mite-preventing electromagnetic-wave-preventing fire-retarding nano-grade fabric used in vehicles. The invention belongs to the technical field of textile fiber fabric production of vehicle-use nano-grade decorative fabric with functions of refreshing and air-purifying. The fabric is a nano-grade functional healthy textile. The nano-grade fabric provided by the invention is produced form chitosan, which is a natural high polymer extracted from shells of shellfishes, crabs and shrimps; a natural antibiotic humectant SCJ-920; a high-efficiency mite-preventing antibacterial agent SCJ-998; nano-grade negative-ion powder SCJ-900; negative-ion far infrared healthcare slurry 700; a fire retarding finishing agent ATF; an aromatic finishing agent SCM; electromagnetic-wave-preventing ferrites Fe2O3, Fe3O4, and Fe; substances such as TiO2, Al2O3, and ZnO used for providing far infrared radiation; an Ag-embedded nano-TiO2 (AT) antibacterial agent; nano-grade selenium or organic selenium which is rare on earth; organic germanium, Chinese herbal medicines, essential oil, maifanite, tourmaline nano-grade powder and other materials. A mixture of the materials is added to cotton, linen, wool, silk, polyamide fiber, acrylic fiber, terylene or viscose fiber spinning liquid, and the nano-grade fabric is produced through weaving.

Owner:丁一

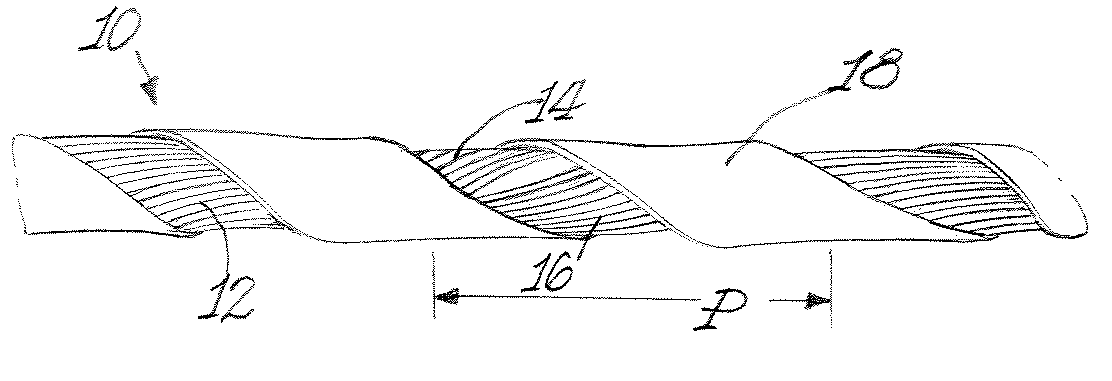

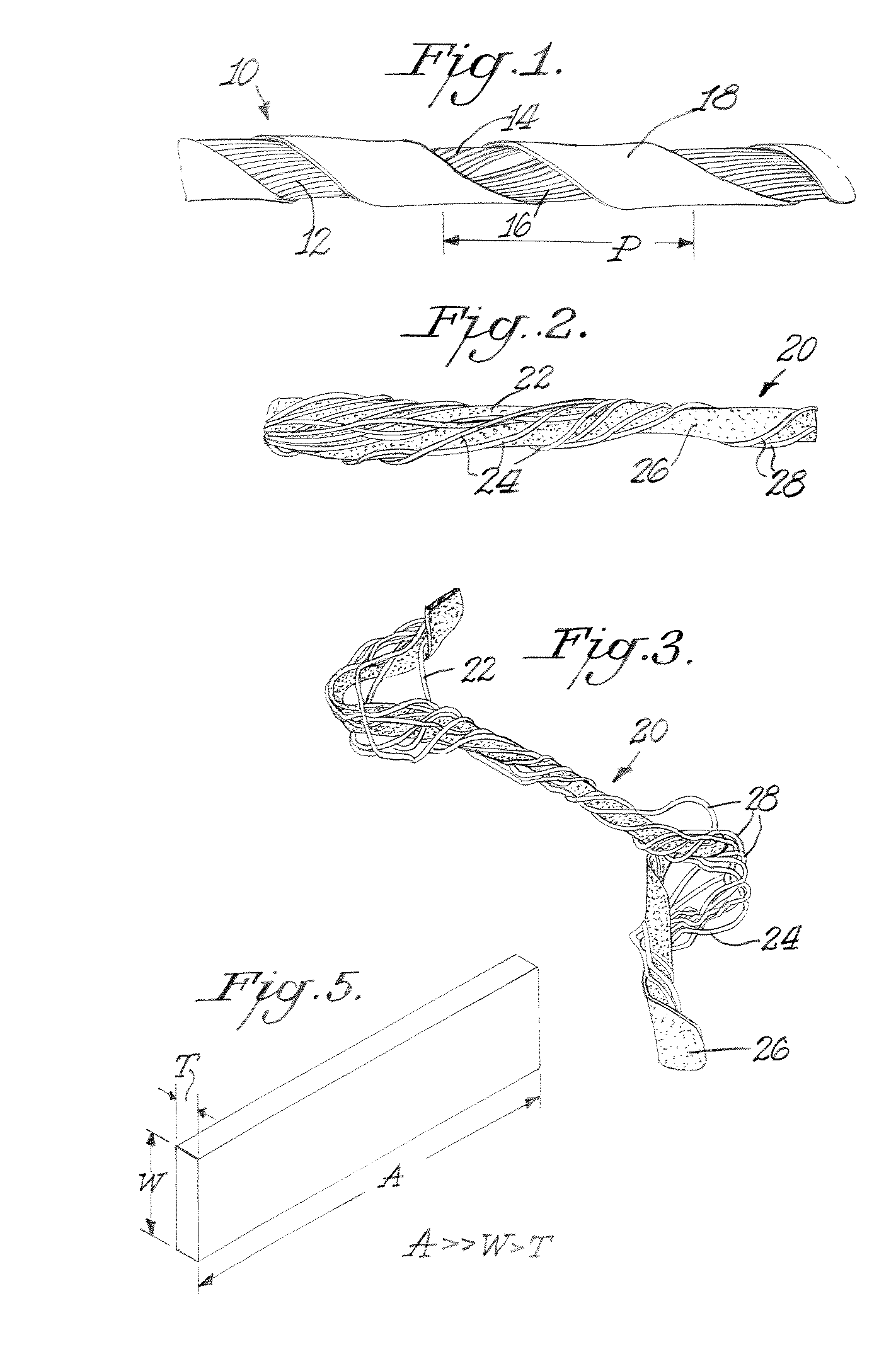

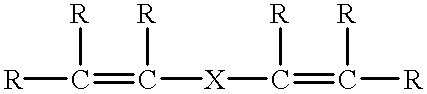

Energy active composite yarn, methods for making the same, and articles incorporating the same

Energy active composite yarns include at least one textile fiber member of either an elastic or inelastic material, and at least one functional substantially planar filament, which surrounds or covers the textile fiber member. The composite yarns can include an optional stress-bearing member, which also surrounds or covers the textile fiber member. The composite yarns may be multifunctional, meaning the functional substantially planar filament can exhibit combinations of electrical, optical, magnetic, mechanical, chemical, semiconductive, and / or thermal energy properties.

Owner:ADIDAS

Anti bacteria natural silk composite nano-fiber material and its preparation method

InactiveCN1904159AGood tissue compatibilityNon-toxicConjugated cellulose/protein artificial filamentsWet spinning methodsTextile fiberResist

This invention discloses a compound antibacterial silk nanometer fibrous material, accounting for weight its component proportion are: Sericin protein 58-90%; chitosan or chitin 0-40%, antibacterial agent 0-5%, electric conduction 1-4%,crossing linking 1-4%. Its process is: dissolve the pure sericin protein, antibiotics separately in polar solvent, join electric conduction medicinal preparation and crosslinking agent, using the static electricity spinning technique, making the average aperture for 0.5-5.0 micron, factor of porosity 60-90%, the mean diameter is 40-100nm and the material is nanometer textile fiber adhesive-bonded membrane. This invention has good organization compatibility with human body, Antibiotics and sericin insoluble is in homogeneous solvent, massive holes among the nanometer textile fiber adhesive-bonded membrane, which has outstanding aqueous percolation permeability, antibacterial agent distributes evenly in the nanometer textile fiber, and the medicine release effect is perfect, so it can be a kind of ideal resist bacteria injured medical material.

Owner:SUZHOU UNIV

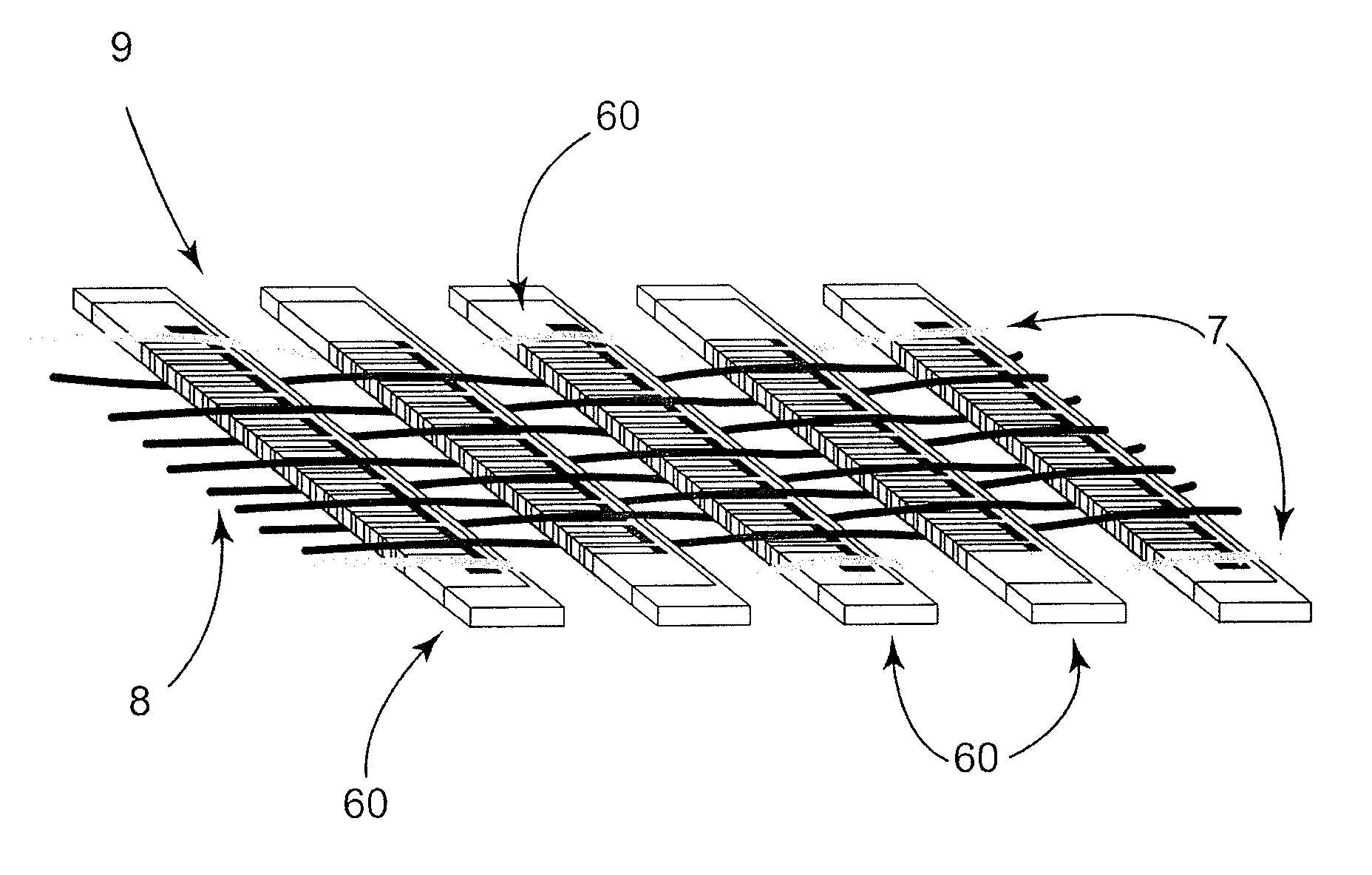

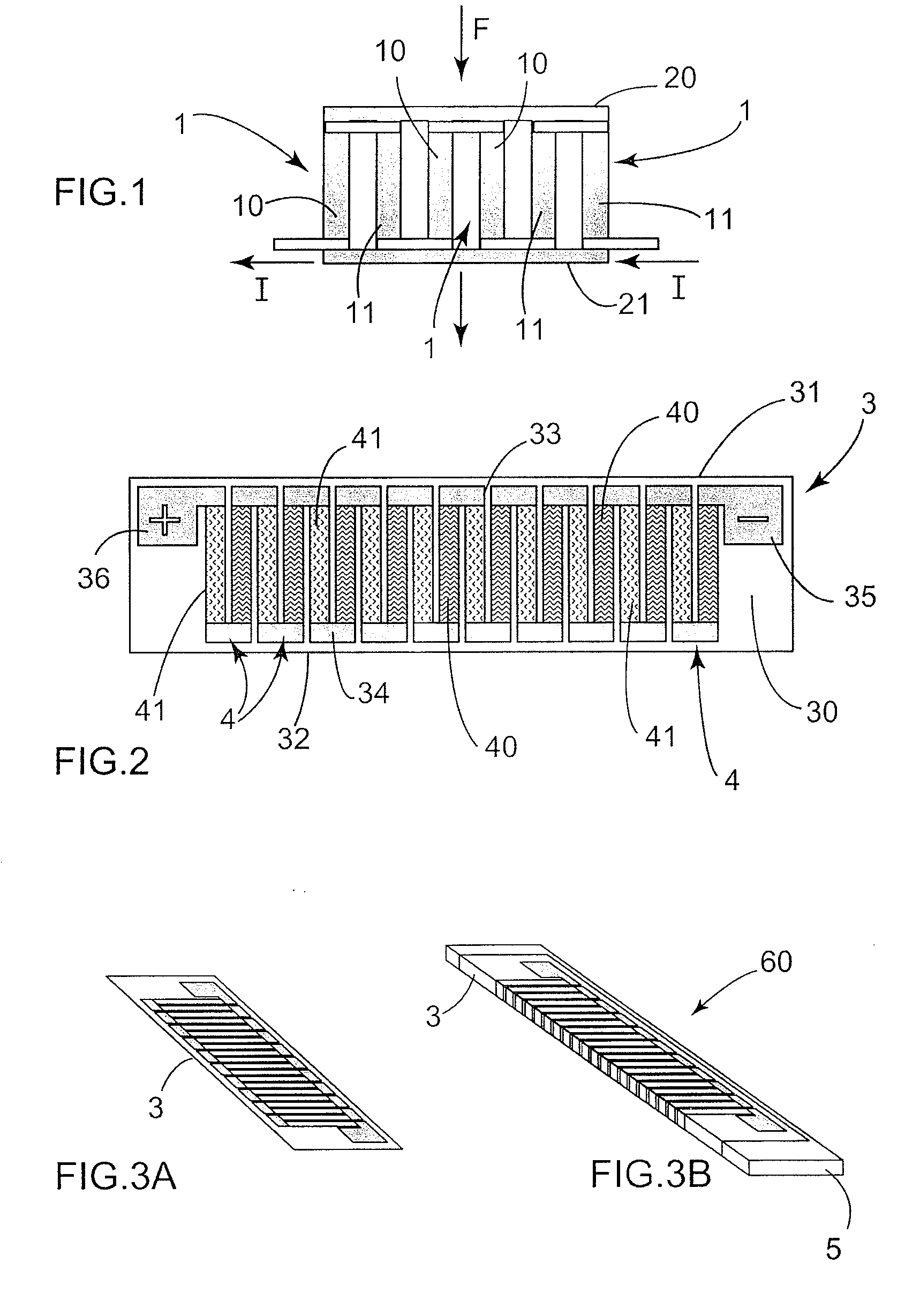

Thermoelectric means and fabric-type structure incorporating such a means

InactiveUS20090025774A1Easy to performThermoelectric device with peltier/seeback effectThermoelectric device junction materialsTextile fiberThermoelectric materials

The invention relates to a thermoelectric means (60) that can be woven or knitted, taking the form of an elongate body and having on its surface at least one converter for converting thermal energy into electrical energy. The invention also relates to a structure for converting a temperature difference over the thickness of the structure into electricity, which consists of an assembly formed by the interlacement of textile fibers (8), of said thermoelectric means (60) and of connection means (7).

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

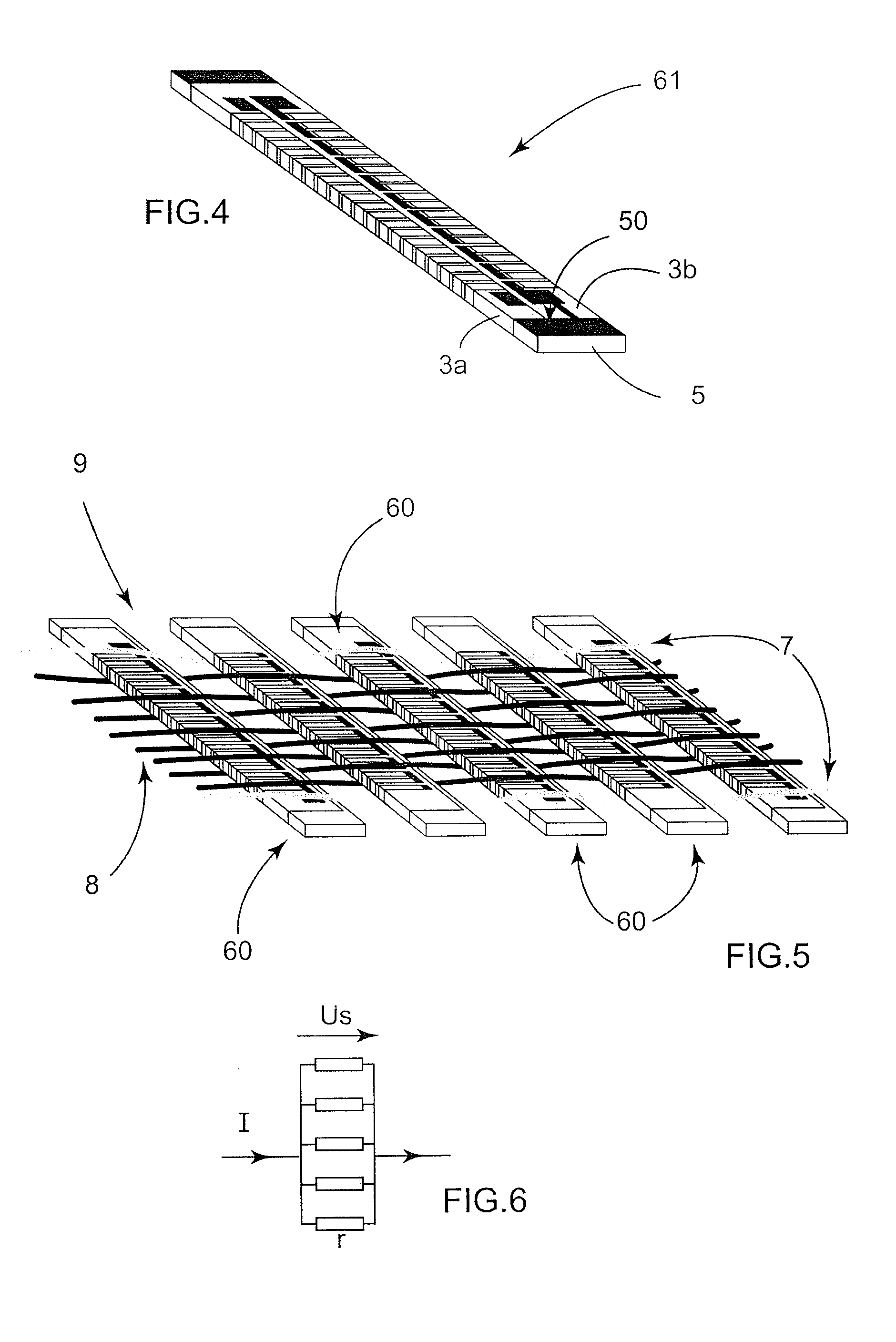

Degradable nonwoven fabric and method for producing same

InactiveCN101302681AEasy to degradeGood flexibilityPaper/cardboard layered productsNon-woven fabricsTextile fiberRough surface

The invention discloses a degradable non-woven fabric and belongs to the technical field of the processing of non-woven products. The degradable non-woven fabric consists of the following raw materials by weight: 1 to 80 parts of short lignosol fiber, and 99 to 20 parts of short textile fiber. The technical proposal disclosed by the invention combines the short lignosol fiber and the short textile fiber into the degradable non-woven fabric, thus not only making up for the disadvantages in the prior art that single lignosol fiber products have bad softness and low intensity, and are fragile and easy to generate dregs, but also eliminating the disadvantages in the prior art that single non-woven fabric products of the short textile fiber have rough surface, bad hydroscopic property and non-degradable property, and obtaining the degradable non-woven fabric which has good softness, ideal intensity and excellent hydroscopic property, and is easy to degrade after disuse and favorable for environmental protection.

Owner:CHANGSHU FEILONG NON WOVEN MACHINERY

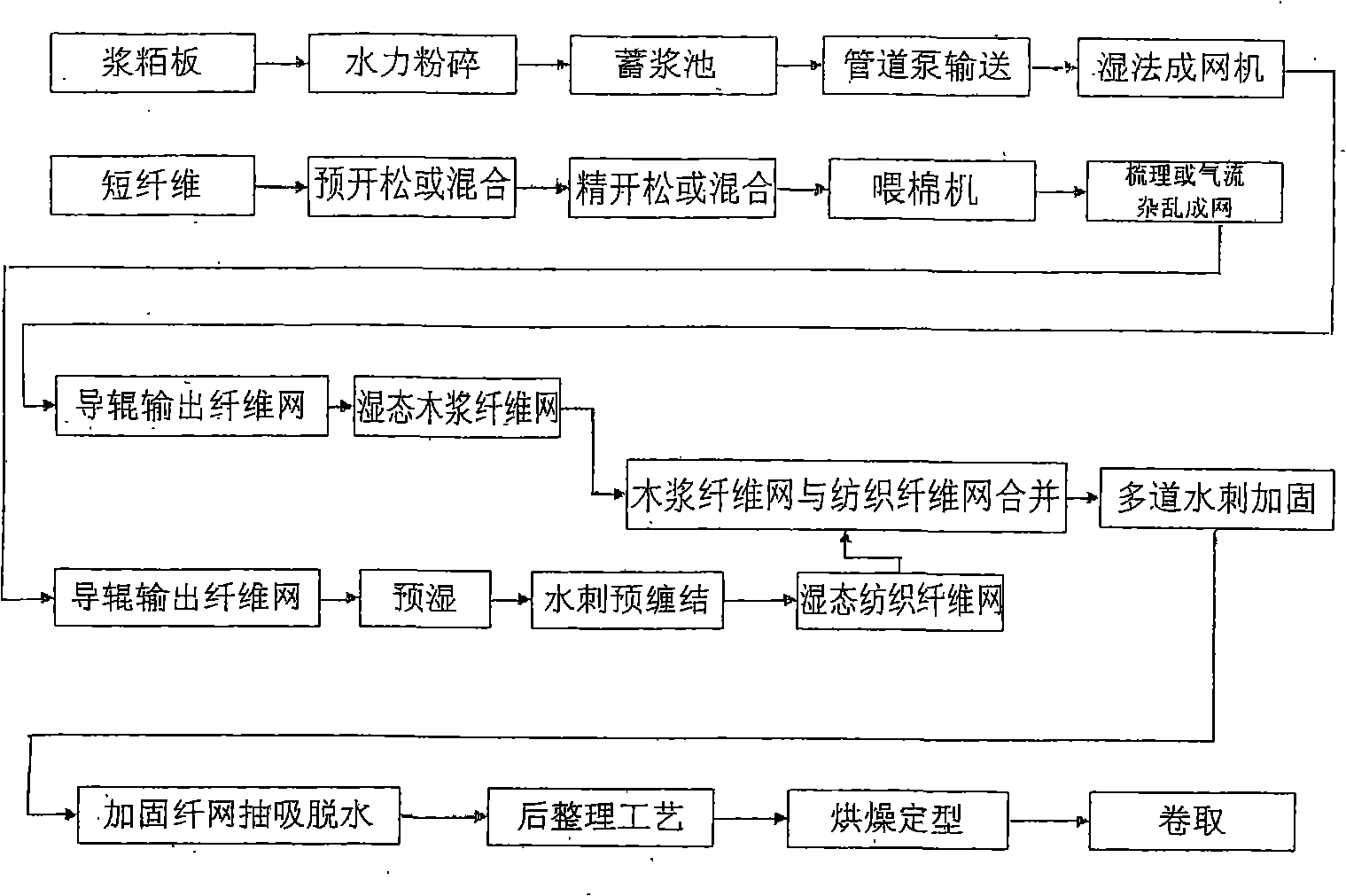

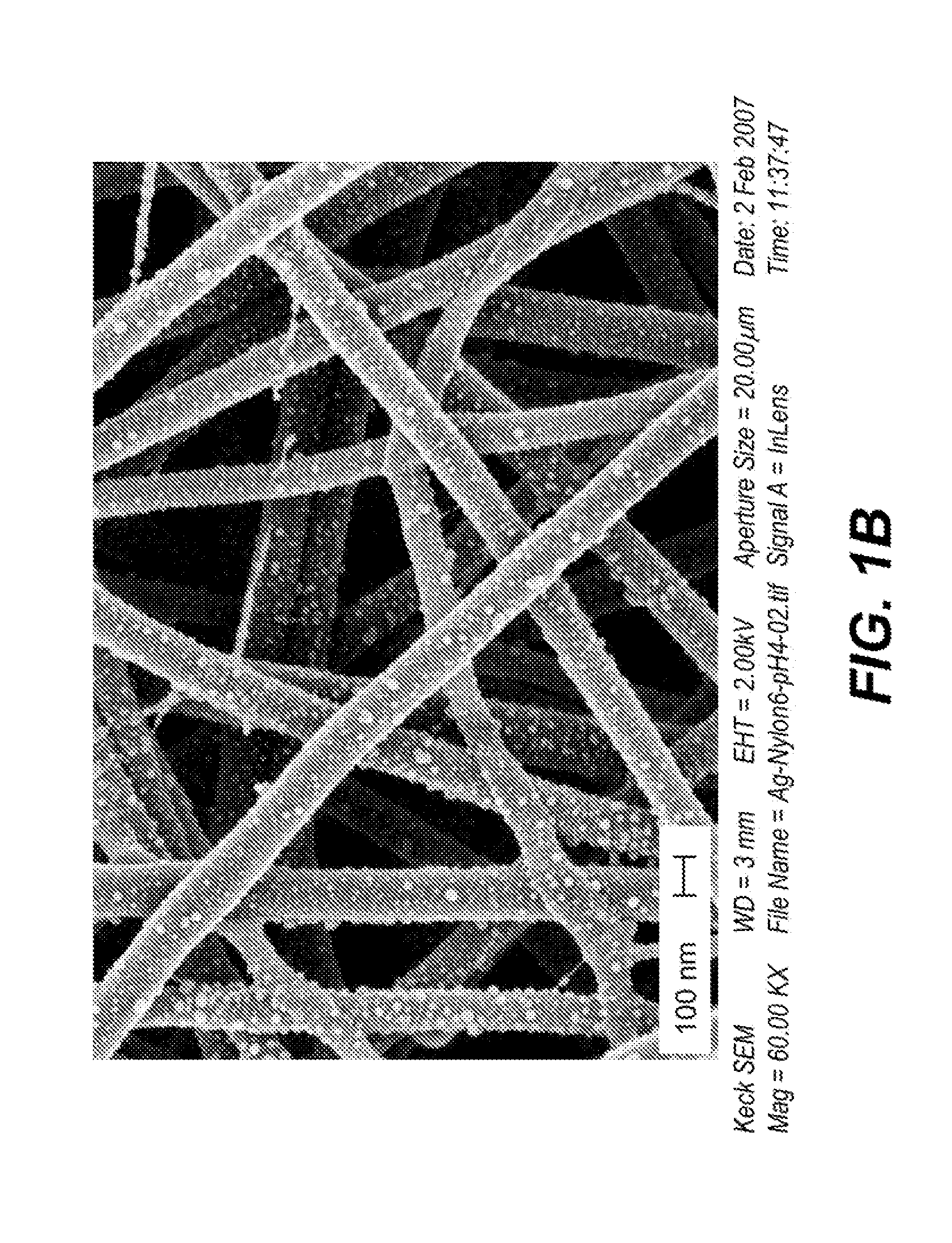

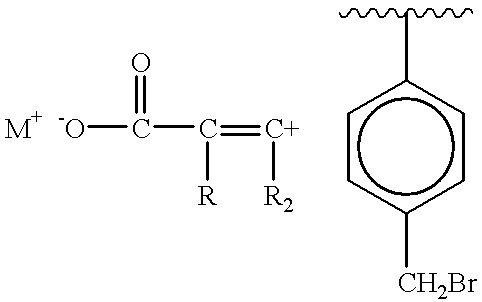

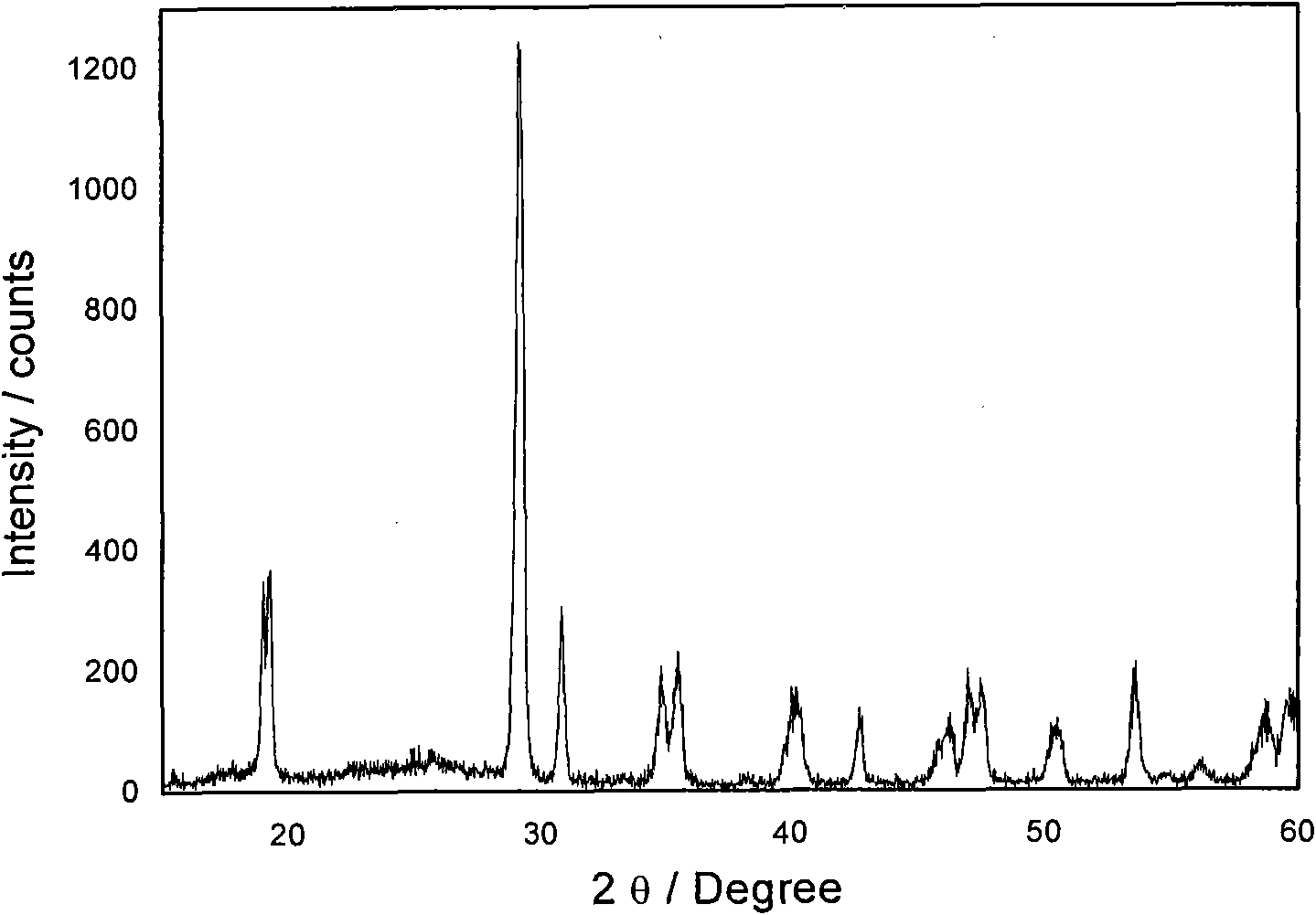

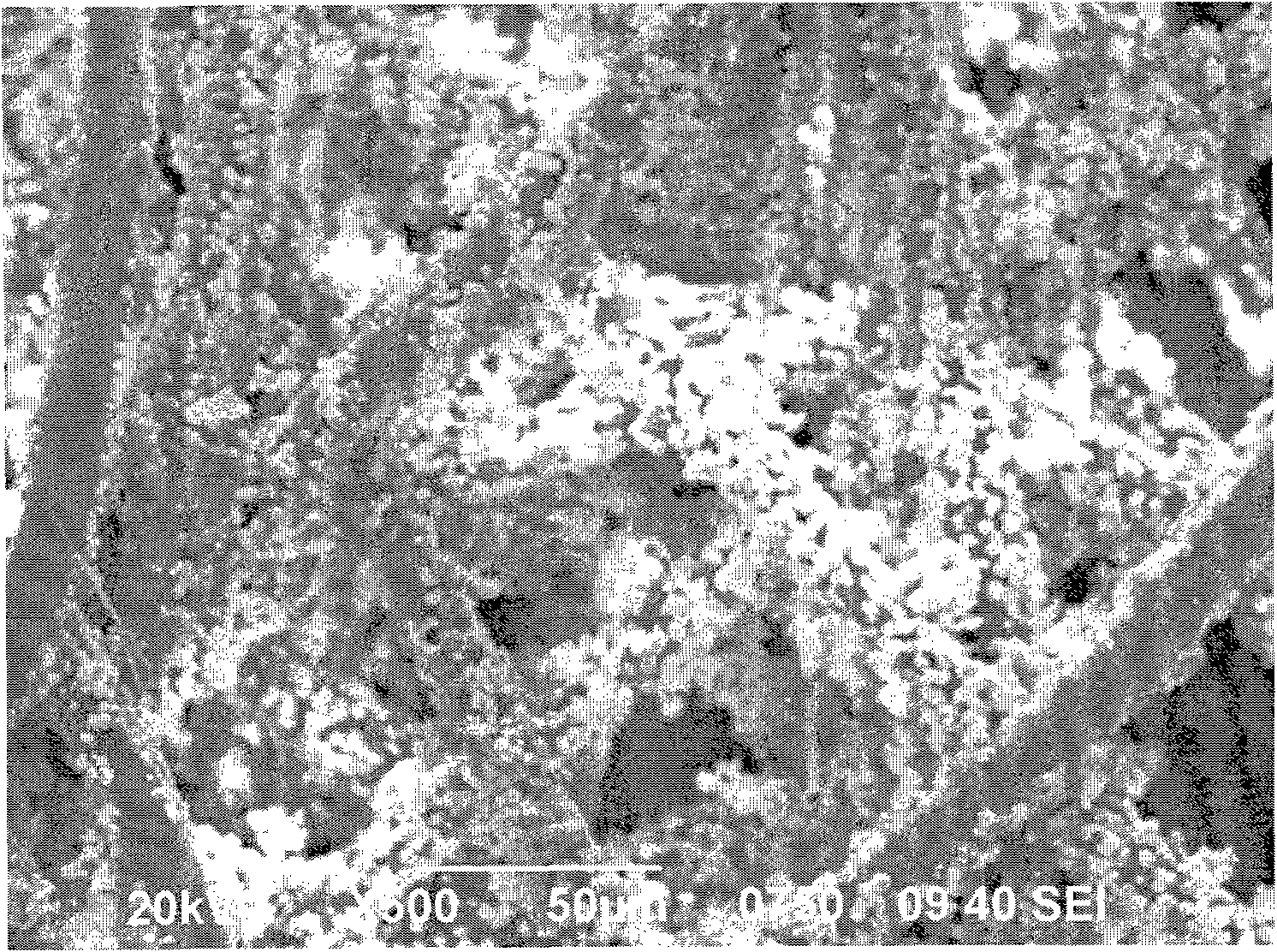

Conformal particle coatings on fiber materials for use in spectroscopic methods for detecting targets of interest and methods based thereon

InactiveUS20120058697A1Good spectral characteristicsMaterial nanotechnologyLayered productsTextile fiberFluorescence

Textile fibers and other fibrous substrates functionalized with particles are provided for use in the detection of targets of interest by spectroscopic methods. In one embodiment, a substrate is provided that comprises a conformal coating on its surface, wherein the coating comprises a plurality of chemically functional particles that are spectroscopically enhancing. Methods for producing such functionalized textile fibers are also provided. These textiles can be used as platforms for spectroscopic detection, including surface-enhanced Raman scattering (SERS), surface-enhanced infrared absorption (SEIRA), and surface-enhanced fluorescence (SEF). Functionalized textile fibers for use in the signature detection methods are produced by performing layer-by-layer self-assembly of particles on natural and synthetic textile substrates.

Owner:CORNELL UNIVERSITY

A tpe composition that exhibits excellent adhesion to textile fibers-

InactiveUS20020010265A1Increase stiffnessHigh modulusFibre typesOther rubber adhesivesTextile fiberPolyester

A combination of a low flexural modulus and low crystallinity polyolefin and a functionalized polyolefin were found to result in an olefin composition with excellent adhesion to metals and polar polymers (e.g. polyesters, polyamides, etc) especially fibers therefrom. When these two polyolefins were added to a thermoplastic vulcanizate (e.g. used to partially or fully replace the semicrystalline polyolefin of a thermoplastic vulcanizate), the thermoplastic vulcanizate was found to have the necessary adhesion to form fiber reinforced thermoplastic vulcanizate.

Owner:EXXONMOBIL CHEM PAT INC

Method for preparing composite fiber material for visible light photocatalytic degradation of organic pollutants

InactiveCN101884917ASolving Recycling ProblemsReduce chance of recombinationWater/sewage treatment by irradiationDispersed particle separationTextile fiberCompound (substance)

The invention provides a composite fiber material applied to visible light photocatalytic purification of sewage and air pollutants and a preparation method thereof. The composite fiber material is synthesized by loading a visible light response type bismuth-based photocatalytic material on a textile fiber material through a green chemical synthetic route. A powdered photocatalyst is solidly loaded by the unique net-like felt structure of the textile fiber material, so that the catalyst is prevented from losing and agglomerating during sewage treatment and air purification, and the separability and reusability are improved.

Owner:于建强 +2

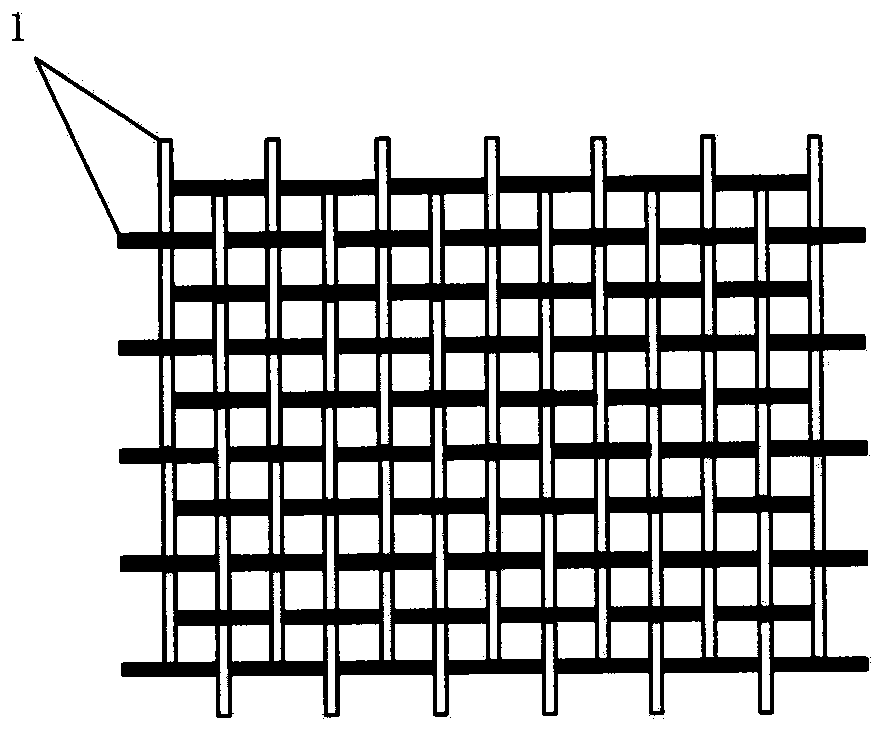

Cored piezoelectric fiber fabric

InactiveCN104233579AImplementation driveRealize functionWeft knittingSolid-state devicesTextile fiberElectricity

The invention relates to a fabric made of cored piezoelectric fibers by weaving or knitting. A plurality of cored piezoelectric fibers are parallelly woven or knitted along a same straight line or curved line direction, crosswise woven or knitted along different straight line or curved line directions, or woven or knitted to form knots extending in the straight line or curved line direction to form an area with the cored piezoelectric fibers, and the area with the cored piezoelectric fibers is woven or knitted with an area formed by weaving or knitting other textile fibers to form one or more layers of the fabric. Thus, the area with the cored piezoelectric fibers in the fabric can serve as a sensor or drive. Due to flexibility and foldability, the cored piezoelectric fiber fabric can be made into wearable structures such as gloves, vests, wrist bands, ankle pads, socks and the like which can be put on a living body or a robot body to serve as sensors for sensing health conditions in the living body, movements of the living body or the robot body or external acting forces; the wearable structures can also serve as drives for adding external signals onto the fabric, the living body can sense the external signals by sensing deformation, vibration and the like of the fabric; the wearable structures can further serve as sonic sensors or sonic drives to sense external sound waves or transmit sound waves.

Owner:YANGZHOU SIBIDE INSTR & EQUIP CO LTD

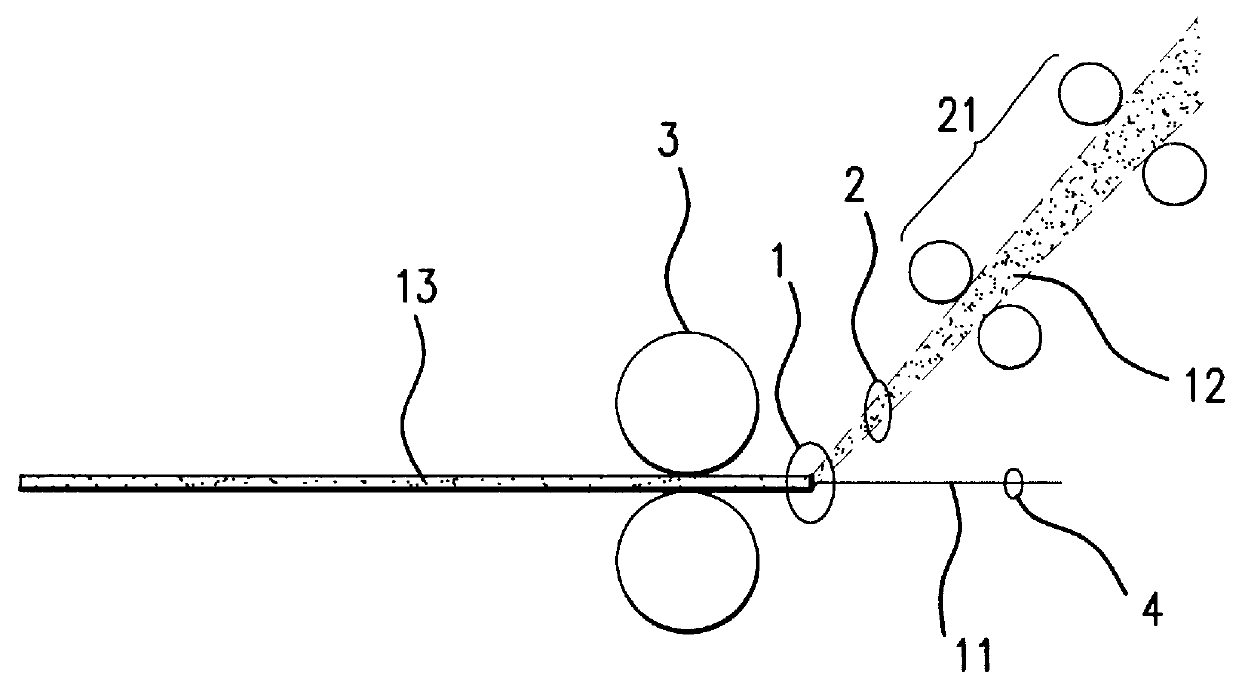

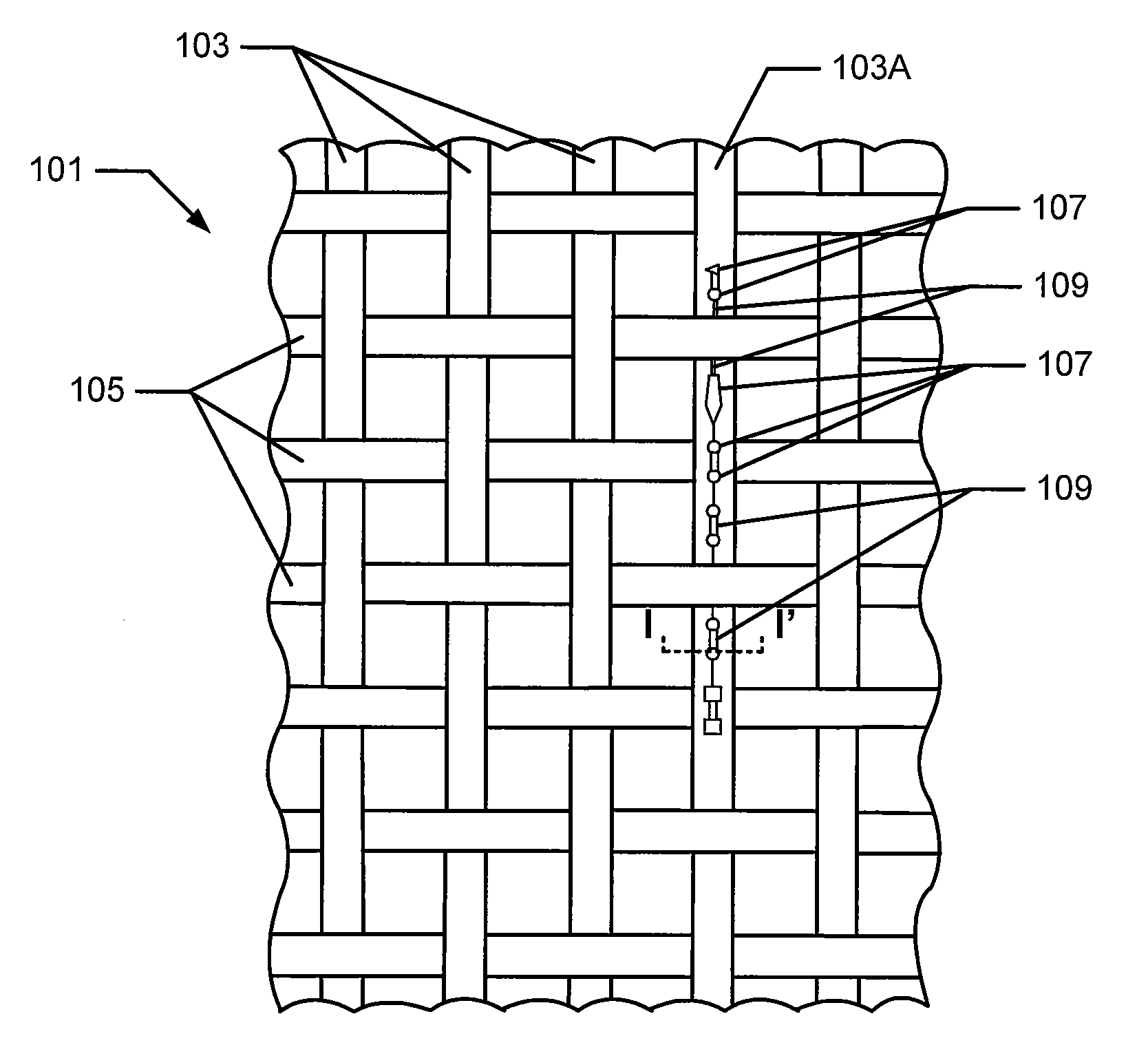

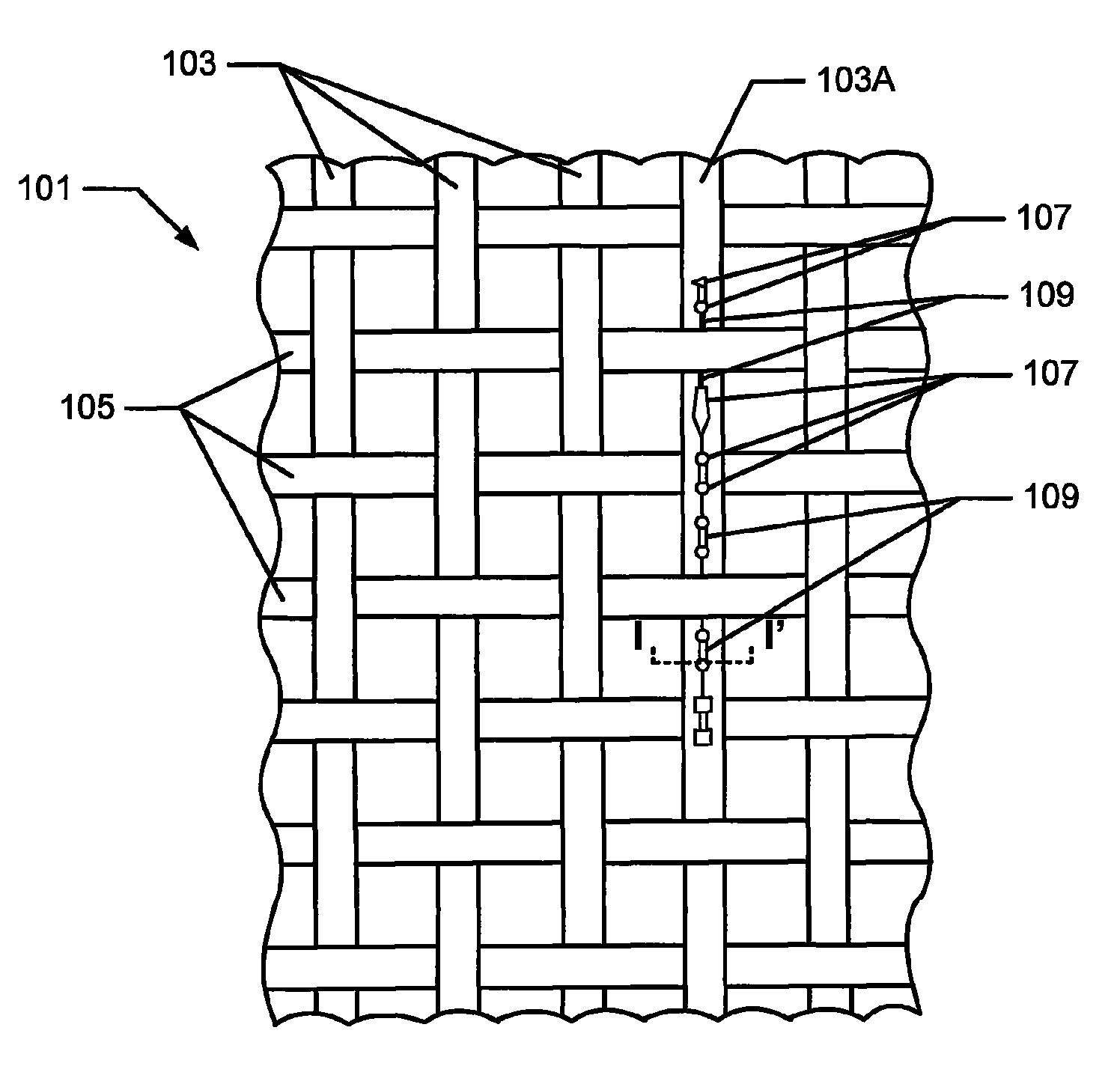

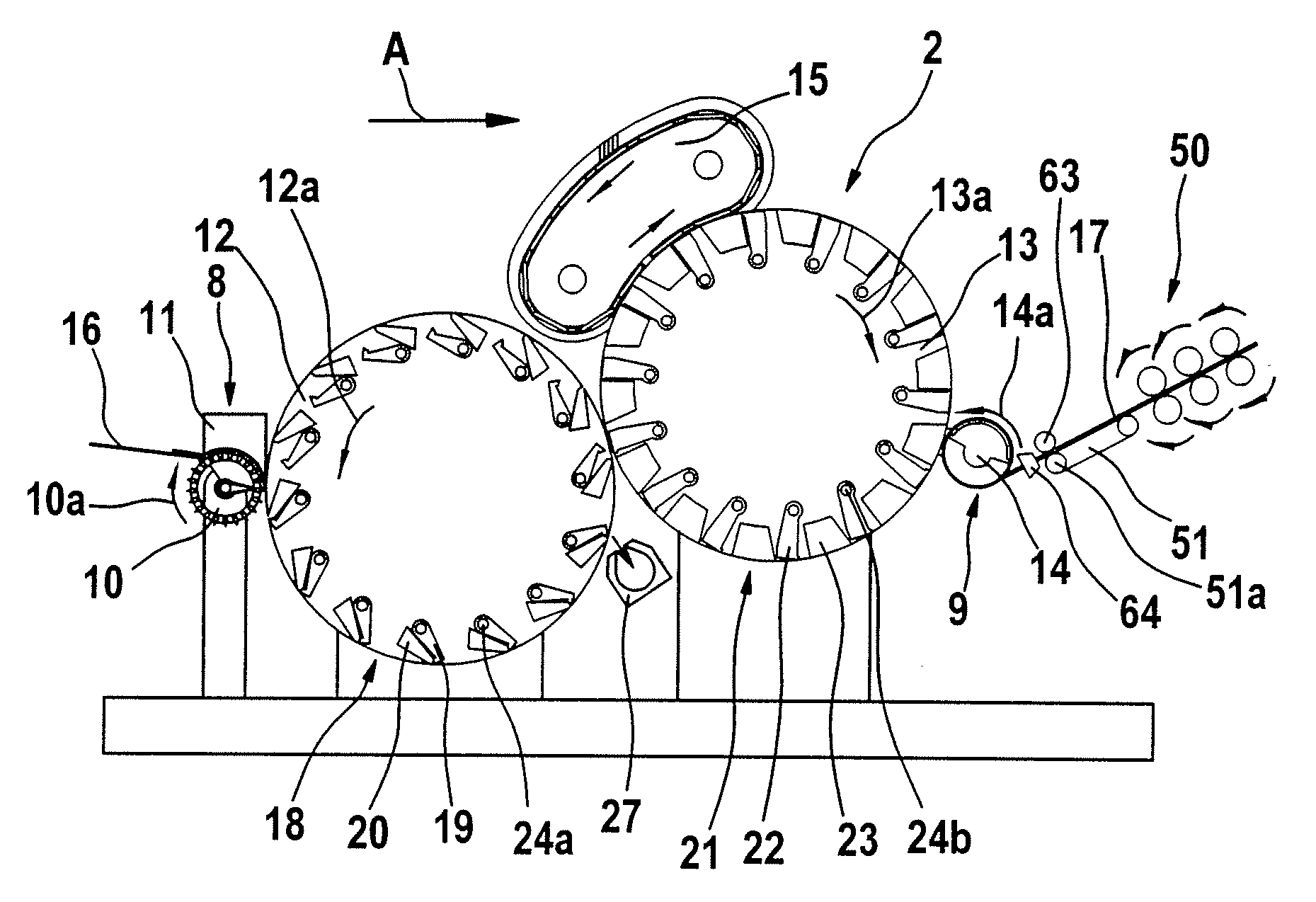

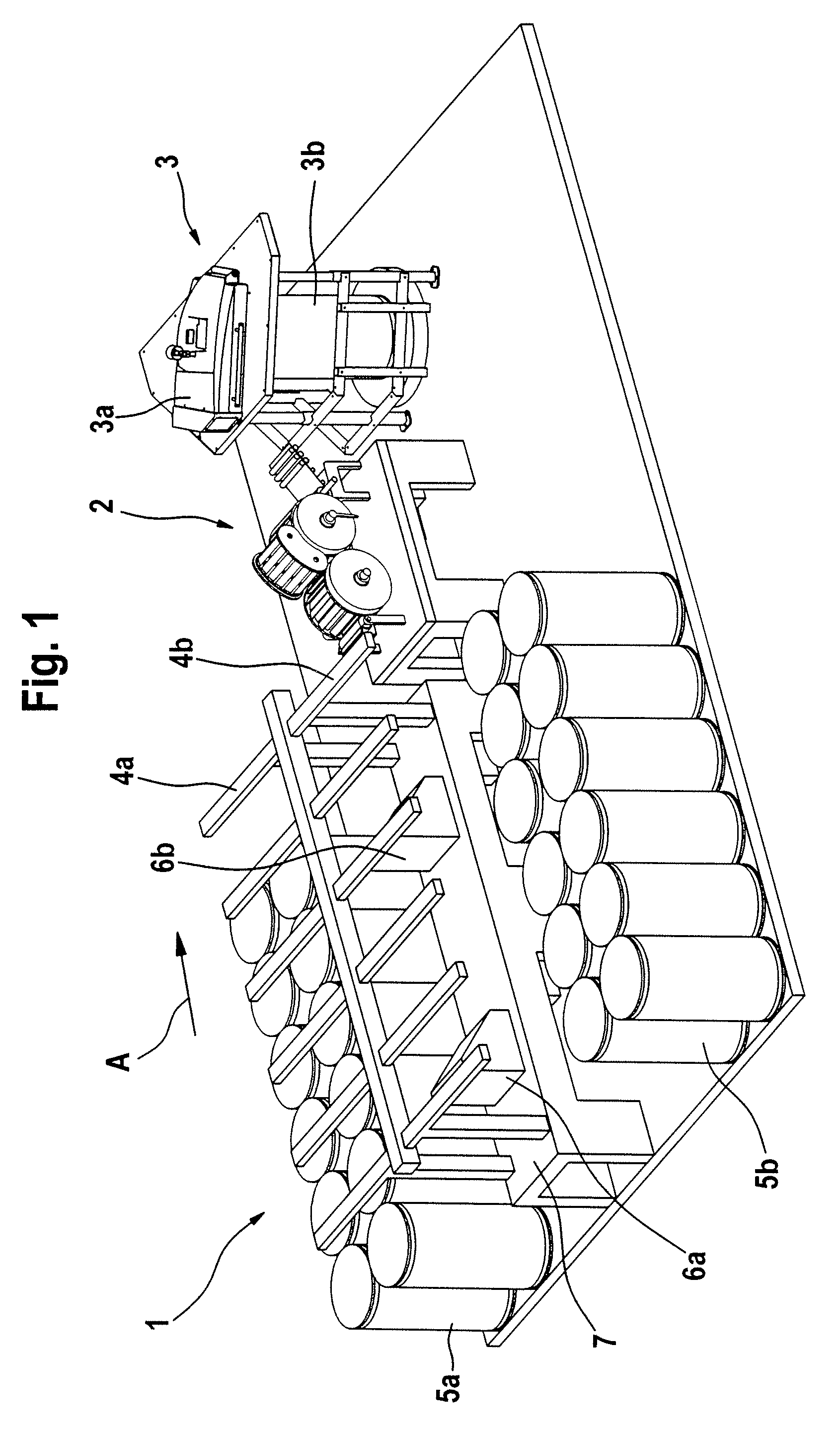

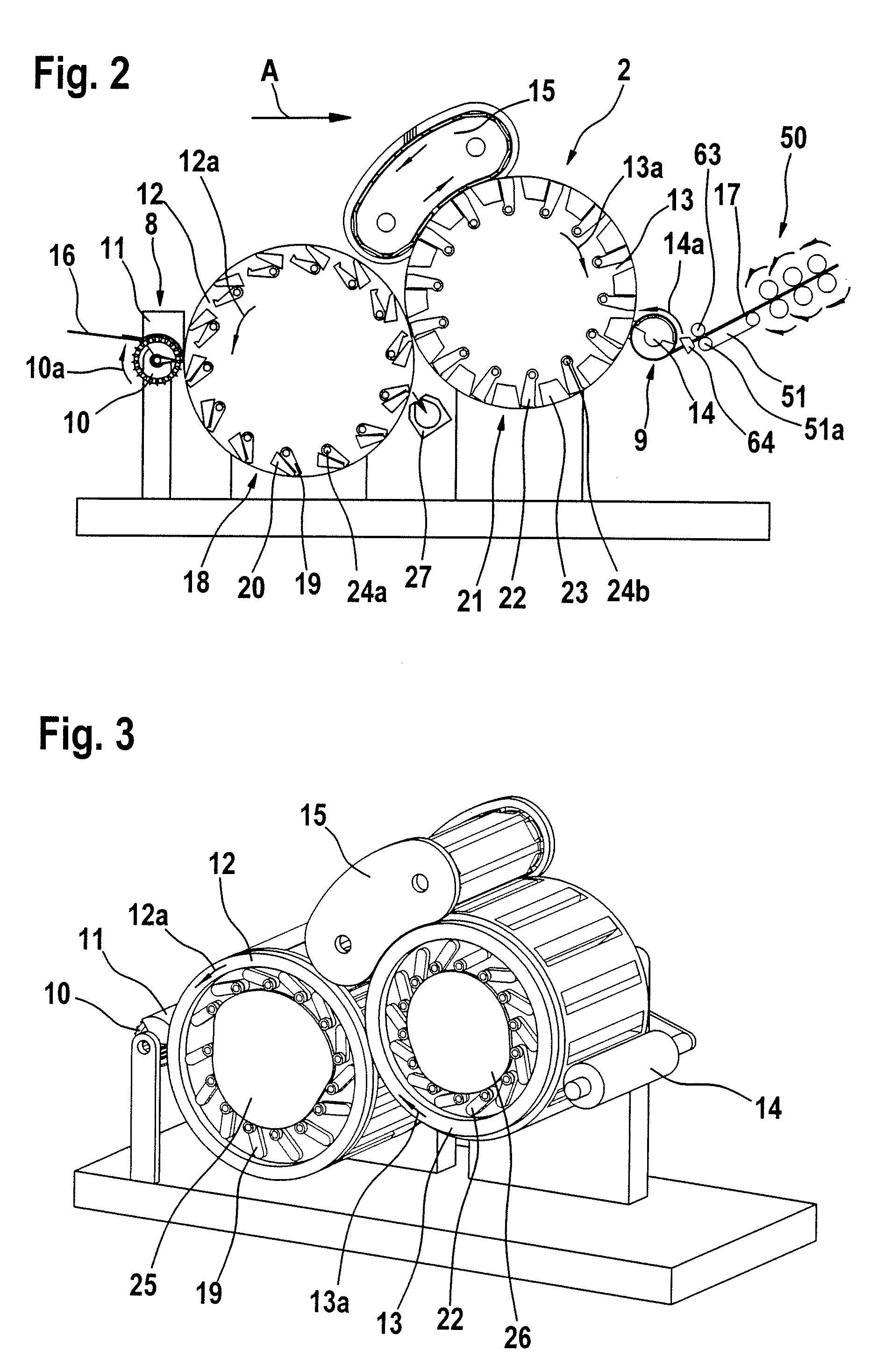

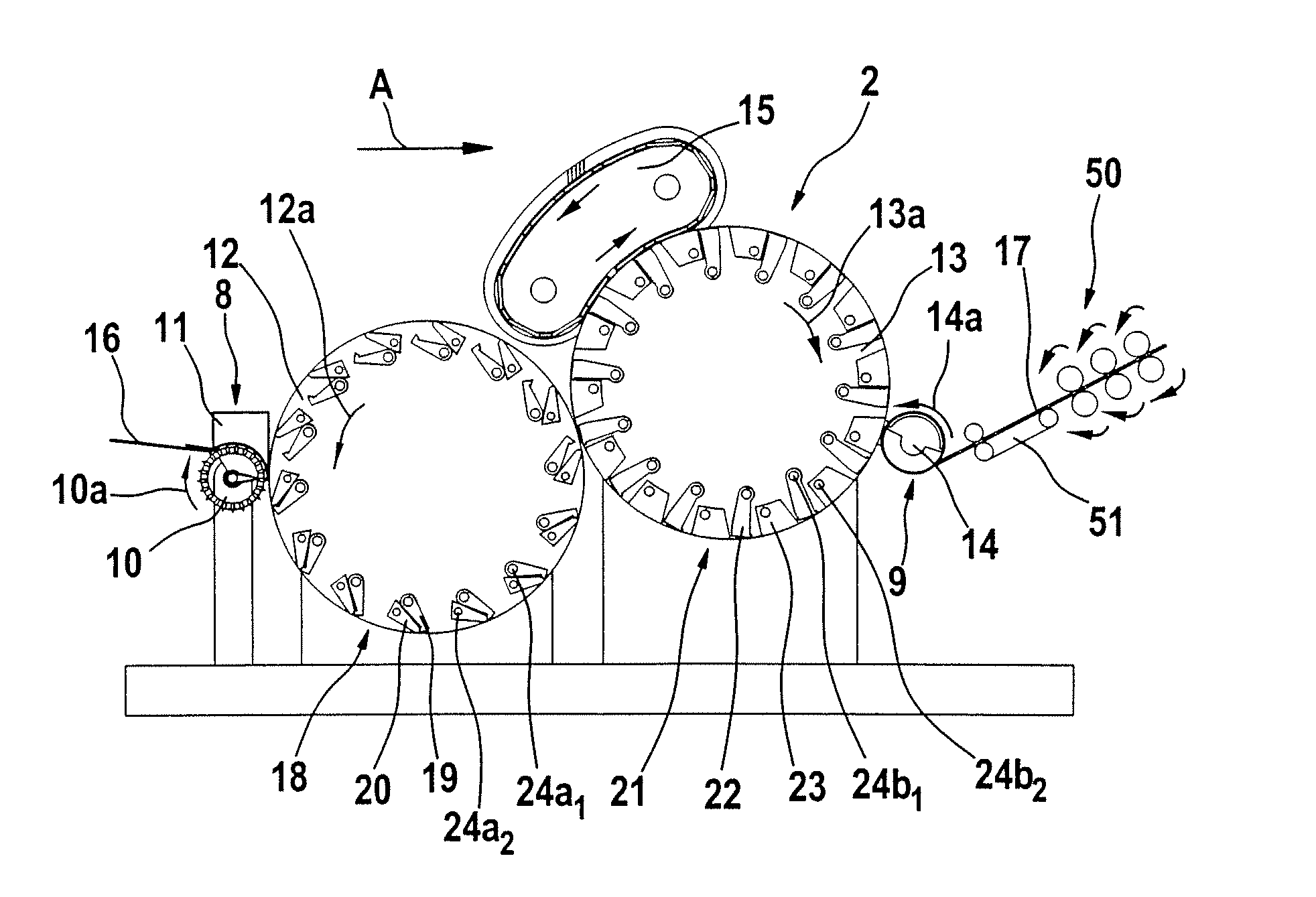

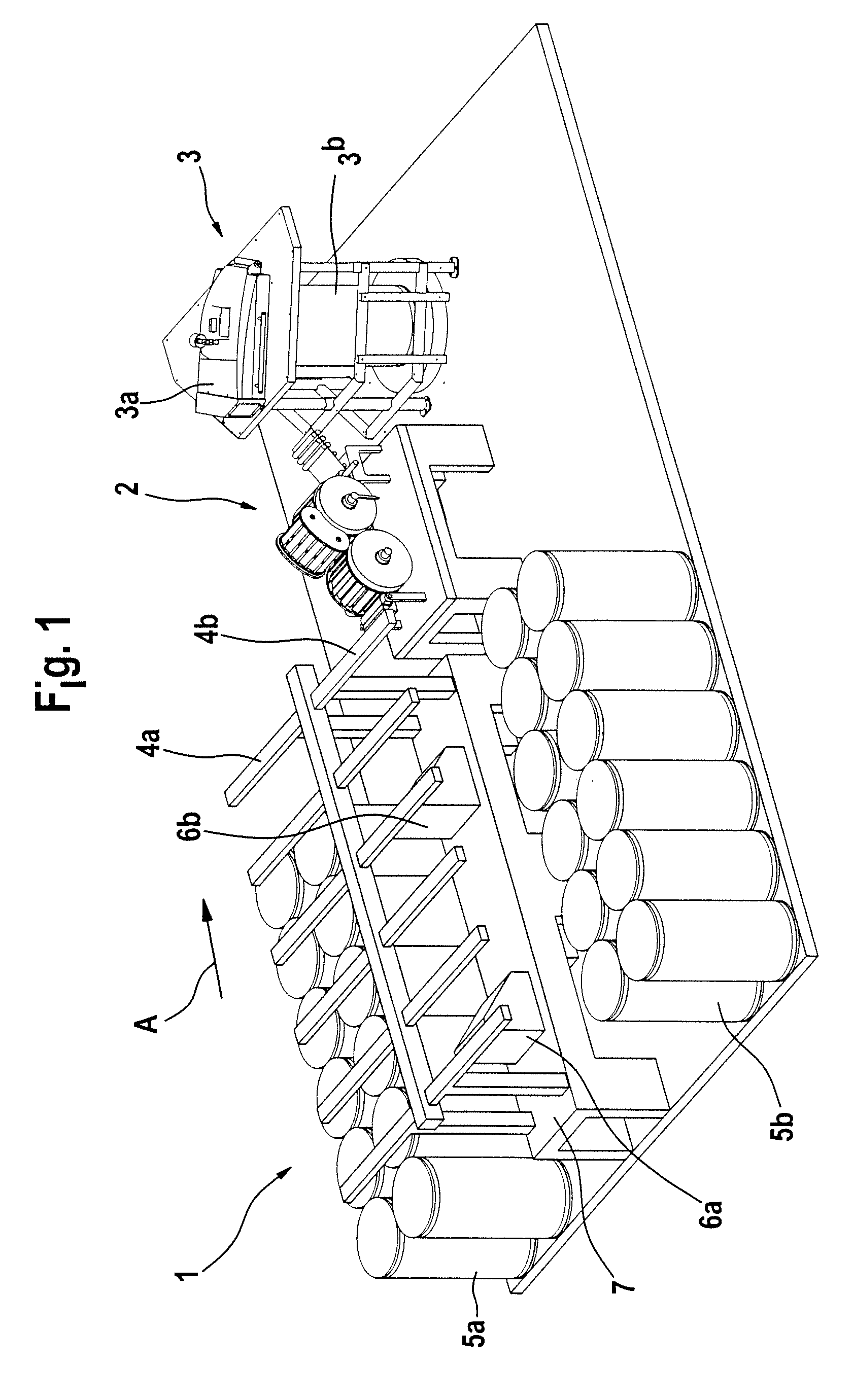

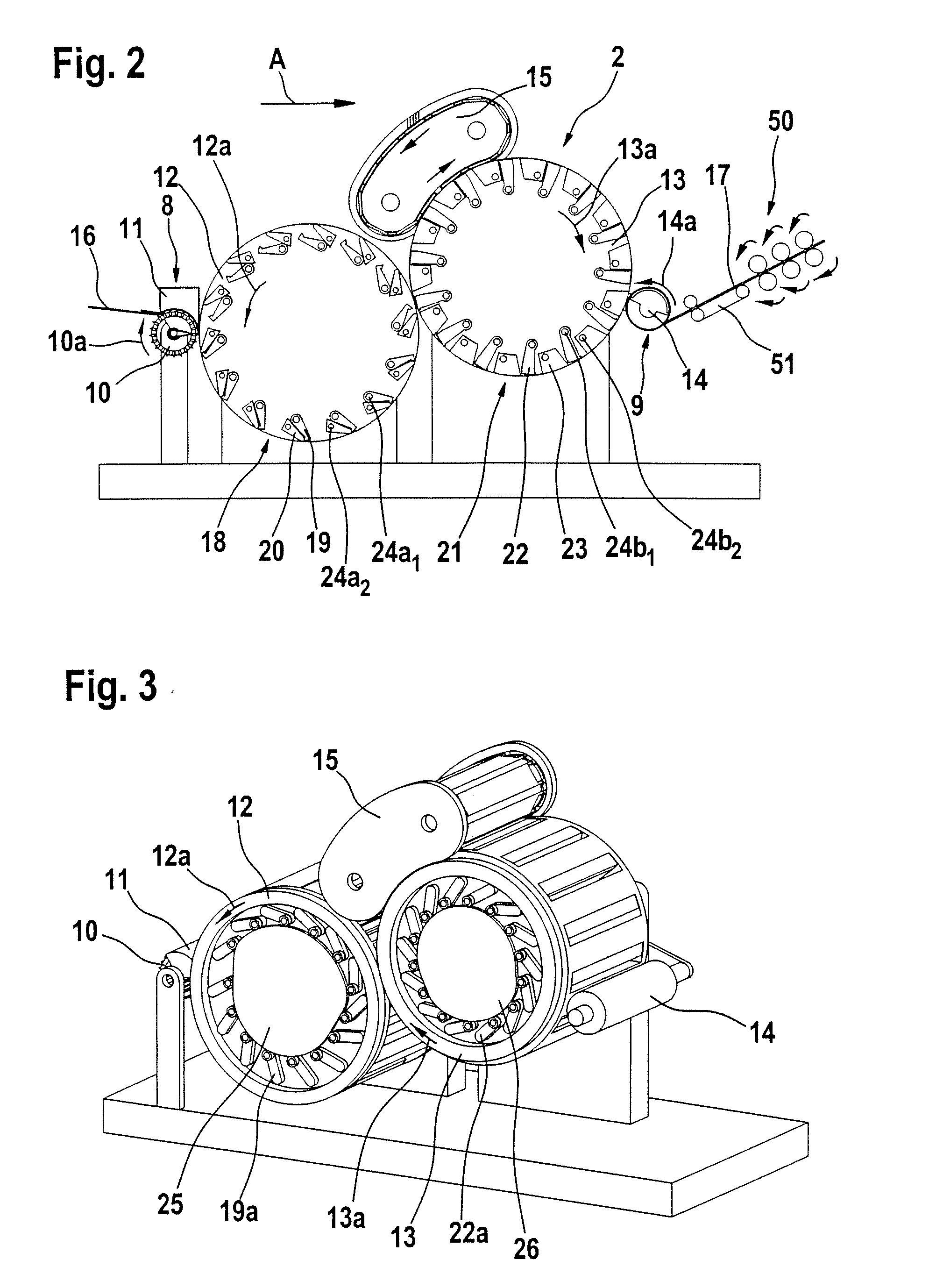

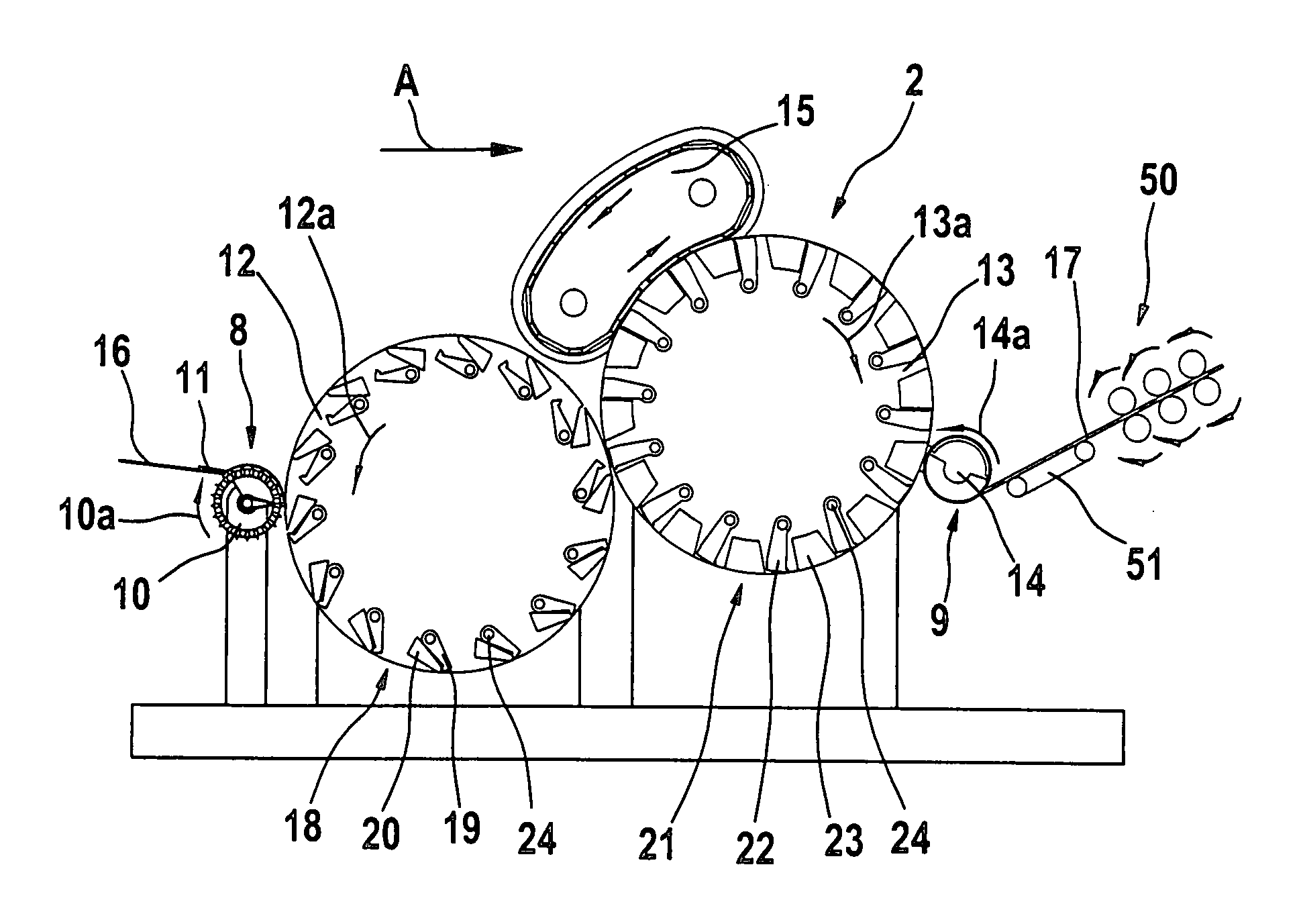

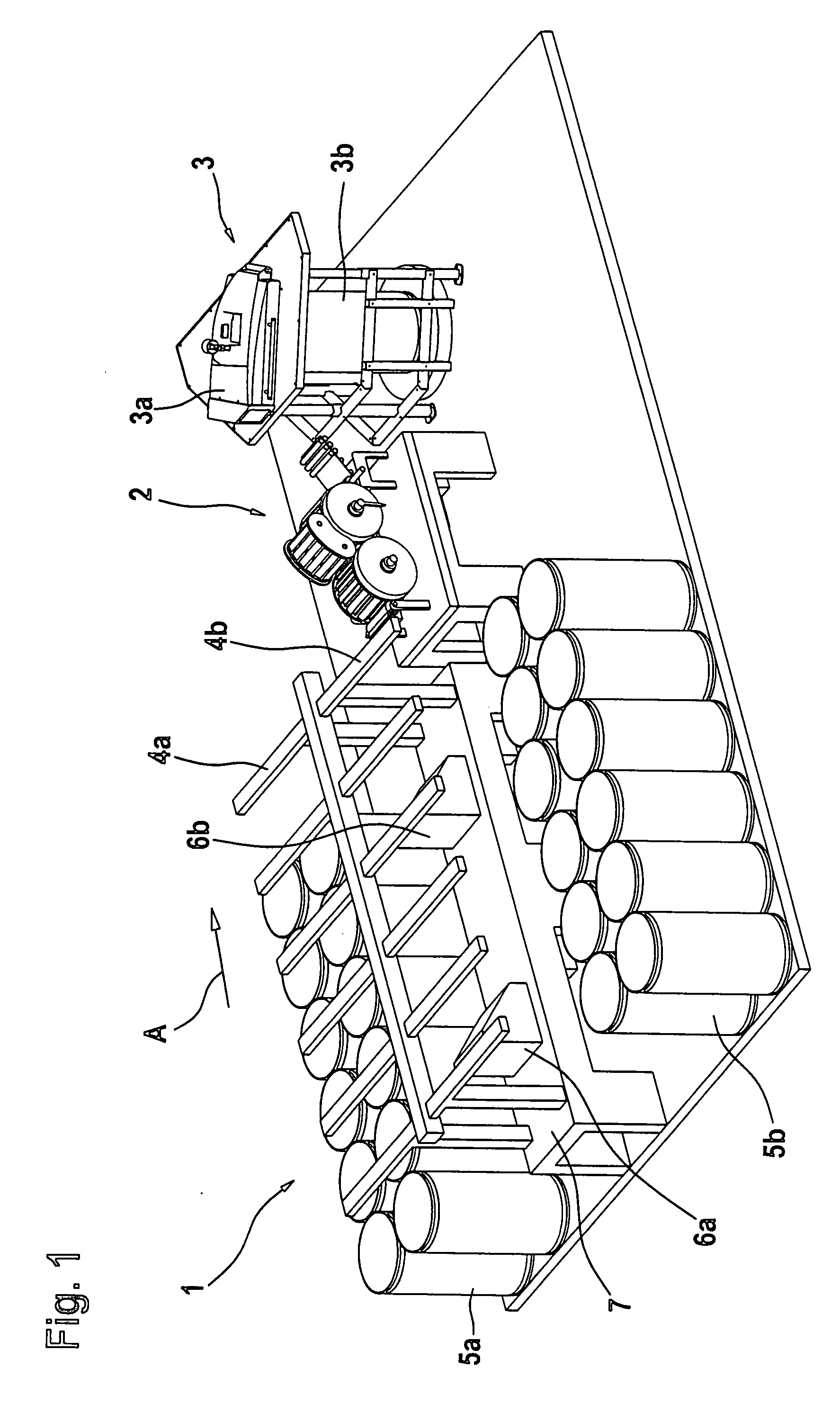

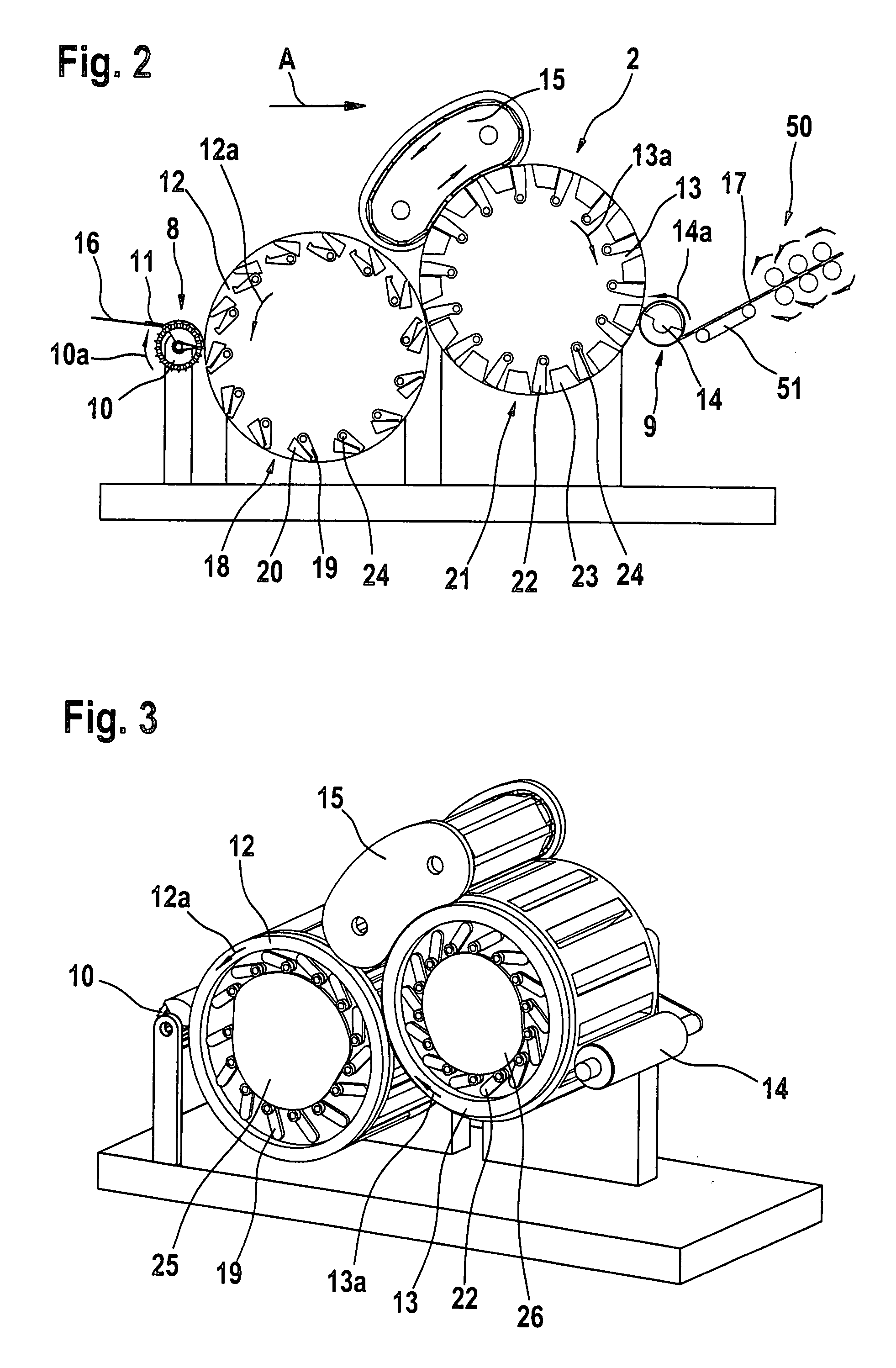

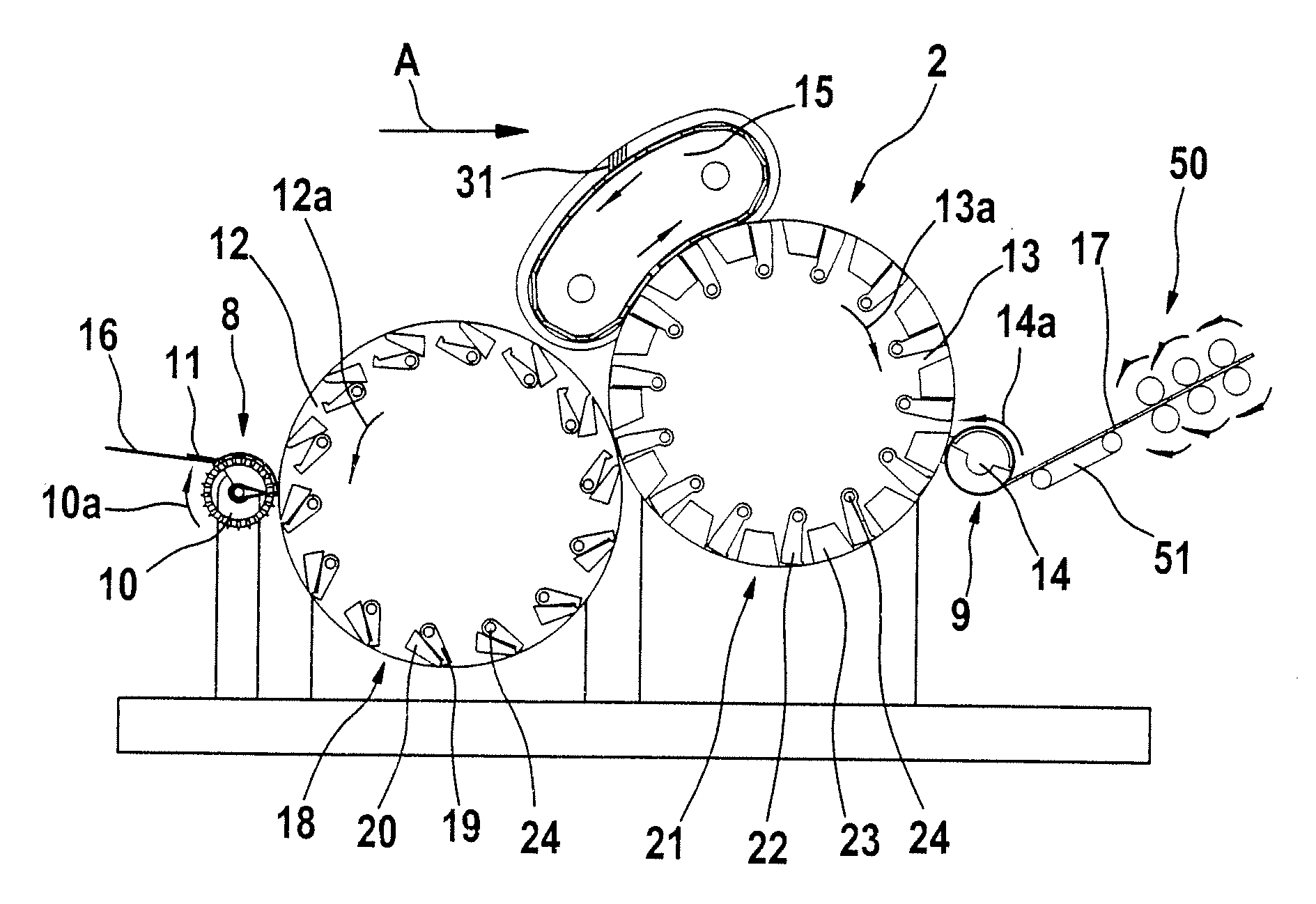

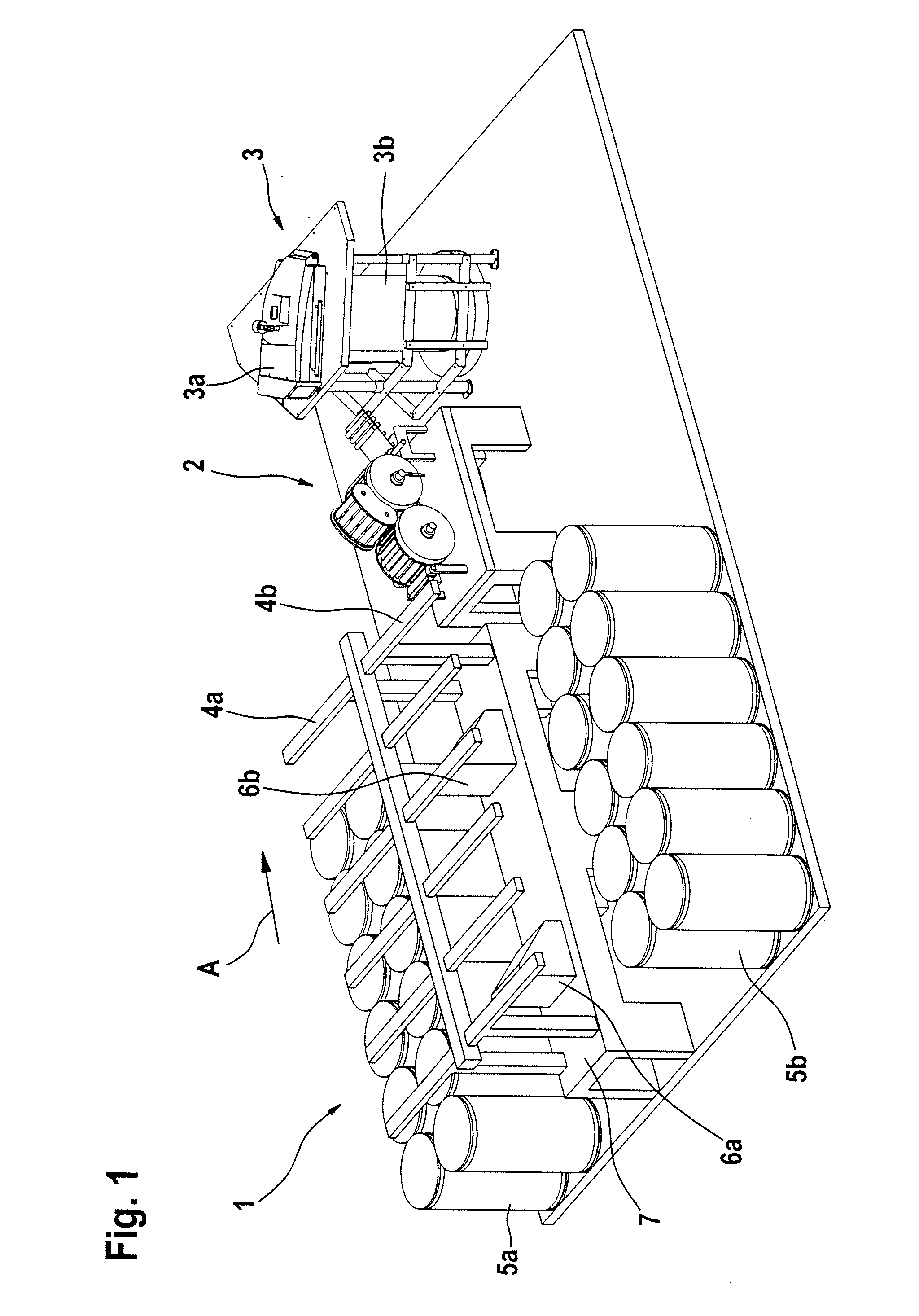

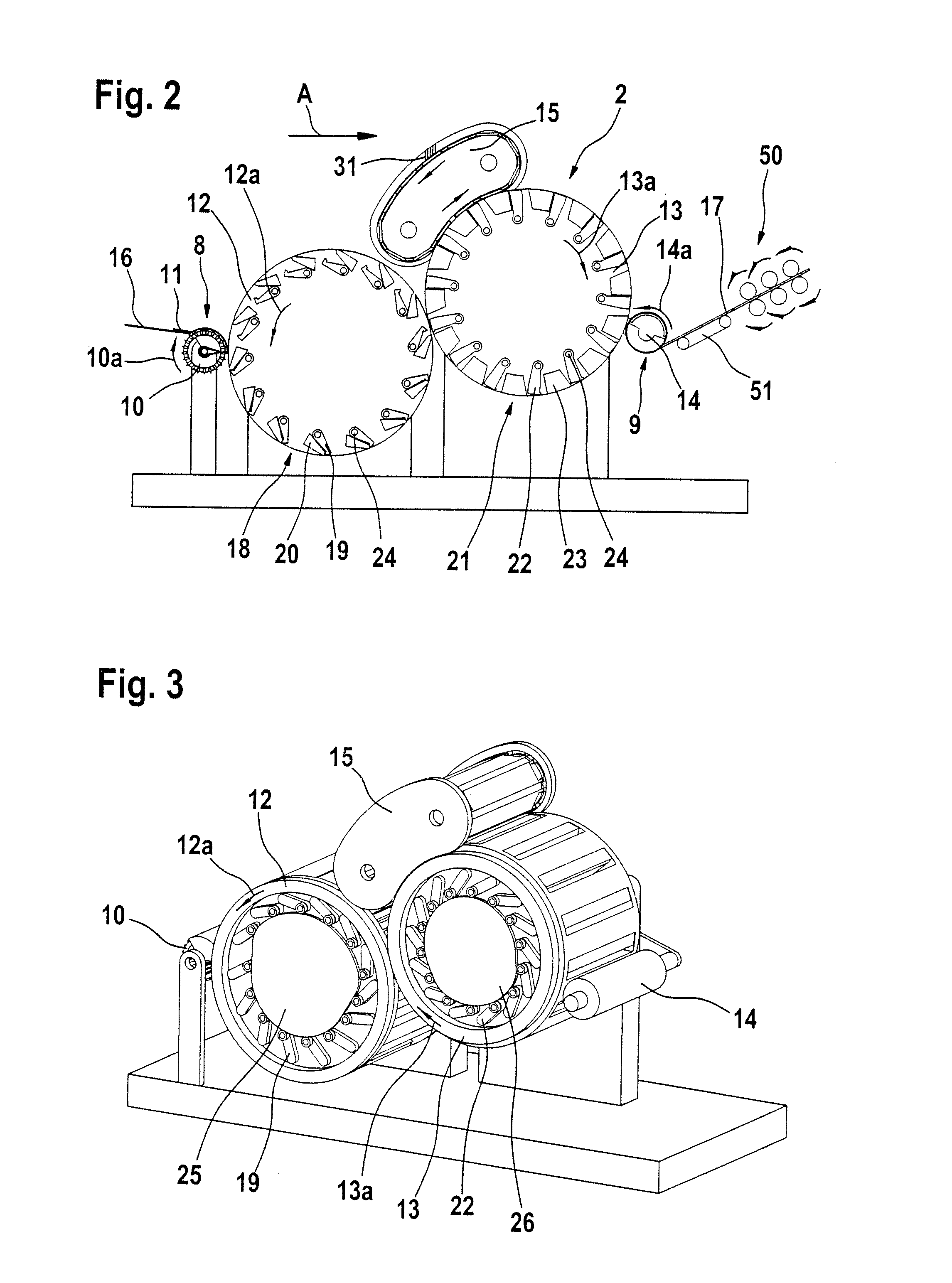

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000071A1Increase volumeImproved combed sliverCombing machinesTextile fiberFiber bundle

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle which is supplied by means of a supply device to a fibre-sorting device, mechanical means are present which generate a combing action in order to loosen and remove non-clamped constituents from the fibre bundle, and a take-off device is present to remove the combed fibre material. To enable an improved combed sliver to be obtained, downstream of the supply device there are arranged at least two rotatably mounted rollers with clamping devices for the fibre bundles, which clamping devices are distributed around the periphery of the rollers, wherein in the region between the rollers, devices are present which provide an optimum feed of the fibre material and / or provide optimum positioning of the fibre material for transfer and take-up from the first roller to the second roller.

Owner:TRUETZSCHLER GMBH & CO KG

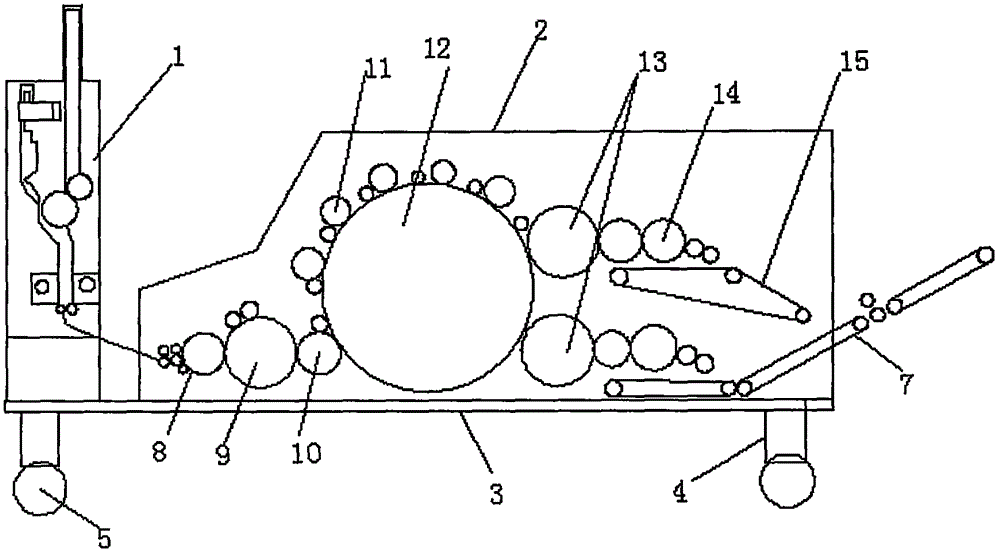

Carding machine equipment for textile fibers

The invention discloses carding machine equipment for textile fibers. The equipment comprises a feeding case, a casing, a machine base, supporting legs, a pre-carding mechanism, a main carding mechanism, double-doffer stripping-carding rollers, a conveying curtain mechanism and a discharging conveying belt, wherein the feeding case and the casing are arranged on the machine base, the supporting legs are arranged below the machine base, and a feeding conveying belt mechanism is arranged above the feeding case. The equipment is simple in structure and convenient to operate; the feeding case and the casing are arranged above the machine base, the pre-carding mechanism, the main carding mechanism, the double-doffer stripping-carding rollers, the conveying curtain mechanism and the discharging conveying belt are arranged in the casing sequentially, small impurities left in the equipment after pre-carding, main carding and processing by the double-doffer stripping-carding rollers and backing-off rollers are cleared, matched cotton composition fibers are sufficiently mild in a single-fiber state, uniform cotton slivers are prepared, requirements of the later process are met, and the practicability is high.

Owner:EASTERN LIAONING UNIV

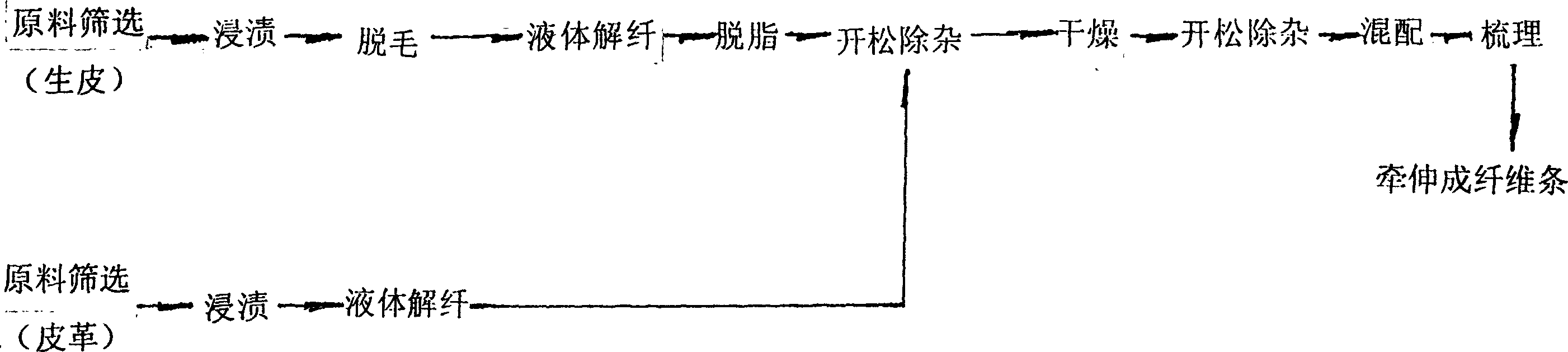

Fabric strip for spinning and its processing method

The invnetion relates to a spinning fiber rod comprised of 5-100% collagen fiber and residual textile fiber. Wherein, the process method comprises: screening material, dipping, defibering, degreasing, cleaning, dewatering, drying, opening to remove impurity, mixing, carding, and drafting. This invention can obtain material from wide source, has well applicability, high tensile strength, well moisture / oil absorption properties, and fit to spread in textile industry.

Owner:张立文

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000077A1Improved sliverIncrease volumeCombing machinesCarding machinesTextile fiberProduction rate

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, which is supplied to a fibre-sorting device, especially a combing device, having clamping devices which clamp the fibre bundle at a distance from its free end, which is combed to remove non-clamped constituents, the clamping devices each comprise two clamping jaws. To increase productivity and to enable an improved combed sliver to be obtained, downstream of the supply device there are arranged at least two rotatably mounted rollers rotating rapidly without interruption, the clamping devices being spaced apart in the region of the periphery of the rollers, and each clamping device comprising at least one nipper part at least partially of a lightweight material. The clamping jaws may have a high coefficient of friction in the region of their clamping surfaces.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the sorting or selection of a fibre sliver comprising textile fibres, especially for combing

An apparatus for the sorting or selection of fibre, especially for combing, is supplied by supply device to a sorting device. Clamping devices are provided which clamp the fibre sliver at a distance from its free end, for combing in order to loosen and remove non-clamped constituents, such as, for example, short fibres, neps, dust and the like from the free end. To enable productivity to be increased and an improved combed sliver to be obtained, downstream of the supply there is arranged at least one rotatably mounted roller which is provided with clamping devices for the fibre sliver, which clamping devices are distributed spaced apart around the periphery of the roller, and combing elements are associated with the periphery of the roller.

Owner:TRUETZSCHLER GMBH & CO KG

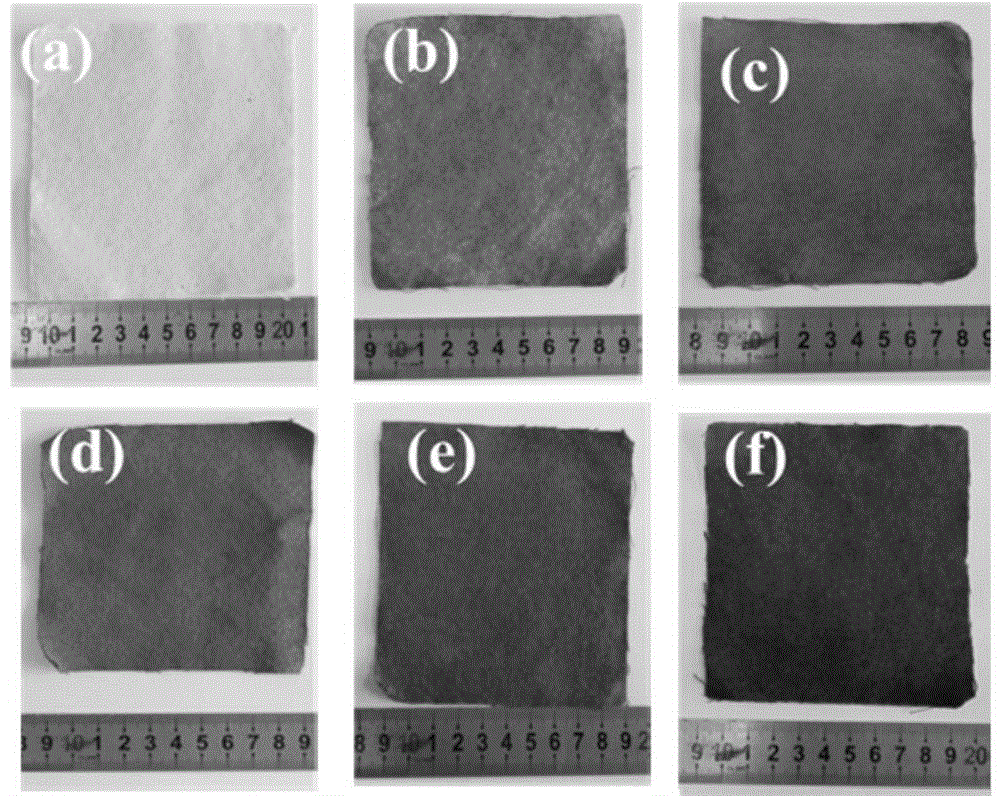

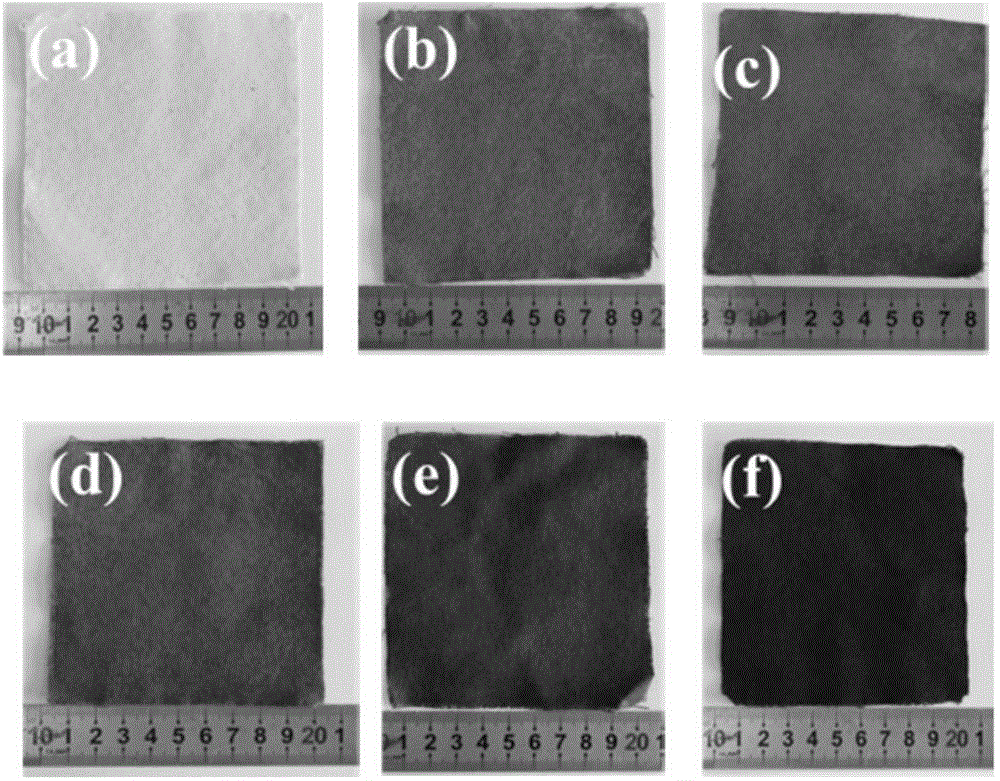

Preparation method for flexible and highly-conductive composite carbon fiber cloth

ActiveCN104882613AImprove bindingSolve conductivity problemsElectrode carriers/collectorsVegetal fibresTextile fiberCarbon composites

The present invention relates to the field of carbon composite materials, more particularly to a preparation method for the flexible and highly-conductive composite carbon fiber cloth, wherein the pure natural cellulose cloth is adopted as a precursor to be uniformly compounded with carbon nanotubes and / or graphene through the impregnation method. In the protective atmosphere, textile fibers are carbonized through the high-temperature heat treatment, and a carbon fiber interface is strongly bonded with the composite carbon nanotubes or the composite graphene. In this way, during the carbonizing process, a strong bonding action is formed between carbon fibers, carbon nanotubes and / or grapheme, so that a coaxial carbon fiber cloth composite structure is formed. According to the invention, the structure and the performance of the composite material are regulated at different treatment temperatures, different treatment times and different compound quantities of carbon nanotubes. In this way, by means of the flexible and highly-conductive composite carbon fiber cloth, the problem that conventional carbon materials do not have the advantages of flexibility, high specific surface area and high electrical conductivity at the same time can be solved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

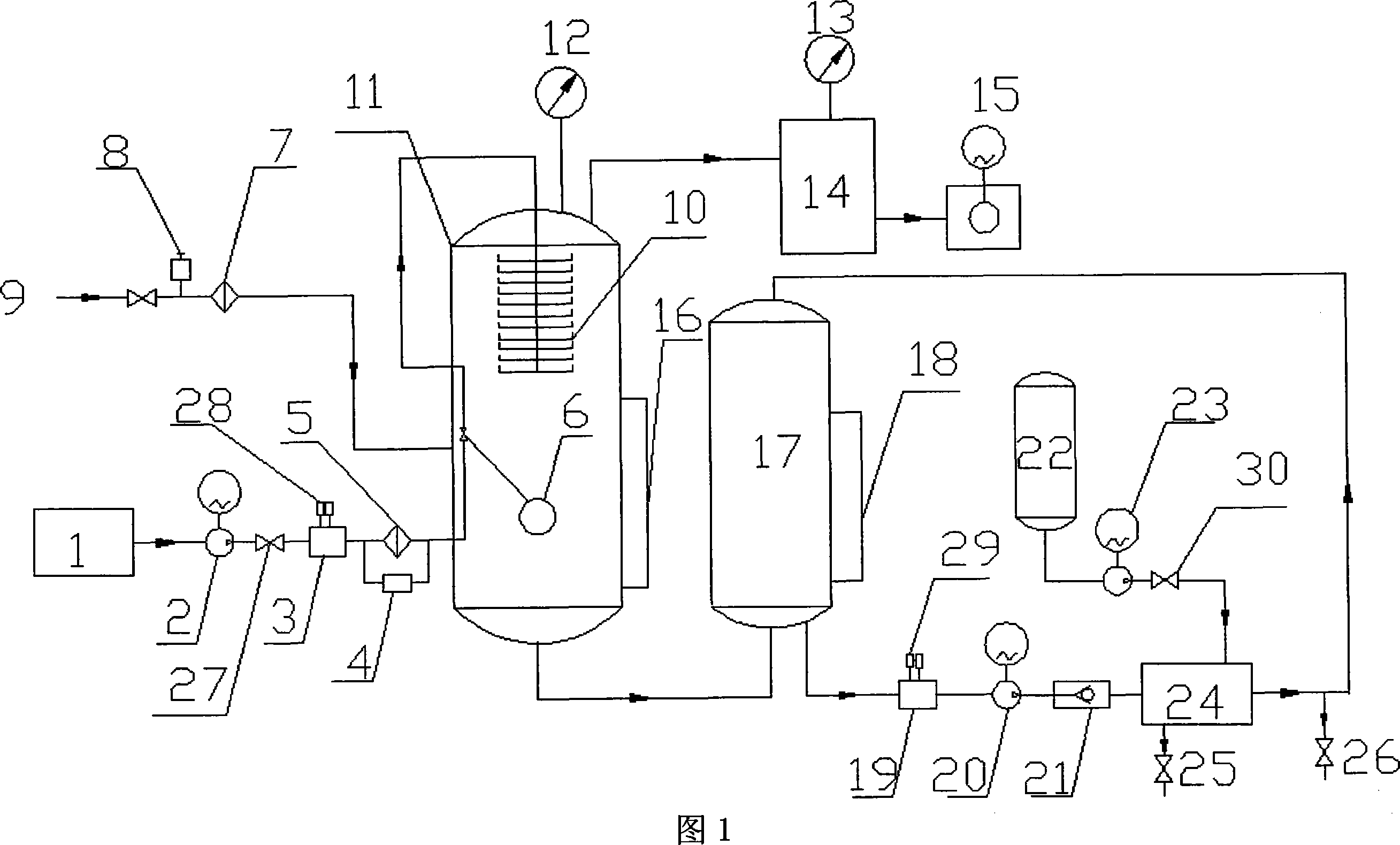

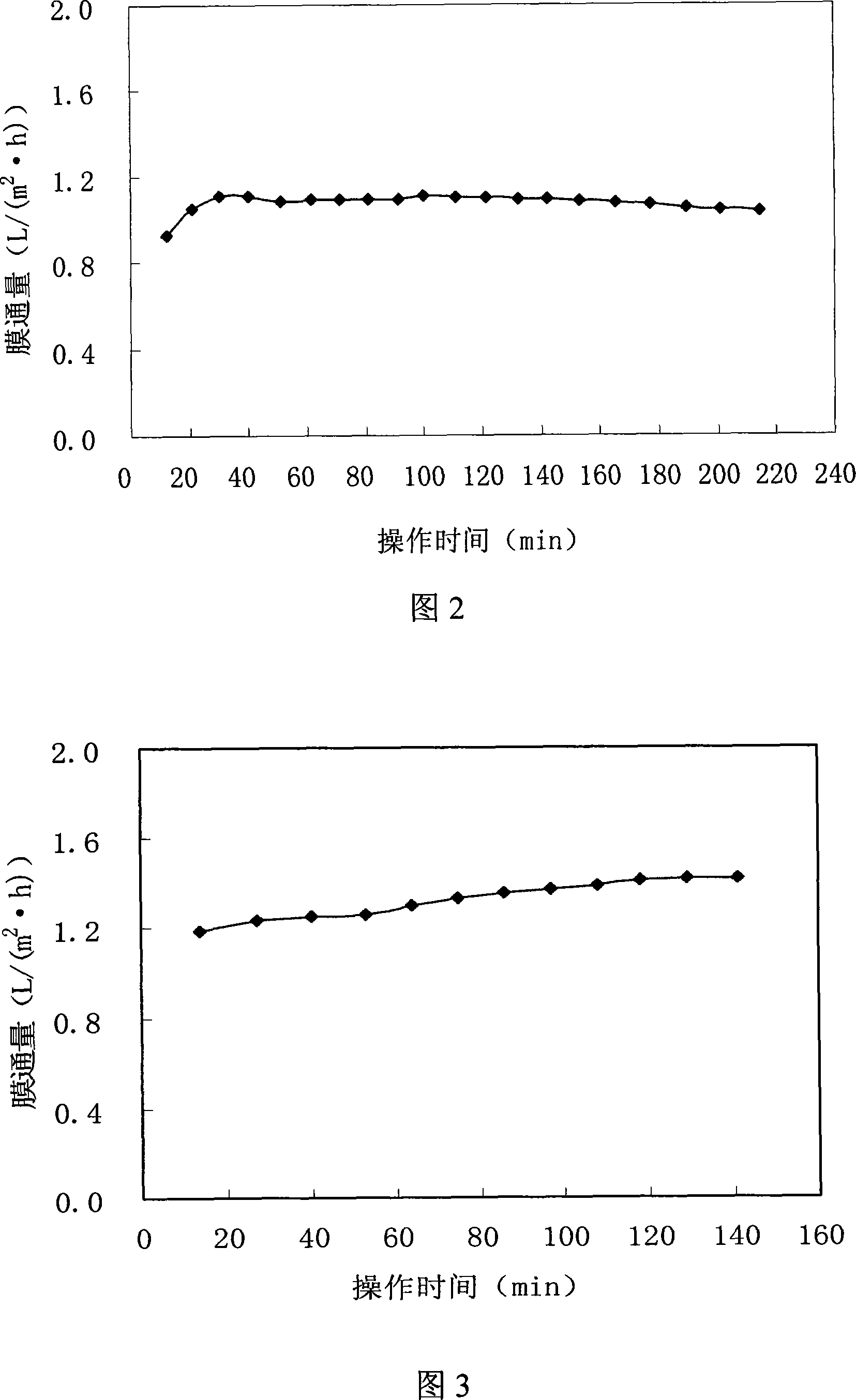

Regeneration method for waste lubricant and apparatus

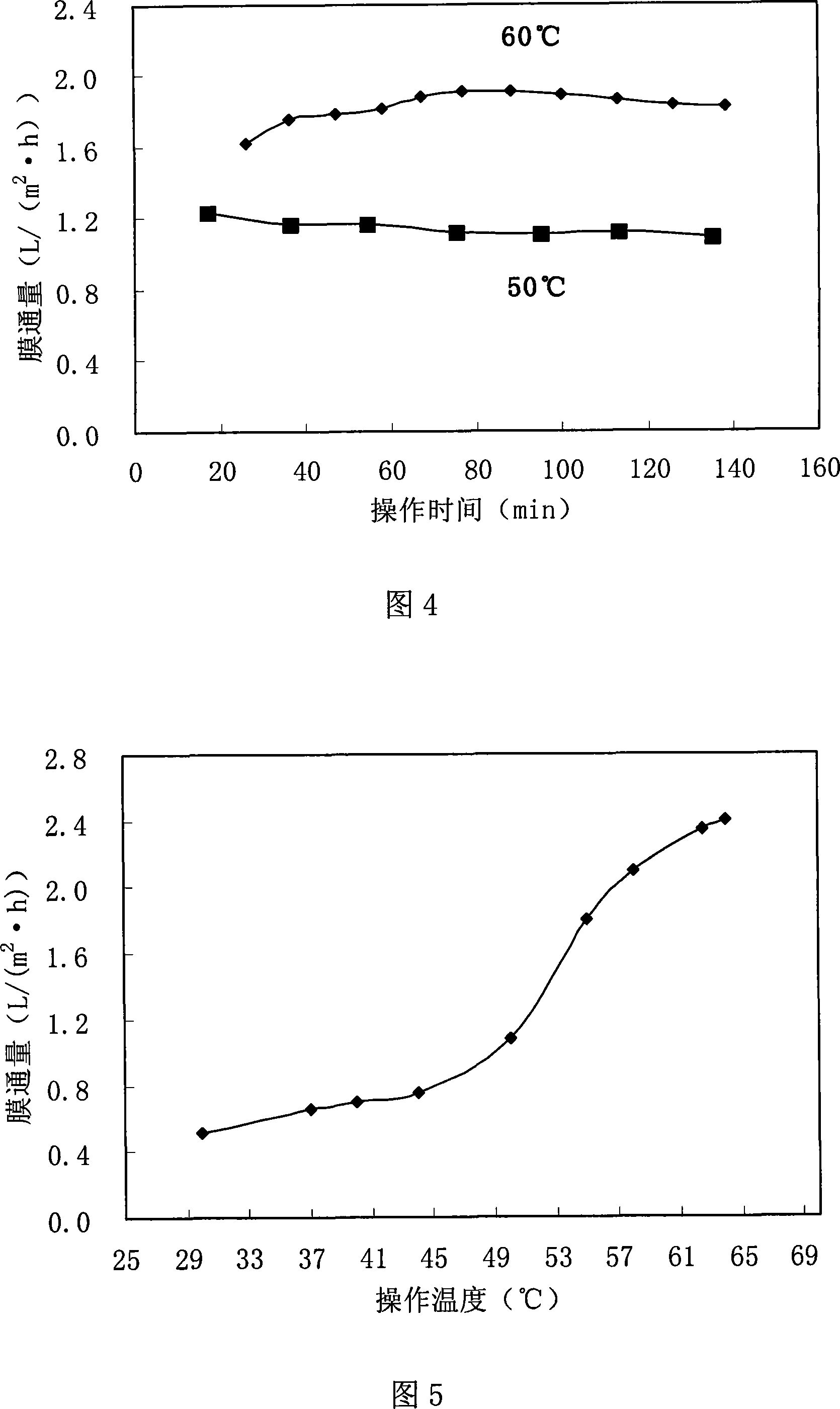

InactiveCN101070507AReduce consumptionSimple processSemi-permeable membranesLubricant compositionTextile fiberHigh energy

This invention relates to the regeneration method and equipment of one kind of waste lubricating oil, the regeneration method includes below crafts: impurity subsidence, pelletthickly filter, vacuum dehydration, its characteristic is that there has heat up craft after the impurity subsidence craft, there also has second time heats up craft and membrane separation craft after vacuum dehydration craft; The temperature of heat up craft is 65-75degree C; the temperature of second time heats up craft is 50-90degree C; The membrane separation craft uses the spatial textile fibermembrane, its average aperture is 0.01-0.5mum, it can bear 80-90degree C high temperature, and can resistant oil corrosion. This regenerative equipment characteristic is that it is suitable for this invention regeneration method, it at least includes a front heater, a set of vacuum dehydration installment, a intermediate storage tank, at least an heater and at least a center spatial textile fiber membrane module. The craft of using this invention method and the equipment is simple, its operation is easy, it is easy to control, high energy conversion rate and good separation effect, it also does not pollute the environment, low energy consumption, it is effective to recycle waste lubricating oil.

Owner:李建新

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

In an apparatus for the fibre-sorting or fibre-selection a fibre bundle which is supplied by means of a supply device to a fibre-sorting device in which clamping devices are provided which clamp the fibre bundle at a distance from its free end, and in which a mechanical device is present which generates a combing action, for removal of the combed fibre material a revolving element is present. To enable the amount produced per hour (productivity) to be substantially increased in a simple manner and to permit a reliable removal and piecing at high production speed, downstream of the supply device there are arranged at least two rotatably mounted rollers with clamping devices for the fibre, which clamping devices are distributed around the periphery of at least one of the rollers and the device for generating a combing action is associated with a said roller, wherein after take-up of the free regions of the combed fibre bundles by the revolving element, the clamping of the ends of the combed fibre bundles is terminated.

Owner:TRUETZSCHLER GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com