Fabric strip for spinning and its processing method

A processing method and fiber strip technology, applied in fiber treatment, fiber chemical post-treatment, yarn, etc., to achieve the effect of wide raw material, good wear resistance and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment one, by weight ratio collagen fiber 100%

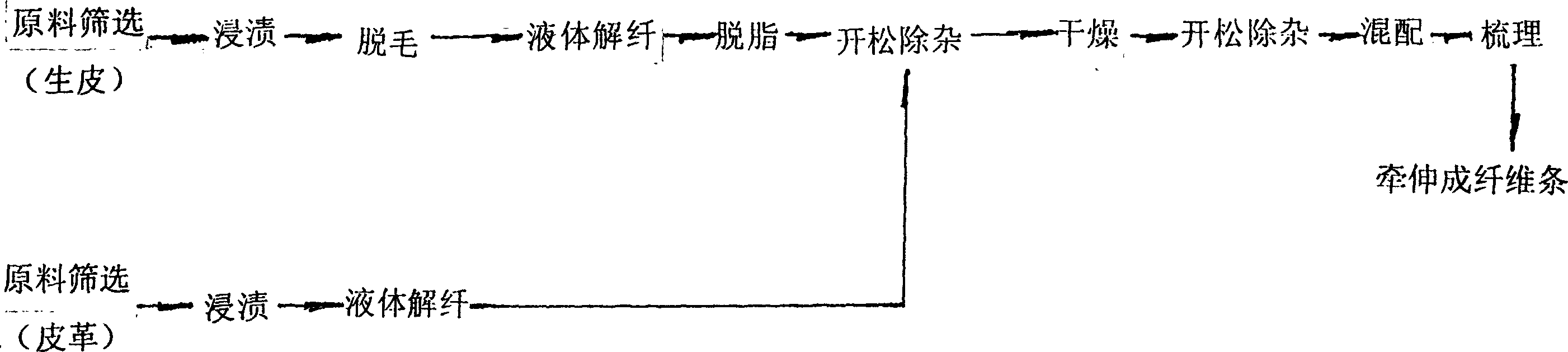

[0015] Technological process: raw material screening - impregnation - depilation - liquid defiberization - degreasing - cleaning and dehydration - drying - opening and removing impurities - mixing - carding - drawing into fiber strips.

[0016] Process description

[0017] 1. Raw material screening: select at least one kind of raw hide from cattle, horse, sheep, pig, dog, deer, rabbit, crocodile and snake, or the corners of untanned leather in the tanning process.

[0018] 2. Soaking: Soak in liquid at room temperature for 1-24 hours to restore the skin to the state of fresh skin.

[0019] 3. Hair removal: use the existing alkaline or enzymatic hair removal technology to remove hair, and this process can be omitted for no fur.

[0020] 4. Liquid defibration: Use a special liquid defibrillator to strike and / or comb the skin repeatedly in the liquid. The liquid defibrating machine can be self-made, and at least one ...

Embodiment 2

[0028] Embodiment two, by weight ratio collagen fiber 100%

[0029] Process flow: raw material screening—dipping—liquid defibrillation—cleaning and dehydration—drying—opening and impurity removal—mixing—carding—drawing into fiber strips.

[0030] 1. Raw material screening: use tanned leather and its corner cuttings and waste leather.

[0031] 2. Dipping: Dipping in the liquid for 10-48 hours at a temperature of 15-60°C.

[0032] The rest of the process is the same as Example 1

[0033] Embodiments 1 and 2 The liquid used for impregnation and liquid defibration is water; according to the difference of leather or leather raw materials, add 0.2-2% detergent, 1-10% grease, 0.2-1.5% penetration and 0.03-0.5% alkali at least one of the substances.

Embodiment 3

[0034] Embodiment 3, the collagen fiber is 5-99.9% and the textile fiber is 0.1-95% by weight.

[0035] Process flow: mixing - carding - drafting into fiber strips.

[0036] Process description:

[0037] 1. Mixing: the collagen fibers processed in Embodiment 1 or 2 are mixed with at least one spinnable fiber in all chemical fibers of cotton, wool, hemp, silk and polyester, acrylic fibers, nylon fibers and viscose, according to the above ratio. match.

[0038] All the other procedures are the same as example one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com